An Overview of the Thermochemical Valorization of Sewage Sludge: Principles and Current Challenges

Abstract

1. Introduction

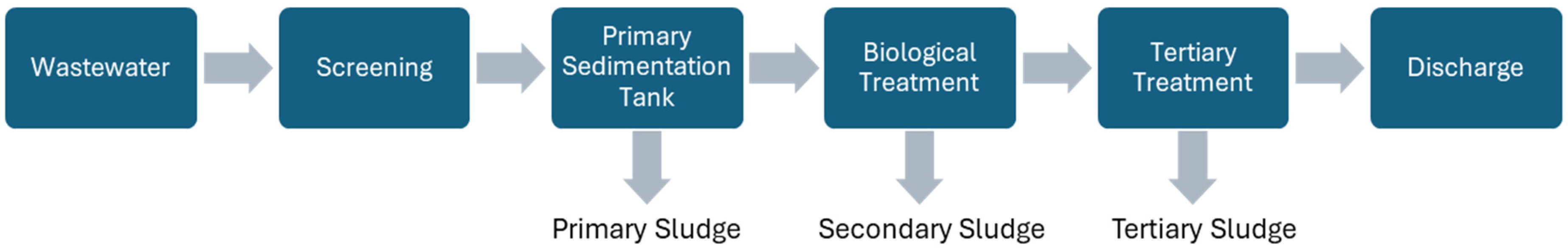

2. Sewage Sludge Composition

3. Thermochemical Conversion of Sewage Sludge

3.1. Gasification

3.2. Pyrolysis

3.3. Hydrothermal Methods

3.3.1. Hydrothermal Carbonization

3.3.2. Hydrothermal Liquefaction

3.3.3. Hydrothermal Gasification

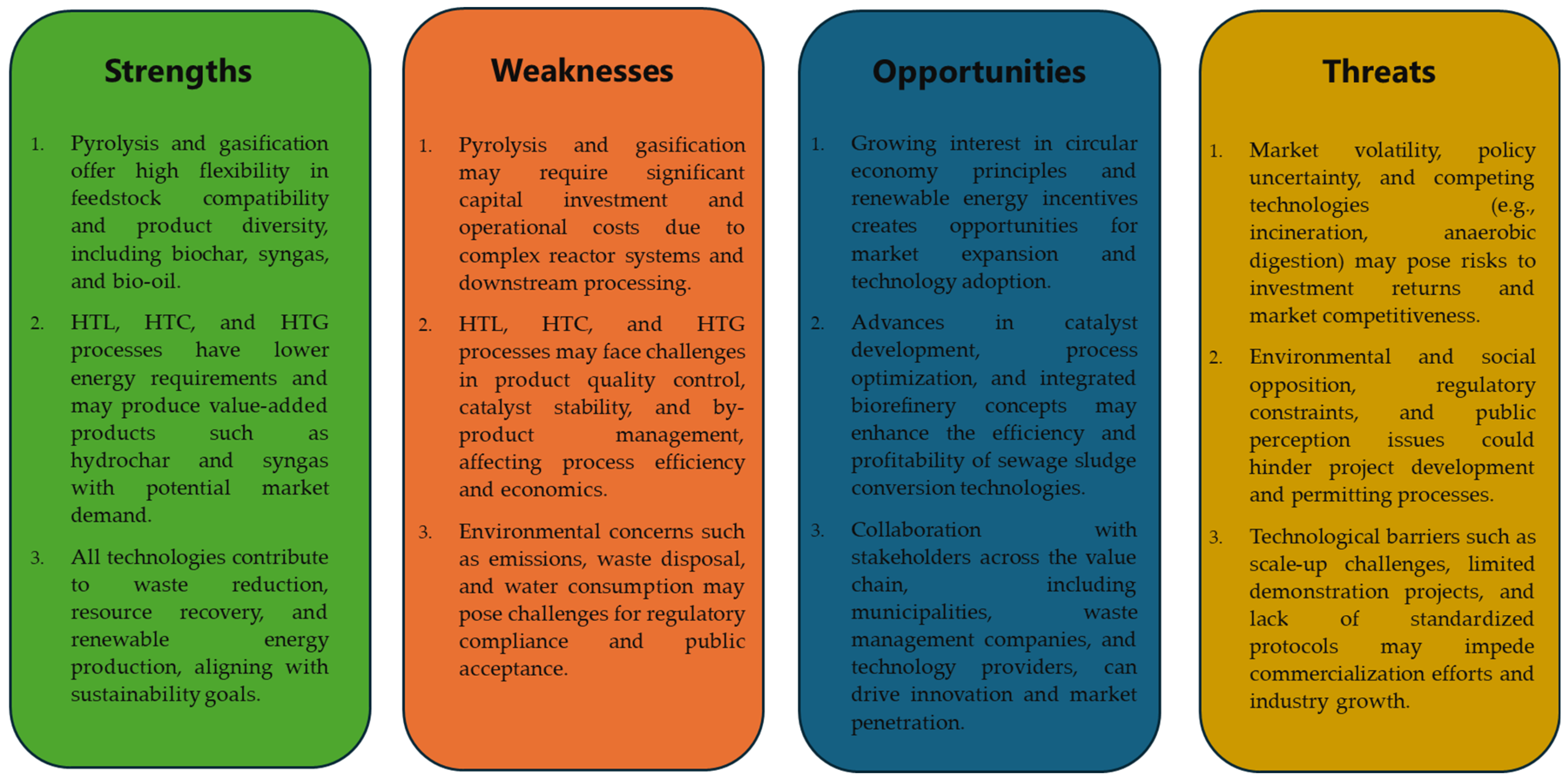

4. SWOT Analysis

5. Current Challenges and Mitigation Strategies

5.1. Sewage Sludge Drying

5.2. Gasification

5.3. Pyrolysis

5.4. Hydrothermal Methods

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eurostat Sewage Sludge Production and Disposal. Available online: https://ec.europa.eu/eurostat/databrowser/view/HLTH_PS_PREV__custom_7978672/bookmark/table?lang=en&bookmarkId=827e0163-fd0f-4ed7-9cd3-f2c20574cb07%0Ahttps://ec.europa.eu/eurostat/databrowser/view/tec00118/default/table?lang=en%0Ahttps://ec.europa.eu/euros (accessed on 26 February 2024).

- Rahman, T.; Jahromi, H.; Roy, P.; Adhikari, S.; Hassani, E. Hydrothermal Liquefaction of Municipal Sewage Sludge: Effect of Red Mud Catalyst in Ethylene and Inert Ambiences. Energy Convers. Manag. 2021, 245, 114615. [Google Scholar] [CrossRef]

- Hoang, S.A.; Bolan, N.; Madhubashani, A.M.P.; Vithanage, M.; Perera, V.; Wijesekara, H.; Wang, H.; Srivastava, P.; Kirkham, M.B. Treatment Processes to Eliminate Potential Environmental Hazards and Restore Agronomic Value of Sewage Sludge: A Review. Environ. Pollut. 2022, 293, 118564. [Google Scholar] [CrossRef]

- Panepinto, D.; Fiore, S.; Genon, G.; Acri, M. Thermal Valorization of Sewer Sludge: Perspectives for Large Wastewater Treatment Plants. J. Clean. Prod. 2016, 137, 1323–1329. [Google Scholar] [CrossRef]

- Cano, R.; Pérez-Elvira, S.I.; Fdz-Polanco, F. Energy Feasibility Study of Sludge Pretreatments: A Review. Appl. Energy 2015, 149, 176–185. [Google Scholar] [CrossRef]

- Manara, P.; Zabaniotou, A. Towards Sewage Sludge Based Biofuels via Thermochemical Conversion—A Review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical Processing of Sewage Sludge to Energy and Fuel: Fundamentals, Challenges and Considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Chan, W.P.; Wang, J.Y. Comprehensive Characterisation of Sewage Sludge for Thermochemical Conversion Processes—Based on Singapore Survey. Waste Manag. 2016, 54, 131–142. [Google Scholar] [CrossRef]

- Kathi, S.; Singh, S.; Yadav, R.; Singh, A.N.; Mahmoud, A.E.D. Wastewater and Sludge Valorisation: A Novel Approach for Treatment and Resource Recovery to Achieve Circular Economy Concept. Front. Chem. Eng. 2023, 5, 1–20. [Google Scholar] [CrossRef]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical Conversion of Sewage Sludge: A Critical Review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Gururani, P.; Bhatnagar, P.; Bisht, B.; Jaiswal, K.K.; Kumar, V.; Kumar, S.; Vlaskin, M.S.; Grigorenko, A.V.; Rindin, K.G. Recent Advances and Viability in Sustainable Thermochemical Conversion of Sludge to Bio-Fuel Production. Fuel 2022, 316, 123351. [Google Scholar] [CrossRef]

- Bianchini, A.; Bonfiglioli, L.; Pellegrini, M.; Saccani, C. Sewage Sludge Drying Process Integration with a Waste-to-Energy Power Plant. Waste Manag. 2015, 42, 159–165. [Google Scholar] [CrossRef]

- Alves, O.; Garcia, B.; Rijo, B.; Lourinho, G.; Nobre, C. Market Opportunities in Portugal for the Water-and-Waste Sector Using Sludge Gasification. Energies 2022, 15, 6600. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, V.; Dhanjal, D.S.; Datta, S.; Bhatia, D.; Dhiman, J.; Samuel, J.; Prasad, R.; Singh, J. A Sustainable Paradigm of Sewage Sludge Biochar: Valorization, Opportunities, Challenges and Future Prospects. J. Clean. Prod. 2020, 269, 122259. [Google Scholar] [CrossRef]

- Durak, H. Comprehensive Assessment of Thermochemical Processes for Sustainable Waste Management and Resource Recovery. Processes 2023, 11, 2092. [Google Scholar] [CrossRef]

- Zaker, A.; Chen, Z.; Wang, X.; Zhang, Q. Microwave-Assisted Pyrolysis of Sewage Sludge: A Review. Fuel Process. Technol. 2019, 187, 84–104. [Google Scholar] [CrossRef]

- Hu, M.; Hu, H.; Ye, Z.; Tan, S.; Yin, K.; Chen, Z.; Guo, D.; Rong, H.; Wang, J.; Pan, Z.; et al. A Review on Turning Sewage Sludge to Value-Added Energy and Materials via Thermochemical Conversion towards Carbon Neutrality. J. Clean. Prod. 2022, 379, 134657. [Google Scholar] [CrossRef]

- Su, Y.; Liu, D.; Gong, M.; Zhu, W.; Yu, Y.; Gu, H. Investigation on the Decomposition of Chemical Compositions during Hydrothermal Conversion of Dewatered Sewage Sludge. Int. J. Hydrogen Energy 2019, 44, 26933–26942. [Google Scholar] [CrossRef]

- Ronda, A.; Haro, P.; Gómez-Barea, A. Sustainability Assessment of Alternative Waste-to-Energy Technologies for the Management of Sewage Sludge. Waste Manag. 2023, 159, 52–62. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Xiao, B.; Wang, X.; Liu, J. Consequences of Sludge Composition on Combustion Performance Derived from Thermogravimetry Analysis. Waste Manag. 2015, 35, 141–147. [Google Scholar] [CrossRef]

- Nyashanu, P.N.; Shafodino, F.S.; Mwapagha, L.M. Determining the Potential Human Health Risks Posed by Heavy Metals Present in Municipal Sewage Sludge from a Wastewater Treatment Plant. Sci. Afr. 2023, 20, e01735. [Google Scholar] [CrossRef]

- Urbaniak, M.; Baran, A.; Giebu, J.; Bednarek, A.; Giebułtowicz, J.; Bednarek, A.; Serwecińska, L. The Occurrence of Heavy Metals and Antimicrobials in Sewage Sludge and Their Predicted Risk to Soil—Is There Anything to Fear? Sci. Total Environ. 2024, 912, 168856. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.; Ye, Z.; Zhang, H.; Chen, B.; Pan, Z.; Wang, J. Thermochemical Conversion of Sewage Sludge for Energy and Resource Recovery: Technical Challenges and Prospects. Environ. Pollut. Bioavailab. 2021, 33, 145–163. [Google Scholar] [CrossRef]

- Quan, L.M.; Kamyab, H.; Yuzir, A.; Ashokkumar, V.; Hosseini, S.E.; Balasubramanian, B.; Kirpichnikova, I. Review of the Application of Gasification and Combustion Technology and Waste-to-Energy Technologies in Sewage Sludge Treatment. Fuel 2022, 316, 123199. [Google Scholar] [CrossRef]

- Tezer, Ö.; Karabağ, N.; Öngen, A.; Ayol, A. Syngas Production from Municipal Sewage Sludge by Gasification Process: Effects of Fixed Bed Reactor Types and Gasification Agents on Syngas Quality. Sustain. Energy Technol. Assess. 2023, 56, 103042. [Google Scholar] [CrossRef]

- Hu, M.; Gao, L.; Chen, Z.; Ma, C.; Zhou, Y.; Chen, J.; Ma, S.; Laghari, M.; Xiao, B.; Zhang, B.; et al. Syngas Production by Catalytic In-Situ Steam Co-Gasification of Wet Sewage Sludge and Pine Sawdust. Energy Convers. Manag. 2016, 111, 409–416. [Google Scholar] [CrossRef]

- Farooq, A.; Ko, C.H.; Park, Y.K. Sewage Sludge Steam Gasification over Bimetallic Mesoporous Al-MCM48 Catalysts for Efficient Hydrogen Generation. Environ. Res. 2023, 224, 115553. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.S.; Mun, T.Y.; Kim, J.S. Two-Stage Gasification of Dried Sewage Sludge: Effects of Gasifying Agent, Bed Material, Gas Cleaning System, and Ni-Coated Distributor on Product Gas Quality. Renew. Energy 2022, 185, 208–216. [Google Scholar] [CrossRef]

- Yang, X.; Kan, T.; Kheradmand, A.; Xu, H.; Strezov, V.; Yu, A.; Jiang, Y. Tunable Syngas Production from Two-Stage Sorption-Enhanced Steam Gasification of Sewage Sludge. Chem. Eng. J. 2021, 404, 126069. [Google Scholar] [CrossRef]

- Kang, B.S.; Farooq, A.; Valizadeh, B.; Lee, D.; Seo, M.W.; Jung, S.C.; Hussain, M.; Kim, Y.M.; Khan, M.A.; Jeon, B.H.; et al. Valorization of Sewage Sludge via Air/Steam Gasification Using Activated Carbon and Biochar as Catalysts. Int. J. Hydrogen Energy 2023, 54, 284–293. [Google Scholar] [CrossRef]

- De Andrés, J.M.; Narros, A.; Rodríguez, M.E. Air-Steam Gasification of Sewage Sludge in a Bubbling Bed Reactor: Effect of Alumina as a Primary Catalyst. Fuel Process. Technol. 2011, 92, 433–440. [Google Scholar] [CrossRef]

- Schmid, M.; Hafner, S.; Biollaz, S.; Schneebeli, J.; Waizmann, G.; Scheffknecht, G. Steam-Oxygen Gasification of Sewage Sludge: Reduction of Tar, H2S and COS with Limestone as Bed Additive. Biomass Bioenergy 2021, 150, 106100. [Google Scholar] [CrossRef]

- Pedroza, M.M.; Sousa, J.F.; Vieira, G.E.G.; Bezerra, M.B.D. Characterization of the Products from the Pyrolysis of Sewage Sludge in 1 Kg/h Rotating Cylinder Reactor. J. Anal. Appl. Pyrolysis 2014, 105, 108–115. [Google Scholar] [CrossRef]

- Chanaka Udayanga, W.D.; Veksha, A.; Giannis, A.; Lisak, G.; Lim, T.T. Effects of Sewage Sludge Organic and Inorganic Constituents on the Properties of Pyrolysis Products. Energy Convers. Manag. 2019, 196, 1410–1419. [Google Scholar] [CrossRef]

- Feng, C.; Xie, W.; Zhang, D.; Gao, X.; Qiao, Y.; Xu, M. Pyrolysis of Sewage Sludge under Conditions Relevant to Applied Smouldering Combustion. Proc. Combust. Inst. 2023, 39, 3447–3456. [Google Scholar] [CrossRef]

- Gao, N.; Li, J.; Qi, B.; Li, A.; Duan, Y.; Wang, Z. Thermal Analysis and Products Distribution of Dried Sewage Sludge Pyrolysis. J. Anal. Appl. Pyrolysis 2014, 105, 43–48. [Google Scholar] [CrossRef]

- Qiu, Z.; Zhai, Y.; Li, S.; Liu, X.; Liu, X.; Wang, B.; Liu, Y.; Li, C.; Hu, Y. Catalytic Co-Pyrolysis of Sewage Sludge and Rice Husk over Biochar Catalyst: Bio-Oil Upgrading and Catalytic Mechanism. Waste Manag. 2020, 114, 225–233. [Google Scholar] [CrossRef] [PubMed]

- Agar, D.A.; Kwapinska, M.; Leahy, J.J. Pyrolysis of Wastewater Sludge and Composted Organic Fines from Municipal Solid Waste: Laboratory Reactor Characterisation and Product Distribution. Environ. Sci. Pollut. Res. 2018, 25, 35874–35882. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, J.; Lopez, G.; Amutio, M.; Artetxe, M.; Barbarias, I.; Arregi, A.; Bilbao, J.; Olazar, M. Characterization of the Bio-Oil Obtained by Fast Pyrolysis of Sewage Sludge in a Conical Spouted Bed Reactor. Fuel Process. Technol. 2016, 149, 169–175. [Google Scholar] [CrossRef]

- Fonts, I.; Juan, A.; Gea, G.; Murillo, M.B.; Sánchez, J.L. Sewage Sludge Pyrolysis in Fluidized Bed, 1: Influence of Operational Conditions on the Product Distribution. Ind. Eng. Chem. Res. 2008, 47, 5376–5385. [Google Scholar] [CrossRef]

- Sun, Y.; Jin, B.; Wu, W.; Zuo, W.; Zhang, Y.; Zhang, Y.; Huang, Y. Effects of Temperature and Composite Alumina on Pyrolysis of Sewage Sludge. J. Environ. Sci. 2015, 30, 1–8. [Google Scholar] [CrossRef]

- Hu, Y.; Yu, W.; Wibowo, H.; Xia, Y.; Lu, Y.; Yan, M. Effect of Catalysts on Distribution of Polycyclic-Aromatic Hydrocarbon (PAHs) in Bio-Oils from the Pyrolysis of Dewatered Sewage Sludge at High and Low Temperatures. Sci. Total Environ. 2019, 667, 263–270. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Qin, L.; Xu, Z.; Chen, W.; Xing, F.; Han, J. The Effects of Fe2O3 Catalyst on the Conversion of Organic Matter and Bio-Fuel Production during Pyrolysis of Sewage Sludge. J. Energy Inst. 2019, 92, 835–842. [Google Scholar] [CrossRef]

- de Souza Souza, C.; Bomfim, M.R.; de Almeida, M.d.C.; Alves, L.d.S.; de Santana, W.N.; da Silva Amorim, I.C.; Santos, J.A.G. Induced Changes of Pyrolysis Temperature on the Physicochemical Traits of Sewage Sludge and on the Potential Ecological Risks. Sci. Rep. 2021, 11, 974. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Zheng, Y.; Zhu, X.; Brewer, C.E.; Brown, R.C. Ex-Situ Catalytic Pyrolysis of Wastewater Sewage Sludge—A Micro-Pyrolysis Study. Bioresour. Technol. 2017, 232, 229–234. [Google Scholar] [CrossRef] [PubMed]

- Azuara, M.; Fonts, I.; Bimbela, F.; Murillo, M.B.; Gea, G. Catalytic Post-Treatment of the Vapors from Sewage Sludge Pyrolysis by Means of γ-Al2O3: Effect on the Liquid Product Properties. Fuel Process. Technol. 2015, 130, 252–262. [Google Scholar] [CrossRef]

- Beckers, W.; Schuller, D.; Vaizert, O. Thermolytical Treatment of Dried Sewage Sludge and Other Biogenic Materials-Including Upgrading of Pyrolysis Vapours by a Cracking Catalyst and Examination of Heavy Metals by X-Ray Fluorescence. J. Anal. Appl. Pyrolysis 1999, 50, 17–30. [Google Scholar] [CrossRef]

- Meng, J.; Wang, J.; Yang, F.; Cheng, F. Study on the Multiple Roles of CaO on Nitrogen Evolution Mechanism of Protein inside Sewage Sludge Pyrolysis. Chem. Eng. J. 2023, 458, 141039. [Google Scholar] [CrossRef]

- Chen, W.; Haque, A.; Lu, T.; Aierzhati, A.; Reimonn, G. A Perspective on Hydrothermal Processing of Sewage Sludge. Curr. Opin. Environ. Sci. Health 2020, 14, 63–76. [Google Scholar] [CrossRef] [PubMed]

- Lachos-Perez, D.; César Torres-Mayanga, P.; Abaide, E.R.; Zabot, G.L.; De Castilhos, F. Hydrothermal Carbonization and Liquefaction: Differences, Progress, Challenges, and Opportunities. Bioresour. Technol. 2022, 343, 126084. [Google Scholar] [CrossRef]

- Romano, P.; Stampone, N.; Di Giacomo, G. Evolution and Prospects of Hydrothermal Carbonization. Energies 2023, 16, 3125. [Google Scholar] [CrossRef]

- Danso-Boateng, E.; Shama, G.; Wheatley, A.D.; Martin, S.J.; Holdich, R.G. Hydrothermal Carbonisation of Sewage Sludge: Effect of Process Conditions on Product Characteristics and Methane Production. Bioresour. Technol. 2015, 177, 318–327. [Google Scholar] [CrossRef]

- Volpe, M.; Fiori, L.; Merzari, F.; Messineo, A.; Andreottola, G. Hydrothermal Carbonization as an Efficient Tool for Sewage Sludge Valorization and Phosphorous Recovery. Chem. Eng. Trans. 2020, 80, 199–204. [Google Scholar] [CrossRef]

- Petrovič, A.; Cenčič Predikaka, T.; Škodič, L.; Vohl, S.; Čuček, L. Hydrothermal Co-Carbonization of Sewage Sludge and Whey: Enhancement of Product Properties and Potential Application in Agriculture. Fuel 2023, 350, 128807. [Google Scholar] [CrossRef]

- Wilk, M.; Sliz, M.; Czerwinska, K.; Sled, M. The Effect of an Acid Catalyst on the Hydrothermal Carbonization of Sewage Sludge. J. Environ. Manag. 2023, 345, 118820. [Google Scholar] [CrossRef]

- Wang, C.; Gui, B.; Wu, C.; He, C.; Li, L.; Ling, X.; Zuo, X. Hydrothermal Carbonization of Sewage Sludge Coupled with Fenton Oxidation Pretreatment: Moderate Oxidation to Enhance Hydrochar Yield and Properties. J. Environ. Chem. Eng. 2023, 11, 110788. [Google Scholar] [CrossRef]

- Piboonudomkarn, S.; Khemthong, P.; Youngjan, S.; Wantala, K. Co-Hydrothermally Carbonized Sewage Sludge and Lignocellulosic Biomass: An Efficiently Renewable Solid Fuel. Arab. J. Chem. 2023, 16, 105315. [Google Scholar] [CrossRef]

- Paiboonudomkarn, S.; Wantala, K.; Lubphoo, Y.; Khunphonoi, R. Conversion of Sewage Sludge from Industrial Wastewater Treatment to Solid Fuel through Hydrothermal Carbonization Process. Mater. Today Proc. 2022, 75, 85–90. [Google Scholar] [CrossRef]

- Cavali, M.; Benbelkacem, H.; Kim, B.; Bayard, R.; Libardi Junior, N.; Gonzaga Domingos, D.; Woiciechowski, A.L.; Castilhos Junior, A.B. de Co-Hydrothermal Carbonization of Pine Residual Sawdust and Non-Dewatered Sewage Sludge–Effect of Reaction Conditions on Hydrochar Characteristics. J. Environ. Manag. 2023, 340, 117994. [Google Scholar] [CrossRef]

- Benavente, V.; Pérez, C.; Jansson, S. Co-Hydrothermal Carbonization of Microalgae and Digested Sewage Sludge: Assessing the Impact of Mixing Ratios on the Composition of Primary and Secondary Char. Waste Manag. 2024, 174, 429–438. [Google Scholar] [CrossRef]

- Huezo, L.; Vasco-Correa, J.; Shah, A. Hydrothermal Carbonization of Anaerobically Digested Sewage Sludge for Hydrochar Production. Bioresour. Technol. Rep. 2021, 15, 100795. [Google Scholar] [CrossRef]

- Fan, Y.; Hornung, U.; Dahmen, N. Hydrothermal Liquefaction of Sewage Sludge for Biofuel Application: A Review on Fundamentals, Current Challenges and Strategies. Biomass Bioenergy 2022, 165, 106570. [Google Scholar] [CrossRef]

- Strugała-Wilczek, A.; Basa, W.; Pankiewicz-Sperka, M.; Xu, D.; Duan, P.; Hao, B.; Wang, Y.; Leng, L.; Yang, L.; Fan, L.; et al. Distribution Characteristics and Migration Pathways of Metals during Hydrothermal Liquefaction of Municipal Sewage Sludge in the Presence of Various Catalysts. Sci. Total Environ. 2024, 920, 171023. [Google Scholar] [CrossRef] [PubMed]

- Prestigiacomo, C.; Fan, Y.; Hornung, U.; Dahmen, N.; Scialdone, O.; Galia, A. Hydrothermal Liquefaction of Sewage Sludge: Use of HCOOH and KOH to Improve the Slurry Pumpability in a Continuously Operated Plant. Heliyon 2024, 10, e26287. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Liu, Q.; Li, X.; Kong, G.; Cao, T.; Cheng, Q.; Zhang, Z.; Zhang, X.; Han, L. Catalytic Hydrothermal Co-Liquefaction of Sewage Sludge and Agricultural Biomass for Promoting Advanced Biocrude Production. J. Clean. Prod. 2023, 428, 139470. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, Y.; Tian, S.; Zhang, X.; Wei, X. Catalytic Hydrothermal Liquefaction of Sewage Sludge: Effect of Metal Support Heterogeneous Catalysts on Products Distribution. J. Energy Inst. 2022, 103, 154–159. [Google Scholar] [CrossRef]

- Fan, Y.; Prestigiacomo, C.; Gong, M.; Tietz, T.; Hornung, U.; Dahmen, N. Comparative Investigation on the Value-Added Products Obtained from Continuous and Batch Hydrothermal Liquefaction of Sewage Sludge. Front. Environ. Sci. 2022, 10, 1–13. [Google Scholar] [CrossRef]

- Silva Thomsen, L.B.; Carvalho, P.N.; dos Passos, J.S.; Anastasakis, K.; Bester, K.; Biller, P.; Bjørn, L.; Thomsen, S.; Carvalho, P.N.; Souza, J.; et al. Hydrothermal Liquefaction of Sewage Sludge; Energy Considerations and Fate of Micropollutants during Pilot Scale Processing. Water Res. 2020, 183, 116101. [Google Scholar] [CrossRef] [PubMed]

- Baudouin, D.; Salionov, D.; Vogel, F.; Bjelić, S. Advanced Analytical Study of Process Streams for a Rational Optimization of Hydrothermal Gasification. ACS Eng. Au 2021, 1, 134–147. [Google Scholar] [CrossRef]

- Yan, M.; Hantoko, D.; Kanchanatip, E.; Zheng, R.; Zhong, Y.; Mubeen, I. Valorization of Sewage Sludge through Catalytic Sub- and Supercritical Water Gasification. J. Energy Inst. 2020, 93, 1419–1427. [Google Scholar] [CrossRef]

- Chen, Y.; Yi, L.; Wei, W.; Jin, H.; Guo, L. Hydrogen Production by Sewage Sludge Gasification in Supercritical Water with High Heating Rate Batch Reactor. Energy 2022, 238, 121740. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, L.; Cao, W.; Jin, H.; Guo, S.; Zhang, X. Hydrogen Production by Sewage Sludge Gasification in Supercritical Water with a Fluidized Bed Reactor. Int. J. Hydrogen Energy 2013, 38, 12991–12999. [Google Scholar] [CrossRef]

- Amrullah, A.; Matsumura, Y. Supercritical Water Gasification of Sewage Sludge in Continuous Reactor. Bioresour. Technol. 2018, 249, 276–283. [Google Scholar] [CrossRef]

- Cui, J.; Wen, X.; Chen, F.; Yan, M.; Hantoko, D. Migration of Nitrogen and Phosphorus during Supercritical Water Gasification of Sewage Sludge: Effect of Alkaline Additives. Fuel Process. Technol. 2023, 245, 107727. [Google Scholar] [CrossRef]

- Weijin, G.; Zizheng, Z.; Yue, L.; Qingyu, W.; Lina, G. Hydrogen Production and Phosphorus Recovery via Supercritical Water Gasification of Sewage Sludge in a Batch Reactor. Waste Manag. 2019, 96, 198–205. [Google Scholar] [CrossRef]

- Hantoko, D.; Antoni; Kanchanatip, E.; Yan, M.; Weng, Z.; Gao, Z.; Zhong, Y. Assessment of Sewage Sludge Gasification in Supercritical Water for H2-Rich Syngas Production. Process Saf. Environ. Prot. 2019, 131, 63–72. [Google Scholar] [CrossRef]

- Xin, C.; Zhao, J.; Ruan, R.; Addy, M.M.; Liu, S.; Mu, D. Economical Feasibility of Bio-Oil Production from Sewage Sludge through Pyrolysis. Therm. Sci. 2018, 22, 459–467. [Google Scholar] [CrossRef]

- Faragò, M.; Damgaard, A.; Logar, I.; Rygaard, M. Life Cycle Assessment and Cost-Benefit Analysis of Technologies in Water Resource Recovery Facilities: The Case of Sludge Pyrolysis. Environ. Sci. Technol. 2022, 56, 17988–17997. [Google Scholar] [CrossRef]

- Farru, G.; Scheufele, F.B.; Paniagua, D.M.; Keller, F.; Jeong, C.; Basso, D. Business and Market Analysis of Hydrothermal Carbonization Process: Roadmap toward Implementation. Agronomy 2024, 14, 541. [Google Scholar] [CrossRef]

- He, C.; Chen, C.L.; Giannis, A.; Yang, Y.; Wang, J.Y. Hydrothermal Gasification of Sewage Sludge and Model Compounds for Renewable Hydrogen Production: A Review. Renew. Sustain. Energy Rev. 2014, 39, 1127–1142. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, Z.; Niu, J.; Du, Z.; Federica, C.; Zhu, Z.; Yang, K.; Li, Y.; Zhao, B.; Pedersen, T.H.; et al. Systematical Analysis of Sludge Treatment and Disposal Technologies for Carbon Footprint Reduction. J. Environ. Sci. 2023, 128, 224–249. [Google Scholar] [CrossRef]

- Schnell, M.; Horst, T.; Quicker, P. Thermal Treatment of Sewage Sludge in Germany: A Review. J. Environ. Manag. 2020, 263, 110367. [Google Scholar] [CrossRef]

- Li, B.; Wang, F.; Chi, Y.; Yan, J.H. Adhesion and Cohesion Characteristics of Sewage Sludge During Drying. Dry. Technol. 2014, 32, 1598–1607. [Google Scholar] [CrossRef]

- Hamawand, I.; Da Silva, W.P.; Eberhard, F.; Antille, D.L. Issues Related to Waste Sewage Sludge Drying under Superheated Steam. Polish J. Chem. Technol. 2015, 17, 5–14. [Google Scholar] [CrossRef]

- Deng, W.; Su, Y. Experimental Study on Agitated Drying Characteristics of Sewage Sludge under the Effects of Different Additive Agents. J. Environ. Sci. 2014, 26, 1523–1529. [Google Scholar] [CrossRef] [PubMed]

- Sukhorukov, D.A.; Kukushkin, R.G.; Alekseeva (Bykova), M.V.; Bulavchenko, O.A.; Zaikina, O.O.; Revyakin, M.E.; Kazakov, M.O.; Yakovlev, V.A. Upgrading of Sewage Sludge-Derived Pyrolysis Oil via Hydrotreatment over NiMo-Based Catalysts. Fuel 2024, 359, 130383. [Google Scholar] [CrossRef]

- Sadooghi, P.; Rauch, R. Mathematical Modeling of Sulfur Deactivation Effects on Steam Reforming of Producer Gas Produced by Biomass Gasification. Fuel Process. Technol. 2013, 110, 46–52. [Google Scholar] [CrossRef]

- Cordero-Lanzac, T.; Palos, R.; Hita, I.; Arandes, J.M.; Rodríguez-Mirasol, J.; Cordero, T.; Bilbao, J.; Castaño, P. Revealing the Pathways of Catalyst Deactivation by Coke during the Hydrodeoxygenation of Raw Bio-Oil. Appl. Catal. B Environ. 2018, 239, 513–524. [Google Scholar] [CrossRef]

- Winchell, L.J.; Ross, J.J.; Brose, D.A.; Pluth, T.B.; Fonoll, X.; Norton, J.W.; Bell, K.Y. Pyrolysis and Gasification at Water Resource Recovery Facilities: Status of the Industry. Water Environ. Res. 2022, 94, e10701. [Google Scholar] [CrossRef]

- Wang, L.; Chang, Y.; Li, A. Hydrothermal Carbonization for Energy-Efficient Processing of Sewage Sludge: A Review. Renew. Sustain. Energy Rev. 2019, 108, 423–440. [Google Scholar] [CrossRef]

- Tasca, A.L.; Puccini, M.; Gori, R.; Corsi, I.; Galletti, A.M.R.; Vitolo, S. Hydrothermal Carbonization of Sewage Sludge: A Critical Analysis of Process Severity, Hydrochar Properties and Environmental Implications. Waste Manag. 2019, 93, 1–13. [Google Scholar] [CrossRef]

- Nguyen, T.A.H.; Bui, T.H.; Guo, W.S.; Ngo, H.H. Valorization of the Aqueous Phase from Hydrothermal Carbonization of Different Feedstocks: Challenges and Perspectives. Chem. Eng. J. 2023, 472, 144802. [Google Scholar] [CrossRef]

- Liu, H.; Basar, I.A.; Nzihou, A.; Eskicioglu, C. Hydrochar Derived from Municipal Sludge through Hydrothermal Processing: A Critical Review on Its Formation, Characterization, and Valorization. Water Res. 2021, 199, 117186. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Liu, X.; Jung, H.; Zhao, S.; Pavlostathis, S.G.; Tang, Y. Effect of Prestage Hydrothermal Treatment on the Formation of Struvite vs Vivianite during Semicontinuous Anaerobic Digestion of Sewage Sludge. ACS Sustain. Chem. Eng. 2021, 9, 9093–9105. [Google Scholar] [CrossRef]

- Watson, J.; Wang, T.; Si, B.; Chen, W.T.; Aierzhati, A.; Zhang, Y. Valorization of Hydrothermal Liquefaction Aqueous Phase: Pathways towards Commercial Viability. Prog. Energy Combust. Sci. 2020, 77, 100819. [Google Scholar] [CrossRef]

- Abeyratne, W.M.L.K.; Bayat, H.; Delanka-Pedige, H.M.K.; Zhang, Y.; Brewer, C.E.; Nirmalakhandan, N. Multi-Criteria Evaluation of Energy Recovery from Urban Wastewater Sludges by Anaerobic Digestion and Hydrothermal Liquefaction. J. Environ. Chem. Eng. 2023, 11, 109628. [Google Scholar] [CrossRef]

- Kritzer, P. Corrosion in High-Temperature and Supercritical Water and Aqueous Solutions: A Review. J. Supercrit. Fluids 2004, 29, 1–29. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, W.; Chen, C.; Zhang, H.; Lin, N.; Su, Y. Influence of Reaction Conditions on the Catalytic Activity of a Nickel during the Supercritical Water Gasification of Dewatered Sewage Sludge. J. Supercrit. Fluids 2018, 140, 356–363. [Google Scholar] [CrossRef]

- Lee, I.G.; Ihm, S.K. Catalytic Gasification of Glucose over Ni/Activated Charcoal in Supercritical Water. Ind. Eng. Chem. Res. 2009, 48, 1435–1442. [Google Scholar] [CrossRef]

- Sinaǧ, A.; Kruse, A.; Rathert, J. Influence of the Heating Rate and the Type of Catalyst on the Formation of Key Intermediates and on the Generation of Gases during Hydropyrolysis of Glucose in Supercritical Water in a Batch Reactor. Ind. Eng. Chem. Res. 2004, 43, 502–508. [Google Scholar] [CrossRef]

| Ultimate Analysis (wt.%) | Proximate Analysis (wt.%) | References | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | S | O | Moisture | Ash | Volatile Matter | Fixed Carbon | HHV (MJ/kg) | ||

| 26–69 | 4–9 | 2–9 | 0.2–2 | 22–56 | 71–89 | 11–76 | 22–82 | 1–22 | 11–16 | [7,16,17,18,19] | |

| Biochemical composition (wt.%) | |||||||||||

| Protein | Lignin | Lipid | Hemicellulose | Cellulose | Others | ||||||

| 22–42 | 18 | 1–14 | 4 | 0.3 | - | [18,20] | |||||

| Heavy metal composition (ppm) | |||||||||||

| Zn | Ni | Cr | Cd | As | Cu | Hg | Pb | ||||

| 603–744 | 20–24 | 42–229 | 1 | 5 | 0–338 | 3–4 | 67–80 | [18,19] | |||

| Raw Material | Type of Reactor | Catalyst | Temperature (°C) | Gasification Agents | HHV (MJ/Nm3) | LHV (MJ/Nm3) | H2/CO Ratio | H2 Yield (%) | Reference |

|---|---|---|---|---|---|---|---|---|---|

| Sewage sludge | Updraft fixed bed | --- | 900 | Air | 12.2 | --- | 1.4 | 42.0 | [25] |

| Oxygen | 14 | --- | 1.4 | 40.0 | |||||

| Downdraft fixed bed | --- | 900 | Air | 12.8 | --- | 1.6 | 46.0 | ||

| Oxygen | 12.7 | --- | 1.1 | 45.0 | |||||

| Sewage sludge | Fluidized bed | --- | 800 | Steam | --- | 9.7 | ≈1.2 | ≈26.0 | [26] |

| Sewage sludge/pine sawdust | 800 | --- | 12.4 | ≈1.5 | ≈37.0 | ||||

| NiO/modified dolomite | 600 | --- | 12.3 | ≈1.4 | ≈36.0 | ||||

| 700 | --- | 11.8 | ≈1.5 | ≈39.0 | |||||

| 800 | --- | 11.3 | ≈1.7 | ≈46.0 | |||||

| 900 | --- | 10.6 | ≈1.7 | ≈48.0 | |||||

| Sewage sludge | Fixed bed | --- | 800 | Steam | --- | --- | ≈2.9 | 35.3 | [27] |

| Ni/HZSM-5 | --- | --- | ≈3.1 | 40.9 | |||||

| Ni/Al-MCM48 | --- | --- | ≈3.2 | 44.8 | |||||

| Ni–Fe/Al-MCM48 | --- | --- | ≈3.2 | 47.9 | |||||

| Ni–Co/Al-MCM48 | --- | --- | ≈3.1 | 51.9 | |||||

| Sewage sludge | Bubbling fluidized bed | Olivine | 809 | Air | --- | 4.1 | 1.4 | 16.8 | [28] |

| Olivine | 799 | Air | --- | 4.7 | 1.6 | 18.8 | |||

| Olivine | 796 | Steam/O2 | --- | 8.8 | 2.1 | 37.7 | |||

| Dolomite | 803 | Steam/O2 | --- | 9.2 | 1.9 | 37.9 | |||

| Limestone | 816 | Steam/O2 | --- | 9.3 | 2.2 | 38.8 | |||

| Sewage sludge (SS) | Fixed bed | --- | 550 | Steam | --- | --- | 4.7 | 27.0 | [29] |

| CaO/SS (1:1) | --- | --- | 1.3 | 81.6 | |||||

| CaO/SS (1:2) | --- | --- | 2.5 | 40.0 | |||||

| Sewage sludge | Fixed bed | - | 800 | Air | --- | --- | 0.2 | 4.3 | [30] |

| Activated Carbon | --- | --- | 1.0 | 15.1 | |||||

| Biochar | --- | --- | 0.7 | 11.4 | |||||

| Activated Carbon | Steam/Air | --- | --- | 0.9 | 15.1 | ||||

| Biochar | --- | --- | 2.0 | 22.5 | |||||

| Sewage Sludge | Bubbling fluidized bed | --- | 750 | Air | 3.0 | 2.8 | 1.1 | 7.6 | [31] |

| 800 | 3.6 | 3.3 | 1.3 | 10.4 | |||||

| 850 | 4.2 | 3.9 | 1.2 | 12.1 | |||||

| 750 | Steam/Air | 3.5 | 3.2 | 1.3 | 10.0 | ||||

| 800 | 3.8 | 3.5 | 1.4 | 12.0 | |||||

| 850 | 4.6 | 4.2 | 1.6 | 16.1 | |||||

| Alumina | 750 | Air | 3.0 | 2.7 | 1.1 | 8.0 | |||

| 800 | 3.8 | 3.5 | 1.4 | 12.3 | |||||

| 850 | 4.7 | 4.3 | 1.2 | 15.0 | |||||

| 800 | Steam/Air | 4.0 | 3.7 | 1.9 | 15.2 |

| Raw Material | Type of Pyrolysis | Type of Reactor | Catalyst | Temperature (°C) | Bio-Oil (wt.%) | Biochar (wt.%) | Gas (wt.%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Sewage sludge | Fast | Fixed-bed reactor | --- | 300 | 33.3–36.3 | 65.3–68.9 | 3.9–4.1 | [35] |

| 600 | 14.5–18.2 | 17.3–19.9 | 31.5–33.4 | |||||

| Sewage sludge | Fast | Tubular reactor | --- | 450 | 43.1 | 47.1 | 9.8 | [36] |

| --- | 650 | 37.5 | 30.0 | 32.5 | ||||

| Slow | --- | 450 | 38.2 | 53.6 | 14.2 | |||

| --- | 650 | 32.2 | 33.2 | 28.6 | ||||

| Sewage sludge (SS) and rice husk (RH) | Fast | Tubular/Fixed-bed reactor | - | 650 | 17.2 | 53.5 | 29.3 | [37] |

| Biochar from SS pyrolysis | 11.3 | 53.4 | 35.3 | |||||

| Biochar from co-pyrolysis of SS and RH | 10.7 | 53.7 | 35.6 | |||||

| Biochar from RH pyrolysis | 9.5 | 53.2 | 37.3 | |||||

| Ash from the RH pyrolysis biochar | 12.0 | 53.1 | 34.9 | |||||

| Sewage sludge | Slow | Tubular reactor | --- | 600 | 33.0 | ≈48.0 | ≈19.0 | [38] |

| --- | 700 | 26.0 | ≈45.0 | ≈29.0 | ||||

| Sewage sludge | Fast | Conical spouted-bed reactor | --- | 450 | 44.8 | 52.2 | 3.0 | [39] |

| --- | 500 | 48.5 | 46.3 | 5.2 | ||||

| --- | 600 | 45.4 | 43.2 | 11.4 | ||||

| Sewage sludge | Slow | Rotating cylinder reactor | --- | 500 | 22.1 | 61.9 | 16.0 | [33] |

| --- | 600 | 24.5 | 54.0 | 21.5 | ||||

| Sewage sludge | Fast | Fluidized-bed reactor | --- | 450 | 31.3 | 51.5 | 17.2 | [40] |

| 550 | 32.3 | 53.2 | 14.5 | |||||

| 650 | 25.0 | 47.2 | 27.9 | |||||

| Sewage sludge and humic acid | Slow | Fixed-bed reactor | --- | 700 | 32.9 | ≈45.0 | 9.8 | [34] |

| Sewage sludge | --- | 38.7 | ≈43.0 | 7.7 | ||||

| Kaolin | 33.0 | 50.3 | 6.7 | |||||

| CaO | 26.8 | 55.3 | 6.8 | |||||

| Sewage sludge | Slow | Fixed-bed reactor | --- | 500 | 47.3 | 35.1 | 17.6 | [41] |

| Composite alumina | 400 | 42.5 | 45.6 | 11.8 | ||||

| 500 | 48.4 | 34.3 | 17.3 | |||||

| 600 | 48.3 | 27.7 | 24.0 | |||||

| Sewage sludge | Slow | Fixed-bed reactor | --- | 450 | 43.1 | --- | --- | [42] |

| 850 | 36.6 | --- | --- | |||||

| Cao | 450 | 37.1 | --- | --- | ||||

| 850 | 35.9 | --- | --- | |||||

| KCl | 450 | 29.9 | --- | --- | ||||

| 850 | 41.7 | --- | --- | |||||

| Na2CO3 | 450 | 30.4 | --- | --- | ||||

| 850 | 46.5 | --- | --- | |||||

| Fe2O3 | 450 | 32.5 | --- | --- | ||||

| 850 | 37.4 | --- | --- | |||||

| Sewage sludge | Slow | Fixed-bed reactor | - | 500 | 32.5 | 58.8 | 8.7 | [43] |

| Fe2O3 | 39.1 | 48.8 | 12.1 |

| Feedstock | Type of Reactor (Volume) | Catalyst | Temperature (°C) | Moisture Content/Solid Content/Solid–Liquid Ratio | Pressure (MPa) | Residence Time (min) | Production Distribution (wt.%) | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Hydrochar | Biocrude | Gas | ||||||||

| Sewage sludge | Batch (1000 mL) | Sulfuric acid (VI), 30% | 200 | 89.9% (moisture content) | 2.5 | 120 | 4.2–6.2 | 89.3–90.6 | 4.2–5.7 | [55] |

| Fenton-oxidized sewage sludge | Batch (50 mL) | --- | 180 | 1:10 (Solid–Liquid) | --- | 240 | 50.7–65.2 | --- | [56] | |

| Sewage sludge | Batch (200 mL) | --- | 200/210/220 | 1:0.25, 1:0.5, 1:1, and 1:3 (Solid–Liquid) | --- | 300 | 54.8–74.1 (200 °C, varying L/S); 57.3–98.5 (210 °C, varying L/S); 53.6–62.5 (220 °C, varying L/S) | --- | [57] | |

| Sewage sludge (co-treatment with spent coffee grounds and bagasse) | --- | 220 | Spent coffee grounds: 50.1–64.6. Bagasse: 42.8–49.9. | --- | ||||||

| Sewage sludge | Batch (300 mL) | --- | 200/250 | 1:6 | --- | 120/300 | 73.0 (200 °C, 120 min) 61.3 (200 °C, 300 min); 63.2 (250 °C, 120 min); 57.1 (250 °C, 300 min) | --- | [54] | |

| Sewage sludge co-treated with cheese whey | Batch (300 mL) | 250 | 300 | 64.1 (250 °C, 300 min) | ||||||

| Sewage sludge | Batch (200 mL) | Acetic acid (AA) (0.4, 0.8, 1.24 M) | 220 | 1:0.025/1:0.5/1:1/1:3 | --- | 300 | 64.0 (1:0.25); 58.2 (1:0.5); 58.3 (1:1); 55.1 (1:3) 77.2 (0.4 AA); 83.6 (0.8 AA); 58.5 (1.2 AA) | --- | [58] | |

| Sewage sludge co-treated with pine sawdust | Batch (1000 mL) | --- | 180–250 | 1:30–1:10 | --- | 60–180 | 54.0–94.2 | --- | [59] | |

| Digested and dewatered sewage sludge co-treated with microalgae | Batch (1000 mL) | --- | 180/215/250 | --- | --- | 120 | 42.9–70.4 | --- | [60] | |

| Primary sewage sludge | Batch (250 mL) | --- | 140/160/180/200 | --- | --- | 15–240 | 60.5–81.1 | --- | Methane yields: 44.6% (140 °C); 43.2–46.8% (160 °C), 43.8–45.5% (180 °C), and 43.7–44.6% (200 °C) | [52] |

| Anaerobic digestion effluent from sewage sludge | Batch (1000 mL) | --- | 163/180/220/260/277 | --- | 0.83/1.10/2.24/4.96/6.07 | 30–70 | 62–78 | 9–27 | 1–22 | [61] |

| Feedstock | Type of Reactor | Catalyst | Temperature (°C) | Moisture Content/Solid Content/Solid–Liquid Ratio | Pressure (MPa) | Residence Time (min) | Production Distribution (wt.%) | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Hydrochar | Liquid | Gas | ||||||||

| Sewage sludge | Batch (1000 mL) Batch (19 L) | --- | 350 | 1:1 (Solid–Liquid) | 180 | 30 | 43.9 | 18.9 | 10.3 | [63] |

| Na2CO3 | 41.5 | 17.7 | 8.7 | |||||||

| Li2CO3 | 41.1 | 19.8 | 9.7 | |||||||

| K2CO3 | 41.8 | 16.8 | 8.5 | |||||||

| Ba(OH)2 | 46.6 | 17.2 | 9.1 | |||||||

| Fe2O3 | 51.7 | 17.0 | 9.3 | |||||||

| CeO2 | 47.9 | 16.2 | 8.3 | |||||||

| NiMo/MoO3 | 49.5 | 18.4 | 9.0 | |||||||

| MoS2 | 50.8 | 17.3 | 9.0 | |||||||

| Ni/NiO | 48.6 | 19.7 | 9.4 | |||||||

| SnO2 | 48.8 | 20.3 | 9.8 | |||||||

| FeS | 48.4 | 15.8 | 6.6 | |||||||

| Sewage sludge * | Batch (25 mL) | - | 350 | 75 wt.% (moisture content) | 2.5 | 30 | 4 | 53 | 7 | [64] |

| KOH | 8 | 47 | 10 | |||||||

| HCOOH | 4 | 38 | 10 | |||||||

| Continuous (2 kg/h) | - | 10 | - | - | - | |||||

| KOH | 38 | 5 | - | |||||||

| HCOOH | 40 | <1 | - | |||||||

| Sewage sludge | Batch (10 mL internal volume) | --- | 300 | 1:10 | --- | 90 | 50.7 | 68.8 | 23.0 | [65] |

| Sewage sludge/wheat straw | 35.6 | 31.9 | 32.5 | |||||||

| Sewage sludge/ cow manure | 42.4 | 28.2 | 29.4 | |||||||

| Sewage sludge/chlorella pyrenoidosa | 27.3 | 39.4 | 33.3 | |||||||

| Sewage sludge | Batch (50 mL) | K2CO3 | 320 | 1:6 | 2.5 | 15 | ≈13.0 | ≈67.0 | ≈20.0 | [66] |

| Al2O3 | ≈17.5 | ≈70.0 | ≈12.5 | |||||||

| Co–Mo/ATP | ≈12.0 | ≈74 | ≈14.0 | |||||||

| Co–Mo/Al2O3 | ≈18.0 | ≈66.0 | ≈16.0 | |||||||

| Sewage sludge | Continuous (2 kg/h) | - | 350 | 10 wt.% (solid content) | 25 | 8 | 1.9 | 80.2 | 17.9 | [67] |

| Raw Material | Type of Reactor | Catalyst | Sludge Concentration (wt.%) | Temperature (°C) | Pressure (MPa) | Residence Time (min) | LHV (MJ/Nm3) | CH4 Yield (%) | H2 Yield (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Sewage sludge | Batch | --- | 8.9 | 750 | 22.5–27.5 | 30 | 10.3 | ≈12.0 | ≈52.0 | [71] |

| --- | 650 | ≈12.0 | ≈19.0 | ≈39.0 | ||||||

| K2CO3 | 20 | ≈11.5 | ≈18.0 | ≈45.0 | ||||||

| RNi-Mo2 | ≈10.5 | ≈14.0 | ≈47.0 | |||||||

| K2CO3/RNi-Mo2 | ≈11.0 | ≈17.0 | ≈43.0 | |||||||

| Sewage sludge | Fluidized bed | --- | 2 | 540 | 25 | --- | --- | ≈10.5 | ≈43.0 | [72] |

| NaOH | ≈9.0 | ≈50.0 | ||||||||

| KOH | ≈7.0 | ≈56.0 | ||||||||

| K2CO3 | ≈7.0 | ≈53.0 | ||||||||

| Na2CO3 | ≈6.0 | ≈52.0 | ||||||||

| Sewage sludge | Continuous | --- | --- | 550 | 25 | 0.08 | --- | ≈18.0 | 38.5 | [73] |

| 600 | ≈27.0 | 39.4 | ||||||||

| Sewage sludge | Batch | - | 10 | 400 | 30 | 60 | --- | =17.0 | =34.0 | [70] |

| Na2CO3 | =16.0 | =33.0 | ||||||||

| K2CO3 | =14.0 | =33.0 | ||||||||

| KOH | =17.0 | =37.0 | ||||||||

| NaOH | =18.0 | =36.0 | ||||||||

| Sewage sludge | Batch | - | 10 | 450 | 25 -27 | 60 | --- | 18.9 | 40.9 | [74] |

| NaOH | =23 | =45.0 | ||||||||

| KOH | =18 | =48.0 | ||||||||

| Ca(OH)2 | =17 | =47.0 | ||||||||

| K2CO3 | =14 | 48.7 | ||||||||

| Na2CO3 | =16 | =48.0 | ||||||||

| Sewage sludge | Batch | --- | 3 | 380 | 27 | 6 | --- | 16.6 | 22.6 | [75] |

| 460 | --- | 22.9 | 55.7 | |||||||

| Sewage sludge | Batch | --- | 10 | 380 | 25 | --- | 8.7 | ≈15.0 | 29.3 | [76] |

| 460 | 28 | --- | 10.5 | ≈13.0 | 50.1 | |||||

| Activated carbon | 400 | 25 | --- | --- | ≈20.0 | 38.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rijo, B.; Nobre, C.; Brito, P.; Ferreira, P. An Overview of the Thermochemical Valorization of Sewage Sludge: Principles and Current Challenges. Energies 2024, 17, 2417. https://doi.org/10.3390/en17102417

Rijo B, Nobre C, Brito P, Ferreira P. An Overview of the Thermochemical Valorization of Sewage Sludge: Principles and Current Challenges. Energies. 2024; 17(10):2417. https://doi.org/10.3390/en17102417

Chicago/Turabian StyleRijo, Bruna, Catarina Nobre, Paulo Brito, and Paulo Ferreira. 2024. "An Overview of the Thermochemical Valorization of Sewage Sludge: Principles and Current Challenges" Energies 17, no. 10: 2417. https://doi.org/10.3390/en17102417

APA StyleRijo, B., Nobre, C., Brito, P., & Ferreira, P. (2024). An Overview of the Thermochemical Valorization of Sewage Sludge: Principles and Current Challenges. Energies, 17(10), 2417. https://doi.org/10.3390/en17102417