Enhancing Biogas Production Amidst Microplastic Contamination in Wastewater Treatment Systems: A Strategic Review

Abstract

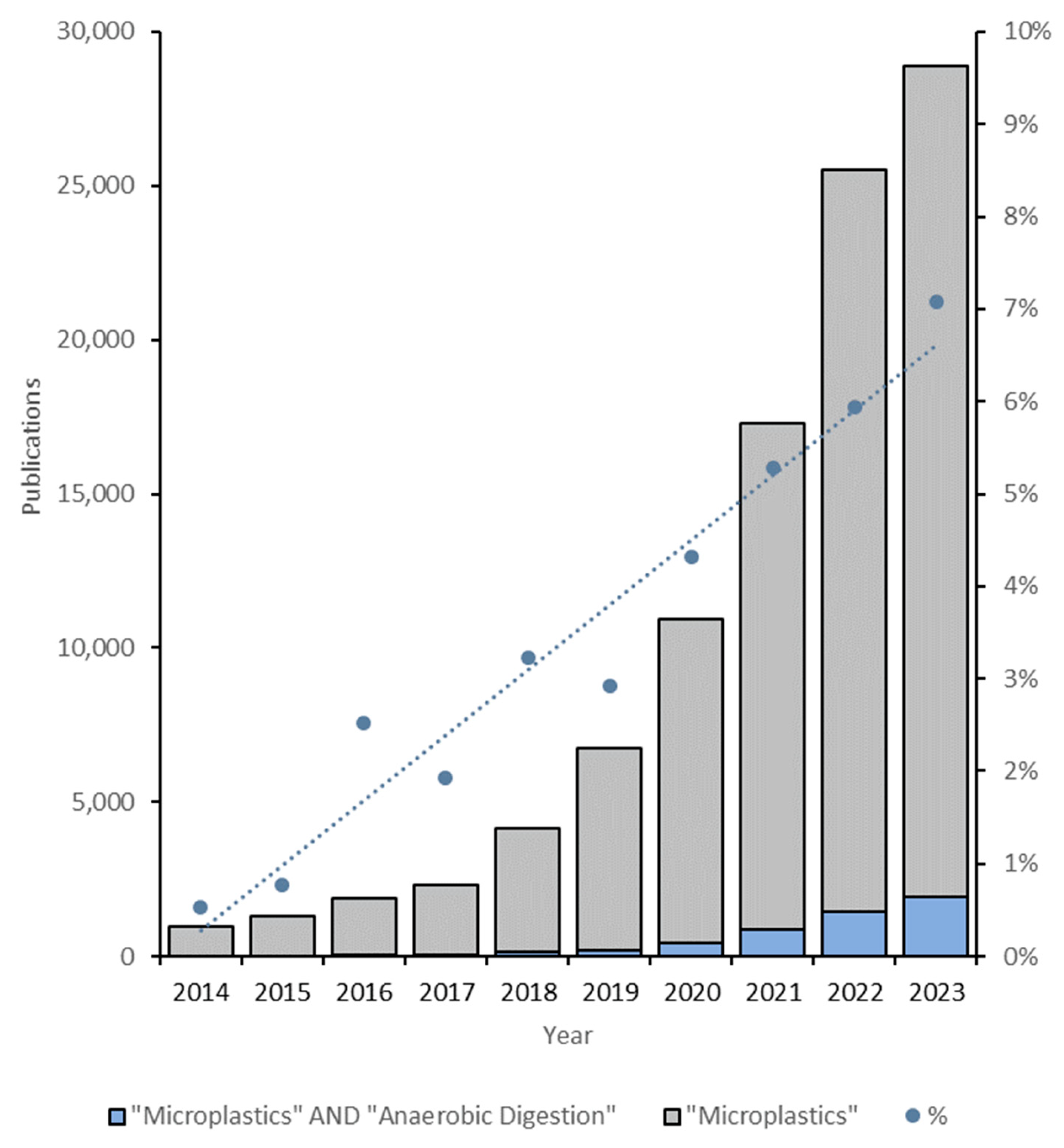

1. Introduction

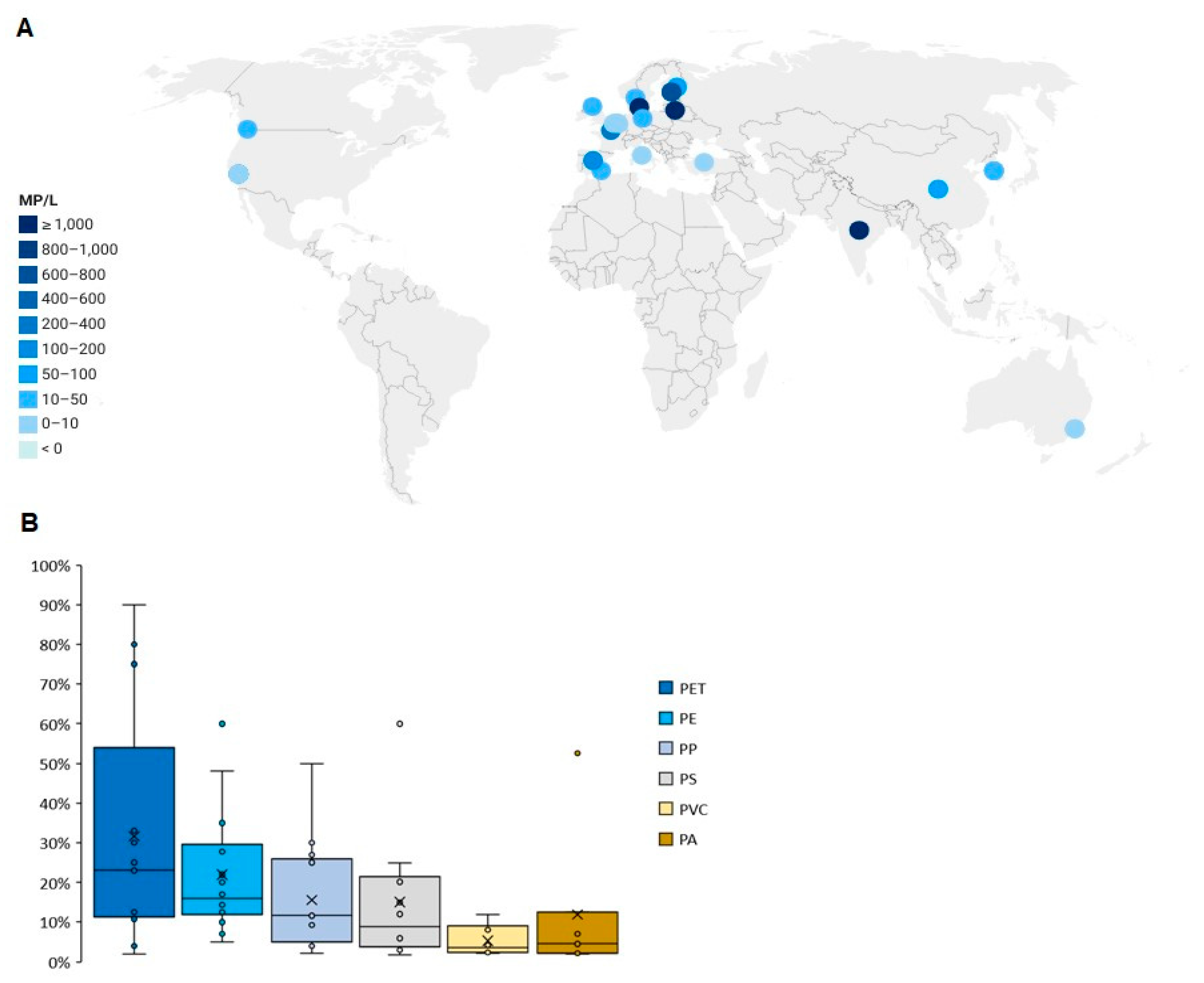

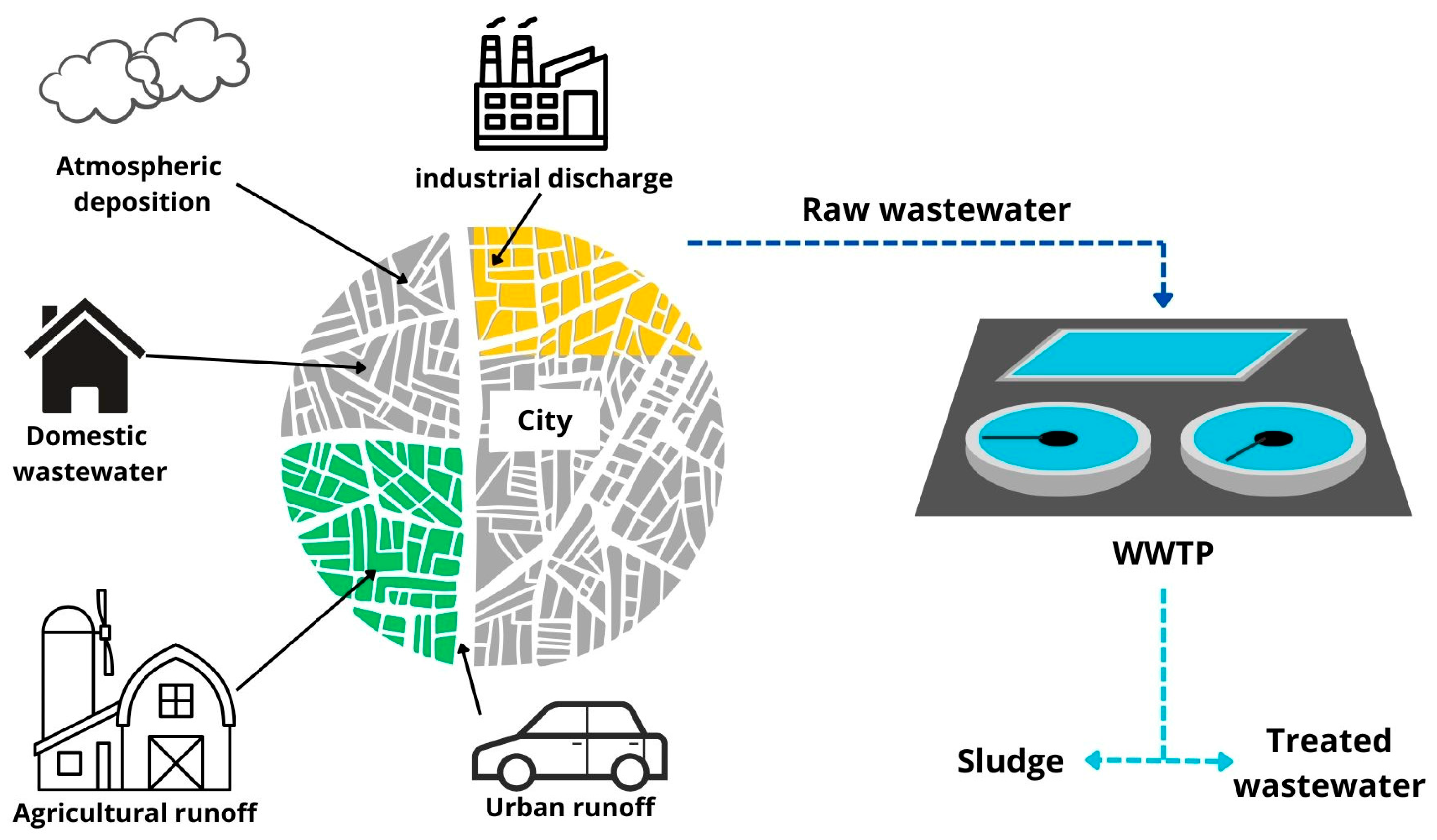

2. MPs in Wastewater Sludge: Sources, Pathways, and Characteristics

3. Impact of MPs on Wastewater Treatment

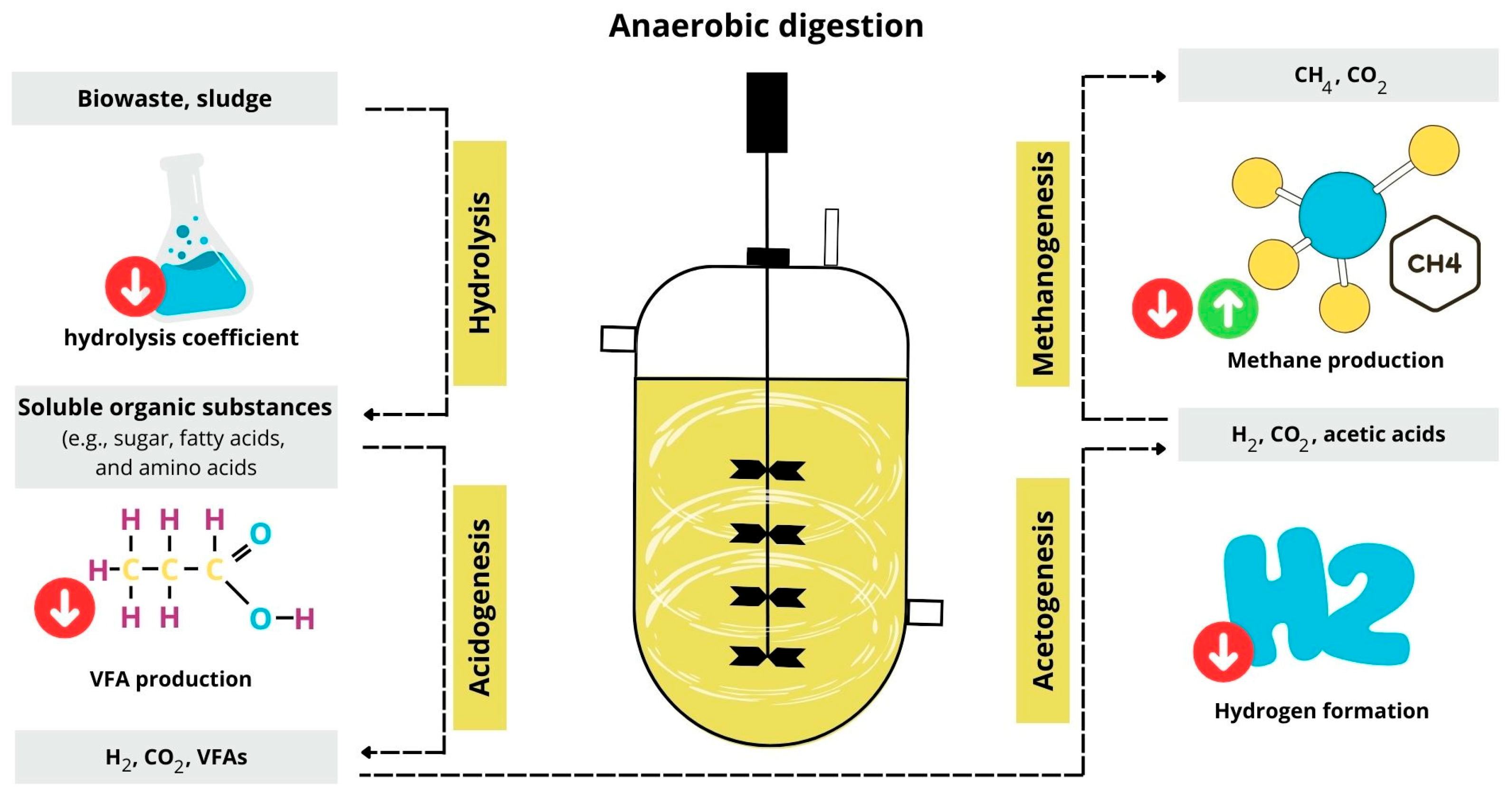

4. Impact of MPs on Biogas Production

4.1. Effect on Hydrolysis

4.2. Effect on Acidogenesis

4.3. Effect on Acetogenesis

4.4. Effect on Methanogenesis

4.5. Effect on Digester Microbiome

5. Mitigation Strategies: Enhancing Biogas Production Amid MP Contamination

5.1. Pretreatment

5.2. Advancements in Microbial Engineering Techniques

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Regulation (EU). Proposal for a DIRECTIVE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL concerning urban wastewater treatment (recast). Off. J. Eur. Union 2020, 345, 1–68.

- Mignogna, D.; Ceci, P.; Cafaro, C.; Corazzi, G.; Avino, P. Production of Biogas and Biomethane as Renewable Energy Sources: A Review. Appl. Sci. 2023, 13, 10219. [Google Scholar] [CrossRef]

- Goswami, R.; Chattopadhyay, P.; Shome, A.; Banerjee, S.N.; Chakraborty, A.K.; Mathew, A.K.; Chaudhury, S. An Overview of Physico-Chemical Mechanisms of Biogas Production by Microbial Communities: A Step towards Sustainable Waste Management. 3 Biotech 2016, 6, 72. [Google Scholar] [CrossRef] [PubMed]

- Manu, M.K.; Luo, L.; Kumar, R.; Johnravindar, D.; Li, D.; Varjani, S.; Zhao, J.; Wong, J. A Review on Mechanistic Understanding of Microplastic Pollution on the Performance of Anaerobic Digestion. Environ. Pollut. 2023, 325, 121426. [Google Scholar] [CrossRef] [PubMed]

- Sadia, M.; Mahmood, A.; Ibrahim, M.; Irshad, M.K.; Quddusi, A.H.A.; Bokhari, A.; Mubashir, M.; Chuah, L.F.; Show, P.L. Microplastics Pollution from Wastewater Treatment Plants: A Critical Review on Challenges, Detection, Sustainable Removal Techniques and Circular Economy. Environ. Technol. Innov. 2022, 28, 102946. [Google Scholar] [CrossRef]

- Wei, W.; Huang, Q.-S.; Sun, J.; Wang, J.-Y.; Wu, S.-L.; Ni, B.-J. Polyvinyl Chloride Microplastics Affect Methane Production from the Anaerobic Digestion of Waste Activated Sludge through Leaching Toxic Bisphenol-A. Environ. Sci. Technol. 2019, 53, 2509–2517. [Google Scholar] [CrossRef]

- Li, L.; Geng, S.; Li, Z.; Song, K. Effect of Microplastic on Anaerobic Digestion of Wasted Activated Sludge. Chemosphere 2020, 247, 125874. [Google Scholar] [CrossRef] [PubMed]

- Kelly, J.J.; London, M.G.; McCormick, A.R.; Rojas, M.; Scott, J.W.; Hoellein, T.J. Wastewater Treatment Alters microbial Colonization of Microplastics. PLoS ONE 2021, 16, e0244443. [Google Scholar] [CrossRef] [PubMed]

- Jachimowicz, P.; Jo, Y.J.; Cydzik-Kwiatkowska, A. Polyethylene Microplastics Increase Extracellular Polymeric Substances Production in Aerobic Granular Sludge. Sci. Total Environ. 2022, 851, 158208. [Google Scholar] [CrossRef] [PubMed]

- Fu, W.; Min, J.; Jiang, W.; Li, Y.; Zhang, W. Separation, Characterization and Identification of Microplastics and Nanoplastics in the Environment. Sci. Total Environ. 2020, 721, 137561. [Google Scholar] [CrossRef] [PubMed]

- He, Z.-W.; Yang, W.-J.; Ren, Y.-X.; Jin, H.-Y.; Tang, C.-C.; Liu, W.-Z.; Yang, C.-X.; Zhou, A.-J.; Wang, A.-J. Occurrence, Effect, and Fate of Residual Microplastics in Anaerobic Digestion of Waste Activated Sludge: A State-of-the-Art Review. Bioresour. Technol. 2021, 331, 125035. [Google Scholar] [CrossRef] [PubMed]

- Mohammad Mirsoleimani Azizi, S.; Hai, F.I.; Lu, W.; Al-Mamun, A.; Ranjan Dhar, B. A Review of Mechanisms Underlying the Impacts of (Nano)Microplastics on Anaerobic Digestion. Bioresour. Technol. 2021, 329, 124894. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Chen, J.; Li, J. The Removal of Microplastics in the Wastewater Treatment Process and Their Potential Impact on Anaerobic Digestion Due to Pollutants Association. Chemosphere 2020, 251, 126360. [Google Scholar] [CrossRef] [PubMed]

- Nasir, M.S.; Tahir, I.; Ali, A.; Ayub, I.; Nasir, A.; Abbas, N.; Sajjad, U.; Hamid, K. Innovative Technologies for Removal of Micro Plastic: A Review of Recent Advances. Heliyon 2024, 10, e25883. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.-J.; Park, H.-J.; Kwon, O.-K.; Lee, W.-S.; Jeong, D.-H.; Ju, B.-K.; Kwon, J.-H. Occurrence of Microplastics in Municipal Sewage Treatment Plants: A Review. Environ. Health Toxicol. 2018, 33, e2018013. [Google Scholar] [CrossRef]

- Wei, F.; Xu, C.; Chen, C.; Wang, Y.; Lan, Y.; Long, L.; Xu, M.; Wu, J.; Shen, F.; Zhang, Y.; et al. Distribution of Microplastics in the Sludge of Wastewater Treatment Plants in Chengdu, China. Chemosphere 2022, 287, 132357. [Google Scholar] [CrossRef]

- Ren, X.; Sun, Y.; Wang, Z.; Barceló, D.; Wang, Q.; Zhang, Z.; Zhang, Y. Abundance and Characteristics of Microplastic in Sewage Sludge: A Case Study of Yangling, Shaanxi Province, China. Case Stud. Chem. Environ. Eng. 2020, 2, 100050. [Google Scholar] [CrossRef]

- Dong, S.; Gao, P.; Li, B.; Feng, L.; Liu, Y.; Du, Z.; Zhang, L. Occurrence and Migration of Microplastics and Plasticizers in Different Wastewater and Sludge Treatment Units in Municipal Wastewater Treatment Plant. Front. Environ. Sci. Eng. 2022, 16, 142. [Google Scholar] [CrossRef]

- Di Bella, G.; Corsino, S.F.; De Marines, F.; Lopresti, F.; La Carrubba, V.; Torregrossa, M.; Viviani, G. Occurrence of Microplastics in Waste Sludge of Wastewater Treatment Plants: Comparison between Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) Technologies. Membranes 2022, 12, 371. [Google Scholar] [CrossRef]

- Sheriff, I.; Yusoff, M.S.; Halim, H.B. Microplastics in Wastewater Treatment Plants: A Review of the Occurrence, Removal, Impact on Ecosystem, and Abatement Measures. J. Water Process Eng. 2023, 54, 104039. [Google Scholar] [CrossRef]

- Can, T.; Üstün, G.E.; Kaya, Y. Characteristics and Seasonal Variation of Microplastics in the Wastewater Treatment Plant: The Case of Bursa Deep Sea Discharge. Mar. Pollut. Bull. 2023, 194, 115281. [Google Scholar] [CrossRef]

- Sun, X.; Jia, Q.; Ye, J.; Zhu, Y.; Song, Z.; Guo, Y.; Chen, H. Real-Time Variabilities in Microplastic Abundance and Characteristics of Urban Surface Runoff and Sewer Overflow in Wet Weather as Impacted by Land Use and Storm Factors. Sci. Total Environ. 2023, 859, 160148. [Google Scholar] [CrossRef] [PubMed]

- Ridall, A.; Farrar, E.; Dansby, M.; Ingels, J. Influence of Wastewater Treatment Plants and Water Input Sources on Size, Shape, and Polymer Distributions of Microplastics in St. Andrew Bay, Florida, USA. Mar. Pollut. Bull. 2023, 187, 114552. [Google Scholar] [CrossRef] [PubMed]

- Ziajahromi, S.; Neale, P.A.; Rintoul, L.; Leusch, F.D.L. Wastewater Treatment Plants as a Pathway for Microplastics: Development of a New Approach to Sample Wastewater-Based Microplastics. Water Res. 2017, 112, 93–99. [Google Scholar] [CrossRef] [PubMed]

- Vercauteren, M.; Semmouri, I.; Van Acker, E.; Pequeur, E.; Janssen, C.R.; Asselman, J. Toward a Better Understanding of the Contribution of Wastewater Treatment Plants to Microplastic Pollution in Receiving Waterways. Environ. Toxicol. Chem. 2023, 42, 642–654. [Google Scholar] [CrossRef] [PubMed]

- Talvitie, J.; Mikola, A.; Setälä, O.; Heinonen, M.; Koistinen, A. How Well Is Microlitter Purified from Wastewater?–A Detailed Study on the Stepwise Removal of Microlitter in a Tertiary Level Wastewater Treatment Plant. Water Res. 2017, 109, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Talvitie, J.; Mikola, A.; Koistinen, A.; Setälä, O. Solutions to Microplastic Pollution—Removal of Microplastics from Wastewater Effluent with Advanced Wastewater Treatment Technologies. Water Res. 2017, 123, 401–407. [Google Scholar] [CrossRef] [PubMed]

- Simon, M.; van Alst, N.; Vollertsen, J. Quantification of Microplastic Mass and Removal Rates at Wastewater Treatment Plants Applying Focal Plane Array (FPA)-Based Fourier Transform Infrared (FT-IR) Imaging. Water Res. 2018, 142, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Pleskytė, S.; Uogintė, I.; Burbulytė, A.; Byčenkienė, S. Characteristics and Removal Efficiency of Microplastics at Secondary Wastewater Treatment Plant in Lithuania. Water Environ. Res. 2023, 95, e10958. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.; Kamdi, P.; Chakraborty, S.; Das, S.; Bafana, A.; Krishnamurthi, K.; Sivanesan, S. Characterization and Removal of Microplastics in a Sewage Treatment Plant from Urban Nagpur, India. Environ. Monit. Assess. 2022, 195, 47. [Google Scholar] [CrossRef] [PubMed]

- Murphy, F.; Ewins, C.; Carbonnier, F.; Quinn, B. Wastewater Treatment Works (WwTW) as a Source of Microplastics in the Aquatic Environment. Environ. Sci. Technol. 2016, 50, 5800–5808. [Google Scholar] [CrossRef] [PubMed]

- Magnusson, K.; Norén, F. Screening of Microplastic Particles in and Down-Stream a Wastewater Treatment Plant; Report C55; Swedish Environmental Research Institute: Stockholm, Sweden, 2014. [Google Scholar]

- Magni, S.; Binelli, A.; Pittura, L.; Avio, C.G.; Della Torre, C.; Parenti, C.C.; Gorbi, S.; Regoli, F. The Fate of Microplastics in an Italian Wastewater Treatment Plant. Sci. Total Environ. 2019, 652, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Zhang, J.; Liu, H.; Guo, X.; Zhang, X.; Yao, X.; Cao, Z.; Zhang, T. A Review of the Removal of Microplastics in Global Wastewater Treatment Plants: Characteristics and Mechanisms. Environ. Int. 2021, 146, 106277. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Kim, Y. Treatment Characteristics of Microplastics at Biological Sewage Treatment Facilities in Korea. Mar. Pollut. Bull. 2018, 137, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Gies, E.A.; LeNoble, J.L.; Noël, M.; Etemadifar, A.; Bishay, F.; Hall, E.R.; Ross, P.S. Retention of Microplastics in a Major Secondary Wastewater Treatment Plant in Vancouver, Canada. Mar. Pollut. Bull. 2018, 133, 553–561. [Google Scholar] [CrossRef] [PubMed]

- Edo, C.; González-Pleiter, M.; Leganés, F.; Fernández-Piñas, F.; Rosal, R. Fate of Microplastics in Wastewater Treatment Plants and Their Environmental Dispersion with Effluent and Sludge. Environ. Pollut. 2020, 259, 113837. [Google Scholar] [CrossRef] [PubMed]

- Dris, R.; Gasperi, J.; Rocher, V.; Saad, M.; Renault, N.; Tassin, B. Microplastic Contamination in an Urban Area: A Case Study in Greater Paris. Environ. Chem. 2015, 12, 592–599. [Google Scholar] [CrossRef]

- Carr, S.A.; Liu, J.; Tesoro, A.G. Transport and Fate of Microplastic Particles in Wastewater Treatment Plants. Water Research 2016, 91, 174–182. [Google Scholar] [CrossRef] [PubMed]

- Bayo, J.; Olmos, S.; López-Castellanos, J. Microplastics in an Urban Wastewater Treatment Plant: The Influence of Physicochemical Parameters and Environmental Factors. Chemosphere 2020, 238, 124593. [Google Scholar] [CrossRef]

- Akarsu, C.; Kumbur, H.; Gökdağ, K.; Kıdeyş, A.E.; Sanchez-Vidal, A. Microplastics Composition and Load from Three Wastewater Treatment Plants Discharging into Mersin Bay, North Eastern Mediterranean Sea. Mar. Pollut. Bull. 2020, 150, 110776. [Google Scholar] [CrossRef] [PubMed]

- Bashir, S.M.; Kimiko, S.; Mak, C.-W.; Fang, J.K.-H.; Gonçalves, D. Personal Care and Cosmetic Products as a Potential Source of Environmental Contamination by Microplastics in a Densely Populated Asian City. Front. Mar. Sci. 2021, 8, 683482. [Google Scholar] [CrossRef]

- Chengappa, S.K.; Rao, A.; Aparna, K.S.; Jodalli, P.S.; Shenoy Kudpi, R. Microplastic Content of Over-the-Counter Toothpastes—A Systematic Review. F1000Research 2023, 12, 390. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Kim, J.; Kwon, M. The Effect of the Physical and Chemical Properties of Synthetic Fabrics on the Release of Microplastics during Washing and Drying. Polymers 2022, 14, 3384. [Google Scholar] [CrossRef] [PubMed]

- Hasan Anik, A.; Hossain, S.; Alam, M.; Binte Sultan, M.; Hasnine, M.D.T.; Rahman, M.d.M. Microplastics Pollution: A Comprehensive Review on the Sources, Fates, Effects, and Potential Remediation. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100530. [Google Scholar] [CrossRef]

- Jiang, C.; Ni, B.-J.; Zheng, X.; Lu, B.; Chen, Z.; Gao, Y.; Zhang, Y.; Zhang, S.; Luo, G. The Changes of Microplastics’ Behavior in Adsorption and Anaerobic Digestion of Waste Activated Sludge Induced by Hydrothermal Pretreatment. Water Res. 2022, 221, 118744. [Google Scholar] [CrossRef]

- Jeong, Y.; Lee, S.; Woo, S.-H. Chemical Leaching from Tire Wear Particles with Various Treadwear Ratings. Int. J. Environ. Res. Public Health 2022, 19, 6006. [Google Scholar] [CrossRef] [PubMed]

- Trudsø, L.L.; Nielsen, M.B.; Hansen, S.F.; Syberg, K.; Kampmann, K.; Khan, F.R.; Palmqvist, A. The Need for Environmental Regulation of Tires: Challenges and Recommendations. Environ. Pollut. 2022, 311, 119974. [Google Scholar] [CrossRef] [PubMed]

- Martín, J.; Santos, J.L.; Aparicio, I.; Alonso, E. Microplastics and Associated Emerging Contaminants in the Environment: Analysis, Sorption Mechanisms and Effects of Co-Exposure. Trends Environ. Anal. Chem. 2022, 35, 130649. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Han, W.; Jiao, J.; Ren, W.; Jia, G.; Huang, C.; Yang, Q. Migration and Transformation Modes of Microplastics in Reclaimed Wastewater Treatment Plant and Sludge Treatment Center with Thermal Hydrolysis and Anaerobic Digestion. Bioresour. Technol. 2024, 400, 130649. [Google Scholar] [CrossRef] [PubMed]

- Bretas Alvim, C.; Bes-Piá, M.A.; Mendoza-Roca, J.A. Separation and Identification of Microplastics from Primary and Secondary Effluents and Activated Sludge from Wastewater Treatment Plants. Chem. Eng. J. 2020, 402, 126293. [Google Scholar] [CrossRef]

- Huang, Z.; Hu, B.; Wang, H. Analytical Methods for Microplastics in the Environment: A Review. Environ. Chem. Lett. 2023, 21, 383–401. [Google Scholar] [CrossRef] [PubMed]

- Ezugworie, F.N.; Aliyu, G.O.; Onwosi, C.O. Microplastics and Anaerobic Digestion. In Microplastics Pollution in Aquatic Media: Occurrence, Detection, and Removal; Sillanpää, M., Khadir, A., Muthu, S.S., Eds.; Springer: Singapore, 2022; pp. 291–312. ISBN 978-981-16-8440-1. [Google Scholar]

- Tanoiri, H.; Nakano, H.; Arakawa, H.; Hattori, R.S.; Yokota, M. Inclusion of Shape Parameters Increases the Accuracy of 3D Models for Microplastics Mass Quantification. Mar. Pollut. Bull. 2021, 171, 112749. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Li, K.; Cui, S.; Kang, Y.; An, L.; Lei, K. Removal of Microplastics in Municipal Sewage from China’s Largest Water Reclamation Plant. Water Res. 2019, 155, 175–181. [Google Scholar] [CrossRef] [PubMed]

- Jani, V.; Wu, S.; Venkiteshwaran, K. Advancements and Regulatory Situation in Microplastics Removal from Wastewater and Drinking Water: A Comprehensive Review. Microplastics 2024, 3, 98–123. [Google Scholar] [CrossRef]

- Jachimowicz, P.; Cydzik-Kwiatkowska, A. Coagulation and Flocculation before Primary Clarification as Efficient Solutions for Low-Density Microplastic Removal from Wastewater. Int. J. Environ. Res. Public Health 2022, 19, 13013. [Google Scholar] [CrossRef]

- Sacco, N.A.; Zoppas, F.M.; Devard, A.; González Muñoz, M.D.P.; García, G.; Marchesini, F.A. Recent Advances in Microplastics Removal from Water with Special Attention Given to Photocatalytic Degradation: Review of Scientific Research. Microplastics 2023, 2, 278–303. [Google Scholar] [CrossRef]

- Lofty, J.; Muhawenimana, V.; Wilson, C.A.M.E.; Ouro, P. Microplastics Removal from a Primary Settler Tank in a Wastewater Treatment Plant and Estimations of Contamination onto European Agricultural Land via Sewage Sludge Recycling. Environ. Pollut. 2022, 304, 119198. [Google Scholar] [CrossRef] [PubMed]

- Moyal, J.; Dave, P.H.; Wu, M.; Karimpour, S.; Brar, S.K.; Zhong, H.; Kwong, R.W.M. Impacts of Biofilm Formation on the Physicochemical Properties and Toxicity of Microplastics: A Concise Review. Rev. Environ. Contam. 2023, 261, 8. [Google Scholar] [CrossRef]

- Cai, Z.; Li, M.; Zhu, Z.; Wang, X.; Huang, Y.; Li, T.; Gong, H.; Yan, M. Biological Degradation of Plastics and Microplastics: A Recent Perspective on Associated Mechanisms and Influencing Factors. Microorganisms 2023, 11, 1661. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhou, X.; Ding, W.; Zhang, Z.; Nghiem, L.D.; Sun, J.; Wang, Q. Do Microplastics Affect Biological Wastewater Treatment Performance? Implications from Bacterial Activity Experiments. ACS Sustain. Chem. Eng. 2019, 7, 20097–20101. [Google Scholar] [CrossRef]

- Adeel, M.; Granata, V.; Carapella, G.; Rizzo, L. Effect of Microplastics on Urban Wastewater Disinfection and Impact on Effluent Reuse: Sunlight/H2O2 vs Solar Photo-Fenton at Neutral pH. J. Hazard. Mater. 2024, 465, 133102. [Google Scholar] [CrossRef] [PubMed]

- Senés-Guerrero, C.; Colón-Contreras, F.A.; Reynoso-Lobo, J.F.; Tinoco-Pérez, B.; Siller-Cepeda, J.H.; Pacheco, A. Biogas-Producing Microbial Composition of an Anaerobic Digester and Associated Bovine Residues. Microbiologyopen 2019, 8, e00854. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.M.; Wright, M.M. Anaerobic Digestion Fundamentals, Challenges, and Technological Advances. Phys. Sci. Rev. 2023, 8, 2819–2837. [Google Scholar] [CrossRef]

- Lin, C.Y.; Chai, W.S.; Lay, C.H.; Chen, C.C.; Lee, C.Y.; Show, P.L. Optimization of Hydrolysis-Acidogenesis Phase of Swine Manure for Biogas Production Using Two-Stage Anaerobic Fermentation. Processes 2021, 9, 1324. [Google Scholar] [CrossRef]

- Akbay, H.E.G.; Akarsu, C.; Isik, Z.; Belibagli, P.; Dizge, N. Investigation of Degradation Potential of Polyethylene Microplastics in Anaerobic Digestion Process Using Cosmetics Industry Wastewater. Biochem. Eng. J. 2022, 187, 108619. [Google Scholar] [CrossRef]

- Al-Sulaimi, I.N.; Nayak, J.K.; Alhimali, H.; Sana, A.; Al-Mamun, A. Effect of Volatile Fatty Acids Accumulation on Biogas Production by Sludge-Feeding Thermophilic Anaerobic Digester and Predicting Process Parameters. Fermentation 2022, 8, 184. [Google Scholar] [CrossRef]

- Fang, W.; Zhang, X.; Zhang, P.; Wan, J.; Guo, H.; Ghasimi, D.S.M.; Morera, X.C.; Zhang, T. Overview of Key Operation Factors and Strategies for Improving Fermentative Volatile Fatty Acid Production and Product Regulation from Sewage Sludge. J. Environ. Sci. 2020, 87, 93–111. [Google Scholar] [CrossRef]

- Zheng, X.; Zhu, L.; Xu, Z.; Yang, M.; Shao, X.; Yang, S.; Zhang, H.; Wu, F.; Han, Z. Effect of Polystyrene Microplastics on the Volatile Fatty Acids Production from Waste Activated Sludge Fermentation. Sci. Total Environ. 2021, 799, 149394. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhao, M.; Li, C.; Miao, H.; Huang, Z.; Dai, X.; Ruan, W. Evaluation the Impact of Polystyrene Micro and Nanoplastics on the Methane Generation by Anaerobic Digestion. Ecotoxicol. Environ. Saf. 2020, 205, 111095. [Google Scholar] [CrossRef] [PubMed]

- Nagarajan, S.; Jones, R.J.; Oram, L.; Massanet-Nicolau, J.; Guwy, A. Intensification of Acidogenic Fermentation for the Production of Biohydrogen and Volatile Fatty Acids—A Perspective. Fermentation 2022, 8, 325. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, Y.-T.; Huang, Q.-S.; Ni, B.-J. Polyethylene Terephthalate Microplastics Affect Hydrogen Production from Alkaline Anaerobic Fermentation of Waste Activated Sludge through Altering Viability and Activity of Anaerobic Microorganisms. Water Res. 2019, 163, 114881. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Wang, X.; Fessler, M.; Jin, B.; Su, Y.; Zhang, Y. Insights into the Impact of Polyethylene Microplastics on Methane Recovery from Wastewater via Bioelectrochemical Anaerobic Digestion. Water Res. 2022, 221, 118844. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Hu, T.; Ma, H.; He, S.; Zhao, Q.; Jiang, J.; Wei, L. Deciphering the Role of Polystyrene Microplastics in Waste Activated Sludge Anaerobic Digestion: Changes of Organics Transformation, Microbial Community and Metabolic Pathway. Sci. Total Environ. 2023, 901, 166551. [Google Scholar] [CrossRef]

- Wang, J.; Ma, D.; Feng, K.; Lou, Y.; Zhou, H.; Liu, B.; Xie, G.; Ren, N.; Xing, D. Polystyrene Nanoplastics Shape Microbiome and Functional Metabolism in Anaerobic Digestion. Water Res. 2022, 219, 118606. [Google Scholar] [CrossRef]

- Dilara Hatinoglu, M.; Dilek Sanin, F. Fate and Effects of Polyethylene Terephthalate (PET) Microplastics during Anaerobic Digestion of Alkaline-Thermal Pretreated Sludge. Waste Manag. 2022, 153, 376–385. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, Y.; Zhao, Y.; Zhang, L.; Zhang, X. Inhibition of Aged Microplastics and Leachates on Methane Production from Anaerobic Digestion of Sludge and Identification of Key Components. J. Hazard. Mater. 2023, 446, 130717. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Conner, N.; Lu, K.; Tunnell, J.W.; Liu, Z. Occurrence, Distribution, and Associated Pollutants of Plastic Pellets (Nurdles) in Coastal Areas of South Texas. Sci. Total Environ. 2022, 842, 156826. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Tang, M.; Yang, X.; Tsang, Y.F.; Wu, Y.; Wang, D.; Zhou, Y. Polyamide 6 Microplastics Facilitate Methane Production during Anaerobic Digestion of Waste Activated Sludge. Chem. Eng. J. 2021, 408, 127251. [Google Scholar] [CrossRef]

- Liu, X.; Deng, Q.; Du, M.; Lu, Q.; Zhou, W.; Wang, D. Microplastics Decrease the Toxicity of Cadmium to Methane Production from Anaerobic Digestion of Sewage Sludge. Sci. Total Environ. 2023, 869, 161780. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Dagnew, M.; Ray, M.B. Microfibers in Anaerobic Digestion: Effect of Ozone Pretreatment. J. Environ. Manag. 2023, 346, 118792. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Dang, Q.; Zhang, C.; Zhao, X. Insight into Effects of Polyethylene Microplastics in Anaerobic Digestion Systems of Waste Activated Sludge: Interactions of Digestion Performance, Microbial Communities and Antibiotic Resistance Genes. Environ. Pollut. 2022, 310, 119859. [Google Scholar] [CrossRef] [PubMed]

- Harirchi, S.; Wainaina, S.; Sar, T.; Nojoumi, S.A.; Parchami, M.; Parchami, M.; Varjani, S.; Khanal, S.K.; Wong, J.; Awasthi, M.K.; et al. Microbiological Insights into Anaerobic Digestion for Biogas, Hydrogen or Volatile Fatty Acids (VFAs): A Review. Bioengineered 2022, 13, 6521–6557. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zou, Z.; Tang, M.; Yang, X.; Tsang, Y.F. Polycarbonate Microplastics Induce Oxidative Stress in Anaerobic Digestion of Waste Activated Sludge by Leaching Bisphenol A. J. Hazard. Mater. 2023, 443, 130158. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Y.; Xiong, W.; Yang, Z.; Xu, R.; Zhang, Y.; Jia, M.; Peng, H.; He, L.; Zhou, C. Microplastics Provide New Hotspots for Frequent Transmission of Antibiotic Resistance Genes during Anaerobic Digestion of Sludge Containing Antibiotics. Chem. Eng. J. 2024, 486, 130158. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Kang, X. Effect and Mechanisms of Microplastics on Anaerobic Digestion of Sludge. Huagong Jinzhan/Chem. Ind. Eng. Prog. 2022, 41, 5037–5046. [Google Scholar] [CrossRef]

- Mitraka, G.C.; Kontogiannopoulos, K.N.; Batsioula, M.; Banias, G.F.; Zouboulis, A.I.; Kougias, P.G. A Comprehensive Review on Pretreatment Methods for Enhanced Biogas Production from Sewage Sludge. Energies 2022, 15, 6536. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Y.; Zou, Z.; Yang, X.; Tsang, Y.F. Thermal Hydrolysis Alleviates Polyethylene Microplastic-Induced Stress in Anaerobic Digestion of Waste Activated Sludge. J. Hazard. Mater. 2024, 470, 134124. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Tang, X.; Fan, C.; Tang, L.; Zhou, M.; Zhang, B.; Wang, R.; Li, G. Evaluating the Effects of Different Pretreatments on Anaerobic Digestion of Waste Activated Sludge Containing Polystyrene Microplastics. ACS Environ. Sci. Technol. Water 2022, 2, 117–127. [Google Scholar] [CrossRef]

- Benn, N.; Zitomer, D. Pretreatment and Anaerobic Co-Digestion of Selected PHB and PLA Bioplastics. Front. Environ. Sci. 2018, 5, 297950. [Google Scholar] [CrossRef]

- Cesaro, A.; Pirozzi, F.; Zafırakou, A.; Alexandraki, A. Microplastics in Sewage Sludge Destined to Anaerobic Digestion: The Potential Role of Thermal Pretreatment. Chemosphere 2022, 309, 136669. [Google Scholar] [CrossRef]

- Urbanek, A.K.; Kosiorowska, K.E.; Mirończuk, A.M. Current Knowledge on Polyethylene Terephthalate Degradation by Genetically Modified Microorganisms. Front. Bioeng. Biotechnol. 2021, 9, 771133. [Google Scholar] [CrossRef] [PubMed]

- Yuan, J.; Ma, J.; Sun, Y.; Zhou, T.; Zhao, Y.; Yu, F. Microbial Degradation and Other Environmental Aspects of Microplastics/Plastics. Sci. Total Environ. 2020, 715, 136968. [Google Scholar] [CrossRef] [PubMed]

- Das, N.; Das, A.; Das, S.; Bhatawadekar, V.; Pandey, P.; Choure, K.; Damare, S.; Pandey, P. Petroleum Hydrocarbon Catabolic Pathways as Targets for Metabolic Engineering Strategies for Enhanced Bioremediation of Crude-Oil-Contaminated Environments. Fermentation 2023, 9, 196. [Google Scholar] [CrossRef]

- Lee, H.; Bae, J.; Jin, S.; Kang, S.; Cho, B.-K. Engineering Acetogenic Bacteria for Efficient One-Carbon Utilization. Front. Microbiol. 2022, 13, 865168. [Google Scholar] [CrossRef] [PubMed]

| Pretreatment Method | Sludge Source | MPs Type | Effect on Overall Methane % | MPs Leachate | Reference |

|---|---|---|---|---|---|

| Thermal (120 °C, 30 min.) | WAS | 1 g/L PET-MPs | +52 | NR | [92] |

| 1 g/L BIO-MPs | +60 | NR | |||

| Thermal (70 °C for 1 h) | WAS | 0.2 g/L PS-MPs | +17.5 | SDS 1.1x | [90] |

| Alkaline (pH 12) | WAS | 0.2 g/L PS-MPs | +20.4 | SDS 2.85x | [90] |

| Fenton (pH 3, 150 rpm for 1 h) | WAS | 0.2 g/L PS-MPs | +18.7 | SDS 2.3x | [90] |

| Ultrasonic (260 W, 20 min) | WAS | 0.2 g/L PS-MPs | +2.1 | SDS 1.4x | [90] |

| Combined alkali-thermal (127 °C for 120 min) | WAS | 0, 1, 3, 6 mg PET/g TS | above +22 for all doses | NR | [77] |

| Ozone 1 mg/L at pH 7.0 | Primary sludge | 20 mg/L microfibers | +12 | NR | [82] |

| 100 mg/L microfibers | X | ||||

| 1000 mg/L microfibers | X | ||||

| Hydrothermal (170 °C for 30 min) | WAS | 0.5 g/kgVS PE-MPs | −12.6 | leached TOC containing toxic additives | [46] |

| 0.5 g/kgVS PS-MPs | X | ||||

| 0.5 g/kgVS PVC-MPs | −52.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Otieno, J.O.; Cydzik-Kwiatkowska, A.; Jachimowicz, P. Enhancing Biogas Production Amidst Microplastic Contamination in Wastewater Treatment Systems: A Strategic Review. Energies 2024, 17, 2555. https://doi.org/10.3390/en17112555

Otieno JO, Cydzik-Kwiatkowska A, Jachimowicz P. Enhancing Biogas Production Amidst Microplastic Contamination in Wastewater Treatment Systems: A Strategic Review. Energies. 2024; 17(11):2555. https://doi.org/10.3390/en17112555

Chicago/Turabian StyleOtieno, Job Oliver, Agnieszka Cydzik-Kwiatkowska, and Piotr Jachimowicz. 2024. "Enhancing Biogas Production Amidst Microplastic Contamination in Wastewater Treatment Systems: A Strategic Review" Energies 17, no. 11: 2555. https://doi.org/10.3390/en17112555

APA StyleOtieno, J. O., Cydzik-Kwiatkowska, A., & Jachimowicz, P. (2024). Enhancing Biogas Production Amidst Microplastic Contamination in Wastewater Treatment Systems: A Strategic Review. Energies, 17(11), 2555. https://doi.org/10.3390/en17112555