Energy Management Scheme for Optimizing Multiple Smart Homes Equipped with Electric Vehicles

Abstract

1. Introduction

- Develop an optimization model that integrates smart appliances, a PV, a BESS, and EVs.

- Design a unique HEM system with a scheduler module to minimize the total electricity cost and provide the optimal schedule for appliances and the optimal pattern in charging and discharging of the BESS and EVs.

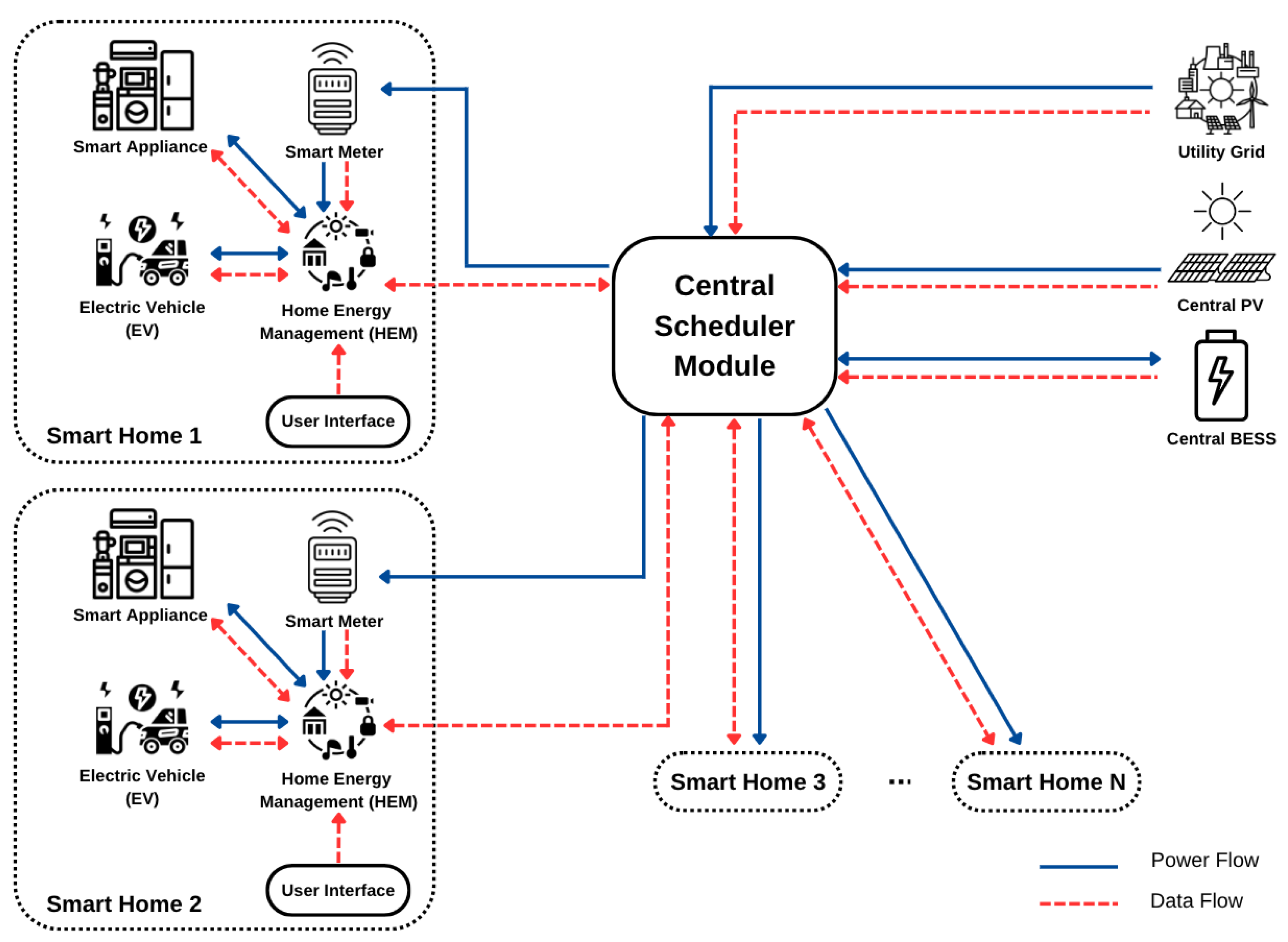

- Propose a centralized system for multiple SHs in which there are PV and BESS systems shared among all SHs that exist in the community or an apartment building.

- Ensure fairness in cost reduction for each user in multiple SH simulations.

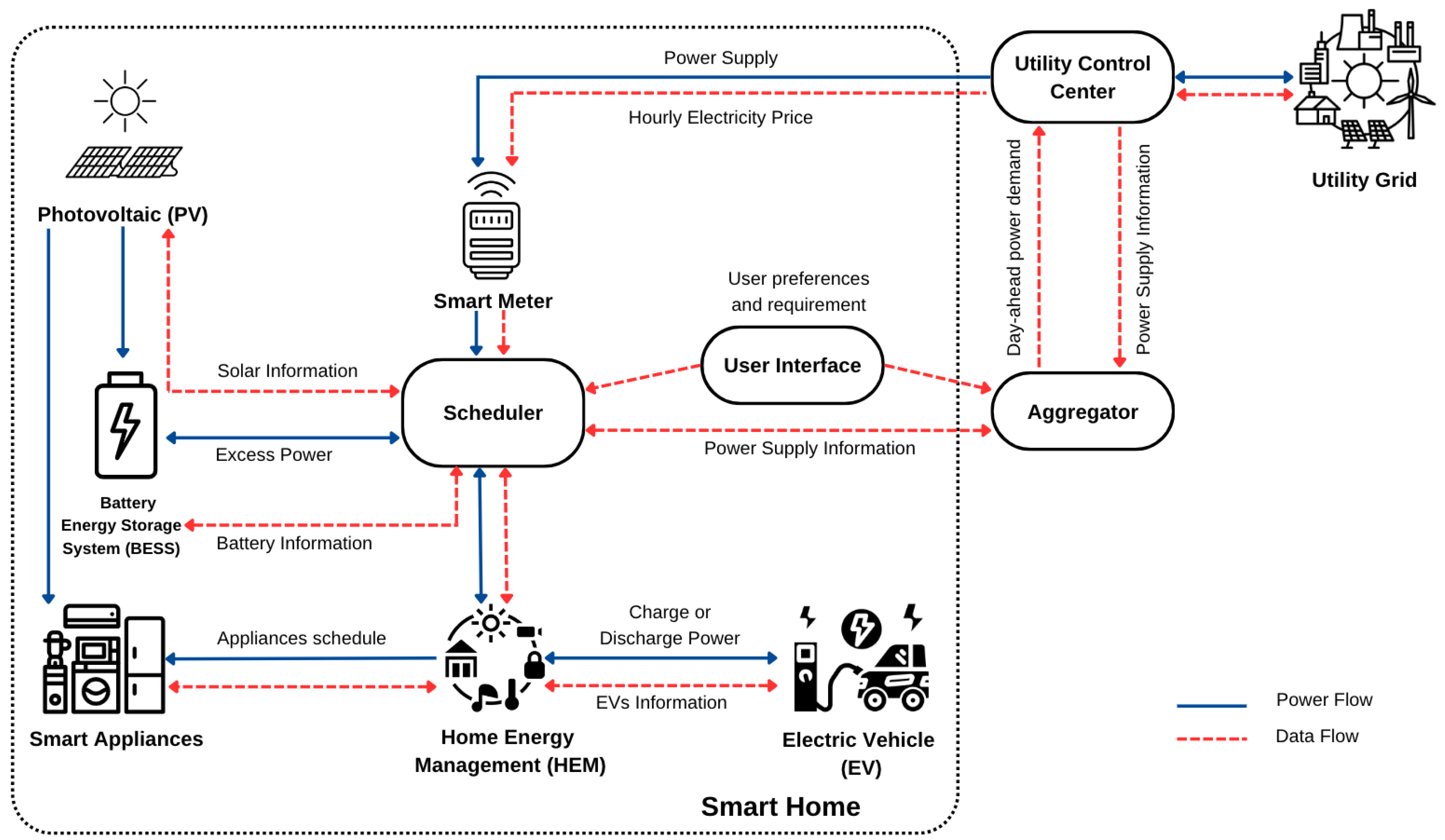

2. System Overview

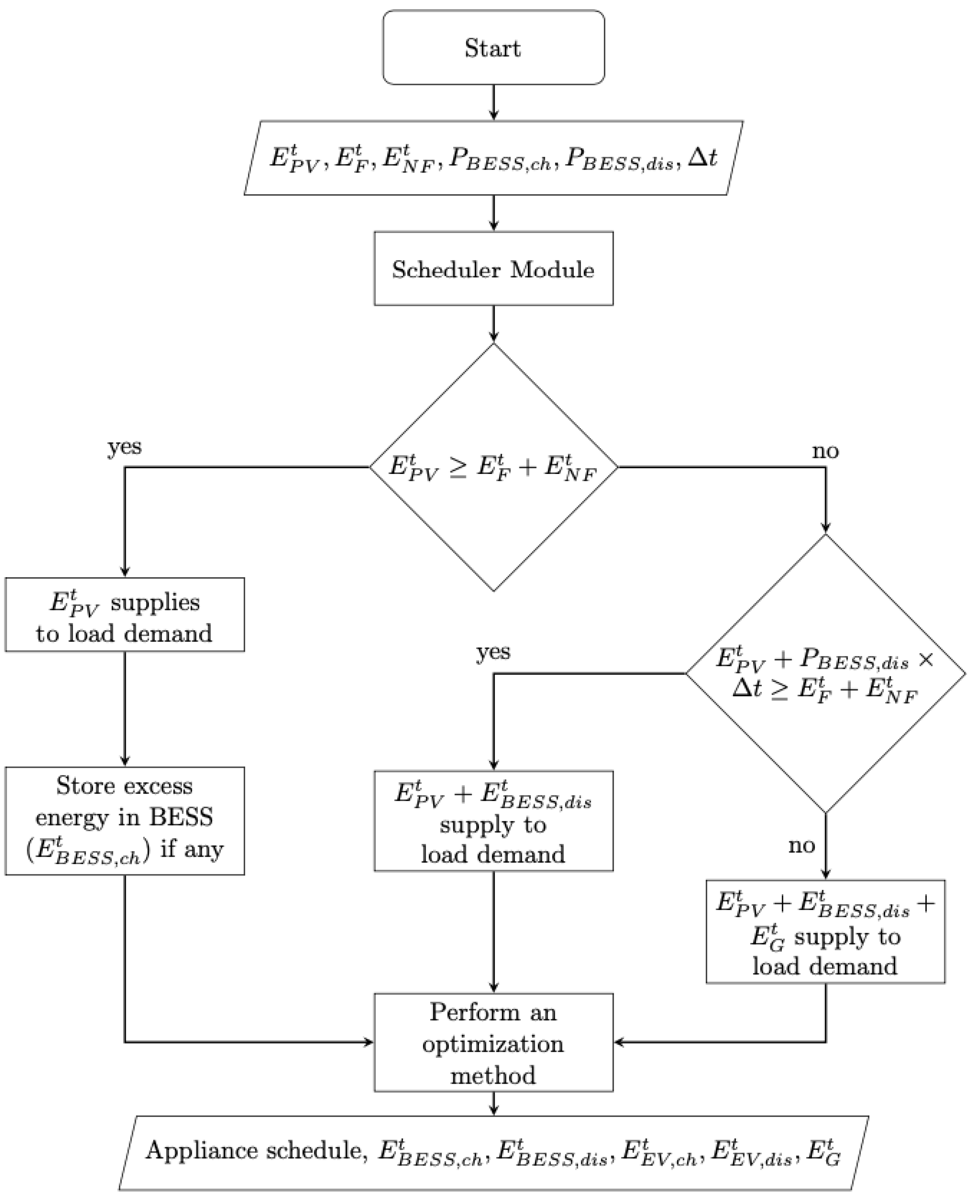

3. Proposed HEM System

3.1. Smart Appliance

3.2. Battery Energy Storage System

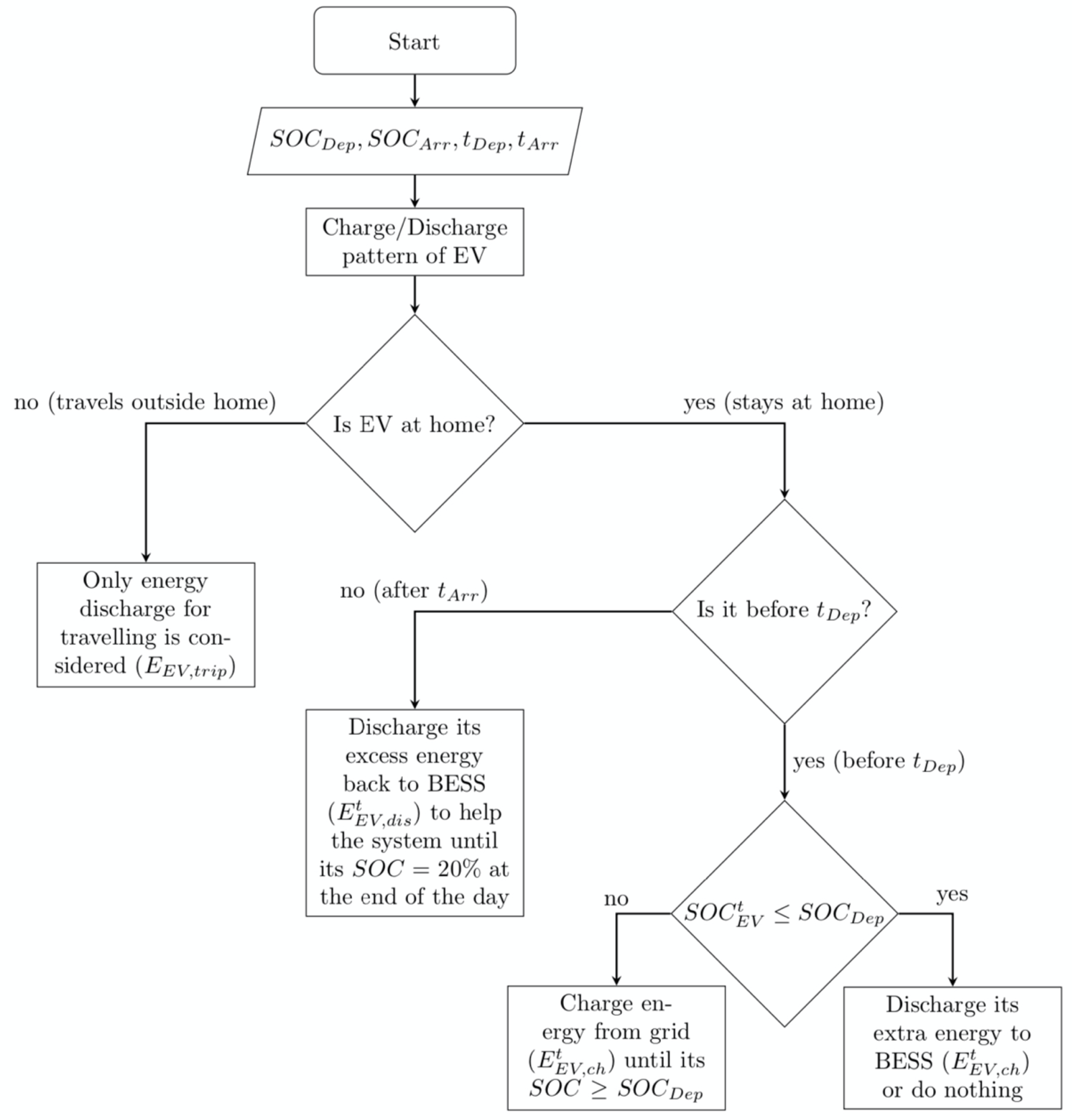

3.3. Electric Vehicle

3.4. Objective Function for a Single SH

3.5. Objective Function for Multiple SHs

4. Results and Discussion

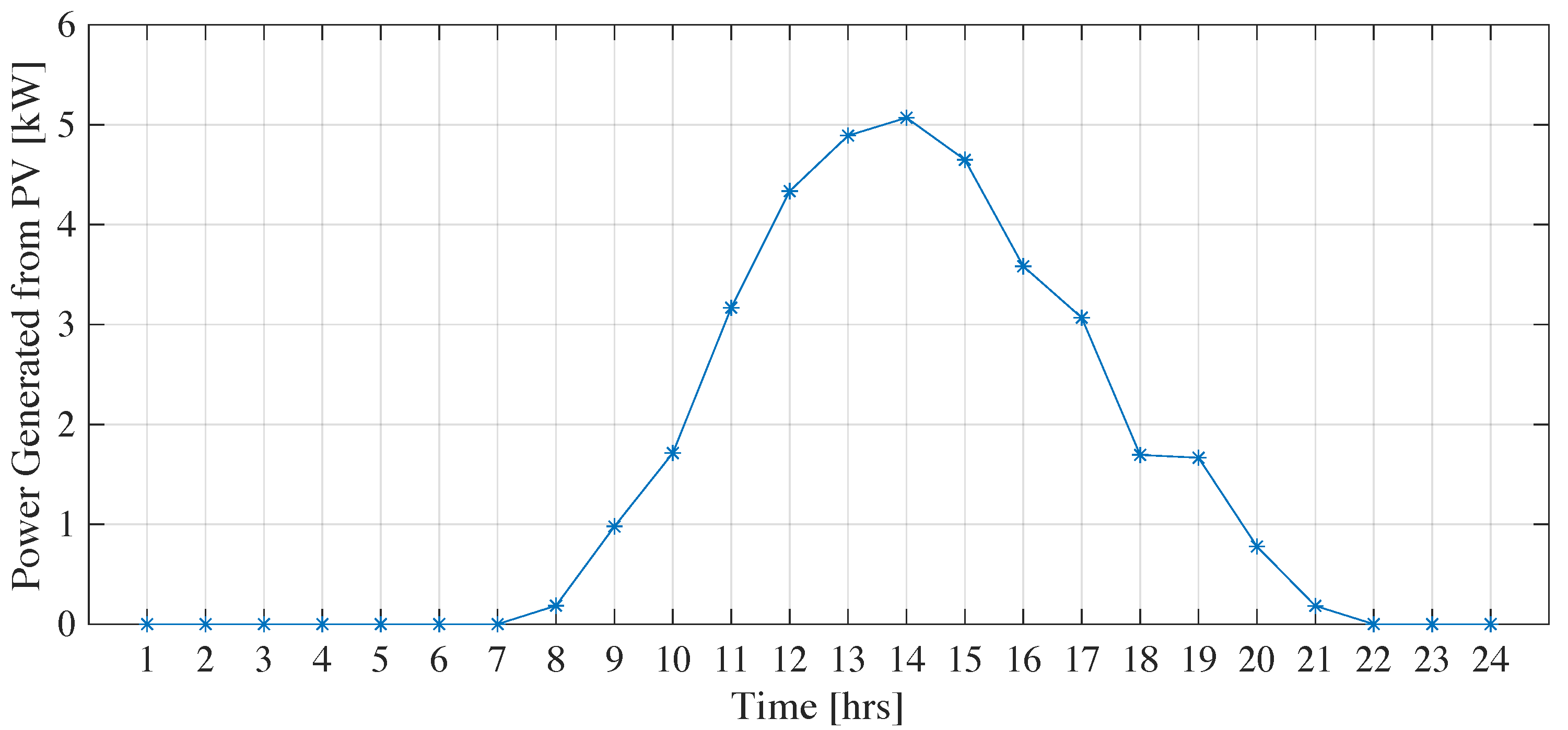

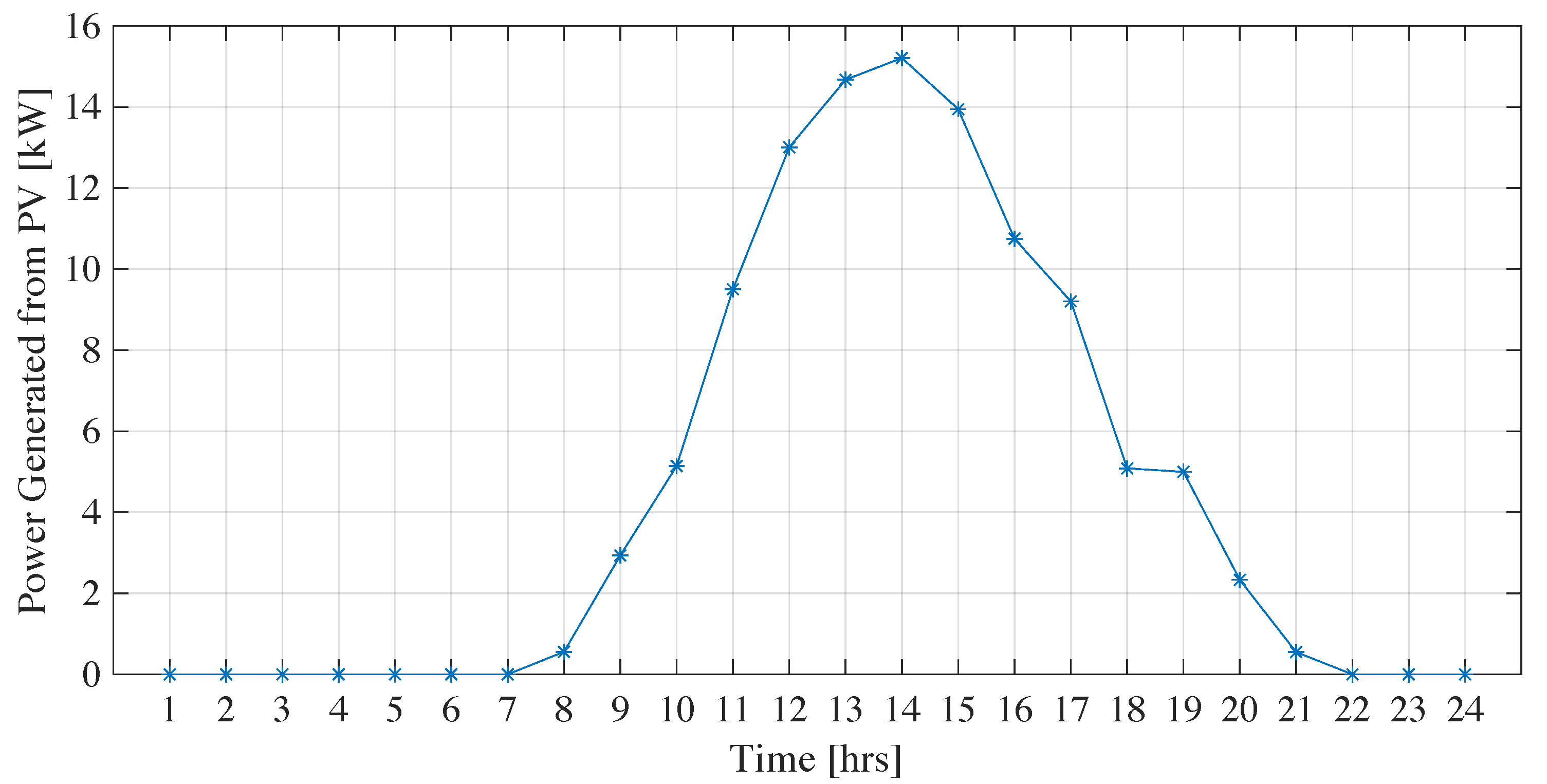

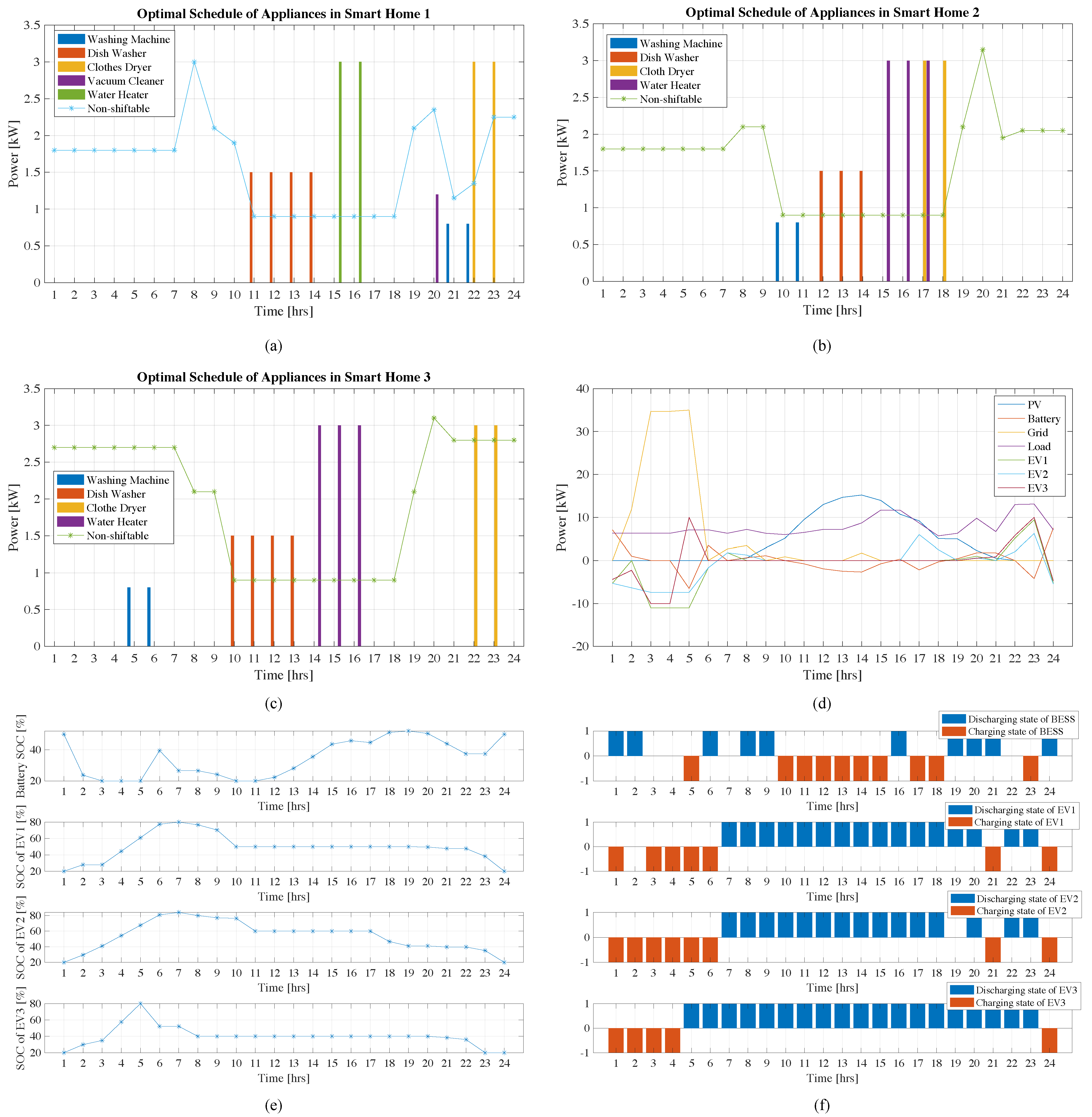

4.1. Case Study 1: Individual SH

4.2. Case Study 2: Multiple SHs

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DG | Distributed Generation |

| DSM | Demand-Side Management |

| HEM | Home Energy Management |

| DR | Demand Response |

| RESs | Renewable energy sources |

| MOMILP | Multi-objective mixed-integer linear programming |

| BESS | Battery Energy Storage System |

| GA | Genetic algorithm |

| PSO | Particle swarm optimization |

| BPSO | Binary particle swarm optimization |

| BFO | Bacterial foraging optimization |

| WDO | Wind-driven optimization |

| HGPO | Hybrid GA-PSO |

| MCA | Musical Chairs Algorithm |

| BLDE | Binary learning differential evolution algorithm |

| EV | Electric Vehicle |

| SG | Smart grid |

| RTP | Real-Time Pricing |

| SH | Smart Home |

| PV | Photovoltaic |

| V2H | Vehicle-to-Home |

| MILP | Mixed-Integer Linear Programming |

| SOC | State of charge |

References

- Panda, S.; Mohanty, S.; Rout, K.; Sahu, B.K.; Bajaj, M.; Zawbaa, H.M.; Kamel, S. Residential Demand Side Management model, optimization and future perspective: A review. Energy Rep. 2022, 8, 3727–3766. [Google Scholar] [CrossRef]

- Hussain, H.M.; Narayanan, A.; Sahoo, S.; Yang, Y.; Nardelli, P.H.; Blaabjerg, F. Home Energy Management Systems: Operation and Resilience of Heuristics Against Cyberattacks. IEEE Syst. Man Cybern. Mag. 2022, 8, 21–30. [Google Scholar] [CrossRef]

- Judge, M.A.; Khan, A.; Manzoor, A.; Khattak, H.A. Overview of smart grid implementation: Frameworks, impact, performance and challenges. J. Energy Storage 2022, 49, 104056. [Google Scholar] [CrossRef]

- International Energy Agency—iea.org. Available online: https://www.iea.org/ (accessed on 3 November 2023).

- Al-Sorour, A.; Fazeli, M.; Monfared, M.; Fahmy, A.A. Investigation of Electric Vehicles Contributions in an Optimized Peer-to-Peer Energy Trading System. IEEE Access 2023, 11, 12489–12503. [Google Scholar] [CrossRef]

- Siano, P. Demand response and smart grids—A survey. Renew. Sustain. Energy Rev. 2014, 30, 461–478. [Google Scholar] [CrossRef]

- Yong, J.Y.; Ramachandaramurthy, V.K.; Tan, K.M.; Mithulananthan, N. A review on the state-of-the-art technologies of electric vehicle, its impacts and prospects. Renew. Sustain. Energy Rev. 2015, 49, 365–385. [Google Scholar] [CrossRef]

- Hamed, S.G.; Kazemi, A. Multi-objective cost-load optimization for demand side management of a residential area in smart grids. Sustain. Cities Soc. 2017, 32, 171–180. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Alotaibi, M.A.; Elsheikh, W.A.; Alolah, A.I.; Ahmed, M.A. Novel Demand Side-Management Strategy for Smart Grid Concepts Applications in Hybrid Renewable Energy Systems. In Proceedings of the 2022 4th International Youth Conference on Radio Electronics, Electrical and Power Engineering (REEPE), Moscow, Russia, 17–19 March 2022. [Google Scholar] [CrossRef]

- Ali, S.; Ullah, K.; Hafeez, G.; Khan, I.; Albogamy, F.R.; Haider, S.I. Solving day-ahead scheduling problem with multi-objective energy optimization for demand side management in smart grid. Eng. Sci. Technol. Int. J. 2022, 36, 101135. [Google Scholar] [CrossRef]

- Jindal, A.; Bhambhu, B.S.; Singh, M.; Kumar, N.; Naik, K. A Heuristic-Based Appliance Scheduling Scheme for Smart Homes. IEEE Trans. Ind. Inform. 2020, 16, 3242–3255. [Google Scholar] [CrossRef]

- Mota, B.; Faria, P.; Vale, Z. Residential load shifting in demand response events for bill reduction using a genetic algorithm. Energy 2022, 260, 124978. [Google Scholar] [CrossRef]

- Ahmad, A.; Khan, A.; Javaid, N.; Hussain, H.M.; Abdul, W.; Almogren, A.; Alamri, A.; Niaz, I.A. An optimized home energy management system with integrated renewable energy and storage resources. Energies 2017, 10, 549. [Google Scholar] [CrossRef]

- Dinh, H.T.; Yun, J.; Kim, D.M.; Lee, K.H.; Kim, D. A Home Energy Management System with Renewable Energy and Energy Storage Utilizing Main Grid and Electricity Selling. IEEE Access 2020, 8, 49436–49450. [Google Scholar] [CrossRef]

- Albogamy, F.R. Optimal Energy Consumption Scheduler Considering Real-Time Pricing Scheme for Energy Optimization in Smart Microgrid. Energies 2022, 15, 8015. [Google Scholar] [CrossRef]

- Bouakkaz, A.; Mena, A.J.; Haddad, S.; Ferrari, M.L. Efficient energy scheduling considering cost reduction and energy saving in hybrid energy system with energy storage. J. Energy Storage 2021, 33, 101887. [Google Scholar] [CrossRef]

- Javaid, N.; Ullah, I.; Akbar, M.; Iqbal, Z.; Khan, F.A.; Alrajeh, N.; Alabed, M.S. An Intelligent Load Management System with Renewable Energy Integration for Smart Homes. IEEE Access 2017, 5, 13587–13600. [Google Scholar] [CrossRef]

- Abdelaal, G.; Gilany, M.I.; Elshahed, M.; Sharaf, H.M.; El’Gharably, A. Integration of Electric Vehicles in Home Energy Management Considering Urgent Charging and Battery Degradation. IEEE Access 2021, 9, 47713–47730. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Rabie, A.H. A Novel Musical Chairs Optimization Algorithm. Arab. J. Sci. Eng. 2023, 48, 10371–10403. [Google Scholar] [CrossRef]

- Khan, M.A.; Haque, A.; Kurukuru, V.S.B. Power Flow Management With Q-Learning for a Grid Integrated Photovoltaic and Energy Storage System. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 5762–5772. [Google Scholar] [CrossRef]

- Erdinc, O.; Paterakis, N.G.; Mendes, T.D.; Bakirtzis, A.G.; Catalão, J.P. Smart Household Operation Considering Bi-Directional EV and ESS Utilization by Real-Time Pricing-Based DR. IEEE Trans. Smart Grid 2015, 6, 1281–1291. [Google Scholar] [CrossRef]

- Hou, X.; Wang, J.; Huang, T.; Wang, T.; Wang, P. Smart Home Energy Management Optimization Method Considering Energy Storage and Electric Vehicle. IEEE Access 2019, 7, 144010–144020. [Google Scholar] [CrossRef]

- Imran, A.; Hafeez, G.; Khan, I.; Usman, M.; Shafiq, Z.; Qazi, A.B.; Khalid, A.; Thoben, K.D. Heuristic-Based Programable Controller for Efficient Energy Management under Renewable Energy Sources and Energy Storage System in Smart Grid. IEEE Access 2020, 8, 139587–139608. [Google Scholar] [CrossRef]

- Alfaverh, K.; Alfaverh, F.; Szamel, L. Plugged-in electric vehicle-assisted demand response strategy for residential energy management. Energy Inform. 2023, 6, 6. [Google Scholar] [CrossRef]

- Golshannavaz, S. Cooperation of electric vehicle and energy storage in reactive power compensation: An optimal home energy management system considering PV presence. Sustain. Cities Soc. 2018, 39, 317–325. [Google Scholar] [CrossRef]

- Chreim, B.; Esseghir, M.; Merghem-Boulahia, L. LOSISH—LOad Scheduling In Smart Homes based on demand response: Application to smart grids. Appl. Energy 2022, 323, 119606. [Google Scholar] [CrossRef]

- Gomes, I.; Ruano, M.; Ruano, A. MILP-based model predictive control for home energy management systems: A real case study in Algarve, Portugal. Energy Build. 2023, 281, 112774. [Google Scholar] [CrossRef]

- Home Appliances Power Consumption Table—unboundsolar.com. Available online: https://unboundsolar.com/solar-information/power-table#tablePower (accessed on 7 November 2023).

- Khan, M.A.; Bayati, N.; Ebel, T. Techno-economic analysis and predictive operation of a power-to-hydrogen for renewable microgrids. Energy Convers. Manag. 2023, 298, 117762. [Google Scholar] [CrossRef]

- Honarmand, M.E.; Hosseinnezhad, V.; Hayes, B.; Shafie-Khah, M.; Siano, P. An Overview of Demand Response: From its Origins to the Smart Energy Community. IEEE Access 2021, 9, 96851–96876. [Google Scholar] [CrossRef]

- andelenergiTimeenergiPris. Timeenergi din Pris Følger Markedet Time for Time—andelenergi.dk. Available online: https://andelenergi.dk/sel/timeenergi/ (accessed on 13 September 2023).

- PES. IEEE Open Data Sets. 2022. Available online: https://site.ieee.org/pes-iss/data-sets/#cons (accessed on 12 October 2023).

| Load Type | Appliance | Power Rating [kW] | Daily Usage [hour] | Start-End Time |

|---|---|---|---|---|

| Flexible | Washing Machine | 0.8 | 2 | - |

| Dishwasher | 1.5 | 4 | - | |

| Clothes Dryer | 3 | 2 | - | |

| Vacuum Cleaner | 1.2 | 1 | - | |

| Water Heater | 3 | 2 | - | |

| Non-flexible | Air Conditioner | 0.9 | 10 | (1 a.m.–8 a.m.), (10 p.m.–12 a.m.) |

| Refrigerator | 0.9 | 24 | - | |

| Electric Oven | 1.2 | 4 | (7 a.m.–9 a.m.), (6 p.m.–8 p.m.) | |

| Microwave | 1 | 1 | (9 a.m.–10 a.m.) | |

| Light | 0.1 | 5 | (7 p.m.–12 a.m.) | |

| TV | 0.15 | 5 | (7 p.m.–12 a.m.) | |

| Desktop | 0.2 | 3 | (9 p.m.–12 a.m.) |

| Total Cost of Traditional SH | Total Cost of Proposed HEM | Reduction |

|---|---|---|

| day | day | 30.43% |

| Load Type | Appliance | Power Rating [kW] | Daily Usage [hour] | Start-End Time |

|---|---|---|---|---|

| Flexible | Washing Machine | 0.8 | 3 | - |

| Dishwasher | 1.5 | 3 | - | |

| Clothes Dryer | 3 | 2 | - | |

| Water Heater | 3 | 3 | - | |

| Non-flexible | Air Conditioner | 0.9 | 12 | (1 a.m.-8 a.m.), (7 p.m.–12 a.m.) |

| Refrigerator | 0.9 | 24 | - | |

| Electric Oven | 1.2 | 4 | (7 a.m.-9 a.m.), (6 p.m.–8 p.m.) | |

| Light | 0.1 | 3 | (9 p.m.–12 a.m.) | |

| TV | 0.15 | 5 | (7 p.m.–12 a.m.) |

| Load Type | Appliance | Power Rating [kW] | Daily Usage [hour] | Start-End Time |

|---|---|---|---|---|

| Flexible | Washing Machine | 0.8 | 2 | - |

| Dishwasher | 1.5 | 4 | - | |

| Clothes Dryer | 3 | 2 | - | |

| Water Heater | 3 | 3 | - | |

| Non-flexible | Air Conditioner 1 | 0.9 | 10 | (1 a.m.–8 a.m.), (10 p.m.–12 a.m.) |

| Air Conditioner 2 | 0.9 | 12 | (1 a.m.–8 a.m.), (7 p.m.–12 a.m.) | |

| Refrigerator | 0.9 | 24 | - | |

| Electric Oven | 1.2 | 4 | (7 a.m.–9 a.m.), (6 p.m.–8 p.m.) | |

| Light | 0.1 | 5 | (7 p.m.–12 a.m.) |

| Type | Parameter | SH 1 | SH 2 | SH 3 |

|---|---|---|---|---|

| Specification | Model of EV | Tesla Model S | Peugeot | Toyota Rev4 EV |

| 60 kWh | 50 kWh | 40 kWh | ||

| Initial and Final | ||||

| 11 kW | kW | 10 kW | ||

| Driving Activity | 8 a.m. | 9 a.m. | 6 a.m. | |

| 7 p.m. | 5 p.m. | 8 p.m. | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prum, P.; Charoen, P.; Khan, M.A.; Bayati, N.; Charoenlarpnopparut, C. Energy Management Scheme for Optimizing Multiple Smart Homes Equipped with Electric Vehicles. Energies 2024, 17, 254. https://doi.org/10.3390/en17010254

Prum P, Charoen P, Khan MA, Bayati N, Charoenlarpnopparut C. Energy Management Scheme for Optimizing Multiple Smart Homes Equipped with Electric Vehicles. Energies. 2024; 17(1):254. https://doi.org/10.3390/en17010254

Chicago/Turabian StylePrum, Puthisovathat, Prasertsak Charoen, Mohammed Ali Khan, Navid Bayati, and Chalie Charoenlarpnopparut. 2024. "Energy Management Scheme for Optimizing Multiple Smart Homes Equipped with Electric Vehicles" Energies 17, no. 1: 254. https://doi.org/10.3390/en17010254

APA StylePrum, P., Charoen, P., Khan, M. A., Bayati, N., & Charoenlarpnopparut, C. (2024). Energy Management Scheme for Optimizing Multiple Smart Homes Equipped with Electric Vehicles. Energies, 17(1), 254. https://doi.org/10.3390/en17010254