Combustion Efficiency of Various Forms of Solid Biofuels in Terms of Changes in the Method of Fuel Feeding into the Combustion Chamber

Abstract

1. Introduction

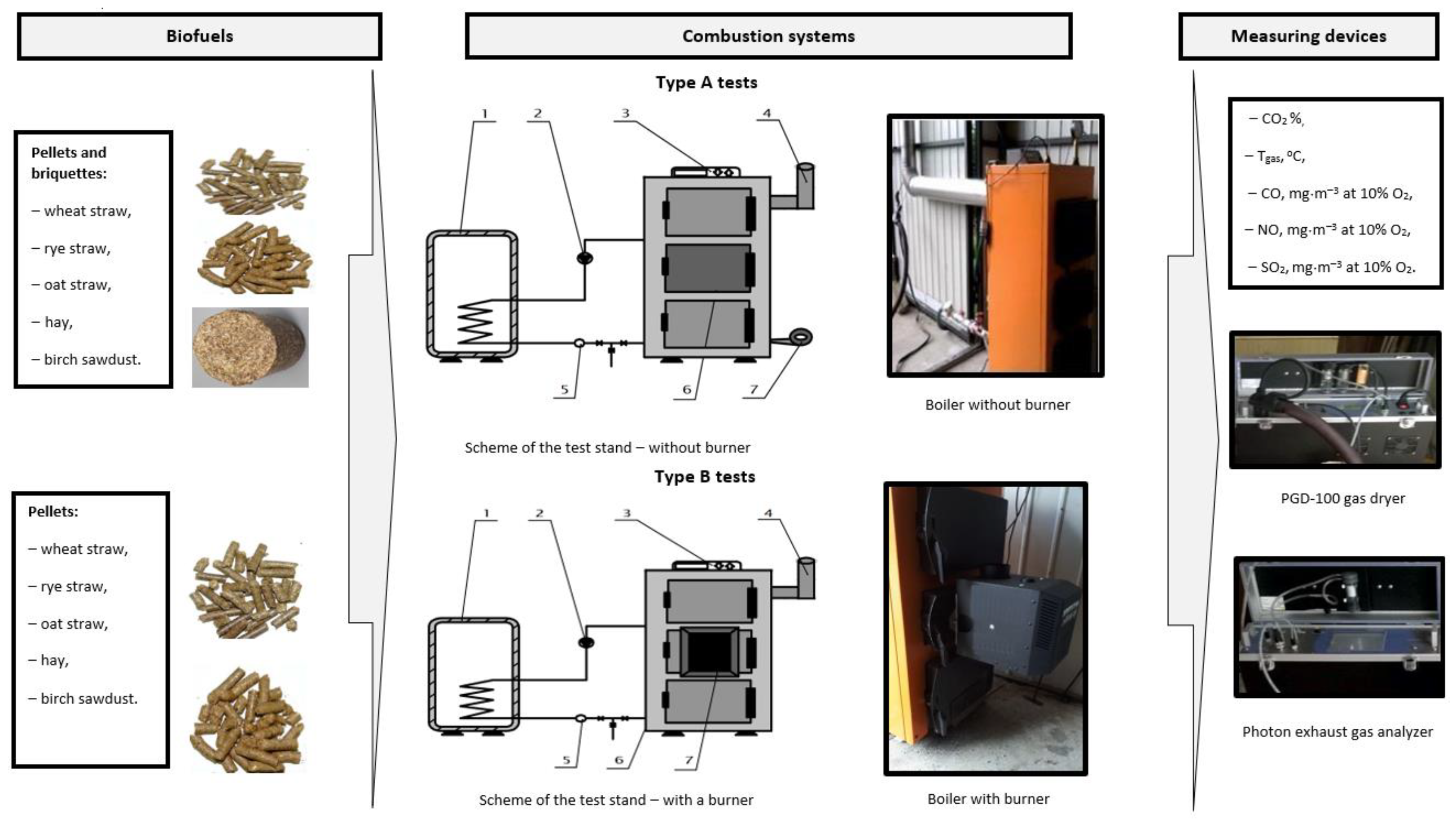

2. Materials and Methods

2.1. Biofuels

2.2. Research Stand

2.3. Course of Combustion Tests

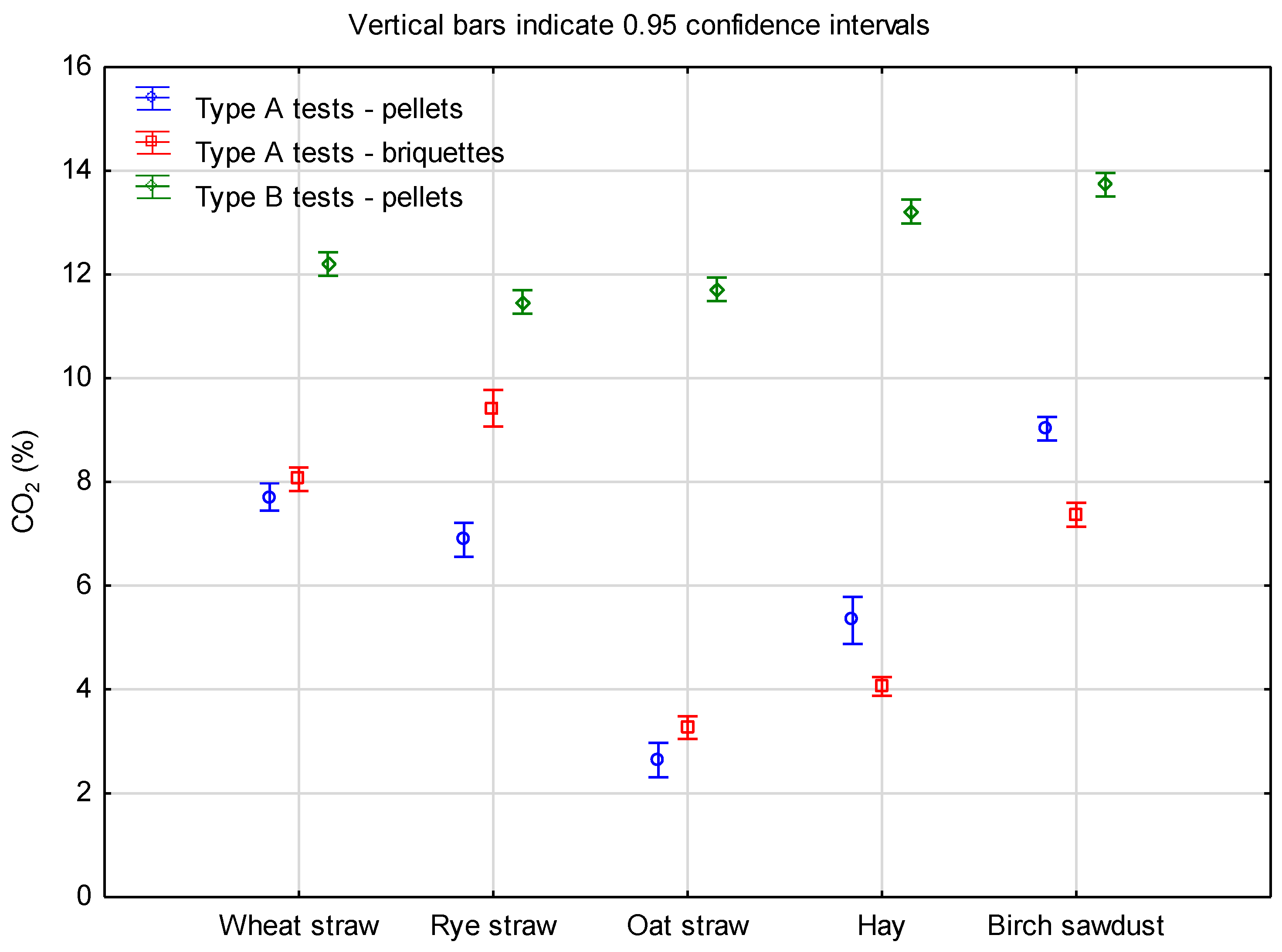

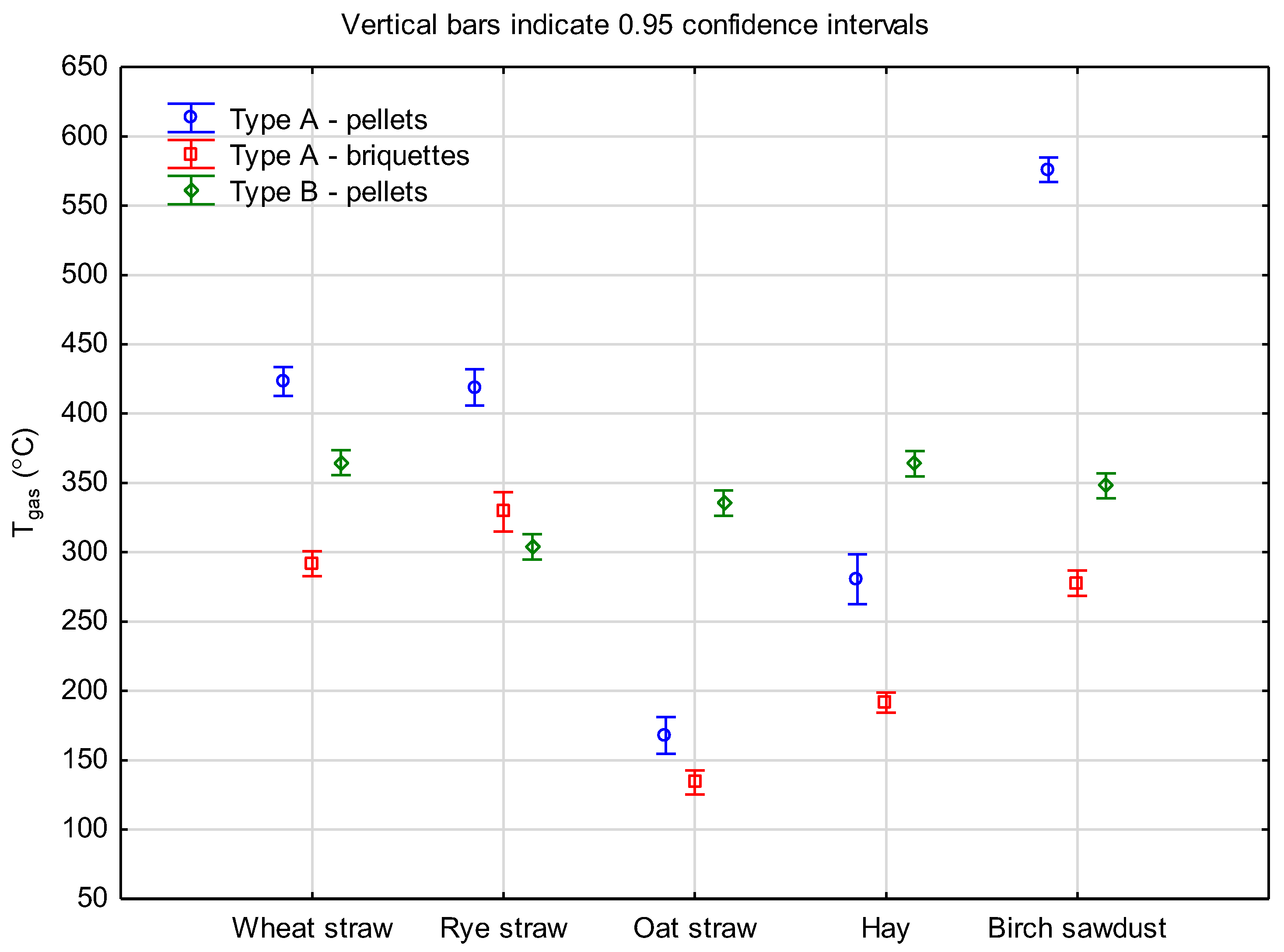

3. Results

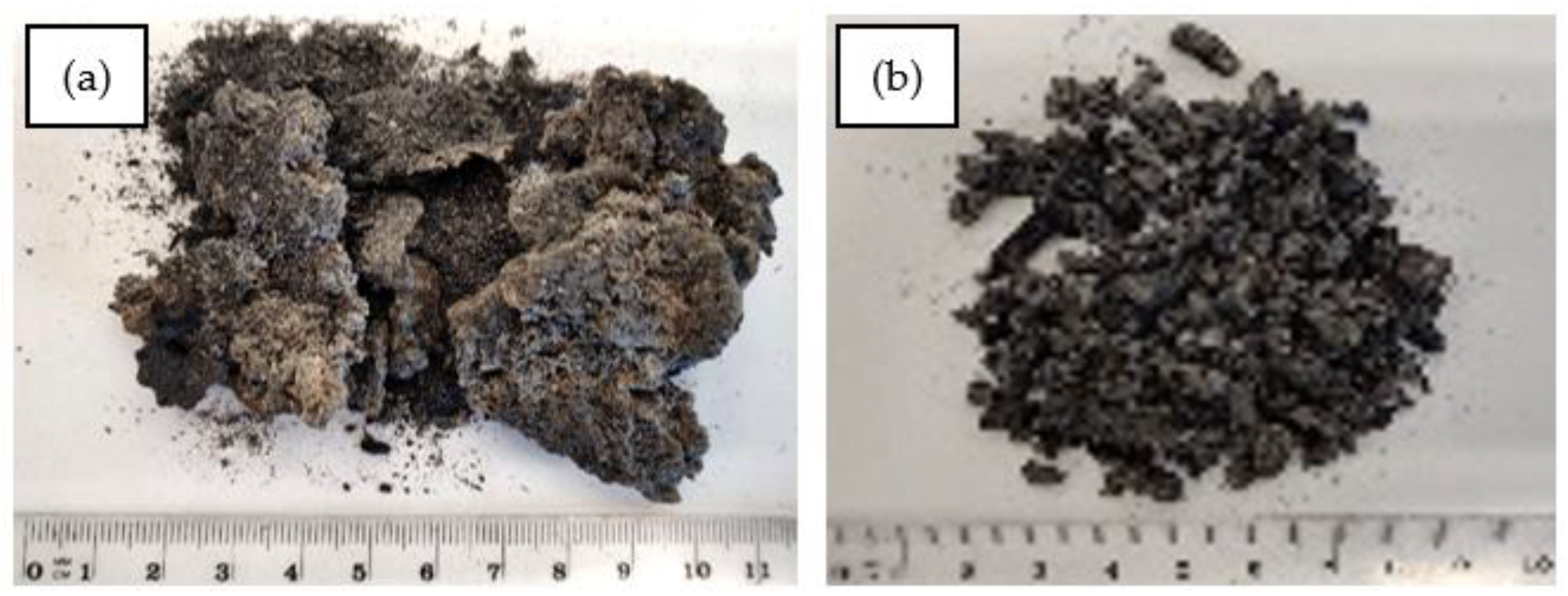

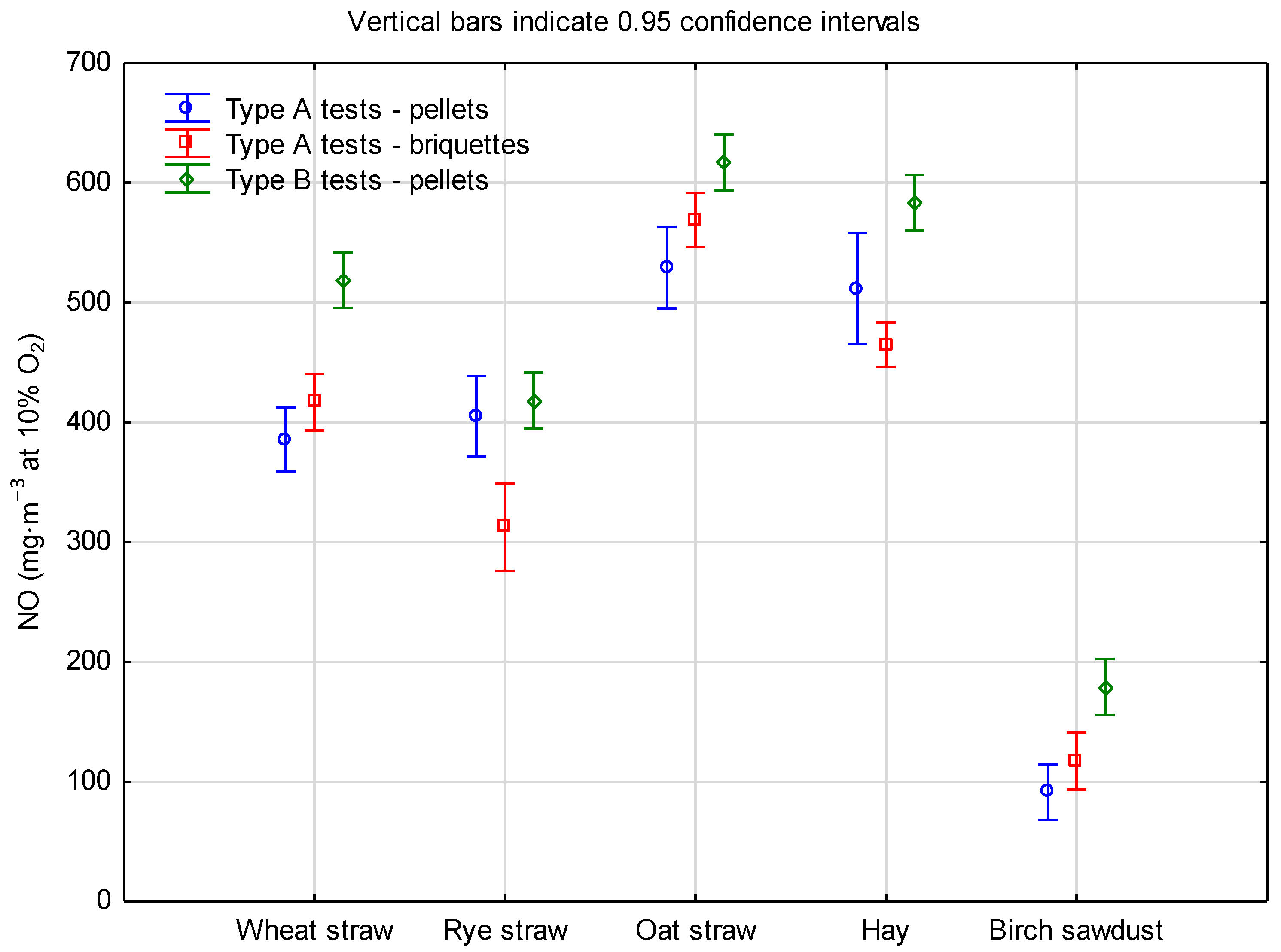

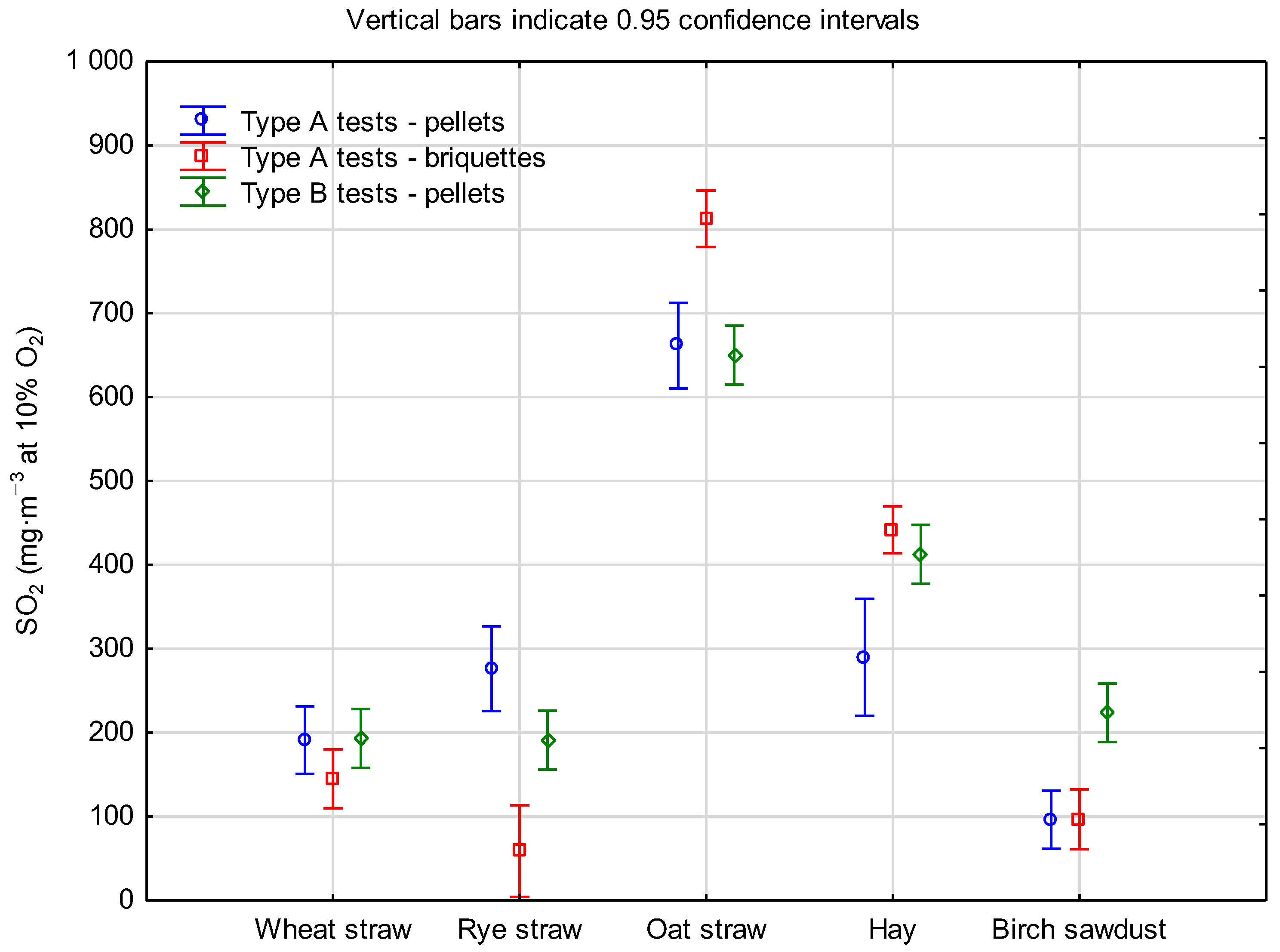

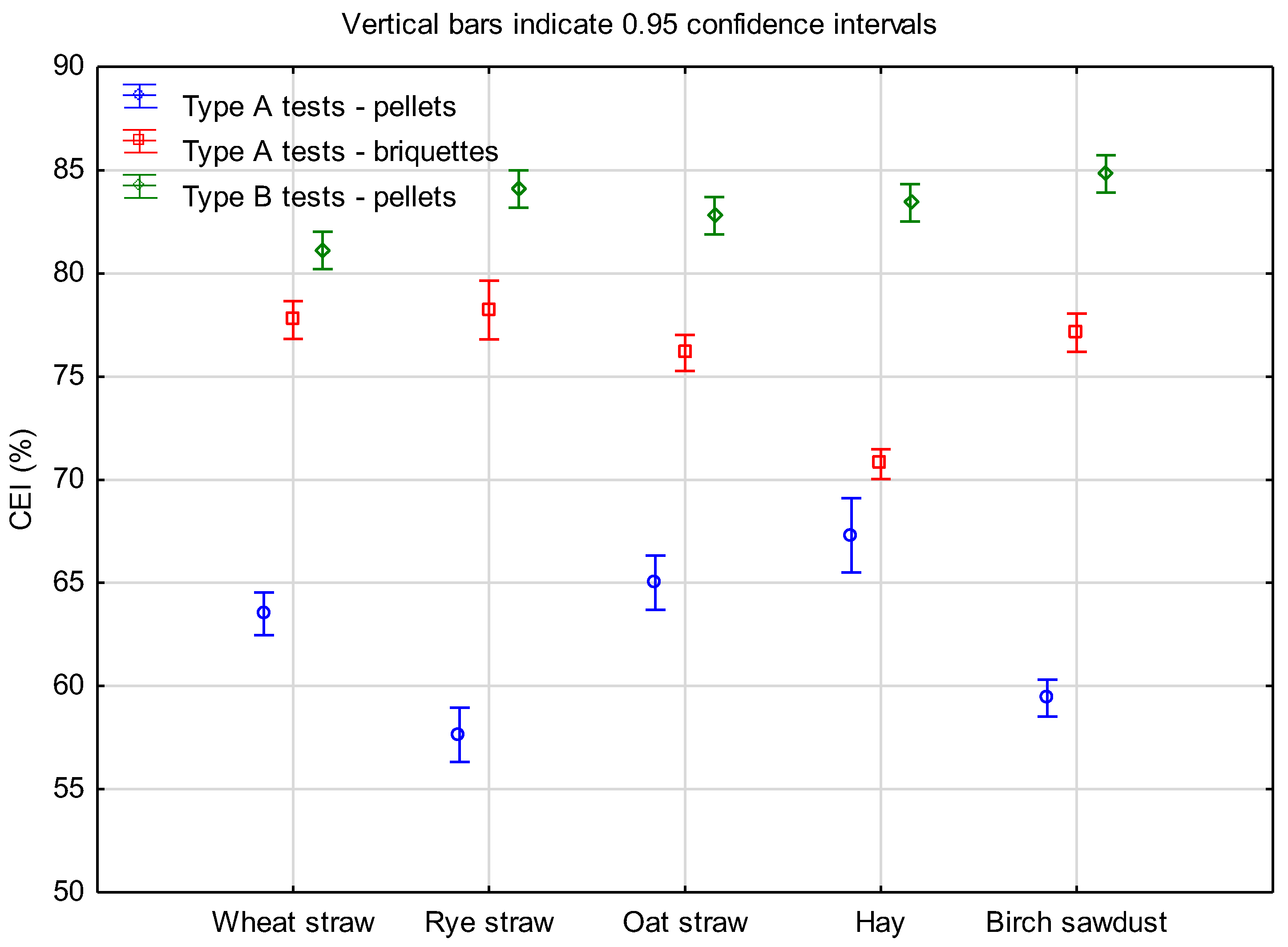

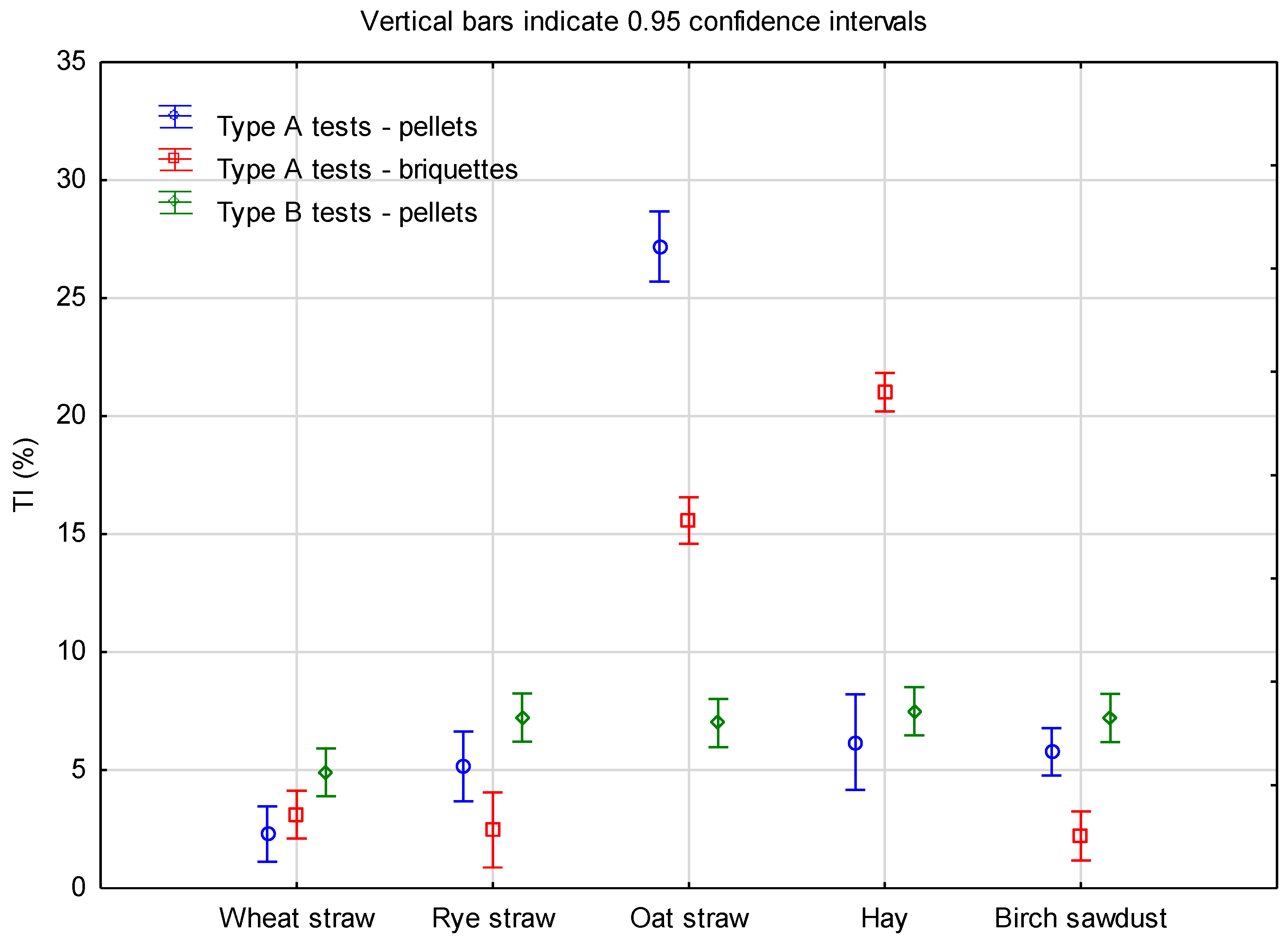

3.1. Results of Combustion Tests

3.2. Statistical Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Munir, O.; Naheed, S.; Volkan, A.; Rizwan, I.; Khalid, R.H.; Mohammad, J.; Faridah, H.I. Biomass and bioenergy: An overview of the development potential in Turkey and Malaysia. Renew. Sustain. Energy Rev. 2017, 79, 1285–1302. [Google Scholar]

- Mitchell, E.J.S.; Lea-Langton, A.R.; Jones, J.M.; Williams, A.; Layden, P.; Johnson, R. The impact of fuel properties on the emissions from the combustion of biomass and other solid fuels in a fixed bed domestic stove. Fuel Process. Technol. 2016, 142, 115–123. [Google Scholar] [CrossRef]

- Pafcuga, M.; Holubcik, M.; Durcansky, P.; Kapjor, A.; Malcho, M. Small Heat Source Used for Combustion of Wheat-Straw Pellets. Appl. Sci. 2021, 11, 5239. [Google Scholar] [CrossRef]

- Ríos-Badrán, I.M.; Luzardo-Ocampo, I.; García-Trejo, J.F.; Santos-Cruz, J.; Gutiérrez-Antonio, C. Production and characterization of fuel pellets from rice husk and wheat straw. Renew. Energy 2020, 145, 500–507. [Google Scholar] [CrossRef]

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 emissions from Biomass Combustion for Bioenergy: Atmospheric Decay and Contribution to Global Warming. Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef]

- Possell, M.; Hewitt, C.N.; Beerling, D.J. The Effects of Glacial Atmospheric CO2 Concentrations and Climate on Isoprene Emissions by Vascular Plants. Glob. Chang. Biol. 2005, 11, 60–69. [Google Scholar] [CrossRef]

- A European Green Deal. Striving to Be the First Climate-Neutral Continent. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 18 March 2023).

- Polityka Energetyczna Unii Europejskiej. Available online: https://www.europarl.europa.eu/factsheets/pl/sheet/68/politykaenergetyczna-zasady-ogolne (accessed on 8 March 2023).

- Stokowiec, K.; Wciślik, S.; Kotrys-Działak, D. Innovative Modernization of Building Heating Systems: The Economy and Ecology of a Hybrid District-Heating Substation. Inventions 2023, 8, 43. [Google Scholar] [CrossRef]

- Obaidullah, M.; Bram, S.; Verma, V.K.; De Ruyck, J. A Review on Particle Emissions from Small Scale Biomass Combustion. Int. J. Renew. Energy Res. 2012, 2, 147–159. [Google Scholar]

- Mlonka-Mędrala, A.; Magdziarz, A.; Dziok, T.; Sieradzka, M.; Nowak, W. Laboratory Studies on the Influence of Biomass Particle Size on Pyrolysis and Combustion Using TG GC/MS. Fuel 2019, 252, 635–645. [Google Scholar] [CrossRef]

- Zajemska, M.; Urbańczyk, P.; Poskart, A.; Urbaniak, D.; Radomiak, H.; Musiał, D.; Golański, G.; Wyleciał, T. The impact of co-firing sunflower husk pellets with coal in a boiler on the chemical composition of flue gas. Energy Fuels 2017, 14, 02021. [Google Scholar] [CrossRef]

- Bala-Litwiniak, A.; Musiał, D. Computational and Experimental Studies of Selected Types of Biomass Combustion in a Domestic Boiler. Materials 2022, 15, 4826. [Google Scholar] [CrossRef] [PubMed]

- Kraszkiewicz, A. Influence of Geometrical Features of Solid Biofuels on the Implementation of the Combustion Process. Combust. Sci. Technol. 2023, 195, 2456–2473. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, J.; Liu, J. Experimental Studies on Preheating Combustion Characteristics of Low-Rank Coal with Different Particle Sizes and Kinetic Simulation of Nitrogen Oxide. Energies 2023, 16, 7078. [Google Scholar] [CrossRef]

- Malaťák, J.; Velebil, J.; Bradna, J.; Gendek, A.; Tamelova, B. Evaluation of CO and NOx emissions in real-life operating conditions of herbaceous biomass briquettes combustion. Acta Technol. Agric. 2020, 2, 53–59. [Google Scholar] [CrossRef]

- Ito, H.; Tokunaga, R.; Nogami, S.; Miura, M. Influence of Biomass Raw Materials on Combustion Behavior of Highly Densified Single Cylindrical Biomass Briquette. Combust. Sci. Technol. 2022, 194, 2072–2086. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Salvachúa, D.; Martínez, M.J.; Diaz, L.F.; Zamorano, M. Analysis of the relation between the cellulose, hemicellulose and lignin content and the thermal behavior of residual biomass from olive trees. Waste Manag. 2013, 33, 2245–2249. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhu, L.; Chen, H.; Xu, B.; Li, C.; Zeng, G. Experimental investigation on NOx emission characteristics of a new solid fuel made from sewage sludge mixed with coal in combustion. Waste Manag. Res. 2015, 33, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Kwon, E.E.; Yi, H.; Kwon, H.H. Energy recovery from microalgal biomass via enhanced thermo-chemical process Biomass. Bioenergy 2014, 63, 46–53. [Google Scholar] [CrossRef]

- Chen, R. A paradigm shift in biomass technology from complete to partial cellulose hydrolysis: Lessons learned from nature. Bioengineered 2015, 6, 69–72. [Google Scholar] [CrossRef]

- Meng, A.; Zhang, Y.; Zhuo, J.; Li, Q.; Qin, L. Investigation on pyrolysis and carbonization of Eupatorium Adenophorum Spreng and Tobacco Stem. J. Energy Inst. 2015, 88, 480–489. [Google Scholar] [CrossRef]

- Lange, J.P. Lignocellulose conversion: An introduction to chemistry, process and economics. Biofuels 2007, 1, 39–48. [Google Scholar]

- Taherymoosavi, S.; Verheyen, V.; Munroe, P.; Joseph, S.; Reynolds, A. Characterization of organic compounds in biochars derived from municipal solid waste. Waste Manag. 2017, 67, 131–142. [Google Scholar] [CrossRef] [PubMed]

- Alvarenga, L.M.; Xavier, T.P.; Barrozo, M.A.S.; Bacelos, M.S.; Lira, T.S. Determination of activation energy of pyrolysis of carton packaging wastes and its pure components using thermogravimetry. Waste Manag. 2016, 53, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Li, J.; Paul, M.C.; Younger, P.L.; Watson, I.; Hossain, M.; Welch, S. Characterization of biomass combustion at high temperatures based on an upgraded single particle model. Appl. Energy 2015, 156, 749–755. [Google Scholar] [CrossRef]

- Obernberger, I. Physical characteristics and chemical composition of solid biomass fuels. In Thermochemical Biomass Conversion; Eindhofen University of Technology: Eindhoven, The Netherlands, 2003; pp. 261–304. [Google Scholar]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical properties of solid biofuels–significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; Mckinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw, and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Wamukonya, L.; Jenkins, B. Durability and relaxation of sawdust and wheat-straw briquettes as possible fuels for Kenya. Biomass Bioenergy 1995, 8, 175–179. [Google Scholar] [CrossRef]

- Zhang, J.; De, X.; Yu, Z.; Guo, W.; Ge, Y.; Chen, X. Effectiveness of Biomass Pellet Parameters on Their Fractal Dimension. Appl. Sci. 2022, 12, 9841. [Google Scholar] [CrossRef]

- Liu, Y.; Edouard, D.; Nguyen, L.D.; Begin, D.; Nguyen, P.; Pham, C.; Pham-Huu, C. High performance structured platelet milli-reactor filled with supported cobalt open cell SiC foam catalyst for the Fischer–Tropsch synthesis. Chem. Eng. J. 2013, 222, 265–273. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. BioResources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 69–94. [Google Scholar] [CrossRef]

- Soleimani, M.; Tabil, X.; Grewal, R.K.; Tabil, L.G. Carbohydrates as binders in biomass densification for biochemical and thermochemical processes. Fuel 2017, 193, 134–141. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Biomass combustion systems: A review on the physical and chemical properties of the ashes. Renew. Sustain. Energy Rev. 2016, 53, 235–242. [Google Scholar] [CrossRef]

- Mian, I.; Li, X.; Dacres, O.D.; Wang, J.; Wei, B.; Jian, Y.; Zhong, M.; Liu, J.; Ma, F.; Rahman, N. Combustion kinetics and mechanism of biomass pellet. Energy 2020, 205, 117909. [Google Scholar] [CrossRef]

- Burchard-Dziubińska, M. Air pollution and health in Poland: Anti-smog movement in the most polluted Polish cities. Econ. Environ. 2019, 2, 76–90. [Google Scholar]

- Zyśk, J.; Szurlej, A.; Olkuski, T.; Kogut, K.; Cieślik, T.; Mirowski, T. Emission factors for heating technologies used in households. Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią Pol. Akad. Nauk. 2019, 109, 79–92. (In Polish) [Google Scholar]

- Munsif, R.; Zubair, M.; Aziz, A.; Zafar, M.N. Industrial Air Emission Pollution: Potential Sources and Sustainable Mitigation. In Environmental Emissions; IntechOpen: London, UK, 2021. [Google Scholar]

- Pełka, G.; Wygoda, M.; Luboń, W.; Pachytel, P.; Jachimowski, A.; Paprocki, M.; Wyczesany, P.; Kotyza, J. Analysis of the Efficiency of a Batch Boiler and Emissions of Harmful Substances during Combustion of Various Types of Wood. Energies 2021, 14, 6783. [Google Scholar] [CrossRef]

- Pełka, G.; Jach-Nocoń, M.; Paprocki, M.; Jachimowski, A.; Luboń, W.; Nocoń, A.; Wygoda, M.; Wyczesany, P.; Pachytel, P.; Mirowski, T. Comparison of Emissions and Efficiency of Two Types of Burners When Burning Wood Pellets from Different Suppliers. Energies 2023, 16, 1695. [Google Scholar] [CrossRef]

- Jaworek, A.; Sobczyk, A.T.; Marchewicz, A.; Krupa, A.; Czech, T. Particulate matter emission control from small residential boilers after biomass combustion. A review. Renew. Sustain. Energy Rev. 2021, 137, 110446. [Google Scholar] [CrossRef]

- Aleksiejczuk, A.; Teleszewski, T.J. Estimation of Sulfur Dioxide Emissions in an Automatic Boiler with a Retort Burner for Coal and Biomass in a Single-Family House Based on the Measurement of the Heat Consumed. Environ. Sci. Proc. 2022, 18, 10. [Google Scholar]

- Rybiński, P.; Syrek, B.; Szwed, M.; Bradło, D.; Żukowski, W.; Marzec, A.; Śliwka-Kaszyńska, M. Influence of Thermal Decomposition of Wood and Wood-Based Materials on the State of the Atmospheric Air. Emissions of Toxic Compounds and Greenhouse Gases. Energies 2021, 14, 3247. [Google Scholar] [CrossRef]

- Mola-Yudego, B.; Selkimäki, M.; González-Olabarria, J.R. Spatial analysis of the wood pellet production for energy in Europe. Renew. Energy 2014, 63, 76–83. [Google Scholar] [CrossRef]

- Wróbel, M.; Frączek, J.; Jewiarz, M.; Mudryk, K.; Dziedzic, K. Impact of Selected Properties of Raw Material on Quality Features of Granular Fertilizers Obtained from Digestates and ASH Mixtures. Agric. Eng. 2016, 20, 207–217. [Google Scholar] [CrossRef][Green Version]

- Mirowski, T. Utilization of Biomass for Energy Purpose Versus Reduction of Emission of Air Pollutants from Municipal and Households Sector. Rocz. Ochr. Sr. 2016, 18, 466–477. [Google Scholar]

- Gaur, P.; Mishra, S.; Bhardwaj, S.; Kumar, S.S.; Bajpai, M.; Verma, A.; Verma, N. Recent Developments for Oral Time Controlled Drug Delivery by Pelletization Techniques: An Overview. J. Pharm. Sci. Pharmacol. 2014, 1, 283–295. [Google Scholar] [CrossRef]

- Manoharan, K.; Bhaskaran, N.A.; Kumar, L. Pellets and Techniques of Pelletization. Res. J. Pharm. Technol. 2019, 12, 6157–6164. [Google Scholar] [CrossRef]

- Woo, D.G.; Kim, S.H.; Kim, T.H. Solid Fuel Characteristics of Pellets Comprising Spent Coffee Grounds and Wood Powder. Energies 2021, 14, 371. [Google Scholar] [CrossRef]

- Cui, X.; Yang, J.; Wang, Z.; Shi, X. Better use of bioenergy: A critical review of co-pelletizing for biofuel manufacturing. Carbon Capture Sci. Technol. 2021, 1, 100005. [Google Scholar] [CrossRef]

- Moran, J.C.; Miguez, J.L.; Porteiro, J.; Patiño, D.; Granada, E. Low-Quality Fuels for Small-Scale Combustion Boilers: An Experimental Study. Energy Fuels 2015, 29, 3064–3081. [Google Scholar] [CrossRef]

- Picchio, R.; Di Marzio, N.; Cozzolino, L.; Venanzi, R.; Stefanoni, W.; Bianchini, L.; Pari, L.; Latterini, F. Pellet Production from Pruning and Alternative Forest Biomass: A Review of the Most Recent Research Findings. Materials 2023, 16, 4689. [Google Scholar] [CrossRef] [PubMed]

- Anca-Couce, A.; Sommersacher, P.; Shiehnejadhesar, A.; Mehrabian, R.; Hochenauer, C.; Scharler, R. CO/CO2 ratio in biomass char oxidation. Energy Procedia 2017, 120, 238–245. [Google Scholar] [CrossRef]

- Choiński, B.; Szatyłowicz, E.; Zgłobicka, I.; Joka Ylidiz, M. A Critical Investigation of Certificated Industrial Wood Pellet Combustion: Influence of Process Conditions on CO/CO2 Emission. Energies 2023, 16, 250. [Google Scholar] [CrossRef]

- Robinson, J.; Makonese, T.; Annegarn, H.J.; Pemberton-Pigott, C. Heterogeneous stove testing protocols for emissions and thermal performance. In Proceedings of the International Conference on the Domestic Use of Energy, Cape Town, South Africa, 29–31 March 2010. [Google Scholar]

- EN ISO 18134-3:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample. Polish Committee for Standardization: Warsaw, Poland, 2015.

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Żukiewicz-Sobczak, W.; Obidziński, S. The use of lignocellulosic waste in the production of pellets for energy purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Niedziółka, I.; Szpryngiel, M.; Kachel-Jakubowska, M.; Kraszkiewicz, A.; Zawiślak, K.; Sobczak, P.; Nadulski, R. Assessment of the energetic and mechanical properties of pellets produced from agricultural biomass. Renew. Energy 2015, 76, 312–317. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Przywara, A.; Parafiniuk, S. Emission of Nitric Oxide during the Combustion of Various Forms of Solid Biofuels in a Low-Power Heating Device. Energies 2022, 15, 5960. [Google Scholar] [CrossRef]

- CEN/TS 15104:2006; Solid Biofuels. Determination of Total Content of Carbon, Hydrogen and Nitrogen. Instrumental Methods. British Standards Institute: London, UK, 2011.

- EN PN-G-04584:2001; Solid Fuels—Determination of Total and Ash Sulfur Content by Automatic Analyzers. Polish Committee for Standardization: Warsaw, Poland, 2001.

- PN-G-04516:1998; Solid Fuels-Determination of Volatile Matter Content by Weight Method. Polish Committee for Standardization: Warsaw, Poland, 1998.

- EN ISO 18122:2016; Solid Biofuels—Determination of Ash Content. Polish Committee for Standardization: Warsaw, Poland, 2016.

- EN ISO 18125:2017; Solid Biofuels. Determination of Calorific Value. Polish Committee for Standardization: Warsaw, Poland, 2017.

- EN ISO 16127:2012; Solid Biofuels—Determination of Length and Diameter of Pellets. Polish Committee for Standardization: Warsaw, Poland, 2012.

- Houshfar, E.; Skreiberg, Ø.; Løvås, T.; Todorović, D.; Sørum, L. Effect of excess air ratio and temperature on NOx emission from grate combustion of biomass in the staged air combustion scenario. Energy Fuels 2011, 25, 4643–4654. [Google Scholar] [CrossRef]

- PN-EN 303-5:2012; Heating Boilers for Solid Fuels with Manual and Automatic Fuel Hopper of Nominal Power Up to 300 kW. Terminology, Requirements, Testing and Marking. Polish Committee for Standardization: Warsaw, Poland, 2012.

- Kraszkiewicz, A. The Combustion of Wood Biomass in Low Power Coal-Fired Boilers. Combust. Sci. Technol. 2016, 188, 389–396. [Google Scholar] [CrossRef]

- Photon Analyzer User Manual; Version 2.2; Eljack-Electronics: Zgierz, Poland, 2014.

- Demirbaş, A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Wang, J.; Preto, F.; Zhu, J.; Xu, C. Ash Deposition in Biomass Combustion or Co-Firing for Power/Heat Generation. Energies 2012, 5, 5171–5189. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Stachowicz, P.; Dudziec, P. Wood pellet quality depending on dendromass species. Renew. Energy 2022, 199, 498–508. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Wojciechowska, N.; Seliwiak, M.; Dobrzański, T.K. Properties of Forest Tree Branches as an Energy Feedstock in North-Eastern Poland. Energies 2024, 17, 1975. [Google Scholar] [CrossRef]

- EN ISO 17225:2021; Solid Biofuels— Fuel Specifications and Classes. Polish Committee for Standardization: Warsaw, Poland, 2021.

- Juszczak, M. Concentrations of carbon monoxide and nitrogen oxides from a 15 kW heating boiler supplied periodically with a mixture of sunflower husk and wood pellets. Environ. Protein Eng. 2014, 40, 65–74. [Google Scholar] [CrossRef]

- Caillat, S.; Vakkilainen, E.K. Large-scale biomass combustion plants: An overview. In Biomass Combustion Science, Technology and Engineering; Woodhead Publishing: Cambridge, UK, 2013; pp. 189–224. [Google Scholar]

- Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products. L285/10–L285/35. 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009L0125 (accessed on 18 March 2022).

- Boman, C.; Pettersson, E.; Westerholm, R.; Boström, D.; Nordin, A. Stove performance and emission characteristics in residential wood log and pellet combustion, Part 1: Pellet stoves. Energy Fuels 2011, 25, 307–314. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.M.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Speth, K.; Murer, M.; Spliethoff, H. Experimental investigation of nitrogen species distribution in wood combustion and their influence on NOx reduction by combining air staging and ammonia injection. Energy Fuels 2016, 30, 5816–5824. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and co-combustion of biomass: Fundamentals, technologies, and primary measures for emission reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Khodaei, H.; Guzzomi, F.; Yeoh, G.H.; Regueiro, A.; Patiño, D. An experimental study into the effect of air staging distribution and position on emissions in a laboratory scale biomass combustor. Energy 2016, 118, 1243–1255. [Google Scholar] [CrossRef]

- Jach-Nocoń, M.; Pełka, G.; Luboń, W.; Mirowski, T.; Nocoń, A.; Pachytel, P. An Assessment of the Efficiency and Emissions of a Pellet Boiler Combusting Multiple Pellet Types. Energies 2021, 14, 4465. [Google Scholar] [CrossRef]

- Lamberg, H. Small-Scale Pellet Boiler Emissions–Characterization and Comparison to Other Combustion Units. In Report Series in Aerosol Science No. 156; Academic Dissertation: Kuopio, Finland, 2014; Volume 156, Available online: https://www.atm.helsinki.fi/faar/reportseries/rs-156.pdf (accessed on 27 April 2022).

- Pałaszyńska, K.; Juszczak, M. Gaseous emissions during agricultural biomass combustion in a 50 kW moving step grate boiler. Chem. Process Eng. 2018, 39, 197–208. [Google Scholar]

- Mentes, D.; Sajti, Z.; Koós, T.; Csaba, P. Optimizing the combustion processes of a small scale solid fuel-fired boiler. Int. J. Eng. Manag. Sci. 2019, 4, 358–369. [Google Scholar]

- Bhattu, D.; Zotter, P.; Zhou, J.; Stefenelli, G.; Klein, F.; Bertrand, A.; Temime-Roussel, B.; Marchand, N.; Slowik, J.G.; Baltensperger, U.; et al. Effect of stove technology and combustion conditions on gas and particulate emissions from residential biomass combustion. Environ. Sci. Technol. 2019, 53, 2209–2219. [Google Scholar] [CrossRef] [PubMed]

- Fachinger, F.; Drewnick, F.; Gieré, R.; Borrmann, S. How the user can influence particulate emissions from residential wood and pellet stoves: Emission factors for different fuels and burning conditions. Atmos. Environ. 2017, 158, 216–226. [Google Scholar] [CrossRef]

- Yanik, J.; Duman, G.; Karlström, O.; Brink, A. NO and SO2 emissions from combustion of raw and torrefied biomasses and their blends with lignite. J. Environ. Manag. 2018, 227, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Qi, J.; Li, H.; Wang, Q.; Han, K. Combustion Characteristics, Kinetics, SO2 and NO Release of Low-Grade Biomass Materials and Briquettes. Energies 2021, 14, 2655. [Google Scholar] [CrossRef]

- Ciupek, B.; Gołoś, K.; Bartoszewicz, J. Effect of the filtration-catalytic system on the emission parameters of low-power boilers fired with wood pellets. Przem. Chem. 2021, 1, 35–38. [Google Scholar]

- Komada, P. Analiza Procesu Termicznej Przeróbki Biomasy; PAN: Warszawa, Poland, 2019. (In Polish) [Google Scholar]

- Hardy, T.; Musialik-Piotrowska, A.; Ciołek, J.; Mościcki, K.; Kordylewski, W. Negatywne Efekty Związane ze Spalaniem i Współspalaniem Biomasy w Kotłach; NOT: Wrocław, Poland, 2010; pp. 145–152. (In Polish) [Google Scholar]

- Smaga, M.; Wielgosiński, G.; Kochański, A.; Korczak, K. Biomass as a Major Component of Pellets. Acta Innov. 2018, 26, 81–92. [Google Scholar] [CrossRef]

- Konieczyński, J.; Komosiński, B.; Cieślik, E.; Konieczny, T.; Mathews, B.; Rachwał, T.; Rzońca, G. Research into properties of dust from domestic central heating boiler fired with coal and solid biofuels. Arch. Environ. Prot. 2017, 43, 20–27. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Carpio, M. Biomass Pelletization Process. In Biomass Pelletization: Standards and Production. WIT Transactions on State of the Art in Science and Engineering; WIT Press: Billerica, MA, USA, 2015; Volume 85, pp. 53–66. [Google Scholar]

- Bhatt, A.; Ravi, V.; Zhang, Y.; Heath, G.; Davis, R.; Tan, E.C.D. Emission factors of industrial boilers burning biomass-derived fuels. J. Air Waste Manag. Assoc. 2023, 73, 241–257. [Google Scholar] [CrossRef] [PubMed]

- Shojaeiarani, J.; Bajwa, D.S.; Bajwa, S.G. Properties of densified solid biofuels in relation to chemical composition, moisture content, and bulk density of the Biomass. BioResources 2019, 14, 4996–5015. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Santoro, F.; Pascuzzi, S. Emmission of sulphur oxides from agricultural solid biofuels combustion. Agric. Eng. 2020, 24, 35–45. [Google Scholar] [CrossRef]

- Krzywanski, J.; Czakiert, T.; Zylka, A.; Nowak, W.; Sosnowski, M.; Grabowska, K.; Skrobek, D.; Sztekler, K.; Kułakowska, A.; Ashraf, W.M.; et al. Modelling of SO2 and NOx Emissions from Coal and Biomass Combustion in Air-Firing, Oxyfuel, iG-CLC, and CLOU Conditions by Fuzzy Logic Approach. Energies 2022, 15, 8095. [Google Scholar] [CrossRef]

- Yilgin, M.; Yildirim, S.; Pehlivan, D. Combustion of hazelnut shell-lignite blends in poly-particulate beds. Biomass Convers. Biorefinery 2021, 13, 5875–5883. [Google Scholar] [CrossRef]

- Lupiáñez, C.; Mayoral, M.C.; Díez, L.I.; Pueyo, E.; Espatolero, S.; Andrés, J.M. The role of limestone during fluidized bed oxy-combustion of coal and biomass. Appl. Energy 2016, 184, 670–680. [Google Scholar] [CrossRef]

- Dyjakon, A. Analysis of slagging and fouling propensities of biofuels in terms of their combustion and co-combustion in the boilers. Inżynieria Rol. 2012, 16, 5–18. [Google Scholar]

- Kraszkiewicz, A.; Kachel-Jakubowska, M.; Niedziółka, I. The chemical composition of ash from the plant biomass in terms of indicators to assess slagging and pollution of surface heating equipment. Fresenius Environ. Bull. 2017, 26, 6383–6389. [Google Scholar]

- Vicente, E.D.; Vicente, A.M.; Evtyugina, M.; Carvalho, R.; Tarelho, L.A.C.; Paniagua, S.; Nunes, T.; Otero, M.; Calvo, L.F.; Alves, C. Emissions from residential pellet combustion of an invasive acacia species. Renew. Energy 2019, 140, 319–329. [Google Scholar] [CrossRef]

| Gas | Measurement Range | Accuracy | Resolution | Type of Measurement |

|---|---|---|---|---|

| CO2 | 0–25% | ±3% | 0.01% | NDIR |

| CO | 0–2% | ±0.0003% | 0.0001% | NDIR |

| NO | 0–0.5% | ±0.0003% | 0.0001% | NDIR |

| SO2 | 0–0.5% | ±0.0003% | 0.0001% | NDIR |

| Tgas | −10 ÷ 1000 °C | ±2 °C | 0.1 °C | Type K thermocouple |

| Fuel Type | L (mm) | D (mm) | MC (%) | VD (kg·m−3) | |

|---|---|---|---|---|---|

| Wheat straw | P | 32 ± 2 a | 8 ± 0.25 a | 10.60 ± 0.14 a | 1130 ± 22 |

| B | 16 ± 1 b | 50 ± 1 b | 10.40 ± 0.17 c | 946 ± 24 | |

| Rye straw | P | 29 ± 3 | 8 ± 0.25 a | 10.40 ± 0.12 b | 1034 ± 21 a |

| B | 19 ± 1 b | 50 ± 1 b | 10.30 ± 0.15 c | 856 ± 20 | |

| Oat straw | P | 34 ± 3 a | 8 ± 0.25 a | 10.50 ± 0.14 ab | 1016 ± 20 a |

| B | 25 ± 2 c | 50 ± 1 b | 10.40 ± 0.13 bc | 1004 ± 29 b | |

| Hay | P | 32 ± 2 a | 8 ± 0.25 a | 9.70 ± 0.19 d | 1063 ± 21 a |

| B | 23 ± 2 c | 50 ± 1 b | 9.50 ± 0.16 e | 1132 ± 33 | |

| Birch sawdust | P | 11 ± 2 | 8 ± 0.25 a | 9.80 ± 0.11 d | 926 ± 18 |

| B | 49 ± 3 | 50 ± 1 b | 9.80 ± 0.12 e | 996 ± 21 b | |

| Fuel Type | C (% DM) | H (% DM) | N (% DM) | S (% DM) | VM (% DM) | LHV (MJ·kg−3) | AC (% DM) |

|---|---|---|---|---|---|---|---|

| Wheat straw | 47.03 ± 0.19 a | 5.79 ± 0.07 a | 0.78 ± 0.01 a | 0.06 ± 0.02 a | 70.70 ± 0.13 b | 16.29 ± 0.10 a | 2.8 ± 0.03 |

| Rye straw | 47.95 ± 0.21 a | 5.92 ± 0.08 b | 0.85 ± 0.01 a | 0.12 ± 0.02 a | 72.20 ± 0.12 a | 16.28 ± 0.12 b | 3.2 ± 0.04 |

| Oat straw | 43.70 ± 0.12 | 5.22 ± 0.04 | 1.04 ± 0.01 | 0.07 ± 0.02 a | 69.50 ± 0.10 b | 15.47 ± 0.8 | 6.5 ± 0.06 a |

| Hay | 46.10 ± 0.13 a | 5.85 ± 0.06 a | 1.4 ± 0.01 | 0.61 ± 0.08 | 68.20 ± 0.09 b | 16.26 ± 0.12 b | 6.2 ± 0.05 a |

| Birch sawdust | 49.10 ± 0.18 | 5.95 ± 0.05 b | 0.22 ± 0.01 | 0.1 ± 0.01 | 73.40 ± 0.11 a | 16.34 ± 0.11 a | 1.3 ± 0.02 |

| Source of Variation | CO2 | Tgas | CO | NO | SO2 | CEI | TI |

|---|---|---|---|---|---|---|---|

| Combustion system (A) | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| Raw material (B) | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | 0.062 * | <0.001 * |

| AxB | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| Variable | C | H | N | S | AC | VM |

|---|---|---|---|---|---|---|

| Type A tests—pellets | ||||||

| CO2 | 0.677976 * | 0.637564 * | −0.219322 * | −0.131930 * | −0.683694 * | 0.563636 * |

| Tgas | 0.784252 * | 0.691406 * | −0.373775 * | −0.190893 * | −0.770876 * | 0.712561 * |

| CO | −0.535296 * | −0.625937 * | −0.159288 * | −0.070670 | 0.502997 * | −0.242398 * |

| SO2 | −0.437705 * | −0.439179 * | 0.074895 | 0.005168 | 0.421543 * | −0.326488 * |

| NO | −0.676691 * | −0.514921 * | 0.559072 * | 0.209989 * | 0.671646 * | −0.765974 * |

| ETA | −0.205695 * | −0.163121 * | 0.123506 * | 0.112864 * | 0.176628 * | −0.175854 * |

| TI | −0.535296 * | −0.625937 * | −0.159288 * | −0.070670 | 0.502997 * | −0.242398 * |

| Type A tests—briquettes | ||||||

| CO2 | 0.704775 * | 0.531746 * | −0.266715 * | −0.436114 * | −0.786516 * | 0.582540 * |

| Tgas | 0.755073 * | 0.642733 * | −0.143999 * | −0.287466 * | −0.760336 * | 0.526193 * |

| CO | −0.503476 * | −0.236352 * | 0.493940 * | 0.579559 * | 0.694502 * | −0.642508 * |

| SO2 | −0.789505 * | −0.722777 * | 0.063510 | 0.132091 * | 0.719139 * | −0.496293 * |

| NO | −0.888629 * | −0.665044 * | 0.412040 * | 0.232889 * | 0.794973 * | −0.796485 * |

| ETA | 0.219691 * | −0.107794 * | −0.632048 * | −0.749744 * | −0.535014 * | 0.573628 * |

| TI | −0.503476 * | −0.236352 * | 0.493940 * | 0.579559 * | 0.694502 * | −0.642508 * |

| Type B tests—pellets | ||||||

| CO2 | 0.287556 * | 0.305380 * | −0.021475 | 0.281295 * | −0.186012 * | 0.248697 * |

| Tgas | −0.075365 * | 0.035404 | 0.172279 * | 0.297782 * | 0.000149 | −0.043886 |

| CO | 0.148532 * | 0.170481 * | 0.008111 | 0.423918 * | 0.152757 * | 0.059172 |

| SO2 | −0.253245 * | −0.257952 * | 0.053194 | −0.139660 * | 0.285812 * | −0.281442 * |

| NO | −0.221545 * | −0.264598 * | −0.011205 | −0.312259 * | 0.193595 * | −0.230791 * |

| ETA | 0.367725 * | 0.291042 * | −0.171742 * | 0.122989 * | −0.109338 * | 0.276779 * |

| TI | −0.005151 | 0.020863 | 0.052841 | 0.297141 * | 0.261704 * | −0.097229 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dula, M.; Kraszkiewicz, A.; Parafiniuk, S. Combustion Efficiency of Various Forms of Solid Biofuels in Terms of Changes in the Method of Fuel Feeding into the Combustion Chamber. Energies 2024, 17, 2853. https://doi.org/10.3390/en17122853

Dula M, Kraszkiewicz A, Parafiniuk S. Combustion Efficiency of Various Forms of Solid Biofuels in Terms of Changes in the Method of Fuel Feeding into the Combustion Chamber. Energies. 2024; 17(12):2853. https://doi.org/10.3390/en17122853

Chicago/Turabian StyleDula, Małgorzata, Artur Kraszkiewicz, and Stanisław Parafiniuk. 2024. "Combustion Efficiency of Various Forms of Solid Biofuels in Terms of Changes in the Method of Fuel Feeding into the Combustion Chamber" Energies 17, no. 12: 2853. https://doi.org/10.3390/en17122853

APA StyleDula, M., Kraszkiewicz, A., & Parafiniuk, S. (2024). Combustion Efficiency of Various Forms of Solid Biofuels in Terms of Changes in the Method of Fuel Feeding into the Combustion Chamber. Energies, 17(12), 2853. https://doi.org/10.3390/en17122853