Study of Performance Changes in Centrifugal Compressors Working in Different Refrigerants

Abstract

1. Introduction

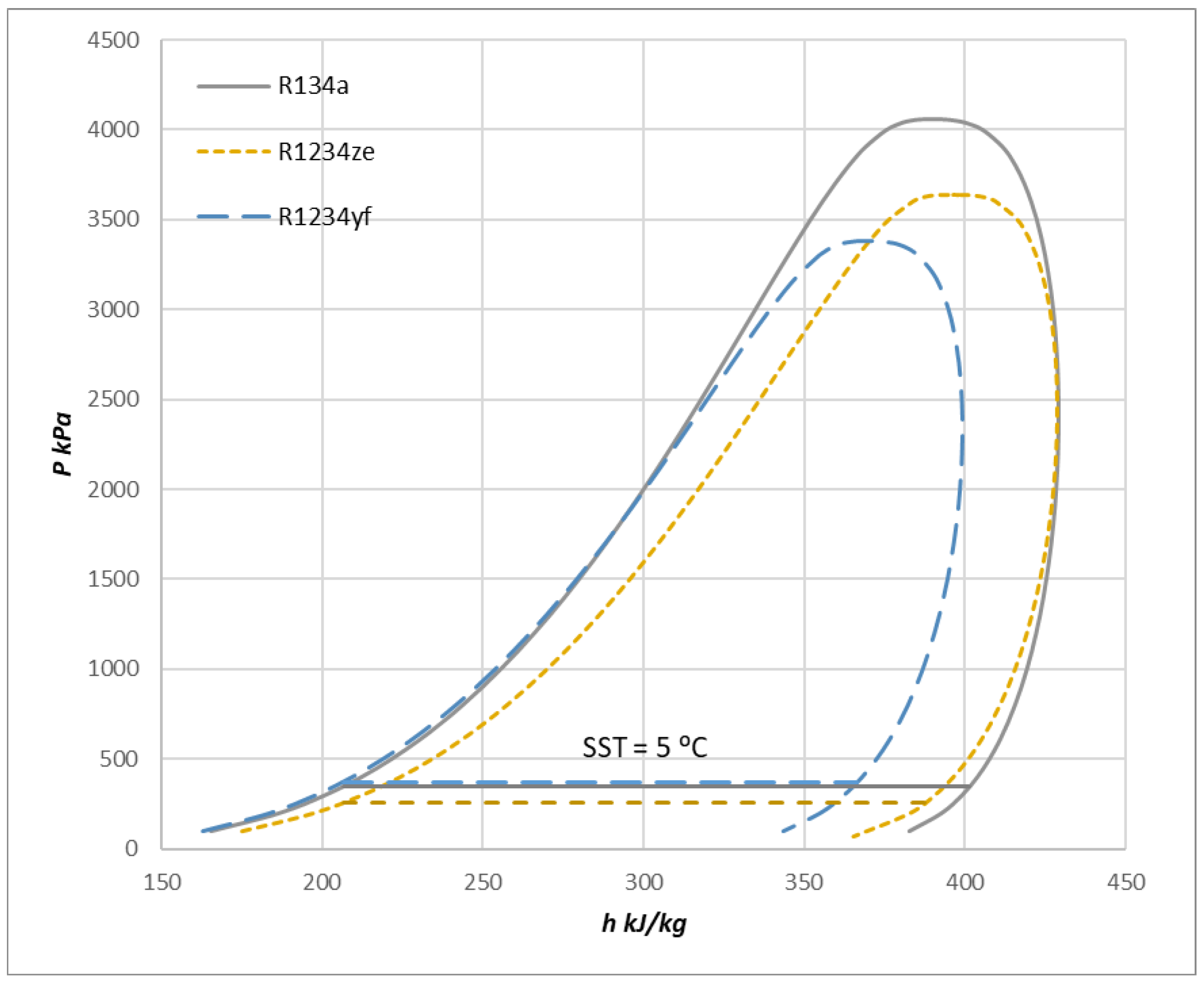

2. Thermodynamic Analysis

3. Methodology

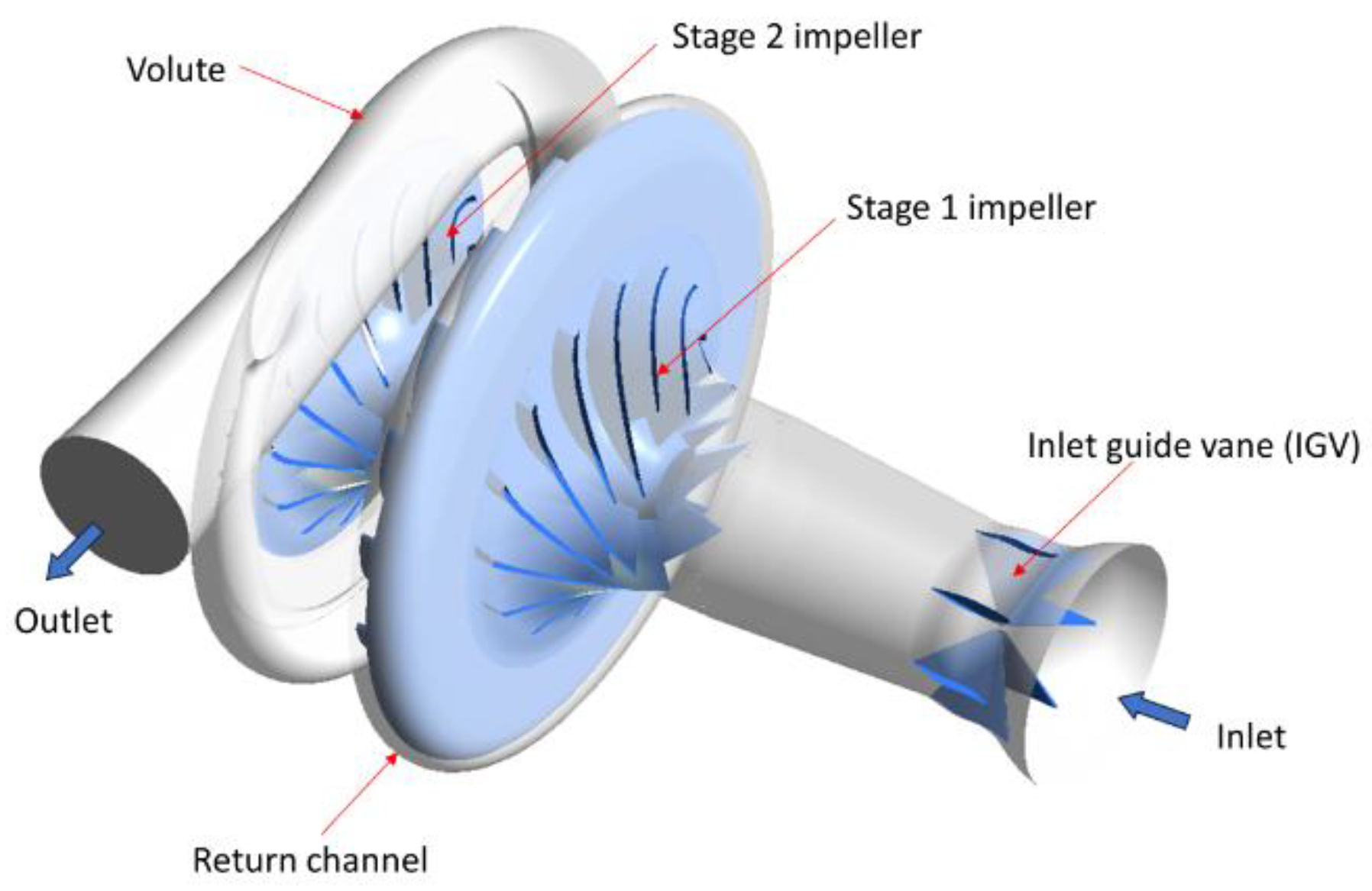

3.1. Compressor Geometry and Test Tig Information

3.2. CFD Modeling

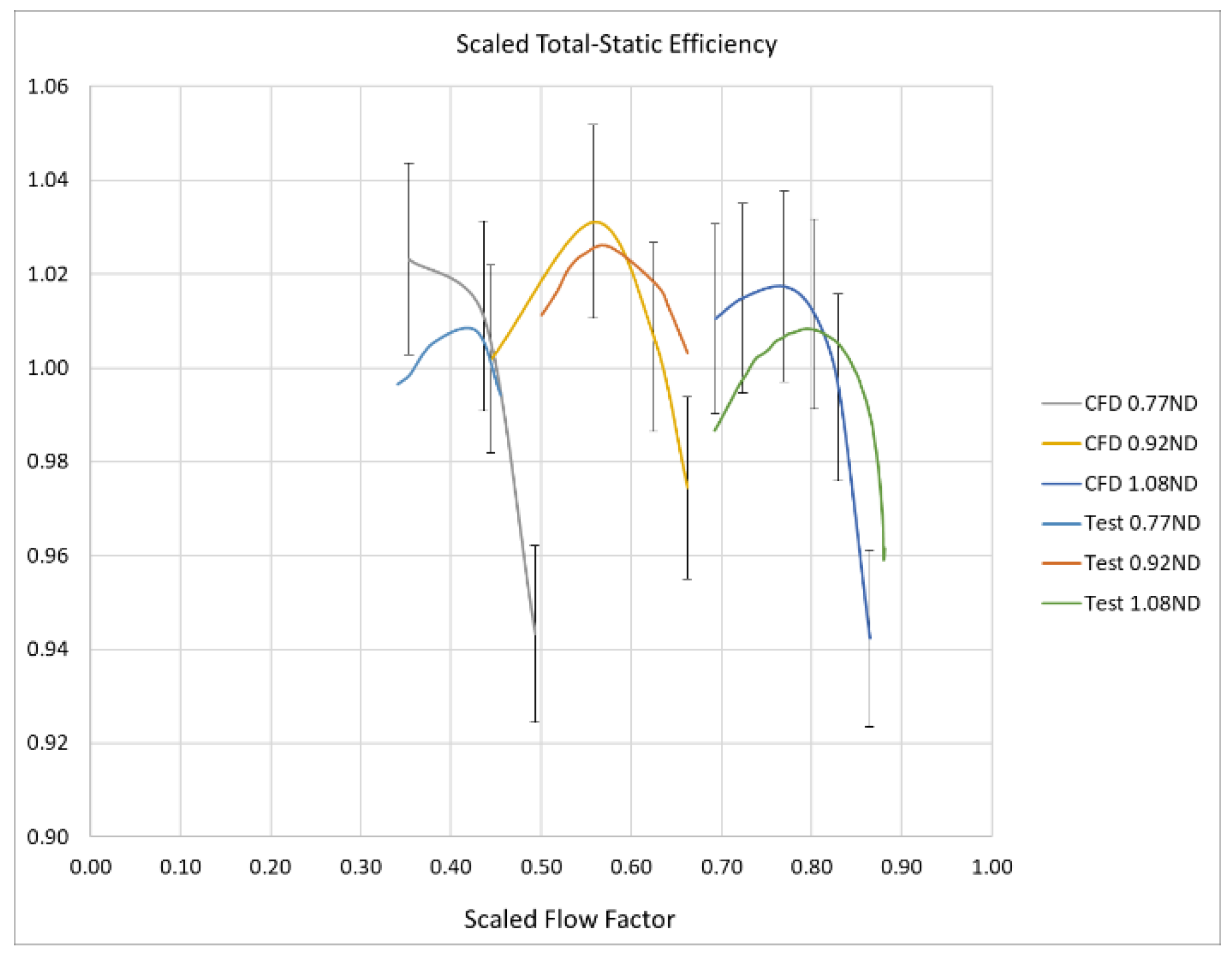

3.3. CFD Model Validation and Compressor Speed Line Expansion

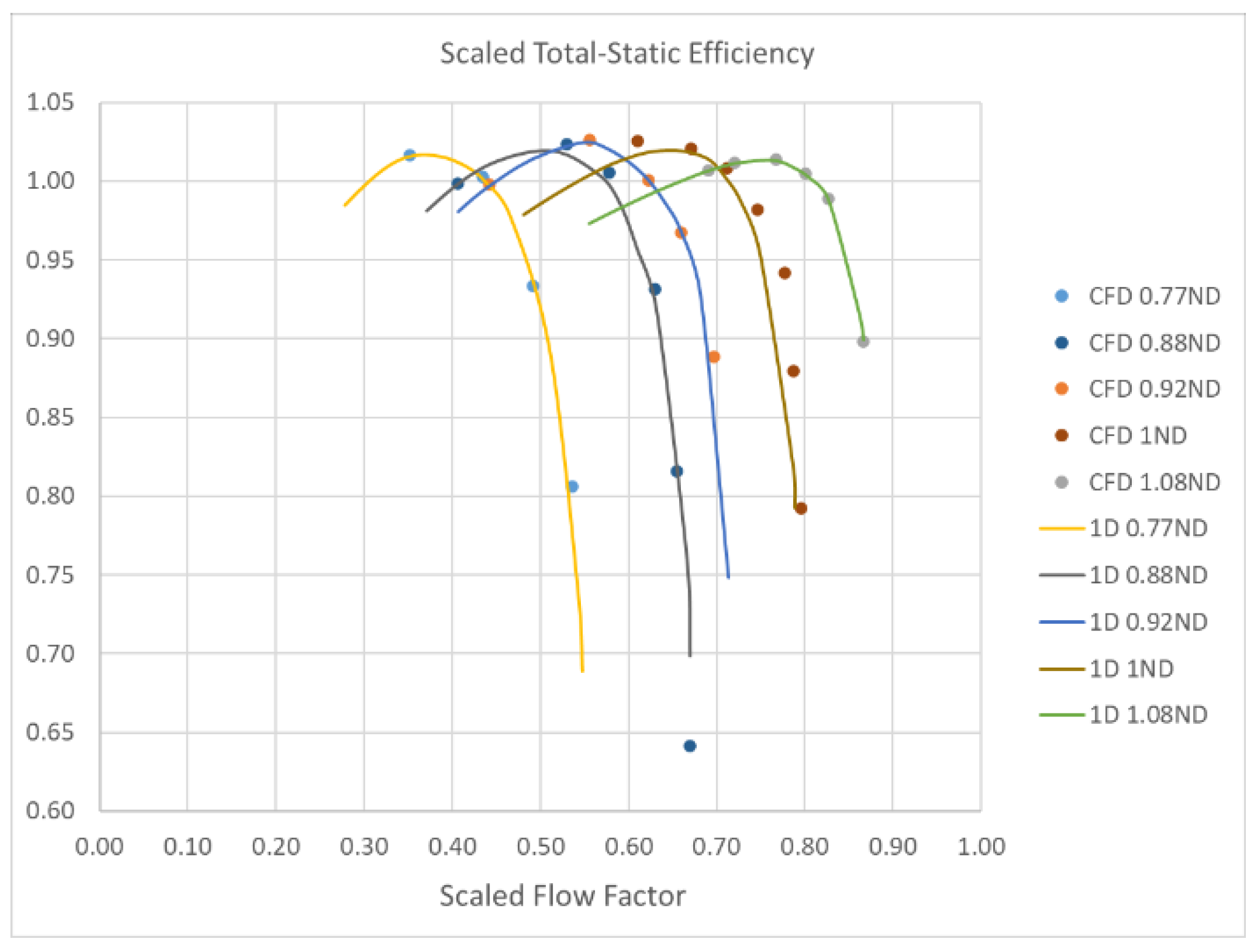

3.4. The 1D Meanline Modal Calibration and Compressor Speed Line Expansion

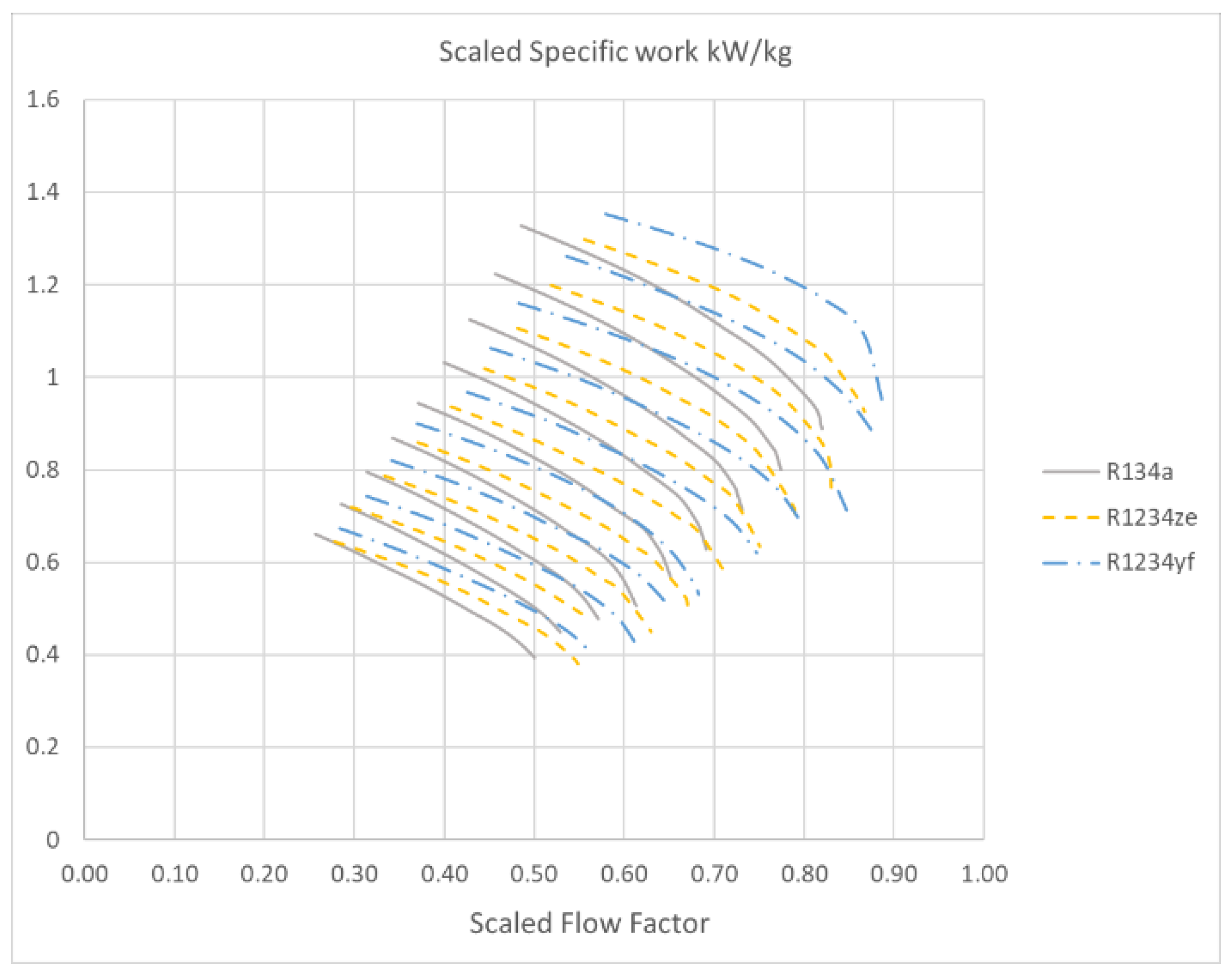

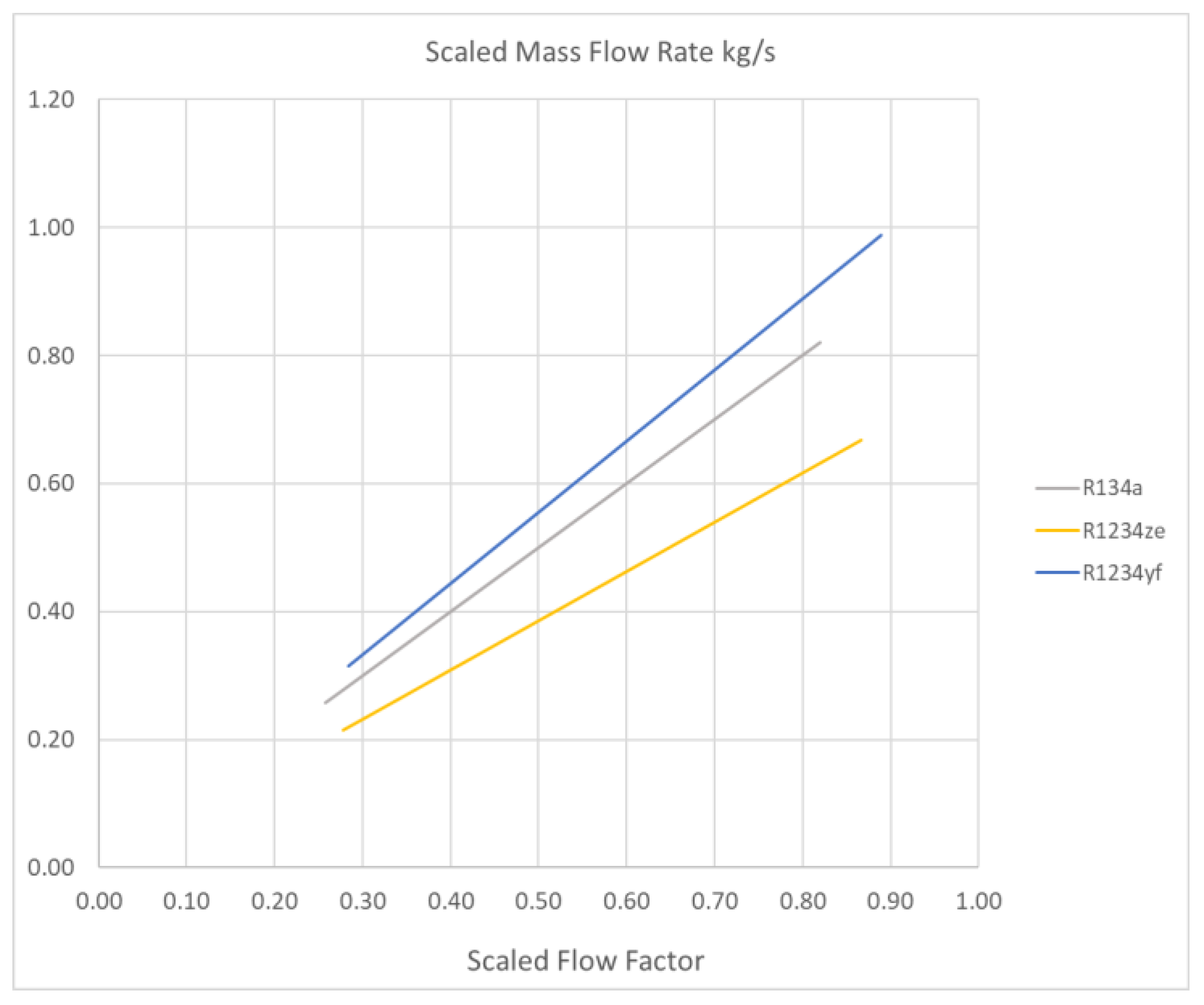

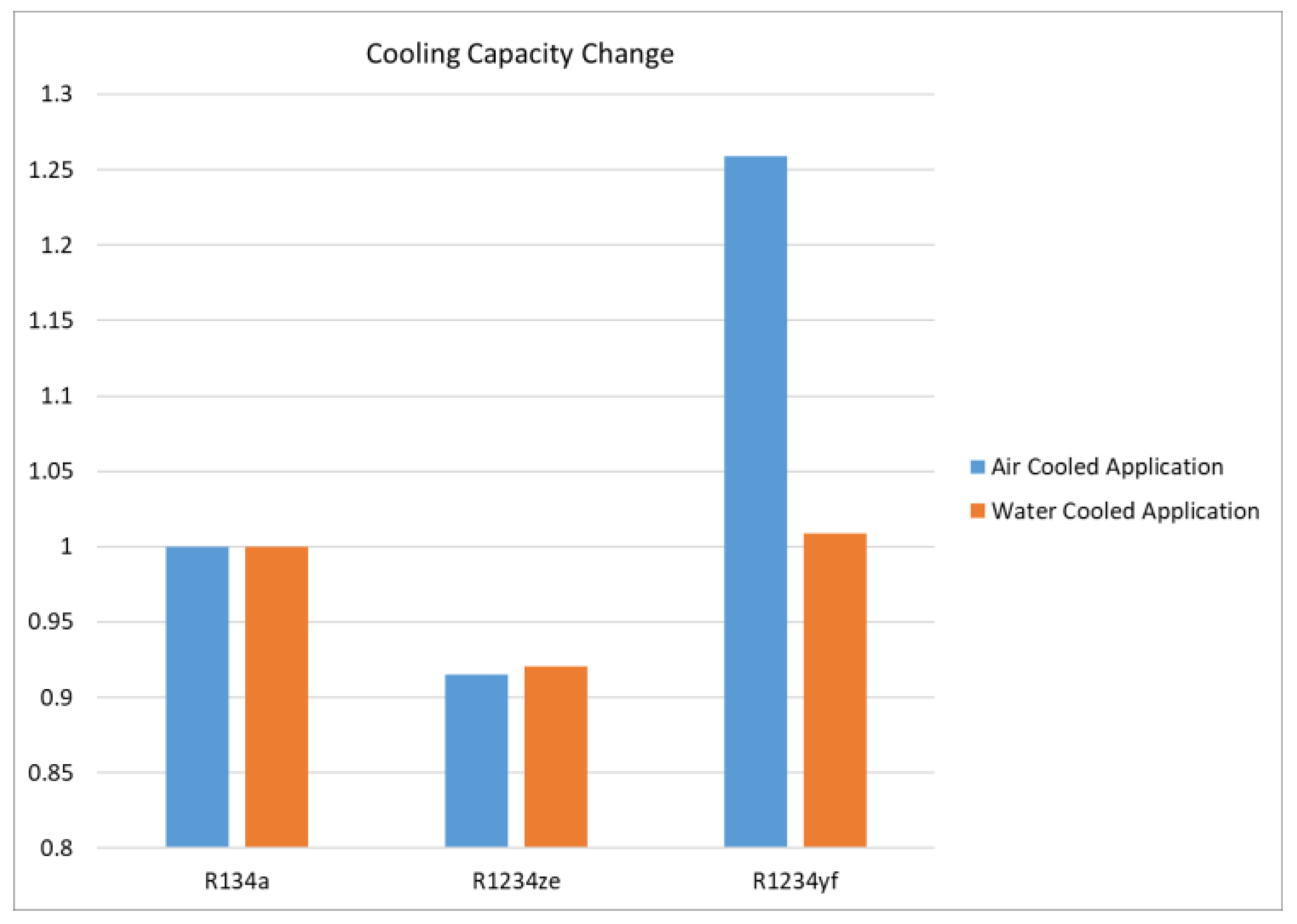

4. Results and Discussion

5. Conclusions

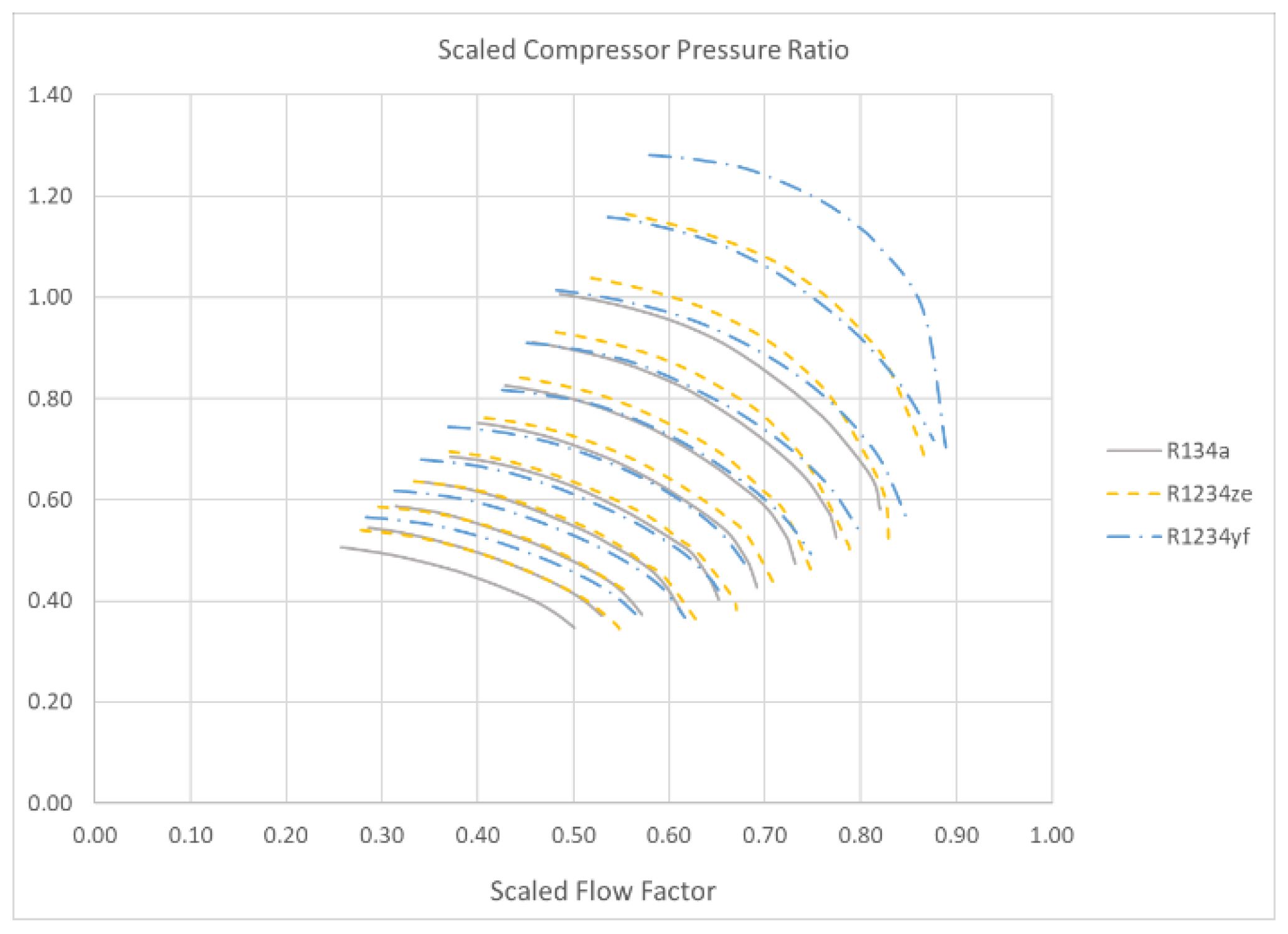

- Pressure ratio changes: R1234yf and R1234ze achieve higher pressure ratios than R134a at the same speed due to the lower inlet speed of sound, which leads to a higher corrected speed. Specifically, the maximum pressure ratio increased by 29% for R1234yf and 16% for R1234ze compared to R134a.

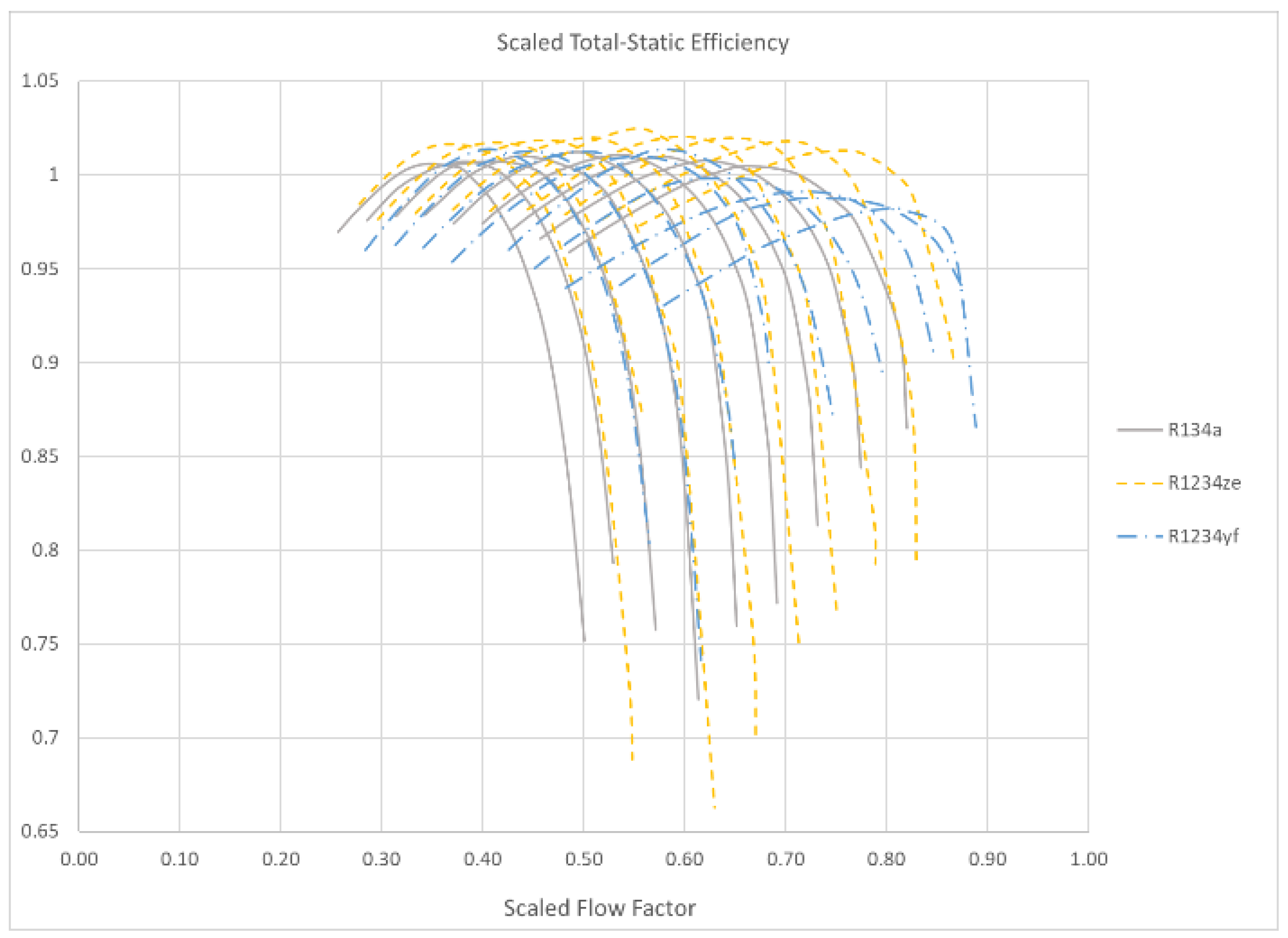

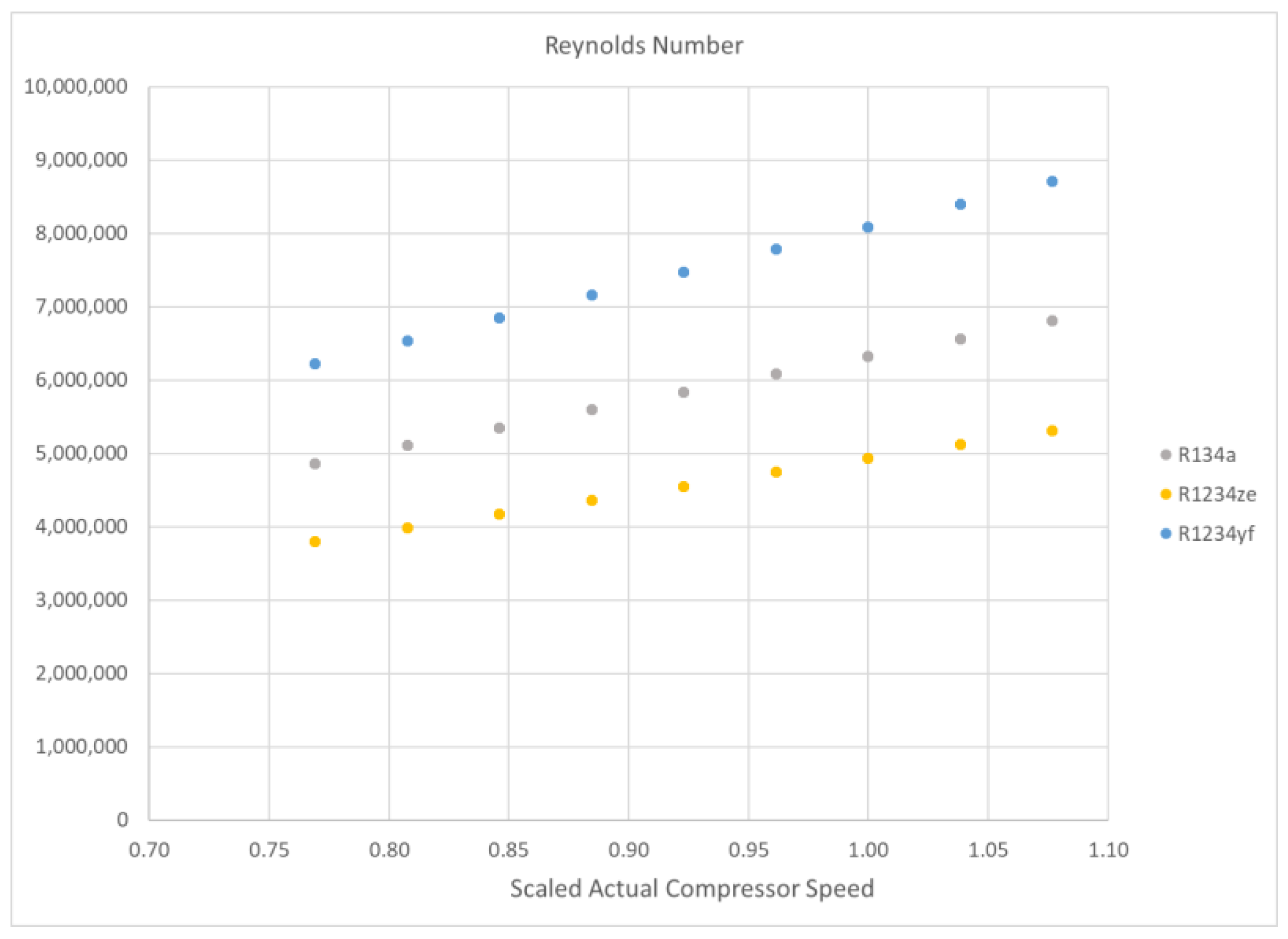

- Efficiency changes: R1234ze exhibits a maximum of 2% higher efficiency than R1234yf and R134a, caused by a combination of the factors including the Reynolds number, isentropic exponents, and the specific compressor geometry.

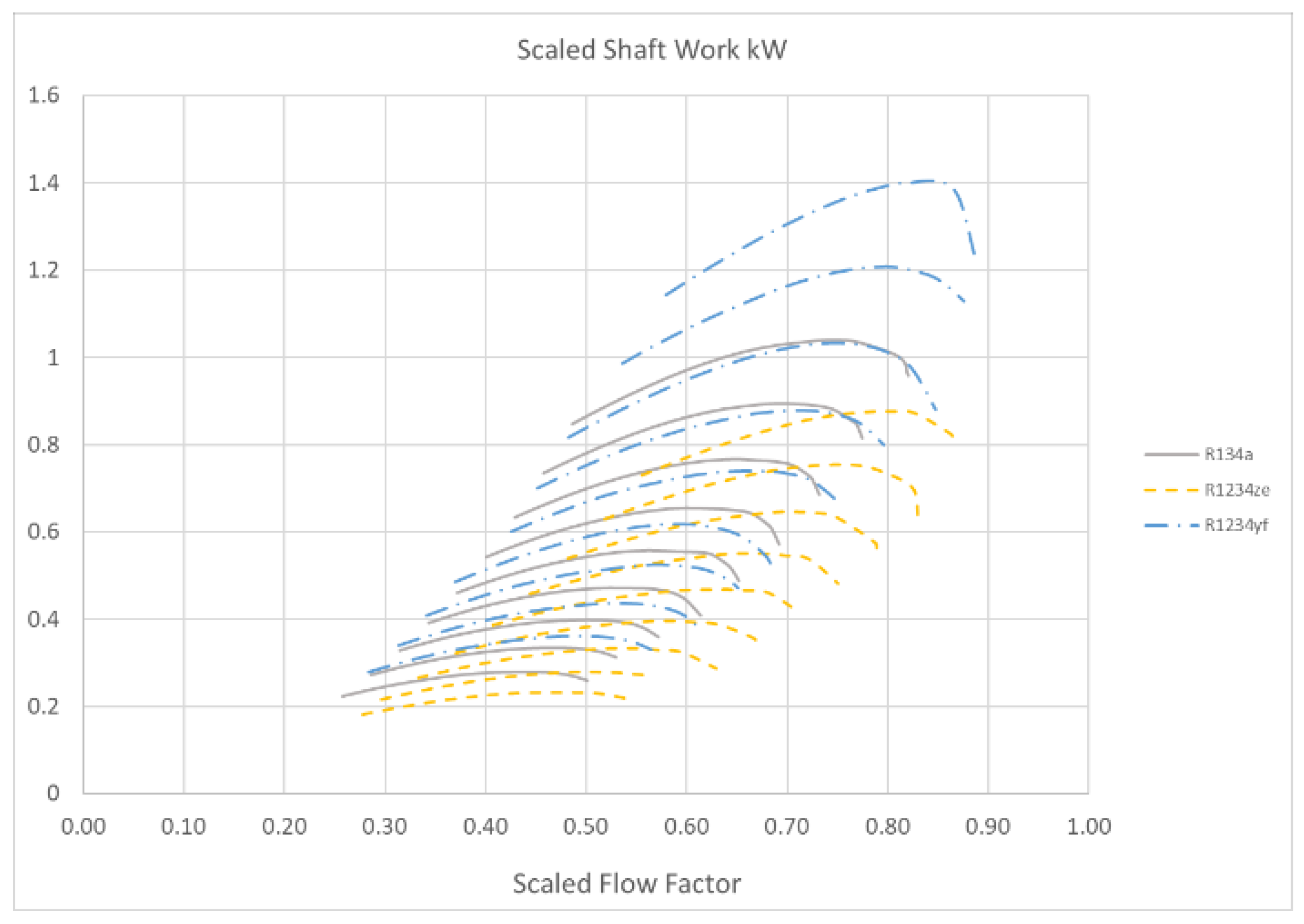

- Power consumption change: R1234yf requires significantly more power to operate at the same speed compared to R134a, which can be a limiting factor for its use as a drop-in replacement. This study observed a maximum power increase of 36% when switching from R134a to R1234yf, whereas R1234ze demonstrated a 16% reduction in maximum power consumption.

- Capacity changes: In water-cooled applications, R1234yf has a maximum capacity close to R134a, while R1234ze experiences an 8% reduction. In air-cooled applications, R1234yf shows a significant increase in maximum capacity due to the higher corrected speed, while R1234ze is limited by the maximum compressor speed and reaches a 9% lower maximum capacity comparing to R134a.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| η | efficiency (-) |

| π | pressure ratio (-) |

| µ | dynamic viscosity (Pa·s−1) |

| γ | isentropic exponent (J·kg−1·K−1) |

| a | speed of sound (m·s−1) |

| h | specific enthalpy (J·kg−1) |

| d | impeller diameter (m) |

| FF | flow factor (m−2) |

| IGV | inlet guide vane (-) |

| N | rotating speed (rad·s−1) |

| Nc | corrected rotating speed (rad·m−1) |

| ND | designed rotating speed (rad·s−1) |

| mass flow rate (kg·s−1) | |

| s | specific entropy (J·kg−1·K−1) |

| SST | saturated suction temperature (°C) |

| SDT | saturated discharge temperature (°C) |

| SSH | suction superheat temperature (°C) |

| VFD | variable frequency drive (-) |

| COP | coefficient of performance (-) |

| CFD | computational fluid dynamics (-) |

| Subscripts | |

| 1 | condition at inlet |

| 01 | total condition at inlet |

| 2 | condition at discharge |

| 02 | total condition at discharge |

| s | isentropic |

| P | evaluated at constant pressure |

| V | evaluated at constant volume |

References

- Copernicus. Record Warm November Consolidates 2023 as the Warmest Year. 2023. Available online: https://climate.copernicus.eu/record-warm-november-consolidates-2023-warmest-year (accessed on 10 January 2024).

- World Meteorological Organization. 2023—A Historic Climatic Year, as WMO Secretary-General Taalas Successfully Completes His Mandate. 2023. Available online: https://wmo.int/news/media-centre/2023-historic-climatic-year-wmo-secretary-general-taalas-successfully-completes-his-mandate#:~:text=According%20to%20WMO’s%20provisional%20State,the%20warmest%20November%20on%20record (accessed on 4 February 2024).

- Roberts, M.W. Finishing the job: The Montreal Protocol moves to phase down hydrofluorocarbons. Rev. Eur. Comp. Int. Environ. Law 2017, 26, 220–230. [Google Scholar] [CrossRef]

- Gopalnarayanan, S. Choosing the right refrigerant. Mech. Eng. 1998, 120, 92–95. [Google Scholar] [CrossRef]

- Fedele, L.; Lombardo, G.; Greselin, I.; Menegazzo, D.; Bobbo, S. Thermophysical Properties of Low GWP Refrigerants: An Update. Int. J. Thermophys. 2023, 44, 80. [Google Scholar] [CrossRef]

- Drofenik, J.; Urbancl, D.; Goričanec, D. Comparison of the New Refrigerant R1336mzz (E) with R1234ze (E) as an Alternative to R134a for Use in Heat Pumps. Processes 2022, 10, 218. [Google Scholar] [CrossRef]

- Giuffre, A.; Colonna, P.; Pini, M. The effect of size and working fluid on the multi-objective design of high-speed centrifugal compressors. Int. J. Refrig. 2022, 143, 43–56. [Google Scholar] [CrossRef]

- Van den Braembussche, R. Design and Analysis of Centrifugal Compressors; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Lüdtke, K.H. Process Centrifugal Compressors: Basics, Function, Operation, Design, Application; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Li, G. Evaluation of Multistage Centrifugal Chiller Performance Metrics with Different Low Global Warming Potential Refrigerants. J. Eng. Thermophys. 2022, 31, 340–374. [Google Scholar] [CrossRef]

- Hsu, C.N.; Wang, S.H. Evaluating the performance of water chillers equipped with constant-or variable-frequency centrifugal compressors. Processes 2021, 9, 1039. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, B.; Ma, H.; Zhang, L.; Duan, C.; Liu, B.; Zhang, Y.; Chen, S.; Yang, Z. Analysis of lower GWP and flammable alternative refrigerants. Int. J. Refrig. 2021, 126, 12–22. [Google Scholar] [CrossRef]

- Sethi, A.; Becerra, E.V.; Motta, S.Y. Low GWP R134a replacements for small refrigeration (plug-in) applications. Int. J. Refrig. 2016, 66, 64–72. [Google Scholar] [CrossRef]

- Colombo, L.P.M.; Lucchini, A.; Molinaroli, L. Experimental analysis of the use of R1234yf and R1234ze (E) as drop-in alternatives of R134a in a water-to-water heat pump. Int. J. Refrig. 2020, 115, 18–27. [Google Scholar] [CrossRef]

- Li, Z.; Liang, K.; Jiang, H. Experimental study of R1234yf as a drop-in replacement for R134a in an oil-free refrigeration system. Appl. Therm. Eng. 2019, 153, 646–654. [Google Scholar] [CrossRef]

- Yataganbaba, A.; Kilicarslan, A.; Kurtbaş, İ. Exergy analysis of R1234yf and R1234ze as R134a replacements in a two evaporator vapour compression refrigeration system. Int. J. Refrig. 2015, 60, 26–37. [Google Scholar] [CrossRef]

- Aized, T.; Rashid, M.; Riaz, F.; Hamza, A.; Nabi, H.Z.; Sultan, M.; Ashraf, W.M.; Krzywanski, J. Energy and exergy analysis of vapor compression refrigeration system with low-Gwp refrigerants. Energies 2022, 15, 7246. [Google Scholar] [CrossRef]

- Aized, T.; Hamza, A. Thermodynamic analysis of various refrigerants for automotive air conditioning system. Arab. J. Sci. Eng. 2019, 44, 1697–1707. [Google Scholar] [CrossRef]

- Li, G. Performance evaluation of low global warming potential working fluids as R134a alternatives for two-stage centrifugal chiller applications. Korean J. Chem. Eng. 2021, 38, 1438–1451. [Google Scholar] [CrossRef]

- Park, J.H.; Shin, Y.; Chung, J.T. Performance prediction of centrifugal compressor for drop-in testing using low global warming potential alternative refrigerants and performance test codes. Energies 2017, 10, 2043. [Google Scholar] [CrossRef]

- Yi, K.; Zhao, Y.; Liu, G.; Yang, Q.; Yu, G.; Li, L. Performance evaluation of centrifugal refrigeration compressor using R1234yf and R1234ze (E) as drop-in replacements for R134a refrigerant. Energies 2022, 15, 2552. [Google Scholar] [CrossRef]

- NIST. Reference Fluid Thermodynamic and Transport Properties Database (REFPROP). 2019. Available online: https://www.nist.gov/image/refroppng (accessed on 29 May 2024).

- Casey, M. The effects of Reynolds number on the efficiency of centrifugal compressor stages. J. Eng. Gas Turbines Power 1985, 107, 541–548. [Google Scholar] [CrossRef]

- Valdés, M.; Sebastián, A.; Abbas, R. Reynolds-number-dependent efficiency characterization of a micro-scale centrifugal compressor using non-conventional working fluids. Energy Convers. Manag. 2018, 177, 224–232. [Google Scholar] [CrossRef]

- Urcia, J.; Yan, J.; Fagundes, T. Economizer Location Optimization for a Centrifugal Compressor with Refrigerant as Working Fluid. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2022. [Google Scholar]

- Ronald, H. Centrifugal Compressors: A Strategy for Aerodynamic Design and Analysis; American Society of Mechanical Engineers Press: New York, NY, USA, 2000. [Google Scholar]

- Casey, M.; Robinson, C. A unified correction method for Reynolds number, size, and roughness effects on the performance of compressors. Proc. Inst. Mech. Eng. Part A J. Power Energy 2011, 225, 864–876. [Google Scholar] [CrossRef]

- Casey, M.; Robinson, C. A method to estimate the performance map of a centrifugal compressor stage. J. Turbomach. 2013, 135, 021034. [Google Scholar] [CrossRef]

- TurboTides. Available online: https://spinpous.com/ (accessed on 29 May 2024).

- Strub, R.A.; Bonciani, L.; Borer, C.J.; Casey, M.V.; Cole, S.L.; Cook, B.B.; Kotzur, J.; Simon, H.; Strite, M.A. Influence of the Reynolds number on the performance of centrifugal compressors. J. Turbomach. 1987, 109, 541–544. [Google Scholar] [CrossRef]

- Tiainen, J.; Jaatinen-Värri, A.; Grönman, A.; Backman, J. Numerical study of the Reynolds number effect on the centrifugal compressor performance and losses. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar]

- Wiesner, F. A new appraisal of Reynolds number effects on centrifugal compressor performance. J. Eng. Power. 1979, 101, 384–392. [Google Scholar] [CrossRef]

- Hoffmann, H.; Stuhldreier, L.; van Rennings, R.; Jeschke, P. Influence of different gases on the Design Point of an Industrial Axial Compressor and deduced aerodynamical Rematching Methodology. J. Glob. Power Propuls. Soc. 2020, 4, 238–252. [Google Scholar] [CrossRef]

- Cravero, C.; Marsano, D.; Sishtla, V.; Halbe, C.; Cousins, W.T. Numerical investigations of near surge operating conditions in a two-stage radial compressor with refrigerant gas. J. Eng. Gas Turbines Power 2024, 146, 021010. [Google Scholar] [CrossRef]

- Zhu, W.; Ren, X.D.; Li, X.S.; Gu, C.W. Analysis and improvement of a two-stage centrifugal compressor used in an MW-level gas turbine. Appl. Sci. 2018, 8, 1347. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yan, J. Study of Performance Changes in Centrifugal Compressors Working in Different Refrigerants. Energies 2024, 17, 2784. https://doi.org/10.3390/en17112784

Wang Y, Yan J. Study of Performance Changes in Centrifugal Compressors Working in Different Refrigerants. Energies. 2024; 17(11):2784. https://doi.org/10.3390/en17112784

Chicago/Turabian StyleWang, Yintao, and Jin Yan. 2024. "Study of Performance Changes in Centrifugal Compressors Working in Different Refrigerants" Energies 17, no. 11: 2784. https://doi.org/10.3390/en17112784

APA StyleWang, Y., & Yan, J. (2024). Study of Performance Changes in Centrifugal Compressors Working in Different Refrigerants. Energies, 17(11), 2784. https://doi.org/10.3390/en17112784