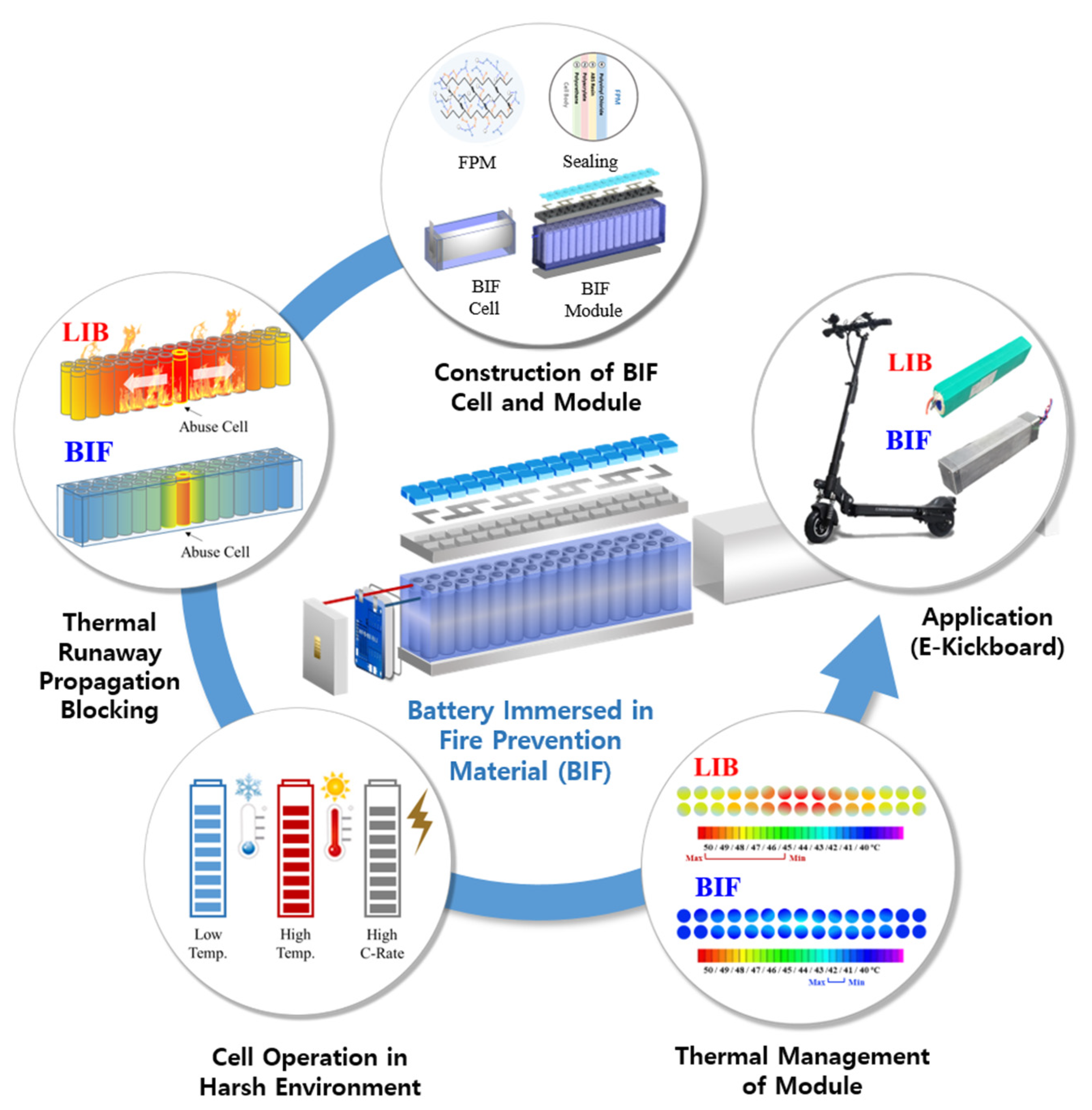

Lithium-Ion Batteries (LIBs) Immersed in Fire Prevention Material for Fire Safety and Heat Management

Abstract

1. Introduction

2. Materials and Methods

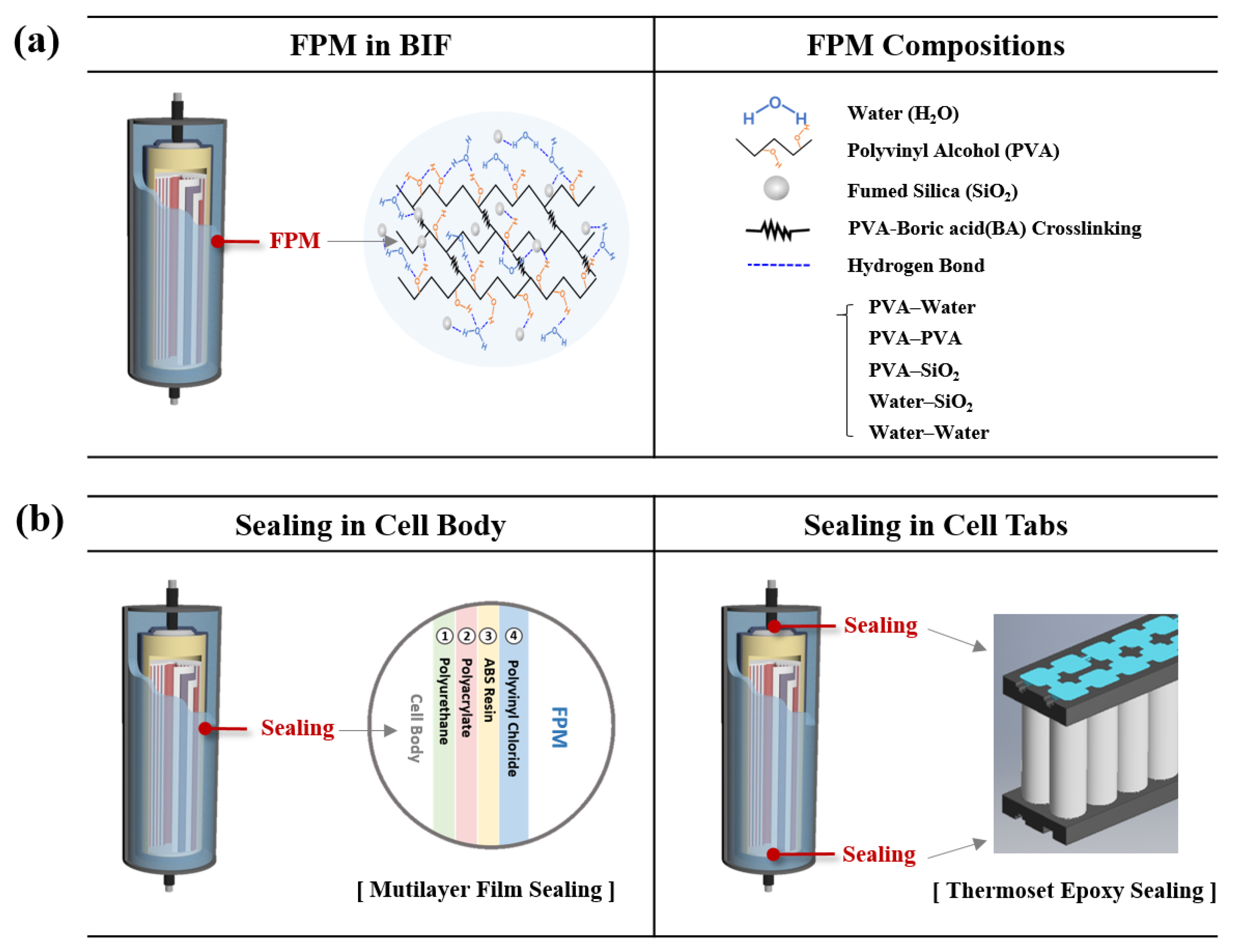

2.1. Components of the BIF

2.1.1. Lithium-Ion Battery (LIB) Cell

2.1.2. Fire Prevention Material (FPM)

2.1.3. Sealing

2.1.4. The Else Components

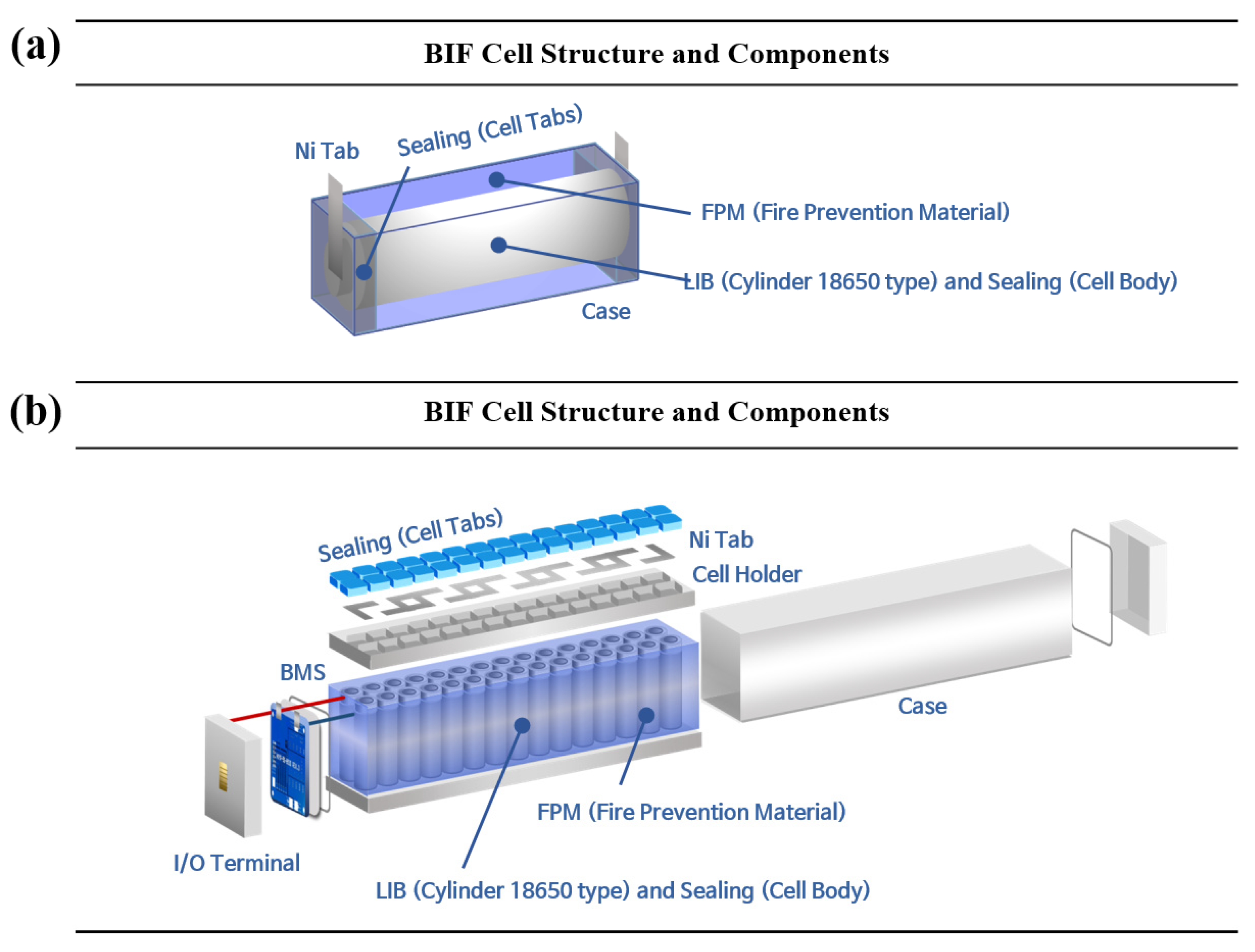

2.2. BIF Cell and Module

2.3. Experiment Conditions

2.3.1. Thermal Management

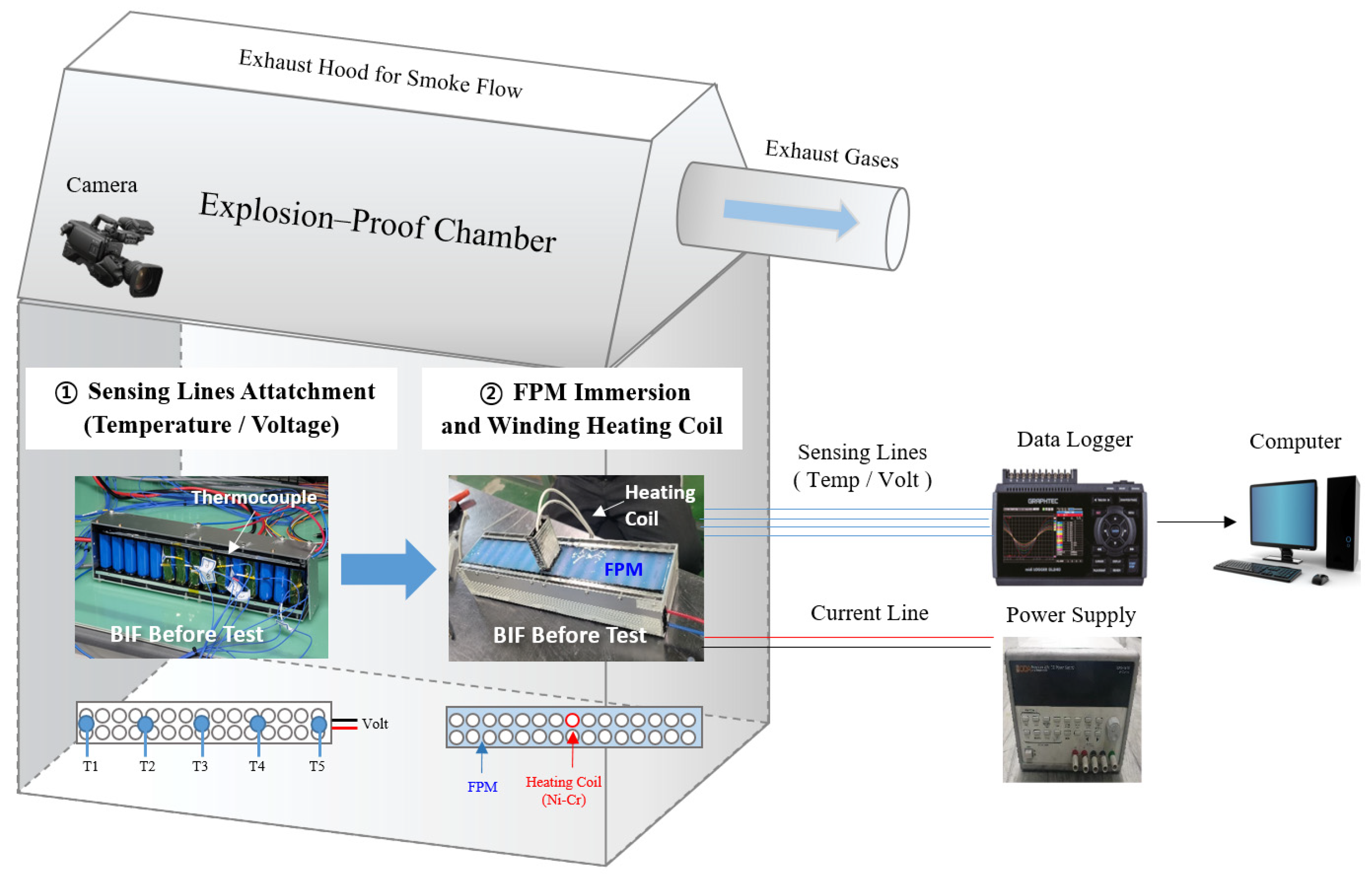

2.3.2. Thermal Runaway Propagation

3. Results and Discussion

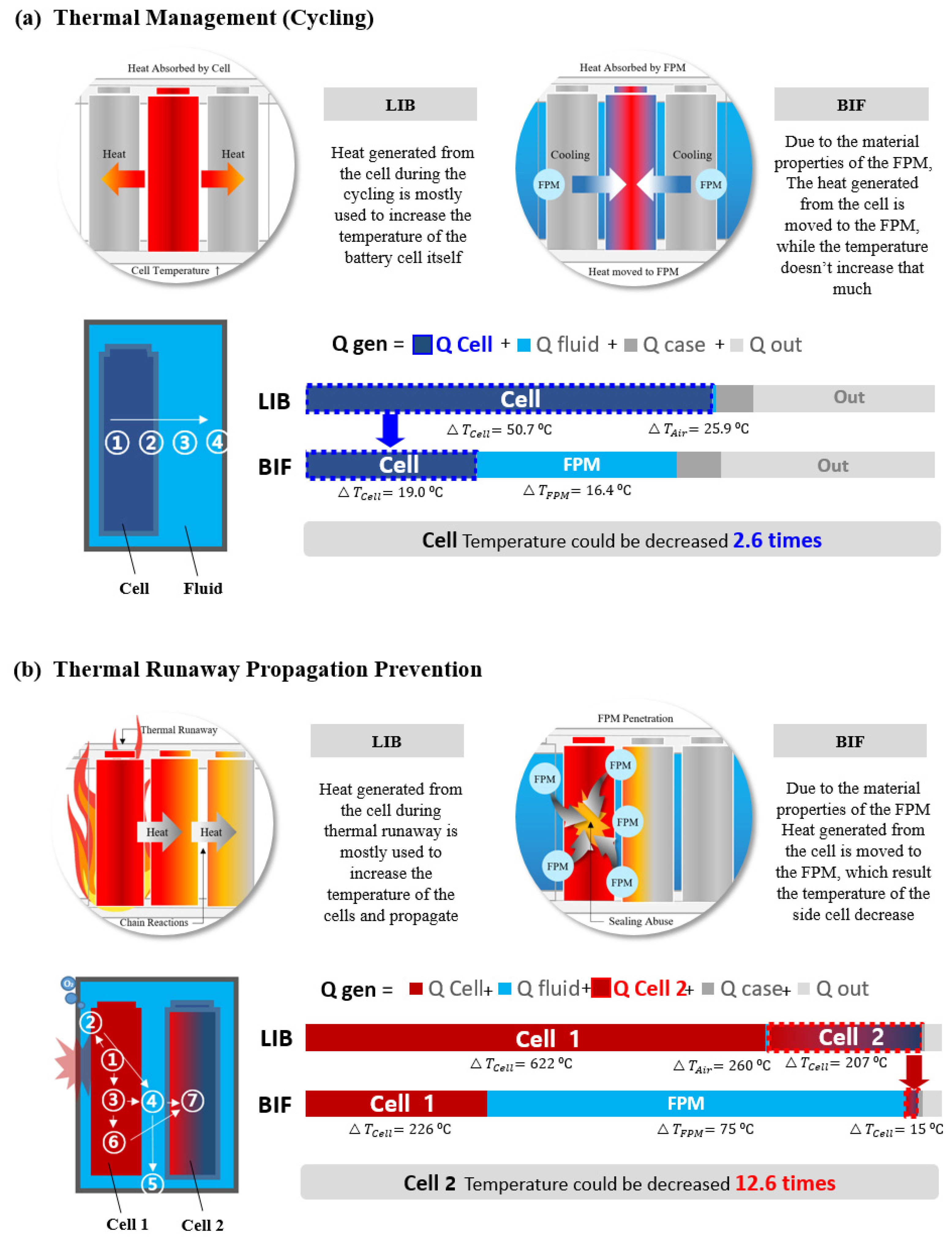

3.1. Mechanism and Heat Transmission Diagram with the Governing Equations

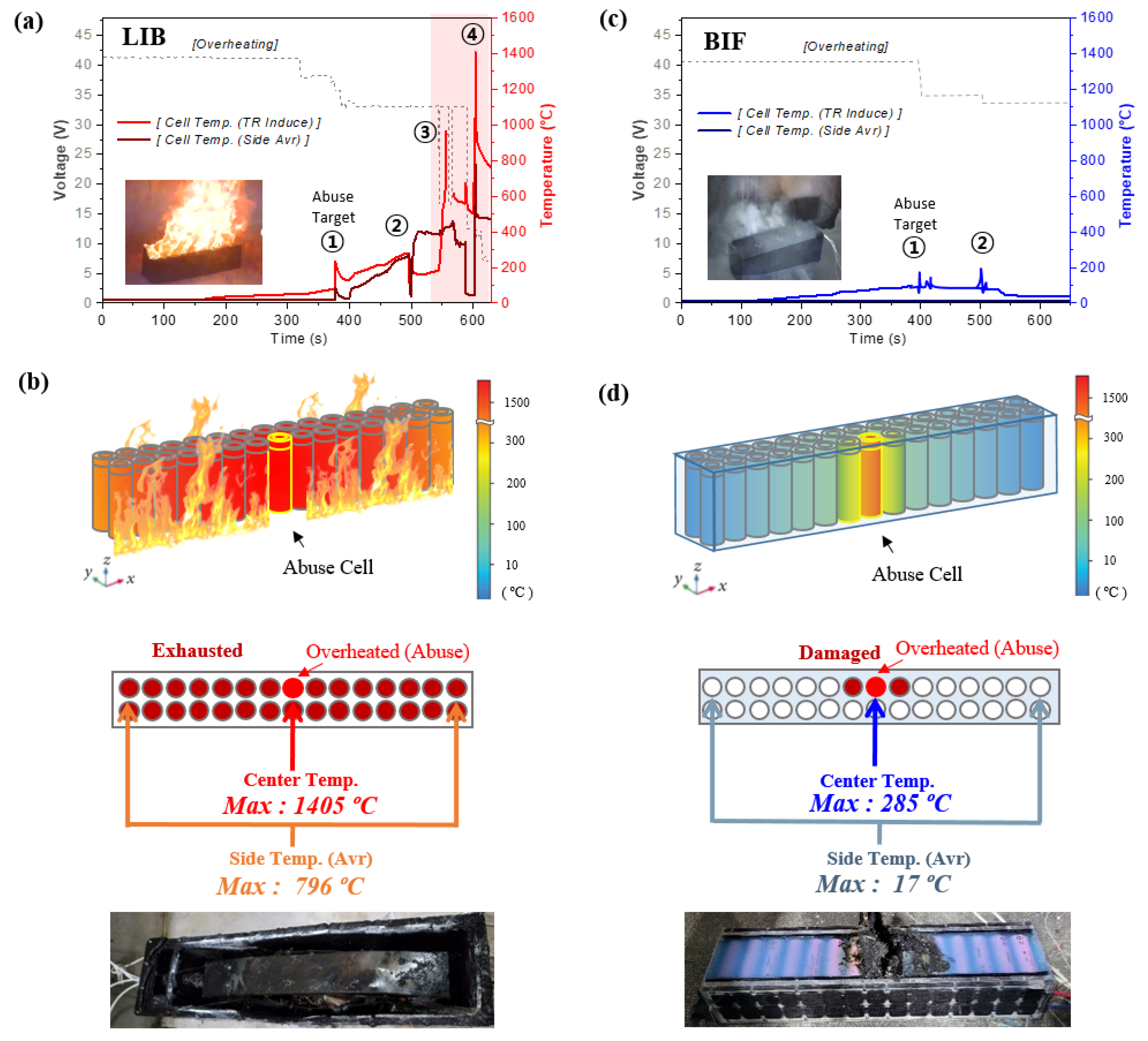

3.2. Thermal Runaway Propagation Test

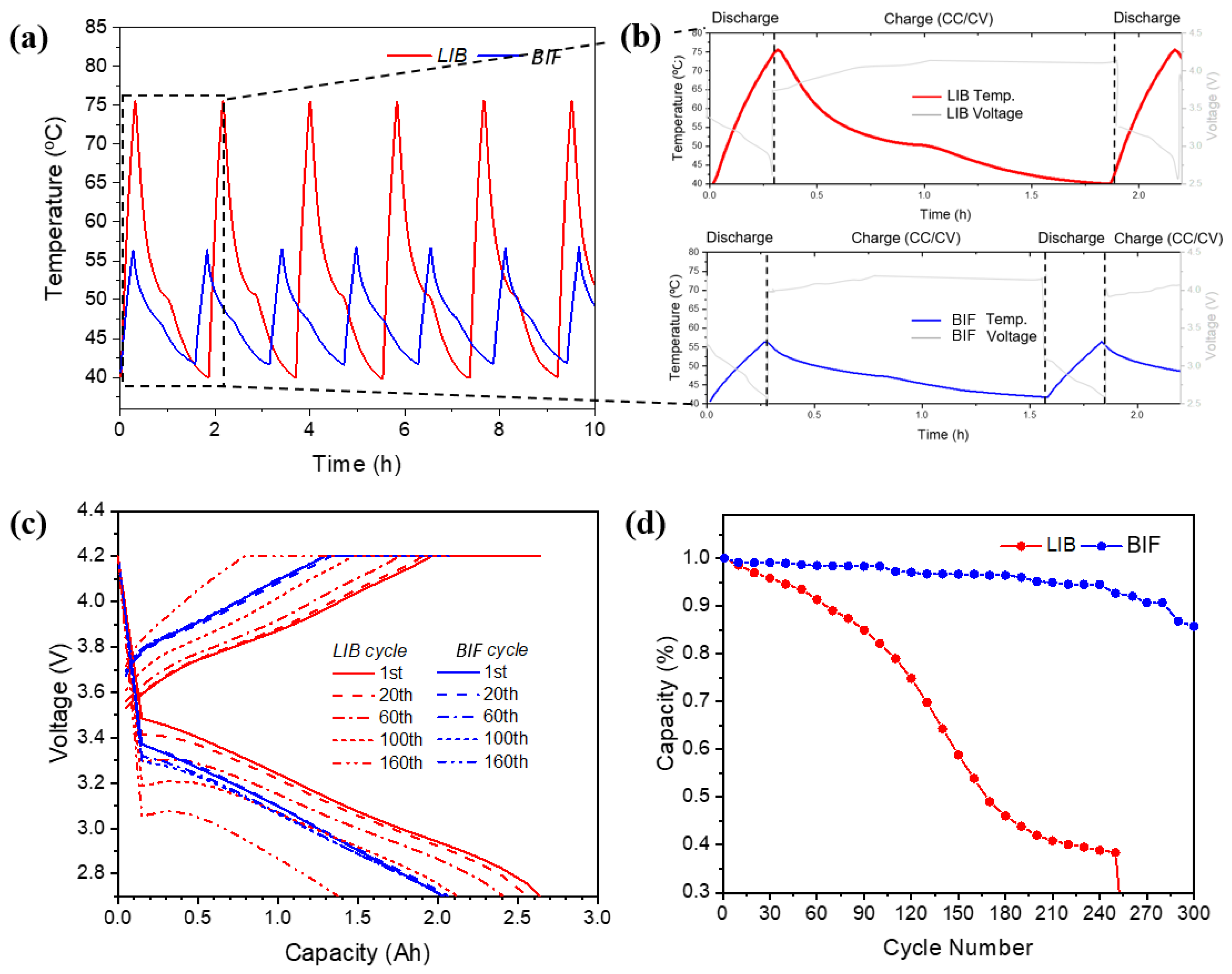

3.3. Heat Management Efficiency during the Operation

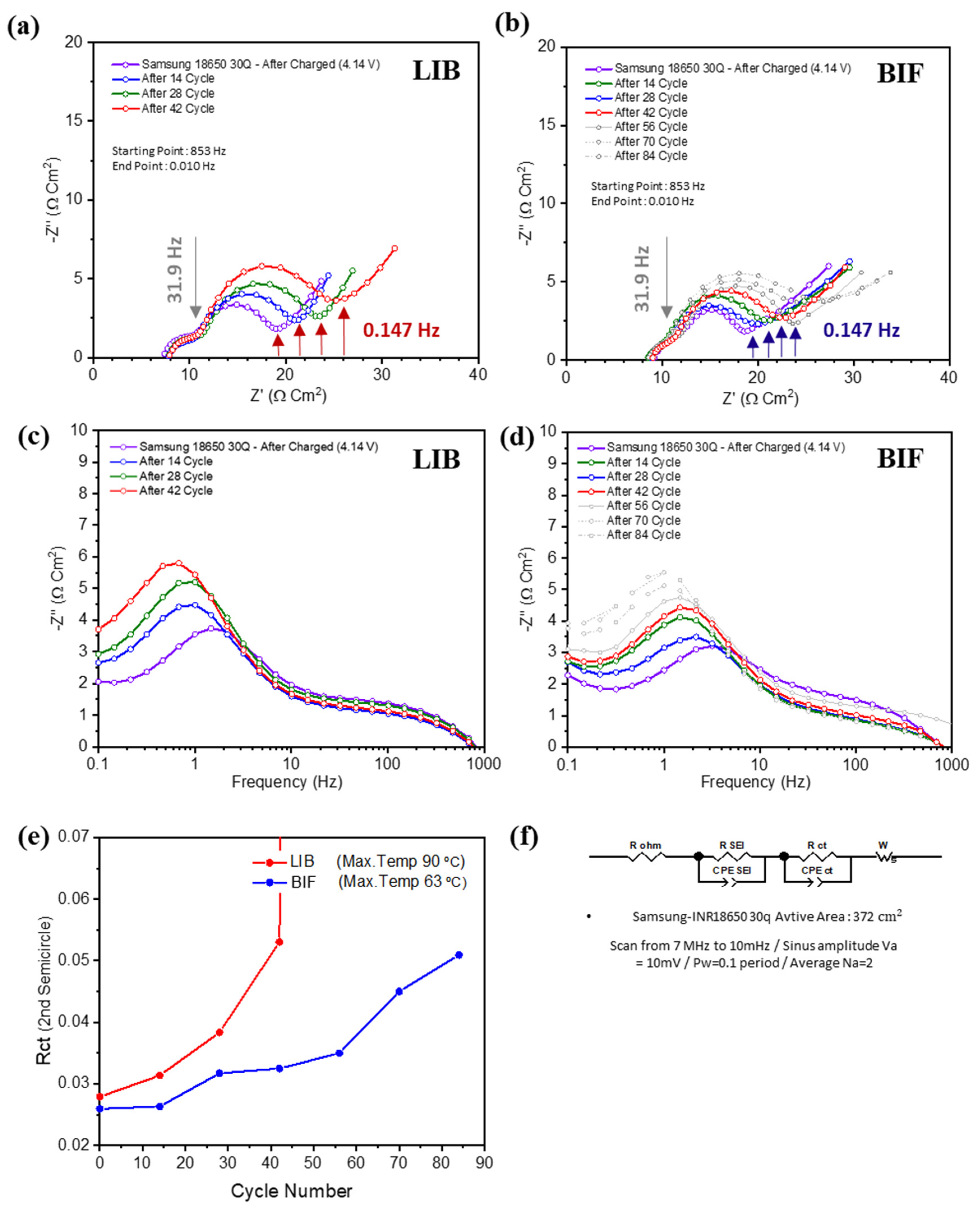

3.4. Electrochemical Impedance Spectroscopy (EIS) Comparison

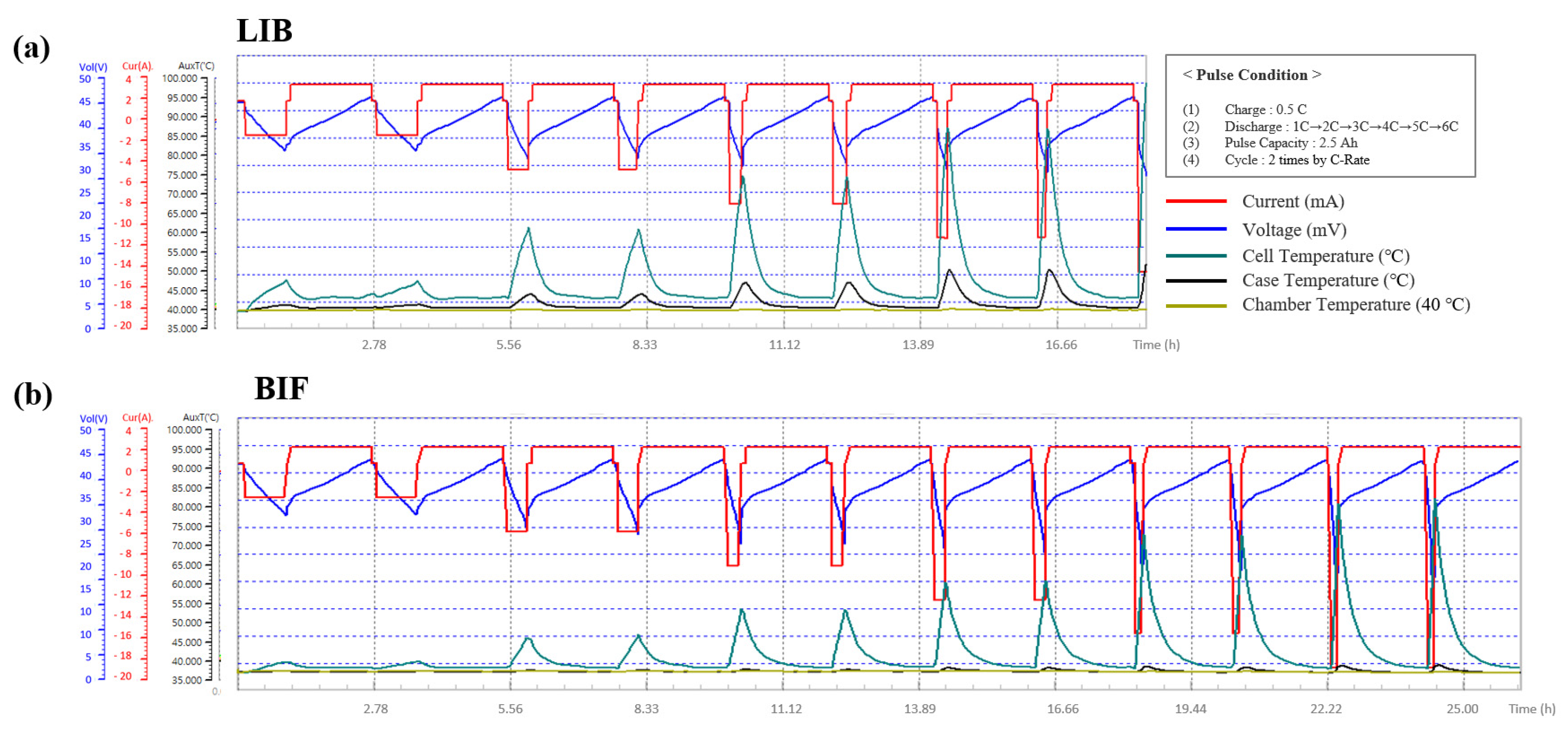

3.5. High Current Performance Comparison Using Pulse Test

3.6. Module Temperature by Spots

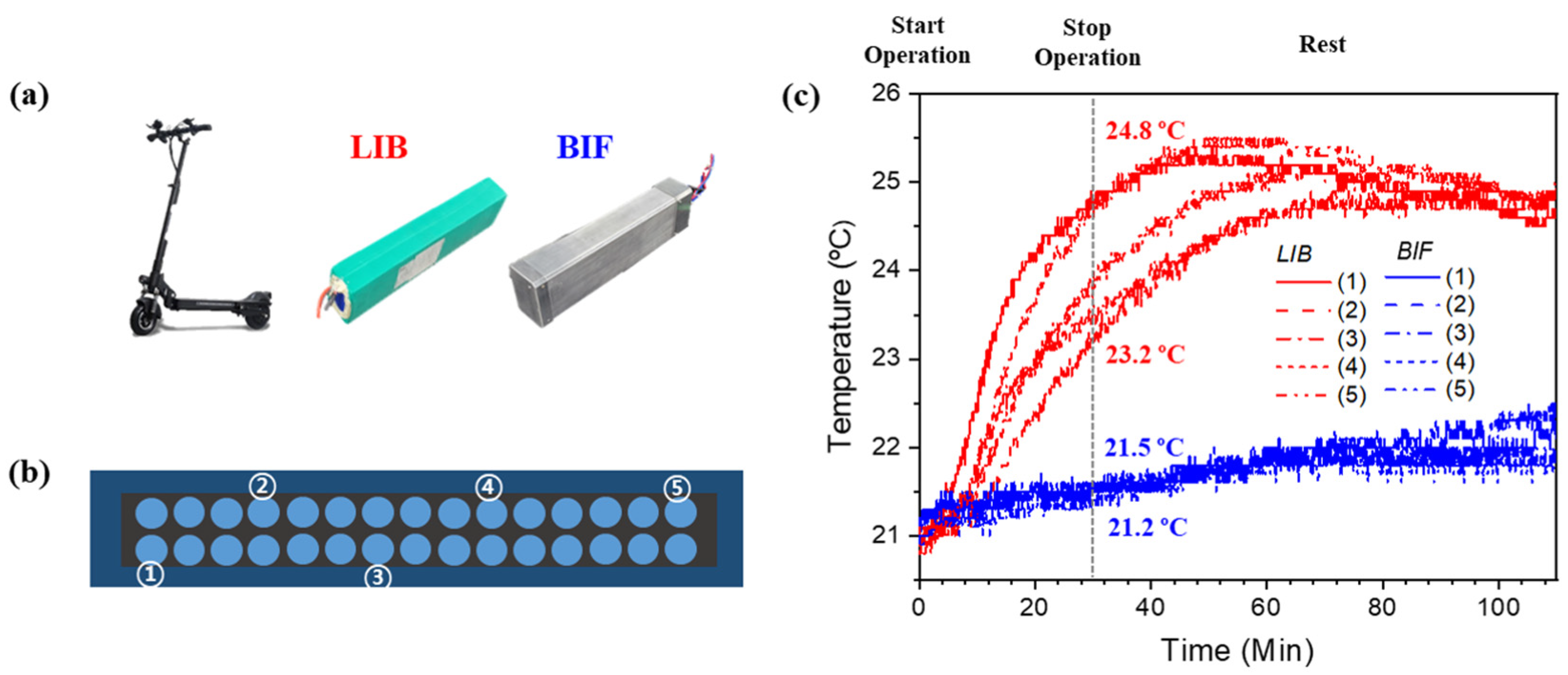

3.7. Module in Application (Kickboard)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hameer, S.; van Niekerk, J.L. A review of large-scale electrical energy storage. Int. J. Energy Res. 2015, 39, 1179–1195. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Z.; Hu, L.; Bai, M.; Gao, L.; Li, Y.; Liu, X.; Li, Y.; Song, Y. Experimental studies of liquid immersion cooling for 18650 lithium-ion battery under different discharging conditions. Case Stud. Therm. Eng. 2022, 34, 102034. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128. [Google Scholar] [CrossRef]

- Feng, X.; Ren, D.; He, X.; Ouyang, M. Mitigating thermal runaway of lithium-ion batteries. Joule 2020, 4, 743–770. [Google Scholar] [CrossRef]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Yuan, S.; Chang, C.; Yan, S.; Zhou, P.; Qian, X.; Yuan, M.; Liu, K. A review of fire-extinguishing agent on suppressing lithium-ion batteries fire. J. Energy Chem. 2021, 62, 262–280. [Google Scholar] [CrossRef]

- Diaz, L.B.; He, X.; Hu, Z.; Restuccia, F.; Marinescu, M.; Barreras, J.V.; Patel, V.; Offer, G.; Rein, G. Meta-review of fire safety of lithium-ion batteries: Industry challenges and research contributions. J. Electrochem. Soc. 2020, 167, 090559. [Google Scholar] [CrossRef]

- Wang, Q.; Shao, G.; Duan, Q.; Chen, M.; Li, Y.; Wu, K.; Liu, B.; Peng, P.; Sun, J. The efficiency of heptafluoropropane fire extinguishing agent on suppressing the lithium titanate battery fire. Fire Technol. 2016, 52, 387–396. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Duan, Q.; Chen, M.; Xu, J.; Zhao, C.; Sun, J.; Wang, Q. Experimental study on the synergistic effect of gas extinguishing agents and water mist on suppressing lithium-ion battery fires. J. Energy Storage 2020, 32, 101801. [Google Scholar] [CrossRef]

- Xu, J.; Guo, P.; Duan, Q.; Yu, X.; Zhang, L.; Liu, Y.; Wang, Q. Experimental study of the effectiveness of three kinds of extinguishing agents on suppressing lithium-ion battery fires. Appl. Therm. Eng. 2020, 171, 115076. [Google Scholar] [CrossRef]

- Yang, X.; Duan, Y.; Zhang, Z.; Feng, X.; Chen, T.; Xu, C.; Rui, X.; Ouyang, M.; Lu, L.; Han, X.; et al. An experimental study on preventing thermal runaway propagation in lithium-ion battery module using aerogel and liquid cooling plate together. Fire Technol. 2020, 56, 2579–2602. [Google Scholar] [CrossRef]

- Liu, Y.; Duan, Q.; Li, K.; Chen, H.; Wang, Q. Experimental study on fire extinguishing of large-capacity lithium-ion batteries by various fire extinguishing agents. Energy Storage Sci. Technol. 2018, 7, 1105. [Google Scholar]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. eTransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Zhang, L.; Jin, K.; Sun, J.; Wang, Q. A Review of Fire-Extinguishing Agents and Fire Suppression Strategies for Lithium-Ion Batteries Fire. Fire Technol. 2022, 1–42. [Google Scholar] [CrossRef]

- Said, A.O.; Stoliarov, S.I. Analysis of effectiveness of suppression of lithium ion battery fires with a clean agent. Fire Saf. J. 2021, 121, 103296. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, P.; Duan, Q.; Zhao, C.; Wang, Q. Experimental investigation on the cooling and suppression effects of liquid nitrogen on the thermal runaway of lithium ion battery. J. Power Sources 2021, 495, 229795. [Google Scholar] [CrossRef]

- Kuznetsov, G.; Kopylov, N.; Sushkina, E.; Zhdanova, A. Adaptation of fire-fighting systems to localization of fires in the premises. Energies 2022, 15, 522. [Google Scholar] [CrossRef]

- Xu, B.; Kong, L.; Wen, G.; Pecht, M.G. Protection devices in commercial 18650 lithium-ion batteries. IEEE Access 2021, 9, 66687–66695. [Google Scholar] [CrossRef]

- Sabbah, R.; Kizilel, R.; Selman, J.R.; Al-Hallaj, S. Active (air-cooled) vs. passive (phase change material) thermal management of high power lithium-ion packs: Limitation of temperature rise and uniformity of temperature distribution. J. Power Sources 2008, 182, 630–638. [Google Scholar] [CrossRef]

- Lan, C.; Xu, J.; Qiao, Y.; Ma, Y. Thermal management for high power lithium-ion battery by minichannel aluminum tubes. Appl. Therm. Eng. 2016, 101, 284–292. [Google Scholar] [CrossRef]

- Niu, H.; Chen, C.; Liu, Y.; Li, L.; Li, Z.; Ji, D.; Huang, X. Mitigating thermal runaway propagation of NCM 811 prismatic batteries via hollow glass microspheres plates. Process Saf. Environ. Prot. 2022, 162, 672–683. [Google Scholar] [CrossRef]

- Weng, J.; Ouyang, D.; Yang, X.; Chen, M.; Zhang, G.; Wang, J. Alleviation of thermal runaway propagation in thermal management modules using aerogel felt coupled with flame-retarded phase change material. Energy Conv. Manag. 2019, 200, 112071. [Google Scholar] [CrossRef]

- Li, L.; Xu, C.; Chang, R.; Yang, C.; Jia, C.; Wang, L.; Song, J.; Li, Z.; Zhang, F.; Fang, B.; et al. Thermal-responsive, super-strong, ultrathin firewalls for quenching thermal runaway in high-energy battery modules. Energy Storage Mater. 2021, 40, 329–336. [Google Scholar] [CrossRef]

- Lin, S.; Ling, Z.; Li, S.; Cai, C.; Zhang, Z.; Fang, X. Mitigation of lithium-ion battery thermal runaway and inhibition of thermal runaway propagation using inorganic salt hydrate with integrated latent heat and thermochemical storage. Energy 2023, 266, 126481. [Google Scholar] [CrossRef]

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. LCA 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Bae, J.; Bae, H.; Cho, J.; Jung, J.; Choi, Y.; Kim, Y. Zero fire battery concept: Water-in-battery. J. Mater. Chem. A 2022, 10, 6481–6488. [Google Scholar] [CrossRef]

- Chin, C.S.; Jia, J.; Chiew, J.H.K.; Da Toh, W.; Gao, Z.; Zhang, C.; McCann, J. System design of underwater battery power system for marine and offshore industry. J. Energy Storage 2019, 21, 724–740. [Google Scholar] [CrossRef]

- Hoelle, S.; Scharner, S.; Asanin, S.; Hinrichsen, O. Analysis on thermal runaway behavior of prismatic Lithium-ion batteries with autoclave calorimetry. J. Electrochem. Soc. 2021, 168, 120515. [Google Scholar] [CrossRef]

- Lamb, J.; Torres-Castro, L.; Hewson, J.C.; Shurtz, R.C.; Preger, Y. Investigating the role of energy density in thermal runaway of lithium-ion batteries with accelerating rate calorimetry. J. Electrochem. Soc. 2021, 168, 060516. [Google Scholar] [CrossRef]

- Chen, M.; Sun, Q.; Li, Y.; Wu, K.; Liu, B.; Peng, P.; Wang, Q. A thermal runaway simulation on a lithium titanate battery and the battery module. Energies 2015, 8, 490–500. [Google Scholar] [CrossRef]

- Wang, K.; Gao, F.; Zhu, Y.; Liu, H.; Qi, C.; Yang, K.; Jiao, Q. Internal resistance and heat generation of soft package Li4Ti5O12 battery during charge and discharge. Energy 2018, 149, 364–374. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Luo, L.; Fan, Y.; Du, Z. A review on thermal management of lithium-ion batteries for electric vehicles. Energy 2022, 238, 121652. [Google Scholar] [CrossRef]

- Kong, D.; Peng, R.; Ping, P.; Du, J.; Chen, G.; Wen, J. A novel battery thermal management system coupling with PCM and optimized controllable liquid cooling for different ambient temperatures. Energy Convers. Manag. 2020, 204, 112280. [Google Scholar] [CrossRef]

- Liu, T.; Tao, C.; Wang, X. Cooling control effect of water mist on thermal runaway propagation in lithium ion battery modules. Appl. Energy 2020, 267, 115087. [Google Scholar] [CrossRef]

- Liu, T.; Hu, J.; Zhu, X.; Wang, X. A practical method of developing cooling control strategy for thermal runaway propagation prevention in lithium ion battery modules. J. Energy Storage 2022, 50, 104564. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Y.; Wang, X.; Kong, X.; Li, G. Cooling control of thermally-induced thermal runaway in 18,650 lithium ion battery with water mist. Energy Conv. Manag. 2019, 199, 111969. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, J.; Zhai, H.; Wang, Q. Experimental investigation on the characteristics of thermal runaway and its propagation of large-format lithium ion batteries under overcharging and overheating conditions. Energy 2021, 233, 121103. [Google Scholar] [CrossRef]

- Kim, S.K.; Choi, S.G.; Jin, S.Y.; Bang, S.S. An experimental study on fire risks due to overcharge and external heat of ESS lithium battery. Fire Sci. Eng. 2019, 33, 59–69. [Google Scholar] [CrossRef]

- Wang, H.; Shi, W.; Hu, F.; Wang, Y.; Hu, X.; Li, H. Over-heating triggered thermal runaway behavior for lithium-ion battery with high nickel content in positive electrode. Energy 2021, 224, 120072. [Google Scholar] [CrossRef]

- Ramadass, P.; Haran, B.; White, R.; Popov, B.N. Capacity fade of Sony 18650 cells cycled at elevated temperatures: Part I. Cycling performance. J. Power Sources 2002, 112, 606–613. [Google Scholar] [CrossRef]

- Liao, L.; Zuo, P.; Ma, Y.; Chen, X.; An, Y.; Gao, Y.; Yin, G. Effects of temperature on charge/discharge behaviors of LiFePO4 cathode for Li-ion batteries. Electrochim. Acta 2012, 60, 269–273. [Google Scholar] [CrossRef]

- Rezvanizaniani, S.M.; Liu, Z.; Chen, Y.; Lee, J. Review and recent advances in battery health monitoring and prognostics technologies for electric vehicle (EV) safety and mobility. J. Power Sources 2014, 256, 110–124. [Google Scholar] [CrossRef]

- Monika, K.; Chakraborty, C.; Roy, S.; Sujith, R.; Datta, S.P. A numerical analysis on multi-stage Tesla valve based cold plate for cooling of pouch type Li-ion batteries. Int. J. Heat Mass Transf. 2021, 177, 121560. [Google Scholar] [CrossRef]

- Yang, S.; Ling, C.; Fan, Y.; Yang, Y.; Tan, X.; Dong, H. A review of lithium-ion battery thermal management system strategies and the evaluate criteria. Int. J. Electrochem. Sci. 2019, 14, 6077–6107. [Google Scholar] [CrossRef]

- Wang, T.; Wang, P.; Pan, L.; He, Z.; Dai, L.; Wang, L.; Liu, S.; Jun, S.C.; Lu, B.; Liang, S.; et al. Stabling zinc metal anode with polydopamine regulation through dual effects of fast desolvation and ion confinement. Adv. Energy Mater. 2023, 13.5, 2203523. [Google Scholar] [CrossRef]

- Li, B.; Ruan, P.; Xu, X.; He, Z.; Zhu, X.; Pan, L.; Peng, Z.; Liu, Y.; Zhou, P.; Lu, B.; et al. Covalent Organic Framework with 3D Ordered Channel and Multi-Functional Groups Endows Zn Anode with Superior Stability. Nano-Micro Lett. 2024, 16, 76. [Google Scholar] [CrossRef]

- Abe, Y.; Hori, N.; Kumagai, S. Electrochemical impedance spectroscopy on the performance degradation of LiFePO4/graphite lithium-ion battery due to charge-discharge cycling under different C-rates. Energies 2019, 12, 4507. [Google Scholar] [CrossRef]

- Heubner, C.; Schneider, M.; Lämmel, C.; Michaelis, A. Local heat generation in a single stack lithium ion battery cell. Electrochim. Acta 2015, 186, 404–412. [Google Scholar] [CrossRef]

- Fly, A.; Chen, R. Rate dependency of incremental capacity analysis (dQ/dV) as a diagnostic tool for lithium-ion batteries. J. Energy Storage 2020, 29, 101329. [Google Scholar] [CrossRef]

- Dubarry, M.; Truchot, C.; Liaw, B.Y.; Gering, K.; Sazhin, S.; Jamison, D.; Michelbacher, C. Evaluation of commercial lithium-ion cells based on composite positive electrode for plug-in hybrid electric vehicle applications: III. Effect of thermal excursions without prolonged thermal aging. J. Electrochem. Soc. 2012, 160, A191. [Google Scholar] [CrossRef]

- Zhang, P.; Yuan, T.; Pang, Y.; Peng, C.; Yang, J.; Ma, Z.F.; Zheng, S. Influence of current density on graphite anode failure in lithium-ion batteries. J. Electrochem. Soc. 2019, 166, A5489. [Google Scholar] [CrossRef]

- Hernandez Lugo, D.; Clarke, S.; Miller, T.; Redifer, M.; Foster, T. X-57 Maxwell Battery from Cell Level to System Level Design and Testing (No. GRC-E-DAA-TN59208). 12 July 2018. Available online: https://ntrs.nasa.gov/citations/20180005737 (accessed on 6 May 2024).

- Kwon, S.J.; Lee, S.E.; Lim, J.H.; Choi, J.; Kim, J. Performance and life degradation characteristics analysis of NCM LIB for BESS. Electronics 2018, 7, 406. [Google Scholar] [CrossRef]

- Rohr, S.; Müller, S.; Baumann, M.; Kerler, M.; Ebert, F.; Kaden, D.; Lienkamp, M. Quantifying uncertainties in reusing lithium-ion batteries from electric vehicles. Procedia Manuf. 2017, 8, 603–610. [Google Scholar] [CrossRef]

- Capron, O.; Samba, A.; Omar, N.; Coosemans, T.; Van den Bossche, P.; Van Mierlo, J. Lithium-ion batteries: Thermal behaviour investigation of unbalanced modules. Sustainability 2015, 7, 8374–8398. [Google Scholar] [CrossRef]

- Kabir, M.M.; Demirocak, D.E. Degradation mechanisms in Li-ion batteries: A state-of-the-art review. Int. J. Energy Res. 2017, 41, 1963–1986. [Google Scholar] [CrossRef]

- Thompson, A.W. Economic implications of lithium ion battery degradation for Vehicle-to-Grid (V2X) services. J. Power Sources 2018, 396, 691–709. [Google Scholar] [CrossRef]

- Momma, T.; Matsunaga, M.; Mukoyama, D.; Osaka, T. Ac impedance analysis of lithium ion battery under temperature control. J. Power Sources 2012, 216, 304–307. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, J.; Pan, Z.; Ouyang, M. Impedance characterization of lithium-ion batteries aging under high-temperature cycling: Importance of electrolyte-phase diffusion. J. Power Sources 2019, 426, 216–222. [Google Scholar] [CrossRef]

- Choi, W.; Shin, H.C.; Kim, J.M.; Choi, J.Y.; Yoon, W.S. Modeling and applications of electrochemical impedance spectroscopy (EIS) for lithium-ion batteries. J. Electrochem. Sci. Technol. 2020, 11, 1–13. [Google Scholar] [CrossRef]

- Vadhva, P.; Hu, J.; Johnson, M.J.; Stocker, R.; Braglia, M.; Brett, D.J.; Rettie, A.J. Electrochemical impedance spectroscopy for all-solid-state batteries: Theory, methods and future outlook. ChemElectroChem 2021, 8, 1930–1947. [Google Scholar] [CrossRef]

- Meddings, N.; Heinrich, M.; Overney, F.; Lee, J.-S.; Ruiz, V.; Napolitano, E.; Seitz, S.; Hinds, G.; Raccichini, R.; Gabers, M.; et al. Application of electrochemical impedance spectroscopy to commercial Li-ion cells: A review. J. Power Sources 2020, 480, 228742. [Google Scholar] [CrossRef]

- Pastor-Fernández, C.; Widanage, W.D.; Marco, J.; Gama-Valdez, M.Á.; Chouchelamane, G.H. Identification and quantification of ageing mechanisms in Lithium-ion batteries using the EIS technique. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 27–29 June 2016; pp. 1–6. [Google Scholar]

- Locorotondo, E.; Cultrera, V.; Pugi, L.; Berzi, L.; Pasquali, M.; Andrenacci, N.; Lutzemberger, G.; Pierini, M. Impedance spectroscopy characterization of lithium batteries with different ages in second life application. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar]

- Rad, M.S.; Danilov, D.L.; Baghalha, M.; Kazemeini, M.; Notten, P.H.L. Adaptive thermal modeling of Li-ion batteries. Electrochim. Acta 2013, 102, 183–195. [Google Scholar]

- Zhu, J.G.; Sun, Z.C.; Wei, X.Z.; Dai, H.F. A new lithium-ion battery internal temperature on-line estimate method based on electrochemical impedance spectroscopy measurement. J. Power Sources 2015, 274, 990–1004. [Google Scholar] [CrossRef]

- Corso, B.L.; Perez, I.; Sheps, T.; Sims, P.C.; Gül, O.T.; Collins, P.G. Electrochemical charge-transfer resistance in carbon nanotube composites. Nano Lett. 2014, 14, 1329–1336. [Google Scholar] [CrossRef]

- Xia, H.; Liu, C.; Shen, L.; Yu, J.; Li, B.; Kang, F.; He, Y.B. Structure and thermal stability of LiNi0.8Co0.15Al0.05O2 after long cycling at high temperature. J. Power Sources 2020, 450, 227695. [Google Scholar] [CrossRef]

- Diaz, F.; Wang, Y.; Moorthy, T.; Friedrich, B. Degradation mechanism of nickel-cobalt-aluminum (NCA) cathode material from spent lithium-ion batteries in microwave-assisted pyrolysis. Metals 2018, 8, 565. [Google Scholar] [CrossRef]

- Andre, D.; Meiler, M.; Steiner, K.; Wimmer, C.; Soczka-Guth, T.; Sauer, D.U. Characterization of high-power lithium-ion batteries by electrochemical impedance spectroscopy. I. Experimental investigation. J. Power Sources 2011, 196, 5334–5341. [Google Scholar] [CrossRef]

- Gaberšček, M. Understanding Li-based battery materials via electrochemical impedance spectroscopy. Nat. Commun. 2021, 12, 6513. [Google Scholar] [CrossRef]

- Edge, J.S.; O’kane, S.; Prosser, R.; Kirkaldy, N.D.; Patel, A.N.; Hales, A.; Ghosh, A.; Ai, W.; Chen, J.; Yang, J.; et al. Lithium ion battery degradation: What you need to know. Phys. Chem. Chem. Phys. 2021, 23, 8200–8221. [Google Scholar] [CrossRef]

- Lee, M.; Han, S.; Park, J.; Kim, J. A Study on the Selection of Failure Factors for Transient State Lithium-Ion Batteries based on Electrochemical Impedance Spectroscopy. J. Korean Soc. Precis. Eng. 2021, 38, 749–756. [Google Scholar] [CrossRef]

- Iurilli, P.; Brivio, C.; Wood, V. On the use of electrochemical impedance spectroscopy to characterize and model the aging phenomena of lithium-ion batteries: A critical review. J. Power Sources 2021, 505, 229860. [Google Scholar] [CrossRef]

- Li, Y.; Abdel-Monem, M.; Gopalakrishnan, R.; Berecibar, M.; Nanini-Maury, E.; Omar, N.; van den Bossche, P.; Van Mierlo, J. A quick on-line state of health estimation method for Li-ion battery with incremental capacity curves processed by Gaussian filter. J. Power Sources 2018, 373, 40–53. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward sustainable reuse of retired lithium-ion batteries from electric vehicles. Resour. Conserv. Recycl. 2021, 168, 105249. [Google Scholar] [CrossRef]

- Waag, W.; Käbitz, S.; Sauer, D.U. Experimental investigation of the lithium-ion battery impedance characteristic at various conditions and aging states and its influence on the application. Appl. Energ. 2013, 102, 885–897. [Google Scholar] [CrossRef]

- Kang, T.W.; Kim, J.H.; Lee, P.Y.; Ha, M.L.; Song, H.C.; Kim, J.H. Analysis of electrical characteristics of 24S1P battery considering temperature and C-rates. In Proceedings of the KIPE Conference, Hoengseong, Republic of Korea, 3–6 July 2018; pp. 474–475. [Google Scholar]

- Vidal, C.; Gross, O.; Gu, R.; Kollmeyer, P.; Emadi, A. xEV Li-ion battery low-temperature effects. IEEE Trans. Veh. Technol. 2019, 68, 4560–4572. [Google Scholar] [CrossRef]

- Hosseinzadeh, E.; Odio, M.X.; Marco, J.; Jennings, P. Unballanced performance of parallel connected large format lithium ion batteries for electric vehicle application. In Proceedings of the 2019 International Conference on Smart Energy Systems and Technologies (SEST), Porto, Portugal, 9–11 September 2019; pp. 1–6. [Google Scholar]

- Karimi, G.; Li, X. Thermal management of lithium-ion batteries for electric vehicles. Int. J. Energ. Res. 2013, 37, 13–24. [Google Scholar] [CrossRef]

- Yang, N.; Zhang, X.; Shang, B.; Li, G. Unbalanced discharging and aging due to temperature differences among the cells in a lithium-ion battery pack with parallel combination. J. Power Sources 2016, 306, 733–741. [Google Scholar] [CrossRef]

- Docimo, D.J.; Fathy, H.K. Analysis and control of charge and temperature imbalance within a lithium-ion battery pack. IEEE Trans. Control. Syst. Technol. 2018, 27, 1622–1635. [Google Scholar] [CrossRef]

- Oeser, D.; Ziegler, A.; Ackva, A. Single cell analysis of lithium-ion e-bike batteries aged under various conditions. J. Power Sources 2018, 397, 25–31. [Google Scholar] [CrossRef]

- Wang, T.; Tseng, K.J.; Zhao, J.; Wei, Z. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.; Huo, Y.; Liu, X.; Li, Y. Thermal management of cylindrical power battery module for extending the life of new energy electric vehicles. Appl. Therm. Eng. 2015, 85, 33–43. [Google Scholar] [CrossRef]

- Lee, S.; Kwon, M.; Kim, Y. Preventing Thermal Runaway Propagation in Lithium-ion Batteries using a Passive Liquid Housing. J. Electrochem. Soc. 2024, 171, 030507. [Google Scholar] [CrossRef]

- Huang, C.K.; Sakamoto, J.S.; Wolfenstine, J.; Surampudi, S. The limits of low-temperature performance of Li-ion cells. J. Electrochem. Soc. 2000, 147, 2893. [Google Scholar] [CrossRef]

| Parameters | Description | |

|---|---|---|

| Battery | Cell | LIB 18650 type |

| Cell Manufacturer | Samsung | |

| Cell Model | INR18650-30Q | |

| Nominal Voltage | 3.7 V | |

| Maximum Voltage | 4.2 V | |

| Capacity | 3 Ah | |

| Energy | 11 Wh | |

| Charge | Maximum Charge Voltage | 4.2 V |

| Continuous Charging Current | 1.5 A | |

| Discharge | Maximum Discharge Voltage | 3.0 V |

| Continuous Discharge Current | 1.5 A | |

| Others | Dimension (B × W × H) | 26 mm × 79 mm × 26 mm |

| Total Weight (FPM Weight) | 58.5 g (FPM: 16.4 g) | |

| Operating Temperature | −10–40 °C | |

| Parameters | Description | |

|---|---|---|

| Battery | Cell | LIB 18650 type (10s3p) |

| Cell Manufacturer | Samsung | |

| Cell Model | INR18650-30Q | |

| Nominal Voltage | 37 V | |

| Maximum Voltage | 42 V | |

| Capacity | 9 Ah | |

| Energy | 333 Wh | |

| Charge | Maximum Charge Voltage | 42 V |

| Continuous Charging Current | 4.5 A | |

| Discharge | Maximum Discharge Voltage | 30 V |

| Continuous Discharge Current | 4.5 A | |

| Others | Dimension (B × W × H) | 45 mm × 350 mm × 80 mm |

| Total Weight (FPM Weight) | 2.8 kg (FPM: 492 g) | |

| Operating Temperature | −10–40 °C | |

| Battery Management System | Function | Over-discharge, Overcharge, Over-current, Balance, etc. |

| Thermal Runaway | ① | ② | ③ | ④ | |

|---|---|---|---|---|---|

| LIB | Step Time (s) | 377 | 134 | 46 | 30 |

| △T () | 152.9 | 163.1 | 741.1 | 900.3 | |

| Propagated Cell Amount | 1 ea (Abuse) | 1 ea | 5 ea | 6 ea | |

| BIF | Step Time (s) | 396 | 129 | - | - |

| △T () | 110.0 | 113.1 | - | - | |

| Propagated Cell Amount | 1 ea (Abuse) | 1 ea | - | - | |

| Rct (2nd Semicircle) | 0 Cycles | 14 Cycles | 28 Cycles | 42 Cycles |

|---|---|---|---|---|

| LIB (Ω) | 0.02791 | 0.03138 | 0.03838 | 0.05305 |

| BIF (Ω) | 0.02597 | 0.02634 | 0.03174 | 0.03250 |

| Temperature (°C) | 1C | 2C | 3C | 4C | 5C | 6C | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LIB Cell | 47.2 | 47.7 | 61.4 | 61.9 | 75.6 | 75.8 | 90.9 | 91.1 | 105.1 | - | - | - |

| LIB Case | 41.6 | 41.7 | 44.2 | 44.3 | 47.9 | 47.9 | 50.8 | 50.9 | 52.6 | - | - | - |

| BIF Cell | 42.5 | 42.6 | 49.1 | 49.2 | 57.3 | 57.4 | 65.3 | 65.4 | 77.6 | 77.7 | 87.8 | 87.9 |

| BIF Case | 40.3 | 40.3 | 40.5 | 40.5 | 40.9 | 40.9 | 41.3 | 41.4 | 41.8 | 41.8 | 42.1 | 42.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, J.; Choi, Y.; Kim, Y. Lithium-Ion Batteries (LIBs) Immersed in Fire Prevention Material for Fire Safety and Heat Management. Energies 2024, 17, 2418. https://doi.org/10.3390/en17102418

Bae J, Choi Y, Kim Y. Lithium-Ion Batteries (LIBs) Immersed in Fire Prevention Material for Fire Safety and Heat Management. Energies. 2024; 17(10):2418. https://doi.org/10.3390/en17102418

Chicago/Turabian StyleBae, Junho, Yunseok Choi, and Youngsik Kim. 2024. "Lithium-Ion Batteries (LIBs) Immersed in Fire Prevention Material for Fire Safety and Heat Management" Energies 17, no. 10: 2418. https://doi.org/10.3390/en17102418

APA StyleBae, J., Choi, Y., & Kim, Y. (2024). Lithium-Ion Batteries (LIBs) Immersed in Fire Prevention Material for Fire Safety and Heat Management. Energies, 17(10), 2418. https://doi.org/10.3390/en17102418