3.2.1. Cellulose Pad and Cellulose Pad + External Shading Net Applications

The external and internal climate parameters measured in the cellulose pad and cellulose pad + external shading net applications are given in

Table 5.

In the CP application, the outdoor solar radiation was determined to be 820.9 W m−2 on average, between 511.4 and 991.3 W m−2. The indoor solar radiation value was measured as 574.6 W m−2 on average, between 373.3 and 765.9 W m−2. In the CP + ESN application, the outdoor solar radiation value was 771.3 W m−2, on average, between 196.3 and 1010.7 W m−2. On average, the indoor solar radiation value was 314.9 W m−2, between 82.4 and 453.2 W m−2. In the CP application, the solar radiation rate reaching the greenhouse environment was determined to be 70.0%. In the CP + ESN application, the solar radiation rate reaching the greenhouse environment was 40.8%.

As shown in

Table 5, the cooling effect in the CP application was 5.5 °C and for the CP + ESN application it was 6.6 °C. In a study on the cooling effect, Gunhan et al. [

44] reported that, for the 5 cm pad thickness and four different air speeds (0.6, 1.0, 1.3, and 1.6 m s

−1), the cooling effects were found to be 4.97 °C, 4.69 °C, 3.91 °C, and 3.99 °C, respectively. Shivpuje et al. [

45] found that the average dry bulb temperature of the air entering the cooling pad varied between 32 °C and 36 °C, and the air exit temperature from the cooling system was between 27 °C and 29 °C. Vala et al. [

46] stated that, with a 10 cm thick Celdek pad, the average cooling effect was 8 °C. These results align with previous findings in the literature. Moreover, it has been determined that indoor temperature values can be brought to values suitable for plant cultivation with CP (23.8 °C) and CP + ESN (23.4 °C) applications. This is because of the additional moisture introduced into the greenhouse through the direct evaporative cooling process. Increasing the relative humidity in the indoor environment increased the cooling effect by decreasing the temperatures. At the same time, by using external shading in the CP + ESN application, the solar radiation reaching the interior was reduced, and the cooling effect was higher than that of the CP application. However, since shading nets will reduce the light reaching the indoor environment, the plants’ light needs should also be considered.

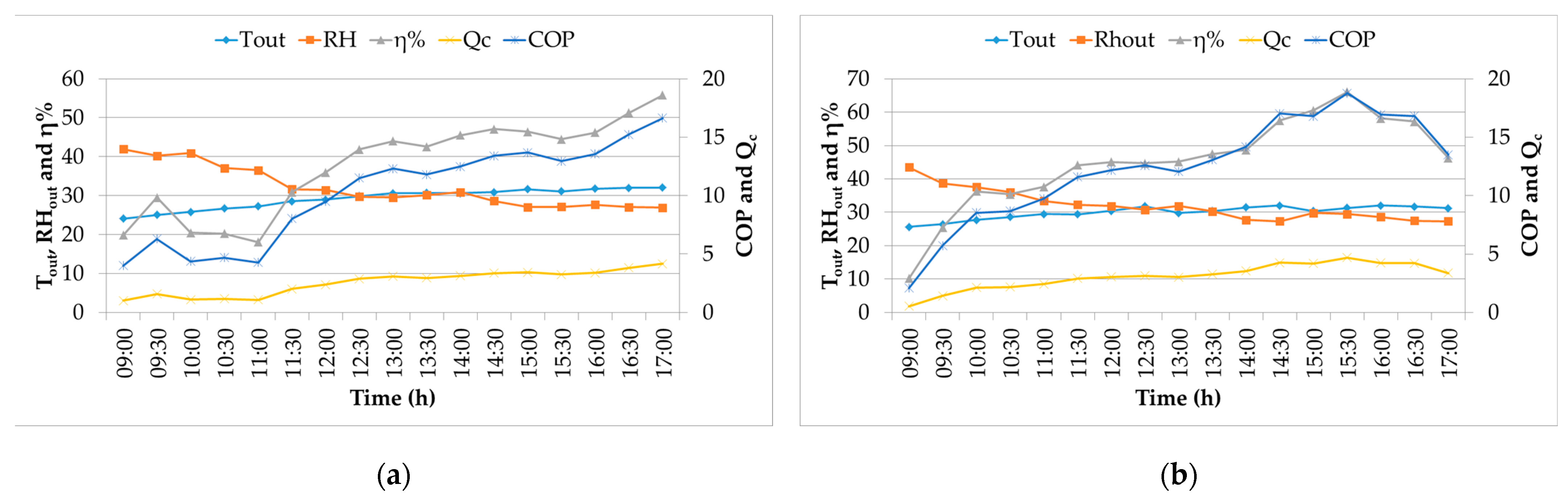

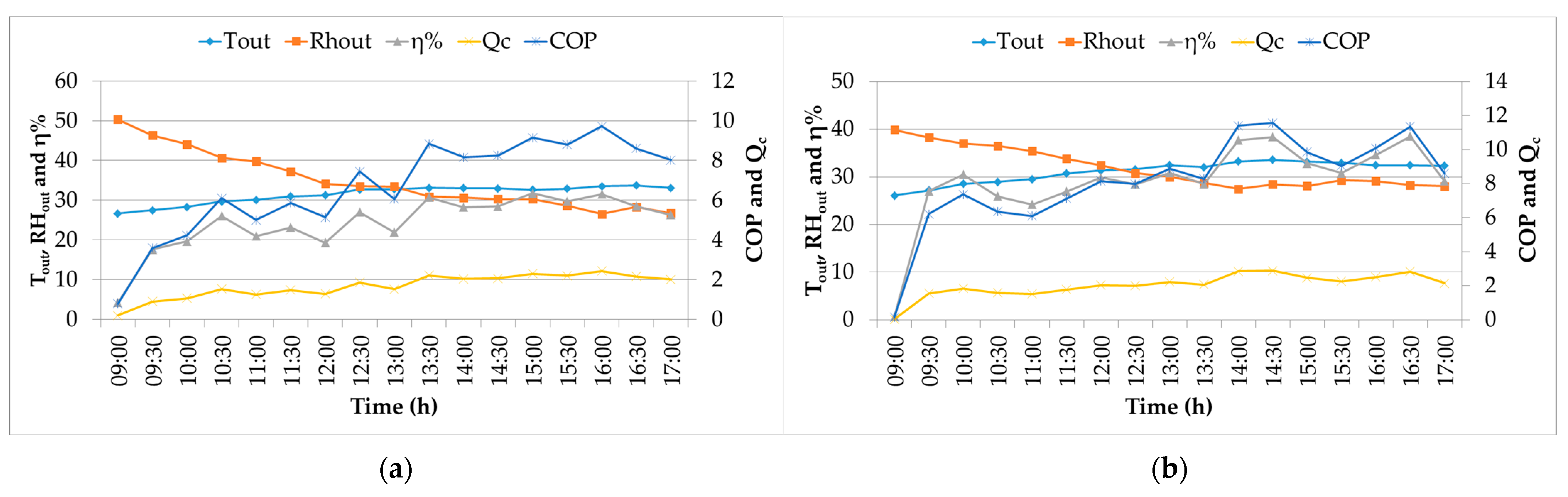

Variations of some performance parameters with time are given in

Figure 3a for the CP application and in

Figure 3b for the CP + ESN application.

In the CP application, the indoor relative humidity values were 27.4% higher on average than those in the external environment. The CP + ESN application’s indoor relative humidity values were 31.3% higher than those of the external environment. According to this, in the CP application, the outdoor VPD value was 2.8 kPa and the indoor VPD value was determined to be 1.2 kPa. In the CP + ESN application, while the outdoor VPD value was 2.9 kPa, the indoor VPD value was determined to be 1.1 kPa. In a study on relative humidity, Gunhan et al. [

44] reported that, for a 5 cm pad thickness and four different air speeds (0.6, 1.0, 1.3, and 1.6 m s

−1), the relative humidity differences were 37.21%, 33.58%, 28.83%, and 27.38%, respectively. Shivpuje et al. [

45] found that the average relative humidity of the air entering the cooling pad varied between 42.1% and 48.2%, and the relative humidity at the exit was between 65.4% and 78.7%. The results of our study are in line with previous findings in the literature. Under conditions of increasing outdoor temperature values, relative humidity values decreased in the outdoor environment (

Figure 3a,b). In this case, the dry air entering the pad took in more moisture, causing the relative humidity values in the indoor environment to increase. In addition, increasing the relative humidity contributed to the decrease in VPD values. Increasing the relative humidity and decreasing VPD values in the CP and CP + ESN applications made the greenhouse indoor environment suitable for plant cultivation. However, due to the external shading net used in the CP + ESN application, the indoor conditions were more suitable than those of the CP application.

In the study, the cooling efficiency of the CP application was determined to be 37.6% on average, between 18.0 and 55.8%. The cooling efficiency of the CP + ESN was determined to be 45.0% on average, between 10.2% and 66.0%. Accordingly, it has been observed that the cooling efficiency of the CP + ESN application is higher than that of the CP application. The results showed that the external shading net positively increased the evaporative cooling efficiency.

Figure 3a,b show that the decreasing relative humidity values in the outdoor environment increased the cooling efficiency. This is because the decreasing temperatures inside the greenhouse increased the difference between the indoor and outdoor temperatures. As the temperature difference increased, the indoor temperatures approached the outdoor wet bulb temperature and the cooling efficiency increased. In a study on cooling efficiency, Gunhan et al. [

44] calculated the evaporation saturation efficiency to be 46.1% for a pad thickness of 5 cm. Vala et al. [

46] stated that, with a 10 cm thick Celdek pad, the saturation efficiency ranged between 90.70 to 57.14%. Franco et al. [

32] reported that the saturation efficiency for a cellulose pad was between 70% and 64%. The results revealed that the cooling efficiency was higher than the results of [

44] showed, where the pad thickness was similar, but lower than the results of [

32,

46], where pad thickness was thinner. Mishra et al. [

47] reported that an increase in the thickness of the pad also increased the cooling efficiency. For this reason, in this study, the resulting differences depended on the external climate (incoming radiation, outdoor relative humidity, etc.) and the pad thickness.

The cooling capacity for the CP application was calculated to be Qc = 9221.5 kJ h

−1 (2.6 kW) and the COP value was calculated to be 10.2. The cooling capacity for the CP + ESN application was calculated to be Qc = 10895.5 kJ h

−1 (3.0 kW) and the COP value was 12.1. In our study, the cooling capacity and COP values were found to be higher in the CP + ESN application than in the CP application. The increasing temperature values in the greenhouse indoor environment lead to the availability of the high heat of vaporization. This results in evaporation and cools the indoor environment. A large temperature difference is obtained when cooling causes the internal temperature of the greenhouse to fall below the ambient temperature, resulting in a high cooling capacity [

47]. In our study, the decrease in greenhouse temperature values in the CP + ESN application (ΔT = 6.6 °C) compared to the CP application (ΔT = 5.5 °C) increased the cooling capacity and the COP. Accordingly, the cooling capacity and the COP values increased in the CP + ESN application. Also,

Figure 3a,b indicate that lower outdoor relative humidity leads to enhanced evaporation, leading to a higher cooling capacity and a higher COP. Shivpuje et al. [

45] found that the system’s cooling capacity varies between 0.7 and 1.1 kW, and the highest COP value in the system is determined to be 19.5. Vala et al. [

46] calculated the cooling capacity to be 2717 kJ h

−1 with a 10 cm thick Celdek pad. Chaomuang et al. [

30] reported that, at the four different air velocities (0.5, 1.0, 1.5, and 2.0 m s

−1), the cooling capacity for the CP was 0.3–0.6 kW and the COP value was around 2.2–4.5. In addition, the cooling capacity shows a direct relationship not only with temperature drop but also with flow rate. Maurya et al. [

38] reported that increasing air velocities increased the cooling capacity. Doğramacı et al. [

29] stated that, as the air speed increased up to a certain value, the COP value and the cooling capacity increased. Compared to the findings of studies conducted by other researchers, the cooling capacities found in this study were lower than those found in [

45] and higher than those found in [

30]. This study’s cooling capacities increased due to the high air velocity, which was 2 m s

−1. The increasing cooling capacity increased the COP value. At the same time, the cooling effect occurring in the greenhouse contributed to the increase in these values.

In the CP application, the water consumption capacity was calculated to be Qω = 26.5 L day

−1 (2.9 L h

−1). In the CP + ESN application, the water consumption capacity was Qω = 27.8 L day

−1 (3.1 L h

−1). There was a difference of 4% for the CP application and 5% for the CP + ESN application between the amount of water added to the system (between 09:00 and 17:00) and the calculated daily water consumption. It was determined that this was caused by losses and leaks in the system. According to the obtained results, water consumption in the CP + ESN application was higher than that in the CP application. Low relative humidity in the outdoor environment allows the evaporative cooler to evaporate more water and consume more water. At the same time, the excess amount of evaporated water contributes to an increase in cooling capacity. The water consumed in the CP + ESN application also increased the cooling capacity compared to the CP application. Vala et al. [

46] stated that the average water evaporation with a 10 cm thick Celdek pad was 4.31 L h

−1. Nikolaou et al. [

48] measured the daily water required for fan-pad evaporative cooling under Mediterranean conditions in a greenhouse that was growing cucumbers; they found that up to 3 L of water was used per m

2 of greenhouse floor area. Franco et al. [

32] reported that the water consumption per unit for cellulose pad varies between 1.8 L h

−1 and 2.62 L h

−1. This study determined that 1.8 L was necessary per m

2 greenhouse floor area for the CP application, and 1.9 L was needed per m

2 greenhouse floor area for the CP + ESN application. These results align with previous findings in the literature. In addition, due to the water shortage in regions with a Mediterranean climate, water consumption per unit area is as important as the cooling of greenhouses. This is because determining the amount of water consumed for cooling will also affect the feasibility of evaporative cooling applications in water-limited areas.

Fan-pad cooling systems reduce heat loads by converting sensible heat in the air to latent heat; this creates a more suitable indoor climate for plant growth [

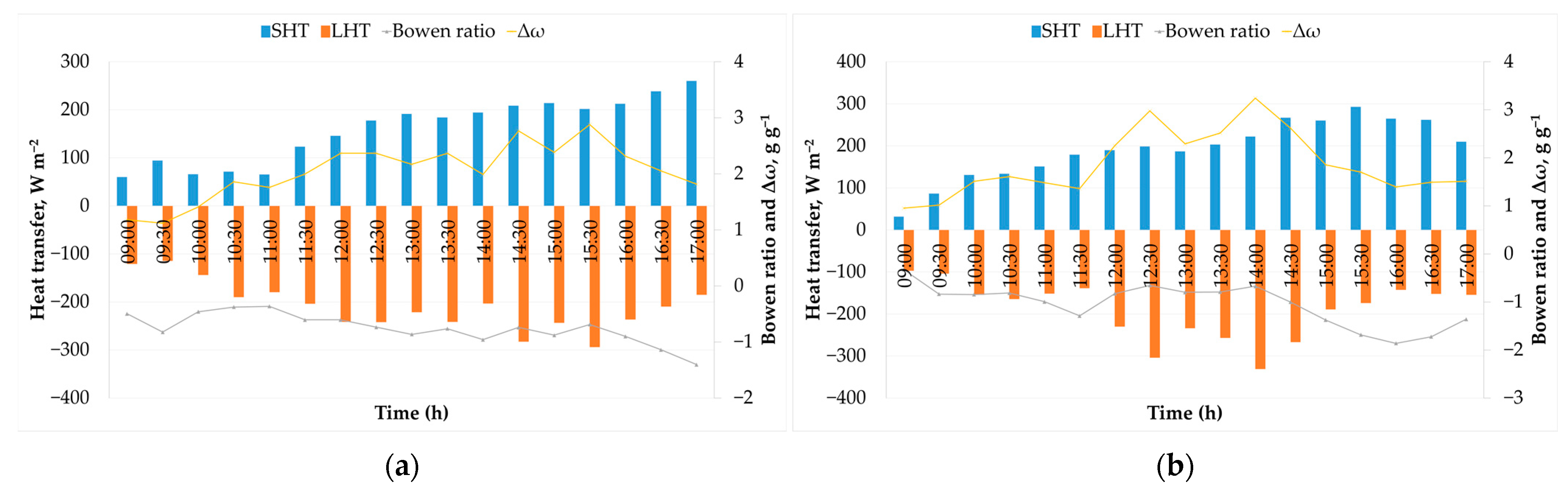

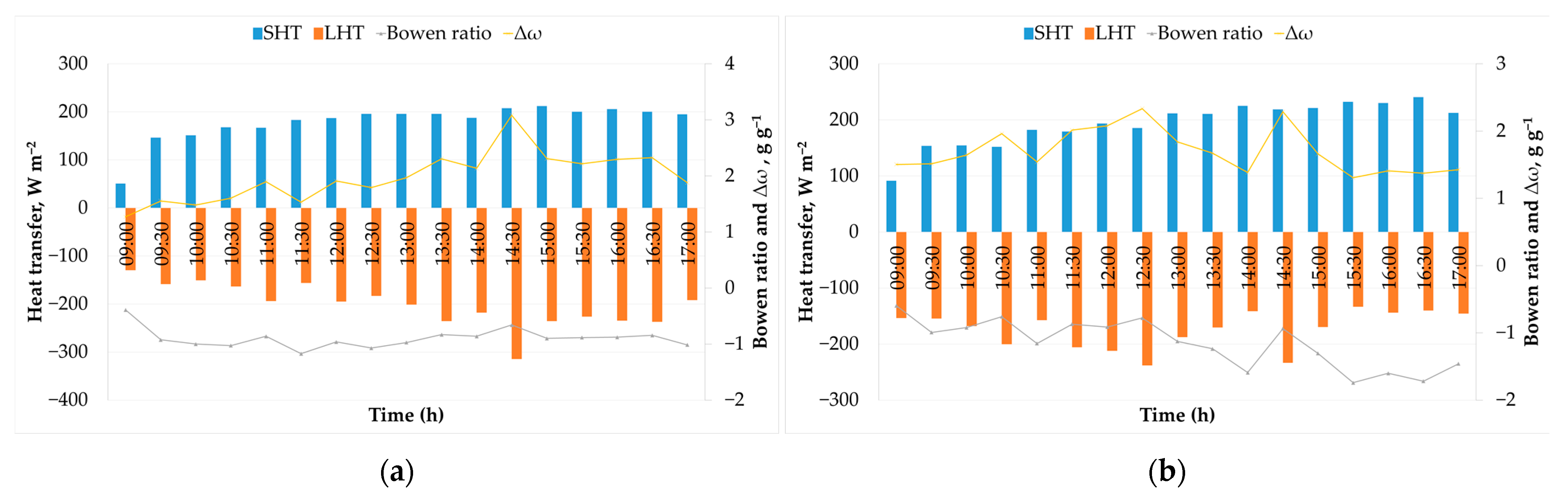

18]. The changes in sensible and latent heat transfer per floor area in the greenhouse, depending on time, are given in

Figure 4a for the CP application and in

Figure 4b for the CP + ESN application.

As seen in

Figure 4a in the CP application, SHT was found to be 159.5 W m

−2 on average, between 59.9 and 260.1 W m

−2. LHT was −209.1 W m

−2 on average, between −114.4 W m

−2 and −294.1 W m

−2. The Bowen ratio was found to be −0.8 on average, between −0.4 and −1.4. The difference in specific humidity was 2.1 g g

−1 on average, between 1.1 and 2.9 g g

−1. As seen in

Figure 4b, in the CP + ESN application, SHT achieved 192.4 W m

−2 on average, between 31.6 and 292.8 W m

−2. LHT was found to be −191.0 W m

−2 on average, between −97.2 and −331.1 W m

−2. The average Bowen ratio was found to be −1.1 between −0.3 and −1.9. The difference in specific humidity was 1.87 g g

−1 on average, between 1.0 and 3.2 g g

−1. In CP and CP + ESN applications, while SHT increased due to the temperature difference (ΔT) increase between the outdoor and indoor areas of the greenhouse, LHT increased due to the increase in the specific humidity difference between the greenhouse environment and the outdoor air (

Figure 4a,b). In addition, the Bowen ratio increased depending on the increase in the specific humidity difference. In their studies, researchers have reported that sensible heat transfer in the greenhouse increases linearly with the temperature difference, and the latent heat transfer increases linearly with the specific humidity difference. At the same time, it was determined that SHT was higher than LHT when the cooling system was operating in the greenhouse [

37,

49,

50]. Similarly, in the CP and CP + ESN applications, we determined that SHT increased linearly with the temperature difference and LHT with the specific humidity difference; additionally, it was found that SHT was higher than LHT when the systems were operating in the greenhouse. Öztürk [

37] stated that SHT was higher than LHT when the β values were considered in the greenhouse trial. A value of β (−) indicates that the air temperature inside the greenhouse is lower than the outdoor air temperature and that the specific humidity is higher than that of the outside environment. Moreover, although SHT occurs towards the vegetation in the greenhouse, LHT occurs from the vegetation under these conditions. Similar to the previous study, in the CP and CP + ESN applications, we determined that LHT was higher than SHT when the cooling system was operating in the greenhouse. However, this increase was greater in the CP + ESN application, and the greenhouse indoor environment became more suitable for plant cultivation.

3.2.2. Luffa Pad and Luffa Pad + External Shading Net Applications

The external and internal climate parameters measured in the luffa pad and the luffa pad + shading net applications are given in

Table 6.

In the LP application, the outdoor solar radiation value was determined to be 778.3 W m−2, between 475.1 and 947.7 W m−2 on average. The indoor solar radiation value was measured to be 571.3 W m−2, between 356.3 and 746.5 W m−2 on average. In the LP + ESN application, the outdoor solar radiation value was 789.3 W m−2 on average, between 494.4 and 969.5 W m−2. On average, the indoor solar radiation value was 336.8 W m−2, between 215.7 and 426.6 W m−2. In the LP application, the solar radiation rate of the solar radiation reaching the greenhouse environment was determined to be 73.4%. In the LP + ESN application, the solar radiation rate reaching the greenhouse environment was found to be 42.7%.

As shown in

Table 6, the cooling effect in the LP application was 6.1 °C; for the LP + ESN application, it was determined to be 6.6 °C. Accordingly, it has been observed that the cooling effect of the LP + ESN application is higher than that of the LP application. This result showed that the shading net positively increased the evaporative cooling effect. Moreover, it has been determined that the indoor temperature values can be brought to values that are suitable for plant cultivation with the LP (26.6 °C) and LP + ESN (25.2 °C) applications. In a study on the cooling effect, Ahmadu et al. [

11] reported that, in applications with luffa fiber—charcoal pad maximum cooling effect of 11 °C was found for the application without dehumidification pad; a charcoal pad maximum cooling effect of 10 °C was found for the application with dehumidification pad. Mishra et al. [

47] reported that, for the luffa pad, the cooling effect for a 3 cm pad was in the range of 10.3 to 9 °C at an air speed of 0.5–1.5 m s

−1. The cooling effect was found in the range of 10.8 to 9.9 °C for 5 cm luffa pads and in the range of 11.5 to 9.9 °C for 7 cm luffa pads. The findings obtained in the study were lower than the results of the previous findings. Mishra et al. [

47] reported that, as the air velocity increases, the exit air temperature increases; this can be due to the decrease in contact time at the air–water interface. In line with previous studies, the low cooling effect in this study could be explained by the reduced contact time of the air entering the pad with the water due to the high air speed.

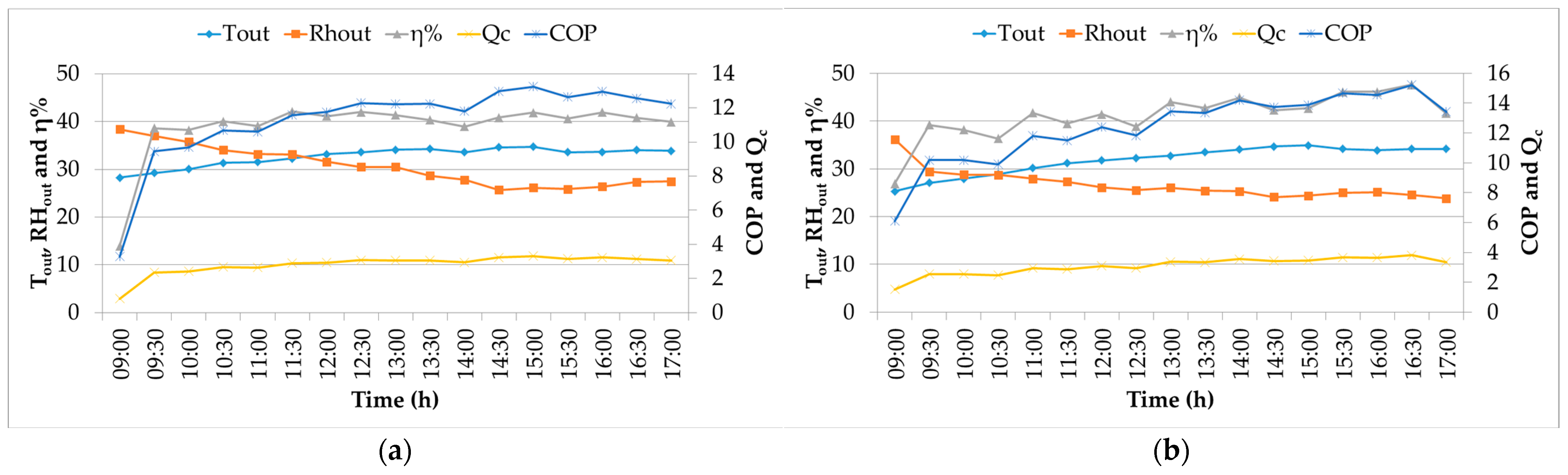

In the study, variations in some performance parameters with time are given in

Figure 5a for the LP application and

Figure 5b for the LP + ESN application.

In the LP application, the indoor relative humidity values were 25.1% higher on average than outdoor ones. In the LP + ESN application, the indoor relative humidity values were 24.9% higher than those of the external environment. According to this, while in the LP application, the outdoor VPD value was 3.5 kPa, the indoor VPD value was determined to be 1.5 kPa. In the LP + ESN application, while the outdoor VPD value was 3.5 kPa, the indoor VPD value was determined to be 1.6 kPa. The increasing temperature values in the outdoor area of the greenhouse decreased the relative humidity values in the outdoor environment (

Figure 5a,b). In this case, the dry air entering the pad took in more moisture, causing the relative humidity values in the indoor environment to increase. In addition, increasing relative humidity values in the indoor environment contributed to the decrease in VPD values. In addition, due to the external shading net used in the LP + ESN application, the indoor conditions were more suitable than those in the LP application. Increasing the relative humidity and decreasing the VPD values in the CP and CP + ESN applications made the greenhouse indoor environment suitable for plant cultivation. In a study on the indoor relative humidity effect, Ahmadu et al. [

11] reported that, when using luffa fiber with charcoal pad (15 cm width), the relative humidity ranged from 45% to 85% without dehumidification pad and from 46% to 49% with dehumidification pad. The lower relative humidity obtained in this study was due to the thinner pad thickness. The decrease in air–water contact has reduced the relative humidity values that reach the indoor environment. In addition, even though the relative humidity values are close compared to the CP and CP + ESN applications, the insertion of CPs into the pad at a certain angle increased the water–air contact. For this reason, the relative humidity values increased in the CP and CP + ESN applications compared to the LP and LP + ESN applications.

In the LP application, the cooling efficiency was calculated to be 38.9% on average, between 14.0 and 42.1%. The cooling efficiency of the LP + ESN pad was calculated to be 41.2% on average, between 26.9% and 47.6%.

Figure 5a,b show that the decreasing relative humidity values in the outdoor environment increased the cooling efficiency. Accordingly, it has been observed that the cooling efficiency of the LP + ESN application is higher than that of the LP application. These results showed that the ESN application positively increased the evaporative cooling efficiency. In studies conducted by researchers, Al-Sulaiman [

12] selected palm fibers (stem), jute, and luffa as wet pads in evaporative cooling; as a comparison, they used a commonly used commercial wet pad. The study calculated the average cooling efficiencies to be 62.1% for jute, 55.1% for luffa fiber, 49.9% for the commonly used commercial pad, and 38.9% for palm fiber. It was also reported that luffa pad has an advantage over other fibers. In a study comparing luffa and zizanoid, Kesevan [

51] reported that the cooling efficiency of the loofah pad was 58% at a pad thickness of 4 cm. de Oliveira et al. [

52] reported that, for a 15 cm pad width, the cooling efficiencies were 77.3% (luffa pad) and 84.5% (commercial pad). Mishra et al. [

47] reported that, for the luffa pad, the cooling efficiency for a 3 cm pad varied in the range of 59.2% to 51.7% for air velocities between 0.5 and 1.5 m s

−1. For the 5 cm pad, ranges between 60.6% and 55.6% were found; for the 7 cm thick pad, values in the range of 65.9% to 56.8% were found. Compared with previous findings, the cooling efficiency was found to be lower than those found by [

47,

52]. This is because the thickness of the pad and the air speed were low. Therefore, different thicknesses, water flow rates, and air flow rates for loofah pads must be investigated.

In the LP application system, the cooling capacity was calculated to be Qc = 10174.9 kJ h

−1 (2.8 kW); meanwhile, in the LP + ESN application, the system cooling capacity was calculated to be Qc = 10740.4 kJ h

−1 (3.0 kW). In this study, while the COP value in the system was calculated to be 11.3 for the LP application, that of the LP + ESP application was calculated to be 11.9. Moreover, the cooling capacity was higher in the LP + ESN application than in the LP application. This is due to the decrease in the greenhouse temperature values in the LP + ESN application (ΔT = 6.6 °C) compared to those of the LP application (ΔT = 6.1 °C), which had increased cooling capacity and COP. Also,

Figure 5a,b indicate that lower outdoor relative humidity leads to enhanced evaporation, leading to a higher cooling capacity and a higher COP. The study conducted by Ahmadu et al. [

11] studied two methods: luffa fiber + charcoal (without dehumidification) and luffa fiber + charcoal (with dehumidification). A maximum cooling capacity of 3.84 kW and a COP of 16.1 were recorded by the system without the dehumidifying pad. When the system was operating with the dehumidifying pad, a cooling capacity of 3.2 kW and a COP value of 13.4 were also recorded. Mishra et al. [

47] reported that, for the 3 cm luffa pad the cooling capacity between 455 and 1203 W for air velocities between 0.5 and 1.5 m s

−1. Moreover, for the 5 cm pad, ranges between 478 and 1323 W were found; for the 7 cm thick pad, ranges between 508 and 1340 W were found. The researchers also reported that, for the luffa pad, the COP values found for the 3 cm pad were 4.13, 6.55, and 8.18 at air speeds of 0.5, 1.0, and 1.5 m s

−1, respectively. The COP values for the 5 cm pad were 4.26, 6.97, and 8.48; for the 7 cm pad, these were 4.34, 7.01, and 8.53. According to Mishra et al. [

47], the cooling capacity for a given pad increases as the air velocity increases. However, the air’s cooling effect is reduced at high air velocities. This is because the contact time between air and water decreases at a high velocity, reducing the rate of water evaporation. But increasing the mass flow rate at higher speeds increases the cooling capacity. In addition, the cooling capacity increases by increasing the pad thickness for the same air speed. Compared with previous findings, the thinner pad thickness (3.5 cm) reduced the cooling capacity in this study. However, increasing air speed (2 m s

−1) increased the cooling capacity.

In the LP application, the water consumption capacity was calculated to be Qω = 25.2 L day

−1 (2.8 L h

−1). In the LP + ESN application, the water consumption capacity was Qω = 29.0 L day

−1 (3.2 L h

−1). There was a difference of 4% for the LP and LP + ESN applications between the amount of water added to the system between 09:00 and 17:00 and the calculated daily water consumption. It was determined that this was caused by losses and leaks in the system. According to the obtained results, the water consumption in the LP + ESN application was higher than that in the LP application. Low relative humidity in the outdoor environment allowed the evaporative cooler to evaporate more water and consume more water. At the same time, the excess evaporated water contributes to an increase in cooling capacity. The water consumed in the LP + ESN application also increased the cooling capacity compared to the LP application. Ahmadu et al. [

11] reported that, in the application with luffa fiber and a charcoal pad, the total water consumed was 0.99 l h

−1 for the condition without dehumidification; this was 1.08 l h

−1 with dehumidification. Mishra et al. [

47] reported that, for the luffa pad, the water consumption for a 3 cm pad varied in a range of 0.353 to 0.930 g s

−1 for air velocities of 0.5 to 1.5 m s

−1. Also, they found that, for the 5 cm pad, these values varied in a range of 0.374 to 1.262 g s

−1; for the 7 cm thick pad, the range was 0.418 to 1.406 g s

−1. The researchers also stated that, with increasing air speed, the rate at which water evaporates is increased. The water consumption in the our study was higher than that reported in the literature. This is because the higher air velocity used in this study also increased the evaporation rate, leading to increased water consumption. Given the water scarcity in the eastern Mediterranean and the necessity of reducing energy consumption in greenhouses, greenhouse cooling continues to be an economic and technical challenge [

53]. This study determined a water consumption value of 1.7 L per m

2 of greenhouse floor area for the LP application and 1.9 L per m

2 for the LP + ESN application. In this case, greenhouse enterprises need to consider water consumption amounts and energy consumption for evaporative cooling.

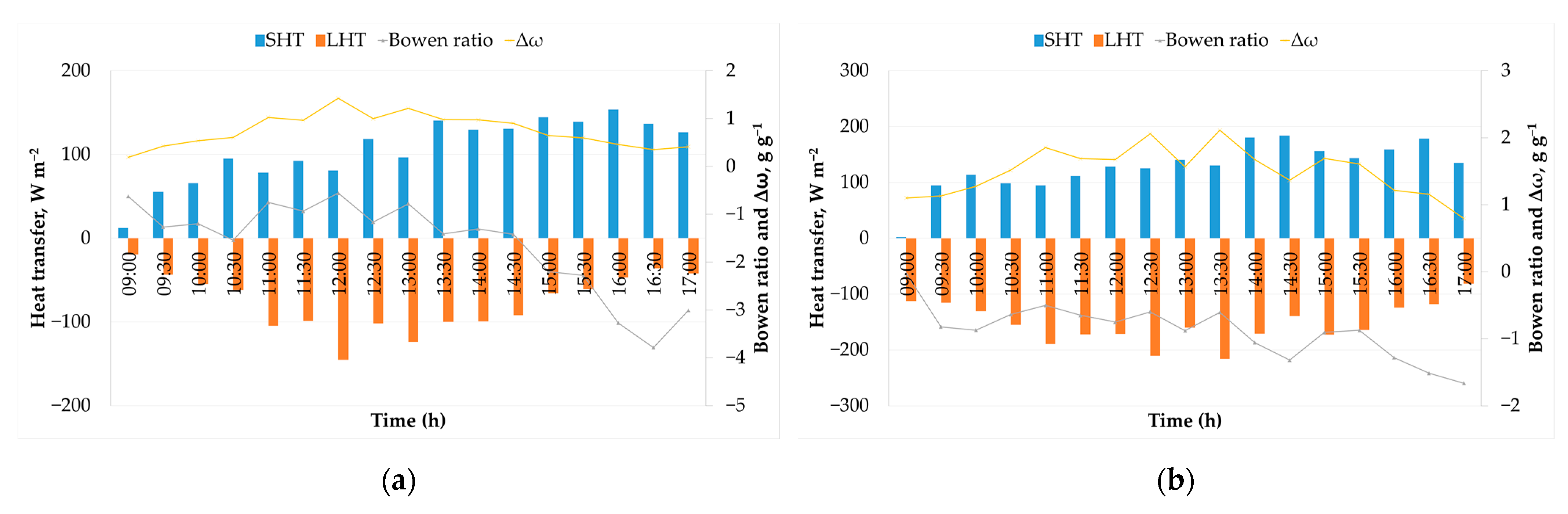

The change in sensible and latent heat transfer per floor area in the greenhouse, depending on time, is given in

Figure 6a for the LP application and in

Figure 6b for the LP + ESN application from this study.

As seen in

Figure 6a, for the LP application, SHT was 179.5 W m

−2 on average, between 50.7 and 212.1 W m

−2. LHT was found to be −201.5 W m

−2 on average, between −129.6 W m

−2 and −314.9 W m

−2. The Bowen ratio was −0.9 on average, between −0.4 and −1.2. The difference in specific humidity achieved 2.0 g g

−1 on average, between 1.3 and 3.1 g g

−1. In the LP + ESN application, as seen in

Figure 6b, SHT was determined to be 193.9 W m

−2 on average, between 91.6 and 240.9 W m

−2. LHT was found to be −173.9 W m

−2 on average, between −133.4 W m

−2 and −238.4 W m

−2. The Bowen ratio was −1.2 on average, between −0.6 and −1.7. The difference in specific humidity was 1.7 g g

−1 on average, between 1.3 and 2.3 g g

−1. In the LP and LP + ESN applications, SHT increased due to the increase in the temperature difference (ΔT) between the outdoor and indoor areas of the greenhouse; meanwhile, LHT increased due to the increase in the specific humidity difference between the greenhouse environment and the outdoor air (

Figure 6a,b). Similar to the CP and CP + ESN applications, the LP and LP + ESN applications also determined that LHT was higher than SHT when the cooling system was operating in the greenhouse. However, this increase was greater in the LP + ESN application and the greenhouse indoor environment became more suitable for plant cultivation.

3.2.3. Shading Net Pad and Shading Net Pad + External Shading Net Application

The external and internal climate parameters measured for the shading net pad and shading net pad + external shading net applications are given in

Table 7.

In the SNP application, the outdoor solar radiation value was determined to be 791.7 W m−2 on average, between 479.9 and 1051.9 W m−2. The indoor solar radiation value was determined to be 559.9 W m−2 on average, between 198.7 and 795.0 W m−2. In the SNP + ESN application, the outdoor solar radiation value was 639.9 W m−2 on average, between 123.6 and 957.4 W m−2. The indoor solar radiation value was 257.6 W m−2 on average, between 46.1 and 424.2 W m−2. In the SNP application, the solar radiation rate reaching the greenhouse environment was determined to be 70.7%. In the SNP + ESN application, the solar radiation rate reaching the greenhouse environment was found to be 40.3%.

As shown in

Table 7, the cooling effect in the SNP application was 3.6 °C; for the SNP + ESN application, this was determined to be 4.4 °C. Accordingly, it has been observed that the cooling effect of the SNP + ESN application is higher than that of the SNP application. The results showed that the shading net positively increased the evaporative cooling effect. In a study on the cooling effect, Gunhan et al. [

44] reported that, for a 5 cm pad thickness and four different air speeds (0.6, 1.0, 1.3, and 1.6 m s

−1), the cooling effects were found to be 2.67, 1.92, 1.72, 1.96 °C, respectively. The cooling effect obtained here was higher than those of previous findings. However, it was lower than those of the CP, CP + ESN, LP, and LP + ESN applications. SNP’s low water retention capacity reduced the relative humidity values transferred to the indoor environment. Therefore, the cooling effect on the indoor environment decreased.

In the study, variations of some performance parameters with time are given in

Figure 7a for the SNP application and

Figure 7b for the SNP + ESN application.

In the SNP application, the indoor relative humidity values were 12.5% higher on average than those in the outdoor environment. SNP + ESN application indoor relative humidity values were 18.2% higher than those of the external environment. According to this, in the SNP application, the outdoor VPD value is 3.1 kPa; meanwhile, the indoor VPD value is determined to be 2.0 kPa. In the SNP + ESN application, while the outdoor VPD value is 3.1 kPa, the indoor VPD value is determined to be 1.8 kPa. The increasing temperature values in the outdoor area of the greenhouse led to decreased relative humidity values in the outdoor environment (

Figure 7a,b). In this case, the dry air entering the pad took in more moisture, causing the relative humidity values in the indoor environment to increase. In addition, the increasing relative humidity values in the indoor environment contributed to the decrease in the VPD values. Moreover, due to the external shading net used in the SNP + ESN application, the indoor conditions were more suitable than those of the SNP application. However, in both applications, the relative humidity was lower than that of the CP, CP + ESN, LP, and LP + ESN applications. In a study on the performance of Celdek pads, Gunhan et al. [

44] reported that, for the 5 cm pad thickness and four different air speeds (0.6, 1.0, 1.3, and 1.6 m s

−1), the relative humidity differences were found to be 17.82%, 12.54%, 11.54%, and 12.29%, respectively. These results align with the previous findings in the literature. The indoor relative humidity values could not be increased due to the low evaporation rate in the SNP and SNP + ESN applications.

In the SNP application, the cooling efficiency was calculated to be 24.0% on average, between 4.2 and 31.7%. The cooling efficiency of the SNP + ESN application was calculated to be 28.0% on average, between 0.7% and 38.5%.

Figure 7a,b show that the decreasing relative humidity values in the outdoor environment increased the cooling efficiency. Accordingly, it has been observed that the cooling efficiency of the SNP + ESN application is higher than that of the SNP application. At the same time, the ESN application positively increased the evaporative cooling efficiency. However, in both applications, the cooling efficiency was lower than that of the CP, CP + ESN, LP, LP + ESN applications. In a study on the cooling efficiency of Celdek pads, Gunhan et al. [

44] calculated the evaporation saturation efficiency as 25.2% for a 5 cm pad thickness. Also, they reported that the shading net has a low saturation efficiency level. However, it was reported that the cooling efficiency of the pad with 0.6 ms

−1 wind speed and 15 cm shading net pad was 51.3% and could be considered as alternative pad materials instead of CELdek pad. The cooling efficiency obtained in this study was near with the researcher for 3 cm pad thickness. Since evaporative cooling efficiency depends on the relative humidity of the outdoor environment and the velocity of the air passing through the pad, the results small vary. For SNP applications, cooling efficiency can be increased by increasing pad thickness and selecting low air velocities.

In the SNP application, the system cooling capacity was calculated to be Qc = 5922.8 kj h

−1 (1.7 kW); in the SNP + ESN application, the system cooling capacity was calculated to be Qc = 7038.4 kJ h

−1 (2.0 kW). In this study, while the COP value in the system was calculated to be 6.6 for the SNP application, that in the SNP + ESP application was calculated to be 7.8. Also,

Figure 7a,b indicate that lower outdoor relative humidity leads to enhanced evaporation, leading to a higher cooling capacity and a higher COP. But, in both applications, the cooling capacity was lower than that in the CP, CP + ESN, LP, and LP + ESN applications. Moreover, the decrease in greenhouse temperature values in the SNP + ESN application (ΔT = 4.4 °C) compared to that in the SNP application (ΔT = 3.6 °C) increased the cooling capacity and the COP. Accordingly, the cooling capacity and COP values increased in the SNP + ESN application compared to the SNP. However, in both applications, lower cooling capacity and COP values were obtained compared to those of the CP, CP + ESN, LP, and LP + ESN applications due to the low cooling effect.

In the SNP application, the water consumption capacity was calculated to be Qω = 21.6 L day−1 (2.4 L h−1). In the SNP + ESN application, the water consumption capacity was Qω = 21.9 L day−1 (2.4 L h−1). There was a difference of 4% for the SNP and SNP + ESN applications between the amount of water added to the system (between 09:00 and 17:00) and the calculated daily water consumption. It was determined that this was caused by losses and leaks in the system. Furthermore, it was determined that 1.4 L was used per m2 of greenhouse floor area in SNP and 1.5 L was used per m2 for greenhouse floor area in SNP + ESN. According to the obtained results, the water consumption in the SNP + ESN application was nearly to that in the SNP application. Compared to the CP, CP + ESN, LP, and LP + ESN applications, the water consumption was lower in the SNP and SNP + ESN applications. Accordingly, the cooling effect, relative humidity, cooling efficiency, and cooling capacity values were lower. The shading net material’s low water-holding capacity was important for this. According to the obtained results, compared to the other applications, the indoor environment of the greenhouse could not be brought to the appropriate temperature or relative humidity values for plant growth.

The changes in the sensible and latent heat transfers per floor area in the greenhouse, depending on time, are given in

Figure 8a for the SNP application and in

Figure 8b for the SNP + ESN application.

As seen in

Figure 8a, in the SNP application, SHT was found to be 105.7 W m

−2 on average, between 12.1 and 153.8 W m

−2. LHT was −76.3 W m

−2 on average, between −19.4 W m

−2 and −145.3 W m

−2. The average Bowen ratio was −0.8, between −0.4 and −1.6. The difference in specific humidity was 0.75 g g

−1 on average, between 0.2 and 1.4 g g

−1. In the SNP + ESN application, as seen in

Figure 8b, SHT was found to be 128.1 W m

−2 on average, between 2.40 and 183.7 W m

−2. LHT was −153.1 W m

−2 on average, between −81.3 W m

−2 and −215.7 W m

−2. The average Bowen ratio was found to be −0.9, between −0.02 and −1.7. The difference in specific humidity was 1.5 g g

−1 on average, between 0.8 and 2.1 g g

−1. In the SNP and SNP + ESN applications, SHT increased due to the increase in the temperature difference (ΔT) between the greenhouse outdoor and indoor; meanwhile, LHT increased due to the increase in the specific humidity difference between the greenhouse environment and the outdoor air (

Figure 8a,b). According to other applications (CP, CP + ESN, LP, and LP + ESN), the SNP and SNP + ESN applications showed higher LHT than SHT when the cooling system was operating in the greenhouse. However, in the SNP and SNP + ESN applications, the LHT values were lower than those in other applications (CP, CP + ESN, LP, and LP + ESN) due to the low evaporation effect of the pads. For this reason, the greenhouse indoor environment was unsuitable for plant growth in the SNP and SNP + ESN applications.