Fast Detection of the Single Point Leakage in Branched Shale Gas Gathering and Transportation Pipeline Network with Condensate Water

Abstract

1. Introduction

1.1. Background

1.2. Related Work

1.2.1. Leak Detection and Location of Single-Phase Flow Pipe Network

1.2.2. Research on Leak Detection and Location of Multiphase Flow Pipelines

1.2.3. Research on Leak Detection and Location of Multiphase Flow Pipe Network

1.3. The Contribution of This Work

2. Materials and Methods

2.1. Problem Description and Model Assumptions

2.2. Transient Model for Gas–Liquid Two Phase Pipe Network Flow and Single Point Leakage

2.3. Verification Method for the Effectiveness of Leak Detection Technology

2.4. Identification Method for Single Point Leakage in Gas-Liquid Two-Phase Flow Pipeline Network Based on Pressure Drop Rate

3. Application Example of Leaking Pipe Segment Identification Method Based on Pressure Drop Rate

3.1. Change Rule of Pipeline Parameters before and after Leakage

3.1.1. The Law of Pressure Change

3.1.2. The Law of Temperature Change

3.1.3. Change Law of Liquid Holdup

3.1.4. The Law of Gas Flow Rate Change

3.1.5. The Law of Change in Liquid Flow Rate

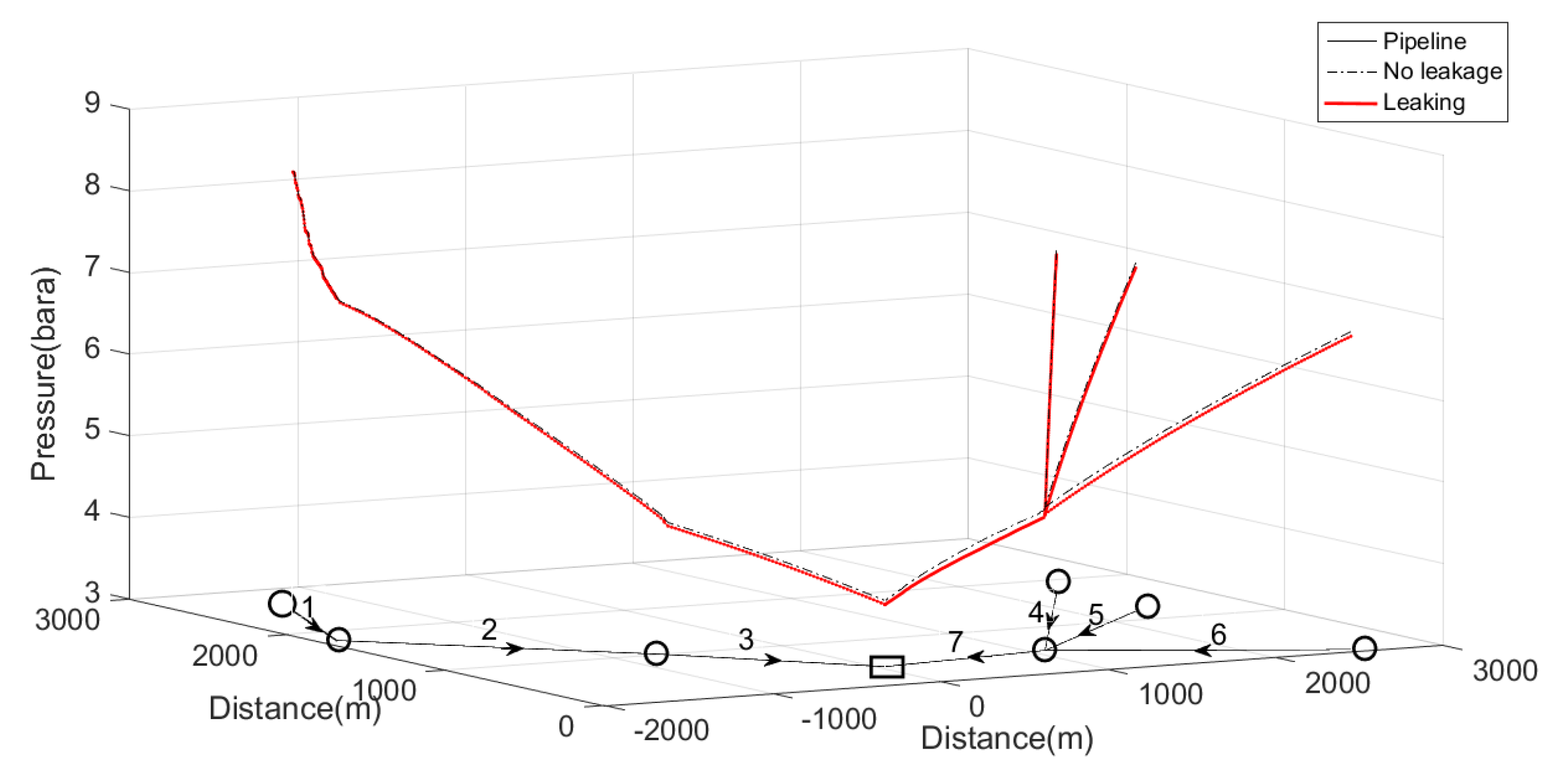

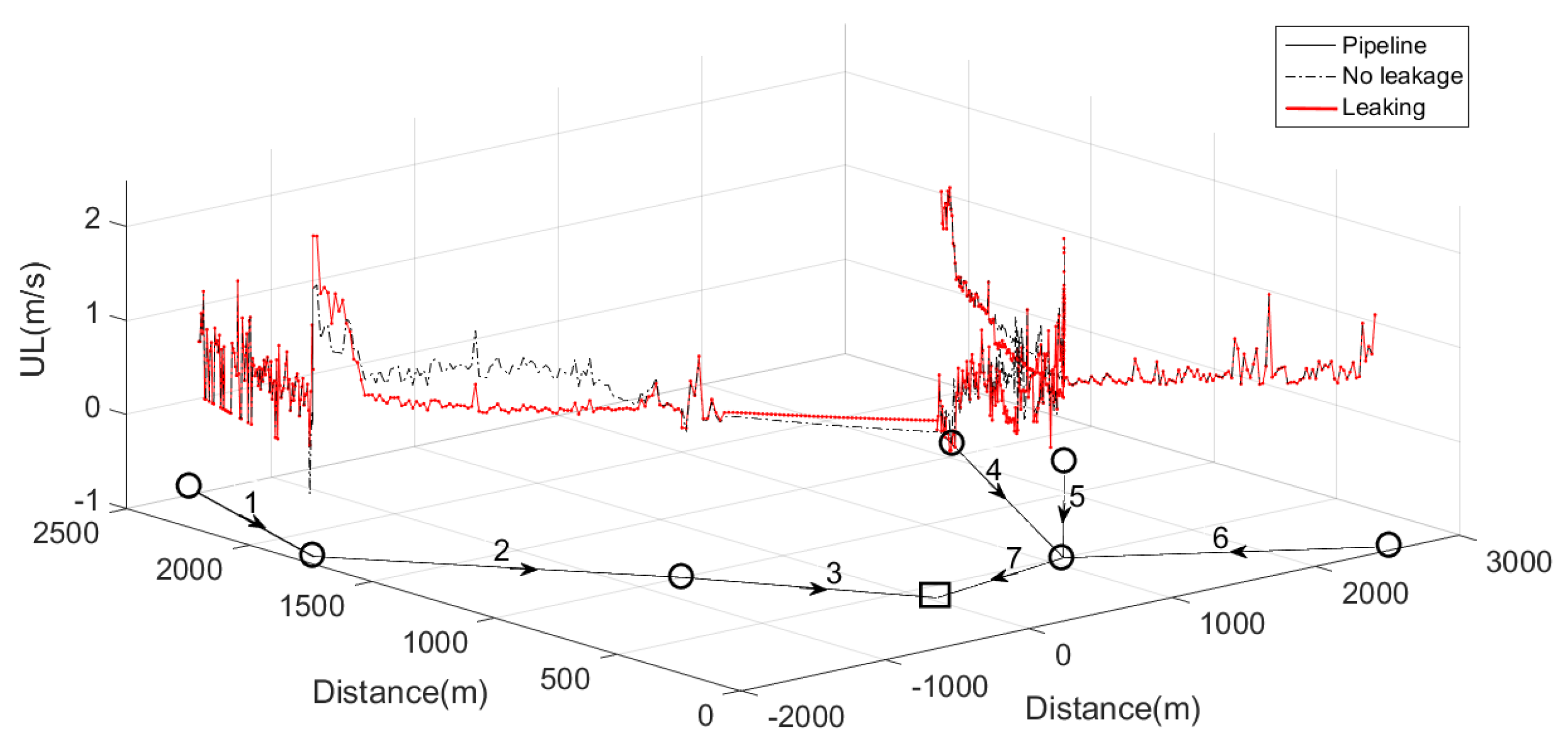

3.2. Changes in the Parameters of the Entire Pipeline Network before and after the Leak

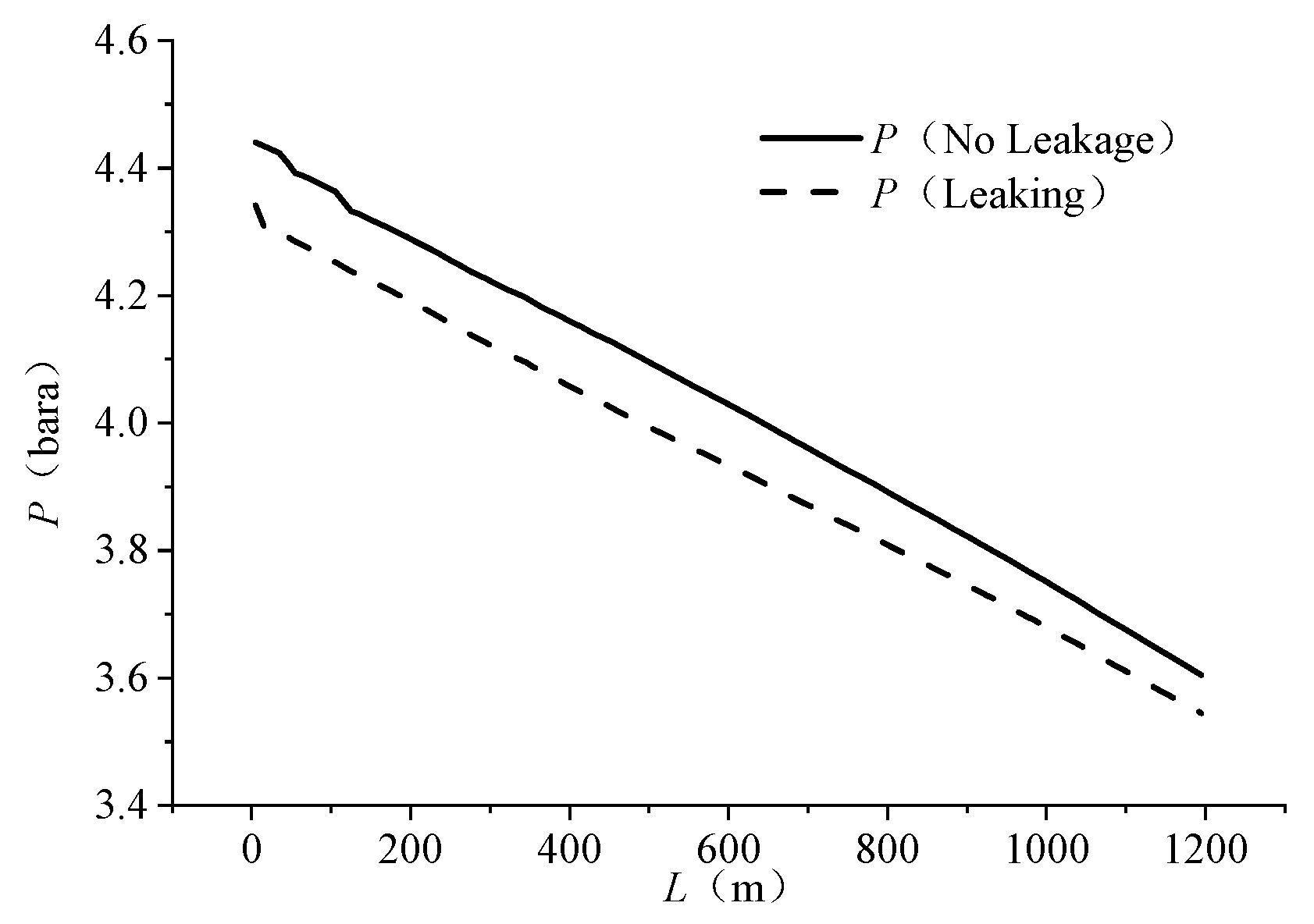

3.2.1. The Law of Pressure Changes along the Pipeline

3.2.2. The Law of Temperature Changes along the Pipeline

3.2.3. The Law of Liquid Holdup Changes along the Pipeline

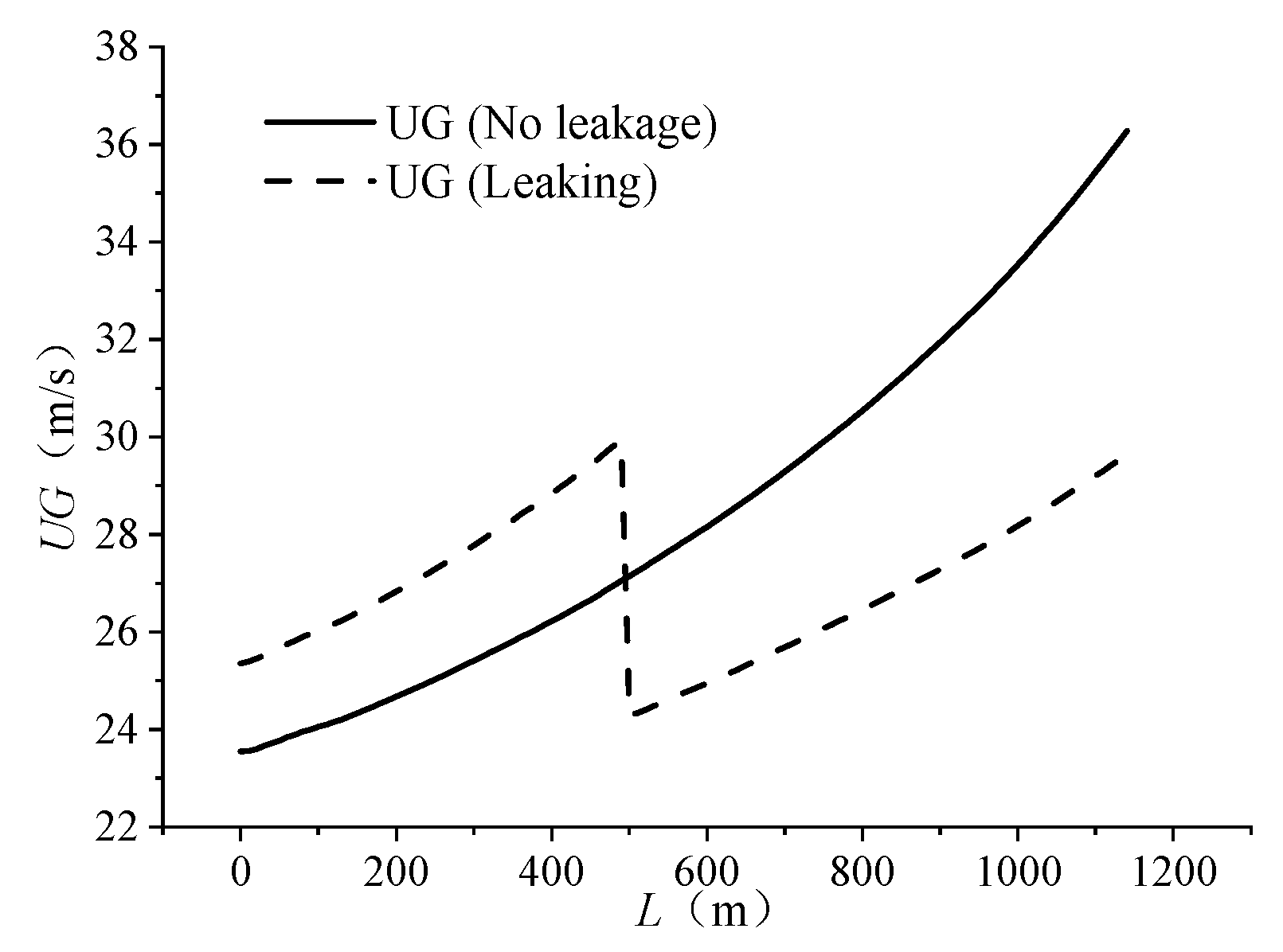

3.2.4. The Gas Flow Rate Changes along the Pipeline

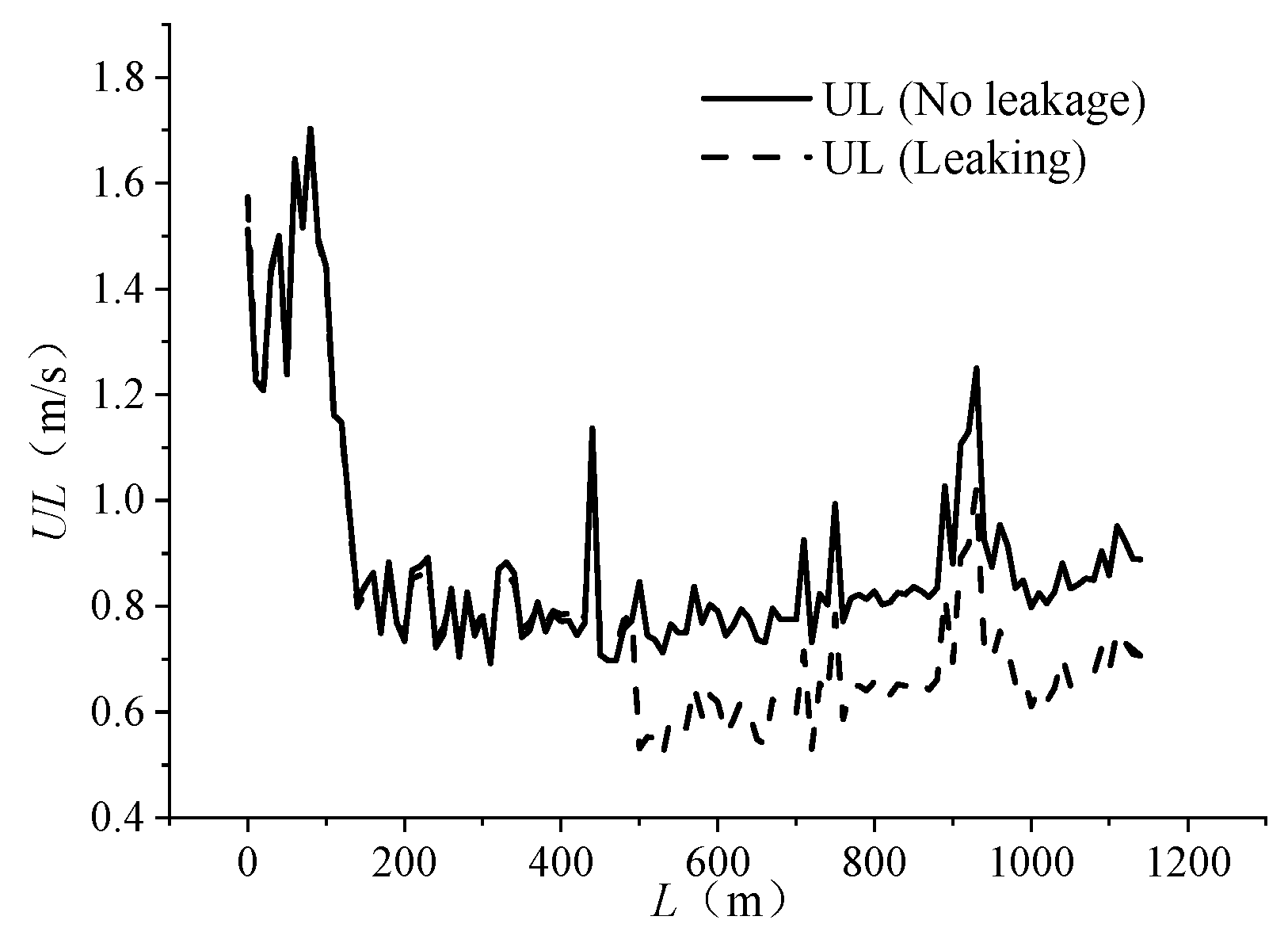

3.2.5. The Law of Liquid Flow Rate Change along the Pipeline

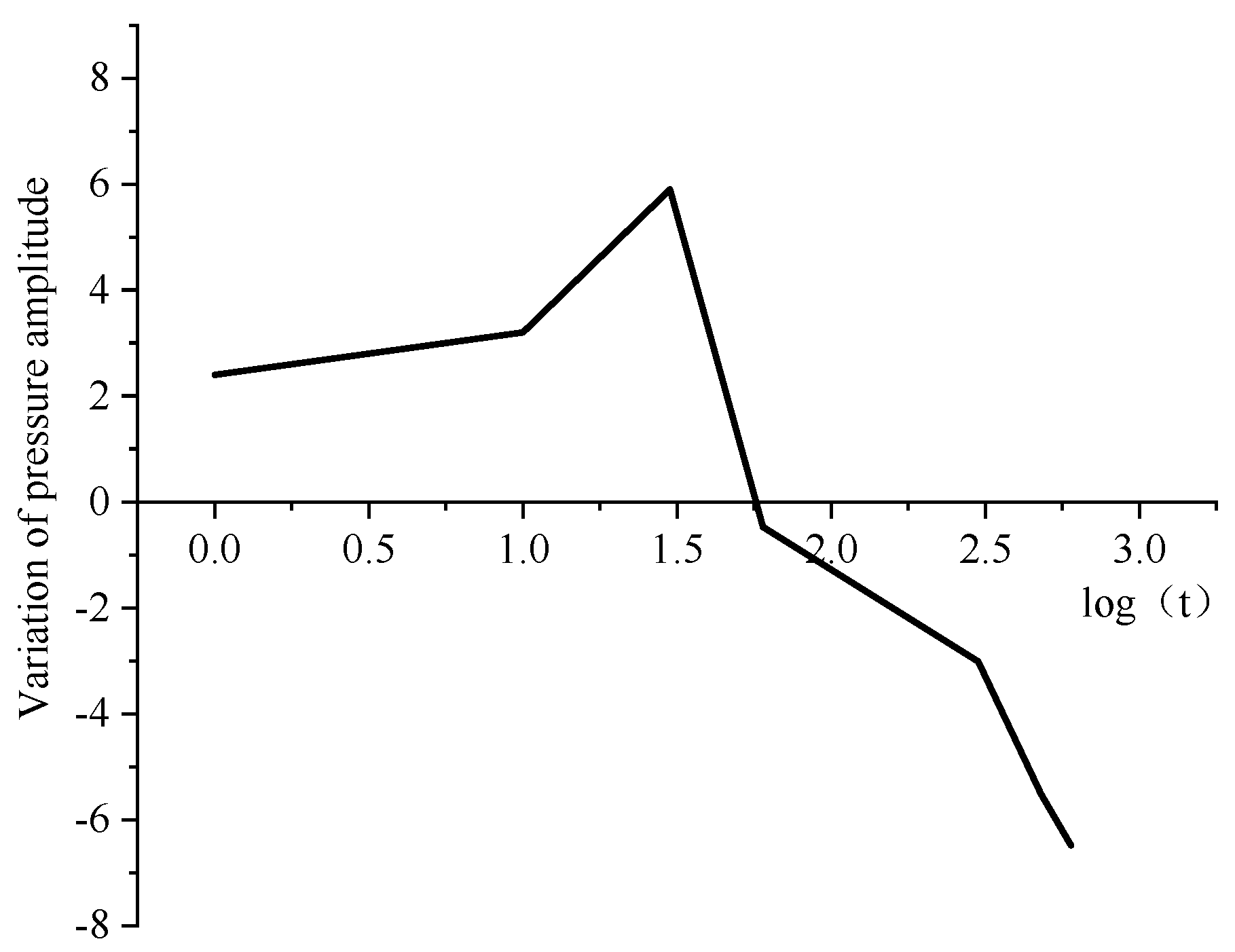

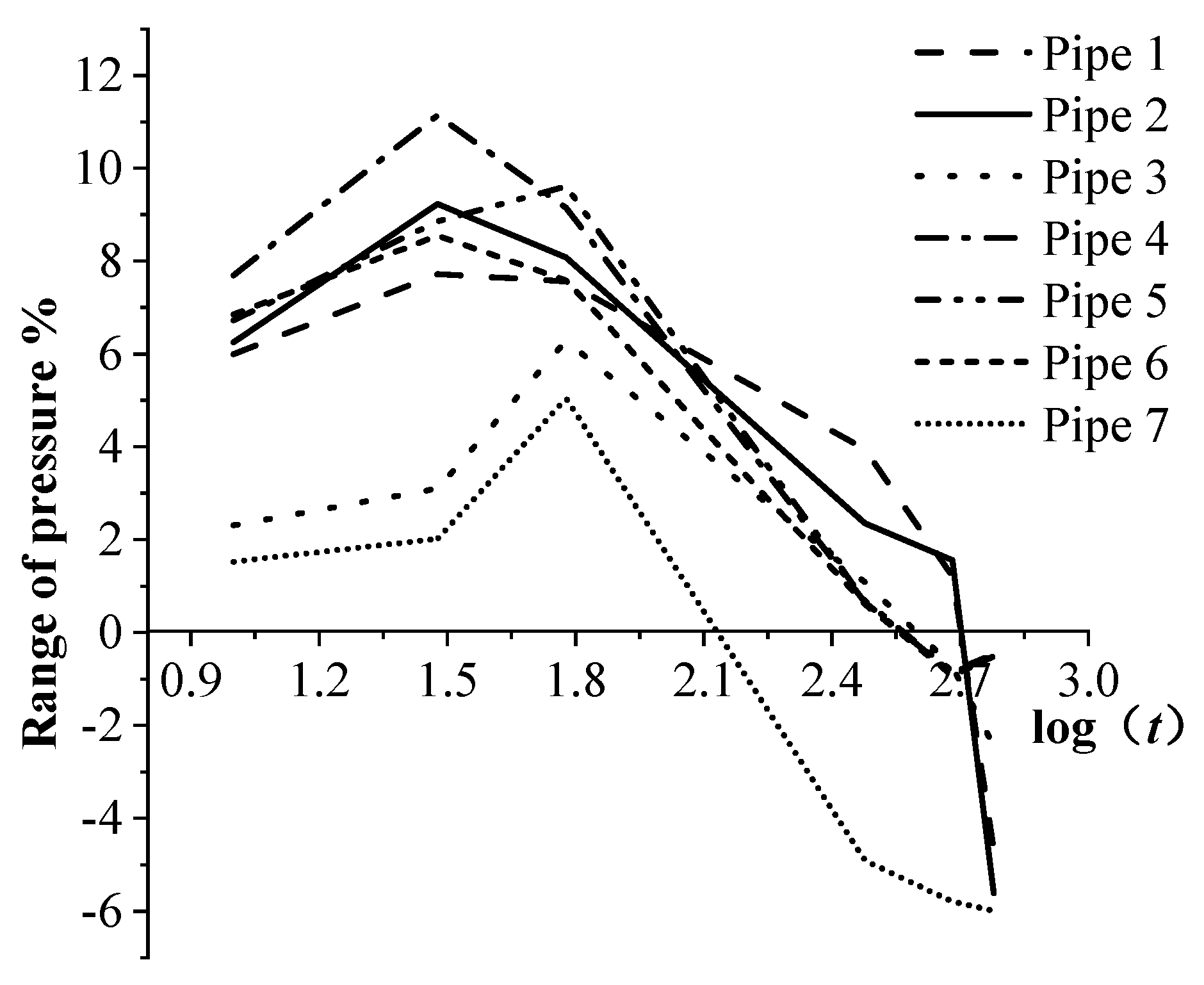

3.3. Identify Leaking Pipe Section Based on Pressure Changes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, P.; Mohapatra, P.K. Simple graphical method for detection of a partial blockage or leak in a single pipeline. J. Press. Vessel Technol. 2021, 143, 054501. [Google Scholar] [CrossRef]

- Qian, F.; Hu, M. Numerical simulation of leakage flow field and acoustic characteristics for safety valve. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 336, p. 01007. [Google Scholar]

- Yang, L.; Guo, Y.; Gao, S. Multi-leak detection in pipeline based on optical fiber detection. Optik 2020, 220, 164996. [Google Scholar] [CrossRef]

- Kim, H.J.; Shin, H.Y.; Pyeon, C.H.; Kim, S.; Lee, B. Fiber-optic humidity sensor system for the monitoring and detection of coolant leakage in nuclear power plants. Nucl. Eng. Technol. 2020, 52, 1689–1696. [Google Scholar] [CrossRef]

- Quy, T.B.; Kim, J.M. Real-Time Leak Detection for a Gas Pipeline Using ak-NN Classifier and Hybrid AE Features. Sensors 2021, 21, 367. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Lee, C.M. A modified leakage localization method using multilayer perceptron neural networks in a pressurized gas pipe. Appl. Sci. 2019, 9, 1954. [Google Scholar] [CrossRef]

- Kabaasha, A.M.; Piller, O.; van Zyl, J.E. Incorporating the modified orifice equation into pipe network solvers for more realistic leakage modeling. J. Hydraul. Eng. 2018, 144, 04017064. [Google Scholar] [CrossRef]

- Li, H.; Li, H.; Pei, H.; Li, Z. Leakage detection of HVAC pipeline network based on pressure signal diagnosis. In Building Simulation; Tsinghua University Press: Beijing, China, 2019; Volume 12, pp. 617–628. [Google Scholar]

- Van der Walt, J.C.; Heyns, P.S.; Wilke, D.N. Pipe network leak detection: Comparison between statistical and machine learning techniques. Urban Water J. 2018, 15, 953–960. [Google Scholar] [CrossRef]

- Liu, C.-W.; Li, Y.-X.; Yan, Y.-K.; Fu, J.-T.; Zhang, Y.-Q. A new leak location method based on leakage acoustic waves for oil and gas pipelines. J. Loss Prev. Process Ind. 2015, 35, 236–246. [Google Scholar] [CrossRef]

- Rai, A.; Kim, J.M. A novel pipeline leak detection approach independent of prior failure information. Measurement 2021, 167, 108284. [Google Scholar] [CrossRef]

- Oyedeko, K.F.K.; Balogun, H.A. Modeling and simulation of a leak detection for oil and gas pipelines via transient model: A case study of the Niger delta. J. Energy Technol. Policy 2015, 5, 16–27. [Google Scholar]

- Lukonge, A.B.; Cao, X.; Pan, Z. Experimental study on leak detection and location for gas pipelines based on acoustic waves using improved Hilbert–Huang transform. J. Pipeline Syst. Eng. Pract. 2021, 12, 04020072. [Google Scholar] [CrossRef]

- Sarkamaryan, S.; Haghighi, A.; Adib, A. Leakage detection and calibration of pipe networks by the inverse transient analysis modified by Gaussian functions for leakage simulation. J. Water Supply Res. Technol.-AQUA 2018, 67, 404–413. [Google Scholar] [CrossRef]

- Aida-zade, K.R.; Ashrafova, Y.R. Numerical solution of inverse problem on determination of leakage for unsteady flow in a pipeline network. IFAC-Pap. 2018, 51, 21–26. [Google Scholar] [CrossRef]

- Jia, W.; Wu, X.; Li, C.; He, Y. Characteristic analysis of a non-equilibrium thermodynamic two-fluid model for natural gas liquid pipe flow. J. Nat. Gas Sci. Eng. 2017, 40, 132–140. [Google Scholar] [CrossRef]

- Coelho, R.C.; Ilha, A.; Doria, M.M.; Pereira, R.M.; Aibe, V.Y. Lattice Boltzmann method for bosons and fermions and the fourth-order Hermite polynomial expansion. Phys. Rev. E 2014, 89, 043302. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Li, Y.; Liang, Y. Research progress on leakage rate models for gas pipelines. Oil Gas Storage Transp. 2020, 39, 512–518. [Google Scholar]

- Jin, J. Numerical Simulation Study on Leakage and Diffusion of Buried Gas Pipelines. Master’s Thesis, Zhejiang Ocean University, Zhoushan, China, 2021. [Google Scholar]

- Zhang, S.; Zhang, Y.; Sheng, H.; Wei, P.; Wang, T. A Distributed Optical Fiber Thermal Pipeline Leakage Monitoring Experimental System and Implementation Method. CN115164116B, 30 December 2022. [Google Scholar]

- Cui, Z.; Tian, L.; Duan, P.; Li, L.; Li, Y.; Liu, C. Setting of pressure drop rate threshold for cut-off valves in mixed hydrogen natural gas pipelines. Oil Gas Storage Transp. 2021, 40, 1293–1298. [Google Scholar]

- Liu, C. Research on Sound Wave Generation and Propagation Characteristics of Gas Pipeline Leakage. Ph.D. Thesis, China University of Petroleum (East China), Qingdao, China, 2016. [Google Scholar]

| Pipeline Leak Detection Technology | Threshold Variable Name | Representative Formula | Value Position | Value Sequence |

|---|---|---|---|---|

| Distributed fiber optic method | Vibration amplitude, temperature | δA, δA/δt | Starting and ending points, intermediate nodes | Time series |

| Transient model method | change/rate of change value | δT, δT/δt | Starting and ending points, | Time series |

| Acoustic wave method | Pressure simulation value | δP, δP/δt | Starting and ending points, intermediate nodes | Time series |

| Pipe Segment No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Diameter (mm) | 160 | 160 | 225 | 160 | 160 | 160 | 325 |

| Length (km) | 1.00 | 1.00 | 0.60 | 1.14 | 1.20 | 1.00 | 1.20 |

| Thickness (mm) | 6.00 | 6.00 | 9.50 | 6.00 | 6.00 | 6.00 | 12.80 |

| Pipe Segment No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Mass flowrate (kg/s) | 1 | 1 | 1 | 2 | 2 | 2 | 0 | 9 |

| Pressure (MPa) | — | — | — | — | — | — | — | 0.3 |

| Temperature (K) | 305 | 305 | 295 | 305 | 305 | 305 | 295 | 285 |

| Gas content ratio (-) | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 |

| Parameter | Equation |

|---|---|

| Initial Condition | |

| Entrance Boundary Conditions | |

| Export Boundary Conditions | |

| Node Boundary Conditions |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, X.; Dai, Z.; Zhang, W.; Wang, Q.; He, G. Fast Detection of the Single Point Leakage in Branched Shale Gas Gathering and Transportation Pipeline Network with Condensate Water. Energies 2024, 17, 2464. https://doi.org/10.3390/en17112464

Zhong X, Dai Z, Zhang W, Wang Q, He G. Fast Detection of the Single Point Leakage in Branched Shale Gas Gathering and Transportation Pipeline Network with Condensate Water. Energies. 2024; 17(11):2464. https://doi.org/10.3390/en17112464

Chicago/Turabian StyleZhong, Xue, Zhixiang Dai, Wenyan Zhang, Qin Wang, and Guoxi He. 2024. "Fast Detection of the Single Point Leakage in Branched Shale Gas Gathering and Transportation Pipeline Network with Condensate Water" Energies 17, no. 11: 2464. https://doi.org/10.3390/en17112464

APA StyleZhong, X., Dai, Z., Zhang, W., Wang, Q., & He, G. (2024). Fast Detection of the Single Point Leakage in Branched Shale Gas Gathering and Transportation Pipeline Network with Condensate Water. Energies, 17(11), 2464. https://doi.org/10.3390/en17112464