Characteristics of Permeability Evolution and Pore Structure of Coal with High Gas

Abstract

:1. Introduction

2. Experimental Tests

2.1. Coal Sample Preparation

2.2. Adsorption-Permeability Experiment

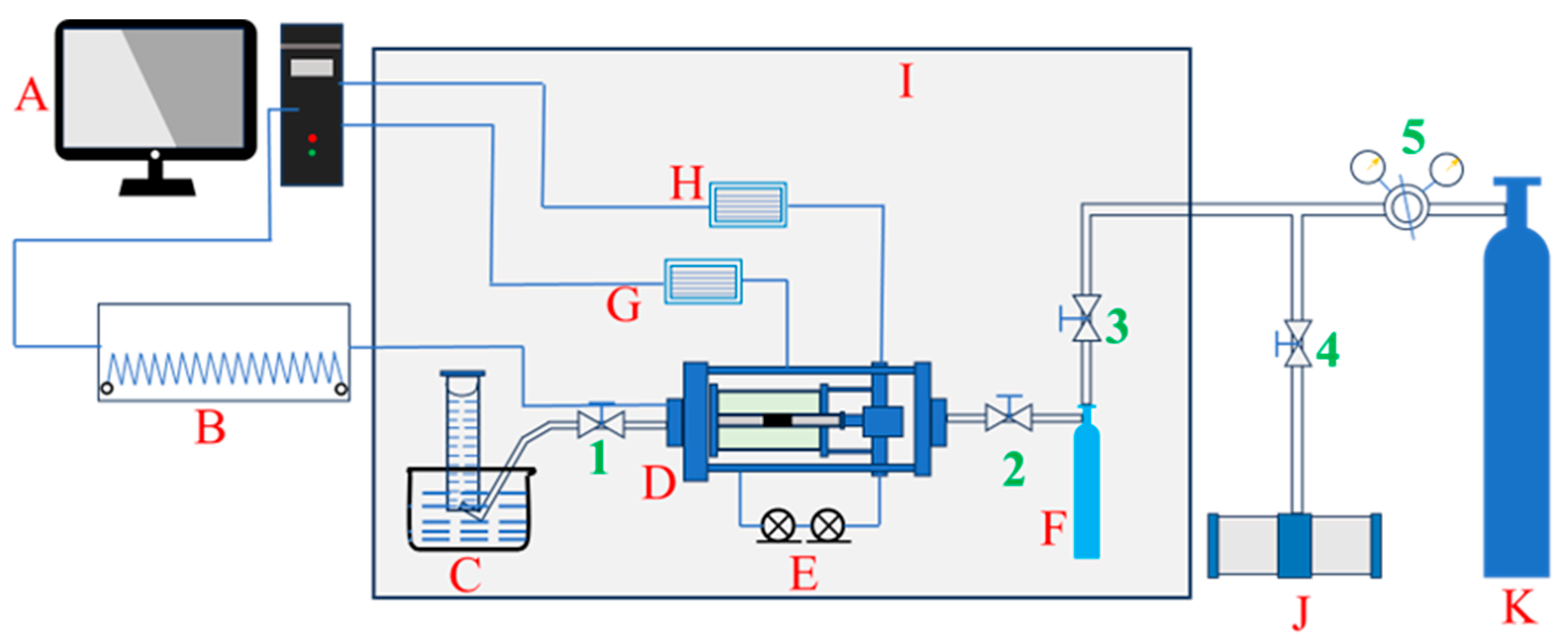

2.2.1. Experimental Equipment

2.2.2. Experimental Method

- (1)

- The dried coal samples were set in the core holder along with two sets of axial–radial resistance strain gauges. With a flex flat cable (FFC), the strain gauges were joined to the axial–radial strain transducer.

- (2)

- To simulate the real stress of coal seam, the axial pressure and confining pressure were kept at 7 MPa, and a vacuum pump was used to vacuum the coal sample, and then the air tightness of the pipeline was checked.

- (3)

- Helium gas (He) was injected into the reference cylinder at a predetermined pressure from the gas source. Helium injection was performed with incremental pressure levels, including 0.3 MPa, 0.5 MPa, 1 MPa, 1.5 MPa, 2 MPa, 2.5 MPa, and 3 MPa. At each injection pressure, the pressure was kept constant while the outlet was sealed before injection. The valve connecting the gas source to the reference cylinder was then closed, while the outlet of the reference cylinder was opened to inject He into the core gripper. This process was maintained for 72 h to calibrate the pore volume of the coal sample.

- (4)

- The outlet valve of the core gripper was kept open to the atmosphere until all specified injection pressures were completed, while measuring the radial strain of the sample under different injection pressures. The flow rate of helium (He) was measured using a gas collection device to calculate the permeability of the coal sample. The gas flow volume was measured by a gas collecting device for a certain period of time, thereby calculating the flow rate, and calculating the coal sample permeability based on Darcy’s law, as demonstrated as Equation (1).where k is coal permeability (10−3 μm2); Q is the flow rate (mL/s) through coal sample; p0 is atmospheric pressure (take 0.1 MPa); μ is the hydrodynamic viscosity (Pa·s); L is the length of coal sample (cm); A is the cross-sectional area of coal sample (cm2) of the cylinder; and p1 and p2 are the gas pressures (MPa) at both ends of the inlet and outlet of coal sample.

- (5)

- We removed the gas pressure and closed the outlet, and then pumped the vacuum for more than 12 h.

- (6)

- Following the same procedure as the helium injection, nitrogen (N2) was introduced for a duration of 72 h to obtain the volume of gas adsorbed by the coal sample. The flow rate was then measured to determine the sample’s permeability.

- (7)

- For each experimental set, the gas pressure was varied, starting from 0.3 MPa and incrementally increasing to 3 MPa, with the entire experimental procedure repeated seven times. The effective stress of the coal samples varied with the increase in pore pressure, calculated by Equation (2).

2.3. Mercury Injection Porosimetry Experiment

2.3.1. Experimental Method

2.3.2. Surface Fractal Dimension Calculation Method

3. Experimental Results and Analysis

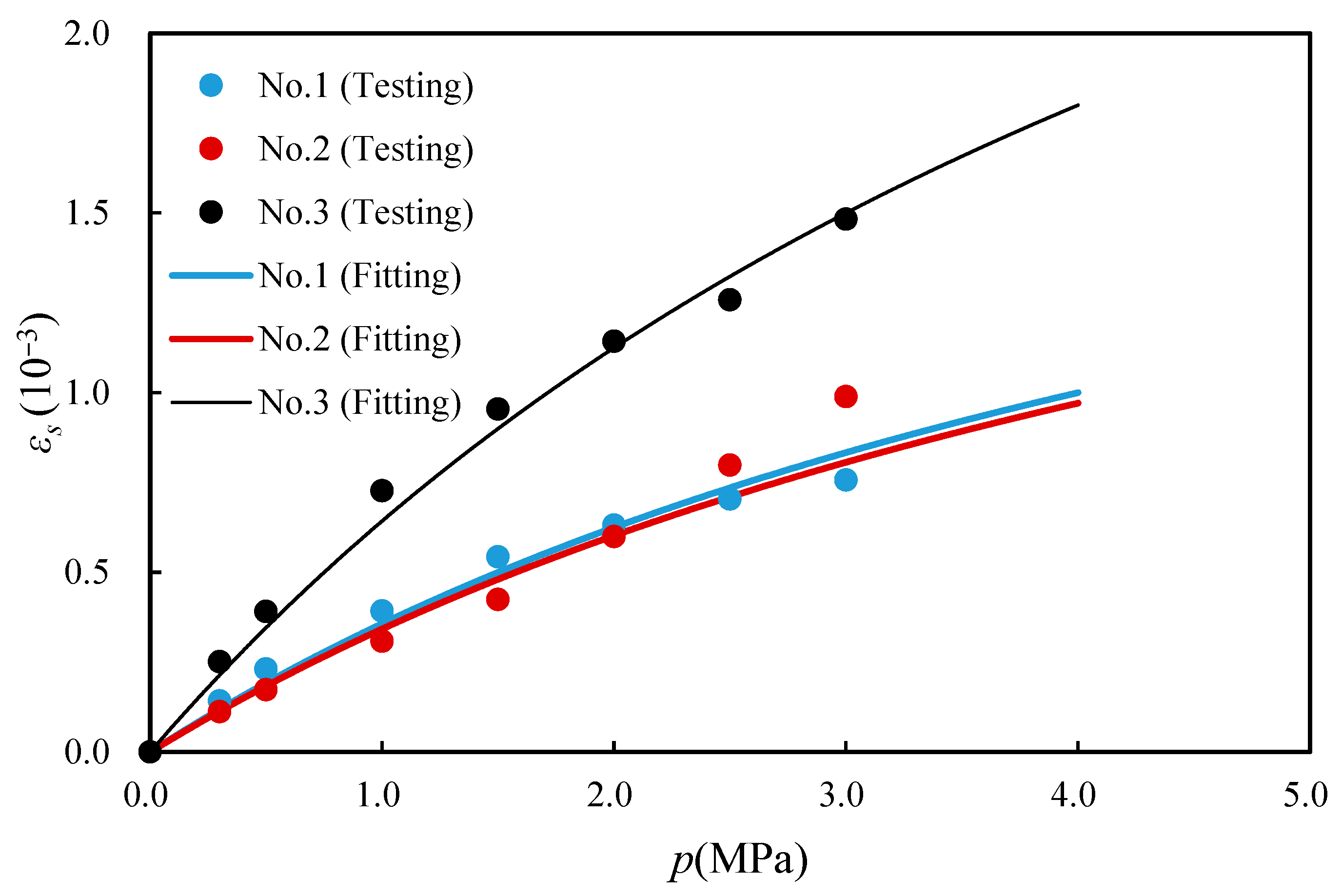

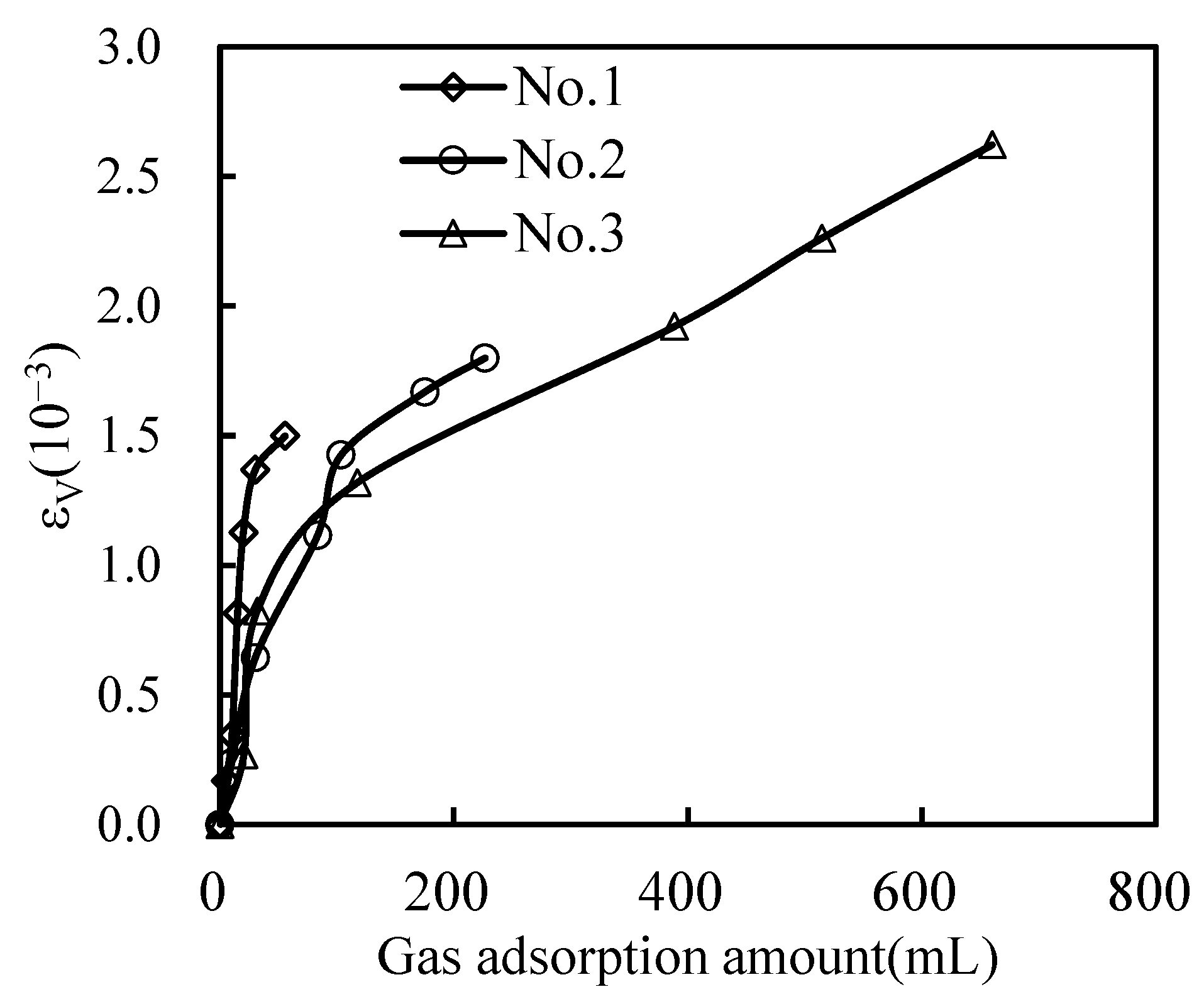

3.1. Nitrogen Adsorption Strain of Coal Samples

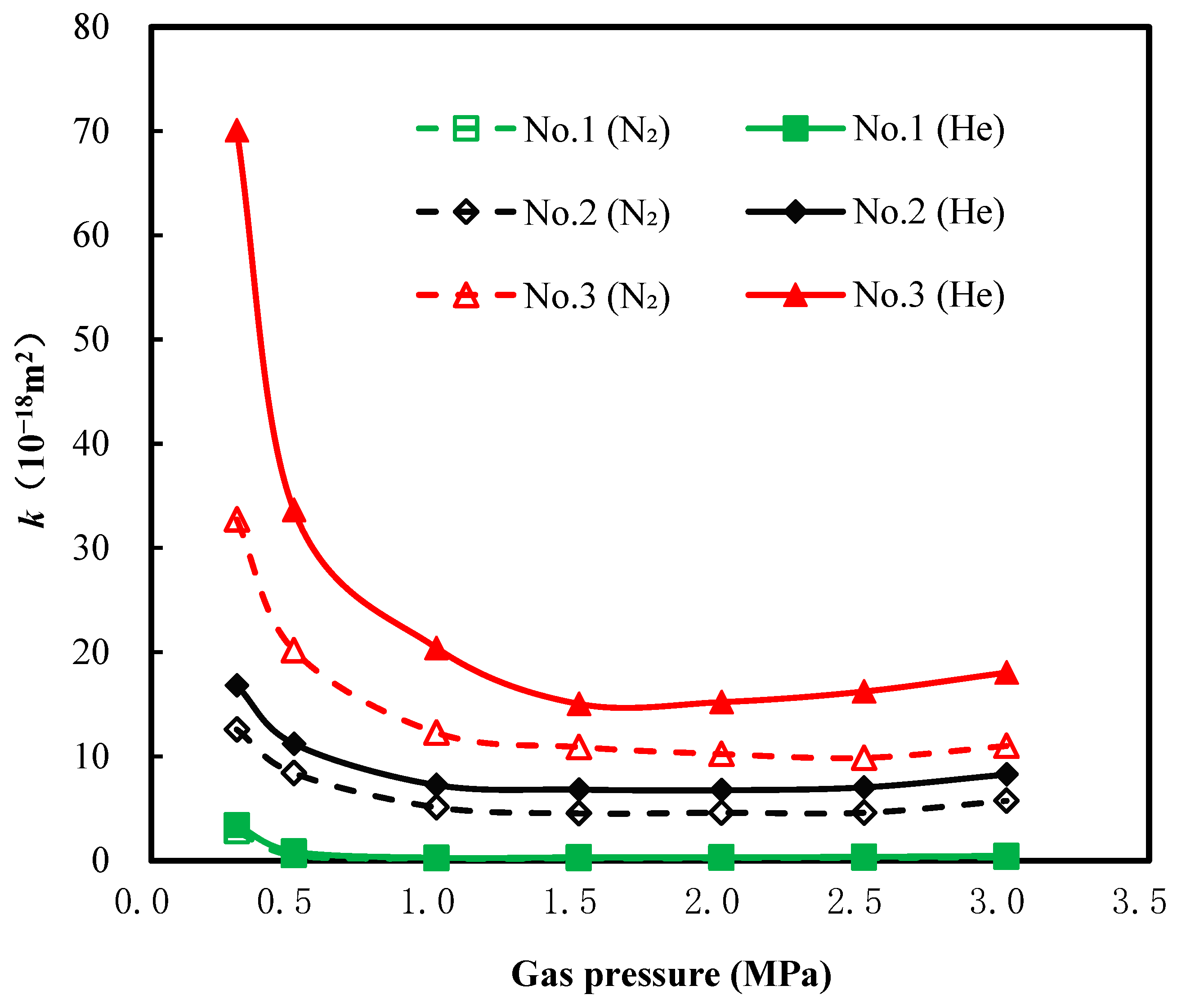

3.2. Coal Permeability under Different Gas Pressure

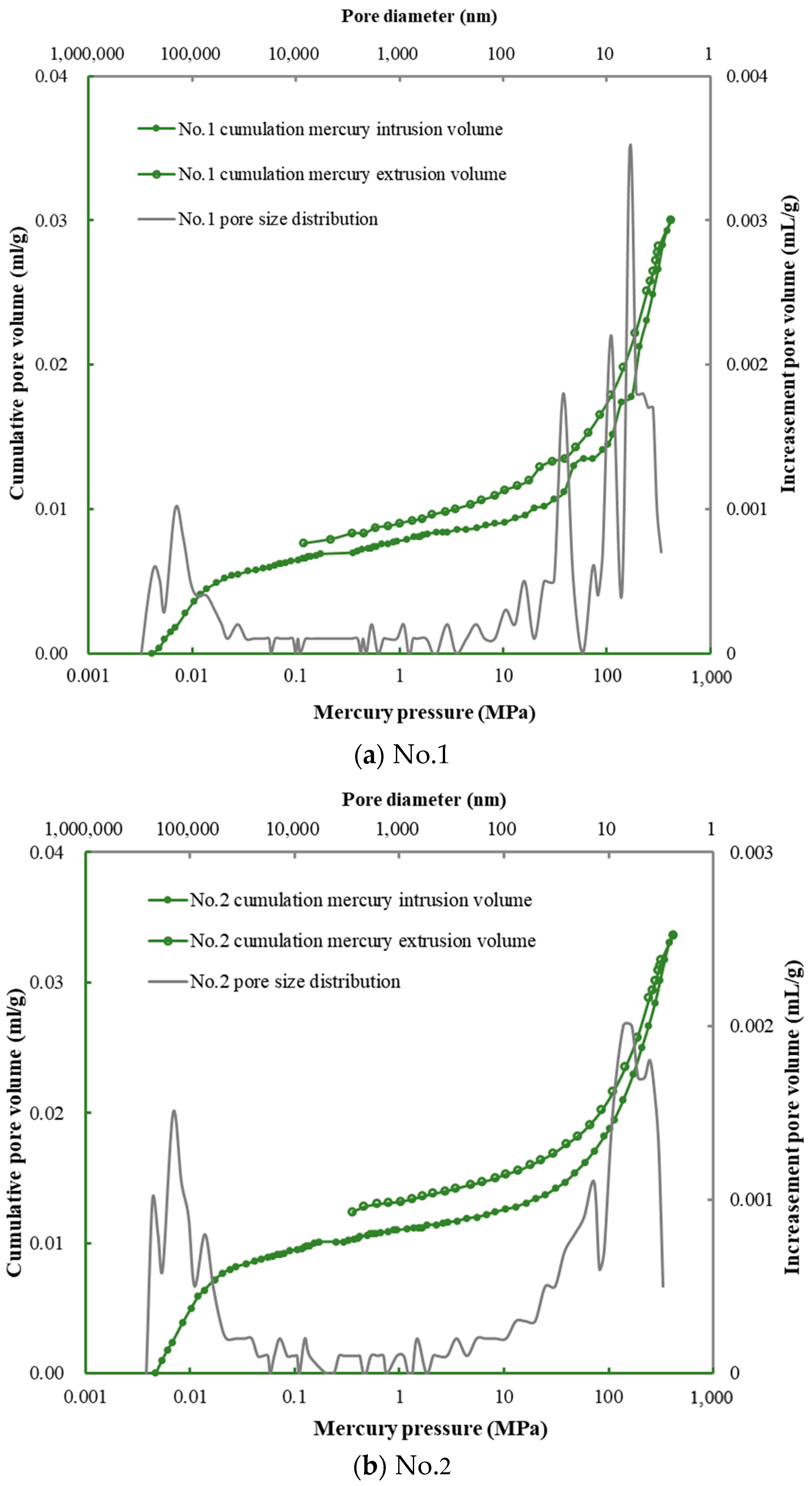

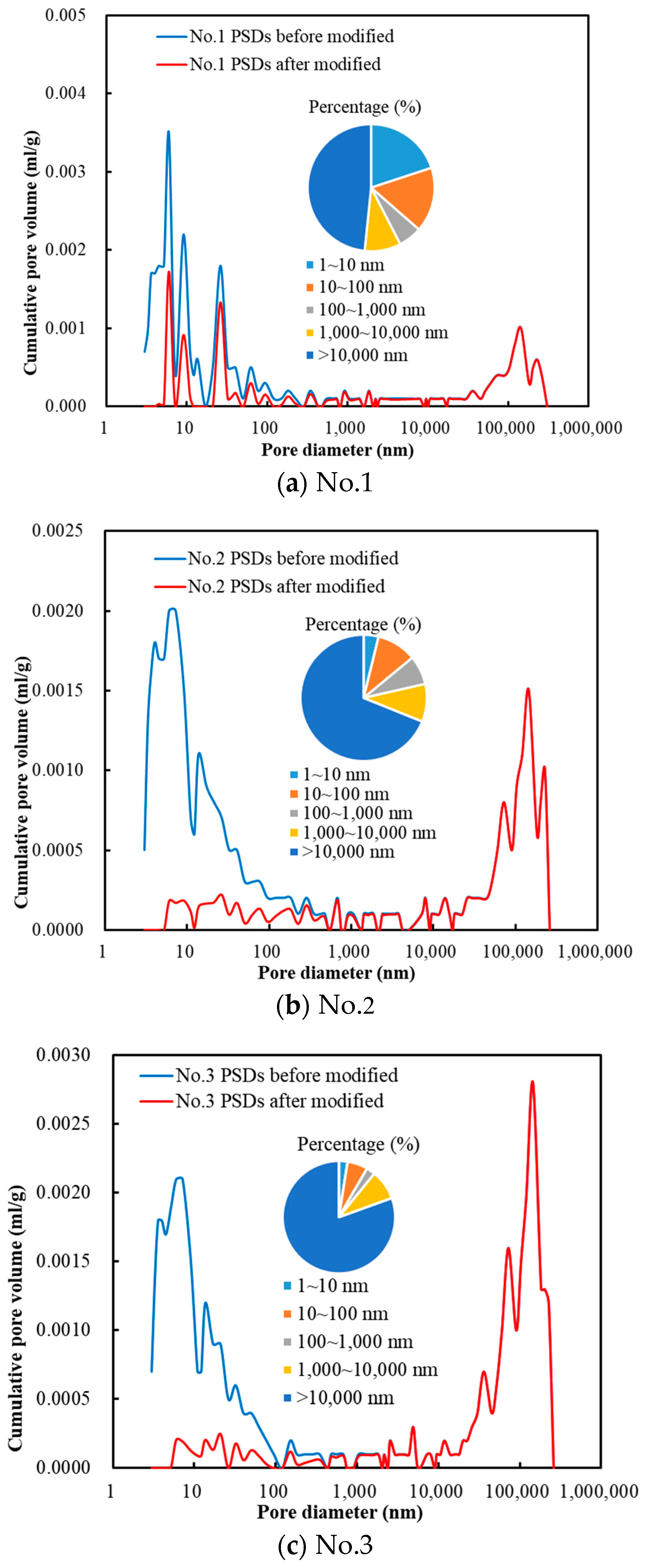

3.3. Pore Structure Characteristics Detected by MIP

4. Discussion

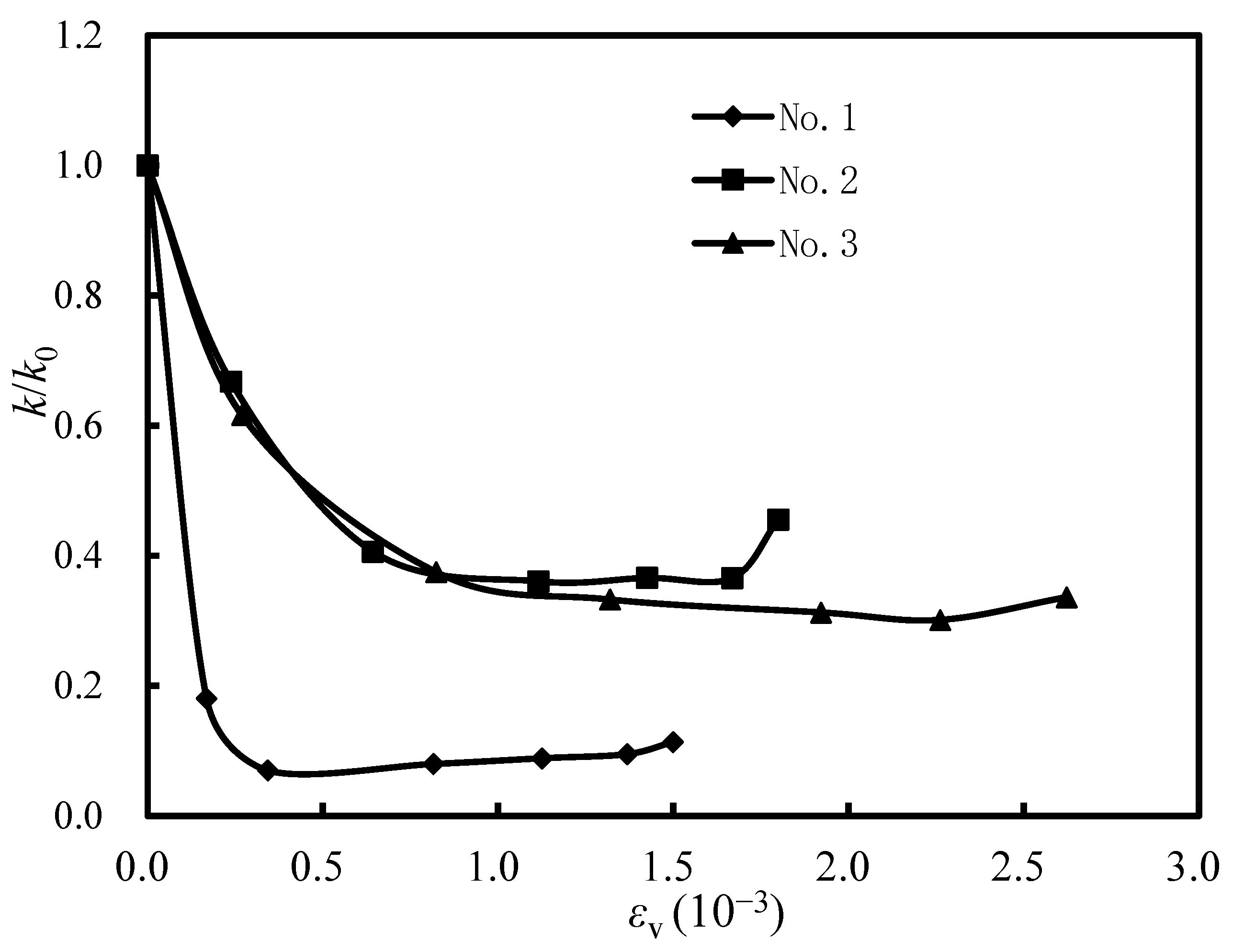

4.1. The Relationship between Permeability and Adsorption Strain

4.2. Pore Size Distributions

4.3. Fractal Analysis on Pore Structure

5. Conclusions

- (1)

- Under the condition that the axial and confining stresses are both 7 MPa, with the increase in gas pressure, the nitrogen adsorption strain aggrandizes and follows the laws of the Langmuir trend. The trend of permeability for helium is similar to a “V” shape, revealing that the permeability of helium is affected by effective stress and the slippage effect. The evolution of nitrogen permeability is similar to that of nitrogen. The permeability difference between them shows the influence of nitrogen adsorption effect on gas permeability, and adsorption effect reduces the permeability of coal samples.

- (2)

- The pore structure characteristics of coal samples with pore sizes ranging from 3 nm to 370 μm was investigated with a high-pressure mercury injection experiment. The coal matrix produces compressibility when the mercury injection pressure is greater than 20 MPa, and the mercury injection data are used merely for compressibility correction in this work. The dominant pores of Tangshan coal samples are micro-cracks, accounting for 66% of the total pore volume. The pores are mainly composed of semi-open pores with one end closed, which is convenient for gas seepage.

- (3)

- Surface fractal dimension Ds can reveal the roughness and complexion of the pore surface, and its value is between two and three. The larger Ds is, the rougher and more complex the pore surface is. The surface fractal dimension Ds1 is larger than Ds2 and Ds3, indicating that the surface roughness of adsorbed pores is higher than that of seepage pores. Ds1 is positively correlated with micropore volume content, while Ds2 and Ds3 are negatively correlated with pore volume content and gas permeability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| A | cross-sectional area of coal sample, cm2 |

| Cf | pore compression factor |

| d | pore diameter injected, nm |

| Ds | surface dimension |

| k | coal permeability, 10−3 μm2 |

| k0 | initial permeability, 10−3 μm |

| kc | matrix compressibility coefficient, m2/N |

| L | length of coal sample, cm |

| p | signifies the gas pressure, in MPa. |

| p0 | atmospheric pressure, MPa |

| p1 | gas pressures at both ends of the inlet of coal sample, MPa |

| p2 | gas pressures at both ends of the outlet of coal sample, MPa |

| pL | Langmuir pressure, MPa |

| P | mercury injection pressure, MPa |

| Pi | mercury injected pressure at step i, MPa |

| Q | flow rate through coal sample, mL/s |

| rn | the smallest pore radius injected by mercury pressure Pi, nm |

| ∆Vi | increment of mercury injected volume at pressure Pi, mL/g |

| Vm | volume of matrix skeleton, m3 |

| coal matrix compressive volume at pressure Pi, m3 | |

| Vbulk | bulk volume of coal sample, m3 |

| Vobs (Pi−1) | represents the observed mercury volume at pressure Pi−1, m3 |

| pore volume at Pi, m3 | |

| pore volume at Pi−1, m3. | |

| Wn | accumulated surface energy, J |

| ε | strain |

| εs | adsorption strain |

| εL | Langmuir strain |

| εv | volumetric strain |

| σ | surface tension of mercury, MPa |

| σe | effective stress, represents, MPa |

| σr | radial stress, MPa |

| σz | axial stress, MPa |

| μ | hydrodynamic viscosity, Pa·s |

| θ | angle of coal surface and mercury, ° |

References

- Lv, Y.; Tang, D.; Xu, H.; Luo, H. Production characteristics and the key factors in high-rank coalbed methane fields: A case study on the Fanzhuang Block, Southern Qinshui Basin, China. Int. J. Coal Geol. 2012, 96–97, 93–108. [Google Scholar] [CrossRef]

- Tao, S.; Wang, Y.; Tang, D.; Xu, H.; Lv, Y.; He, W.; Li, Y. Dynamic variation effects of coal permeability during the coalbed methane development process in the Qinshui Basin, China. Int. J. Coal Geol. 2012, 93, 16–22. [Google Scholar] [CrossRef]

- Shi, J.Q.; Durucan, S. Drawdown Induced Changes in Permeability of Coalbeds: A New Interpretation of the Reservoir Response to Primary Recovery. Transp. Porous Media 2004, 56, 1–16. [Google Scholar] [CrossRef]

- Gray, I. Reservoir Engineering in Coal Seams: Part 1—The Physical Process of Gas Storage and Movement in Coal Seams. SPE Reserv. Eng. 1987, 2, 28–34. [Google Scholar] [CrossRef]

- Meng, Y.; Li, Z.; Lai, F. Experimental study on porosity and permeability of anthracite coal under different stresses. J. Pet. Sci. Eng. 2015, 133, 810–817. [Google Scholar] [CrossRef]

- Gentzis, T.; Deisman, N.; Chalaturnyk, R.J. Geomechanical properties and permeability of coals from the Foothills and Mountain regions of western Canada. Int. J. Coal Geol. 2007, 69, 153–164. [Google Scholar] [CrossRef]

- Lin, B.; Zhou, S. Experimental Investigation on the Permeability of the Coal Samples Containing Methane. J. China Univ. Min. Technol. 1987, 16, 21–28. [Google Scholar]

- Pan, Z.; Connell, L.D. Modelling permeability for coal reservoirs: A review of analytical models and testing data. Int. J. Coal Geol. 2012, 92, 1–44. [Google Scholar] [CrossRef]

- McKee, C.R.; Bumb, A.C.; Koenig, R.A. Stress-Dependent Permeability and Porosity of Coal and Other Geologic Formations. SPE Form. Eval. 1988, 3, 81–91. [Google Scholar] [CrossRef]

- Seidle, J.P.; Jeansonne, M.W.; Erickson, D.J. Application of Matchstick Geometry to Stress Dependent Permeability in Coals. In Proceedings of the SPE Rocky Mountain Regional Meeting, Casper, WY, USA, 18–21 May 1992; pp. 433–444. [Google Scholar]

- Connell, L.D.; Mazumder, S.; Sander, R.; Camilleri, M.; Pan, Z.; Heryanto, D. Laboratory characterisation of coal matrix shrinkage, cleat compressibility and the geomechanical properties determining reservoir permeability. Fuel 2016, 165, 499–512. [Google Scholar] [CrossRef]

- Schraufnagel, R.A.; Sawyer, W.K.; Paul, G.W. Development and Application of a 3D Coalbed Simulator Petroleum Society of Cim/Society of Petroleum Engineers Paper Development and Application of a 3D Coalbed Simulator By. In Proceedings of the Annual Technical Meeting, Calgary, AB, Canada, 10–13 June 1990. [Google Scholar]

- Harpalani, S.; Chen, G. Influence of gas production induced volumetric strain on permeability of coal. Geotech. Geol. Eng. 1997, 15, 303–325. [Google Scholar] [CrossRef]

- Connell, L. Coupled flow and geomechanical processes during gas production from coal seams. Int. J. Coal Geol. 2009, 79, 18–28. [Google Scholar] [CrossRef]

- Zhengguang, Z.; Yong, Q.; Geoff, W.; Hansen, S.; Zhenjiang, Y.; Jun, J.; Zhaobiao, Y. Evaluation of Coal Body Structures and Their Distributions by Geophysical Logging Methods: Case Study in the Laochang Block, Eastern Yunnan, China. Nat. Resour. Res. 2021, 30, 2225–2239. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; Yi, T.; You, Z.; Yang, Z. Pore Structure Characteristics of Coal and Their Geological Controlling Factors in Eastern Yunnan and Western Guizhou, China. ACS Omega 2020, 5, 19565–19578. [Google Scholar] [CrossRef]

- Chen, H.; Tian, W.; Chen, Z.; Zhang, Q.; Tao, S. Genesis of Coalbed Methane and Its Storage and Seepage Space in Baode Block, Eastern Ordos Basin. Energies 2022, 15, 81. [Google Scholar] [CrossRef]

- Li, X.; Chen, D.; Kang, Y.; Meng, X. Characterization of Pores and Fractures of Coal Based on CT Scan. Coal Geol. Explor. 2016, 44, 58–62+70. [Google Scholar] [CrossRef]

- Shadrin, A.V. Geophysical criterion of pre-outburst crack propagation in coal beds. J. Min. Sci. 2016, 52, 670–682. [Google Scholar] [CrossRef]

- Bai, P. Analysis of Pore Comprehensive Fractal Feature of Medium and Low Rank Coal in Xinjiang Region. Shaanxi Coal 2019, 38, 11–27. [Google Scholar]

- Groen, J.C.; Peffer, L.A.; Pérez-Ramirez, J. Pore size determination in modified micro- and mesoporous materials. Pitfalls and limitations in gas adsorption data analysis. Microporous Mesoporous Mater. 2003, 60, 1–17. [Google Scholar] [CrossRef]

- Yu, S.; Bo, J.; Ming, L.; Chenliang, H.; Shaochun, X. A review on pore-fractures in tectonically deformed coals. Fuel 2020, 278, 118248. [Google Scholar] [CrossRef]

- Wang, C.; Zhai, P.; Chen, Z.; Liu, J.; Wang, L.; Xie, J. Experimental study of coal matrix-cleat interaction under constant volume boundary condition. Int. J. Coal Geol. 2017, 181, 124–132. [Google Scholar] [CrossRef]

- Suuberg, E.M.; Deevi, S.C.; Yun, Y. Elastic behaviour of coals studied by mercury porosimetry. Fuel 1995, 74, 1522–1530. [Google Scholar] [CrossRef]

- Shao, P.; Wang, X.; Song, Y.; Li, Y. Study on the characteristics of matrix compressibility and its influence factors for different rank coals. J. Nat. Gas Sci. Eng. 2018, 56, 93–106. [Google Scholar] [CrossRef]

- Li, Y.; Song, D.; Liu, S.; Ji, X.; Hao, H. Evaluation of pore properties in coal through compressibility correction based on mercury intrusion porosimetry: A practical approach. Fuel 2021, 291, 120130. [Google Scholar] [CrossRef]

- Sun, B.; Yang, Q.; Zhu, J.; Shao, T.; Yang, Y.; Hou, C.; Li, G. Pore size distributions and pore multifractal characteristics of medium and low-rank coals. Sci. Rep. 2020, 10, 22353. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquérol, J.; Siemieniewaka, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Ma, Y.-K.; Nie, B.-S.; He, X.-Q.; Li, X.-C.; Meng, J.-Q.; Song, D.-Z. Mechanism investigation on coal and gas outburst: An overview. Int. J. Miner. Met. Mater. 2020, 27, 872–887. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, R.; Zhang, Y.; He, F. The fractal characteristics of pore size distribution in cement-based materials and its effect on gas permeability. Sci. Rep. 2019, 9, 17191. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Luo, M.; Pang, X.; Li, L.; Li, K. Surface fractal dimension: An indicator to characterize the microstructure of cement-based porous materials. Appl. Surf. Sci. 2013, 282, 302–307. [Google Scholar] [CrossRef]

- Wang, J. Multi-Fractal Characteristics of Pore Structure of Coal Rock in Low and Medium Rank CBM Reservoirs. Shiyou Huagong Gaodeng Xuexiao Xuebao/J. Petrochem. Univ. 2019, 32, 26–32. [Google Scholar] [CrossRef]

- Mahamud, M.M. Textural characterization of active carbons using fractal analysis. Fuel Process. Technol. 2006, 87, 907–917. [Google Scholar] [CrossRef]

- Kravchenko, A.N.; Boast, C.W.; Bullock, D.G. Multifractal Analysis of Soil Spatial Variability. Agron. J. 1999, 91, 1033–1041. [Google Scholar] [CrossRef]

- Wang, F.; Li, S. Determination of the Surface Fractal Dimension for Porous Media by Capillary Condensation. Ind. Eng. Chem. Res. 1995, 34, 1383–1386. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, W.; Liu, X. Scale-dependent nature of the surface fractal dimension for bi- and multi-disperse porous solids by mercury porosimetry. Appl. Surf. Sci. 2006, 253, 1349–1355. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, J.; Jiang, Y. Multiscale Experiments and Multifractal Analysis of Bituminous Coals: Dominant Pore Properties for Gas Permeability. J. Test. Eval. 2019, 47, 2847–2866. [Google Scholar] [CrossRef]

- Cheng, Y.; Luo, X.; Hou, B.; Zhang, S.; Tan, C.; Xiao, H. Pore Structure and Permeability Characterization of Tight Sandstone Reservoirs: From a Multiscale Perspective. Energy Fuels 2023, 37, 9185–9196. [Google Scholar] [CrossRef]

- Qin, X.; Cai, J.; Wang, G. Pore-scale modeling of pore structure properties and wettability effect on permeability of low-rank coal. Int. J. Min. Sci. Technol. 2023, 33, 573–584. [Google Scholar] [CrossRef]

- Zuowei, H.; Sijing, H.; Donghuan, W.; Yongkun, M.; Xiaoning, L. Application of Multiple Stepwise Regression to Influential Evaluation of Pore-Throat Size on Low-Permeability Sandstone Reservoirs. J. Guilin Univ. Technol. 2013, 33, 21–25. [Google Scholar]

- SYT 5336-2006; Practices for Core Analysis. Petroleum Industry Press: Beijing, China, 2006.

- Wang, S.; Elsworth, D.; Liu, J. Permeability evolution in fractured coal: The roles of fracture geometry and water-content. Int. J. Coal Geol. 2011, 87, 13–25. [Google Scholar] [CrossRef]

- Battistutta, E.; van Hemert, P.; Lutynski, M.; Bruining, H.; Wolf, K.-H. Swelling and sorption experiments on methane, nitrogen and carbon dioxide on dry Selar Cornish coal. Int. J. Coal Geol. 2010, 84, 39–48. [Google Scholar] [CrossRef]

- GB/T 21650.1-2008; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption-Part 1: Mercury Porosimetry. China Standard Press: Beijing, China, 2008.

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. B 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Farmer, I.; Pooley, F. A hypothesis to explain the occurrence of outbursts in coal, based on a study of west wales outburst coal. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1967, 4, 189–193. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. A theoretical model for gas adsorption-induced coal swelling. Int. J. Coal Geol. 2007, 69, 243–252. [Google Scholar] [CrossRef]

- Liu, S.; Harpalani, S. A new theoretical approach to model sorption-induced coal shrinkage or swelling. AAPG Bull. 2013, 97, 1033–1049. [Google Scholar] [CrossRef]

- Meng, Y.; Liu, S.; Li, Z. Experimental study on sorption induced strain and permeability evolutions and their implications in the anthracite coalbed methane production. J. Pet. Sci. Eng. 2018, 164, 515–522. [Google Scholar] [CrossRef]

- Yu, S.; Bo, J.; Jie-Gang, L. Nanopore Structural Characteristics and Their Impact on Methane Adsorption and Diffusion in Low to Medium Tectonically Deformed Coals: Case Study in the Huaibei Coal Field. Energy Fuels 2017, 31, 6711–6723. [Google Scholar] [CrossRef]

- Debelak, K.A.; Schrodt, J. Comparison of pore structure in Kentucky coals by mercury penetration and carbon dioxide adsorption. Fuel 1979, 58, 732–736. [Google Scholar] [CrossRef]

- Li, Y.; Lu, G.; Rudolph, V. Compressibility and Fractal Dimension of Fine Coal Particles in Relation to Pore Structure Characterization Using Mercury Porosimetry. Part. Part. Syst. Charact. 1999, 16, 25–31. [Google Scholar] [CrossRef]

| Stress Condition | Value | ||||||

|---|---|---|---|---|---|---|---|

| Gas inlet pressure (MPa) | 0.3 | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 |

| Effective stress (MPa) | 6.8 | 6.7 | 6.45 | 6.2 | 5.95 | 5.7 | 5.45 |

| Pressure/MPa | No. 1 (10−3) | No. 2 (10−3) | No. 3 (10−3) |

|---|---|---|---|

| 0.3 | 0.142 | 0.112 | 0.251 |

| 0.5 | 0.231 | 0.173 | 0.391 |

| 1.0 | 0.392 | 0.308 | 0.727 |

| 1.5 | 0.543 | 0.424 | 0.954 |

| 2.0 | 0.631 | 0.599 | 1.143 |

| 2.5 | 0.704 | 0.798 | 1.258 |

| 3.0 | 0.757 | 0.989 | 1.483 |

| Sample Number | No.1 | No.2 | No.3 |

|---|---|---|---|

| εL (10−3) | 2.516 | 2.524 | 4.513 |

| pL (MPa) | 6.0 | 6.3 | 6.0 |

| Sample No. | Porosity/% | Median Pore Diameter in Volume/nm | Average Pore Size/nm | Total Pore Volume/cm3/g | The Efficiency of Mercury Withdrawal/% |

|---|---|---|---|---|---|

| No. 1 | 3.963 | 11.4 | 9.7 | 0.03 | 74.7 |

| No. 2 | 5.586 | 127.5 | 13.8 | 0.0336 | 63.1 |

| No. 3 | 5.451 | 52.6 | 12.9 | 0.042 | 54.8 |

| Sample No. | Volume of Coal Matrix Skeleton (cm3/g) | Bulk Volume of Coal Sample (cm3/g) | km (×10−11 m2/N) | Pore Volume before Modified (cm3/g) | Pore Volume after Modified (cm3/g) | Volume Correction Rate (%) |

|---|---|---|---|---|---|---|

| No.1 | 0.7269 | 0.7569 | 6.9616 | 0.0300 | 0.0136 | 54.557 |

| No.2 | 0.7135 | 0.7557 | 7.1995 | 0.0336 | 0.0141 | 58.124 |

| No.3 | 0.7283 | 0.7702 | 7.4372 | 0.0420 | 0.0215 | 48.868 |

| Sample No. | Ds1 | Ds2 | Ds3 | Va (mL/g) | Vs (mL/g) | Permeability N2 * (10−18 m2) |

|---|---|---|---|---|---|---|

| No. 1 | 2.99 | 2.76 | 2.56 | 0.0050 | 0.0087 | 0.32 |

| No. 2 | 2.89 | 2.53 | 2.55 | 0.0020 | 0.0121 | 5.73 |

| No. 3 | 2.89 | 2.53 | 2.55 | 0.0018 | 0.0197 | 13.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Shao, T.; Lan, T.; Cheng, Z.; Zhang, Y.; Wang, Q.; Lin, L. Characteristics of Permeability Evolution and Pore Structure of Coal with High Gas. Energies 2024, 17, 66. https://doi.org/10.3390/en17010066

Zhu J, Shao T, Lan T, Cheng Z, Zhang Y, Wang Q, Lin L. Characteristics of Permeability Evolution and Pore Structure of Coal with High Gas. Energies. 2024; 17(1):66. https://doi.org/10.3390/en17010066

Chicago/Turabian StyleZhu, Jie, Tangsha Shao, Tianxiang Lan, Zhiyuan Cheng, Yubo Zhang, Quanqi Wang, and Li Lin. 2024. "Characteristics of Permeability Evolution and Pore Structure of Coal with High Gas" Energies 17, no. 1: 66. https://doi.org/10.3390/en17010066

APA StyleZhu, J., Shao, T., Lan, T., Cheng, Z., Zhang, Y., Wang, Q., & Lin, L. (2024). Characteristics of Permeability Evolution and Pore Structure of Coal with High Gas. Energies, 17(1), 66. https://doi.org/10.3390/en17010066