Abstract

Wastewater treatment systems produce large volumes of sludge which is not used; its final disposal is in soil or landfill. This sludge represents a biomethane-energy alternative through anaerobic co-digestion, contributing to reducing the environmental impacts caused by their inadequate disposal. Biomethane production by the two-stage production method in batch digesters with pH and temperature control was evaluated by two qualities of waste-activated sludge (SLB50 and SLB90) and with a mixture of two co-substrates: cow manure (CEV50 and CEV90) and residual edible oil (CAV50 and CAV90). Bacteria in good-quality sludge (SLB90) showed a faster adaptation of 2 days than those in low-quality sludge (SLB50), with a 25-day lag phase. The highest CH4 production was for SLB90 (303.99 cm3 d−1) compared to SLB50 (4.33 cm3 d−1). However, the cow manure–sludge mixture (CEV90) contributed to the increased production of CH4 (42,422.8 cm3 d−1) compared to CEV50 (12,881.45 cm3 CH4 d−1); for CAV90 and CAV50, these were 767.32 cm3 d−1 and 211.42 cm3 d−1, respectively. The addition of sludge co-substrates improves the nutrient balance and C/N ratio; consequently, methane production improves. This methodology could be integrated into concepts of the circular economy.

1. Introduction

Rapid economic growth in numerous cities has led to a high dependence on fossil fuels and gas for energy production, causing a significant increase in greenhouse gas emissions [1,2]. Liquid bio-fuels (biodiesel and bio-ethanol) have been part of the strategies for reducing emissions of pollutants into the atmosphere. Likewise, biomethane is another alternative considered as a source of renewable energy that can be used for the production of energy and heat, as well as fuel for vehicles [3], and thus contributes to reducing emission of greenhouse gasses.

It is a fact that large cities present great challenges, such as achieving environmental sustainability and the creation of strategies for the treatment of waste produced by anthropogenic activities [4]. The combustion of fossil fuel as an energy source is a contributor to greenhouse gas emissions; however, untreated waste biomass also contributes to greenhouse gas emissions, in addition to soil and water pollution [5]. The Agenda for Sustainable Development proposes energy as an important component and support of economic growth [6]. Therefore, the use of organic waste (food waste, domestic sewage, and biological sludge) can contribute to energy production, and consequently, to environmental sustainability.

Biomethane is commonly produced using one-stage fermentation techniques, consisting of the fermentation process and biomethane production occurring in a single reactor. In this process, bacteria degrade complex organic compounds in an acidic environment, subsequently collaborating with methane-producing archaea requiring a neutral pH environment. This process causes complex organic compound degradation into simple organic compounds during the acetogenic stage, with these simple organic compounds converting, in parallel, into biomethane at the methanogenic stage. Negative effects can occur with (one-stage) biodigesters due to the increase in organic load, causing acetogenic bacteria to work more actively than methanogenic archaea. When this occurs, inhibitors such as volatile fatty acids and hydrogen appear, decreasing biomethane production [7]. To solve this problem, some studies have proposed the use of anaerobic biodigesters using a two-stage production system, i.e., the separation of the acidification phase (acetogenesis stage) and the biomethane formation stage (metanogenesis stage). This method has proven versatile, since a better biomethane production performance can be achieved even with a mixture of substrates, with pH being the variable to control in each reactor in which acetogenic (pH 5) and methanogenic (pH 7) fermentation occurs.

In this context, the topic of study is that biomethane production can vary in quantity and quality, depending on the raw material source (organic substrate); the diverse substrates (cow manure, food waste, agro-industrial waste, waste-activated sludge, among others) used for biomethane production have different chemical compositions [8,9,10]. Some of the control parameters considered to improve biomethane production are water content, pH, nitrogen content, organic carbon content, and C/N ratio. Studies suggest a minimum humidity requirement in the range of 81.9–97.25% for the fermentation stage and a C/N ratio of the raw material or mixture with substrates among the range of 20–30; a lower C/N ratio would cause the accumulation of ammonium, becoming toxic to bacteria [11]. On the other hand, the mixture content of total solids determines the efficiency of the process; the optimal value for continuous digesters is estimated to be 8–12% of total solids, while in discontinuous digesters it can be between 40% and 60%.

A relevant raw material for the production of biomethane that is available and abundant is waste-activated sludge obtained from wastewater treatment systems. According to Lee et al. [12], in the U.S., many wastewater treatment systems spend between 40% and 50% of their budget on the treatment and disposal of waste-activated sludge (WAS), with approximately 62% of this WAS being treated in landfills or incinerated [13]. WAS management costs have increased due to rapid population growth and strict environmental regulations. In México in 2014 and 2016, each Mexican generated an average of 60 m3/year (~164 l/d) of municipal wastewater [14]. Therefore, the national volume of wastewater increased to 228.9 m3/s, indicating that water treatment at the national level is insufficient. The National Water Commission of Mexico (CONAGUA) estimates that worldwide, between 80% and 95% of wastewater is discharged directly into rivers, lakes, and oceans without receiving prior treatment. Consequently, waste-activated sludge remaining from the municipal wastewater is produced with considerable concentrations of organic matter, microorganisms, and other non-biodegradable toxic compounds.

This waste-activated sludge with high concentrations of biodegradable organic matter could be used as a substrate in anaerobic digestion [15]. However, studies have considered that with these biowastes that have previously been processed by a biological system, the production of biomethane is significantly lower than that of other substrates [16]. For this reason, the nutrient balance can be improved through the co-digestion of sludge with other organic substrates. On the other hand, if the quantity and quality of biomethane that can be produced depends on the characteristics of the raw materials, then it is important to consider the origin and quality of the biological waste sludge, which directly depends on the operating efficiency of biological wastewater treatment plants. By being able to maintain the operating efficiency of the treatment plants, three benefits could be obtained: the removal of contaminants from wastewater; the biodigestion of biological sludge; and the production of biomethane. Therefore, the objective of this study was to evaluate the effect on the production of biomethane using waste-activated sludge from wastewater treatment systems with low and high removal efficiency, with a mixture of two co-substrates (cow manure and edible residual oil) in complete mixing reactors.

2. Materials and Methods

2.1. Substrate and Co-Substrate Preparation

The substrate used was waste-activated sludge (SLB) obtained from two aerobic biological treatment plants from urban wastewater (PTAR) from Ciudad del Carmen and Campeche. This geographical location in the southeast of Mexico places the city within the Flora and Fauna Laguna de Terminos Protection area, an ecosystem that is a refuge for many species of flora and fauna and is threatened by oil companies, fisheries, and urban development [17]. The treatment plants were selected according to the removal efficiency (50% and 90%) of the biochemical oxygen demand (BDO). Approximately 20 L of waste-activated sludge (SLB) was collected from biological reactors and kept refrigerated at 4 °C for at least 2 to 4 days until use and subsequent analysis.

To evaluate the effect of the characteristics of the two waste-activated sludge samples on the biomethane production, they were mixed with two co-substrates: (1) cow manure (CEV), collected (20 Kg) from the location’s livestock region (18°37′47.30″ N, 91°56′36.12″ W) and preserved at room temperature (20–25 °C) until later use; and (2) residual edible oil (CAV), which was collected (700 mL) from restaurants and previously filtered to eliminate the presence of solid particles in the oil (food waste), and stored at 4 °C. The analysis of the compositions of SLB and CEV consisted of the prior centrifugation of approximately 200 mL of biological sludge (SLB) and 20 g of cow manure (CEV) at 2500 rpm for 15 min at 17° C. These samples were dried in an oven at 40 ± 5 °C for 48 h [18]; later on, they were ground and stored in airtight glass containers to avoid humidity in the samples. Both SLB and CEV samples were analyzed by determining the pH using a Thermo Orion Star A211 instrument; organic carbon (OC), organic matter (OM), total nitrogen (TN), and total phosphorus (TP) were analyzed according to the techniques described by the official Mexican standard [19]. Total solids (TS) and volatile solids (VS) were determined by the standard gravimetric methods and according to the Mexican standard [20].

2.2. Experimental Design

An experimental design was proposed for two-stage anaerobic fermentation by separating the acidification phase (hydrolysis/acetogenesis) and the biomethane formation stage (methanogenesis). The biomethane production process was carried out in batch mode in triplicate in reactors with a 1.5 L operating volume; this consisted of adding the raw material (biological sludge) to each reactor with a sludge/water mixture volume ratio (v/v) of 1:1. The treatments (Table 1) were in triplicate and consisted of the installation of a control reactor (SLB) containing only waste-activated sludge substrate; another two series of reactors in triplicate were installed with SLB plus the addition of residual edible oil (CAV) and cow manure (CEV), respectively, with a proportion of 25% of total volume of the bioreactor, facilitating correct mixing within the biodigester (Table 1).

Table 1.

Experimental design for biomethane production on a laboratory scale.

Prior to the acetogenesis and methanogenesis processes, the raw material was fermented for 15 days at pH 7.0, regulated by the addition of Na2CO3 (10%) buffer. Subsequently, the first stage (acetogenic process) consisted of adjusting the pH to approximately 5.3–5.7 by adding a solution of H2SO4 at 20% to fermented effluent at room temperature (26 °C), which promoted the conversion of organic matter into short-chain organic acids (acetic acid, propionic acid, and butyric acid), which are intermediate products of the anaerobic degradation of organic matter and were essential for the next stage of the process.

After a period of 14 days, the fermented effluent was neutralized to pH 7.0–7.5 with sodium carbonate solution (Na2CO3 at 10%), stimulating the methanogenic stage (second stage), where organic acids produced in the first stage (hydrolysis–acidogenesis) were transformed into biomethane, mainly methane and carbon dioxide, by methanogenic archaea. During the two-stage co-digestion process, different microorganisms are involved; pH is an important variable because acidogenic and methanogenic archaea are highly sensitive to changes in the acidity or alkalinity of the medium [21]. Thus, the system was monitored with pH control and agitation (approximately 120 rpm) to maintain the optimal conditions of each stage. For the bio-digestion process of the matter, some factors were considered (Table 2), maintaining ideal conditions for the production of biomethane.

Table 2.

Factors considered for methane production (cm3 CH4 min−1).

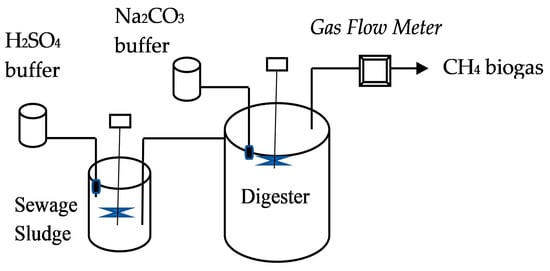

The reactors used were Batch Corning® brand polycarbonate with a total volume of 3000 mL (1500 mL operating volume) and magnetic stirring. For each reactor, a pH electrode was incorporated that enabled daily monitoring of the acidity or alkalinity of the fermented medium. Likewise, the reactor maintained a direct connection to the methane flow sensor using Gas Flow Meter (Cole-Parmer, series: 32908-51) (Figure 1).

Figure 1.

Schematic diagram for the treatment of sewage sludge and biomethane production in a batch reactor.

2.3. Statistical Analyses

For statistical comparisons, the methane production rate for the different mixtures of raw materials was analyzed by analysis of variance (ANOVA) using Statistic software (version 6.1, StatSoft Inc., Tulsa, OK, USA). The Tukey test (p ≤ 0.05) was applied when the results exhibited significant differences.

3. Results and Discussion

3.1. Effect of Waste-Activated Sludge and Co-Substrate

Anaerobic digestion is a widely used technology for the degradation and stabilization of organic matter. Under these conditions, the organic matter is oxidized and transformed into biomethane. The metabolic process involves various reaction mechanisms where anaerobic bacteria intervene in the transformation through sequenced biological reactions. However, during the transformation stages, various inhibitors can intervene and affect the production of biomethane, and although they have been studied in bioreactors for better control, the manipulation of the variables aims to improve the transformation of organic matter, and consequently, the production of biomethane. In most cases, this depends on the type of substrate, inoculum size, period of adaptability of the bacteria, and the balance of nutrients.

The quantity and quality of biomethane that can be produced depends on the characteristics of the raw materials. One raw material of greatest interest is waste-activated sludge produced from biological wastewater treatment plants. This waste is a promising material to be used for the production of biomethane. It is of utmost importance within the circular economy objectives; however, it is not possible to generalize its use because one of the factors to consider is the origin and quality of the waste-activated sludge. In the present study, two qualities of waste-activated sludge (SLB50 and SLB90) were considered, based on the operating efficiency of biological wastewater treatment plants. The results show that a low-quality sludge (SLB50) can present a higher TS (44.91 ± 0.056 g L−1) compared to a high-quality sludge (SLB90) (35.58 ± 0.055 g L−1); the VS content tends to be inversely proportional to the TS content, which was observed with a higher VS content in SLB90 (24.24 ± 0.339 g L−1) compared to SLB50 (11.56 ± 0.346 g L−1) (Table 3). This suggests that treatment plants that function efficiently carry out the efficient digestion of organic matter, providing a remaining substrate that could contribute to anaerobic digestion. This was confirmed by the high content (%) of OM and OC in waste-activated sludge (SLB90), which indicates a greater bioavailability for the diversity of biomethane-producing archaea. Therefore, good-quality waste-activated sludge could be used as a raw material to achieve efficient biomethane production in biodigesters (Table 3).

Table 3.

Composition (± standard deviation) of the two types of waste-activated sludge (SLB90 and SLB50) from a wastewater treatment plant and cow manure (CEV).

To evaluate the effect of co-substrates for improving the balance of organic matter and nutrients in biodigesters and methane production, the present study used two types of waste: cow manure and edible residual oil. In fact, unlike residual oil, cow manure contributes high contents of TS and VS, of +156 ± 0.02 g L−1 and 32.5 ± 0.02 g L−1, respectively (Table 3); therefore, the mixture with the co-substrate of cow manure (CEV) increased the contents of OM and OC in CEV90 and CEV50 reactors (Table 4).

Table 4.

Composition (± standard deviation) of the two types of sewage sludge from wastewater treatment plant with a mixture of co-substrates (cow manure and residual edible oil).

The significant improvements in organic matter content, organic carbon, and organic nitrogen resulted in the C/N ratio increasing from 3.080 (SLB90) to 23.16 for CEV90 reactors and for SLB50 to increase from 0.558 to 6.26 in CEV50 reactors (Table 4). The mixture of waste-activated sludge with residual edible oil did not exhibit a significant increase due to the particular chemical properties of the oil. According to what is reported in the literature, the C/N ratio of the CEV90 mixture suggests a desirable range for the anaerobic digestion process, with a recommended C/N ratio of 20–30 [22,23]. In the present study, the control of this variable limited the accumulation of ammonium in the reactors, which can be a toxic compound for bacteria.

According to Ellacuriaga et al. [21], excessive nitrogen levels within digesters can inhibit methanogenesis; therefore, a nitrogen range of 2.7–3.1 g L−1 is recommended, becoming tolerant for previously adapted bacteria, while concentrations greater than 4.0 g L−1 cause an inhibitory effect on biomethane production. This was confirmed in the present study for the CEV90 reactor, which exhibited a low nitrogen content and indicated its potential use for biomethane production. Various studies have evaluated the effect of ammonium–nitrogen in anaerobic digestion systems and determined the high complexity between the ammonium concentration, pH, temperature, and acclimatization of the micro-flora [24,25,26]. For this reason, in the present study, each of the variables in the two-stage anaerobic digestion system were controlled, and the biomethane production could be evaluated.

3.2. Biomethane Production

In the present study, the waste-activated sludge/co-substrate mixture was considered to evaluate the effect of waste-activated sludge quality on methane production. The average biomethane production (cm3 d−1) for only good-quality sludge (SLB90) was higher (303.99 cm3 CH4 d−1) compared to that of low-quality sludge (SLB50), of 4.33 cm3 CH4 d−1 (Table 5). An advantage of using SLB90 is the reduction in the lag phase or adaptation by approximately 2 days, compared to low-quality sludge. SLB50 demonstrated a prolonged lag phase of 25 days (Table 5), suggesting that for anaerobic digestion purposes and biomethane production, sludge from treatment plants should operate with high treatment efficiency since this could guarantee bioavailable M.O and C.O contents and bacteria with greater adaptability in biodigesters.

Table 5.

Daily biomethane production (cm3 d−1) using biological waste sludge (SLB) with a mixture of cattle waste (CEV) and residual edible oil (CAV).

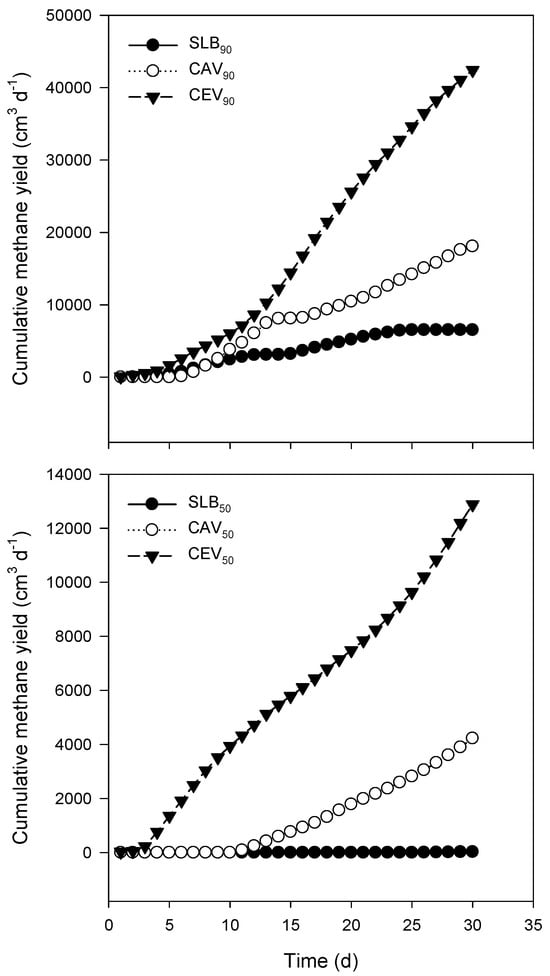

In the present study, the highest accumulated biomethane production was obtained for the anaerobic digester (CEV90) with a mixture of biological waste sludge and cow manure of 42,422.8 cm3 d−1. In comparison, CEV50 digesters had a lower production of 12,881.45 cm3 d−1. On the other hand, the co-substrate of residual edible oil (CAV), which was present in significant quantities in the treatment plants, was evaluated in the anaerobic digesters, showing that the mixture (CAV90) resulted in a greater production of biomethane (767.32 cm3 d−1) with 5 days of adaptation, compared to the CAV50 digester values of 211.42 cm3 d−1 of biomethane produced and 11 days of adaptation. The results suggest that the residual edible oil present in treatment plants and biological waste sludge could provide a source of energy for bacteria, which can be observed in the increase in biomethane production compared cultures only with sludge (SLB50 and SLB90) (Table 5).

The CEV90 treatment was the mixture with the highest biomethane production and was proposed to improve biomethane production given that both sludge and cow manure provide nutrients and carbon sources, which establishes a favorable (C/N) balance for biomethane production. Therefore, this treatment can be considered as contributing to achieving the circular economy to convert environmental damage into social and economic benefits for the use of waste biomass as a renewable energy source [21].

The production of biomethane obtained in the present analysis in the different mixtures of substrate with waste-activated sludge showed an improvement in the production of biomethane, being higher in the digesters with a mixture of cow manure. The biomethane contents were higher than those reported by other studies (Table 6) in which municipal solid waste, vegetable waste, and food waste were used, as well as a mixture of cow manure and cattle slurry. This proposes sludge for two reasons: as a source of both organic carbon and nutrients. Studies such as that reported by Díaz et al. [4] suggest that the use of activated sludge facilitates an improvement in biomethane production of 63.6 ± 1.1% v/v. Lee et al. [12] reported a biomethane production of 191.0 ± 8 mL CH4 g−1 VS, similar to that reported by Cabbai et al. [27], of 248.7 ± 4.13 mL CH4 g−1 VS. However, in the present study, unlike those reported by other authors, it can also be concluded that biological sludge from treatment plants with low operating efficiency does not significantly favor biomethane production in anaerobic biodigesters (Figure 2).

Table 6.

Biomethane production reported in the literature under different predominant substrates and inocula.

Figure 2.

Cumulative biomethane yields for batch reactors with only waste activated sludge (SLB) and different mixing substrates (CAV and CEV).

4. Conclusions

The quantity and quality of biomethane that can be produced depends on the characteristics of the raw material. Biological sludge produced by wastewater treatment processes is proposed for the production of biomethane and as part of achieving circular economy objectives. The quality of the residual sludge and the mixture with cow manure contribute to improving the production of biomethane, given the increase in nutrients and improvement of the C/N ratio by around 20–30, desirable for the anaerobic digestion process.

Good-quality sludge (SLB90) reduces the adaptation phase to 2 days and with greater biomethane production compared to SLB50, starting biomethane production after 25 days. Biomethane production was increased with the mixture of biological sludge with cow manure at levels of 42,422.8 cm3 CH4 d−1 and 12,881.45 cm3 CH4 d−1 for CEV90 and CEV50, respectively. Likewise, for the digesters with sludge and residual edible oil, biomethane production of 767.32 cm3 d−1 and 211.42 cm3 d−1 for CAV90 and CAV50 was achieved, respectively. In fact, the biological sludge from treatment plants with low operating efficiency does not significantly favor biomethane production in anaerobic biodigesters.

Author Contributions

All authors participated together in contributing to this manuscript, including the conceptualization, methodology, research; writing—original draft preparation, and writing—review. All authors have read and agreed to the published version of the manuscript.

Funding

Universidad Autonoma del Carmen, Master’s postgraduate program in Environmental Engineering.

Data Availability Statement

The concentration of PAHs and granulometry data used to support the findings of this study are included within the article and are available from the corresponding author upon request.

Acknowledgments

The authors acknowledge the members of CAEC in Environmental Engineering and Universidad Autonoma del Carmen (UNACAR. for their encouragement and support.

Conflicts of Interest

The authors declare that they have no conflict of interest, financial or otherwise.

References

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Romulo, H.G.J.; Jovani, T.S.; Fabio, N.P.; Cassiano, M.P.; Antonio, C.F. Biodigester location problems, its economic-environmental-social aspects and techniques: Areas yet to be explored. Energy Rep. 2021, 7, 3998–4008. [Google Scholar]

- Díaz, I.; Pérez, S.I.; Ferrero, E.M.; Fdz-Polanco, M. Effect of oxygen dosing point and mixing on the microaerobic removal of hydrogen sulphide in sludge digesters. Bioresour. Technol. 2011, 102, 3768–3775. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, V.A.; Almeida, F.T.S.; Marotta, H.; Guiller, J.F.M.; Aparecida, C.F.R.; Fatima, D.C.; Batista, S.F. New compact biodigester model for organic waste treatment in urban residences and buildings. J. Environ. Eng. 2021, 147, 04020156. [Google Scholar]

- Wang, X.; Gou, M.; Koppelaar, R.H.E.M.; Van Dam, K.H.; Triantafyllidis, C.P.; Shah, N.A. Nexus approach for sustainable urban energy-water-systems planning and operation. Environ. Sci. Technol. 2018, 52, 3257–3266. [Google Scholar] [CrossRef] [PubMed]

- Nerini, F.F.; Tomei, J.; To, L.S.; Bisaga, I.; Parikh, P.; Black, M.; Borrion, A.; Spataru, C.; Castán Broto, V.; Anandarajah, G.; et al. Mapping synergies and trade-offs between energy and the sustainable development goals. Nat. Energy 2018, 3, 10–15. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Wainaina, S.; Awasthi, M.K.; Sarsaiya, S.; Chen, H.; Singh, E.; Kumar, A.; Ravindran, B.; Awasthi, S.K.; Liu, T.; Duan, Y. Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour. Technol. 2020, 301, 122778. [Google Scholar] [CrossRef]

- Loizia, P.; Neofytou, N.; Zorpas, A.A. The concept of circular economy strategy in food waste management for the optimization of energy production through anaerobic digestion. Environ. Sci. Pollut. Res. 2019, 26, 14766–14773. [Google Scholar] [CrossRef]

- Ribic, B.; Voca, N.; Ilakovac, B. Concept of sustainable waste management in the city of Zagreb: Towards the implementation of circular economy approach. J. Air Waste Manag. Assoc. 2016, 67, 241–259. [Google Scholar] [CrossRef]

- Langer, S.G.; Gabris, C.; Einfalt, D.; Wemheuer, B.; Kazda, M.; Bengelsdorf, F.R. Different response of bacteria, archaea and fungi to process parameters in nine full-scale anaerobic digesters. Microb. Biotechnol. 2016, 12, 1210–1225. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.; Bittencourt, P.; Casimir, L.; Jimenez, E.; Wang, M.; Zhang, Q.; Ergas, S.J. Biogas production from high solids anaerobic co-digestion of food waste, yard waste and waste activated sludge. Waste Manag. 2019, 95, 432–439. [Google Scholar] [CrossRef] [PubMed]

- Seiple, T.E.; Coleman, A.M.; Skaggs, R.L. Municipal wastewater sludge as a sustainable bioresource in the United States. J. Environ. Manag. 2017, 197, 673–680. [Google Scholar] [CrossRef] [PubMed]

- SEMARNAT. Informe del Medio Ambiente. Sistema Nacional de Información Ambiental y de Recursos Naturales 2018. Available online: https://apps1.semarnat.gob.mx:8443/dgeia/informe18/tema/cap6.html (accessed on 5 December 2022).

- Kiselev, A.; Magaril, E.; Magaril, R.; Panepinto, D.; Ravina, M.; Zanetti, M.C. Towards circular economy: Evaluation of sewage sludge biogas solutions. Resources 2019, 8, 91. [Google Scholar] [CrossRef]

- Mattioli, A.; Gatti, G.B.; Mattuzzi, G.P.; Cecchi, F.; Bolzonella, D. Co-digestion of the organic fraction of municipal solid waste and sludge improves the energy balance of wastewater treatment plants: Rovereto case study. Renew. Energy 2017, 113, 980–988. [Google Scholar] [CrossRef]

- Ruiz-Marin, A.; Campos-Garcia, S.; Zavala-Loria, J.; Canedo-Lopez, Y. Hydrological aspects of the lagoons of Atasta and Pom, Mexico. Trop. Subtrop. Agroecosyst. 2009, 10, 63–74. [Google Scholar]

- Salgado, L.D.; Marques, A.E.M.L.; Kramer, R.D.; de Oliveira, F.G.; Moretto, S.L.; de Lima, B.A.; Prodocimo, M.M.; Cestari, M.M.; de Azevedo, J.C.R.; de Assis, H.C.S. Integrated assessment of sediment contaminant levels and biological responses in sentinel fish species Atherinella brasiliensis from a subtropical estuary in south Atlantic. Chemosphere 2019, 219, 15–27. [Google Scholar] [CrossRef] [PubMed]

- Norma Oficial Mexicana NOM-021-RECNAT-2000; Que Establece las Especificaciones de Fertilidad, Salinidad y Clasificación de Suelos. Estudios, Muestreo y Análisis; Diario Oficial de La Federación: Mexico City, Mexico, 2002.

- Norma Mexicana. NMX-AA-034-SCFI-2015. Análisis de Agua—Medición de Sólidos y Sales Disueltas en Aguas Naturales, Residuales y Residuales Tratadas—Método de Prueba. Diario Oficial de La Federación 2015. Available online: https://www.gob.mx/cms/uploads/attachment/file/166146/nmx-aa-034-scfi-2015.pdf (accessed on 5 December 2022).

- Ellacuriaga, M.; Garcia-Cascallana, J.; Gomez, X. Biogas production from organic wastes: Integrating concepts of circular economy. Fuels 2021, 2, 144–167. [Google Scholar] [CrossRef]

- Yen, H.; Brune, D.E. Anaerobic Co-Digestion of Algal Sludge and Waste Paper to Produce Methane. Bioresour. Technol. 2007, 98, 130–134. [Google Scholar] [CrossRef]

- Wang, X.; Yang, G.; Li, F.; Feng, Y.; Ren, G.; Han, X. Evaluation of two statistical methods for optimizing the feeding composition in anaerobic co-digestion: Mixture design and central composite design. Bioresour. Technol. 2013, 131, 172–178. [Google Scholar] [CrossRef]

- Dareioti, M.A.; Dokianakis, S.N.; Stamatelatou, K.; Zafiri, C.; Kornaros, M. Biogas production from anaerobic co-digestion of agroindustrial wastewaters under mesophilic conditions in a two-stage process. Desalination 2009, 248, 891–906. [Google Scholar] [CrossRef]

- Yenigún, O.; Demirel, B. Ammonia inhibition in anaerobic digestion: A review. Process Biochem. 2013, 48, 901–911. [Google Scholar] [CrossRef]

- Chan, P.C.; Lu, Q.; de Toledo, R.A.; Gu, J.D.; Shim, H. Improved anaerobic co-digestion of food waste and domestic wastewater by copper supplementation—Microbial community change and enhanced effluent quality. Sci. Total Environ. 2019, 670, 337–344. [Google Scholar] [CrossRef] [PubMed]

- Cabbai, V.; Ballico, M.; Aneggi, E.; Goi, D. BMP tests of source selected OFMSW to evaluate anaerobic codigestion with sewage sludge. Waste Manag. 2013, 33, 1626–1632. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, K.; Aslanzadeh, S.; Johansson, F.; Taherzadeh, M.J. Experimental and economical evaluation of a novel biogas digester. Energy Convers. Manag. 2013, 74, 183–191. [Google Scholar] [CrossRef]

- Nwaigwe, K.N.; Enweremadu, C.C. Comparative análisis of a locally developed biogas digester using selected substrates. In Proceedings of the ASME 2016 10th International Conference on Energy Sustainability Collocated with the ASME 2016 Power Conference and the ASME 2016 14th International Conference on Fuel Cell Science, Engineering and Technology, Charlotte, NC, USA, 26–30 June 2016; ASTM: New York, NY, USA, 2016. [Google Scholar]

- Walker, M.; Theaker, H.; Yaman, R.; Poggio, D.; Nimmo, W.; Bywater, A.; Blanch, G.; Pourkashanian, M. Assessment of micro-scale anaerobic digestion for management of urban organic waste. A case study in London, UK. Waste Manag. 2017, 61, 258–268. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).