Grinding and Pelleting Characteristics of Municipal Solid Waste Fractions

Abstract

:1. Introduction

Objectives

2. Materials and Methods

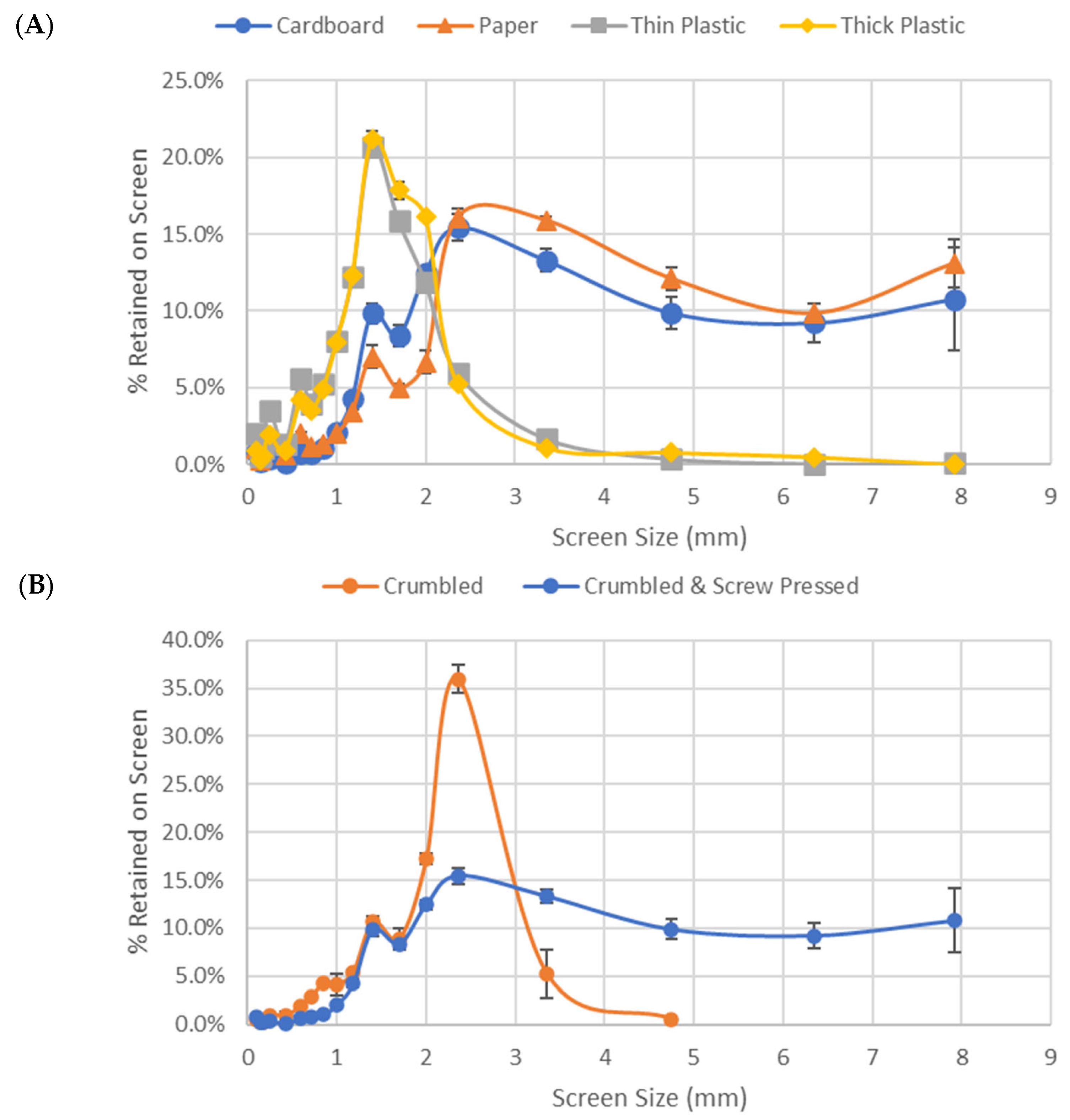

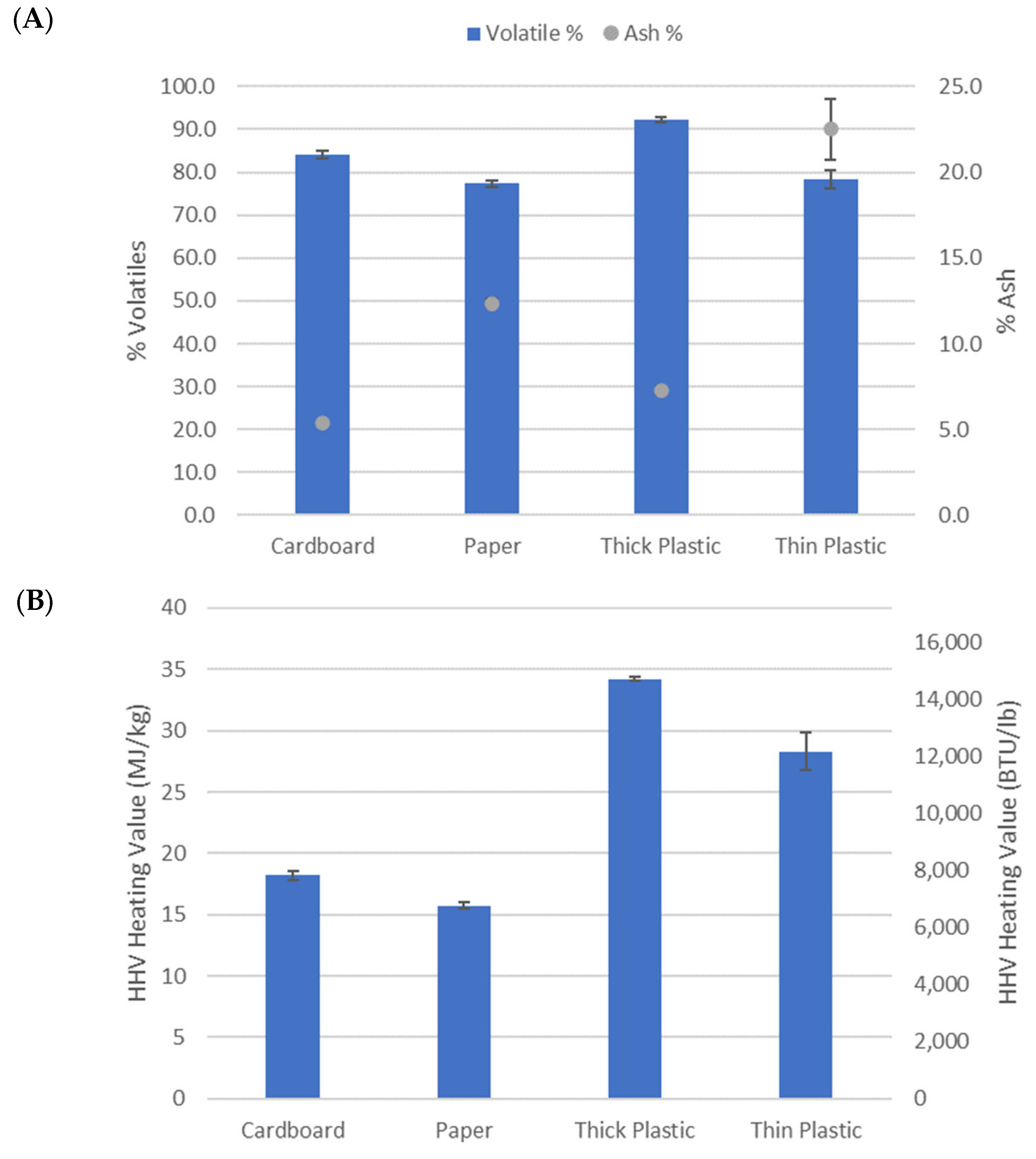

3. Results

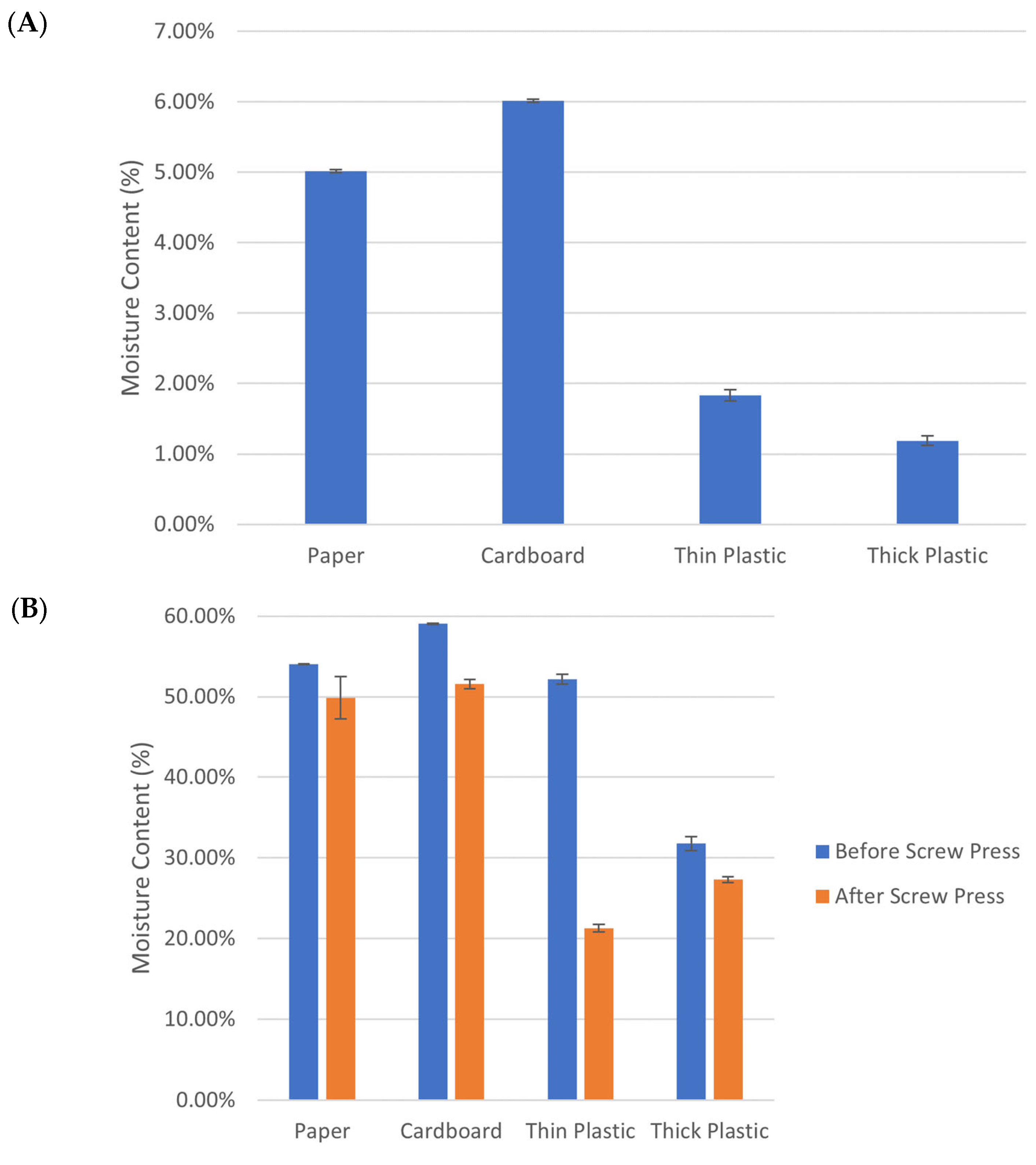

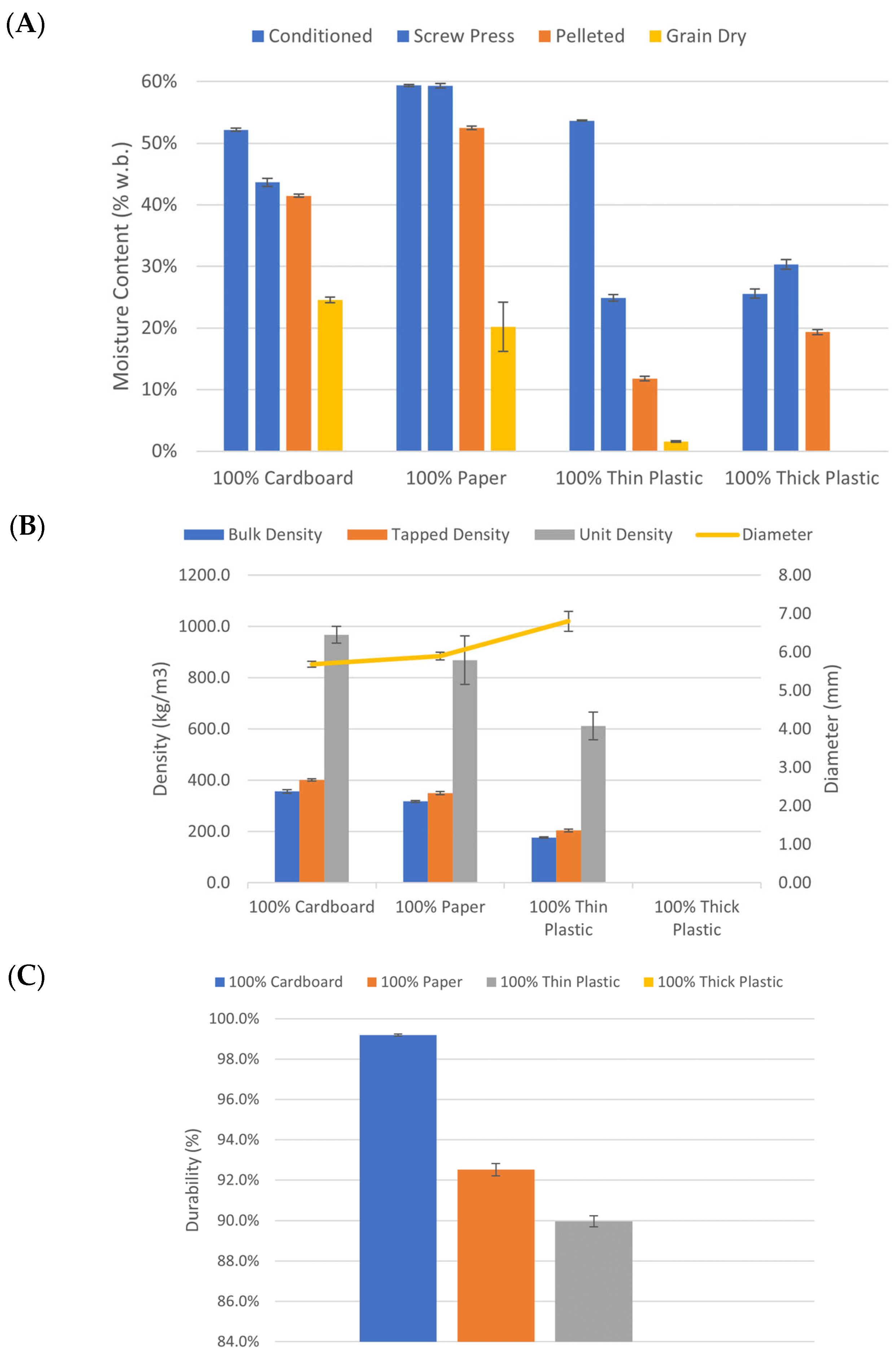

3.1. Mechanical Dewatering

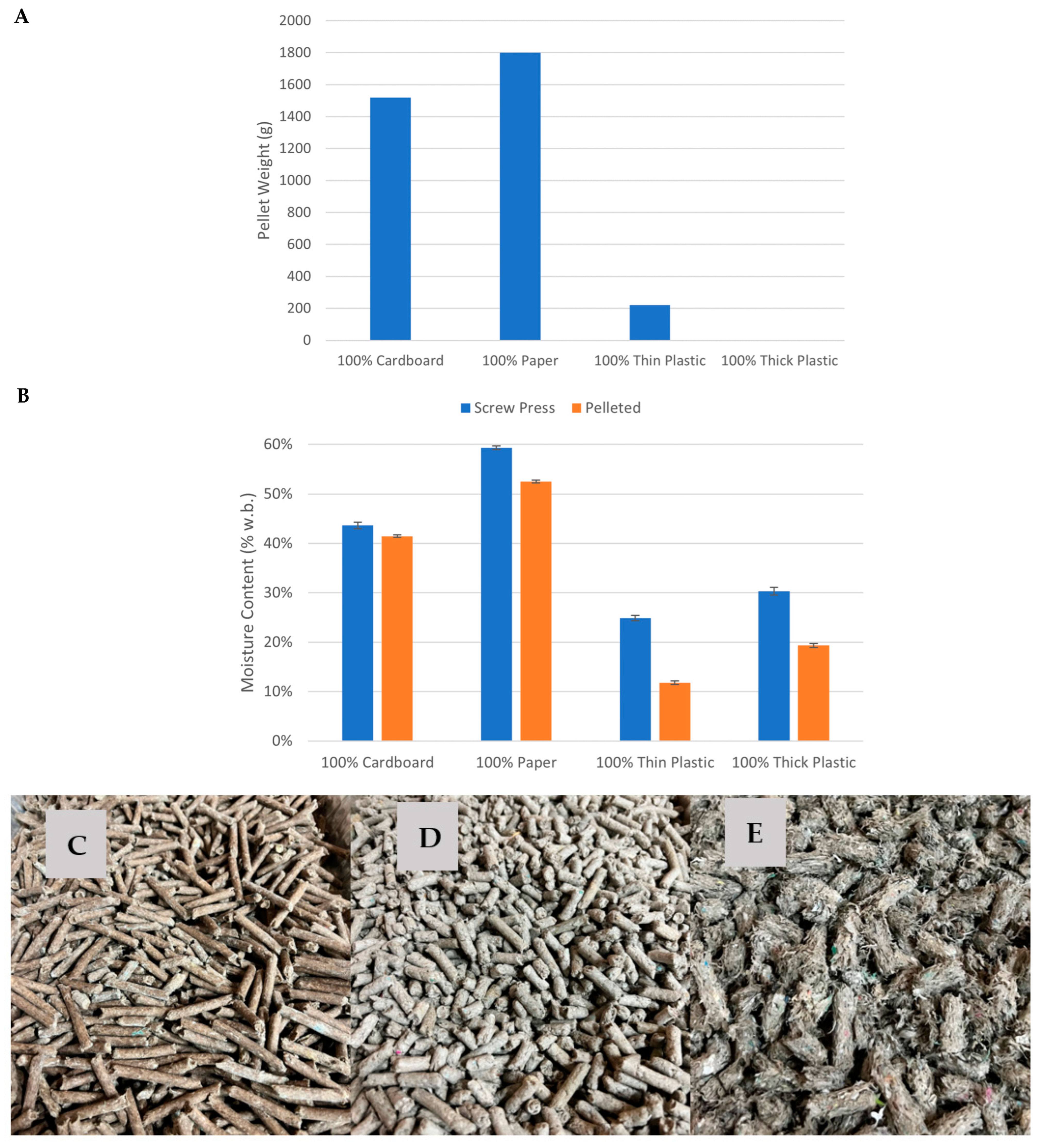

3.2. Pelleting

4. Discussion

5. Conclusions

- Mechanical dewatering using a screw press was shown to be less effective at moisture removal from paper and cardboard fractions, while it showed to be effective at moisture removal from plastic fractions.

- High-moisture pelleting resulted in highly durable (>99%) and dense (>300 kg/m3) pellets that were formed from paper and cardboard fractions at initial moisture contents nearing 50%.

- High-moisture processing is a feasible option for reducing processing energy requirements and costs by eliminating rotary dryers from the processing flowchart.

- Plastic fractions did not produce quality pellets at high moisture levels.

- The high-moisture MSW pellets were able to be dried using a grain-type low-temperature dryer to produce a moisture content that was suitable for storage (<10%).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Disclaimer

References

- EPA. Advancing Sustainable Materials Management: 2018 Fact Sheet. 2020. Available online: https://www.epa.gov/sites/default/files/2021-01/documents/2018_ff_fact_sheet_dec_2020_fnl_508.pdf (accessed on 11 July 2023).

- Carriquiry, M.A.; Du, X.; Timilsina, G.R. Second generation biofuels: Economics and policies. Energy Policy 2011, 39, 4222–4234. [Google Scholar] [CrossRef]

- Gaeta-Bernardi, A.; Parente, V. Organic municipal solid waste (MSW) as feedstock for biodiesel production: A financial feasibility analysis. Renew. Energy 2016, 86, 1422–1432. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Alam, M.D.T.; Krishna, B.B.; Bhaskar, T.; Perkins, G. A review on the production of renewable aviation fuels from the gasification of biomass and residual wastes. Bioresour. Technol. 2020, 312, 123596. [Google Scholar] [CrossRef] [PubMed]

- Qiu, B.; Tao, X.; Wang, J.; Liu, Y.; Li, S.; Chu, H. Research progress in the preparation of high-quality liquid fuels and chemicals by catalytic pyrolysis of biomass: A review. Energy Convers. Manag. 2022, 261, 115647. [Google Scholar] [CrossRef]

- Qiu, B.; Yang, C.; Shao, Q.; Liu, Y.; Chu, H. Recent advances on industrial solid waste catalysts for improving the quality of bio-oil from biomass catalytic cracking: A review. Fuel 2022, 315, 123218. [Google Scholar] [CrossRef]

- Sprenger, C.J. Classification and Densification of Municipal Solid Waste for Biofuels Applications. Ph.D. Thesis, Department of Chemical and Biological Engineering, University of Saskatchewan, Saskatoon, SK, Canada, 2017. [Google Scholar]

- Staley, B.F.; Barlaz, M.A. Composition of Municipal Solid Waste in the United States and Implications for Carbon Sequestration and Methane Yield. J. Environ. Eng. 2009, 135, 901–1083. [Google Scholar] [CrossRef]

- Kumar, A. Estimation of GHG emission and energy recovery potential from MSW landfill sites. Sustain. Energy Technol. Assess. 2014, 5, 50–61. [Google Scholar] [CrossRef]

- Williams, L.; Emerson, R.M.; Tumuluru, J.S. Biomass Compositional Analysis for Conversion to Renewable Fuels and Chemicals. In Biomass Volume Estimation and Valorization for Energy; Tumuluru, J.S., Ed.; InTech: London, UK, 2017. [Google Scholar]

- Rezaei, H.; Yazdanpanah, F.; Lim, C.J.; Sokhansanj, S. Pelletization properties of refuse-derived fuel—Effects of particle size and moisture content. Fuel Process. Technol. 2020, 205, 106437. [Google Scholar] [CrossRef]

- Gaitán-Alvarez, J.; Moya, R.; Puente-Urbina, A.; Rodriguez-Zuñiga, A. Physical and Compression Properties of Pellets Manufactured with the Biomass of Five Woody Tropical Species of Costa Rica Torrefied at Different Temperatures and Times. Energies 2017, 10, 1205. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Yancey, N. Conventional and Advanced Mechanical Preprocessing Methods for Biomass: Performance Quality Attributes and Cost Analysis. In Biomass Preprocessing and Pretreatments for Production of Biofuels; Tumuluru, J.S., Ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Tumuluru, J.S. Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resource Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Jackson, J.; Turner, A.; Mark, T.; Montross, M. Densification of biomass using a pilot scale flat ring roller pellet mill. Fuel Process. Technol. 2016, 148, 43–49. [Google Scholar] [CrossRef]

- DOE. Memorandum of Understanding. Sustainable Aviation Fuel Grand Challenge. 8 September. 2021. Available online: https://www.energy.gov/sites/default/files/2021-09/S1-Signed-SAF-MOU-9-08-21_0.pdf (accessed on 10 August 2023).

- GAO. Sustainable Aviation Fuel: Agencies Should Track Progress toward Ambitious Federal Goals. March 2023. GAO-23-105300. 2023. Available online: https://www.gao.gov/assets/gao-23-105300.pdf (accessed on 9 August 2023).

- Pradhan, P.; Arora, A.; Mahajani, S.M. Pilot scale evaluation of fuel pellets production from garden waste biomass. Energy Sustain. Dev. 2018, 43, 1–14. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Mwamufiya, M. FCIC DFO—Moisture Management and Optimization in Municipal Solid Waste Feedstock through Mechanical Processing; No. INL/MIS-21-61653-Rev000; Idaho National Lab (INL): Idaho Falls, ID, USA, 2021. [Google Scholar]

- Wahlund, B.; Yan, J.; Westermark, M. Increasing biomass utilization in energy systems: A comparative study of CO2 reduction and cost for different bioenergy processing options. Biomass Bioenergy 2004, 26, 531–544. [Google Scholar] [CrossRef]

- Karkania, V.; Fanara, E.; Zabaniotou, Z. Review of sustainable biomass pellets production—A study for agricultural residues pellets’ market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Filbakk, T.; Skjevrak, G.; Hoibo, O.; Dibdiakova, J.; Jirjis, R. The influence of storage and drying methods for Scots pine raw material on mechanical pellet properties and production parameters. Fuel Process. Technol. 2011, 92, 871–878. [Google Scholar] [CrossRef]

- Lange, J.-P. Managing Plastic Waste—Sorting, Recycling, Disposal, and Product Redesign. ACS Sustain. Chem. Eng. 2021, 9, 15722–15738. [Google Scholar] [CrossRef]

- Nguyen, P.H.L.; Kuruparan, P.; Visvanathan, C. Anaerobic digestion of municipal solid waste as a treatment prior to landfill. Bioresour. Technol. 2007, 98, 380–387. [Google Scholar] [CrossRef]

- Yi, J.; Li, X.; He, J.; Duan, X. Drying efficiency and product quality of biomass drying: A review. Dry. Technol. 2020, 38, 2039–2054. [Google Scholar] [CrossRef]

- ASABE S269.4; Cubes, Pellets, and Crumbles—Definitions and Methods for Determining Density, Durability, and Moisture Content. American Society of Agricultural and Biological Engineers: St. Joseph, MO, USA, 2007.

- ASABE Standards S424; A Method of Determining and Expressing Particle Size of Chopped Forage Materials by Screening. American Society of Agricultural and Biological Engineers: St. Joseph, MO, USA, 2007; Volume 608.

- ASTM D7582-15; Standard Test Methods for Proximate Analysis of Coal and Coke by Macro Thermogravimetric Analysis. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2015.

- ASTM D3176-15; Standard Practice for Ultimate Analysis of Coal and Coke. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2015.

- ASTM D5865/D5868M-19; Standard Test Method for Gross Calorific Value of Coal and Coke. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2019.

- ASTM D7481-18; Standard Test Methods for Determining Loose and Tapped Bulk Densities of Powders Using a Graduated Cylinder. ASTM: West Conshohocken, PA, USA, 2018.

- Araujo, J.R.; Waldman, W.R.; DePaoli, M.A. Thermal properties of high-density polyethylene composites with natural fibers: Coupling agent effect. Polymer Degradation. Stab. 2008, 93, 1770–1775. [Google Scholar] [CrossRef]

- Sen, S.K.; Raut, S. Microbial degradation of low density polyethylene (LDPE): A review. J. Environ. Chem. Eng. 2015, 3, 462–473. [Google Scholar]

- Karak, T.; Bhagat, R.M.; Bhattacharyya, P. Municipal Solid Waste Generation, Composition, and Management: The World Scenario. Crit. Rev. Environ. Sci. Technol. 2012, 15, 1509–1630. [Google Scholar] [CrossRef]

- Couth, R.; Trois, C. Carbon Emissions reduction strategies in Africa from improved waste management: A review. Waste Manag. 2010, 30, 2336–2346. [Google Scholar] [CrossRef] [PubMed]

- U.S. Environmental Protection Agency. Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and figures for 2007; EPA-530-F-08-018; U.S. Environmental Protection Agency: Washington, DC, USA, 2008.

- Jun, D.; Chi, Y.; Tang, Y.; Ni, M.; Nzihou, A.; Weiss-Hortala, E.; Huang, Q. Effect of Operating Parameters and Moisture Content on Municipal Solid Waste Pyrolysis and Gasification. Energy Fuels 2016, 30, 3994–4001. [Google Scholar]

- Nawshad, H.; Somerville, M. Techno-Economic and environmental Evaluation of Biomass Dryer. Procedia Eng. 2013, 56, 650–655. [Google Scholar]

- Pang, S.; Mujumdar, A.S. Drying of Woody Biomass for Bioenergy: Drying Technologies and Optimization for an Integrated Bioenergy Plant. Dry. Technol. 2010, 28, 690–701. [Google Scholar] [CrossRef]

- Yan, Q.; Modigell, M. Mechanical pretreatment of lignocellulosic biomass using a screw press as an essential step in the biofuel production. Chem. Eng. 2012, 29, 601–606. [Google Scholar]

- Ding, L.; Ray, A.; Donohoe, B.; Gruber, C.L.J. Distribution of bound and free water in anatomical fractions of pine residues and corn stover as a function of biological degradation. ACS Sustain. Chem. Eng. 2021, 9, 15884–15896. [Google Scholar] [CrossRef]

- Li, C.; Aston, J.E.; Lacey, J.A.; Thompson, V.S.; Thompson, D.N. Impact of feedstock quality and variation on biochemical and thermochemical conversion. Renew. Sustain. Energy Rev. 2016, 65, 525–536. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smith, Z.; Isaac, B.; Tumuluru, J.S.; Yancey, N. Grinding and Pelleting Characteristics of Municipal Solid Waste Fractions. Energies 2024, 17, 29. https://doi.org/10.3390/en17010029

Smith Z, Isaac B, Tumuluru JS, Yancey N. Grinding and Pelleting Characteristics of Municipal Solid Waste Fractions. Energies. 2024; 17(1):29. https://doi.org/10.3390/en17010029

Chicago/Turabian StyleSmith, Zachary, Blesson Isaac, Jaya Shankar Tumuluru, and Neal Yancey. 2024. "Grinding and Pelleting Characteristics of Municipal Solid Waste Fractions" Energies 17, no. 1: 29. https://doi.org/10.3390/en17010029

APA StyleSmith, Z., Isaac, B., Tumuluru, J. S., & Yancey, N. (2024). Grinding and Pelleting Characteristics of Municipal Solid Waste Fractions. Energies, 17(1), 29. https://doi.org/10.3390/en17010029