1.1. Potential Uses and Applications of Composite Energetic Materials

Composite energetic materials offer the prospect of improved reactive performance, concurrently facilitating safe handling contingent upon their sensitivity thresholds [

1]. Their deployment spans military and commercial domains, with endeavors striving towards enhancing reliability and safety while concomitantly addressing the environmental impact [

2]. Nonetheless, these materials are not exempt from limitations and challenges. For instance, the development of novel composite energetic materials necessitates an extensive and resource-intensive process, often relying on iterative trial-and-error methodologies rather than a well-defined optimization framework [

3]. Furthermore, the industry is confronted with regulatory pressures to curtail or eliminate hazardous substances from the workflow while simultaneously striving for product improvements manifested as escalations in performance and safety metrics, coupled with the pursuit of more environmentally benign alternatives for product development [

2].

Nano-energetic materials have evinced the potential of elevated heat release rates, tailorable burning rates, and reduced sensitivity, thereby occupying a pivotal role in defense applications [

4], with widespread deployment in modern engineering [

3], and routinely applied in other diverse fields encompassing automotive industry, aviation, aerospace, renewable energy, and even biomedical sectors, as illustrated in

Figure 1. Nanocomposite energetic materials are characterized by the intimate intermixing of reactive components at the nanometer to atomic scale, engendering rapid combustion dynamics and efficient energy release mechanisms. A preceding investigation [

5] elucidated the various preparatory methodologies and composite systems, underscoring their high energy density and release rate attributes, which have garnered significant research interest.

1.2. Ignition and Combustion of Metal and Metalloid Particles

Metal and metalloid particles possess and exhibit unique properties that render them attractive candidates for deployment across a diverse array of practical applications. However, each distinct metal or metalloid particle presents its own set of limitations and challenges in their deployment. Beryllium, for instance, is a highly energetic metal that finds limited utilization due to its extreme toxicity, scarcity, and prohibitive cost [

6]. Boron, comparatively speaking, boasts the highest volumetric energy density among its counterparts, yet its ignition and combustion dynamics are significantly impeded by the presence of its oxide layer [

7,

8,

9]. This delay in ignition and combustion has constrained its usage in practical applications. Nonetheless, researchers are actively exploring novel passivation materials and approaches to enhance its combustion characteristics. In contrast to beryllium and boron, aluminum, which is relatively safe to handle [

10], exhibits extensive application prospects in the domains of thermites, pyrotechnics, explosives, and propellants [

11] and can be deployed in space and underwater propulsion systems [

10,

12], as well as hydrogen generation applications [

13].

The use of nano-aluminum in solid propellants has evinced the potential for enhancing combustion performance and reducing combustion times, thereby catalyzing improvements in jet momentum characteristics and mitigating slag formation propensities [

14,

15]. The synthesis of aluminum nanoparticles for fuel applications has been explored [

16], underscoring their prospective integration into micro-electromechanical systems and as reactive nanomaterials across diverse application domains. Nano-sized aluminum particles have demonstrated significantly reduced ignition delay times in comparison to their micro-sized counterparts [

14,

17,

18]. While nano-sized aluminum exhibited a relatively subdued effect on ignition delay time, micro-sized aluminum manifested an exponential influence on this parameter [

14]. Furthermore, nano-sized aluminum exhibited more intense combustion dynamics and superior self-sustaining performance characteristics relative to their micro-sized counterparts [

14]. Conversely, escalations in ambient temperature or oxygen content not only showed reductions in the ignition delay time of the particles but also exerted an influence on the combustion time [

18,

19]. Although aluminum nanoparticles exhibit lower ignition temperature thresholds in comparison to their micro-sized counterparts, they also exhibit a propensity for sintering and agglomeration due to solid-state diffusion and viscous flow phenomena [

20]. The sintering and agglomeration of nanoparticles can facilitate the contact and condensation of fuel and oxidizer aggregates, thereby engendering reactive sintering and rapid melting and coalescence of the agglomerated particles. Recent endeavors [

21,

22] have indicated that reactive sintering constitutes a pivotal component of the combustion dynamics of nanocomposite energetic materials.

The sintering phenomenon in nanocomposites is a thermally activated process encompassing mass transport events manifesting at the atomic scale [

23]. The sintering process is complex, subject to modulation by an array of factors, including chemical composition, thermodynamic parameters, pressure, time, temperatures, atmospheric conditions, degree of agglomeration, particle shape and size distribution, and the rates of heating and cooling [

23]. The size distribution of the agglomerates is governed by the maximum entropy state of the agglomerate ensemble, calculated employing the Gibbs formula of entropy [

24]. The small size of nanoparticles leads to high surface energy levels, thereby promoting different interactions with the surrounding environment and exerting an influence on their mobility characteristics, primarily dictated by Brownian motion [

25].

Additionally, the presence of defects, cracks, and voids within a particle structure can exert a profound influence on its ignition dynamics, modulating its sensitivity and ignition threshold parameters. The spatial distribution of hotspot regions within the particle is contingent upon these defects, and as the reaction rate increases, the ignition mechanism transitions from a bulk-dominated regime to a surface-driven ignition. Thermal shock phenomena can also precipitate the formation of cracks within the particle, thereby exerting a further modulating influence on its ignition behavior [

23,

24,

25]. Mesoscale simulations can be employed to explicitly account for defects and quantify their effects on shock sensitivity, enabling the prediction of ignition thresholds and probabilities for particles exhibiting varying degrees of initial grain cracking or interfacial debonding [

26]. A spatially resolved rate theory approach can be utilized to investigate the coupling between point-defect diffusion/recombination dynamics and concentrated stress fields in the vicinity of crack tips, facilitating an understanding of void formation mechanisms near microstructural stressors [

23]. Defects can also exert an influence on the melting temperatures [

27], which are constant for void volumes below 1 nm

3 but diminish with further increments in void volumes. For voids with volumes exceeding 8 nm

3, the particle becomes unable to withstand the destabilizing forces associated with the void, culminating in an abrupt collapse of the crystal structure at 700 K [

28].

Moreover, particle ignition is also associated with the melting of the oxide layer, wherein the corresponding melting point is considered to be the bulk melting temperature of the oxide layer, approximated at 2350 K [

29,

30]. The thickness of the oxide layer emerges as a crucial factor in this regard, with the melting temperature of the passivation layer playing a pivotal role in governing the ignition and combustion characteristics of metal-based energetic nanomaterials [

28,

31]. In addition, the combustion of metal particles is subject to profound influence by the boiling temperature. The boiling point of a substance is contingent upon intermolecular forces such as hydrogen bonding, ionic interactions, and Van der Waals forces [

32,

33]. These forces exert a governing influence in determining the boiling points of substances, which can subsequently impact the ignition behavior of thermites. The boiling temperatures of metal nanoparticles deviate from those of their bulk counterparts, a phenomenon that can exert a significant impact on the propensity for vapor-phase combustion. It is generally observed that the boiling temperatures of metals are lower than those of their respective oxides, with notable exceptions such as boron, silicon, and zirconium. When it comes to the ignition and combustion characteristics of nano-aluminum, these parameters have been extensively investigated across diverse environmental conditions [

14,

16,

34,

35,

36,

37,

38].

The ignition temperature of aluminum particles is primarily contingent upon their size dimensions, albeit subject to modulation by factors such as heating rate profiles, oxide layer thickness, and oxidizer composition, among others. For aluminum particles exhibiting diameters in the vicinity of 10 µm, the ignition temperature regime spans 1000–2350 K, evincing a trend of diminishing ignition temperature thresholds with decreasing particle size. As an illustration, ignition can be initiated at temperatures as low as 1000 K, a value significantly lower than the bulk melting point of the oxide shell [

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53,

54]. The ignition delay can be quantified through energy balance analysis [

36]. In modeling particle oxidation dynamics, the gas temperature is typically set at 2500 K, employing Mott–Cabrera kinetics. The burning time of particles exceeding 20 µm exhibits a near-quadratic proportionality with respect to the particle size [

39,

55], while the burning time of smaller particles exhibits a weaker dependence on particle size. It is noteworthy that the ambient gas temperature exerts a profound influence on the combustion characteristics of nanoparticles [

56]. Numerical simulations have also elucidated that increasing the initial temperature facilitates the ignition of nano-aluminum, with the two-stage ignition regime gradually dissipating with increments in the initial temperature [

34]. The combustion process of nano-aluminum in air and CO

2 atmospheres exhibits no discernible difference under temperature-programmed conditions, with the oxygen concentration exerting a significant influence on the combustion dynamics [

35].

1.3. Combustion Properties and Characteristics of Aluminum-Based Nano-Thermites

Aluminum-based thermites typically comprise aluminum as the reducing agent, coupled with various metal oxides serving as oxidizers [

57,

58,

59]. Commonly employed oxidizers in aluminum-based thermites encompass CuO, Fe

2O

3, Fe

3O

4, MoO

3, and MnO

2 [

57,

58,

59,

60]. Nano-thermites not only exhibit elevated energy density, but their combustion rate kinetics can be readily tailored by modulating the fuel and oxidizer particle size, packing density, and compositional parameters [

61].

Fundamental research endeavors and initiatives delving into the combustion dynamics of nano-thermites can be traced back to 1995 [

62]. Flame propagation velocities of Al/MoO

3 nano-thermites with average particle dimensions spanning the 20–50 nm range were found to exhibit an increase of orders of magnitude greater than their conventional micro-sized counterparts. This phenomenon was ascribed to the reduced diffusion length scales arising from the intimate interfacial contact manifested at the nanoscale level. The study elucidated the superior reactivity of nano-thermites, marking the inception of extensive research efforts directed toward these materials.

Initial studies [

63] suggested that the substitution of nano-aluminum particles for their micro-sized counterparts exerted a detrimental effect on the burning rate of thermites. This observation was attributed to the prolonged exposure of micro-thermites to the laser beam, resulting in significant preheating and, consequently, higher burning rates. Subsequent research initiatives, however, have unequivocally demonstrated that the addition of nanoparticles engenders enhancements in the burning rates. The burning rate is typically quantified by loosely packing the thermite within a burn tube, followed by ignition [

64]. Photodetectors, pressure sensors, and high-speed cameras are commonly employed to acquire optical, pressure, and visual data, respectively, pertaining to the burning process. The packing density of the powder was maintained within the range of 5–10% of the theoretical maximum density. The results unveiled that the burning rate exhibited an escalation with diminishing particle size dimensions and manifested independence from the particle size below a threshold in the range of 80–110 nm.

Other studies have demonstrated that aluminum-based thermites exhibit elevated heat release characteristics, wherein the heat release of Al/MoO

3 is significantly higher in comparison to other thermite compositions [

58,

65]. The critical reaction temperature of super thermites undergoes a diminution of 200–400 °C upon the addition of aluminum nanoparticles, implying an enhanced reactivity [

58]. The ignition temperatures of reactive aluminum-based thermites are consistent with the temperature of the polymorphic phase change of alumina, suggesting that the rate-limiting initiation step is the acceleration of the outward diffusion flux of aluminum [

59].

The thermal characteristics and combustion dynamics of aluminum-based thermites are contingent upon their morphological attributes, wherein Al/ribbon-MoO

3 compositions evince a pronounced escalation in heat release and combustion performance in comparison to their Al/rod-MoO

3 counterparts [

66]. The diffusion of Al and O atoms through the oxide shell of aluminum particles exerts an influence on the thermodynamic properties of Al

2O

3, a phenomenon that can subsequently impact the ignition process of the thermite. The doping of Al and O interstitial atoms within the Al

2O

3 matrix can engender modulations in its thermodynamic properties, rendering the oxide shell more ductile and potentially susceptible to spallation during the ignition phase [

67].

Ensuring judicious handling protocols for aluminum-based thermites necessitates a comprehensive understanding of their thermal stability characteristics and the aging phenomena they undergo. As an illustration, thermal annealing at specific temperature regimes can precipitate unanticipated accelerated reactions and pressurization rates for certain thermites, underscoring the intricate nature of aging processes manifested in powdered nano-thermites [

57].

1.4. The Crucial Role of Selecting the Appropriate Fuel and Oxidizer

Selecting the appropriate fuel and oxidizer plays a crucial role in determining the energy threshold requisite for initiating a chemical reaction, the heat generated during the reaction process, and the efficiency with which energy is harnessed. Recent studies [

68] have elucidated the feasibility of increasing the energy output characteristics of aluminum-based energetic materials by employing oxidizer-activated aluminum fuel particles in combination with energetic polymers. This innovative approach evinces the potential to reduce the activation energy needed for the reaction, resulting in a more efficient energy release.

The addition of CuO to Al-Mg alloys in thermite reduces the activation energy of the reaction, with the best performance observed in Al

0.8Mg

0.2(MoO

3)

0.5CuO

0.5 [

69]. The addition of CuO to Al-Mg alloys increases the exothermic heat in high-temperature regions of the thermite reaction [

69], while the addition of KClO

4 to Al/Bi

2O

3 nano-thermite also reduces the activation energy, with Al/Bi

2O

3/10wt%-KClO

4 exhibiting the highest heat release among other samples [

70], while the lowest activation energy was observed in Al/Bi

2O

3/30wt%-KClO

4 [

70].

Additionally, the impact of doping La

2O

3 on the reactive characteristics of Al/CuO thermite altered the flame propagation mode, indicating a potential influence on the fraction of energy feedback [

71]. The velocity of the luminous front in loosely packed Al/CuO thermites was influenced by the fill length and open porosity, impacting the burning rate [

71].

The burning rate of thermites is influenced by thermodynamic and kinetic parameters such as mixture density, specific heat, thermal conductivity, activation energy, and pre-exponential factors [

72]. Activation energy and specific heat emerge as the predominant contributing factors governing the burning velocity, reaction zone thickness, ignition delay, ignition temperature, and peak temperature [

72]. The burning rate of thermite compositions under confinement is influenced by the pressure-driven flow, pore size, and fluid viscosity [

73]. A study investigating the effects of thermodynamic and kinetic parameters on simulated Fe

2O

3-2Al thermite reaction propagation found that higher activation energy resulted in a slower and thicker reaction propagation wave [

72]. Diluted Fe

2O

3-2Al thermite system with alumina was found to suppress burning rate, peak temperature, and expelled mass, signifying potential cost-effective and controlled applications in thermal processes [

74]. Therefore, the key factors determining the activation energy, heat of reaction, and fraction of energy feedback in thermite include the choice of fuel and oxidizer and thermodynamic and kinetic parameters [

69,

70,

72,

75]. These factors interact synergistically to exert their influence on the thermite reaction propagation, heat release, and combustion performance [

69,

72].

1.5. Synthesis Methods of Composite Energetic Materials

The conventional approaches for the fabrication of composite energetic materials involve the physical intermixing of fuel and oxidizer particles. A major drawback of these methods is the formation of highly non-uniform and disorganized agglomerates [

76]. In contrast, material synthesis techniques encompass the manufacturing of nascent metal particles, followed by a passivation process in a well-controlled oxidizing environment. This passivation step ensures the preservation of the active metal content within the particles while conferring stability to the system. When undertaking material synthesis, it is imperative to satisfy certain requisite criteria, including the capability to work with diverse material systems, produce particles spanning a wide and controllable size range, and mitigate the formation of impurities, spontaneous reactions, and agglomeration phenomena while concurrently maintaining elevated levels of productivity and economic viability and ensuring reproducibility of the resultant characteristics [

76,

77,

78,

79,

80,

81,

82,

83,

84,

85,

86,

87,

88,

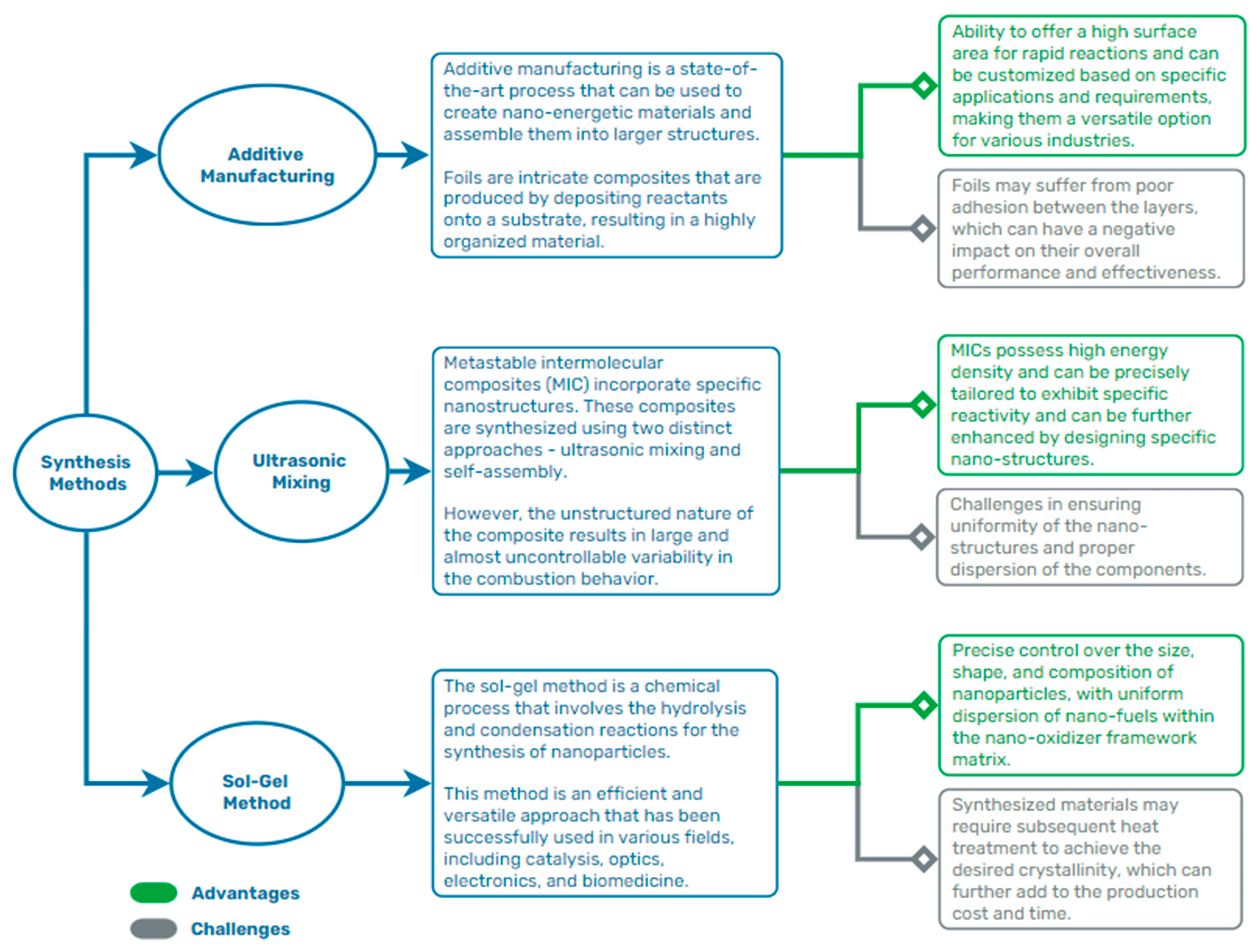

89]. As shown in

Figure 2, the synthesis techniques specifically tailored for thermite applications and their suitability are contingent upon the specific performance requirements and criteria, offering a multitude of advantages and trade-offs [

76,

77,

78,

79,

80,

81,

82,

83,

84,

85,

86,

87,

88,

89].

The sol–gel method facilitates the judicious tailoring of the chemical composition of the gel matrices by means of combining precursors, thereby enabling the deliberate modulation of the resultant material properties [

90,

91]. This attribute renders the sol–gel approach conducive to the fabrication of energetic nanocomposites exhibiting tunable performance characteristics [

92]. The sol–gel technique is distinguished by its versatility, cost-effectiveness, and amenability for large-scale production at economically viable costs, rendering it suitable for a diverse array of material systems spanning metal, inorganic, organic, and hybrid compositions [

93,

94].

The sol–gel process constitutes a wet chemical synthesis route wherein a homogeneous colloidal suspension, termed a ‘sol’, is formed from precursors, subsequently undergoing gelation within a continuous liquid phase to engender the formation of a three-dimensional network structure, referred to as a ‘gel’, after which comes the subsequent drying, a sequence that can facilitate the production of nanoparticle materials with diverse chemical compositions [

93]. The hydrolysis and condensation reaction pathways govern the sol–gel process dynamics, exerting a modulating influence on the formation of the final gel matrix and the sol-to-gel transition phenomena [

95,

96]. The controlled modification of sol–gel derived coatings and their respective applications can also contribute to enhancing reactivity at the molecular level [

94]. The relative surface area of nanomaterials exhibits an augmentation in comparison to their bulk counterparts, contributing to enhanced reactivity [

97].

Nonetheless, in-depth comprehension of the underlying chemical principles is imperative to attain optimal material property outlines and harness the myriad possibilities afforded by the sol–gel method, as the gel synthesis proceeds under the governance of kinetic control mechanisms, resulting in amorphous and metastable materials [

90]. Additionally, conventional sol–gel approaches encounter limitations stemming from the disparate reactivities of the precursors and the high surface tension of water, thereby complicating the synthesis of hybrid compositions [

98].

The judicious selection of the material construct, whether aerogels, xerogels, or cryogels, exerts a profound influence on the combustion dynamics and performance metrics of thermites, owing to their distinctive characteristics and properties such as surface area, thermal conductivity, and porosity [

92,

99,

100,

101]. The disparities manifested in the thermal stability and reactivity of thermites synthesized employing aerogels, xerogels, and cryogels are ascribed to the unique properties inherent to these materials [

92,

99,

100,

101,

102].

Aerogels are distinguished by their unique properties, encompassing high surface areas, sharp pore size distributions, low thermal conductivities, and high sorption capacities, rendering them attractive candidates for a myriad of applications, including the synthesis of thermites [

99,

102]. Aerogels may enhance the combustion behavior and performance of thermites by providing efficient heat transfer and favorable reaction sites [

99,

102]. Aerogels can enhance the reactivity and energy release of thermites. However, their synthesis may necessitate the implementation of specific processing protocols and stringent synthetic control over the structural properties [

92,

102].

Xerogels are lightweight, high surface area mesoporous materials that can maintain their mesoporous structure at elevated temperatures, making them suitable for thermal superinsulation applications [

100]. Xerogels may also contribute to improved combustion behavior and performance of thermites by facilitating rapid heat dissipation and reaction kinetics [

100]. However, their limitations in terms of temperature stability and drying methods have to be considered [

100].

Cryogels, particularly nitrogen-doped cryogels, evince outstanding specific and normalized capacitances, rendering them suitable for supercapacitor electrode applications [

101]. Cryogels may offer distinctive advantages in enhancing the combustion behavior and performance of thermites, potentially influencing their reactivity and energy release during combustion [

101]. However, the influence of nitrogen- and oxygen-based moieties has to be carefully considered [

101].

1.6. Key Factors Affecting the Choice of Ignition System–Thermite Combinations

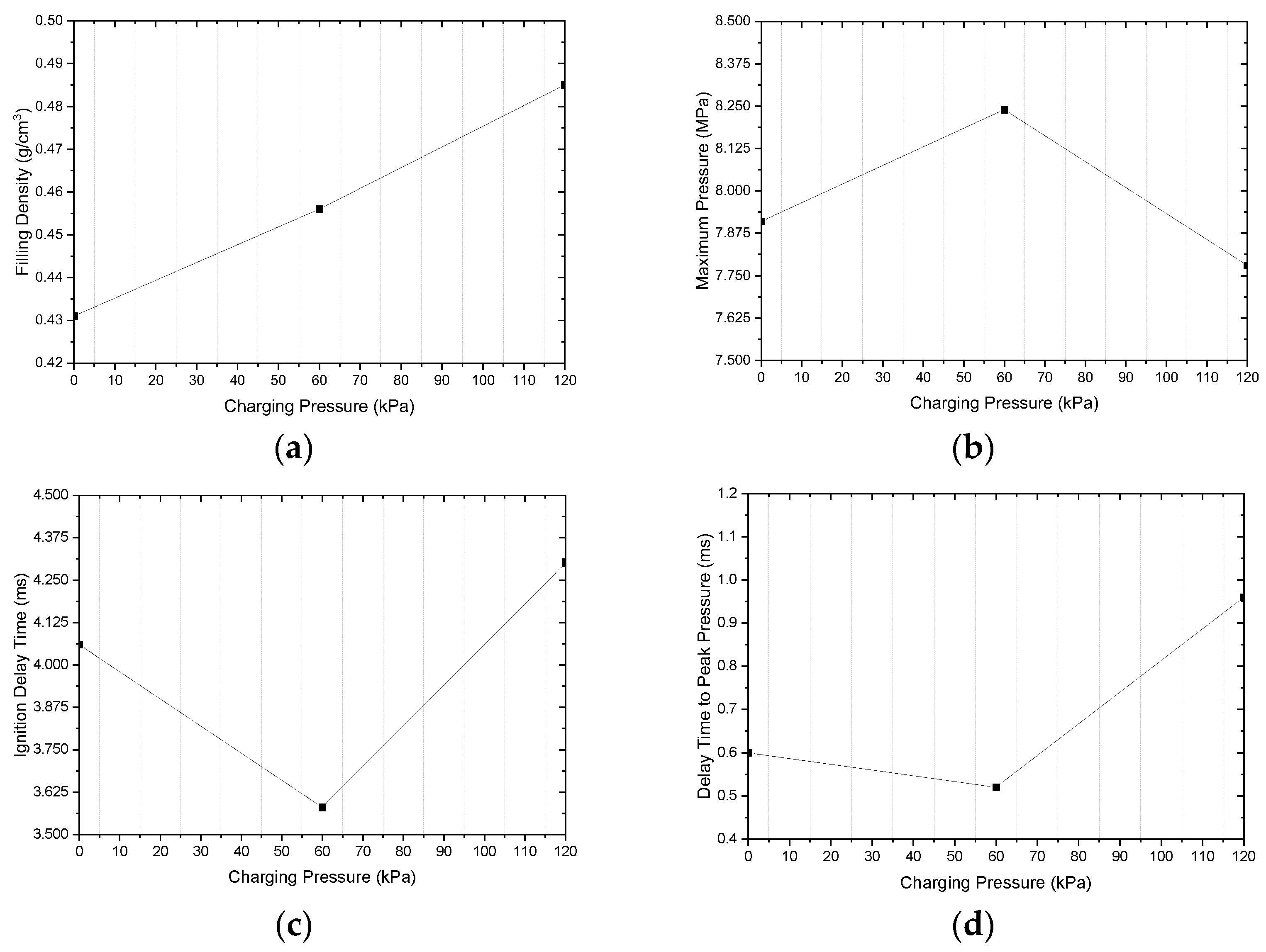

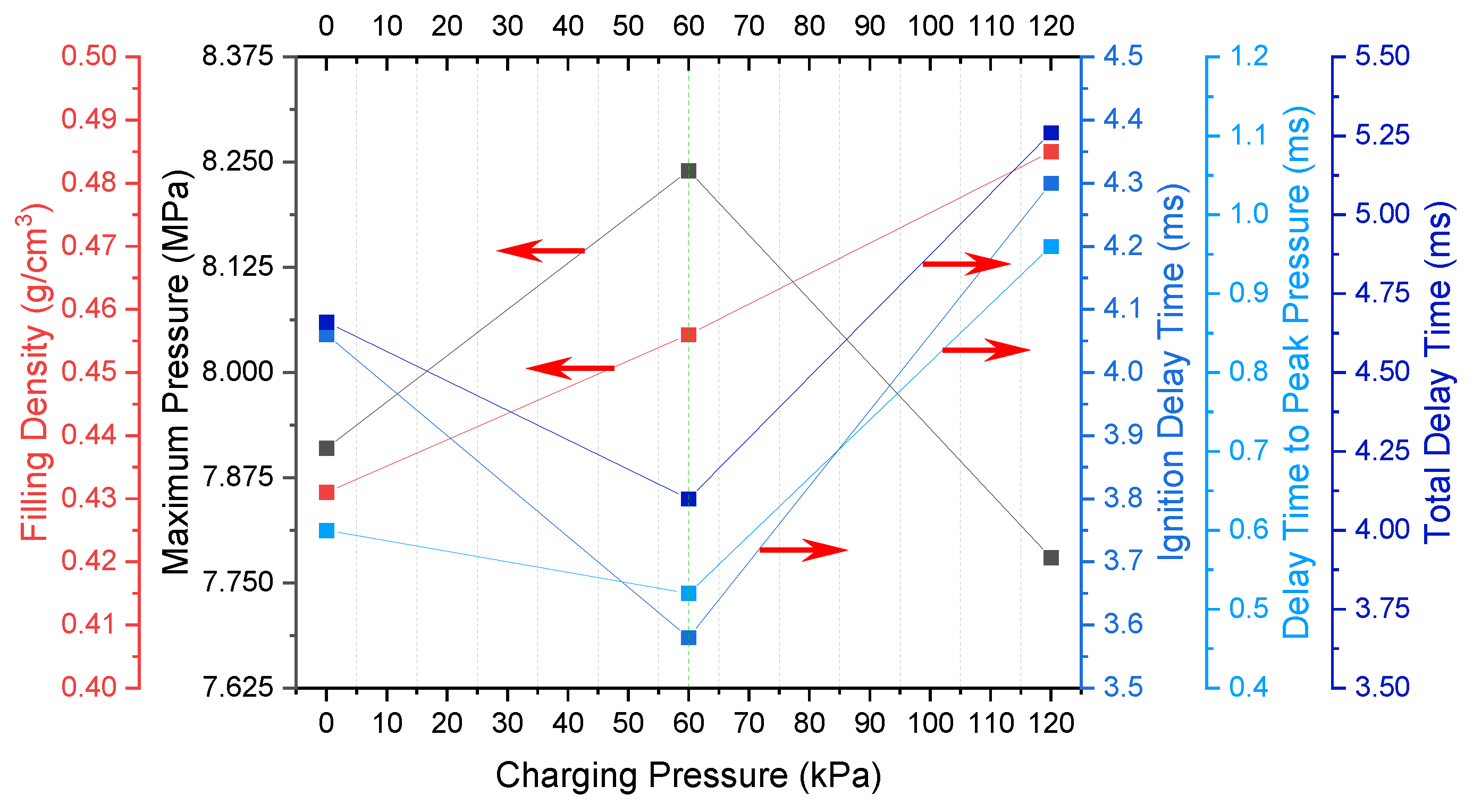

The efficiency of aluminum thermite reactions is impacted by the choice of the ignition system, wherein parameters such as ignition delay time, delay time to peak pressure, peak pressure, and decay after peak pressure influence reactivity and efficiency [

103]. Indeed, different ignition systems manifest different performance implications in aluminum thermite reactions, resulting in certain thermites generating elevated pressure and shorter burning time in comparison to others, implying varying reactivity levels [

59], while others exhibit a lower peak pressure, indicative of a higher reactivity [

103,

104].

The choice of ignition system in aluminum thermite reactions can include impact ignition, electric-spark initiation, and thermal trigger methods [

103,

105]. Impact ignition involves examining pressure build-up and decay in thermites upon ignition, which influences reactivity based on the holistic pressure history [

103]. Electric-spark initiation has been studied in thermite mixtures based on nano-sized powders of aluminum and copper oxide, providing insights into the effect of the electric spark discharge energy on the ignition delay [

105]. The hot bridge-wire, on the other hand, is classified as a thermal trigger method rather than an impact ignition method. This classification is based on the mechanism by which the detonator functions, involving the rapid heating and vaporization of the wire to create a shock wave and thermal energy that initiates the reaction, making it a thermal trigger method [

106,

107]. The type of hot bridge-wire that functions with specific current and resistance values is typically designed for applications where precise resistance values are crucial. This specific configuration allows the bridge-wire to handle a specific current while maintaining the corresponding resistance, ensuring reliable and consistent performance in systems requiring controlled resistance levels [

106,

107].

This initiation method must demonstrate a high degree of reliability and speed, providing a significant amount of energy for efficient ignition and combustion, along with safety and simplicity of use [

106,

107]. In contrast with bridge-wire ignition [

108], laser systems require more precise alignment and control. They may also produce stray electromagnetic radiation that can interfere with other equipment. Additionally, they may require more maintenance and calibration. However, it is important to note that laser ignition systems have their own advantages, such as the ability to ignite materials in a non-contact manner and the ability to precisely control the ignition energy. The choice of ignition method will depend on the specific requirements of the application.

When selecting an ignition system for aluminum thermite reactions, key factors to consider include the particle size of aluminum, the species of oxidants, and the mass content of additives [

58,

104,

109]. The particle size has been identified as a key factor affecting the reaction activity of thermites, with nano-sized particles exhibiting lower critical reaction temperatures and higher reaction activity compared to their micro-sized counterparts [

58].

1.7. Controversial and Diverging Hypotheses

Some findings challenge some of the traditional assumptions about nano-thermite reactions and suggest the need for further investigation into the complex behavior of these energetic materials. The controversial hypotheses on nano-thermite ignition and combustion revolve around the reaction process, ignition delay time, temperature, peak pressure, oxygen providers, and the nature of the nano-thermite reactions.

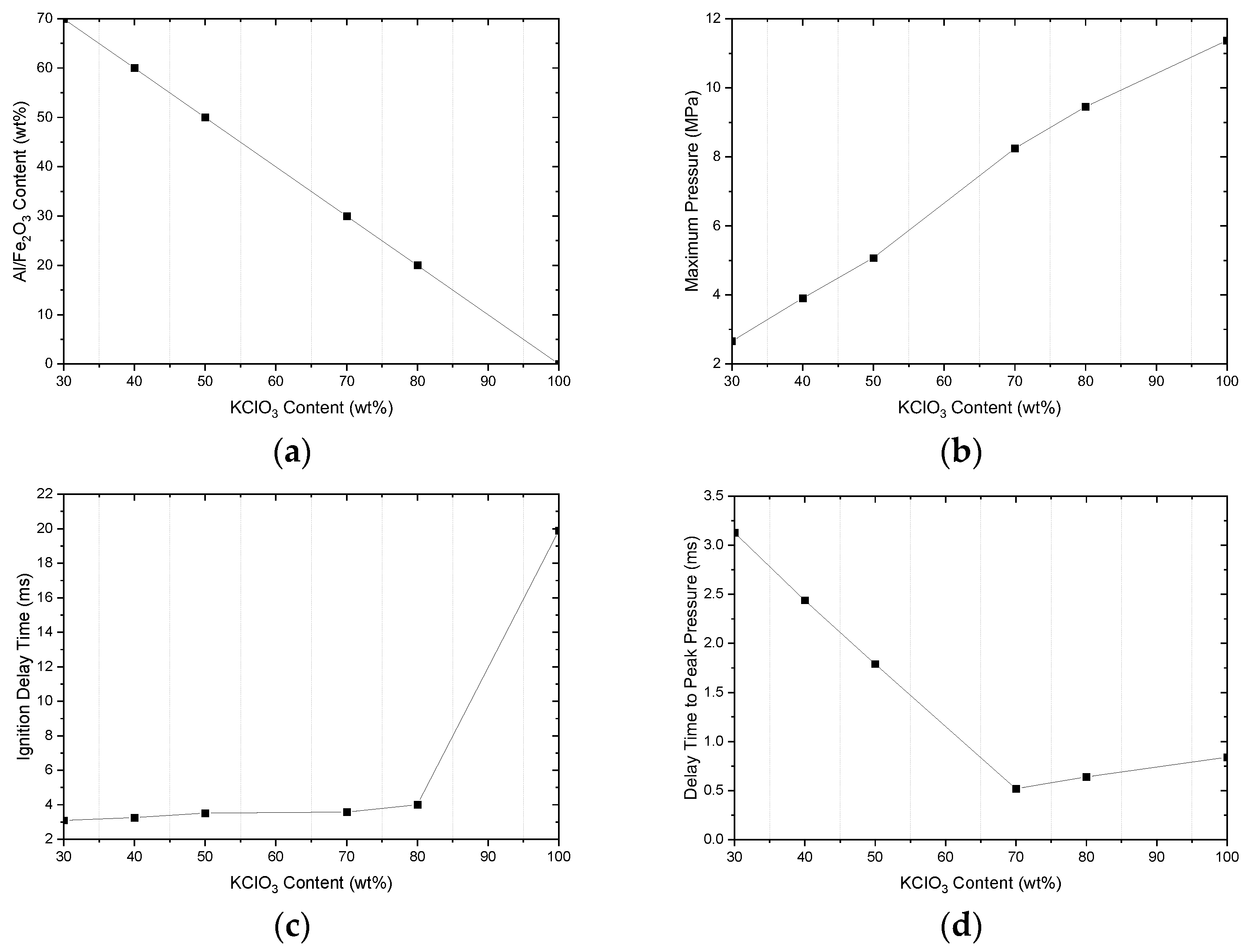

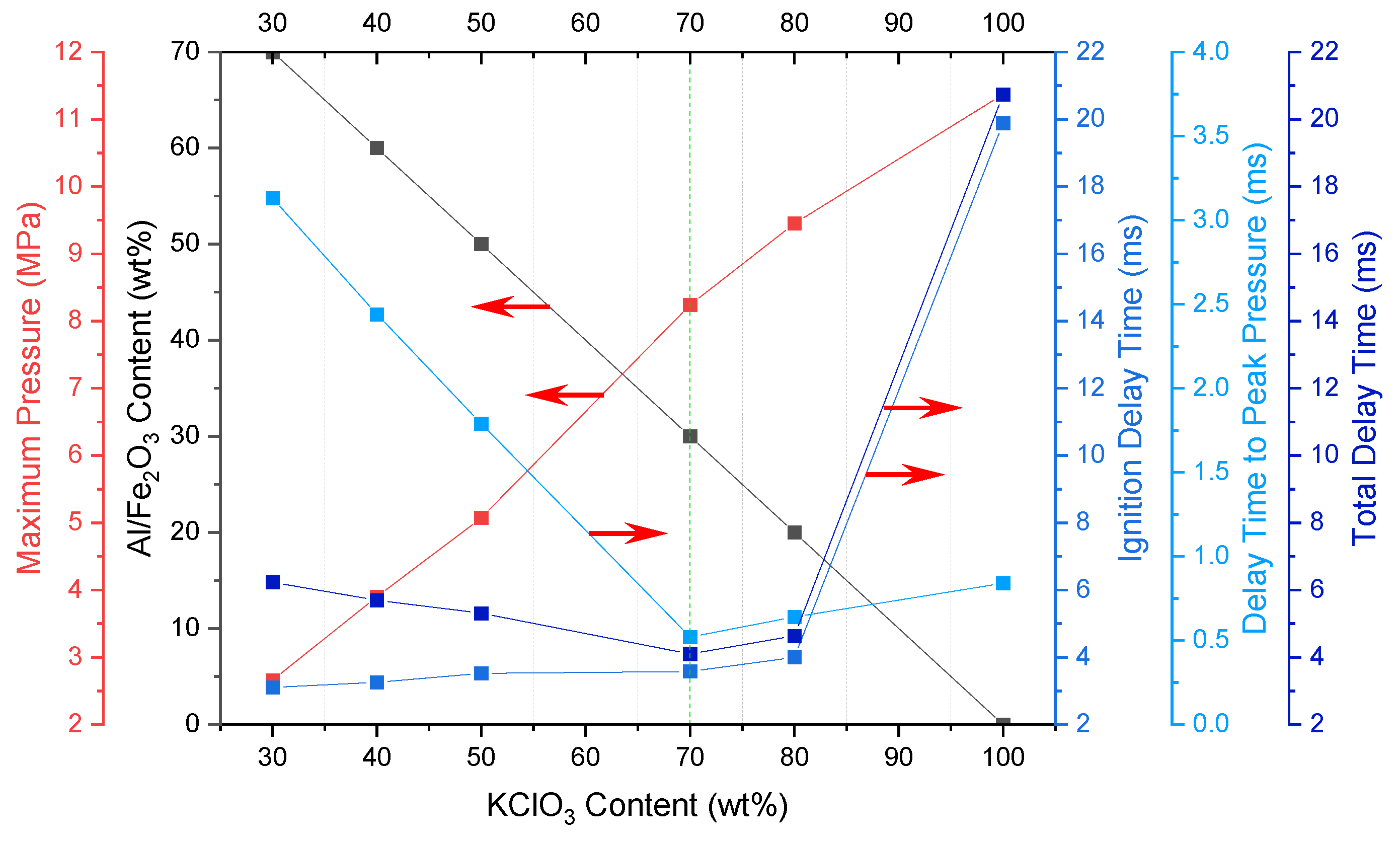

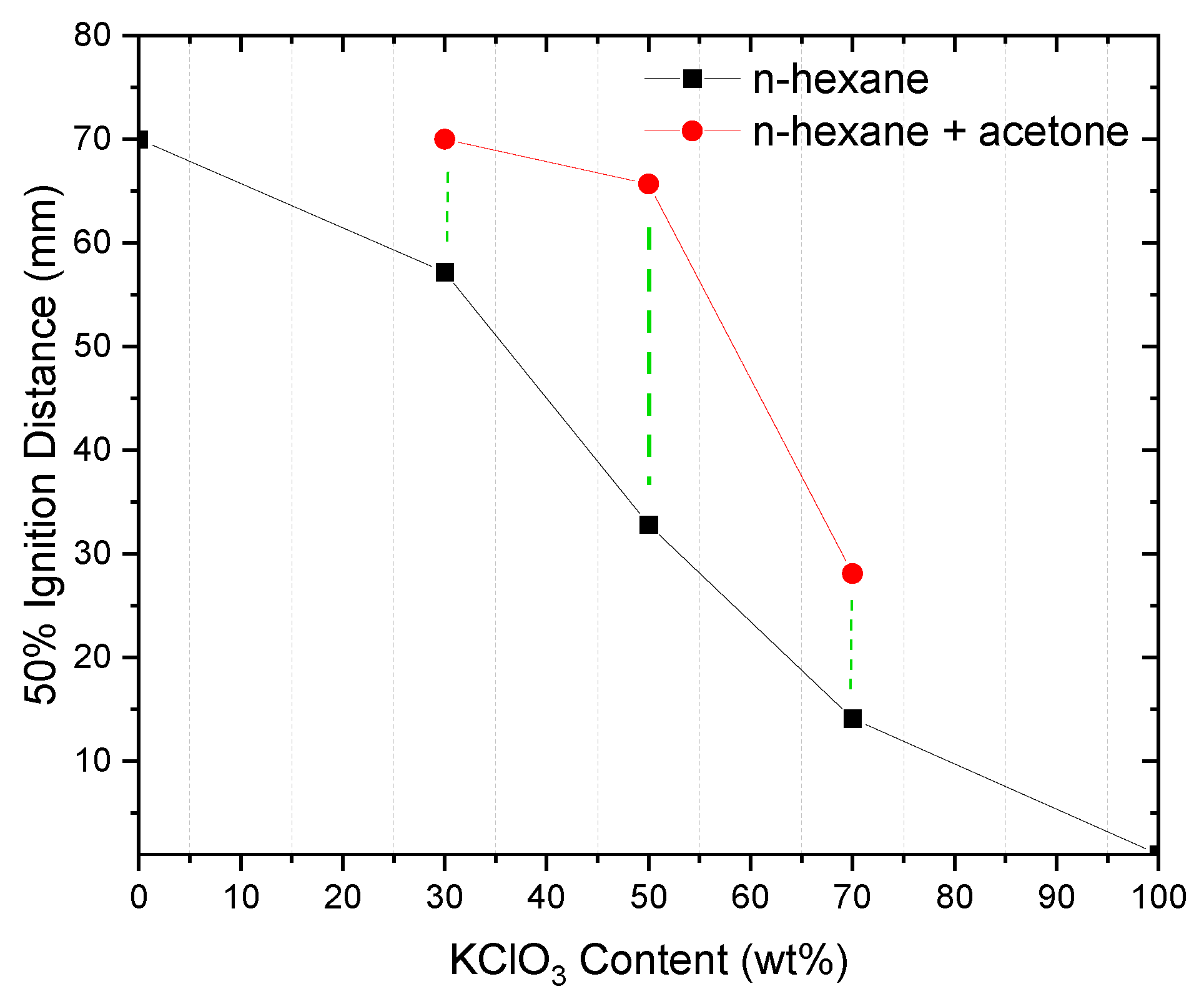

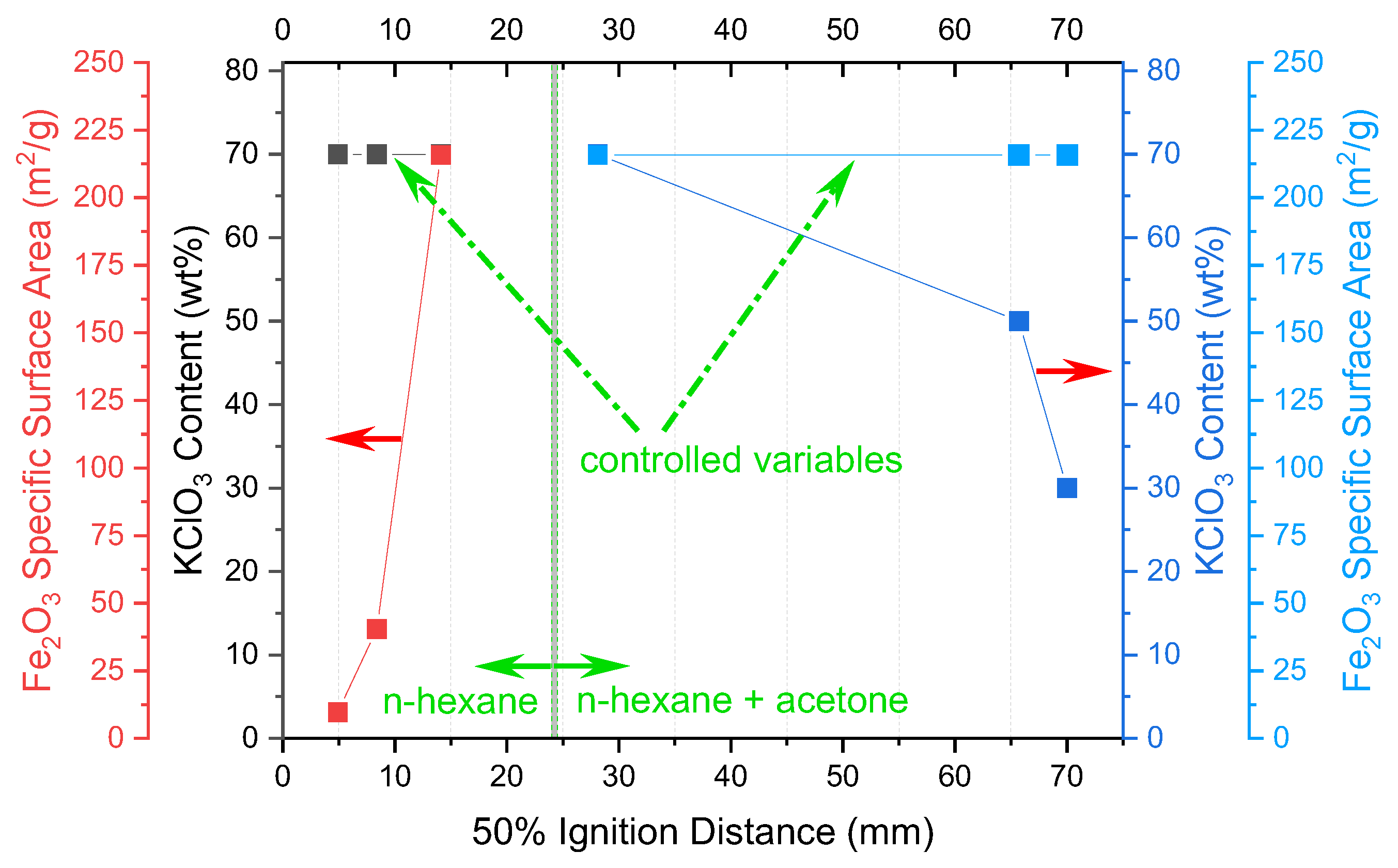

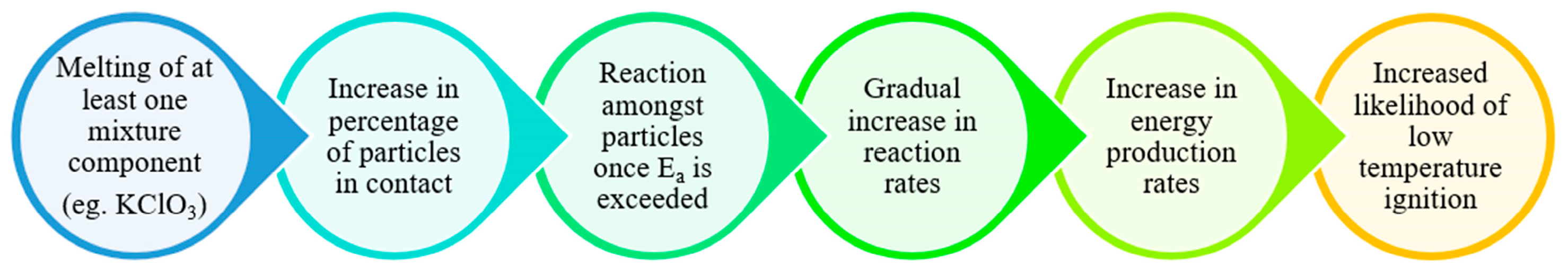

For instance, it is deemed true that the addition of KClO3 results in lower activation energy and lower ignition delay times and temperatures. However, in some cases, it is more likely to observe an increase instead of a decrease in activation energy and ignition delay times and temperatures.

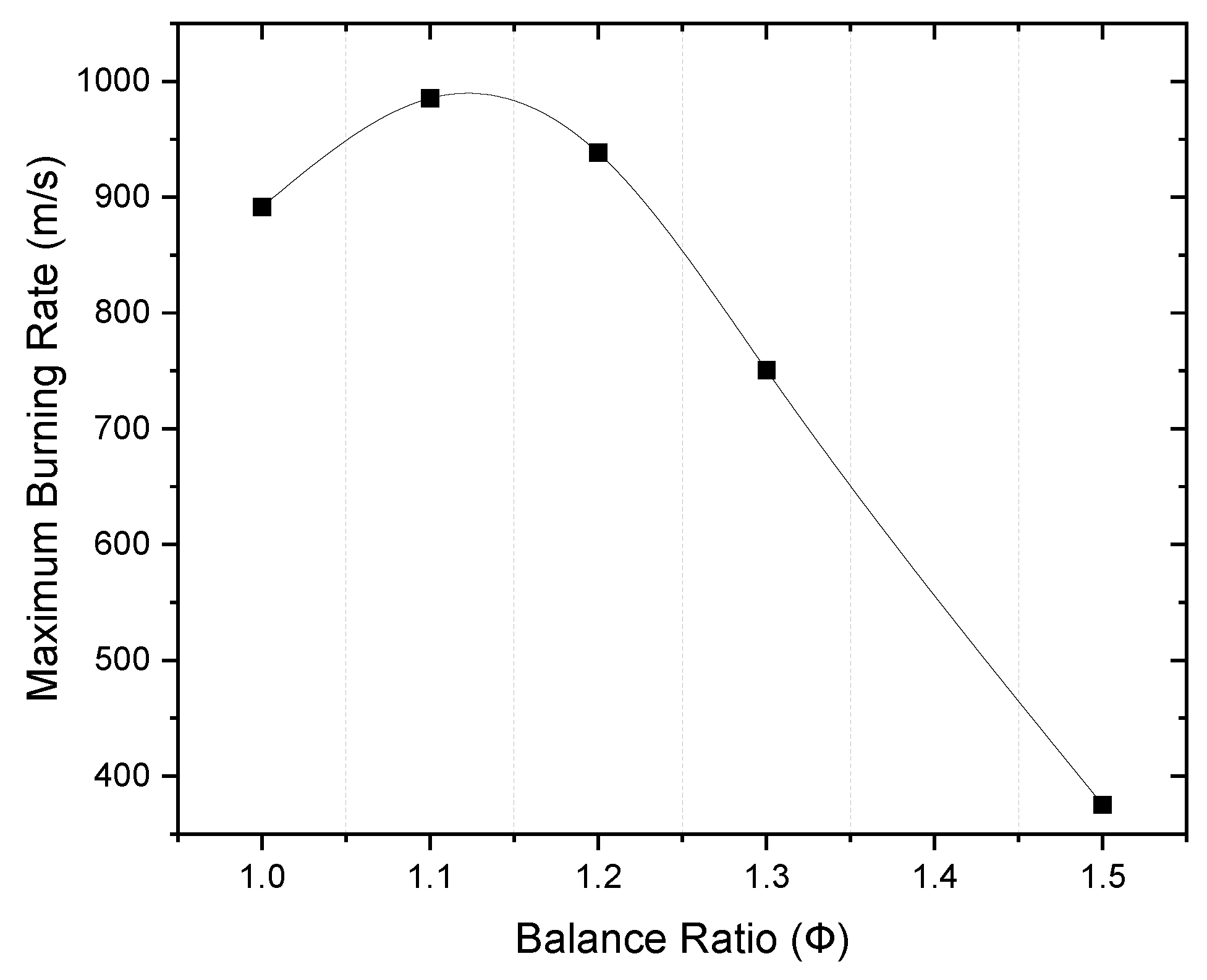

In other instances, it is assumed that there is a direct and proportional relationship between the charging pressure and peak pressure. But once again, in some other cases, it was shown that the relationship is not always directly proportional but rather represented by a local maximum at which the ignition efficiency and combustion performance are at their maximum.

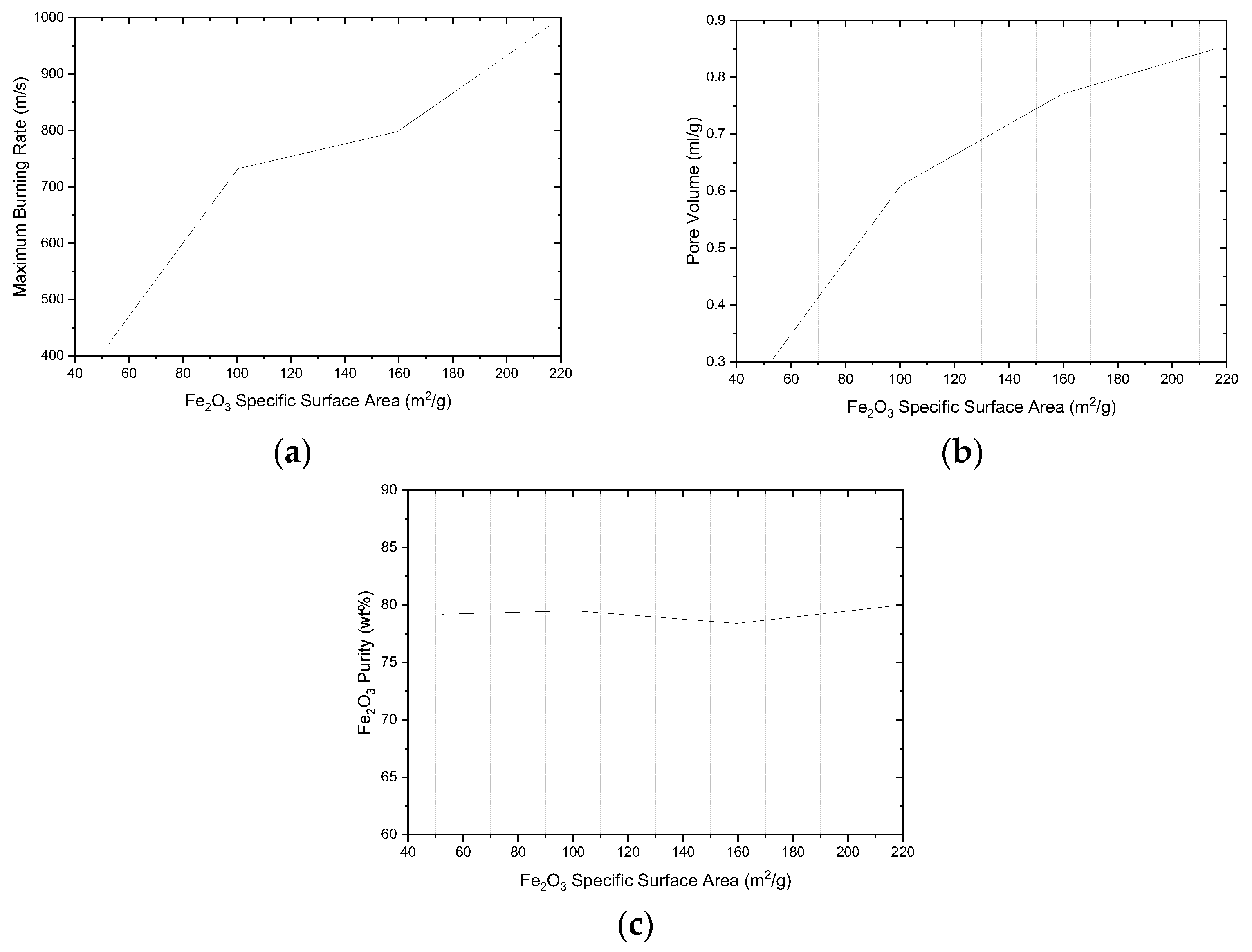

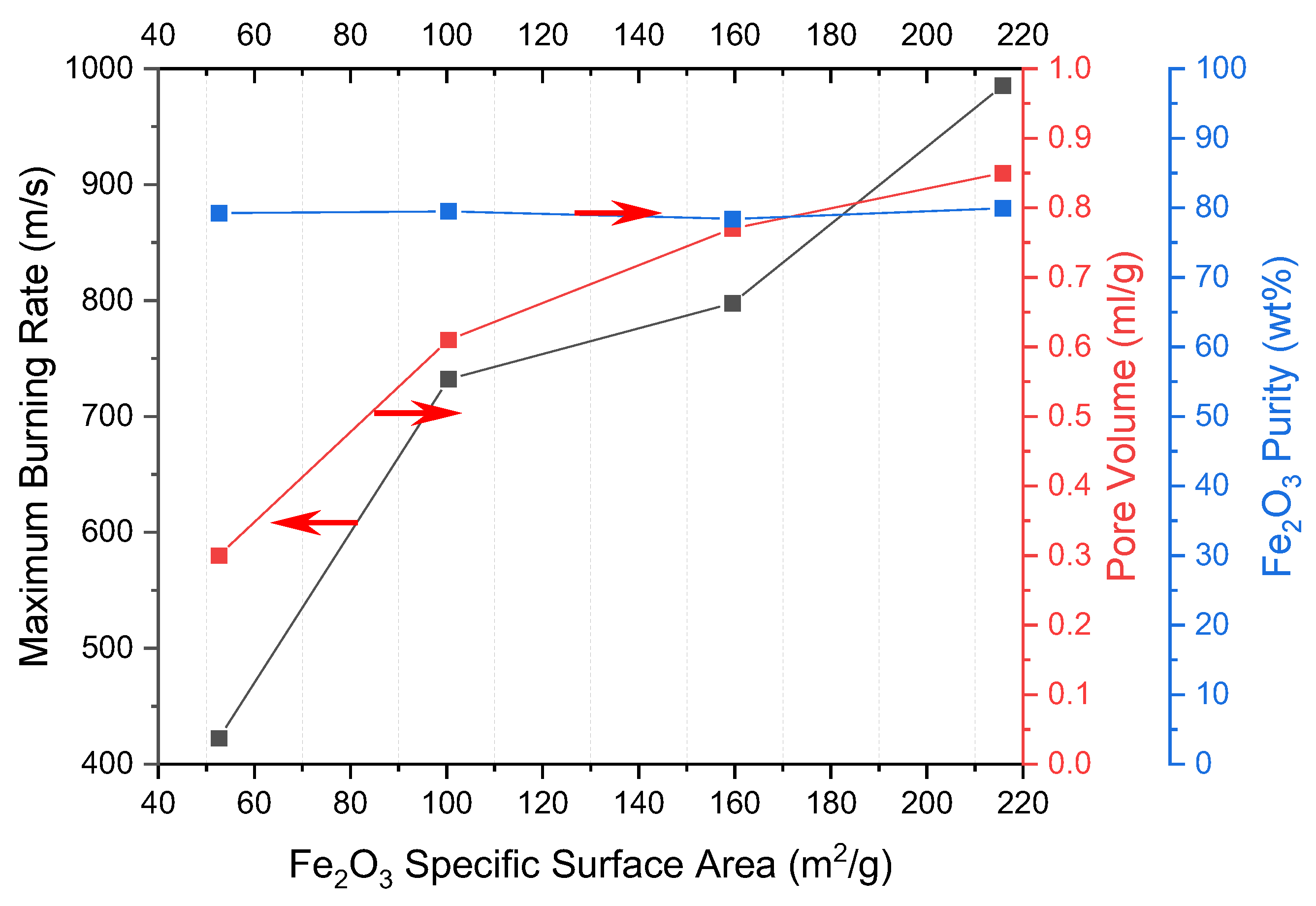

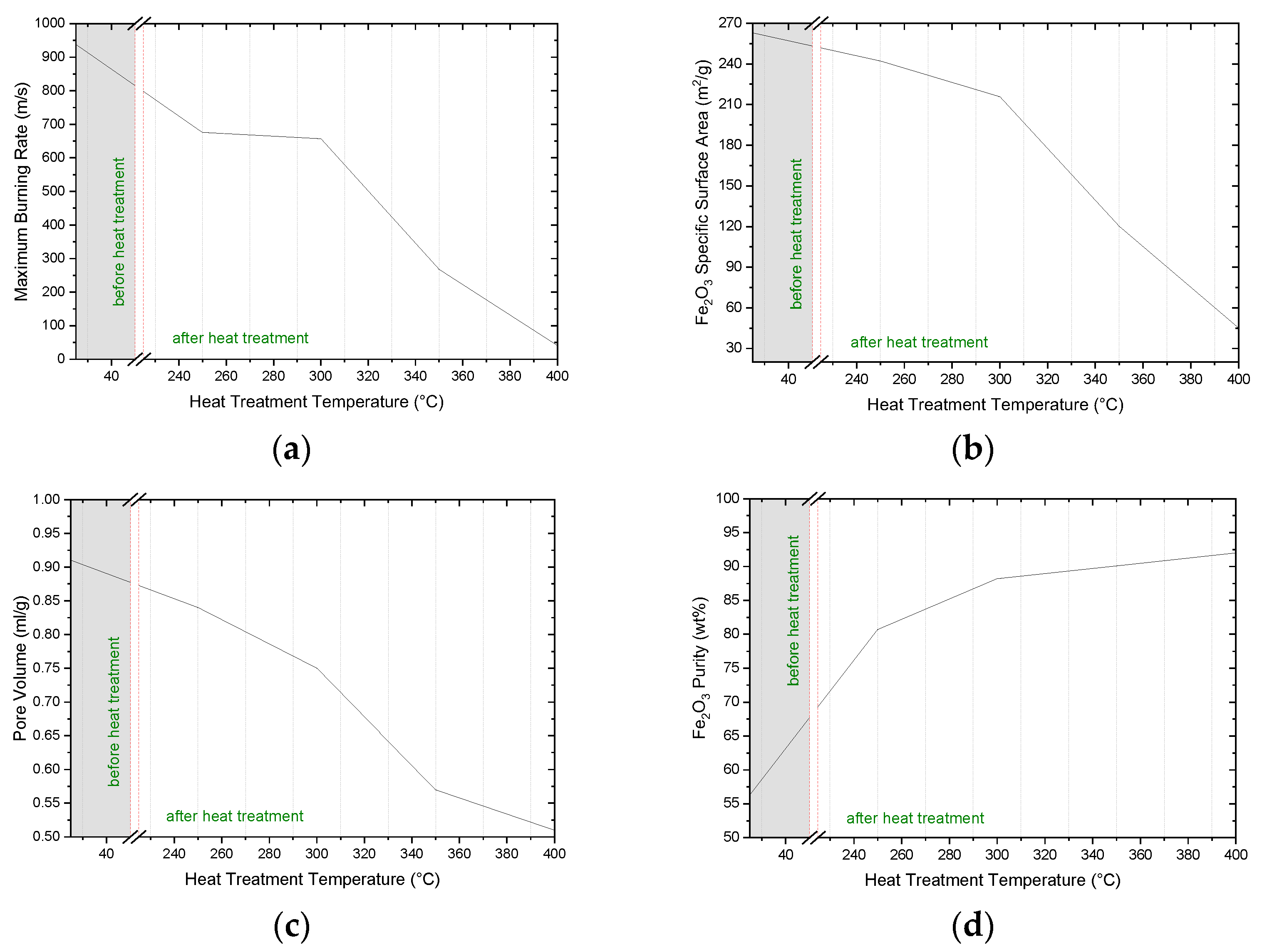

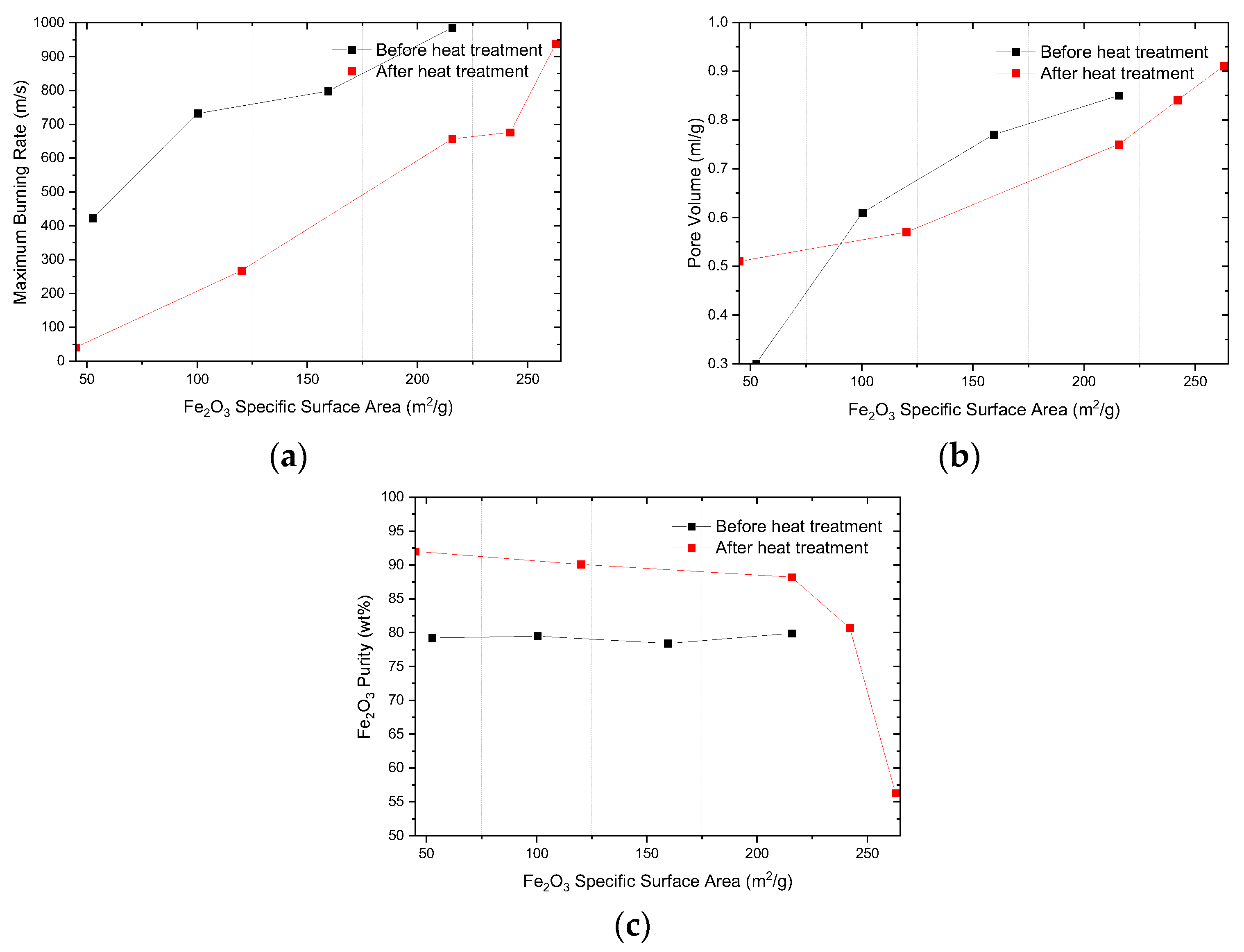

Also, the relationship between the maximum burning rate and purity was believed to be straightforward but appeared to be contrary to the expected trend, and higher purity does not always result in faster burning rates.

In another example, the optimum equivalence ratio was believed to be constant regardless of the oxidizer and based only on the chemistry involved with the reaction. However, the optimum equivalence ratio varies for each oxidizer synthesis technique. These variations may be attributed to the impurities present in the oxidizer.

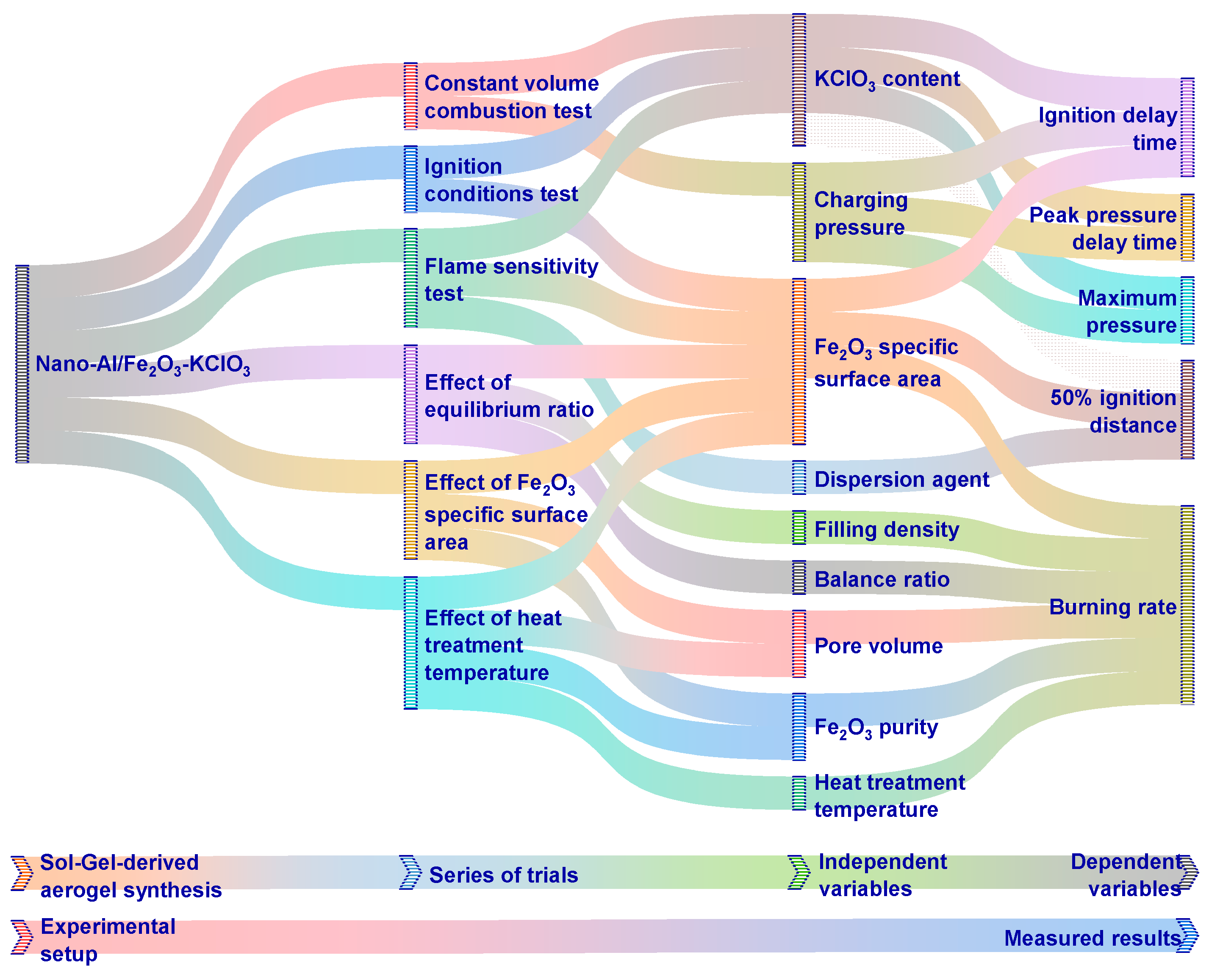

In our research, a systematic and thorough approach is adopted to address each of the aforementioned key challenges and controversial and diverging hypotheses. The relevant factors are described in well-defined steps and carefully examined, and the data is analyzed in a methodical fashion. This step-by-step process provides comprehensive and well-supported conclusions.