Flue Gas Recirculation System for Biomass Heating Boilers—Research and Technical Applications for Reductions in Nitrogen Oxides (NOx) Emissions

Abstract

1. Introduction

2. Materials and Methods

2.1. Heating Devices

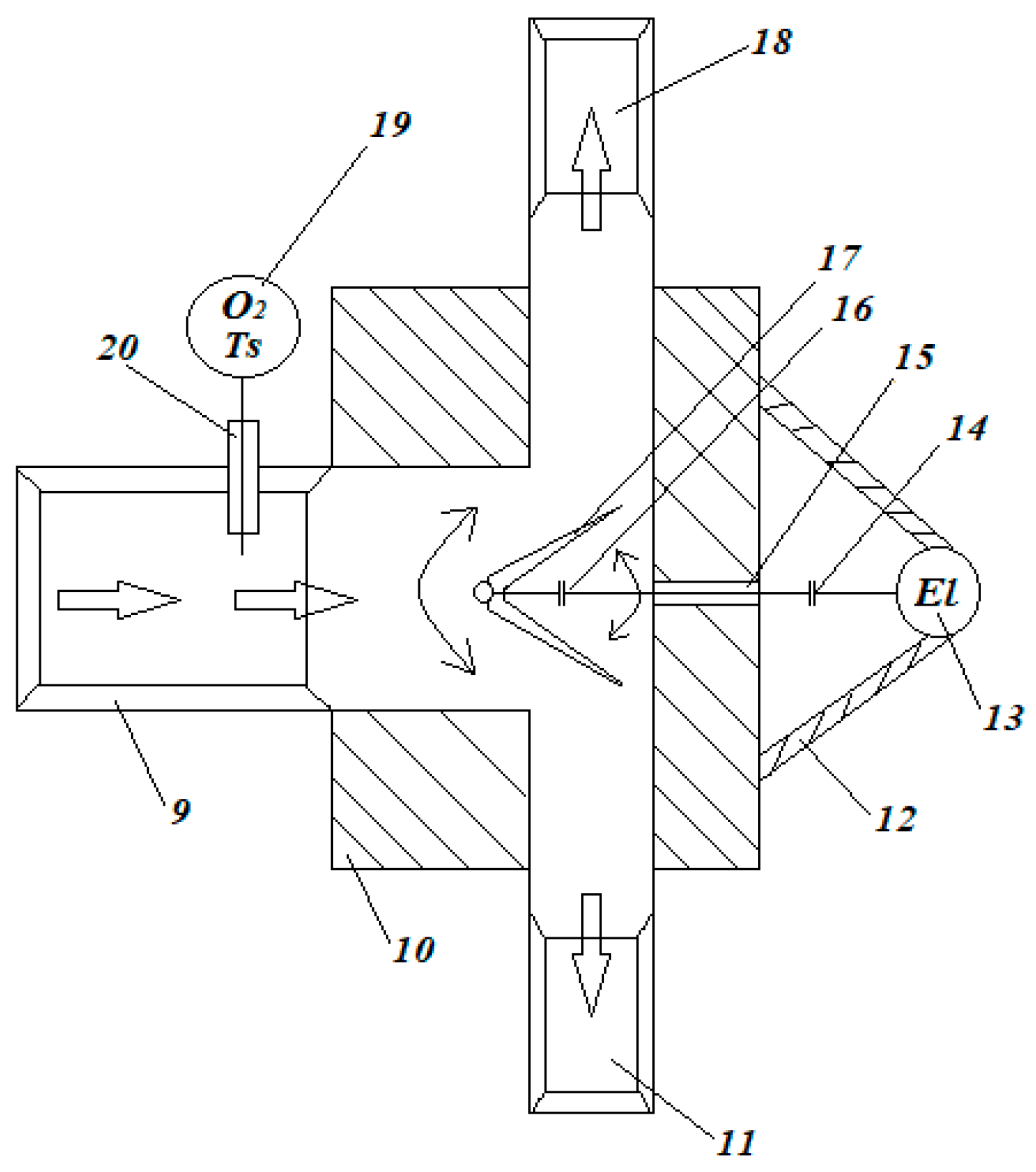

2.2. Flue Gas Distribution Valve

2.3. Chemical Parameters of the Fuel

2.4. Emission Measurement Devices

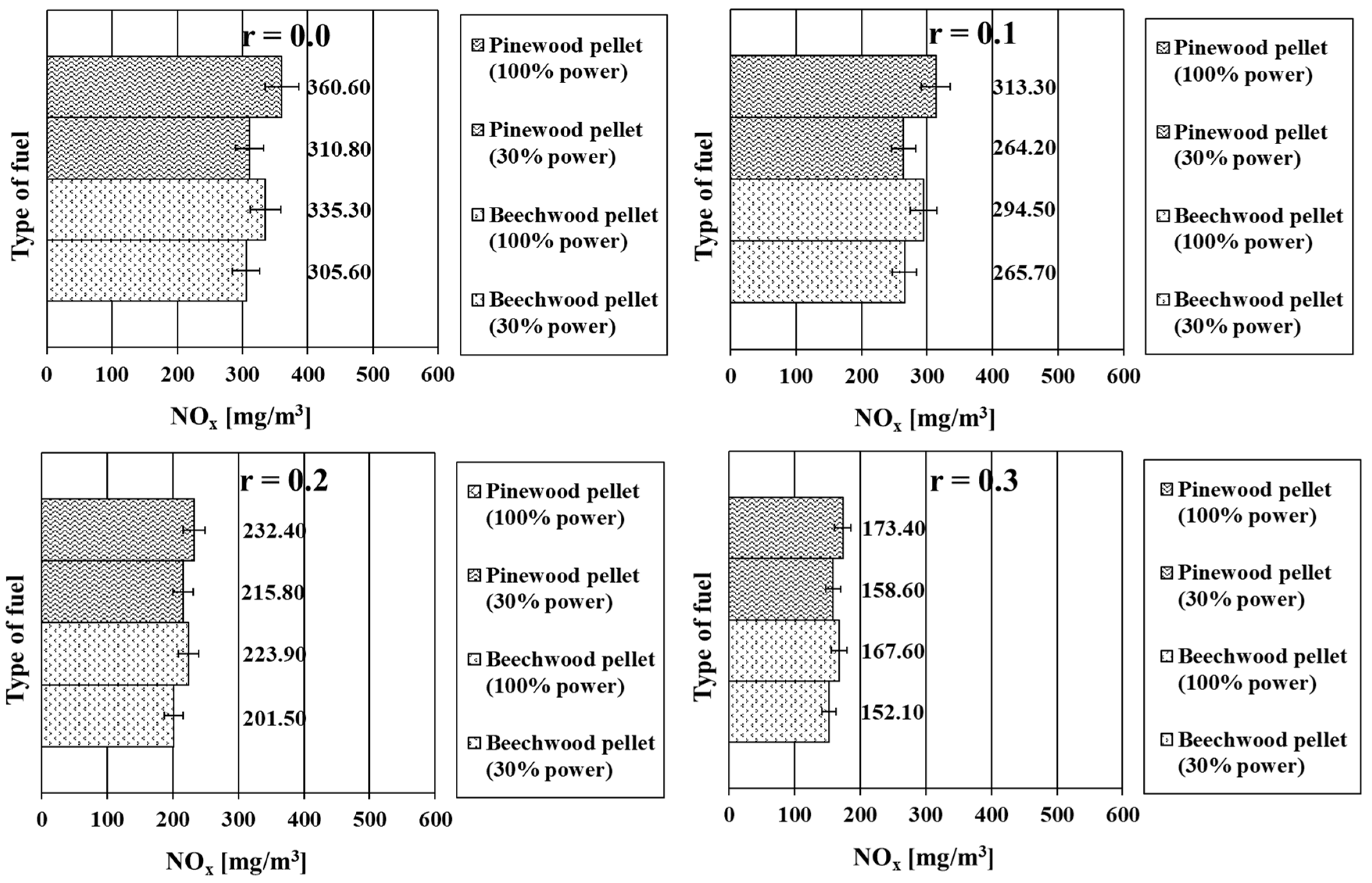

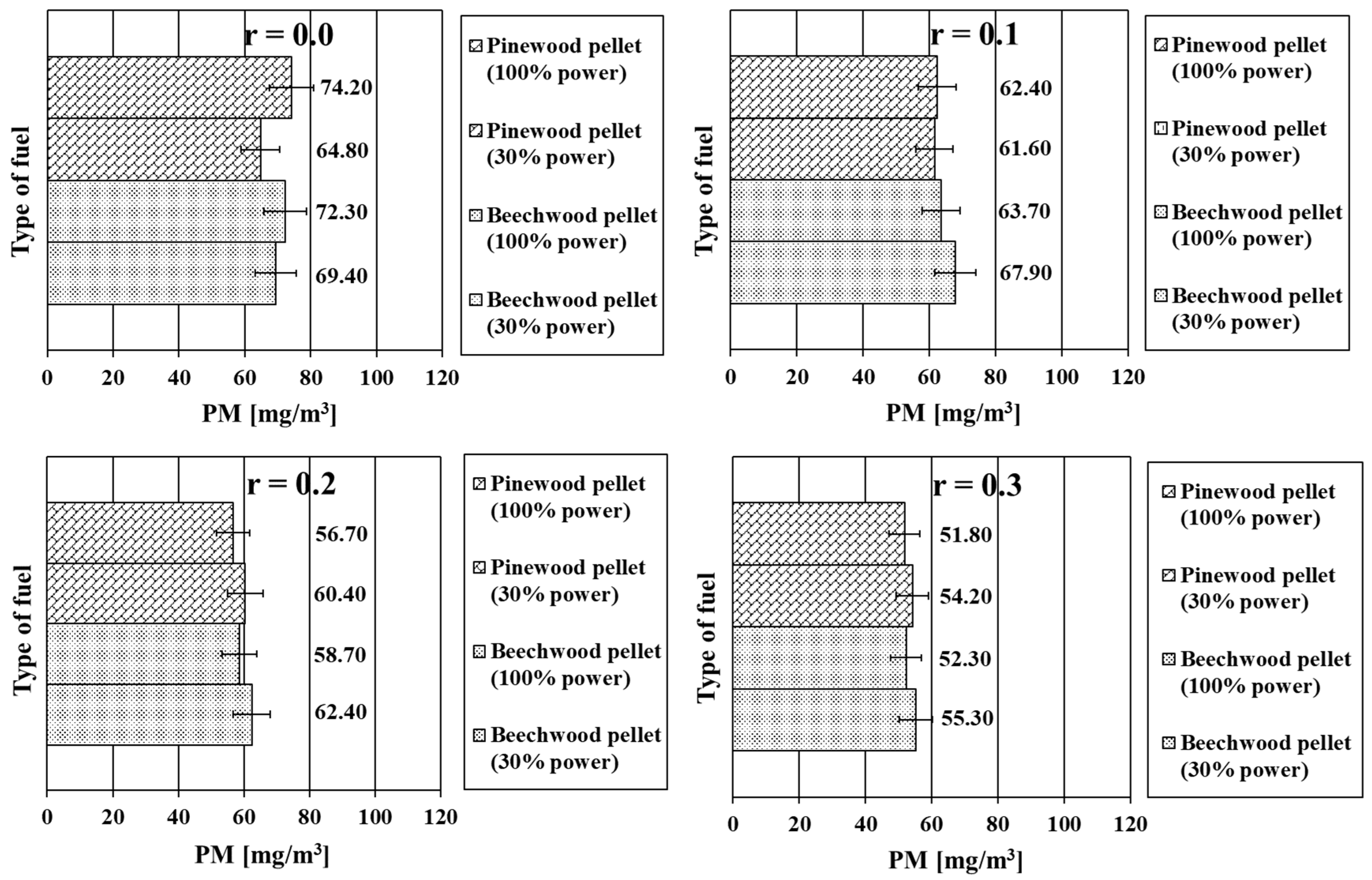

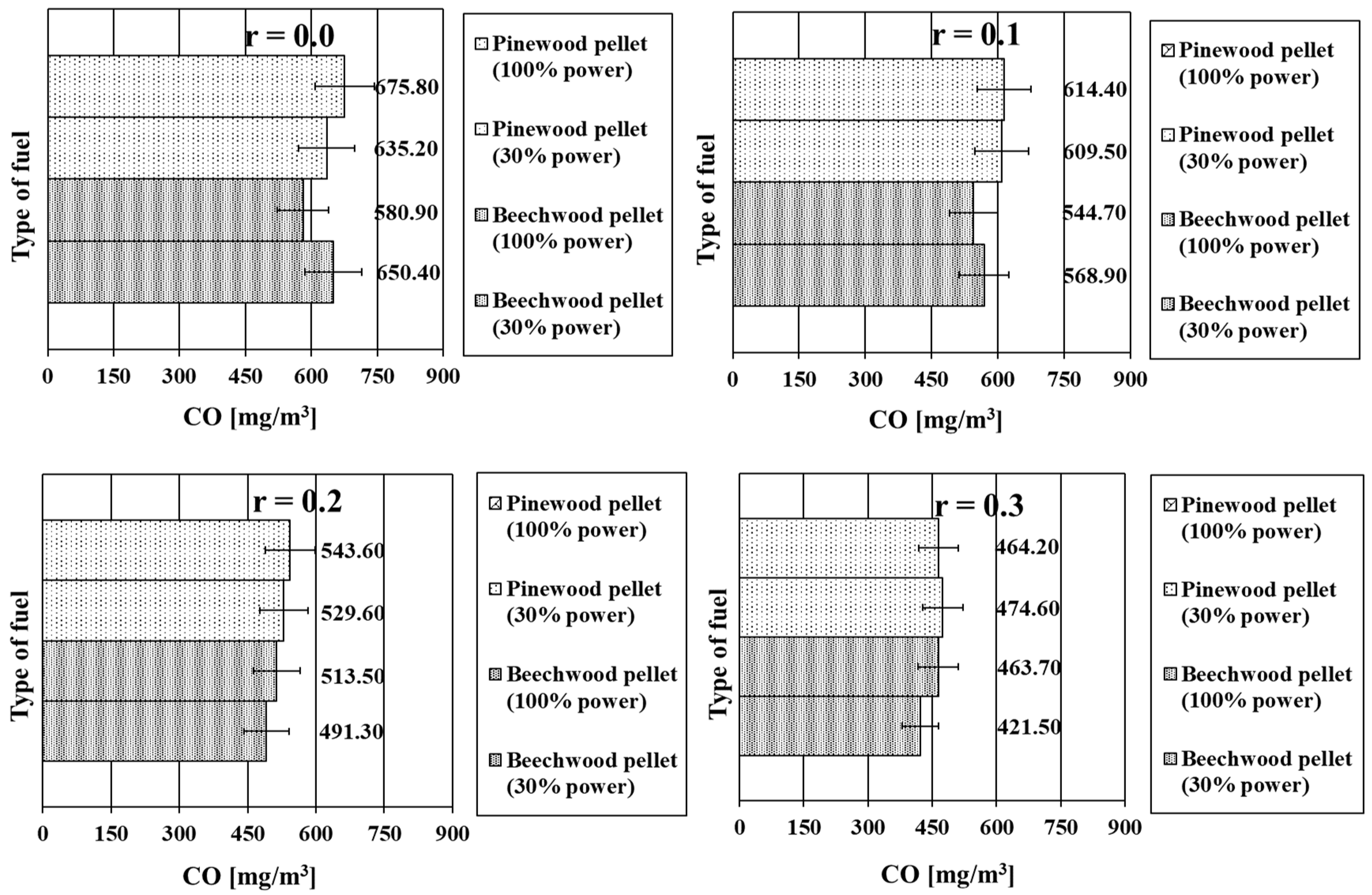

3. Results and Discussion

- −

- The temperature to which the recirculated flue gases are heated should be higher than the initial temperature of the flue gases, in order to prevent the formation of thermal nitrogen oxides, mainly when temperature peaks appear (Tf < 1500 K);

- −

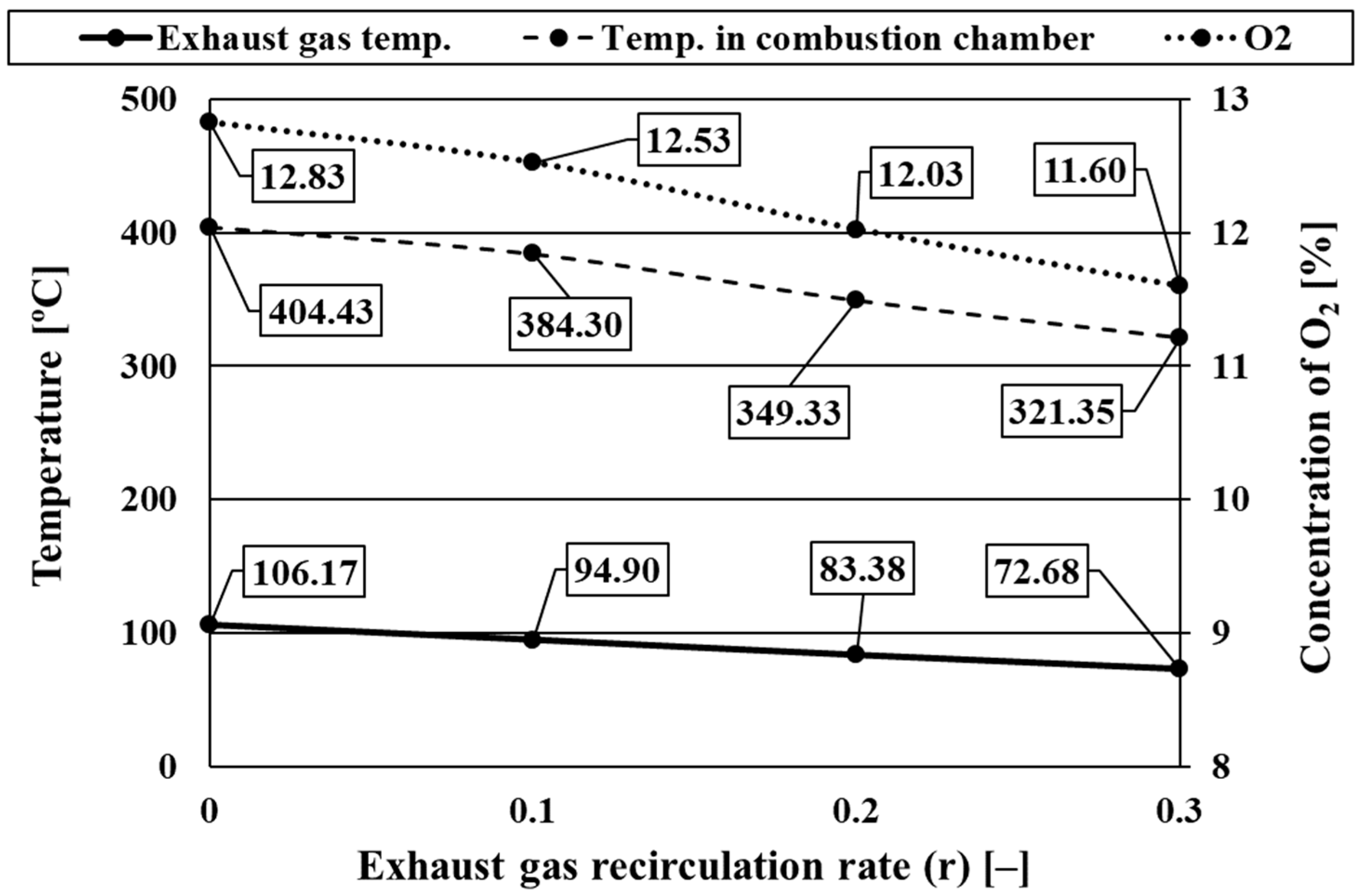

- The recirculation of flue gases at temperatures up to 1073 K should be carried out to prevent the local concentration of oxygen in the area of high-temperature combustion. In the developed flue gas distribution valve solution, when the recirculation rate ‘r’ is increased, the emissions of NOx, PM and CO decrease, and, at the same time, decreases in both the flue gas temperature and the temperature in the combustion chamber are observed. In the solution under consideration, the appearance of thermal and immediate nitrogen oxides is not visible, due to the use of precise regulation of the recirculation rate based on the oxygen content in the flue gases and their temperature;

- −

- The main problem in the case of flue gas recirculation systems used in industrial solutions is the occurrence of excessive CO and PM emissions during radical flue gas recirculation. In the case of high-temperature and flameless combustion, low NOx and CO emissions are observed only in the case of gaseous fuels. In the case of solid fuels, which include biomass, in the case of low-temperature combustion, typical of heating boilers, flameless combustion is impossible; therefore, from analyzing the obtained test results, it can be assumed that, for this group of devices, a regulated flue gas recirculation system, implemented by a system of valves with full automation control, is the right step for further research and industrial implementations;

- −

- Special attention should be paid to flue gas recirculation rates greater than r = 0.3 in the case of low-temperature biomass combustion in heating boilers, due to the close proximity of the flue gas dew point temperature, and the possibility of moisture condensation in the system recirculation channels. This problem may have the opposite effect than that intended and will manifest itself in a significant amount of carbon monoxide emissions, with an observed decline in nitrogen oxide emissions. More information on emissions during combustion in a humid atmosphere can be found in [30].

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| CO | carbon monoxide, colorless oxidation |

| CO2 | carbon dioxide |

| EEC | excess enthalpy combustion |

| EGR | exhaust gas recirculation |

| FGR | flue gas recirculation |

| FLOX | flameless oxidation |

| GAFT | gasdynamic abated flame temperature |

| HTAC | high temperature air combustion |

| NO | nitric oxide |

| NO2 | nitrogen dioxide |

| N2O | nitrous oxide |

| N2O3 | dinitrogen trioxide |

| N2O5 | dinitrogen pentoxide |

| NOx | nitrogen oxides |

| O2 | oxygen |

| PM | particulate matters |

| SGR | semilar gas recycling |

| Tf | exhaust gas temperature |

References

- Judt, W.; Ciupek, B.; Urbaniak, R. Numerical study of a heat transfer process in a low power heating boiler equipped with afterburning chamber. Energy 2020, 196, 117093. [Google Scholar] [CrossRef]

- Ciupek, B.; Judt, W.; Urbaniak, R.; Kłosowiak, R. The emission of carbon monoxide and nitrogen oxides from boilers supplied by a pellet under the influence of changes in the air-fuel equivalence ratio. J. Ecol. Eng. 2019, 20, 34–38. [Google Scholar] [CrossRef] [PubMed]

- Ciupek, B.; Janeba-Bartoszewicz, E.; Urbaniak, R. Effect of fineness and increased humidity of carbonaceous fuels on the chemical composition of exhaust gases. Chem. Ind. 2019, 1, 8. [Google Scholar] [CrossRef]

- Ciupek, B. Study on hard coal combustion in heating boilers equipped with a steam-fed afterburning chamber. Chem. Ind. 2020, 99, 8. [Google Scholar] [CrossRef]

- Szufa, S.; Wielgosiński, G.; Piersa, P.; Czerwińska, J.; Dzikuć, M.; Adrian, Ł.; Lewandowska, W.; Marczak, M. Torrefaction of Straw from Oats and Maize for Use as a Fuel and Additive to Organic Fertilizers—TGA Analysis, Kinetics as Products for Agricultural Purposes. Energies 2020, 13, 2064. [Google Scholar] [CrossRef]

- Dudek, M.; Adamczyk, B.; Grzywacz, P.; Lach, R.; Sitarz, M.; Leśniak, M.; Gajek, M.; Mech, K.; Wilk, M.; Rapacz-Kmita, A.; et al. The Utilisation of Solid Fuels Derived from Waste Pistachio Shells in Direct Carbon Solid Oxide Fuel Cells. Materials 2021, 14, 6755. [Google Scholar] [CrossRef] [PubMed]

- Godzisz, K.; Dzikuć, M.; Kułyk, P.; Piwowar, A.; Kuryło, P.; Szufa, S. Selected Determinants of Sustainable Transport in the Context of the Development of a Low-Carbon Economy in Poland. Energies 2021, 14, 5418. [Google Scholar] [CrossRef]

- Wilk, M.; Gajek, M.; Śliz, M.; Czerwińska, K.; Lombardi, L. Hydrothermal Carbonization Process of Digestate from Sewage Sludge: Chemical and Physical Properties of Hydrochar in Terms of Energy Application. Energies 2022, 15, 6499. [Google Scholar] [CrossRef]

- Zardzewiały, M.; Bajcar, M.; Saletnik, B.; Puchalski, C.; Gorzelany, J. Biomass from Green Areas and Its Use for Energy Purposes. Appl. Sci. 2023, 13, 6517. [Google Scholar] [CrossRef]

- Ciupek, B.; Gołoś, K. Concentration of Nitrogen Oxides When Burning Wood Pellets of Various Origins. J. Ecol. Eng. 2020, 21, 229–233. [Google Scholar] [CrossRef]

- Kačániová, M.; Vukovic, N.L.; Čmiková, N.; Galovičová, L.; Schwarzová, M.; Šimora, V.; Kowalczewski, P.Ł.; Kluz, M.I.; Puchalski, C.; Bakay, L.; et al. Salvia sclarea Essential Oil Chemical Composition and Biological Activities. Int. J. Mol. Sci. 2023, 24, 5179. [Google Scholar] [CrossRef] [PubMed]

- Aleksiejczuk, A.; Teleszewski, T.J. Estimation of Sulfur Dioxide Emissions in an Automatic Boiler with a Retort Burner for Coal and Biomass in a Single-Family House Based on the Measurement of the Heat Consumed. Environ. Sci. Proc. 2022, 18, 10. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Przywara, A.; Parafiniuk, S. Emission of Nitric Oxide during the Combustion of Various Forms of Solid Biofuels in a Low-Power Heating Device. Energies 2022, 15, 5960. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Przywara, A.; Anifantis, A.S. Impact of Ignition Technique on Pollutants Emission during the Combustion of Selected Solid Biofuels. Energies 2020, 13, 2664. [Google Scholar] [CrossRef]

- Graham, S.; Ogunfayo, I.; Hall, M.R.; Snape, C.; Quick, W.; Weatherstone, S.; Eastwick, C. Changes in mechanical properties of wood pellets during artificial degradation in a laboratory environment. Fuel Process. Technol. 2016, 148, 395–402. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical properties of solid biofuels–significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Spanish biofuels heating value estimation. Part II: Proximate analysis data. Fuel 2014, 117, 1139–1147. [Google Scholar] [CrossRef]

- Boman, C.; Pettersson, E.; Westerholm, R.; Boström, D.; Nordin, A. Stove performance and emission characteristic in residential wood log and pellet combustion. Part 1: Pellet stoves. Energy Fuels 2011, 25, 307–314. [Google Scholar] [CrossRef]

- Liu, H.; Chaney, J.; Li, J.; Sun, C. Control of NOx emissions of a domestic/small-scale biomass pellet boiler by air staging. Fuel 2013, 103, 792–798. [Google Scholar] [CrossRef]

- Bhattu, D.; Zotter, P.; Zhou, J.; Stefenelli, G.; Klein, F.; Bertrand, A.; Temime-Roussel, B.; Marchand, N.; Slowik, J.G.; Baltensperger, U.; et al. Effect of stove technology and combustion conditions on gas and particulate emissions from residential biomass combustion. Environ. Sci. Technol. 2019, 53, 2209–2219. [Google Scholar] [CrossRef]

- Fachinger, F.; Drewnick, F.; Gieré, R.; Borrmann, S. How the user can influence particulate emissions from residential wood and pellet stoves: Emission factors for different fuels and burning conditions. Atmos. Environ. 2017, 158, 216–226. [Google Scholar] [CrossRef]

- Mitchell, E.J.S.; Lea-Langton, A.R.; Jones, J.M.; Williams, A.; Layden, P.; Johnson, R. The impact of fuel properties on the emissions from the combustion of biomass and other solid fuels in a fixed bed domestic stove. Fuel Process. Technol. 2016, 142, 115–123. [Google Scholar] [CrossRef]

- Houshfar, E.; Skreiberg, Ø.; Løvås, T.; Todorovic, D.; Sorum, L. Effect of excess air ratio and temperature on NOx emission from grate combustion of biomass in the staged air combustion scenario. Energy Fuels 2011, 25, 4643–4654. [Google Scholar] [CrossRef]

- Malico, I.; Pereira, R.N.; Gonçalves, A.C.; Sousa, A.M.O. Current status and future perspectives for energy production from solid biomass in the European industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- Bogusz, M.; Matysik-Pejas, R.; Krasnodębski, A.; Dziekański, P. The Concept of Zero Waste in the Context of Supporting Environmental Protection by Consumers. Energies 2021, 14, 5964. [Google Scholar] [CrossRef]

- Ozgen, S.; Cernuschi, S.; Caserini, S. An overview of nitrogen oxides emissions from biomass combustion for domestic heat production. Renew. Sustain. Energy Rev. 2021, 135, 110113. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and Co-combustion of Biomass: Fundamentals, Technologies, and Primary Measures for Emission Reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Demirbas, A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Speth, K.; Murer, M.; Spliethoff, H. Experimental investigation of nitrogen species distribution in wood combustion and their influence on NOx reduction by combining air staging and ammonia injection. Energy Fuels 2016, 30, 5816–5824. [Google Scholar] [CrossRef]

- Ciupek, B.; Gołoś, K.; Jankowski, R.; Nadolny, Z. Effect of Hard Coal Combustion in Water Steam Environment on Chemical Composition of Exhaust Gases. Energies 2021, 14, 6530. [Google Scholar] [CrossRef]

- Khodaei, H.; Guzzomi, F.; Yeoh, G.H.; Regueiro, A.; Pati, D. An experimental study into the effect of air staging distribution and position on emissions in a laboratory scale biomass combustor. Energy 2016, 118, 1243–1255. [Google Scholar] [CrossRef]

- Gołoś, K.; Ciupek, B.; Judt, W.; Urbaniak, R. Impact of replacement of solid fuel heating boilers on air quality in Poland in 2000–2020. Chem. Ind. 2021, 100, 96–99. [Google Scholar] [CrossRef]

- Kurc, B.; Lijewski, P.; Rymaniak, Ł.; Fuć, P.; Pigłowska, M.; Urbaniak, R.; Ciupek, B. High-Energy Solid Fuel Obtained from Carbonized Rice Starch. Energies 2020, 13, 4096. [Google Scholar] [CrossRef]

- Krzyżaniak, M.; Stolarski, M.J.; Szczukowski, S.; Tworkowski, J. Thermophysical and chemical properties of biomass obtained from willow coppice cultivated in one- and three-year rotation cycles. J. Elem. 2014, 1, 161–175. [Google Scholar] [CrossRef]

- Obaidullah, M.; Bram, S.; Verma, V.K.; De Ruyck, J. A Review on Particle Emissions from Small Scale Biomass Combustion. Int. J. Renew. Energy Res. 2012, 2, 147–159. [Google Scholar]

- Ciupek, B.; Judt, W.; Gołoś, K.; Urbaniak, R. Analysis of Low-Power Boilers Work on Real Heat Loads: A Case of Poland. Energies 2021, 14, 3101. [Google Scholar] [CrossRef]

- Pełka, G.; Wygoda, M.; Lubo’n, W.; Pachytel, P.; Jachimowski, A.; Paprocki, M.; Wyczesany, P.; Kotyza, J. Analysis of the Efficiency of a Batch Boiler and Emissions of Harmful Substances during Combustion of Various Types of Wood. Energies 2021, 14, 6783. [Google Scholar] [CrossRef]

- Lisowski, A.; Dąbrowska-Salwin, M.; Ostrowska-Ligęza, E.; Nawrocka, A.; Stasiak, M.; Świętochowski, A.; Klonowski, K.; Sypuła, M.; Lisowska, B. Effects of the biomass moisture content and pelleting temperature on the pressure-induced agglomeration process. Biomass Bioenergy 2017, 107, 376–383. [Google Scholar] [CrossRef]

- Andersen, V.; Solheim, I.; Gaertner, H.; Sægrov-Sorte, B.; Einarsrud, K.E.; Tranell, G. Pilot-Scale Test of Flue Gas Recirculation for The Silicon Process. J. Sustain. Metall. 2023, 9, 81–92. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, Y.; Lee, S.M.; Ahn, K.Y. NO reduction in 0.03–0.2 MW oxy-fuel combustor using flue gas recirculation technology. Proc. Combust. Inst. 2007, 31, 3377–3384. [Google Scholar] [CrossRef]

- Fan, X.; Wong, G.; Gan, M.; Chen, X.; Yu, Z.; Ji, Z. Establishment of refined sintering flue gas recirculation patterns for gas pollutant reduction and waste heat recycling. J. Clean. Prod. 2019, 235, 1549–6526. [Google Scholar] [CrossRef]

- Cholewiński, M.; Pospolita, W. Application of Biomass Swirl Burners in High-Power Boilers. Tech. Issues 2016, 2, 3–10. [Google Scholar]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H. The effects of exhaust gas recirculation on diesel combustion and emissions. Int. J. Engine Res. 2000, 1, 107–126. [Google Scholar] [CrossRef]

- Abd-Alla, G.H. Using exhaust gas recirculation in internal combustion engines: A review. Energy Convers. Manag. 2002, 43, 1027–1042. [Google Scholar] [CrossRef]

- Wei, H.; Zhu, T.; Shu, G.; Tan, L.; Wang, Y. Gasoline engine exhaust gas recirculation—A review. Appl. Energy 2012, 99, 534–544. [Google Scholar] [CrossRef]

- ElKady, A.M.; Evulet, A.; Brand, A.; Ursin, T.P.; Lynghjem, A. Application of Exhaust Gas Recirculation in a DLN F-Class Combustion System for Postcombustion Carbon Capture. J. Eng. Gas Turbines Power 2009, 131, 034505. [Google Scholar] [CrossRef]

- Cairns, A.; Blaxill, H. The Effects of Combined Internal and External Exhaust Gas Recirculation on Gasoline Controlled Auto-Ignition; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Guethe, F.; de la Cruz García, M.; Burdet, A. Flue Gas Recirculation in Gas Turbine: Investigation of Combustion Reactivity and NOX Emission. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air. Volume 2: Combustion, Fuels and Emissions, Orlando, FL, USA, 8–12 June 2009; ASME: New York, NY, USA, 2009; pp. 179–191. [Google Scholar]

- Baltasar, J.; Carvalho, M.G.; Coelho, P.; Costa, M. Flue gas recirculation in a gas-fired laboratory furnace: Measurements and modelling. Fuel 1997, 76, 919–929. [Google Scholar] [CrossRef]

- Liuzzo, G.; Verdone, N.; Bravi, M. The benefits of flue gas recirculation in waste incineration. Waste Manag. 2007, 27, 106–116. [Google Scholar] [CrossRef]

- Diego, L.F.; de las Obras-Loscertales, M.; Rufas, A.; García-Labiano, F.; Gayán, P.; Abad, A.; Adánez, J. Pollutant emissions in a bubbling fluidized bed combustor working in oxy-fuel operating conditions: Effect of flue gas recirculation. Appl. Energy 2013, 102, 860–867. [Google Scholar] [CrossRef]

- Haryanto, A.; Hong, K.S. Modeling and simulation of an oxy-fuel combustion boiler system with flue gas recirculation. Comput. Chem. Eng. 2011, 35, 25–40. [Google Scholar] [CrossRef]

- EN 303-5:2012; Heating Boilers—Part 5: Heating Boilers for Solid Fuels, Manually and Auto-Matically Stocked, Nominal Heat Output of up to 500 kW—Terminology, Requirements, Testing and Marking. Polish Committee for Standardization: Warsaw, Poland, 2012.

- 2009/125/EC; Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products. European Parliament: Warsaw, Poland, 2009.

- 2015/1189; Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Solid Fuel Boilers. Commision Regulation (EU): Brussels, Belgium, 2015.

- Available online: https://www.walsc.pl/kociol-klasy-5,12 (accessed on 3 November 2023).

- EN ISO 18122:2016; Solid Biofuels—Determination of Ash Content. Polish Committee for Standardization: Warsaw, Poland, 2016.

- EN ISO 18125:2017; Solid Biofuels. Determination of Calorific Value. Polish Committee for Standardization: Warsaw, Poland, 2017.

- EN ISO 16127:2012; Solid Biofuels. Determination of Length and Diameter of Pellets. Polish Committee for Standardization: Warsaw, Poland, 2012.

- EN ISO 18134-2:2017; Solid Biofuels. Determination of Moisture Content. Oven Dry Method. Polish Committee for Standardization: Warsaw, Poland, 2017.

- EN ISO 18123:2015; Solid Biofuels. Determination of Volatile Matter. Polish Committee for Standardization: Warsaw, Poland, 2015.

- Available online: https://www.testo.com (accessed on 3 November 2023).

| Stage of Testing | Type of Boiler | Power Setting | Type of Fuel (Pellets) | Exhaust Gas Recirculation Rate | |

|---|---|---|---|---|---|

| 1. | BIOVERT 21 | 100% | pinewood | r = 0.0 | [m3·h−1] |

| 2. | beechwood | ||||

| 3. | 30% | pinewood | |||

| 4. | beechwood | ||||

| 5. | 100% | pinewood | r = 0.1 | [m3·h−1] | |

| 6. | beechwood | ||||

| 7. | 30% | pinewood | [m3·h−1] | ||

| 8. | beechwood | ||||

| 9. | 100% | pinewood | r = 0.2 | [m3·h−1] | |

| 10. | beechwood | ||||

| 11. | 30% | pinewood | [m3·h−1] | ||

| 12. | beechwood | ||||

| 13. | 100% | pinewood | r = 0.3 | [m3·h−1] | |

| 14. | beechwood | ||||

| 15. | 30% | pinewood | [m3·h−1] | ||

| 16. | beechwood | ||||

| Type of Measurement | Pinewood Pellets | Beechwood Pellets |

|---|---|---|

| Hygroscopic moisture content (Wh) % | 1.93 | 3.63 |

| Excess moisture content (Wex) % | 3.14 | 6.61 |

| Total moisture content (Wt) % | 5.00 | 10.00 |

| Volatile matter % | 73.61 | 77.53 |

| Ash content % | 0.47 | 0.41 |

| C % | 54.74 | 52.19 |

| S % | 0.09 | 0.08 |

| H2 % | 4.97 | 4.77 |

| N2 % | 0.19 | 0.82 |

| O2 % | 34.54 | 31.73 |

| High calorific value (Qs) MJ/kg | 14.93 | 17.38 |

| Low calorific value (Qi) MJ/kg | 14.32 | 16.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciupek, B.; Urbaniak, R.; Kinalska, D.; Nadolny, Z. Flue Gas Recirculation System for Biomass Heating Boilers—Research and Technical Applications for Reductions in Nitrogen Oxides (NOx) Emissions. Energies 2024, 17, 259. https://doi.org/10.3390/en17010259

Ciupek B, Urbaniak R, Kinalska D, Nadolny Z. Flue Gas Recirculation System for Biomass Heating Boilers—Research and Technical Applications for Reductions in Nitrogen Oxides (NOx) Emissions. Energies. 2024; 17(1):259. https://doi.org/10.3390/en17010259

Chicago/Turabian StyleCiupek, Bartosz, Rafał Urbaniak, Dobrosława Kinalska, and Zbigniew Nadolny. 2024. "Flue Gas Recirculation System for Biomass Heating Boilers—Research and Technical Applications for Reductions in Nitrogen Oxides (NOx) Emissions" Energies 17, no. 1: 259. https://doi.org/10.3390/en17010259

APA StyleCiupek, B., Urbaniak, R., Kinalska, D., & Nadolny, Z. (2024). Flue Gas Recirculation System for Biomass Heating Boilers—Research and Technical Applications for Reductions in Nitrogen Oxides (NOx) Emissions. Energies, 17(1), 259. https://doi.org/10.3390/en17010259