Abstract

Carbon Dioxide-Enhanced Coalbed Methane (CO2-ECBM), a progressive technique for extracting coalbed methane, substantially boosts gas recovery and simultaneously reduces greenhouse gas emissions. In this process, the dynamics of coalbed fractures, crucial for CO2 and methane migration, significantly affect carbon storage and methane retrieval. However, the extent to which fracture roughness, under the coupled thermal-hydro-mechanic effects, impacts engineering efficiency remains ambiguous. Addressing this, our study introduces a pioneering, cross-disciplinary mathematical model. This model innovatively quantifies fracture roughness, incorporating it with gas flow dynamics under multifaceted field conditions in coalbeds. This comprehensive approach examines the synergistic impact of CO2 and methane adsorption/desorption, their pressure changes, adsorption-induced coalbed stress, ambient stress, temperature variations, deformation, and fracture roughness. Finite element analysis of the model demonstrates its alignment with real-world data, precisely depicting fracture roughness in coalbed networks. The application of finite element analysis to the proposed mathematical model reveals that (1) fracture roughness ξ markedly influences residual coalbed methane and injected CO2 pressures; (2) coalbed permeability and porosity are inversely proportional to ξ; and (3) adsorption/desorption reactions are highly sensitive to ξ. This research offers novel insights into fracture behavior quantification in coalbed methane extraction engineering.

1. Introduction

Coalbed Methane (CBM) is a vital natural gas resource, playing a significant role in our energy supply and environmental sustainability. With the escalating global energy demand and continuous concern over greenhouse gas emissions, the extraction and utilization of CBM have emerged as salient topics in the energy sector [1,2,3,4]. As a novel technology capable of enhancing CBM production while sequestering CO2, the technique of Carbon Dioxide-Enhanced Coalbed Methane (CO2-ECBM) has been extensively studied and applied to mitigate the adverse atmospheric impacts of CBM extraction [5,6,7]. CO2-ECBM technology not only reduces CO2 emissions but also increases the recoverable reserves of CBM, thereby enhancing the economic and environmental benefits of the projects. However, the process of CO2 displacement in coalbeds faces numerous challenges, including the complexity of injection techniques, coalbed characteristics, and geological conditions. And the evolution of the physical-mechanical properties of coal seams under coupled thermo-hydro-mechanical effects is a focal point of research. Furthermore, the changes in the number, complexity, and surface roughness of coalbed fractures, along with gas desorption, matrix deformation, gas pressure evolution, and fracture–matrix interactions, have garnered widespread attention from industry professionals and researchers [8,9,10].

In recent years, the process of CO2-ECBM has increasingly garnered the attention of scholars and industry practitioners. Current research primarily focuses on three aspects: (1) Experimental studies on coalbed characteristics during the CO2 displacement process [11,12,13] concentrate on how CO2 displaces methane in coalbeds to enhance CBM recovery. These studies predominantly involve experiments, including the mechanism of CO2 injection, the displacement effects under various conditions, and the detailed analysis of the reaction between CO2 and coalbeds. (2) Mechanism analyses of multi-field coupling during the CO2-ECBM process [14,15,16] primarily employ numerical simulation and constitutive model development to explore the displacement efficiency of CO2 under different pressures, temperatures, and in situ stress, as well as its impact on the microstructure of coalbeds. (3) Research on the supercritical CO2 displacement of coalbed methane [17,18,19] focuses on the characteristics of supercritical CO2 and how it displaces methane in coalbeds. This includes the physicochemical properties of supercritical CO2, its behavior under various coalbed conditions, and a detailed analysis of its interaction with coalbed methane. Although these studies have conducted thorough and comprehensive research on CO2-ECBM projects from engineering conditions, coalbed geological factors, and multi-coupling effects, a quantitative and comprehensive exploration (under various mining conditions and different coalbed multi-field coupling effects) of the behavior of coalbed fracture networks, particularly the impact of fracture roughness on gas migration resistance and gas production, during the CO2-ECBM project process still remains insufficiently addressed [20,21].

Since 2020, practitioners and scholars in the field have increasingly recognized the importance of studying fracture behavior in coalbed methane extraction. Guo et al. developed a simplified model for the evolution of coalbed methane permeability, considering the effects of equivalent-scale characteristics of coalbed fracture structures, effective stress, and matrix adsorption strain on permeability evolution [22]. Armstrong et al. characterized the multiscale structure and rock physical properties of coalbeds using digital coal models and micro-CT scanning technology [23]. Li et al. based on fractal theory, studied the porosity and fracture characteristics of coal during CBM extraction, exploring their relationship with coal mine dynamic disasters [24]. Ye et al. proposed the quantitative impact of cross-scale fracture networks in coalbeds during extraction [25,26]. Chen et al. introduced a permeability model that accounts for the impact of coalbed methane flow characteristics under the same gas pressure on coalbed permeability [27]. Liu et al. proposed a permeability evolution model based on coalbed fracture displacement [28]. Although these studies have thoroughly explored the significant contribution of coalbed fractures in coalbed methane extraction (including CO2-ECBM projects), research on fracture roughness has mainly involved the experimental measurement of surface roughness [29], measuring changes in fracture roughness under different temperatures and pressures [30], and explaining the impact of surface roughness on contact angles using Wenzel’s theory [31]. However, despite these studies advancing the research on fracture roughness contributions in gas extraction, they fall short in achieving a quantitative evolution analysis of fracture roughness under the multi-field coupling effects in CO2-ECBM projects. This has significant implications for the assessment of the coalbed methane recovery rate and the effectiveness of CO2 displacement.

Therefore, to address this industry challenge of accurately analyzing the quantitative evolution of coalbed fracture roughness in CO2-ECBM projects, and to precisely and quantitatively assess the impact of fracture roughness on CO2 storage and coalbed methane recovery, this study has developed an innovative, interdisciplinary mathematical model. The model introduces a novel parameter that can quantitatively characterize the roughness of coal fractures in CO2-ECBM projects. Moreover, the study comprehensively considers the combined effects of CO2 and CH4 adsorption/desorption, the pressure evolution of both gases, adsorption and pressure-induced coalbed stress, in situ stress, coalbed temperature, coalbed deformation, and fracture roughness. It is noteworthy that practitioners can perform comprehensive assessments of different coalbed conditions simply by altering initial values and boundary conditions in the solution process. This research is anticipated to provide novel insights into the quantitative analysis of fracture behavior in CBM extraction engineering.

2. Conceptual Model

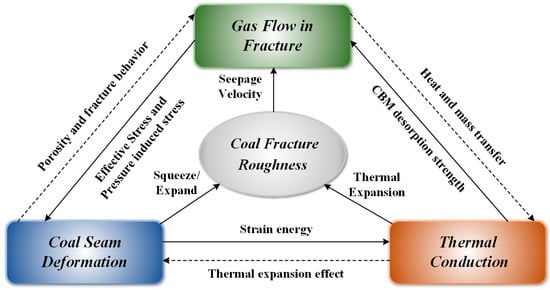

The interdisciplinary model proposed in this study comprehensively considers the combined effects of CO2 and methane adsorption/desorption, the evolution of gas pressures, adsorption and pressure-induced coalbed stresses, in situ stress, coalbed temperature, deformation, and fracture roughness within the CO2-ECBM process. Therefore, elucidating the intricate couplings of these factors to practitioners and interested readers is essential before introducing the numerical model. In field projects, alterations in fracture roughness directly influence the velocity of the gas flow within fractures, thereby affecting gas pressure and ultimately altering gas production rates. Concurrently, under the combined influence of temperature, deformation, and pressure, changes in coalbed temperature lead to variations in thermal expansion effects, causing deformation in coalbed fractures and, consequently, alterations in fracture roughness. Additionally, coalbed deformation under multiple factors leads to the expansion or contraction of the coal matrix, resulting in varying degrees of changes in the existing fracture system and, subsequently, in the roughness of the fractures.

Furthermore, the multi-field effects in coalbed methane during the CO2-ECBM process exhibit complex interactions under the influence of coalbed fracture roughness. Changes in fracture roughness leading to variations in gas pressure alter the intensity of the thermal conduction and mass transfer effects during the desorption of gas from the matrix to the fractures and its subsequent migration to the extraction pipelines. These alterations, in turn, affect the coalbed’s temperature; the temperature change then impacts the adsorption–desorption behavior of the coalbed methane, consequently influencing its permeation through the fracture system. Changes in coalbed temperature lead to variations in thermal expansion effects, causing coalbed deformation; this deformation alters the strain energy and also affects the intensity of the thermal conduction. Additionally, the deformation of the coalbed leads to changes in porosity, thereby causing alterations in gas permeation and gas pressure; changes in gas pressure, in turn, result in effective stress variations, leading to varying degrees of coalbed deformation.

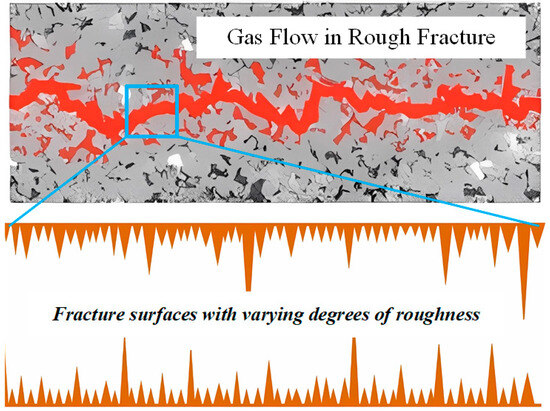

The interplay of these multiple factors in CO2-ECBM projects has been thoroughly and comprehensively investigated in this study. The multi-field coupling mechanisms are illustrated in Figure 1, and the impacts of fracture roughness on the gas seepage behavior are illustrated in Figure 2. In the subsequent chapters, the conceptual model proposed in Section 2 will be translated into the mathematical model, followed by the resolution and comprehensive exploration of field engineering scenarios.

Figure 1.

Interactions among the multiple factors in CO2-ECBM projects.

Figure 2.

The impacts of fracture roughness.

3. Governing Equations

In the field of CO2-ECBM projects, the production of CBM involves a complex interplay of factors, including the competitive adsorption of CH4 and CO2, adsorption and pressure-induced coalbed stresses, the pressure evolution of both gases, in situ stress, coalbed temperature, coalbed deformation, and fracture roughness. This study primarily investigates how the evolution of fracture roughness under the coupled effects of these factors influences gas permeation behavior. To establish these fully coupled models, the following assumptions are made [32,33]: (1) the anisotropy in the coalbed is disregarded; (2) CH4 is initially saturated in the coalbed prior to extraction; (3) CH4 and CO2 are treated as ideal gases, and the effect of temperature on dynamic viscosity is neglected; and the (4) deformation of the coal reservoir is considered to be infinitesimal.

3.1. Permeability and Porosity Models Considering Fracture Roughness Evolution in CO2-ECBM Projects

Kong et al. proposed the porosity model that comprehensively considers the effects of gas pressure, temperature, and coal matrix deformation due to adsorption and desorption effects [34]:

where is the fracture volume for the coal seam, is the total volume, the subscript i refers to the state before extraction, is the volumetric strain, and is the solid volume of the coal.

Additionally, during the CO2 injection process, the total volume of gas adsorbed can be determined by the following equation [33]:

where and are the Langmuir Volume Constants for CH4 and CO2, and are the Langmuir Pressure Constants for CH4 and CO2, and and are the partial pressures for CH4 and CO2.

During the extraction process, the expansion and contraction of the matrix due to the gas adsorption and desorption caused by CO2 displacement result in a total volumetric strain, which is expressed as [33]:

where and are the Langmuir Volume Strain Constants for CH4 and CO2.

Additionally, the volumetric strain of the coalbed solid due to the extraction effects in CO2-ECBM projects is given as:

where is the coal Biot coefficient, is the strain caused by adsorption/desorption effects, is the volume modulus for the coal solid, and is the coal seam thermal expansion coefficient.

Combining Equations (1)–(4), the porosity considering the multi-field effect can be expressed as:

Additionally, for the fracture roughness evolution in the coal seam, Shi et al. proposed the model as follows [35]:

where is the diameter of the fracture, is the fracture height distribution, is the ratio of the contact area to the fracture area, and is the initial fracture aperture. refers to the fracture roughness and has no impact on gas pressure. That is:

While this model adeptly delineates the nexus between fracture permeability and surface roughness, its genesis from laboratory experiments renders it less amenable to macroscopic analysis in engineering contexts. Furthermore, the model falls short in providing an exhaustive examination of the multifaceted influences encountered during shale gas extraction.

In Equation (6), coal permeability is defined in terms of (the initial width of the fracture), (the root mean square value of the fracture height distribution with respect to the fracture surface roughness), (the gas pressure in the fractures, affected by the coupled multi-field effects), and (the initial gas pressure of the fracture network). Among these parameters, is influenced by a combination of factors during CO2-ECBM, such as coal deformation, adsorption/desorption effects, and in situ stress; whereas the parameters directly related to rough fracture behavior are and (with being a constant) [35]. Thus, the fracture roughness constant can be defined as:

Since is a constant, from the definition of , it can be understood that is inversely proportional to the roughness degree of shale reservoir fractures. From the above equations, it is evident that is related to the fracture’s aperture and roughness, directly quantifying the roughness of fractures during CO2-ECBM.

Thus:

In the subsequent research, Equation (9) will be integrated into a gas permeation equation that considers multi-field effects, thereby facilitating a comprehensive assessment of fracture roughness under the influence of multiple factors.

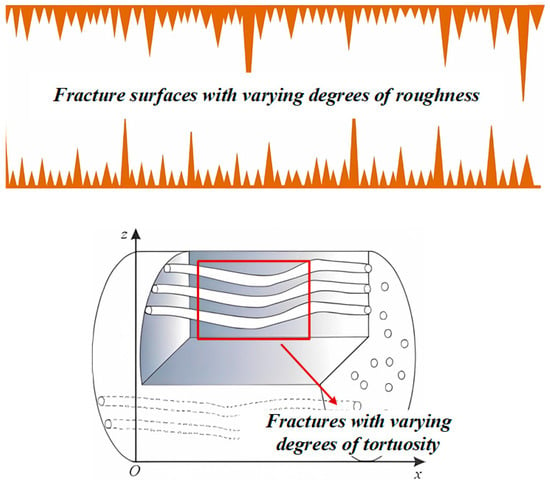

Additionally, although the study’s focus on the impact of fracture roughness on gas permeability is similar to that of fracture tortuosity, they are distinctly different concepts. Fracture roughness characteristics influence gas permeability by affecting the internal surfaces of fractures, thereby impacting the ability of the gas to flow. In contrast, the essence of fracture tortuosity lies in increasing the path length of gas permeation, thereby affecting gas flow. This is illustrated in Figure 3. Equation (6), derived from the published literature exploring the analytical equations of fracture roughness behavior [35], involves parameters directly related to the degree of fracture roughness. Furthermore, this equation has been extensively used in numerous published studies [36,37,38,39] to evaluate fracture roughness. These references distinctly outline the differences between our study and research focused on fracture tortuosity.

Figure 3.

The impact of fracture roughness and tortuosity on gas seepage.

3.2. The Gas Flow Model in CO2-ECBM Projects

Based on the law of mass conservation, and employing the dynamic dispersion law of fluids and the fluid continuity equation, the applicable convection permeation equation for CO2-ECBM projects is derived as follows [40]:

where is the gas mass volume, is the aerodynamic dispersion coefficient, is the fracture permeability, and is the dynamic viscosity.

The mass transfer equation for the two gases is as follows:

where and are the molar mass for CBM and CO2.

By substituting Equations (9) and (11) into Equation (10), the resulting binary gas transport equation that accounts for the fracture roughness in the CO2-ECBM process is obtained as:

3.3. The Thermal Conduction Model in CO2-ECBM Projects

In accordance with the law of energy conservation and Fourier’s law, the energy conservation equation for the coalbed and gas during the coalbed methane extraction process is as follows:

where is the heat capacity, , , and are the specific heat capacities for CBM, the coal seam, and CO2, is the coefficient for the isotropic thermal conductivity, , , and are the coefficients for CBM, CO2, and the coal seam, and is the isotropic heat adsorption. The permeability influenced by the fracture roughness can be obtained by Equation (9).

Equations (13) to (16) indicate that the thermal conduction effect in the coalbed is influenced by a combination of internal energy, thermal convection, heat conduction, thermal deformation energy, and the heat generated by adsorption–desorption effects. Specifically, the heat generated by thermal convection (Equation (16)) is affected by the permeability of the fracture system, which in turn is directly influenced by the fracture roughness (Equation (9)). Moreover, the heat conduction effects caused by adsorption–desorption and the permeation of both gases are also directly influenced by fracture roughness (Equation (12)). This approach realizes a highly integrated coupling of the innovative fracture roughness parameter proposed in this study with the multi-field effects in CO2-ECBM projects, a quantification not achievable in the previously published literature.

3.4. The Coalbed Deformation Model

The relationship induced by adsorption leading to deformation can be expressed as:

where is the component of the strain tensor, is the coal shear modulus, is the component of the stress tensor, is the Kronecker delta, and is the component of normal stress.

In the process of shale gas extraction, reservoir strain and displacement satisfy the following relationship:

where is the volume force component, and and are the force component and the total stress component of the coal seam.

Simplifying Equation (17), and combining Equations (18) and (19), the Navier–Stokes-type equation for coal and gas deformation during the CO2-ECBM process is:

In Equation (20), factors such as the gas pressure, adsorption–desorption effects, and the thermal expansion induced by temperature evolution are quantitatively influenced by fracture roughness (refer to Section 3.2 and Section 3.3). This achieves a quantitative analysis of the interplay between fracture roughness and the CO2-ECBM process under multiple factors.

4. The Verification of Model Correctness and Advantages

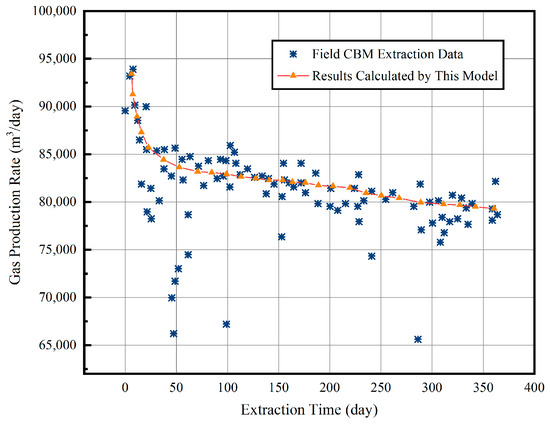

Prior to conducting further field engineering analysis using the proposed model that incorporates fracture roughness and multi-field effects in CO2-ECBM projects, validating the model’s accuracy is crucial. For the model validation step, we utilized field data from coalbed methane extraction performed by Mora and Wattenbarger [41]. This study used “Case 4” from the dataset obtained by Mora and Wattenbarger, a horizontal well for gas extraction. In the field extraction data, the simulated area is a rectangle measuring 568 × 568 m2. The left, right, and bottom boundaries of the model are fixed-end constraints, while the upper boundary is subjected to a gas pressure of 100 psia. Other major physical parameters are shown in Table 1. The primary data are taken from Table 1 in Reference [41]. The main data on gas production are derived from Reference [41]. Subsequently, our model is implemented in COMSOL v5.6 using finite element analysis methods. The boundary conditions, initial values of the coalbed and extraction, and extraction periods were all consistent with those reported in the literature.

Table 1.

The primary field data from Mora and Wattenbarger.

Simulation calculations are performed to obtain the gas production data for different extraction days, which are then compared with actual field production data, as shown in Figure 4. As Figure 4 indicates, the simulation results of field coalbed methane extraction using our proposed model closely align with the actual field data. Thus, the accuracy and reliability of our model, considering fracture roughness and multi-field effects, have been validated. It is worth noting that in the field extraction process, characteristic data values, such as those occurring over approximately 50 days, may arise due to fluctuations in meteorological, hydrological, and geological conditions. However, these specific factors causing data fluctuations were not considered in our simulation process. This omission is the primary reason for the main errors in the numerical simulation results.

Figure 4.

The validation of the model proposed in this study.

Furthermore, as shown in Figure 4, although the simulation results of the interdisciplinary model proposed by this study align well with the actual gas production data, there are still some data discrepancies in the early stages of extraction (around 50 days). This is because the simulation primarily employs the finite element method, which requires mesh division during the calculation process. Consequently, the size and quality of the mesh are directly related to the computational accuracy. While it is possible to choose the smallest mesh size during the calculation, this approach requires significant computational time and resources. In this study, after multiple comparisons between computational results and resource consumption, we select the following mesh settings and computational accuracy: the maximum mesh size is 2 m, the minimum mesh size is 0.0075 m, the maximum cell growth rate is 1.2, the curvature factor is 0.25, and the total number of meshes is 74,415. With this level of computational accuracy, the computational time is 1395 s.

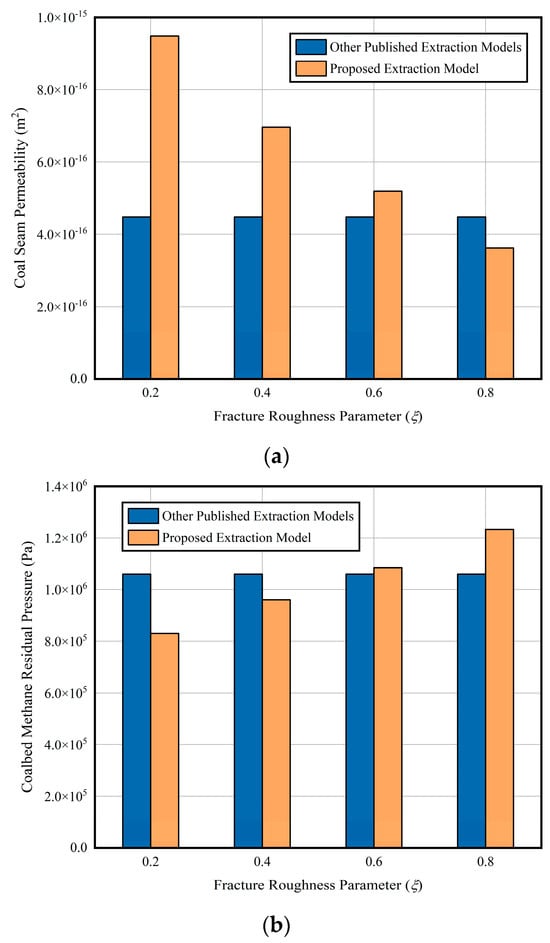

Furthermore, to further verify the advantages of the CO2-ECBM model proposed in this study, which can simultaneously and quantitatively explore the combined effects of thermo-hydro-mechanical coupling, extraction disturbances, and coal seam fracture roughness, we compared the stimulation results of this study with those of other models already published. Figure 5 shows a comparison of the coal seam permeability and residual gas pressure after 3650 days of extraction. As indicated by Figure 5, this study can explore the effects of the roughness of coal seam fracture on extraction efficiency under the combined thermo-hydro-mechanical effects. Therefore, the permeability of the coal seam and the pressure of coalbed methane significantly evolve with changes in fracture roughness. In contrast, other models of coalbed methane extraction published so far [2,3,7,15] cannot quantitatively characterize this feature. Hence, the analytical advantages of this study are fully highlighted.

Figure 5.

The analytical advantages of the model proposed in this study. (a) A comparison of the coal seam permeabilities. (b) A comparison of the coalbed methane residual pressures.

In the process of coalbed methane extraction, the evolution of coal seam permeability is the most important indicator for assessing extraction efficiency and the gas seepage capacity. The changes in fracture roughness parameters proposed in this study directly affect the gas seepage capacity. Therefore, to more visually demonstrate the direct impact of fracture roughness on coal seam permeability and to more directly showcase the advantages of this study, we chose to analyze permeability rather than selecting the more macroscopic indicator of gas production.

Additionally, the model proposed in this study is applicable to most CO2-ECBM project conditions. Relevant practitioners and interested readers can easily adjust the boundary conditions, initial values, calculation parameters, and mesh in the finite element analysis process to perform the desired engineering calculations. The good alignment of the calculation results with the actual data indicates that the model proposed in this study is correct and reliable, meaning that using the interdisciplinary model presented in Section 3 to analyze other extraction scenarios will yield accurate results.

5. Results and Discussion

It is worth noting that in Section 4, we employed the model proposed in this study that includes a fracture roughness constant to calculate the field coalbed methane extraction project, and compared the results with field data, achieving good consistency. This thorough verification formed the basis for the detailed calculations and analysis in this section. That is to say, the analysis results in this section are conducted on the basis of a strong match between the model and the actual field monitoring data.

5.1. The Numerical Model for the Field CO2-ECBM Project

Following the validation of the model’s accuracy, we employ it to conduct a comprehensive exploration of the interactions between fracture roughness and multi-field effects in a real-field project. The project is conducted in the Qinshui Basin coalbed methane reservoir, located in the central-southern part of Shanxi Province, China. The Qinshui Basin coalbed methane reservoir is China’s largest, most representative, and most promising reservoir for extraction. And, this region is one of the most active and promising for commercial coalbed methane development in China, with a significant number of CO2-ECBM projects having been undertaken in the Qinshui Basin coalbed methane reservoir. The central area of the basin offers a stable structural environment, weak hydrodynamic conditions, and a well-integrated cap rock, presenting favorable geological conditions for CO2-ECBM projects [33,42].

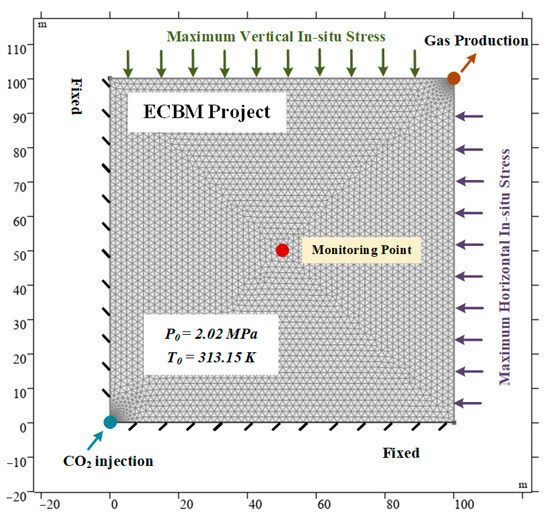

Our model is adopted to simulate a typical extraction layout for the CO2-ECBM project in the Qinshui Basin [33,42], as illustrated in Figure 6. Due to symmetry, only a quarter of the project area, approximately 200 m × 200 m × 5 m, is selected for the numerical simulation. The CO2 injection well is positioned in the lower left corner of the model, and the coalbed methane production well is located in the upper right corner, with all wells having a diameter of 0.1 m. An observation point is established at the central position of the coal layer to monitor the simulation results, with its two-dimensional coordinates at (50, 50). The CO2 injection period for this simulation is set to 3650 days.

Figure 6.

The Numerical Model of the Field CO2-ECBM Project.

Additionally, the parameters required for this simulation are sourced from geological data of the Jincheng No. 3 coal seam and the relevant literature [33,40,42], as shown in Table 2. The CO2 injection pressure is 4 MPa, with the initial coalbed methane pressure at 2.02 MPa and the initial temperature at 313.15 K.

Table 2.

The coal and gas parameters for stimulation.

5.2. The Simulation Results of the Field CO2-ECBM Project

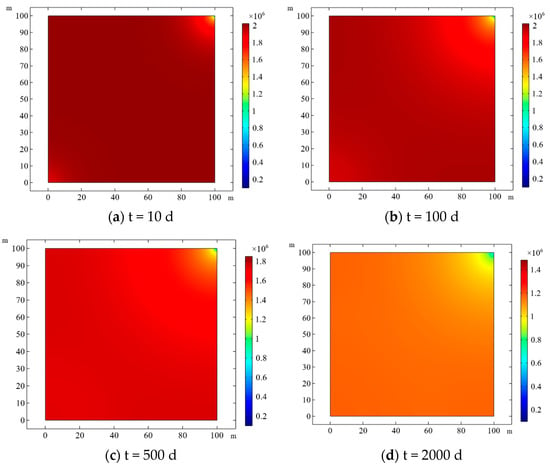

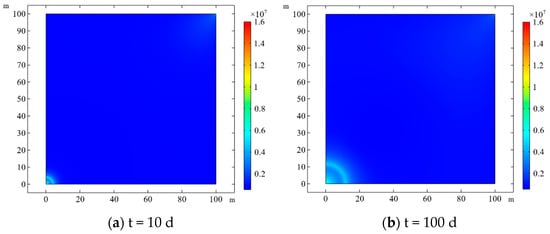

Subsequently, we investigate the spatiotemporal evolution of key parameters in the coalbed under the multi-field effect at different CO2 injection times, as shown in Figure 7, Figure 8 and Figure 9. Figure 7 illustrates the evolution of methane pressure in the coalbed at various CO2 injection times (extraction time = 10 d, 100 d, 500 d, and 2000 d). As depicted in Figure 7, with the progression of the project, coalbed methane is progressively extracted from the well under the influence of CO2 displacement. The low-pressure areas are concentrated around the extraction well.

Figure 7.

The evolution of CBM Pressure at different CO2 injection times (Unit: Pa).

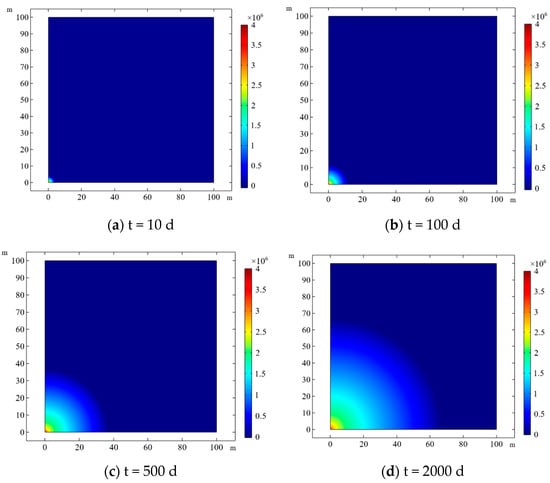

Figure 8.

The evolution of CO2 pressure at different CO2 injection times (Unit: Pa).

Figure 9.

The evolution of coalbed stress at different CO2 injection times (Unit: Pa).

Figure 8 depicts the distribution of CO2 contents in the coalbed at different CO2 injection times. As Figure 8 illustrates, under the influence of high pressure being present at the injection well, CO2 gradually diffuses into the coalbed and becomes sequestered. The high-pressure areas are predominantly located near the injection well. Compared to the pressure of CBM, the evolution of CO2 pressure is less intense. Notably, although this pattern aligns with engineering experience and is evident, our numerical model uniquely accounts for the contribution of fracture roughness in CO2-ECBM projects, a detail not quantitatively captured in previously published models. Furthermore, the results in Figure 8 provide new insights for CO2 geological sequestration and clean extraction. We will quantitatively explore this contribution in our subsequent research.

Subsequently, we examine the spatiotemporal distribution of coalbed stress at different CO2 injection times, as shown in Figure 9. The precise analysis of the evolution of coalbed stress under the influence of multiple factors is crucial for assessing the safety of coalbed methane extraction projects. Although the pressure of the CO2 in the coalbed increases and the pressure of CBM decreases due to the combined effect of CO2 injection and CBM production, Figure 9 reveals that the high-stress areas in the coalbed are primarily concentrated around the injection well. This indicates that CO2 injection has a more significant impact on coalbed stress changes compared to CBM production.

5.3. Quantitative Investigation for the Impact of Fracture Roughness on CO2-ECBM Projects

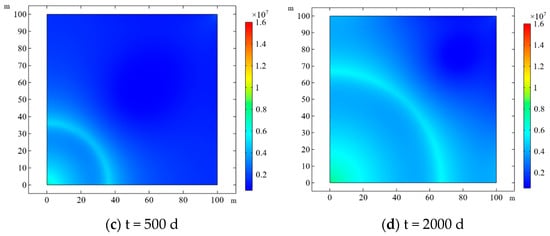

Further, we conduct a quantitative investigation into the contribution of fracture roughness in CO2-ECBM projects, focusing on its impact on CO2 injection, CBM production, and coalbed characteristics. Initially, we explore the influence of the innovative fracture roughness quantification parameter proposed in this study on the gas pressures of CO2 and CBM during different stages of extraction, as depicted in Figure 10 and Figure 11. The baseline value for is derived from reference [35], and we explore variations of within the same order of magnitude. Figure 10 shows the evolution of the residual methane gas pressure at the monitoring point (see Figure 6, located at (50, 50)) under different extraction times and . As Figure 10 indicates, the residual pressure of CBM decreases over time regardless of the value of roughness parameter . At the same extraction time, the residual methane pressure gradually increases with the augmentation of . A higher leads to a slower decline in methane gas pressure due to extraction. As Section 3 elucidates, a larger implies rougher coalbed fractures, consequently making gas permeation more challenging. Therefore, with greater roughness, CBM extraction becomes more difficult, resulting in more gas remaining in the coalbed and, as a consequence, a higher residual gas pressure.

Figure 10.

The evolution of the CBM residual pressure under varying extraction times and ξ values.

Figure 11.

The evolution of CO2 pressure under varying extraction times and ξ values.

Figure 11 depicts the influence of ξ on CO2 pressure within the coal seam at different CO2 injection intervals. As indicated by Figure 11, the CO2 pressure at the monitoring point incrementally escalates with prolonged injection. This tendency is consistent under varying degrees of fracture roughness, quantitatively characterized by ξ. Notably, at equivalent production intervals, a higher ξ leads to diminished CO2 pressure within the coal seam. Prior sections elucidate that an increased ξ correlates with more pronounced roughness in coalbed fractures, thus hindering CO2 permeation. Consequently, under identical parameters, a lower ξ facilitates greater CO2 injection. Hence, there exists an inverse relationship between ξ and CO2 pressure. Significantly, these findings also offer novel insights for CO2 sequestration strategies.

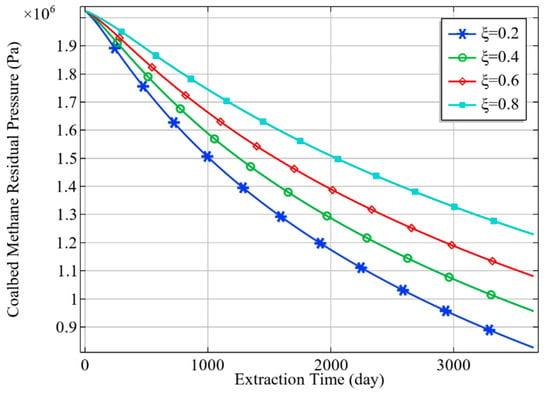

Furthermore, our research probes into the contribution of the fracture roughness parameter ξ to the permeability properties of the coal seam. Figure 12 and Figure 13 present the evolution of coal seam permeability and porosity under different ξ values. Figure 11 specifically examines coal seam permeability during varying CO2 injection intervals and under different ξ-induced fracture roughness. It emerges that, as extraction progresses, the coal seam permeability under different ξ values incrementally increases, influenced by a confluence of factors including reduced in situ stress, thermal expansion effects, and gas pressure-induced coal seam contraction. Importantly, at consistent extraction intervals, a lower ξ engenders enhanced coal seam permeability. This also corroborates the accuracy of our model, positing that a lower ξ, indicating less roughness in fractures, results in increased coal seam permeability.

Figure 12.

The evolution of coal permeability under varying times and ξ values.

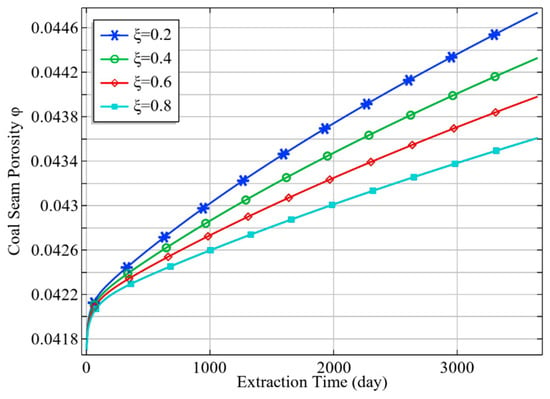

Figure 13.

The evolution of coal porosity under varying times and ξ values.

A lower ξ facilitates easier gas permeation, resulting in higher gas pressures within the coal seam. Under the influence of multi-field coupling effects (specifically hydro-mechanics coupling effects), higher gas pressures induce greater stress in the coal seam, leading to more significant deformation. Under this expansion effect, the original porosity of the coal seam consequently increases.

Figure 13 elucidates the evolution of coal seam porosity under different extraction times and ξ values, revealing a uniform increase in coal seam permeability at varying ξ levels as extraction progresses. Additionally, at similar extraction intervals, a lower ξ induces greater coal seam porosity. This observation further validates the correctness of the model presented in this study.

In the CO2-ECBM project, the evolution of coal seam permeability and porosity directly influences extraction efficiency, offering novel and significant insights for precise gas production assessment.

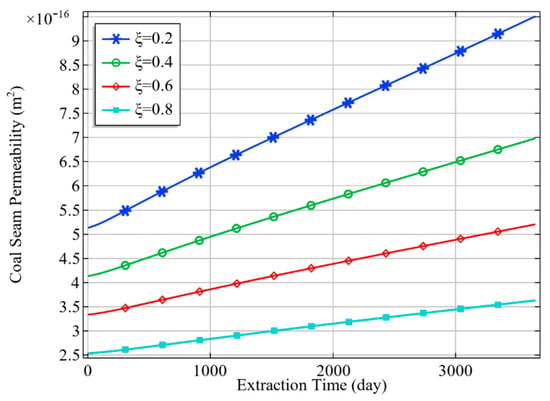

The CO2-ECBM process is influenced by a multitude of factors, including differential gas adsorption characteristics, pressure and temperature effects, fracture structure alterations, and gas exchange dynamics. Methane in coal seams is physically adsorbed within the coal’s porous structure, while carbon dioxide exhibits a stronger affinity and can replace methane in these pores. When CO2 is injected into the coalbed, it preferentially adheres to the coal surface, displacing the previously adsorbed methane. As Figure 12 and Figure 13 demonstrate, changes in fracture roughness directly affect porosity and permeability. Therefore, quantitatively analyzing the impact of fracture roughness on adsorption–desorption intensity in the CO2-ECBM process is vital for accurately evaluating extraction efficiency.

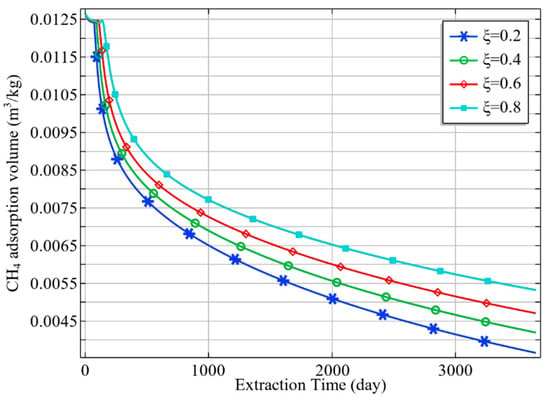

Consequently, we explored the influence of varying fracture roughness parameters on the methane content in the adsorbed state and the CO2 adsorption volume, as depicted in Figure 14 and Figure 15. Figure 14 reveals the evolution of the methane adsorption volume over different extraction periods and under various ξ values. It indicates that the methane adsorption volume gradually decreases due to CO2 competition over time, transitioning from an adsorbed to a free state and being produced during extraction. At the same extraction intervals, a higher ξ results in increased methane adsorption. When ξ increases from 0.2 to 0.8, the methane content in the adsorbed state after 3000 days of extraction increases by 24.6%, with a maximum increase of 30.2% in methane adsorption. A greater ξ implies a more complex fracture surface, making gas production more challenging. Consequently, higher residual methane pressure within the coal seam is observed, resulting in less methane desorption to a free state.

Figure 14.

The evolution of the CH4 adsorption volume under varying times and ξ values.

Figure 15.

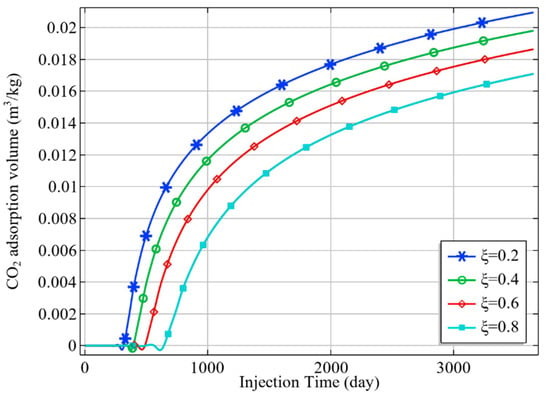

The evolution of the CO2 adsorption volume under varying times and ξ values.

Figure 15 shows the evolution of CO2 adsorption under different CO2 injection intervals and varying ξ values. The figure indicates that CO2 adsorption gradually increases over the extraction process under different ξ levels. With other parameters constant, an increase in ξ results in reduced CO2 adsorption. As previously mentioned, an increase in ξ makes gas percolation more challenging; and, as shown in Figure 11, a smaller ξ leads to greater CO2 pressure. Naturally, an increase in the amount of CO2 content within the coal seam results in increased adsorption. When ξ decreases from 0.8 to 0.2, the CO2 adsorption after 3000 days of extraction increases by 20.8%, with a maximum increase of 23.5%.

It is worth noting that the focus of this study is on the impact of fracture roughness on Enhanced Coalbed Methane (ECBM) projects. Therefore, it does not explore all the factors that may affect gas migration, such as pore roughness, the Joule–Thomson effect for CO2, cross-scale microstructures, and a two-phase flow. We will focus on these factors in our subsequent research.

6. Conclusions

To quantitatively analyze the impact of fracture roughness evolution on CO2-Enhanced Coalbed Methane (CO2-ECBM) engineering efficiency under multi-physical field coupling effects, this study introduces an innovative, interdisciplinary mathematical model. The model proposes a novel parameter capable of quantitatively characterizing fracture roughness, defining permeability as a function of this parameter. It comprehensively couples factors such as CO2 and methane adsorption/desorption, the evolution of gas pressures, adsorption and pressure-induced coal seam stress, in situ stress, coal seam temperature, and deformation in the CO2-ECBM process. When applied to typical field CO2-ECBM projects, the model yields the following main conclusions:

- The model accurately and quantitatively characterizes the contribution of fracture roughness in CO2-ECBM engineering, showing significant interactions between the two gas pressures, their adsorption strengths, and the coal layer’s permeability, all correlated with ξ.

- The quantitative parameter ξ for fracture roughness substantially influences coal layer porosity and permeability. At identical extraction times, a smaller ξ results in higher coal layer permeability and porosity.

- The adsorption strength of CO2 and CH4 is highly sensitive to ξ. Changes in fracture roughness alter the pressures of both gases in the coal layer, as well as altering their adsorption quantities significantly. When ξ decreases from 0.8 to 0.2, CO2 adsorption increases by 20.8%, and the adsorbed CH4 content increases by 24.6% after 3000 days of extraction.

This research offers a novel perspective for quantitatively analyzing CO2-ECBM engineering efficiency from the viewpoint of fracture roughness. Practitioners can apply this analytical model to most coal seam scenarios with simple modifications to initial values, boundary conditions, and meshes. Notably, the gas pressure of CO2 in the coal layer is significantly affected by ξ, potentially providing technical support for CO2 geological sequestration and low-carbon mining.

Author Contributions

L.Z.: Conceptualization, software, validation, formal analysis, writing—original draft preparation, resources; Y.S.: conceptualization, investigation, resources, writing—review and editing, supervision, project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author [Yafei Shan], upon reasonable request.

Acknowledgments

This work was initiated, conducted, and summarized with the full support of the College of Safety Science and Engineering of Liaoning Technical University.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xue, H.T.; Gui, X.H.; Wang, G.D.; Yang, X.; Gong, H.R.; Du, F. Prediction of gas drainage changes from nitrogen replacement: A study of a TCN deep learning model with integrated attention mechanism. Fuel 2024, 357, 129797. [Google Scholar] [CrossRef]

- Ye, D.Y.; Liu, G.N.; Zou, X.; Yang, Y.G.; Wang, F.T.; Gao, F. A Dual Fractal Approach to Thermal-Hydrological-Mechanical Interactions of Unconventional Reservoir. Rock Mech. Rock Eng. 2022, 55, 7081–7101. [Google Scholar] [CrossRef]

- Liang, S.; Liang, Y.; Elsworth, D.; Yao, Q.; Fu, X.; Kang, J.; Hao, Y.; Wang, M. Permeability evolution and production characteristics of inclined coalbed methane reservoirs on the southern margin of the Junggar Basin, Xinjiang, China. Int. J. Rock Mech. Min. Sci. 2023, 171, 105581. [Google Scholar] [CrossRef]

- Shi, Y.; Lin, B.; Liu, T.; Zhao, Y.; Hao, Z. Synergistic ECBM extraction technology and engineering application based on hydraulic flushing combing gas injection displacement in low permeability coal seams. Fuel 2022, 318, 123688. [Google Scholar] [CrossRef]

- Mukherjee, M.; Misra, S. A review of experimental research on Enhanced Coal Bed Methane (ECBM) recovery via CO2 sequestration. Earth-Sci. Rev. 2018, 179, 392–410. [Google Scholar] [CrossRef]

- Faltinson, J.; Gunter, B. Integrated Economic Model CO2 capture, transport, ECBM and saline aquifer storage. Energy Procedia 2009, 1, 4001–4005. [Google Scholar] [CrossRef][Green Version]

- Fang, H.; Sang, S.; Wang, Z.; Guo, J.; Liu, H.; Xu, H.; Kang, J.; Hao, Y.; Wang, M. Numerical analysis of temperature effect on CO2 storage capacity and CH4 production capacity during the CO2-ECBM process. Energy 2023, 171, 130022. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Booth, P.; Nemcik, J. Experimental study of the adsorption-induced coal matrix swelling and its impact on ECBM. J. Earth Sci. 2017, 28, 917–925. [Google Scholar] [CrossRef]

- Ye, D.Y.; Liu, G.N.; Wang, F.T.; Gao, F.; Yang, T.T.; Zhu, J.Y. Fractal hydrological-thermal-mechanical analysis of unconventional reservoir: A fracture-matrix structure model for gas extraction. Int. J. Heat Mass Transf. 2023, 202, 123670. [Google Scholar] [CrossRef]

- Asif, M.; Wang, L.; Naveen, P.; Longinos, S.N.; Hazlett, R.; Ojha, K.; Panigrahi, D.C. Influence of competitive adsorption, diffusion, and dispersion of CH4 and CO2 gases during the CO2-ECBM process. Fuel 2024, 358, 130065. [Google Scholar] [CrossRef]

- Fang, H.; Yu, S.; Zhang, S.; Sang, S.; Guo, J.; Wang, Z.; Wang, X. Coupling Mechanism of THMC Fields in Crushed Soft Coal with Low Permeability after CO2 Injection and Its Application in CO2-ECBM Technology. Energy Fuels 2024, 38, 6891–6911. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Sang, S.; Liu, D.; Wang, M.; Liu, S. Dynamic characterization of multiphase methane during CO2-ECBM: An NMR relaxation method. Fuel 2022, 324, 124526. [Google Scholar] [CrossRef]

- Niu, Q.; Cao, L.; Sang, S.; Wang, W.; Zhou, X.; Yuan, W.; Ji, Z.; Chang, J.; Li, M. Experimental study on the softening effect and mechanism of anthracite with CO2 injection. Int. J. Rock Mech. Min. Sci. 2021, 138, 104614. [Google Scholar] [CrossRef]

- Fang, H.; Xu, H.; Sang, S.; Liu, S.; Song, S.; Liu, H. 3D reconstruction of coal pore network and its application in CO2-ECBM process simulation at laboratory scale. Front. Earth Sci. 2022, 16, 523–539. [Google Scholar] [CrossRef]

- Liu, X.; Sang, S.; Zhou, X.; Wang, Z.; Niu, Q.; Mondal, D. Modelling of geomechanical response for coal and ground induced by CO2-ECBM recovery. Gas Sci. Eng. 2023, 113, 204953. [Google Scholar] [CrossRef]

- Talapatra, A. A study on the carbon dioxide injection into coal seam aiming at enhancing coal bed methane (ECBM) recovery. J. Pet. Explor. Prod. Technol. 2020, 10, 1965–1981. [Google Scholar] [CrossRef]

- Liu, Z.D.; Chen, X.H.; Tian, F.C.; Zhu, W.C.; Hu, Z.; Su, W.W.; Wang, G. Dynamic effects of rough elements in fractures on coal permeability during different stages of methane extraction. Gas Sci. Eng. 2023, 119, 205118. [Google Scholar] [CrossRef]

- Najafi, M.; Abousadi, Z.A.; Honarvar, B.; Sajadian, S.A. Publisher Correction: Separation of hydrocarbons from activated carbon as a porous substance in a glycol regeneration process using supercritical carbon dioxide. Sci. Rep. 2022, 12, 21607. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Du, X.; Wang, X.; Hou, Q.; Wang, Z.; Yi, J.; Li, M. Pore and permeability changes in coal induced by true triaxial supercritical carbon dioxide fracturing based on low-field nuclear magnetic resonance. Energy 2024, 286, 129492. [Google Scholar] [CrossRef]

- Hol, S.; Gensterblum, Y.; Massarotto, P. Sorption and changes in bulk modulus of coal—experimental evidence and governing mechanisms for CBM and ECBM applications. Int. J. Coal Geol. 2014, 128, 119–133. [Google Scholar] [CrossRef]

- Tang, S.L.; Liu, Q.; Tang, H.; Yang, F. Study on the Movement of Pulverized Coal Particles in Fractal Fracture Network. ACS Omega 2023, 8, 26369–26378. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.J.; Tang, H.L.; Wu, Y.C.; Wang, K.; Xu, C. Gas seepage in underground coal seams: Application of the equivalent scale of coal matrix-fracture structures in coal permeability measurements. Fuel 2021, 288, 119641. [Google Scholar] [CrossRef]

- Jing, Y.; Armstrong, R.T.; Mostaghimi, P. Digital coal: Generation of fractured cores with microscale features. Fuel 2017, 207, 93–101. [Google Scholar] [CrossRef]

- Li, Y.T.; Zhao, Y.X.; Jiang, Y.D.; Zhang, B.; Song, H.H.; Liu, B. Characteristics of Pore and Fracture of Coal with Bursting Proneness Based on DIC and Fractal Theory. Energies 2020, 13, 5404. [Google Scholar] [CrossRef]

- Ye, D.Y.; Liu, G.N.; Zhou, J.H.; Yang, T.T.; Cheng, G.J.; Fan, S.D. A fractal power-law approach for investigating the interactions between reservoir microstructure and gas migration. Phys. Fluids 2023, 35, 016604. [Google Scholar] [CrossRef]

- Ye, D.; Liu, G.; Ma, T.; Cheng, G.; Fan, S.; Yang, T. The mechanics of frost heave with stratigraphic microstructure evolution. Eng. Geol. 2023, 319, 107119. [Google Scholar] [CrossRef]

- Li, L.; Zhang, S.F.; Li, Z.Q.; Chen, X.J.; Wang, L.; Feng, S.L. An Experimental and Numerical Study of Abrupt Changes in Coal Permeability with Gas Flowing through Fracture-Pore Structure. Energies 2022, 15, 7842. [Google Scholar] [CrossRef]

- Liu, X.X.; Sheng, J.C.; Liu, J.S.; Hu, Y.J. Evolution of Coal Permeability during Gas InjectionFrom Initial to Ultimate Equilibrium. Energies 2018, 11, 2800. [Google Scholar] [CrossRef]

- Morga, R. Changes of semifusinite and fusinite surface roughness during heat treatment determined by atomic force microscopy. Int. J. Coal Geol. 2011, 88, 218–226. [Google Scholar] [CrossRef]

- Xia, W.C.; Li, Y.F. Role of Roughness Change on Wettability of Taixi Anthracite Coal Surface before and after the Heating Process. Energy Fuels 2016, 30, 281–284. [Google Scholar] [CrossRef]

- Chen, Y.R.; Xia, W.C.; Xie, G.Y. Contact angle and induction time of air bubble on flat coal surface of different roughness. Fuel 2018, 222, 35–41. [Google Scholar] [CrossRef]

- Xia, T.Q.; Zhou, F.B.; Gao, F.; Kang, J.H.; Liu, J.S.; Wang, J.G. Simulation of coal self-heating processes in underground methane-rich coal seams. Int. J. Coal Geol. 2015, 141–142, 1–12. [Google Scholar] [CrossRef]

- Fang, H.H.; Sang, S.X.; Liu, S.Q. Establishment of dynamic permeability model of coal reservoir and its numerical simulation during the CO2-ECBM process. J. Pet. Sci. Eng. 2019, 179, 885–898. [Google Scholar] [CrossRef]

- Kong, X.G.; Wang, E.Y.; Liu, Q.L.; Li, Z.H.; Li, D.X.; Cao, Z.Y.; Niu, Y. Dynamic permeability and porosity evolution of coal seam rich in CBM based on the flow-solid coupling theory. J. Nat. Gas Sci. Eng. 2017, 40, 61–71. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, W.; Hu, Q.; Zhai, G.; Wang, R.; Xu, X.; Xu, Z.; Meng, F.; Liu, F. Pressure–dependent fracture permeability of marine shales in the Northeast Yunnan area, Southern China. Int. J. Coal Geol. 2019, 214, 103237. [Google Scholar] [CrossRef]

- Ye, D.; Lin, X.; Yang, X.; Li, X.; Zhao, R.; Ma, H. How to quantitatively investigate the effect of fracture roughness on gas flow: A new fully coupled interdisciplinary model. Phys. Fluids 2023, 35, 126610. [Google Scholar] [CrossRef]

- Yang, H.; Wang, L.; Yang, C.; Guo, I.; Guo, W.; Bi, Z.; Zhao, G. Visualization and quantitative statistics of experimental hydraulic fracture network based on optical scanning. J. Nat. Gas Sci. Eng. 2022, 105, 104718. [Google Scholar] [CrossRef]

- Li, W.; Frash, L.P.; Welch, N.J.; Carey, W.I.; Meng, M.; Wigand, M. Stress-dependent fracture permeability measurements and implications for shale gas production. Fuel 2021, 290, 119984. [Google Scholar] [CrossRef]

- Guo, P.; Li, X.; Li, S.; Yang, W. Quantitative analysis of anisotropy effect on hydrofracturing efficiency and process in shale using X-ray computed tomography and acoustic emission. Rock Mech. Rock Eng. 2021, 54, 5715–5730. [Google Scholar] [CrossRef]

- Fan, J.; Feng, R.; Wang, J.; Wang, Y. Laboratory investigation of coal deformation behavior and its influence on permeability evolution during methane displacement by CO2. Rock Mech. Rock Eng. 2017, 50, 1725–1737. [Google Scholar] [CrossRef]

- Mora Carlos, A.; Wattenbarger, R.A.; McKetta, S. Comparison of computation methods for CBM performance. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 12–14 June 2007. [Google Scholar]

- Fang, H.; Sang, S.; Liu, S. The coupling mechanism of the thermal-hydraulic-mechanical fields in CH4-bearing coal and its application in the CO2-enhanced coalbed methane recovery. J. Pet. Sci. Eng. 2019, 181, 106177. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).