Research on Evolutionary Laws of Mechanical Properties and Pore Structure during CO2 Pre-Injection Fracturing in Shale Reservoirs

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Experimental Apparatus and Methods

3. Results

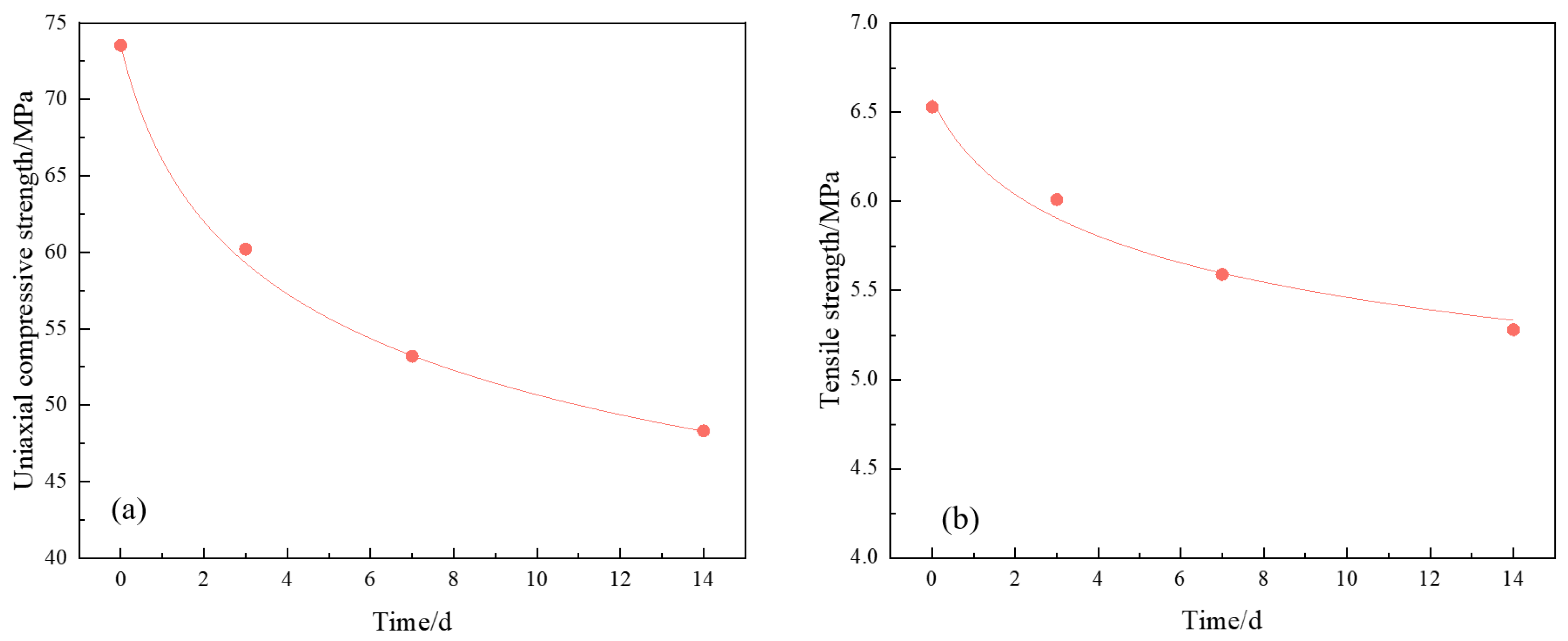

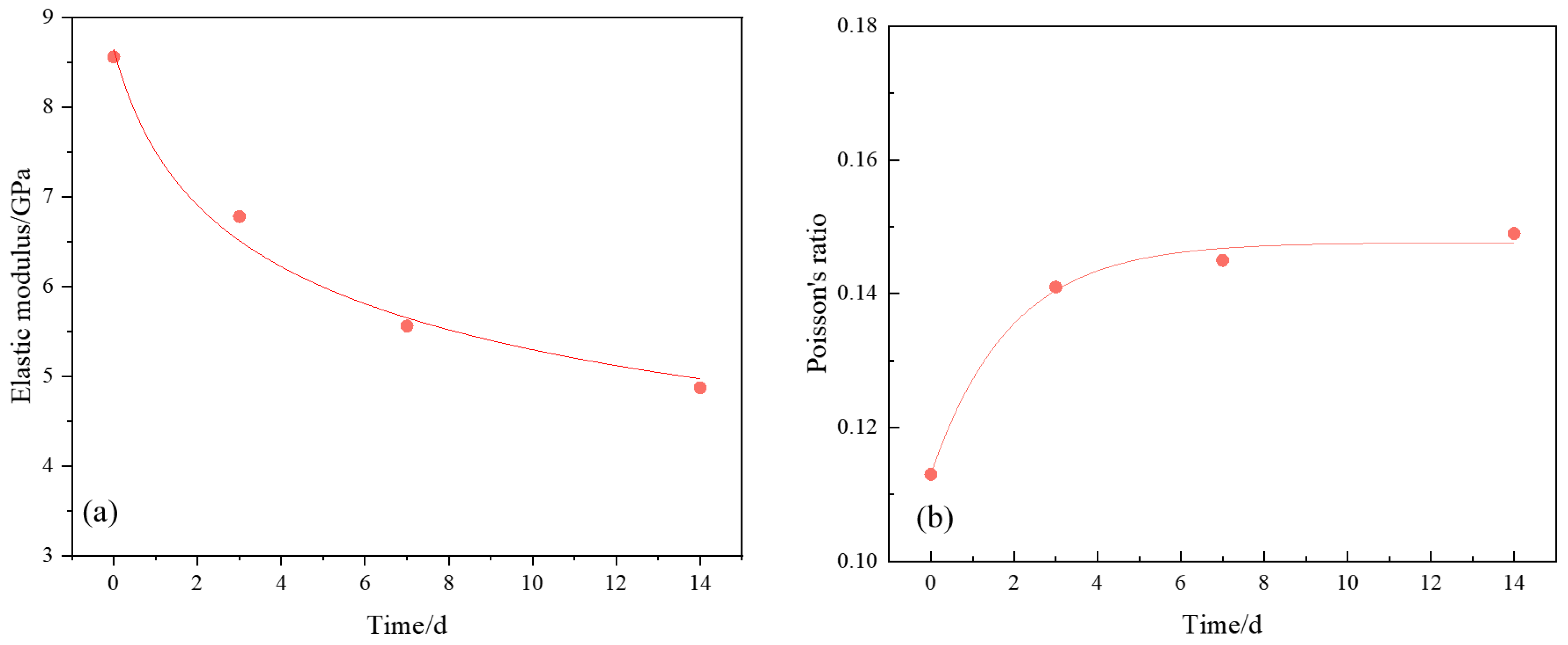

3.1. Evolution of Macro-Mechanical Parameters of Shale before and after CO2 Treatment

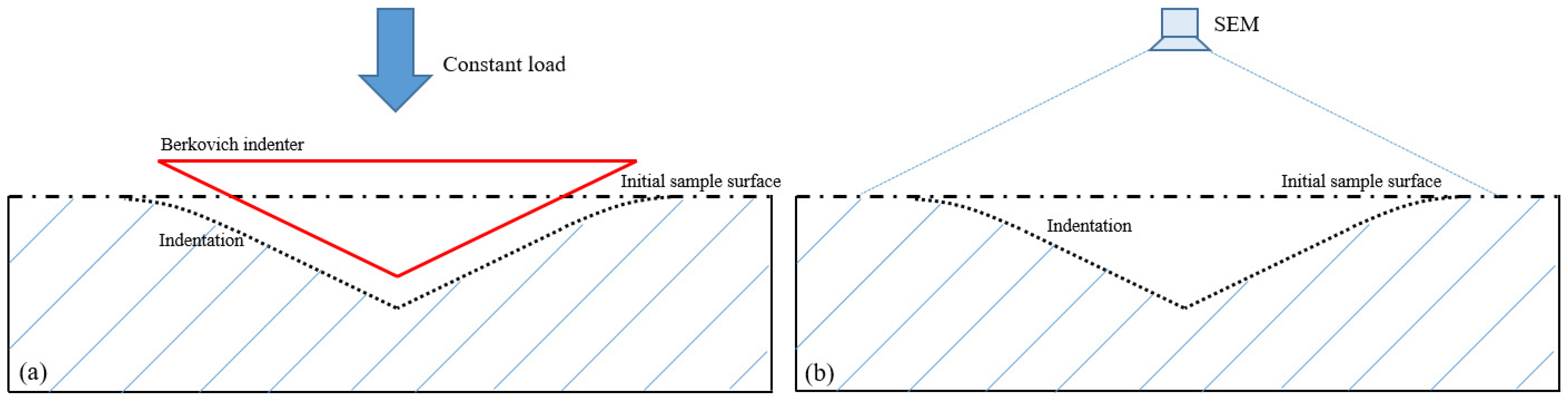

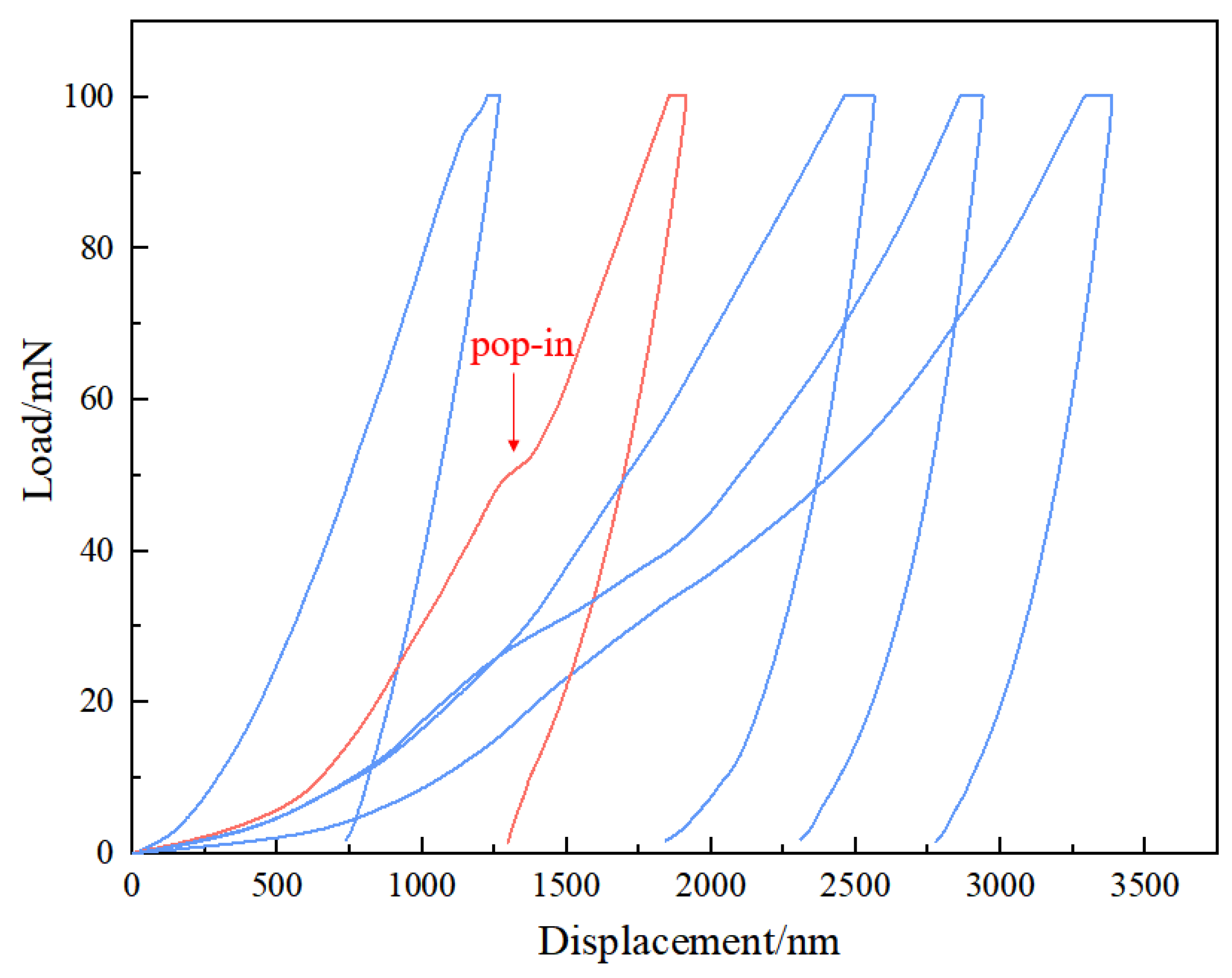

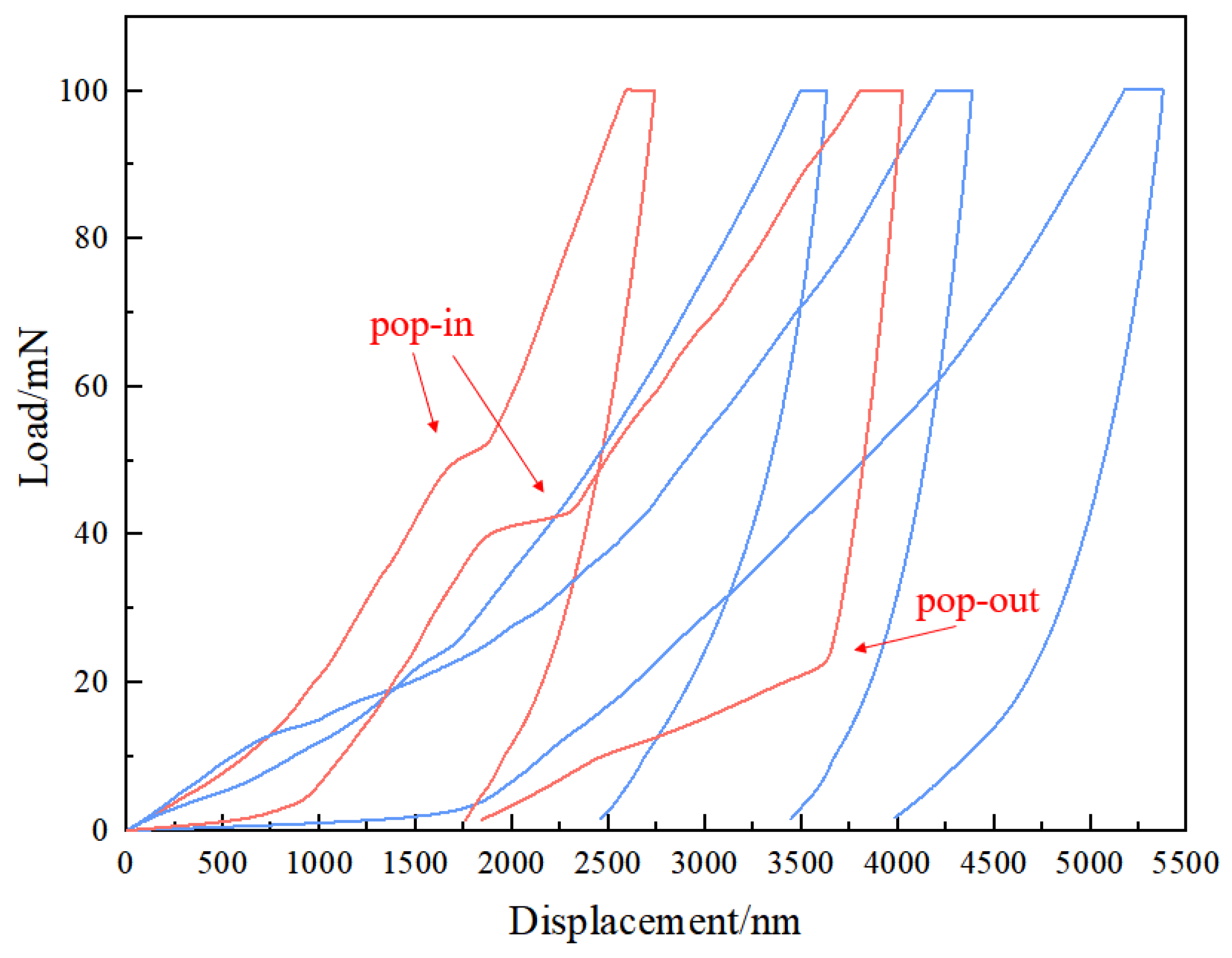

3.2. Evolution of Micro-Mechanical Parameters of Shale before and after CO2 Treatment

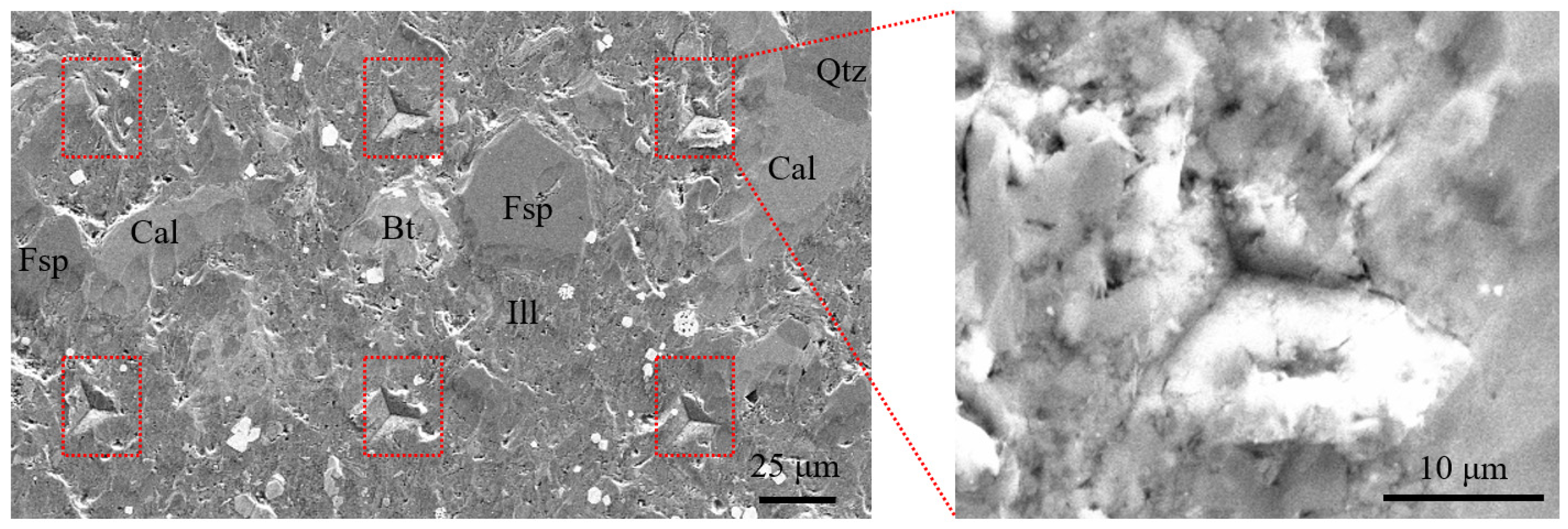

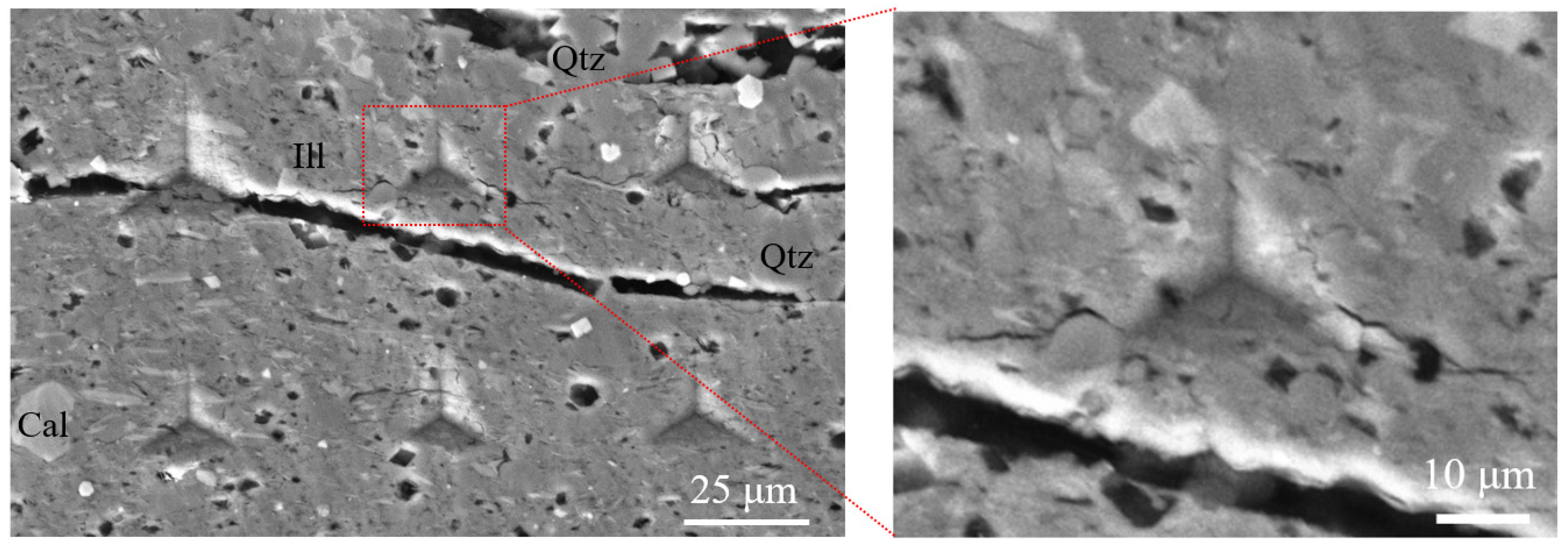

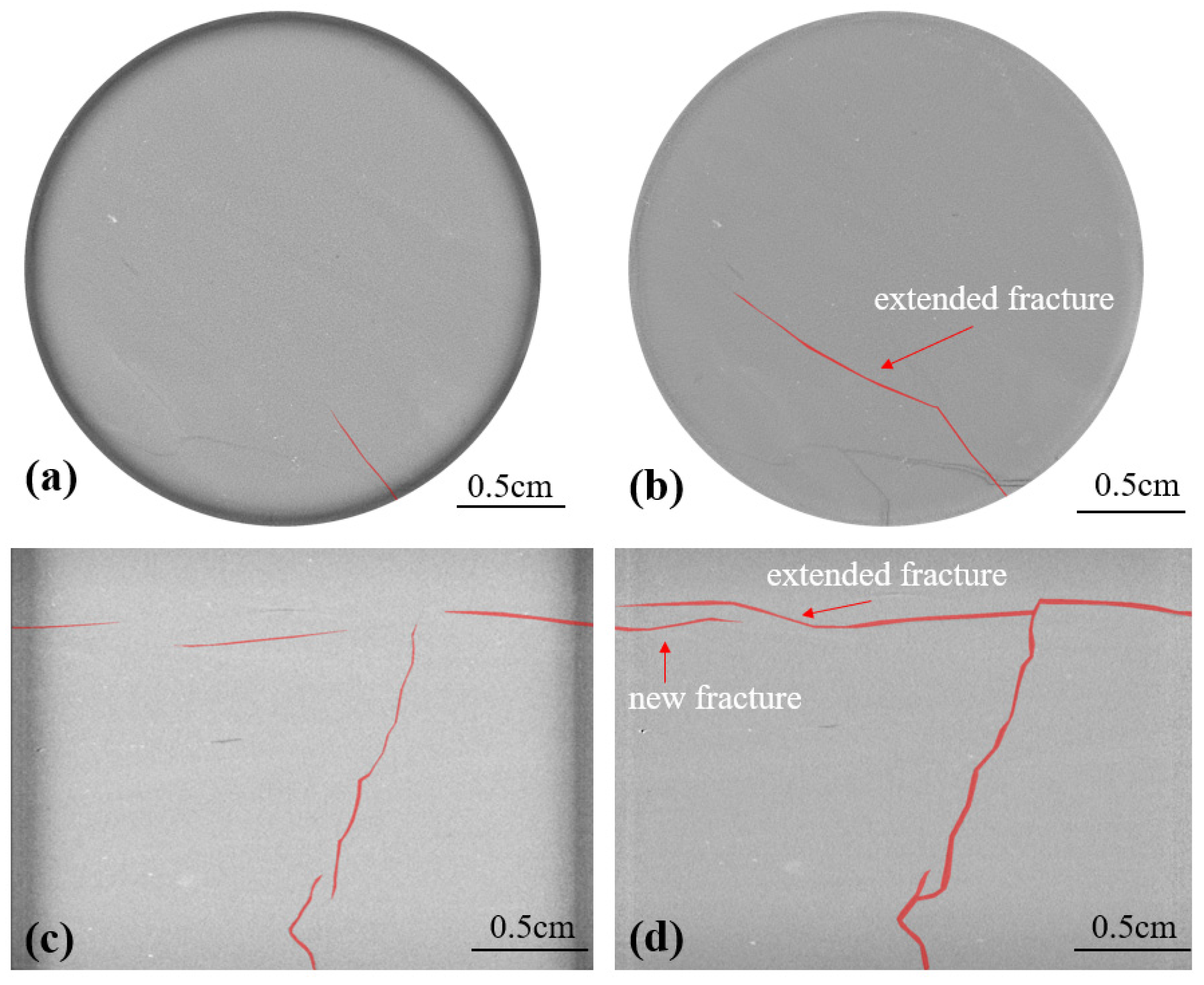

3.3. Influences of CO2 on the Development of Shale Micro-Fractures

3.4. Effects of CO2 on the Shale Micro-Pore Structure

4. Discussion

5. Conclusions

- (1)

- CO2 treatment leads to a significant reduction in the tensile strength, uniaxial compressive strength, and elastic modulus of shale, with the degradation of these mechanical parameters progressively increasing with treatment time. However, as reactive minerals become depleted, the mechanical parameters of shale tend toward stabilization. The Poisson’s ratio increases with extended CO2 treatment duration, ultimately reaching a stable value. After 14 days of CO2 treatment, the uniaxial compressive and tensile strengths of shale drop by 34.29% and 19.14%, respectively. CO2 treatment can effectively reduce the mechanical strength of the Qingshankou Formation shale and improve the fracturing performance.

- (2)

- CO2 treatment has significant effects on the micro-mechanical properties of shale. The phenomena of pop-in during loading and pop-out during unloading increase greatly in the displacement-load curves, and a notable compaction stage occurs in the curve, which shows that the original shale framework changes after CO2 treatment, and the volume of micro-pores and fractures in shale increases. After CO2 treatment, the elastic modulus and hardness of shale decrease by 51.3% and 63.3%, respectively. The micro-mechanical properties of shale decrease greatly, which leads to the degradation of shale macro-mechanical strength.

- (3)

- After CO2 treatment, the propagation of original fractures is accompanied by the opening of structural weak planes, resulting in the formation of additional new fractures. Under the effects of CO2 treatment, micro-fractures in shale continue to extend. The fracture width increases significantly, and the fractures connect with each other to form complex fracture networks. Moreover, CO2 treatment promotes the development of the pore structure in shale. After CO2 treatment, a large number of dissolution pores occur in shale. These new micro-pores and micro-fractures greatly change the original framework of shale, considerably reduce its mechanical strength, lower the difficulty of subsequent fracturing operations and improve the fracturing performance.

- (4)

- With the increasing CO2 treatment time, the macro-mechanical strength of shale decreases greatly and a large number of dissolution pores occur in shale. However, in field, the overall duration of fracturing operations is relatively short, so the reaction time and range of CO2 injected into formations are limited, and the decline of the mechanical strength of shale is small, which has relatively fewer influences on fracturing performance compared with lengthy treatment times. If proper soaking is performed following CO2 injection, the CO2 reaction time can be prolonged, and the CO2 affected range can be expanded. Then a sufficient overall reduction of the mechanical strength can be expected to significantly reduce the breakdown pressure of formations, lower the requirements for treatment equipment and improve the fracturing performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, S.K.; Dong, D.Z.; Tao, K.; Guo, W.; Li, X.J.; Zhang, S.R. Experiences and lessons learned from China’s shale gas development: 2005–2019. J. Nat. Gas Sci. Eng. 2020, 85, 103658. [Google Scholar] [CrossRef]

- Song, Z.J.; Song, Y.L.; Li, Y.Z.; Bai, B.J.; Song, K.P.; Hou, J.R. A critical review of CO2 enhanced oil recovery in tight oil reservoirs of North America and China. Fuel 2020, 276, 118006. [Google Scholar] [CrossRef]

- Jia, B.; Tsau, J.S.; Barati, R. A review of the current progress of CO2 injection EOR and carbon storage in shale oil reservoirs. Fuel 2019, 236, 404–427. [Google Scholar] [CrossRef]

- Du, J.H.; Hu, S.Y.; Pang, Z.L.; Lin, S.H.; Hou, L.H.; Zhu, R.K. The types, potentials and prospects of continental shale oil in China. China Petrol. Explor. 2019, 24, 560–568. [Google Scholar]

- Sheng, J.J.; Chen, K. Evaluation of the EOR potential of gas and water injection in shale oil reservoirs. J. Unconv. Oil Gas Resour. 2014, 5, 1–9. [Google Scholar] [CrossRef]

- Gong, D.Y.; Bai, L.X.; Gao, Z.Y.; Qin, Z.J.; Wang, Z.W.; Wei, W.H.; Yang, A.D.; Wang, R.J. Occurrence Mechanisms of Laminated-Type and Sandwich-Type Shale Oil in the Fengcheng Formation of Mahu Sag, Junggar Basin. Energy Fuels 2023, 37, 13960–13975. [Google Scholar] [CrossRef]

- Fakher, S.; Imqam, A. Application of carbon dioxide injection in shale oil reservoirs for increasing oil recovery and carbon dioxide storage. Fuel 2020, 265, 116944. [Google Scholar] [CrossRef]

- Seales, M.B.; Ertekin, T.; Wang, J.Y. Recovery efficiency in hydraulically fractured shale gas reservoirs. J. Energy Resour. Technol. 2017, 139, 042901. [Google Scholar] [CrossRef]

- Yang, Z.; Zou, C.N. Exploring petroleum inside source kitchen: Connotation and prospects of source rock oil and gas. Petrol. Explor. Dev. 2019, 46, 176–187. [Google Scholar] [CrossRef]

- Solarin, S.A.; Gil-Alana, L.A.; Lafuente, C. An investigation of long range relief on shale oil and shale gas production in the U.S. market. Energy 2020, 195, 116933. [Google Scholar] [CrossRef]

- Chen, G.H.; Lu, S.; Zhang, J.F.; Wang, M.; Wang, J. Estimation of enriched shale oil resource potential in E2s4L of Damintun Sag in Bohai Bay Basin, China. Energy Fuels 2017, 31, 3635–3642. [Google Scholar] [CrossRef]

- Zou, C.N.; Zhu, R.K.; Wu, S.T.; Yang, Z.; Tao, S.Z.; Yuan, X.J.; Hou, L.H.; Yang, H.; Xu, C.C.; Li, D.H.; et al. Types, characteristics, genesis and prospects of conventional and unconventional hydrocarbon accumulations: Taking tight oil and tight gas in China as in-stance. Acta Petrol. Sin. 2012, 33, 173–187. [Google Scholar]

- Wang, J.L.; Feng, L.Y.; Steve, M.; Tang, X.; Gail, T.E.; Mikael, H. China’s unconventional oil: A review of its resources and out-look for long-term production. Energy 2015, 82, 31–42. [Google Scholar] [CrossRef]

- Wang, J.G.; Gu, D.H.; Guo, W.; Zhang, H.J.; Yang, D.Y. Determination of total organic carbon content in shale formations with regression analysis. J. Energy Resour. Technol. 2019, 141, 012907. [Google Scholar] [CrossRef]

- Yang, Z.; Hou, L.H.; Tao, S.Z.; Cui, J.W.; Wu, S.T.; Lin, S.H.; Pan, S.Q. Formation conditions and “sweet spot” evaluation of tight oil and shale oil. Petrol. Explor. Dev. 2015, 42, 555–565. [Google Scholar]

- Li, G.X.; Zhu, R.K. Progress, challenges and key issues of unconventional oil and gas development of CNPC. China Petrol. Explor. 2020, 25, 1–13. [Google Scholar]

- Wu, J.; Wang, H.Y.; Shi, Z.S.; Wang, Q.; Zhao, Q.; Dong, D.Z.; Li, S.X.; Liu, D.X.; Sun, S.S.; Qiu, Z. Favorable lithofacies types and genesis of marine-continental transitional black shale: A case study of Permian Shanxi Formation in the eastern margin of Ordos Basin, NW China. Petrol. Explor. Dev. 2021, 48, 1137–1149. [Google Scholar] [CrossRef]

- Feng, Y.; Xiao, X.M.; Wang, E.Z.; Gao, P.; Lu, C.G.; Li, G. Gas storage in shale pore system: A review of the mechanism, control and assessment. Petrol. Sci. 2023, 20, 2605–2636. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.L.; Fu, X.F.; Bai, Y.F.; Bai, L.H.; Jia, M.C.; He, B. Lithofacies and depositional setting of a highly prospective lacustrine shale oil succession from the Upper Cretaceous Qingshankou Formation in the Gulong sag, northern Songliao Basin, northeast China. AAPG Bull. 2019, 103, 405–432. [Google Scholar] [CrossRef]

- Sun, L.D.; He, W.Y.; Feng, Z.H.; Zeng, H.S.; Jiang, H.; Pan, Z.J. Shale Oil and Gas Generation Process and Pore Fracture System Evolution Mechanisms of the Continental Gulong Shale, Songliao Basin, China. Energy Fuels 2022, 36, 6893–6905. [Google Scholar] [CrossRef]

- Gupta, I.; Rai, C.; Sondergeld, C.; Devegowda, D. Rock Typing in Eagle Ford, Barnett, and Woodford Formations. SPE Reserv. Eval. Eng. 2018, 21, 654–670. [Google Scholar] [CrossRef]

- Ojha, S.P.; Misra, S.; Tinni, A.; Sondergeld, C.; Rai, C. Pore connectivity and pore size distribution estimates for Wolfcamp and Eagle Ford shale samples from oil, gas and condensate windows using adsorption-desorption measurements. J. Petrol. Sci. Eng. 2017, 158, 454–468. [Google Scholar] [CrossRef]

- Wu, T.; Pan, Z.J.; Liu, B.; Connell, L.D.; Sander, R.; Fu, X.F. ”Laboratory Characterization of Shale Oil Storage Behavior: A Comprehensive Review. Energy Fuels 2021, 35, 7305–7318. [Google Scholar] [CrossRef]

- Tian, H.; He, K.; Huangfu, Y.H.; Liao, F.R.; Wang, X.M.; Zhang, S.C. Oil content and mobility in a shale reservoir in Songliao Basin, Northeast China: Insights from combined solvent extraction and NMR methods. Fuel 2024, 357, 129678. [Google Scholar] [CrossRef]

- Guo, T.K.; Gong, F.C.; Lin, X.; Lin, Q.; Wang, X.Z. Experimental investigation on damage mechanism of guar gum fracturing fluid to low-permeability reservoir based on nuclear magnetic resonance. J. Energy Resour. Technol. 2018, 140, 072906. [Google Scholar] [CrossRef]

- Meng, M.M.; Ge, H.K.; Shen, Y.H.; Ji, W.M. Evaluation of the pore structure variation during hydraulic fracturing in marine shale reservoirs. J. Energy Resour. Technol. 2021, 143, 083002. [Google Scholar] [CrossRef]

- Wu, S.; Ge, H.K.; Li, T.T.; Wang, X.Q.; Li, N.; Zou, Y.S.; Gao, K. Characteristics of fractures stimulated by supercritical carbon dioxide fracturing in shale based on acoustic emission monitoring. Int. J. Rock Mech. Min. Sci. 2022, 152, 105065. [Google Scholar] [CrossRef]

- Kohshou, I.Q.; Barati, R.; Yorro, M.C.; Leshchyshyn, T.; Adejumo, A.T.; Ahmed, U.; Kugler, I.; Reynolds, M.; McAndrew, J. Economic assessment and review of waterless fracturing technologies in shale resource development: A case study. J. Earth Sci. 2017, 28, 933–948. [Google Scholar] [CrossRef]

- Gupta, N.; Verma, A. Supercritical Carbon Dioxide Utilization for Hydraulic Fracturing of Shale Reservoir, and Geo-Storage: A Review. Energy Fuels 2023, 37, 14604–14621. [Google Scholar] [CrossRef]

- Yu, H.Y.; Xu, H.; Fu, W.R.; Lu, X.; Chen, Z.W.; Qi, S.C.; Wang, Y.; Yang, W.P.; Lu, J. Extraction of shale oil with supercritical CO2: Effects of number of fractures and injection pressure. Fuel 2021, 285, 118977. [Google Scholar] [CrossRef]

- Li, S.H.; Zhang, S.C.; Zou, Y.S.; Ma, X.F.; Ding, Y.; Li, N.; Zhang, X.; Kasperczyk, D. Pore structure alteration induced by CO2–brine–rock interaction during CO2 energetic fracturing in tight oil reservoirs. J. Petrol. Sci. Eng. 2020, 191, 107147. [Google Scholar] [CrossRef]

- Zou, Y.S.; Li, N.; Ma, X.F.; Zhang, S.C.; Li, S.H. Experimental study on the growth behavior of supercritical CO2-induced fractures in a layered tight sandstone formation. J. Nat. Gas Sci. Eng. 2018, 49, 145–156. [Google Scholar] [CrossRef]

- Wang, X.Z.; Sun, X.; Guo, X.; Zheng, L.M.; Luo, P. Study on the influence of supercritical CO2 with high temperature and pressure on pore-throat structure and minerals of shale. ACS Omega 2024, 9, 15259–15270. [Google Scholar] [CrossRef]

- Zou, Y.S.; Li, Y.C.; Li, S.H. Influence of CO2 pre-injection on fracture mophology and the petrophysical properties in shale fracturing. Nat. Gas Ind. 2021, 41, 83–94. [Google Scholar]

- Xia, Y.L.; Li, L.; Wang, Z. Experimental and numerical study on influencing factors of replacement capacity and slickwater flowback efficiency using pre-CO2 fracturing in tight oil reservoirs. J. Petrol. Sci. Eng. 2022, 215, 110697. [Google Scholar] [CrossRef]

- Zhou, J.P.; Yang, K.; Zhou, L.; Jiang, Y.D.; Xiao, X.F.; Zhang, C.P.; Tian, S.F.; Fan, M.L.; Lu, Z.H. Microstructure and mechanical properties alterations in shale treated via CO2/CO2-water exposure. J. Petrol. Sci. Eng. 2021, 196, 108088. [Google Scholar] [CrossRef]

- Ao, X.; Lu, Y.Y.; Tang, J.R.; Chen, Y.T.; Li, H.L. Investigation on the physics structure and chemical properties of the shale treated by supercritical CO2. J. CO2 Util. 2017, 20, 274–281. [Google Scholar] [CrossRef]

- Liu, D.Q.; Wang, Z.; Zhang, X.Y.; Wang, Y.; Zhang, X.L.; Li, D. Experimental investigation on the mechanical and acoustic emission characteristics of shale softened by water absorption. J. Nat. Gas Sci. Eng. 2018, 50, 301–308. [Google Scholar] [CrossRef]

- Amadei, B.; Rogers, J.D.; Goodman, R.E. Elastic Constants and Tensile Strength of Anisotropic Rocks. In Proceedings of the 5th ISRM Congress, Melbourne, Australia, 10–15 April 1983. [Google Scholar]

- Hudson, J.A.; Crouch, C.L.; Fairhurst, C. Soft, stiff and servo-controlled testing machines: A review with reference to rock failure. Eng. Geol. 1972, 6, 155–189. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Lu, S.F.; He, Z.L.; Li, D.J.; Wang, Z.X.; Xiao, D.S. Investigation of mechanical properties of bedded shale by nanoindentation tests: A case study on Lower Silurian Longmaxi Formation of Youyang area in Southeast Chongqing, China. Petrol. Explor. Dev. 2019, 46, 155–164. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, J.; Meng, S.; Li, D.; Jin, X.; Liang, L.; Liu, H. Research on Evolutionary Laws of Mechanical Properties and Pore Structure during CO2 Pre-Injection Fracturing in Shale Reservoirs. Energies 2024, 17, 2470. https://doi.org/10.3390/en17112470

Tao J, Meng S, Li D, Jin X, Liang L, Liu H. Research on Evolutionary Laws of Mechanical Properties and Pore Structure during CO2 Pre-Injection Fracturing in Shale Reservoirs. Energies. 2024; 17(11):2470. https://doi.org/10.3390/en17112470

Chicago/Turabian StyleTao, Jiaping, Siwei Meng, Dongxu Li, Xu Jin, Lihao Liang, and He Liu. 2024. "Research on Evolutionary Laws of Mechanical Properties and Pore Structure during CO2 Pre-Injection Fracturing in Shale Reservoirs" Energies 17, no. 11: 2470. https://doi.org/10.3390/en17112470

APA StyleTao, J., Meng, S., Li, D., Jin, X., Liang, L., & Liu, H. (2024). Research on Evolutionary Laws of Mechanical Properties and Pore Structure during CO2 Pre-Injection Fracturing in Shale Reservoirs. Energies, 17(11), 2470. https://doi.org/10.3390/en17112470