1. Introduction

The conventional means of electrical energy generation, primarily relying on fossil fuel power plants, have long been associated with significant environmental and economic challenges. These drawbacks include detrimental contributions to air pollution and greenhouse gas emissions, leading to climate change and adverse effects on human health. Moreover, such energy production methods are fundamentally unsustainable as they rely on finite resources like coal, oil, and gas, which are inexorably depleting [

1,

2]. Additionally, these conventional power plants often impose severe consequences on local ecosystems and wildlife through habitat destruction and water pollution. The economic burden of electricity generation through these means is equally substantial, encompassing both financial and environmental costs [

3].

Conversely, renewable energy generation has emerged as a promising alternative [

4]. However, it is not without limitations. Renewable sources, such as solar and wind power, can be intermittent and subject to the unpredictability of weather conditions [

5,

6]. This intermittency necessitates the development of backup systems and energy storage solutions [

7]. Furthermore, while renewable energy infrastructure costs have decreased over time, the initial investment remains relatively high. Additionally, not all geographical locations are conducive to certain types of renewable energy generation, limiting their widespread adoption [

8].

In response to these challenges, microgrids (MGs) have emerged as a viable solution for localized energy generation [

9]. These MGs typically comprise components such as low-voltage (LV) distribution systems, distributed energy resources (DERs) (e.g., photovoltaics, fuel cells, micro-turbines), energy storage components (batteries, energy capacitors, and flywheels), and flexible loads [

10]. MGs can operate in both non-autonomous (grid-tied) and autonomous (grid-independent) modes, offering flexibility and resilience [

11,

12].

The HOMER Pro microgrid software from HOMER Energy stands out as the industry standard for microgrid design optimization. It leverages the Hybrid Optimization Model for Multiple Energy Resources (HOMER) to simulate and analyze various equipment configurations to find optimal system designs. HOMER simulates the operation of hybrid microgrids over the course of a year, providing insights at varying time steps, from one minute to one hour [

13]. In [

14], the focus is on the design, performance analysis, and optimization of a grid-connected hybrid microgrid for hospital applications employing HOMER software. Ref. [

15] explores the design of an off-grid (stand-alone) hybrid (AC/DC) microgrid intended for a community system using HOMER software. Ref. [

16] presents the optimization of a grid-connected microgrid for three different cities in Pakistan employing HOMER software. In [

17], researchers present the modeling and optimization of a community microgrid situated in a housing estate in Cape Town, South Africa, employing HOMER software. Ref. [

18] addresses the design considerations for a microgrid in Rwanda, specifically engineered to provide low-cost electricity employing HOMER software. PVsyst software is the best approach for analyzing PV generation, as solar design depends on various factors, including its longitude, range, climatic conditions like temperature, wind speed, and sun-oriented irradiance. By evaluating these factors, it will be possible to increase the efficiency of a sunlight-based PV module and predict the cost of the system [

19,

20,

21,

22,

23]. Ref. [

19] conducts a performance analysis on a grid-connected PV plant generating 4908 MWh annually for a university in Bahawalpur, Pakistan, employing PVsyst software. Ref. [

20] focuses on the design and installation of a stand-alone solar PV system, utilizing PVsyst software to meet the annual energy requirement of 1086.24 kWh for a college in India. Ref. [

21] details the design of a 100 MW grid-connected PV plant for a university in Saudi Arabia, employing PVsyst software. Ref. [

22] delves into the analysis and design of a 700 KWp grid-connected solar power plant in the Daikundi province of Afghanistan using PVsyst software. Ref. [

23] presents the modeling and simulation of a 1 MW PV plant in the north of Morocco, employing PVsyst software. SAM software can be used for performance analysis of hybrid microgrids by monitoring and analyzing the software components that contribute to the overall performance of the system [

24,

25,

26,

27,

28,

29,

30]. Ref. [

24] introduces Cascade Extended Analysis as a methodology to ascertain the optimal capacities and sizes of diverse power generation and energy storage systems (ESSs) with a renewable energy plant, applicable to both grid-connected and stand-alone setups, facilitated by SAM software. Ref. [

25] conducts an analysis of energy generation from on-grid PV plants across all regions of Brazil. Ref. [

29] details the design and performance analysis of an 8 kW PV grid-connected system incorporating an ESS, employing SAM software. Ref. [

30] presents an analysis of a PV system and BESS for the community using SAM software.

This research paper is dedicated to the optimization, simulation, performance analysis, and design of hybrid stand-alone microgrids tailored to meet the energy needs of facilities. It aims to validate the proposed designs through empirical test results and experiment reports. To achieve this, a combination of various software tools will be utilized, each offering distinct advantages and limitations. For instance, PVsyst is particularly valuable for PV plant design and conducting detailed analysis with real-time parameters. HOMER Pro excels in optimization and analysis, while SAM software proves advantageous for studying the performance analysis of hybrid stand-alone microgrids with battery energy storage systems. Including test findings and experiment reports will provide robust validation for the proposed hybrid stand-alone microgrid designs, advancing the field of sustainable energy solutions.

The following is how this paper is structured: In

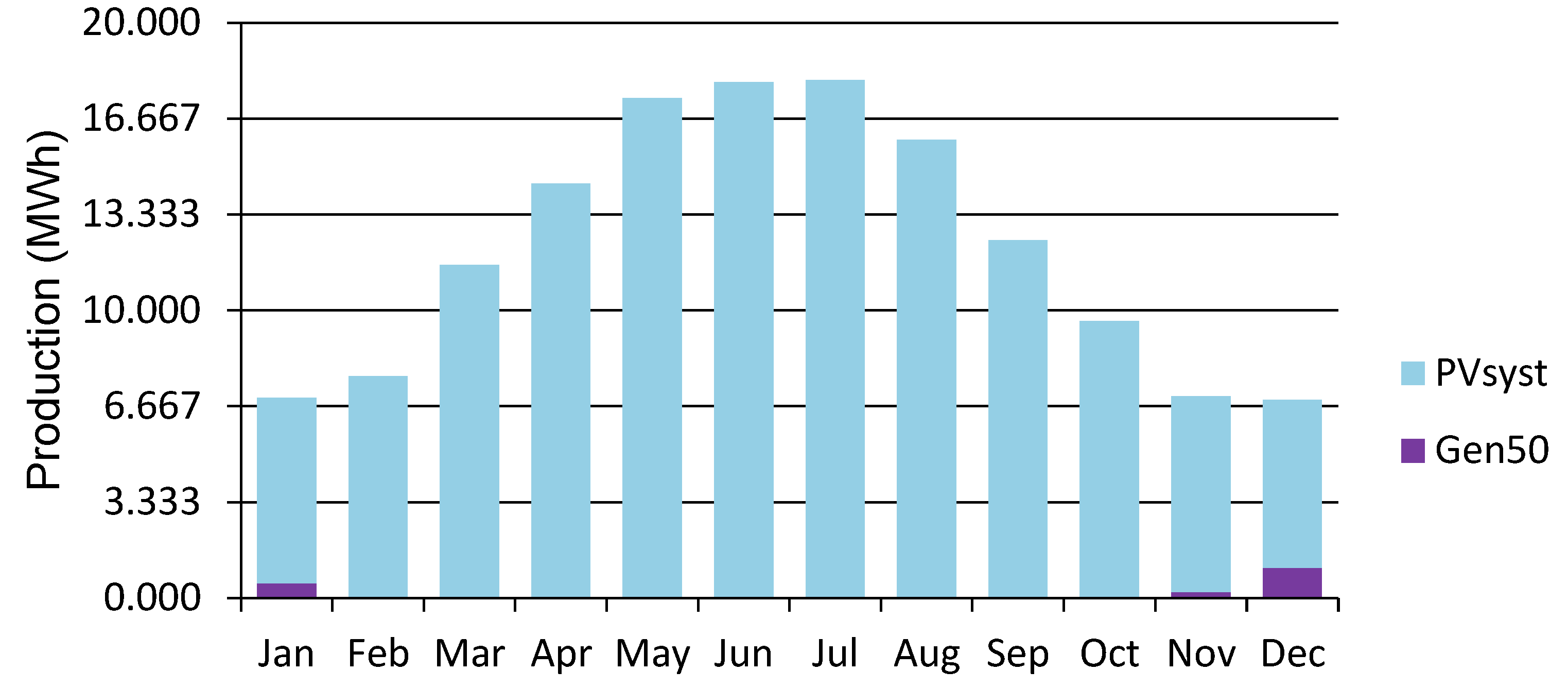

Section 2, a comprehensive overview of the proposed hybrid stand-alone microgrid is presented. It begins with an exploration of the microgrid’s structural design, followed by an in-depth analysis of the electrical load schedule and system sizing calculations. The modeling of the photovoltaic (PV) system is then elucidated, covering the design parameters and calculations that are discretized for utilization in PVsyst software, employed in the subsequent PV plant designing phase. Subsequently, the microgrid’s design is explicated using HOMER Pro software, incorporating data files from PVsyst software. The section culminates with the performance analysis methodology for the proposed microgrid, employing the System Advisor Model (SAM) software. In the subsequent

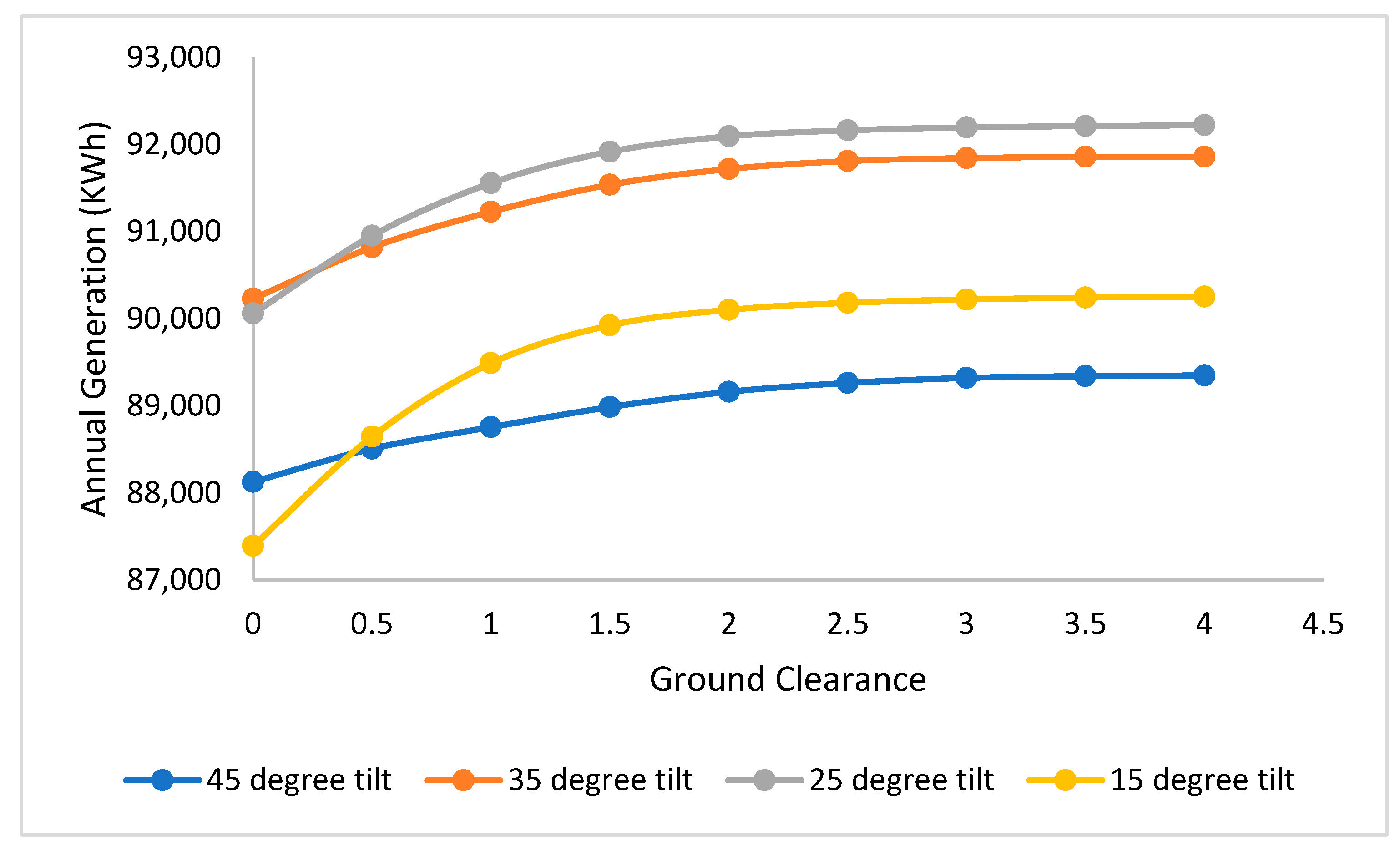

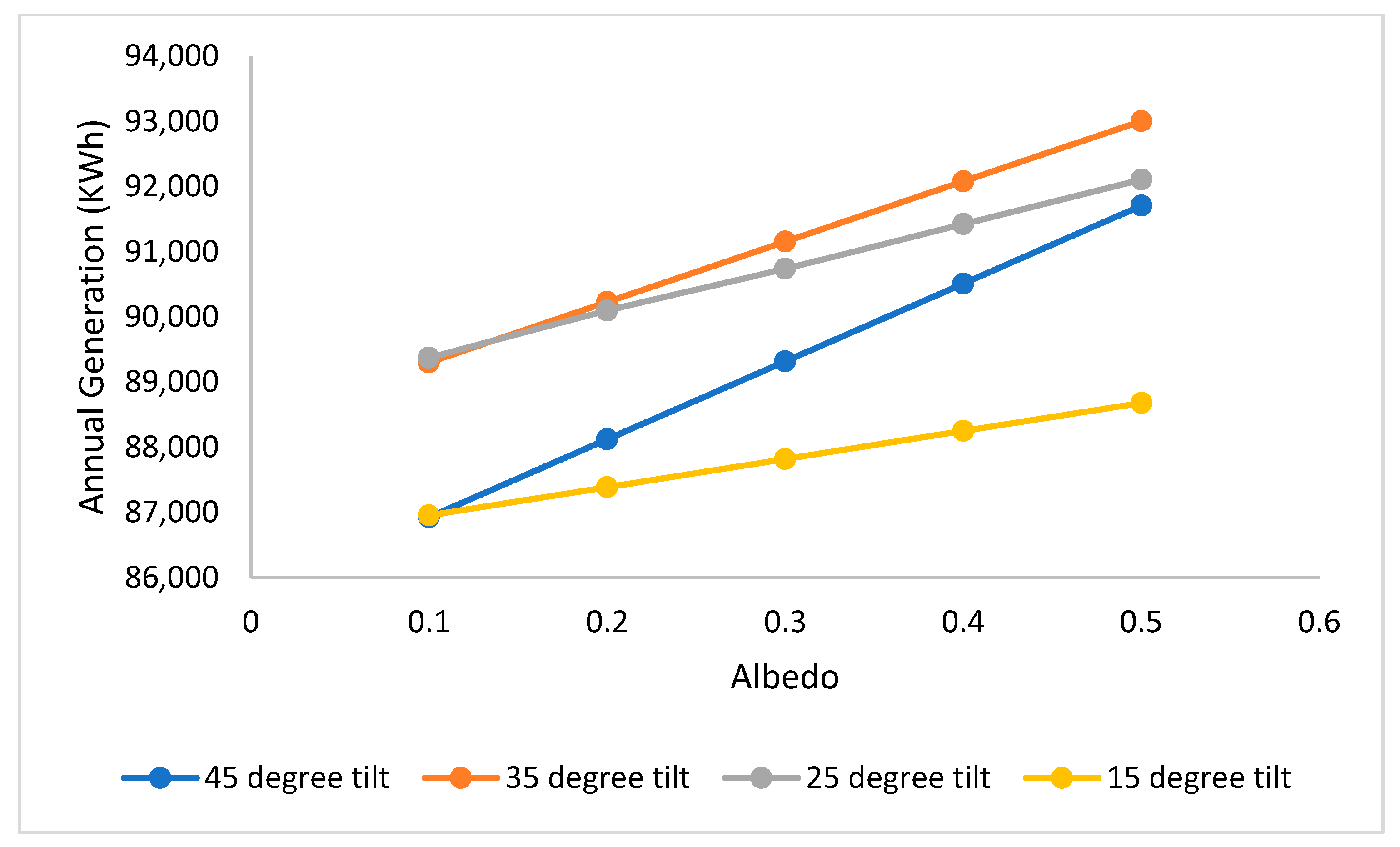

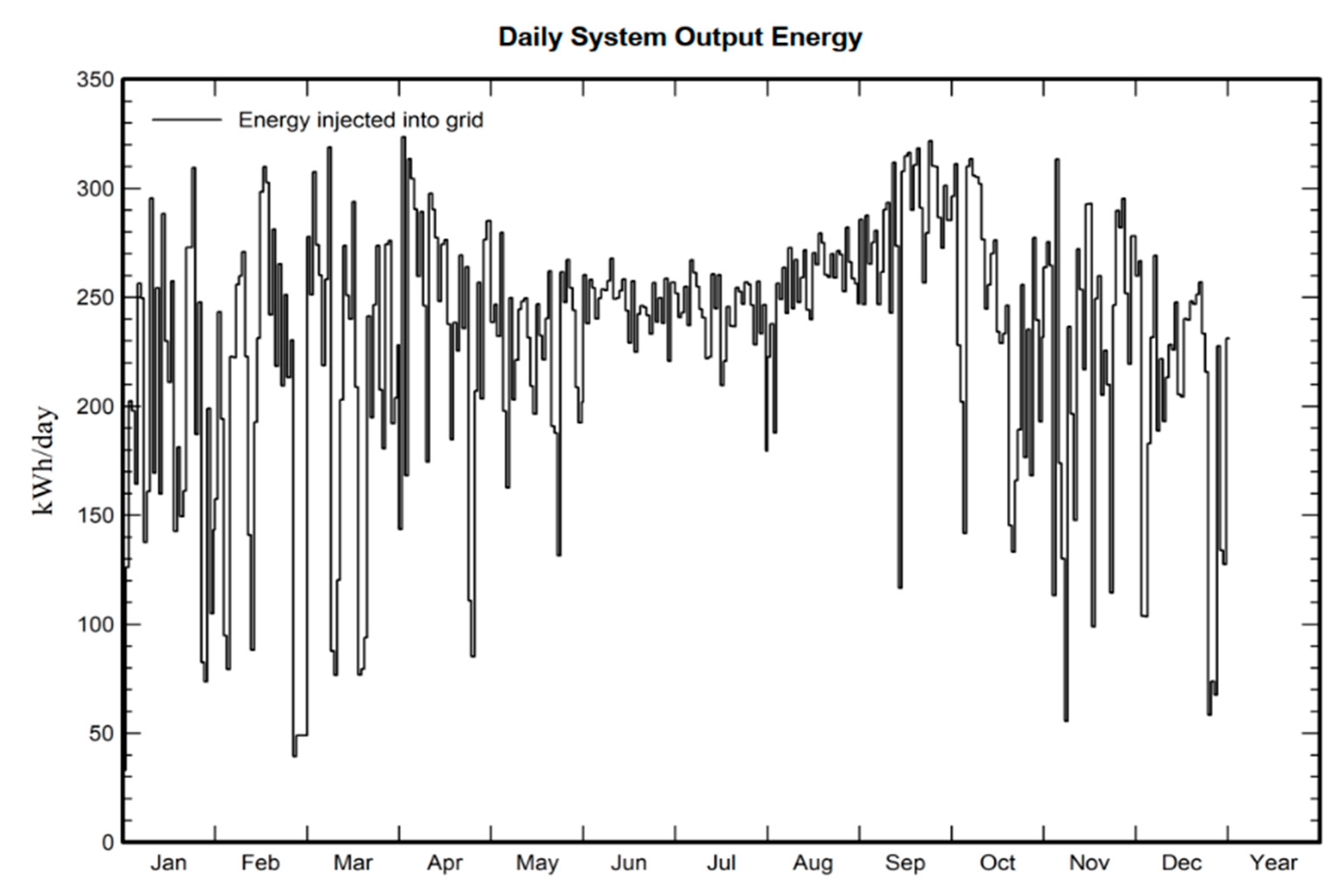

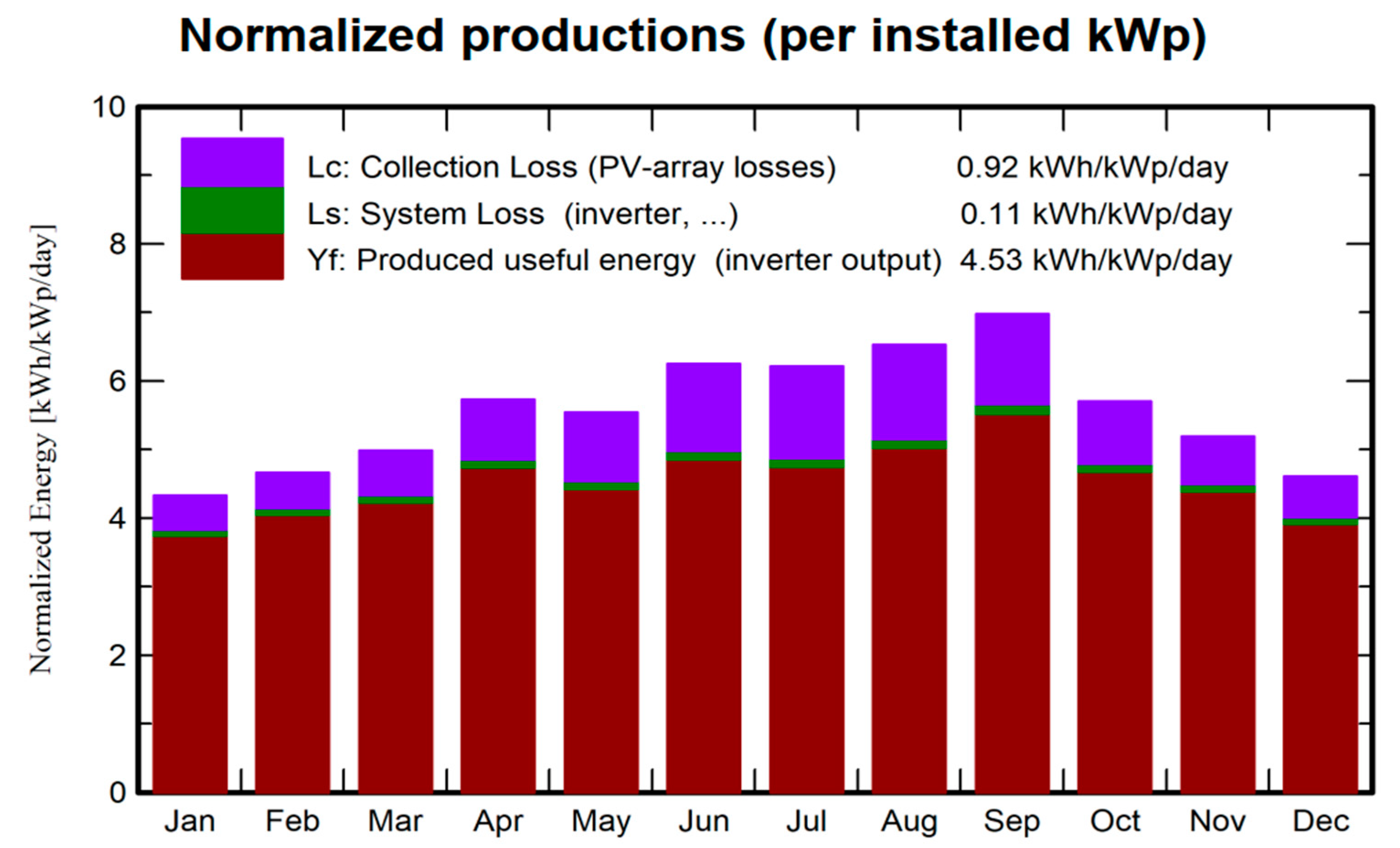

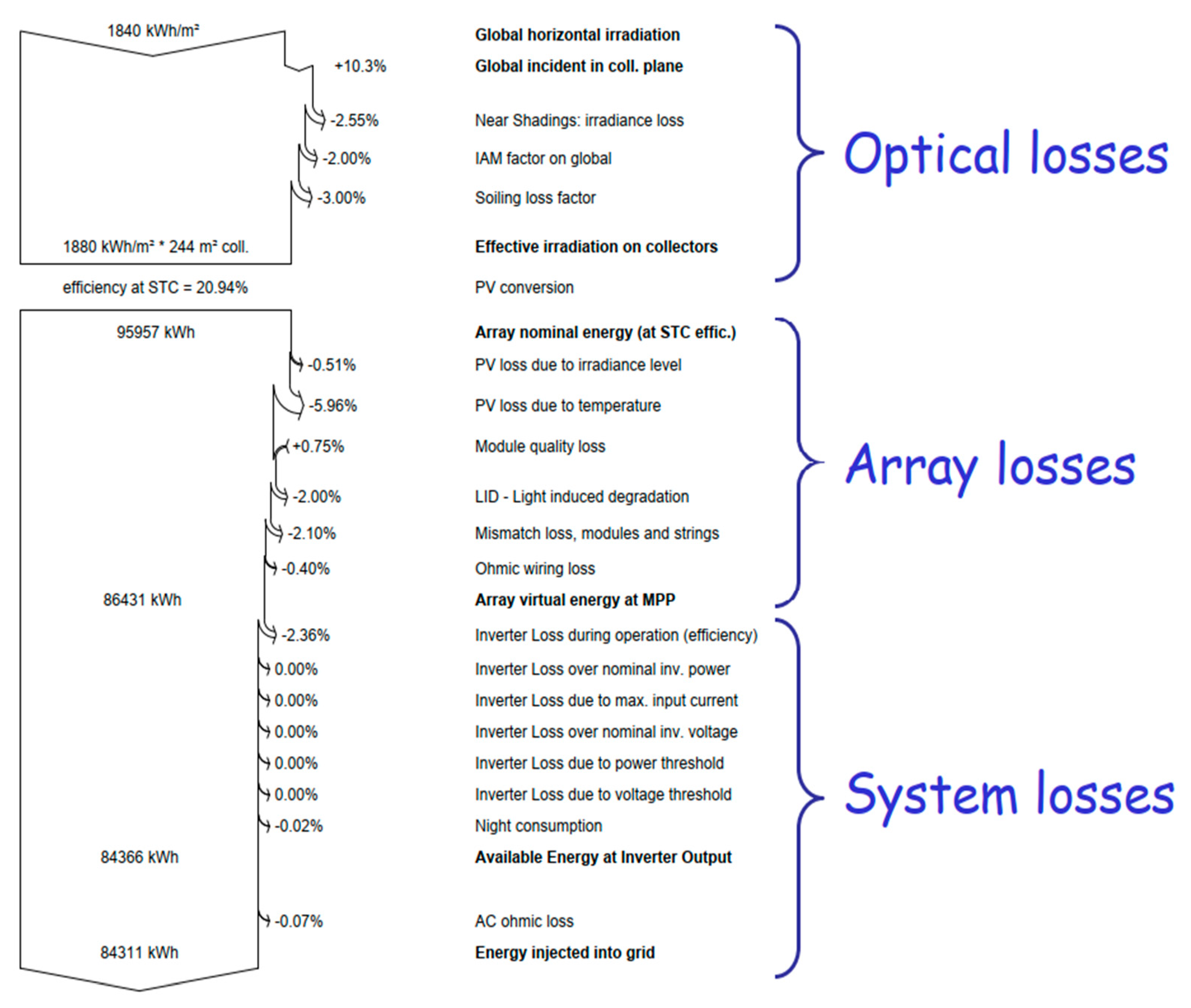

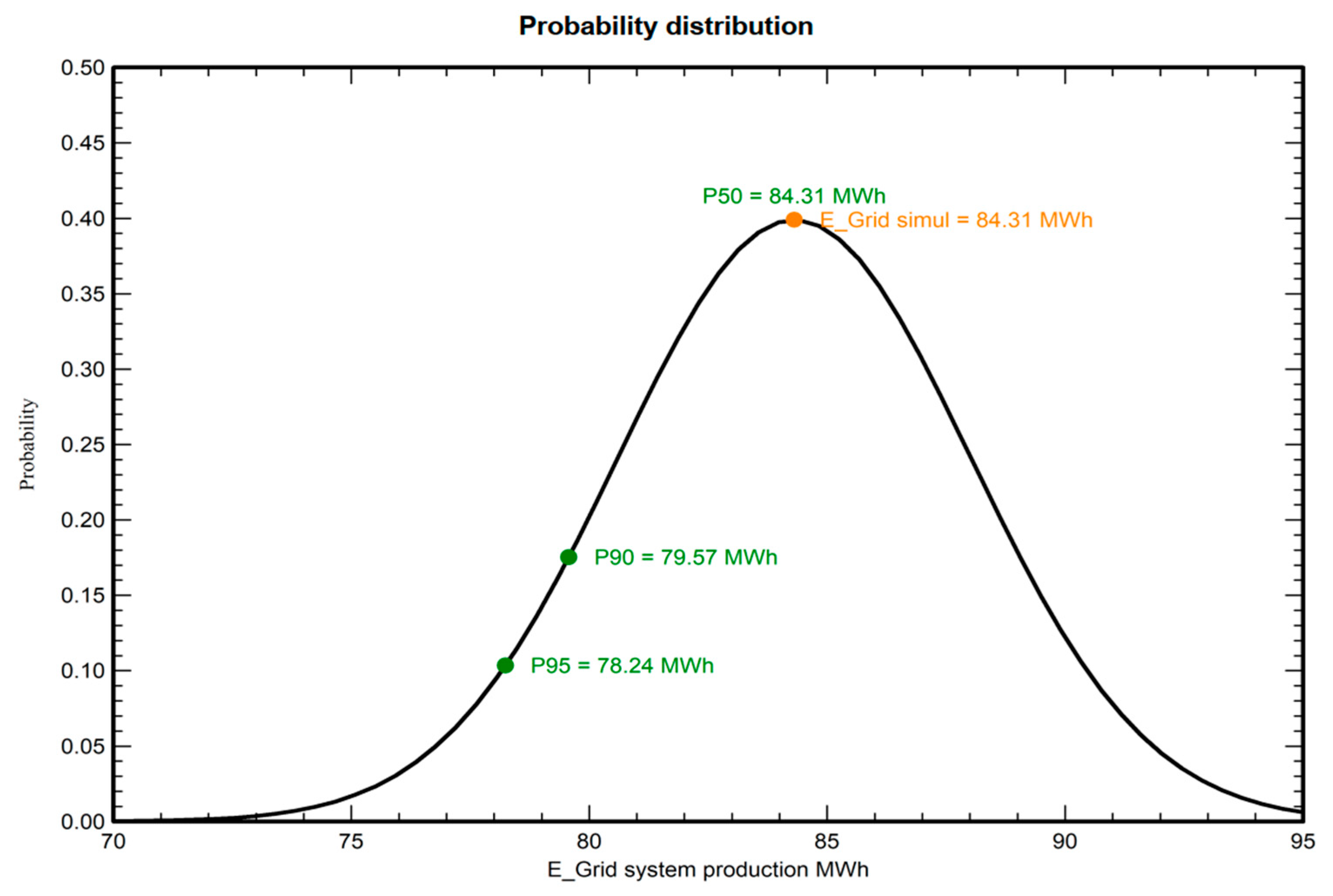

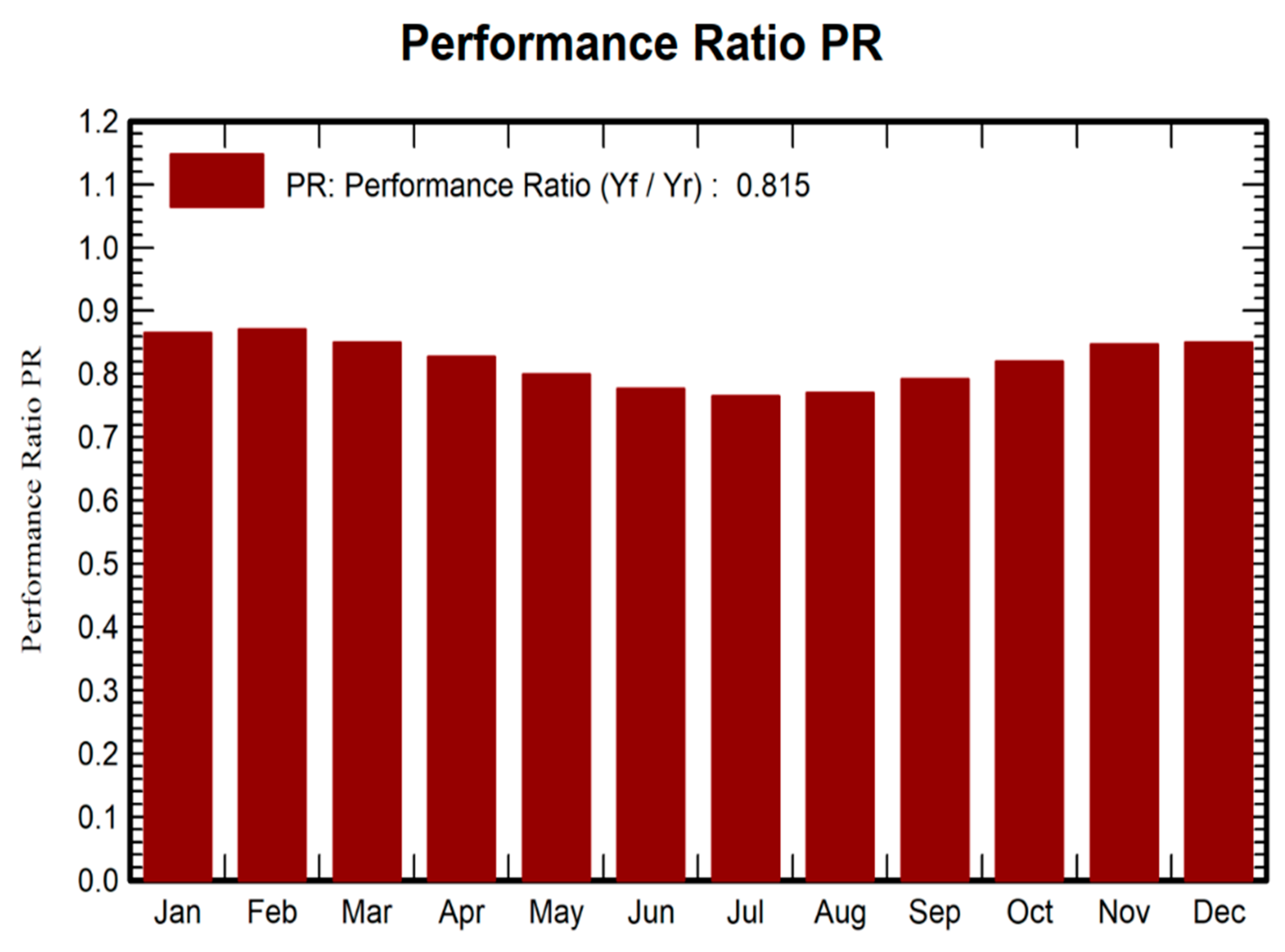

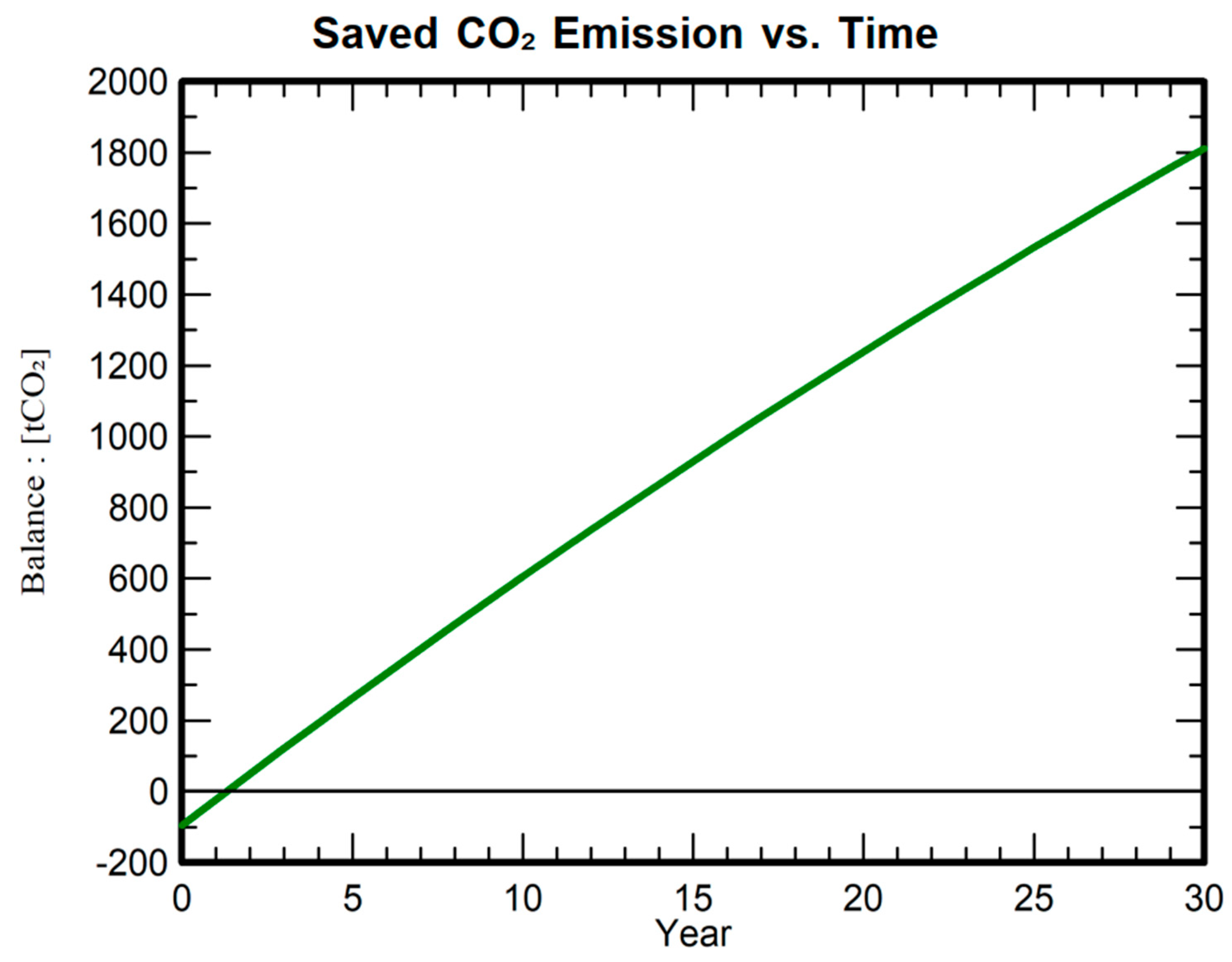

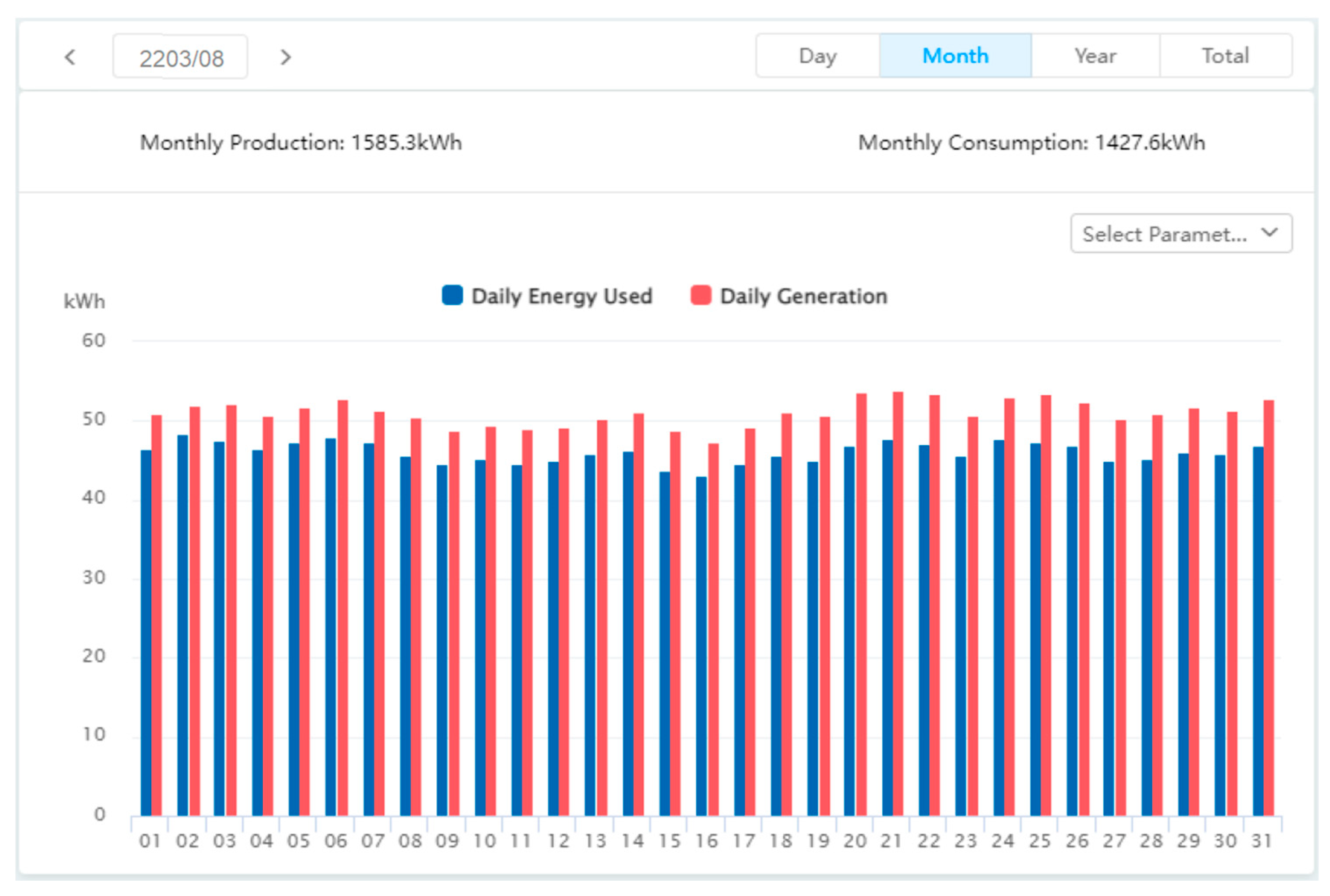

Section 3, the focus is on the outcomes derived from PVsyst software. This includes an exploration of the impact of ground clearance and ground albedo on the annual generation, considering various tilt angles of bifacial PV modules. For monofacial PV modules integrated into the proposed microgrid, the discussion encompasses daily output energy, normalized production per installed kWp, loss analysis, probability distribution, performance ratio, capacity factor, and saved CO

2 emissions projected over the next 30 years. The results obtained from HOMER Pro software, detailing power injection from the PV system and an emergency diesel generator (EDG) into the microgrid, as well as the expected PV and EDG output power for the entire year, are thoroughly examined. The performance analysis of the microgrid, using SAM software, is then discussed. Finally, the section concludes with an analysis of practical results. This paper concludes with a final section summarizing the key findings and insights gained from this research.

2. Materials and Methods

This section aims to provide a comprehensive understanding of the proposed hybrid stand-alone microgrid. Firstly, it will delve into the structure of the microgrid, highlighting its various components and their interconnections. Following this, the electrical load schedule and system sizing calculation will be discussed, providing insights into the planning and optimization of the microgrid’s energy usage. Subsequently, the modeling of the photovoltaic (PV) system will be explained, shedding light on the technical aspects of integrating renewable energy sources into the microgrid. Moving forward, the design of the hybrid stand-alone microgrid will be elaborated upon, emphasizing the considerations and strategies employed. Lastly, the performance analysis of the microgrid will be presented.

2.1. Structure of the Proposed Hybrid Stand-Alone Microgrid

The hybrid stand-alone microgrid taken into consideration in this study will be used to meet the demand requirements of a facility in Iraq. Since there is currently no distribution network in the area where the facility is located, building a dedicated line to the site would need a substantial capital investment. This is the rationale for choosing to build a microgrid. Therefore, an autonomous microgrid would be better from that point of view because energy consumption would then be provided for free during the project’s lifespan. Additionally, a microgrid that mainly uses renewable energy sources would make it easier to reduce CO2 emissions, which would improve the environment and play a significant role in the transition to a carbon-free world.

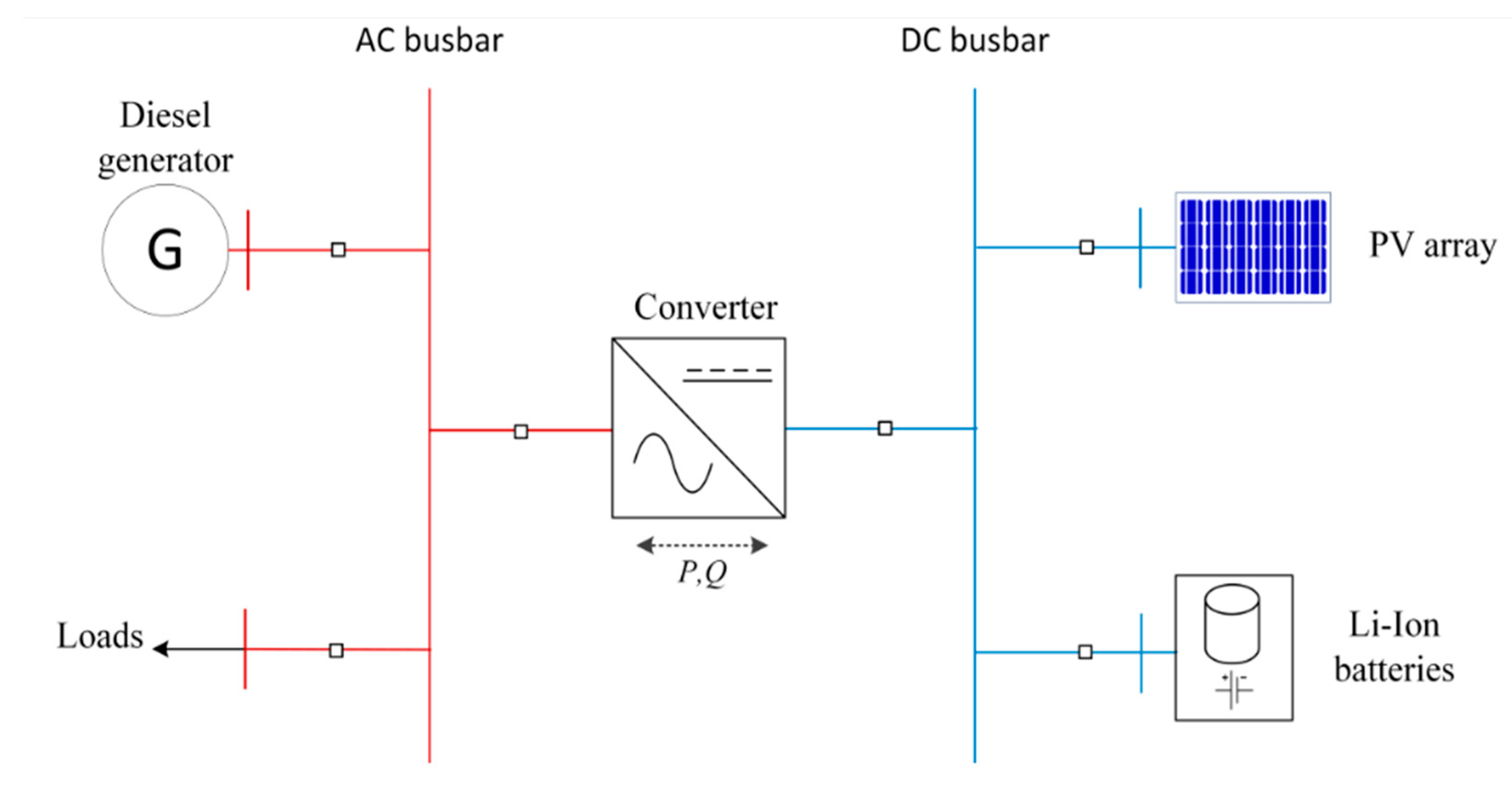

Photovoltaic (PV) panels, a battery energy storage system (BESS), and a diesel generator form the autonomous system under consideration, which is designed to handle extended periods of darkness, illustrated in

Figure 1.

2.2. Electrical Load Schedule and System Sizing Calculation

The site consists of industrial loads. Therefore, the site’s peak load will not differ considerably neither during summer and winter nor during weekends and weekdays. The detailed electrical load schedule of an existing facility is presented in

Table 1. Note that

Table 1 lists the current facility’s detailed electrical load schedule,

Table 2 lists the input data, and

Table 3 lists the sizing calculation of the diesel generator. However, a 50 kVA generator is selected considering the load of the facility as well as the charging load of BESS during an emergency condition. Moreover,

Table 4 lists the sizing calculation of BESS.

System sizing is modeled considering the industrial load as essential load. For reliability of power supply, all system components are designed with the torque load of the facility taken into account. Furthermore, the system is designed in such a way that during the sun hours, the PV plant will supply electricity to the load and the BESS, while during off sun hours, the BESS will supply electricity to the load, and a backup diesel generator will supply electricity to the load in an emergency.

2.3. Modeling of PV System

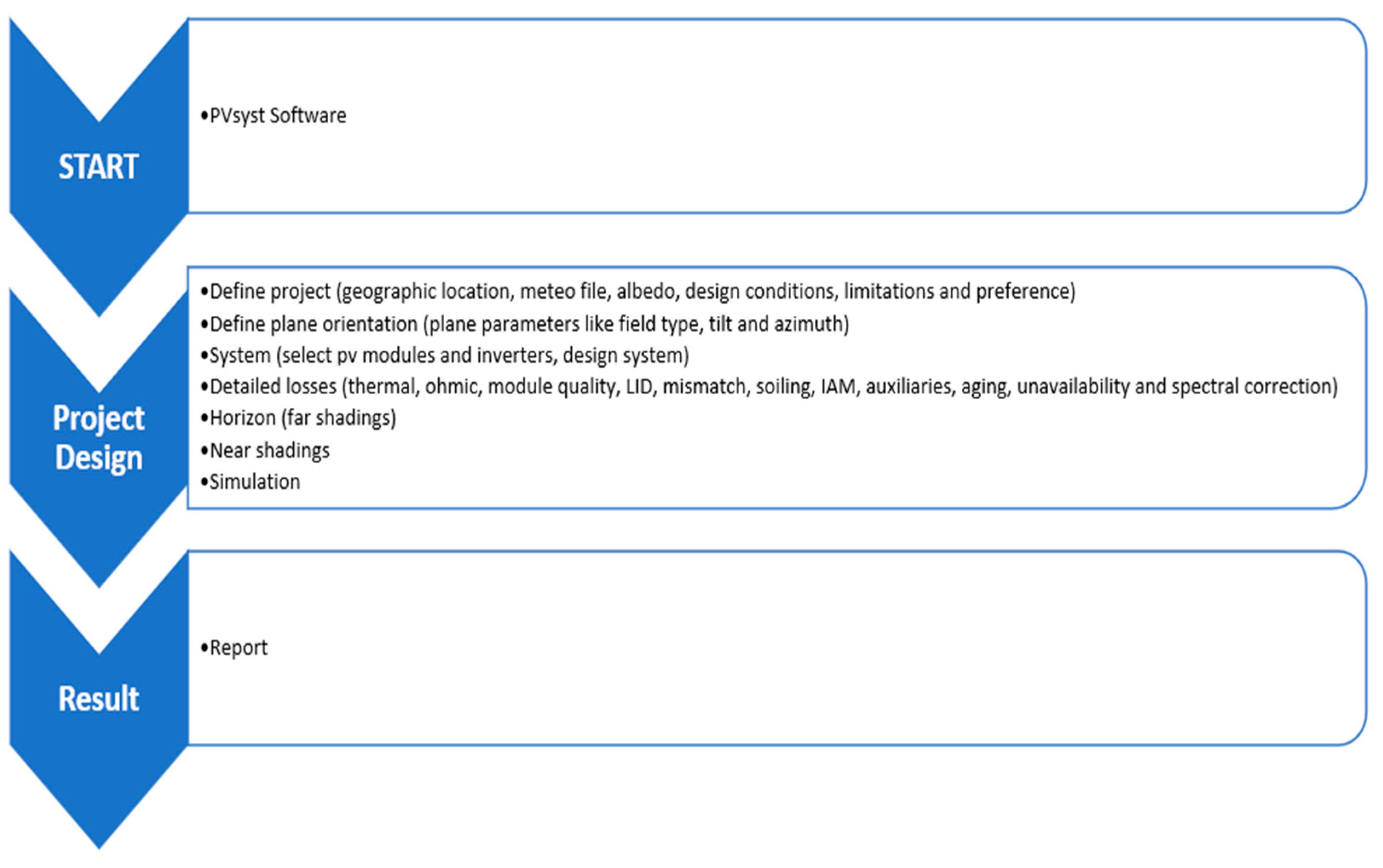

PVsyst version 7.3.1 software is used to model PV systems. PVsyst software is a powerful tool for solar energy system design, simulation, and performance analysis. It allows us to accurately assess the energy production potential of a photovoltaic system by considering factors such as location, shading, module characteristics, and system configuration. With PVsyst, one can optimize system sizing, evaluate different design scenarios, and estimate the financial viability of solar projects. It is a valuable software in the renewable energy industry.

Figure 2 illustrates the flowchart for PVsyst software.

Results are presented by PVsyst software as a comprehensive report with relevant graphs and tables. The information may be exported for use in other applications.

PVsyst software is a comprehensive tool used for designing PV arrays with three different methods: grid-connected, stand-alone, and pumping. In this research, the grid-connected method has been selected to design the PV arrays. There are a total of four PV arrays in this design. Three of these arrays consist of one string inverter per PV array and two strings of 13 PV modules per PV array, each module with a power output of 500 Wp. The remaining PV array consists of one string inverter and two strings of 12 PV modules, each with a power output of 500 Wp. These PV arrays are designed for a fixed tilted plane field type arrangement, ensuring optimal sunlight exposure and energy generation during winter.

2.3.1. Define Project

The geographical coordinates of the facility are 36.5144907 and 43.9887378, respectively. The facility is situated in a region of dry mountains. Hence, 0.2 is chosen as the albedo value. Based on data gathered from the site, the following design parameters were taken into consideration for the project: −1 °C for lower temperature for absolute voltage limit, 20 °C for winter operating temperature for VmppMax design, 45 °C for usual operating temperature under 1000 W/m

2, and 50 °C for summer operating temperature for VmppMax design.

Here, Average Sun is the average number of hours per day with bright sunshine, and Average Ins. is the average insolation of the location. The area unit is kWh/m

2.

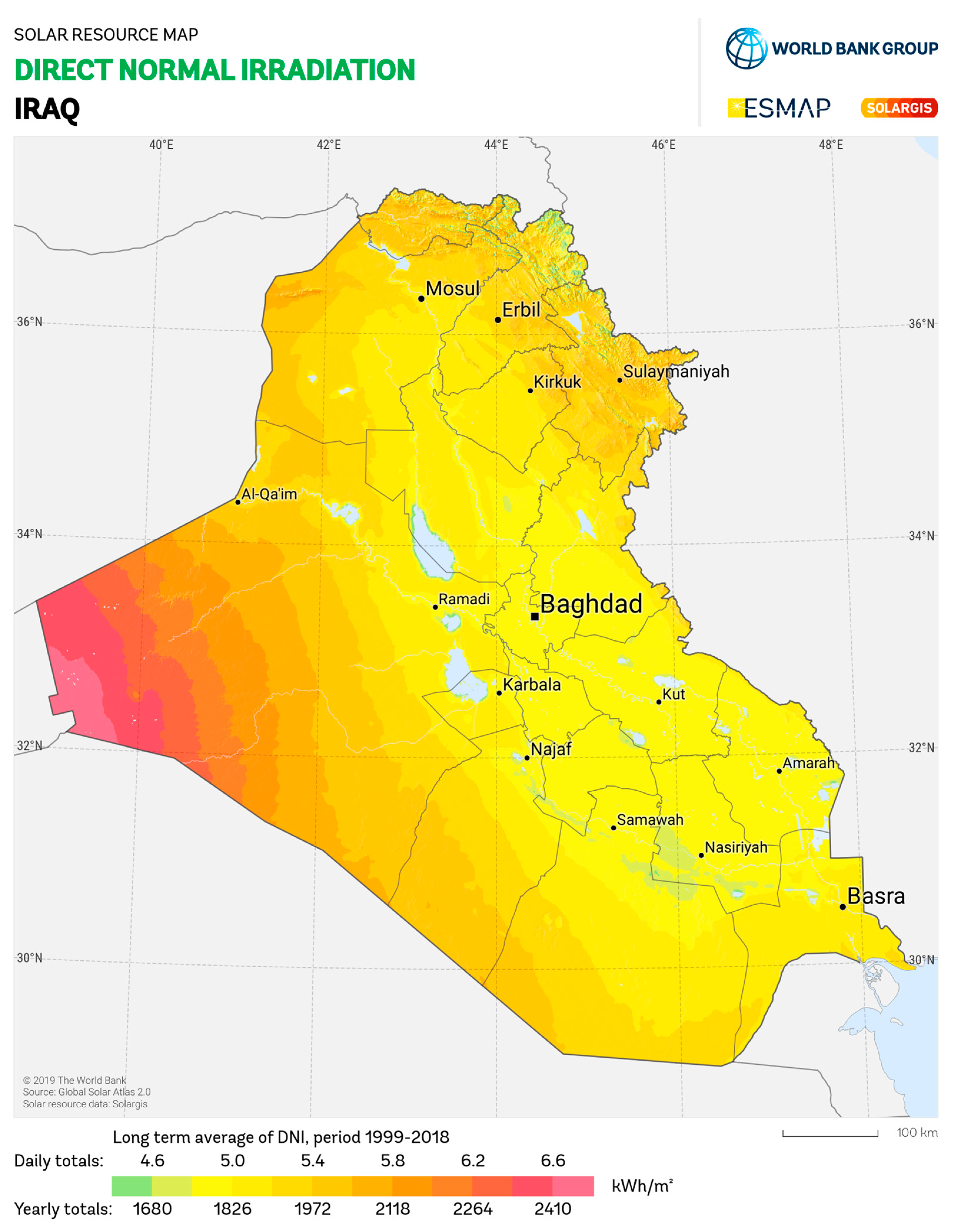

The solar radiation data were obtained from Meteonorm version 8.1 and the global solar radiation on horizontal surfaces in the project site, and it was observed that it varies from 234.3 kWh/m

2/month to 77.4 kWh/m

2/month during the complete year. The relatively low observed solar radiation from November to February is due to the prevailing high moisture content and heavy clouds during the rainy season in this area. The meteorological data of the site are given in

Table 5. Additionally, the SOLARGIS in

Figure 3 provides a location map of the solar resources.

2.3.2. Define Plane Orientation

A fixed tilted plane is considered in this study. The filed parameters are azimuth of 0° and tilt of 45° to obtain maximum yield in winter; global irradiance calculated at this angle is 928 kWh/m2.

2.3.3. PV Power Plant Design

In total, 102 TSM-DE18M(II) PV modules form the PV power plant, which has a total installed capacity of 51 kW. The specifications for PV module are represented in

Table 6. The 102 modules are assembled into four units, and each unit is connected to a three-phase SUN-12K-SG04LP3 inverter having a rated output power of 15.6 kW. The specifications for the inverter are represented in

Table 7. Each unit has two strings; three units have thirteen modules each, for a total of 26 modules per inverter, and one unit has twelve, for a total of 24 modules per inverter. The inverter’s maximum power tracking voltage range is 800 V, and the Voc computed per string is 715.79 V for three units and 660.73 V for one unit. The combined Isc for each string is 12.28 A, which is less than the inverter’s maximum PV short-circuit current range of 17 A.

2.3.4. Detailed Losses

In this design, thermal parameter is selected for modules with air circulation, ohmic losses for 2 × 16 m of 2× single-core 6 mm2 DC cable per string and 10 m of four-core 10 mm2, module quality is selected from specifications, LID loss factor as 2%, module mismatch losses as 2%, string voltage mismatch as 0.1%, and soiling losses as 3%.

2.3.5. Shading Analysis

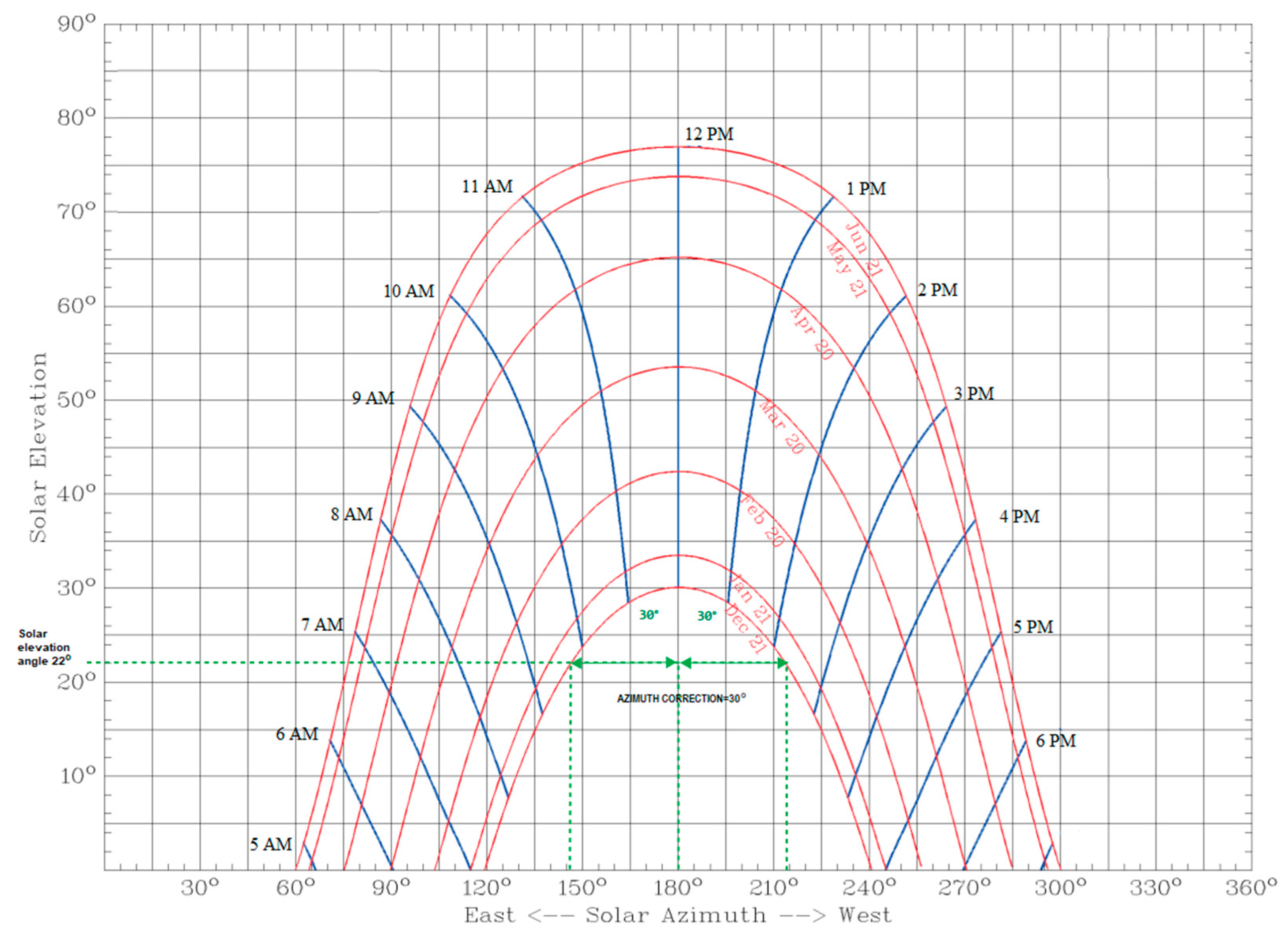

The effect of far shading is neglected because no adjacent object is casting a shadow on the modules. For the geographic location, the height of the sun’s elevation above the sky is essential, as it is understood that the lowest is on the winter solstice, i.e., in December.

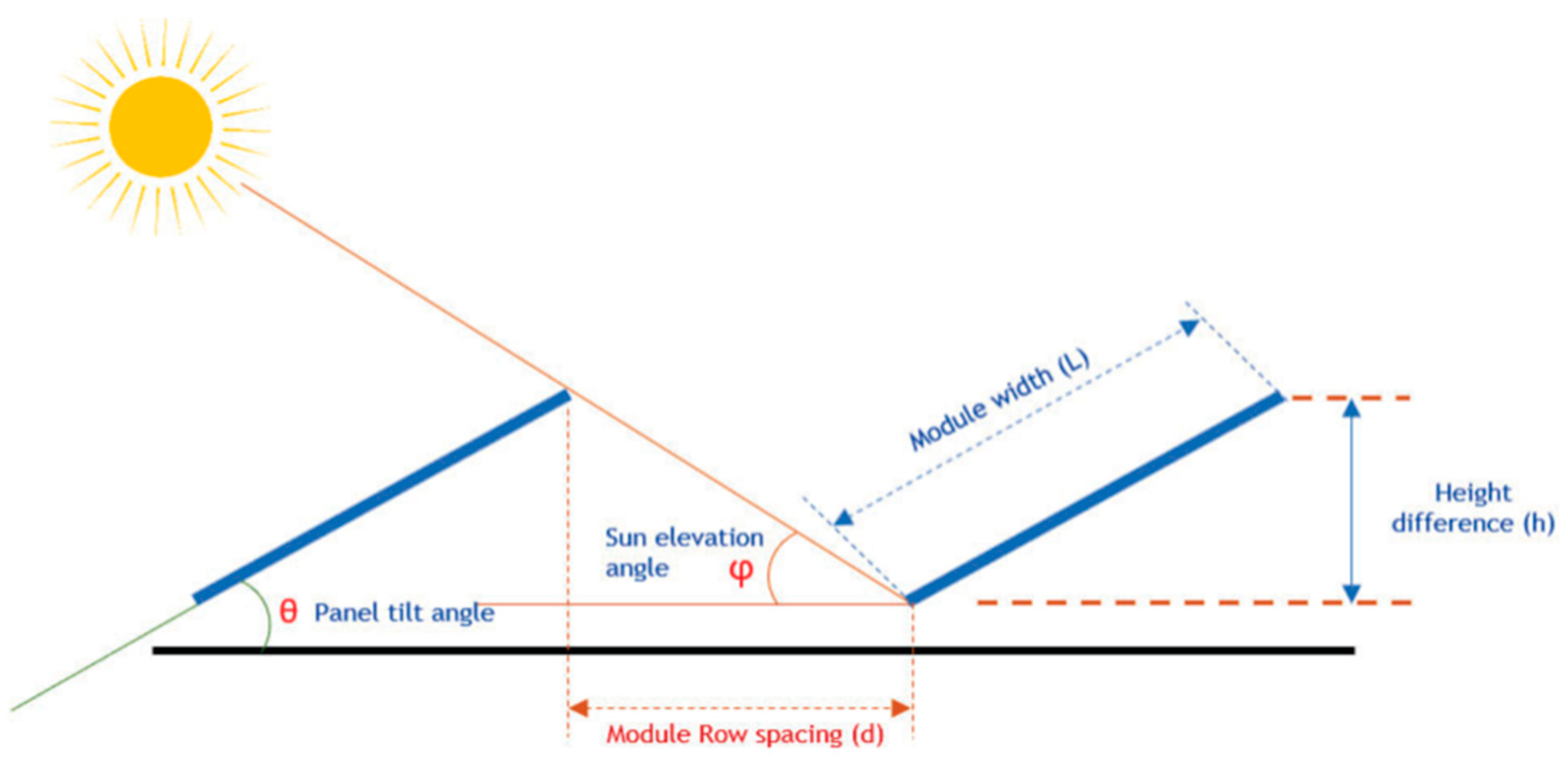

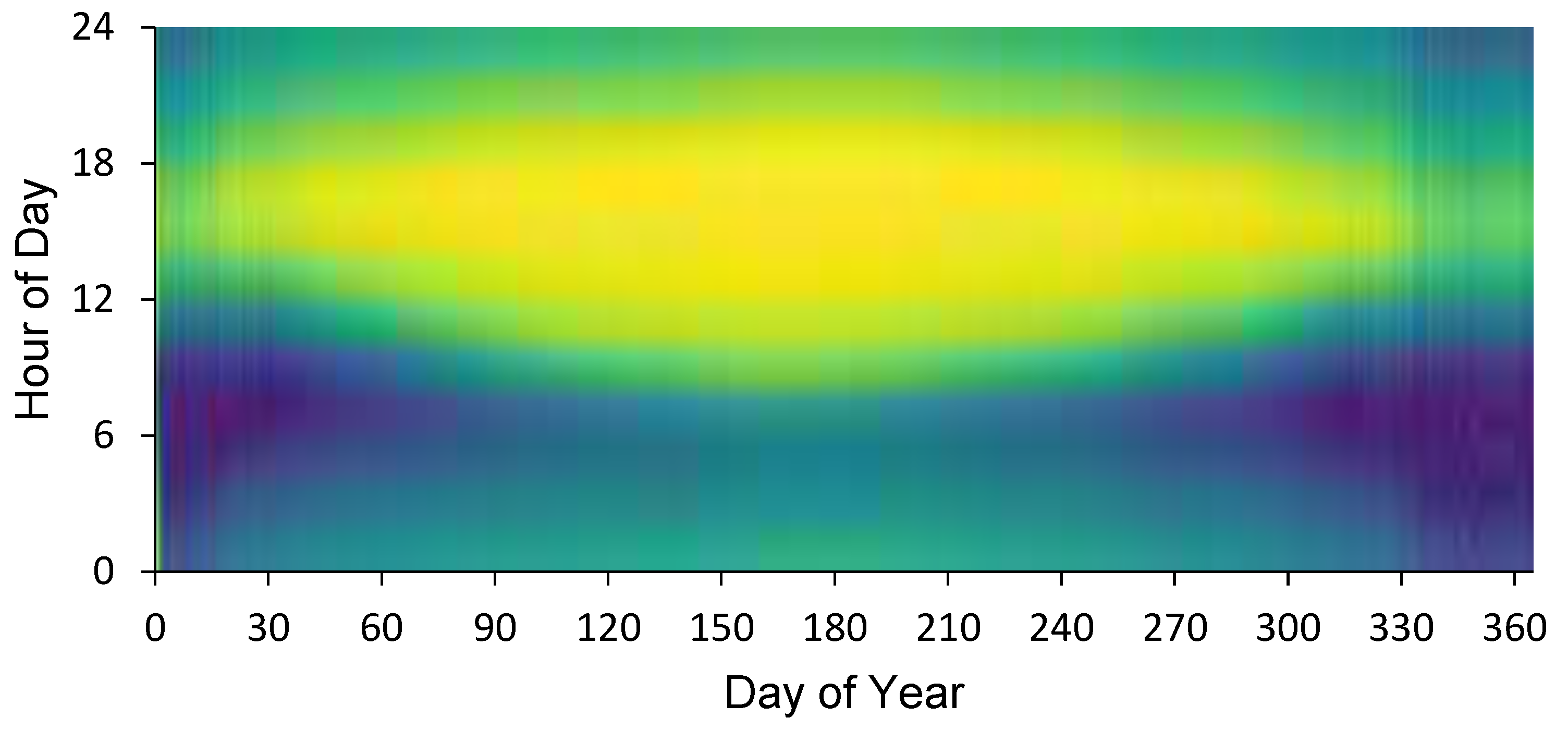

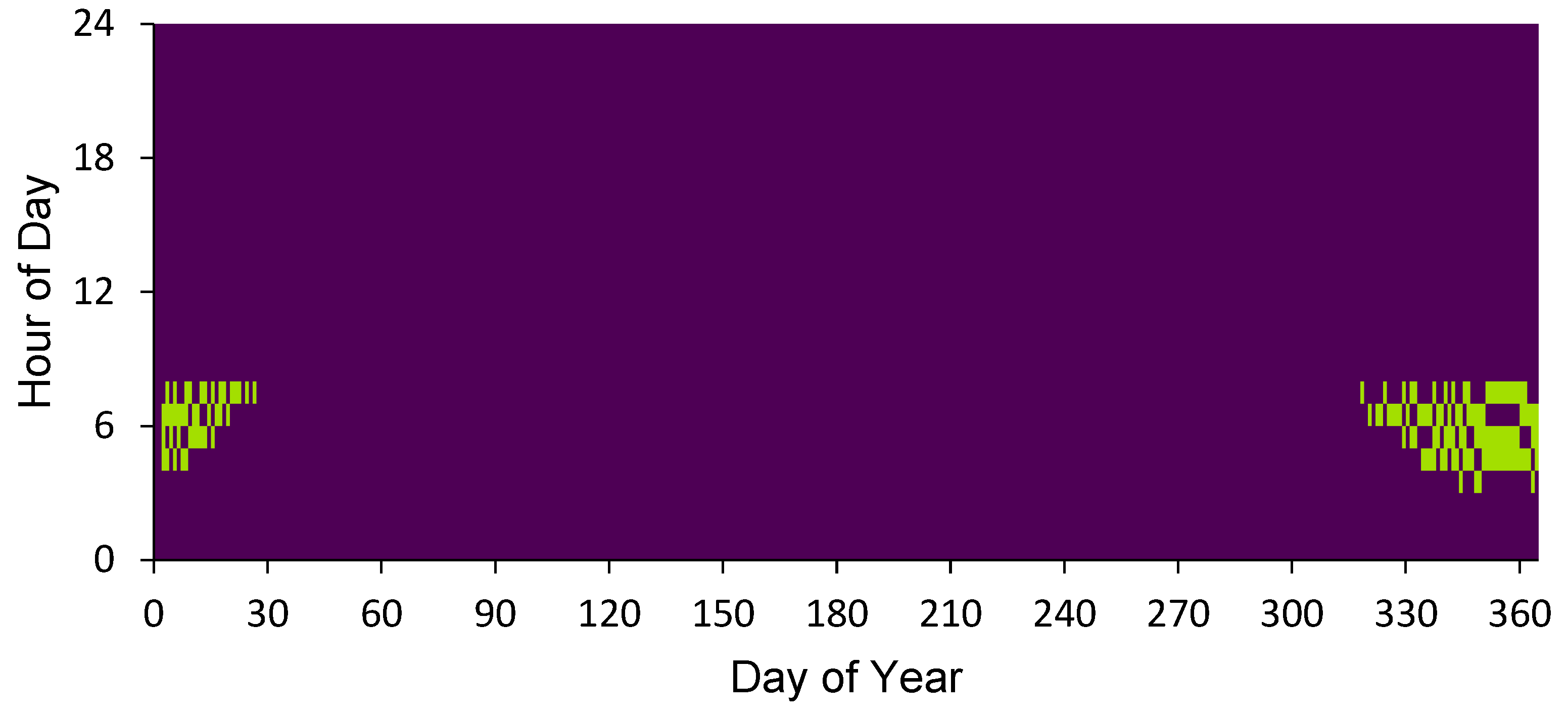

Figure 4 represents the solar elevation angle corresponding to the field coordinates. Depending on the geographic location—the hemisphere, zone, and the exact location expressed in degrees—the sun’s height can be calculated as shown in

Figure 5.

Here, θ is tilt angle (°) and L is module width (m). The selected solar panel width is 2.176 m. There are two panels in a module width; hence, the module width is 2 × 2.176 = 4.352 m.

Here, h is the height difference (m) and φ is the sun elevation angle (°) from the plot, the sun elevation angle for December 21st, and the picked-up time frame for 10 a.m. to 2 p.m. is 24°.

Further, the azimuth angle correction shall be considered to calculate the minimum row spacing (d). For this location, the calculated azimuth angle for December 21 is 30°.

Here, d is the minimum module shading length and α is the azimuth correction angle (reference from the sun elevation angle plot,

Figure 4). Results of shading calculations are shown in

Table 8. Moreover,

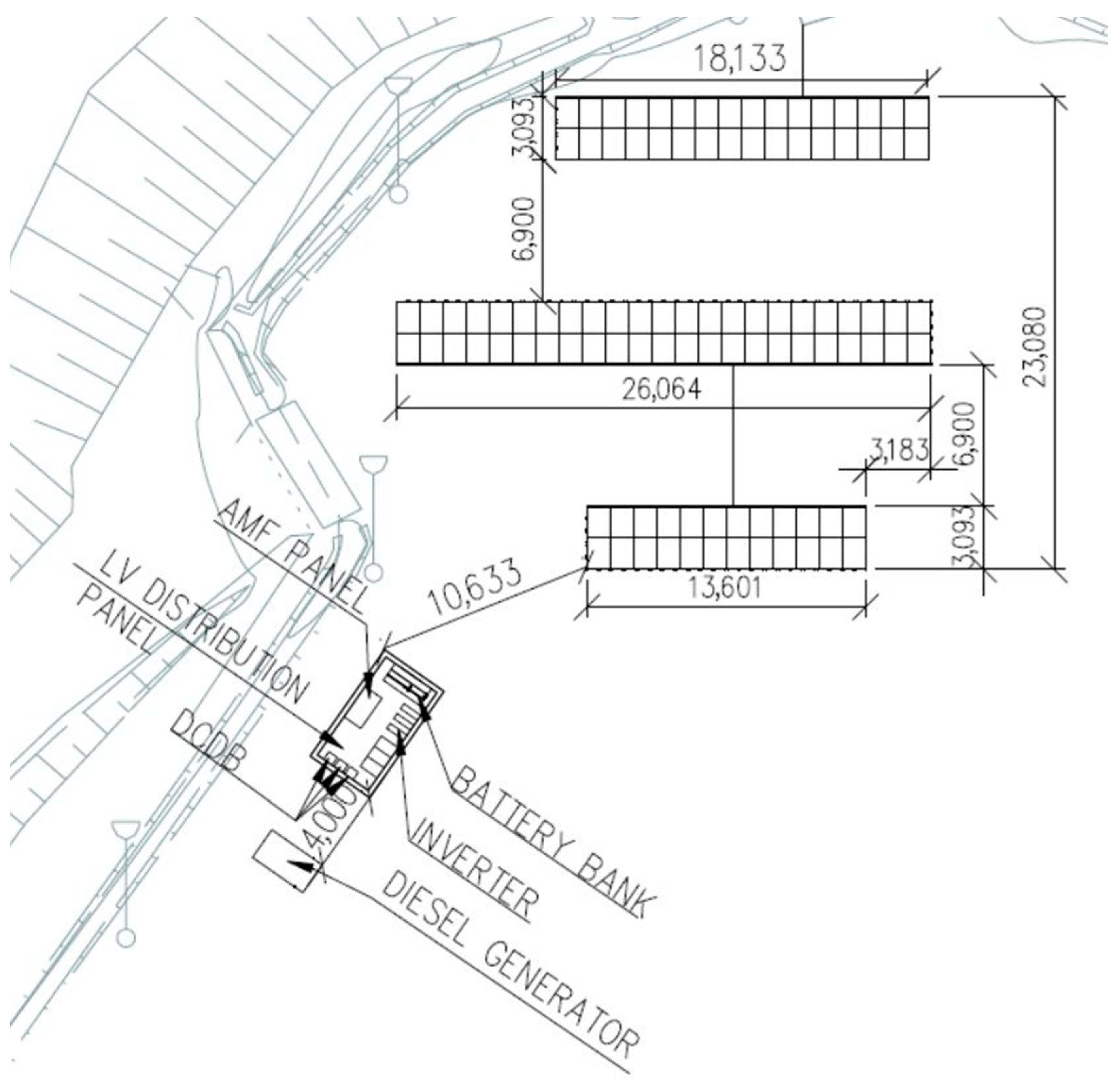

Figure 6 shows the architectural layout for the PV power plant at the site.

2.4. Designing the Hybrid Stand-Alone Microgrid

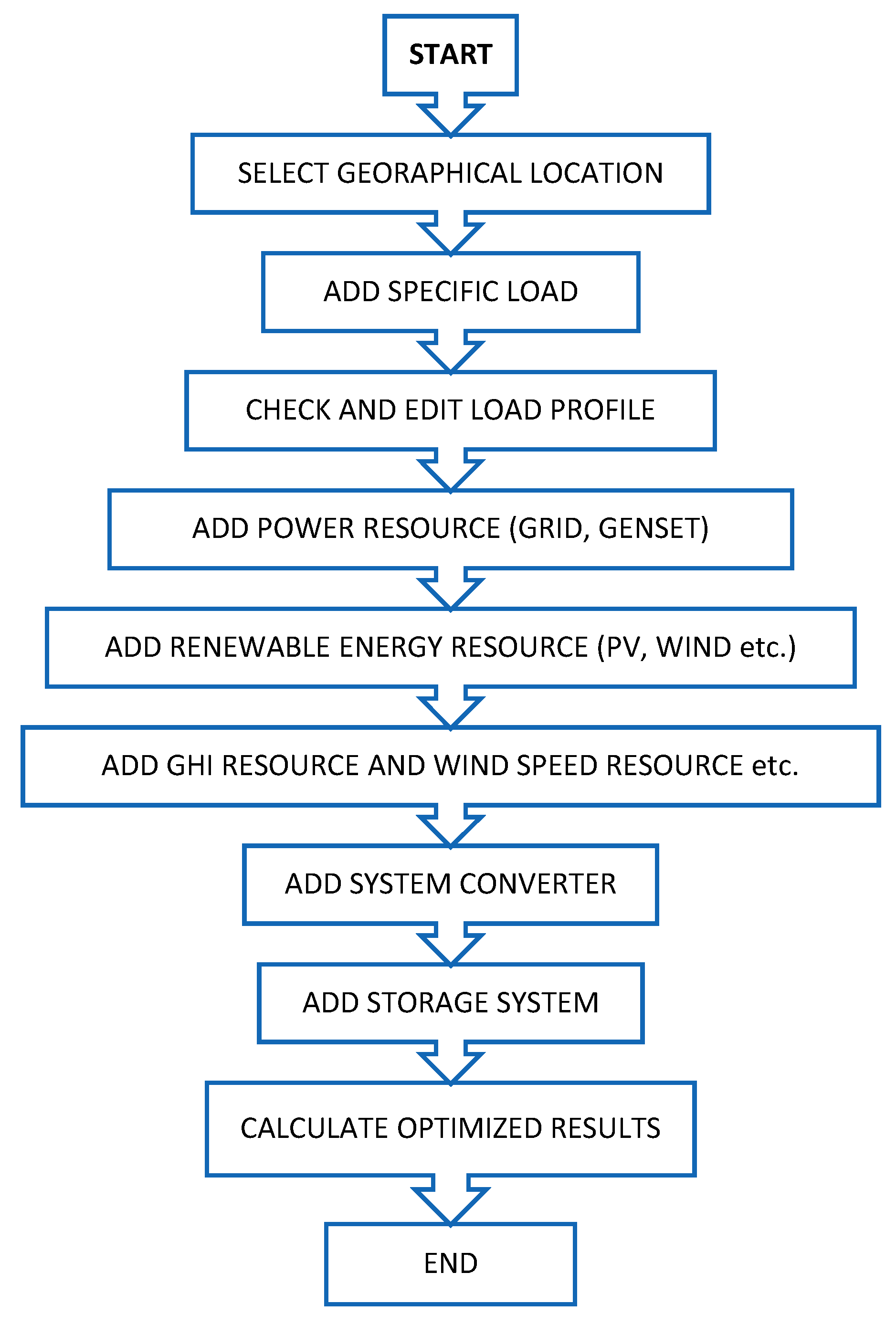

The HOMER Pro version 3.14.2 software has many advantages and is utilized for the hybrid stand-alone microgrid model’s planning, design, and optimization. These advantages include its capacity to accommodate various renewable energy resources and several other elements needed for the reliable hybrid stand-alone microgrid model. The software is quite competent in determining the model’s economic and technological viability. The flowchart for designing the hybrid stand-alone microgrid using HOMER Pro software is shown in

Figure 7. The HOMER Pro software imports the PV plant’s CSV file from the PVsyst software for better results.

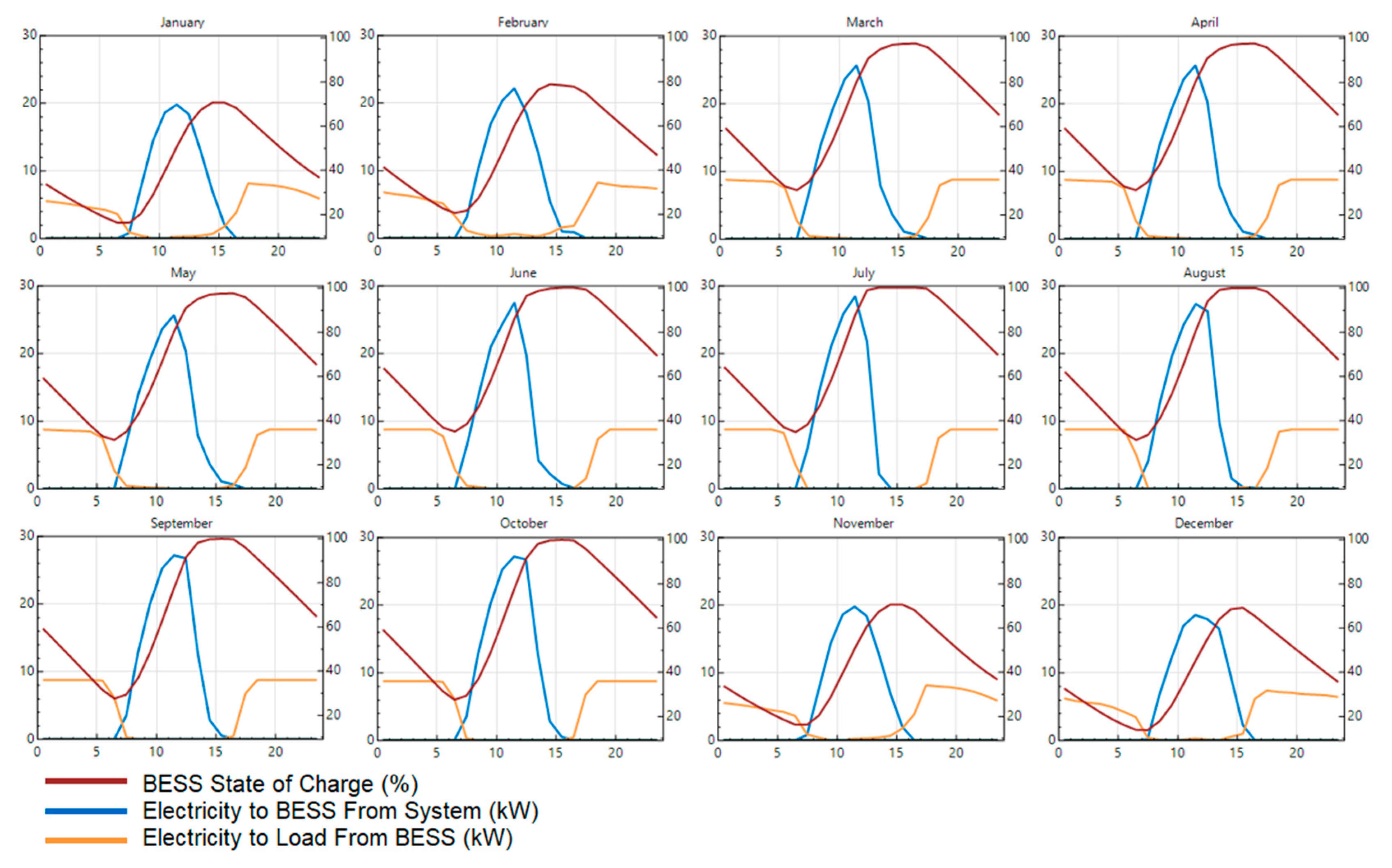

Moreover,

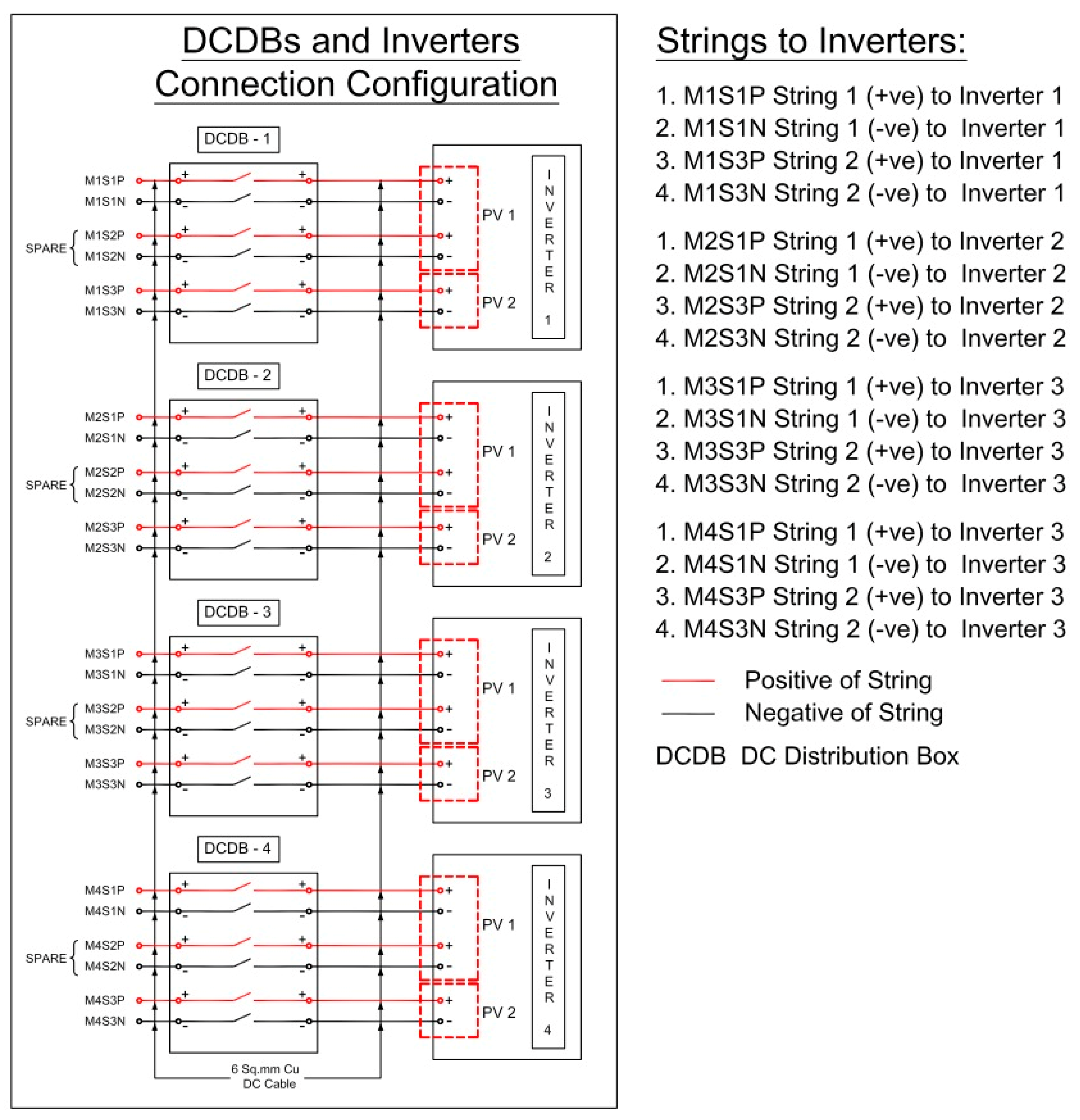

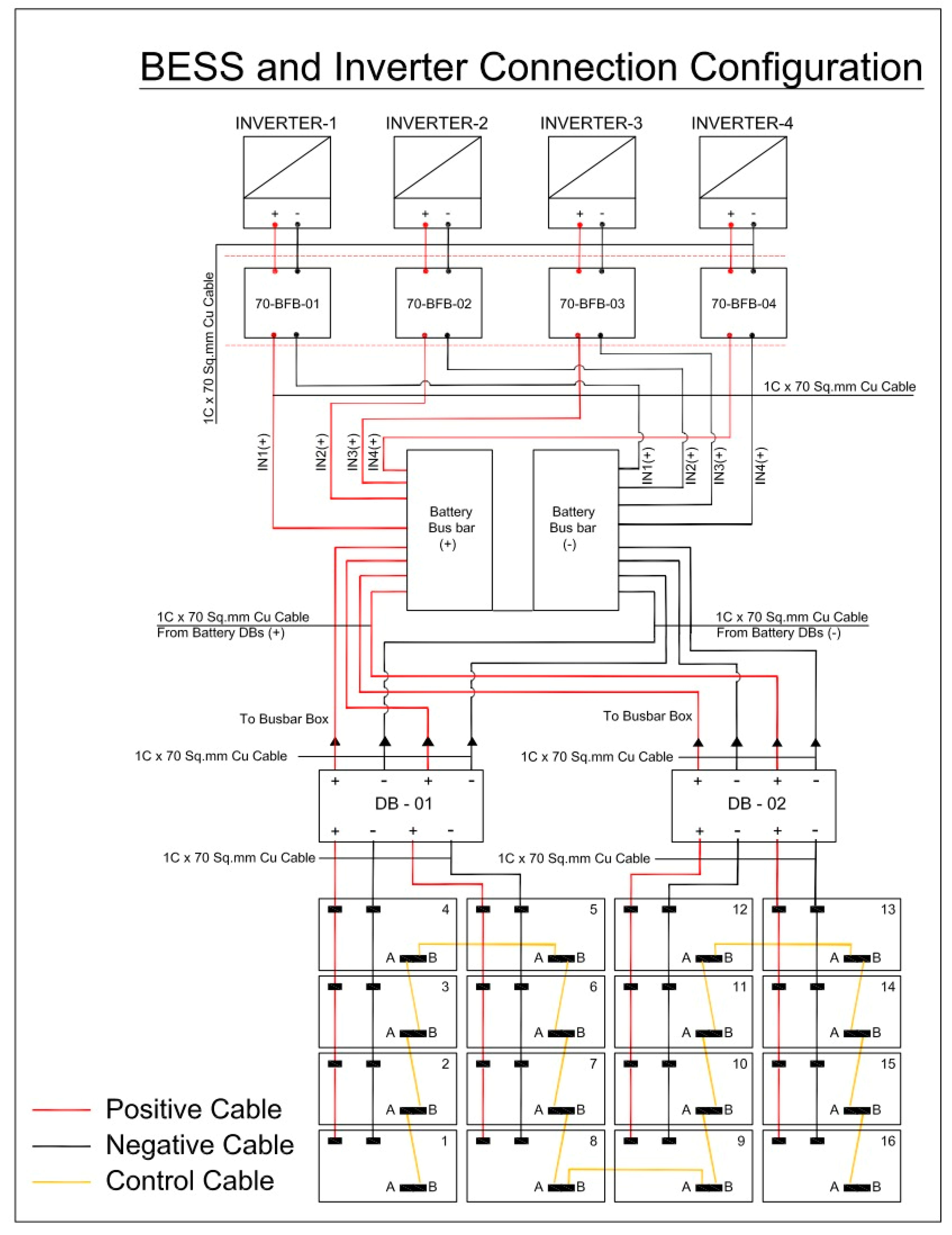

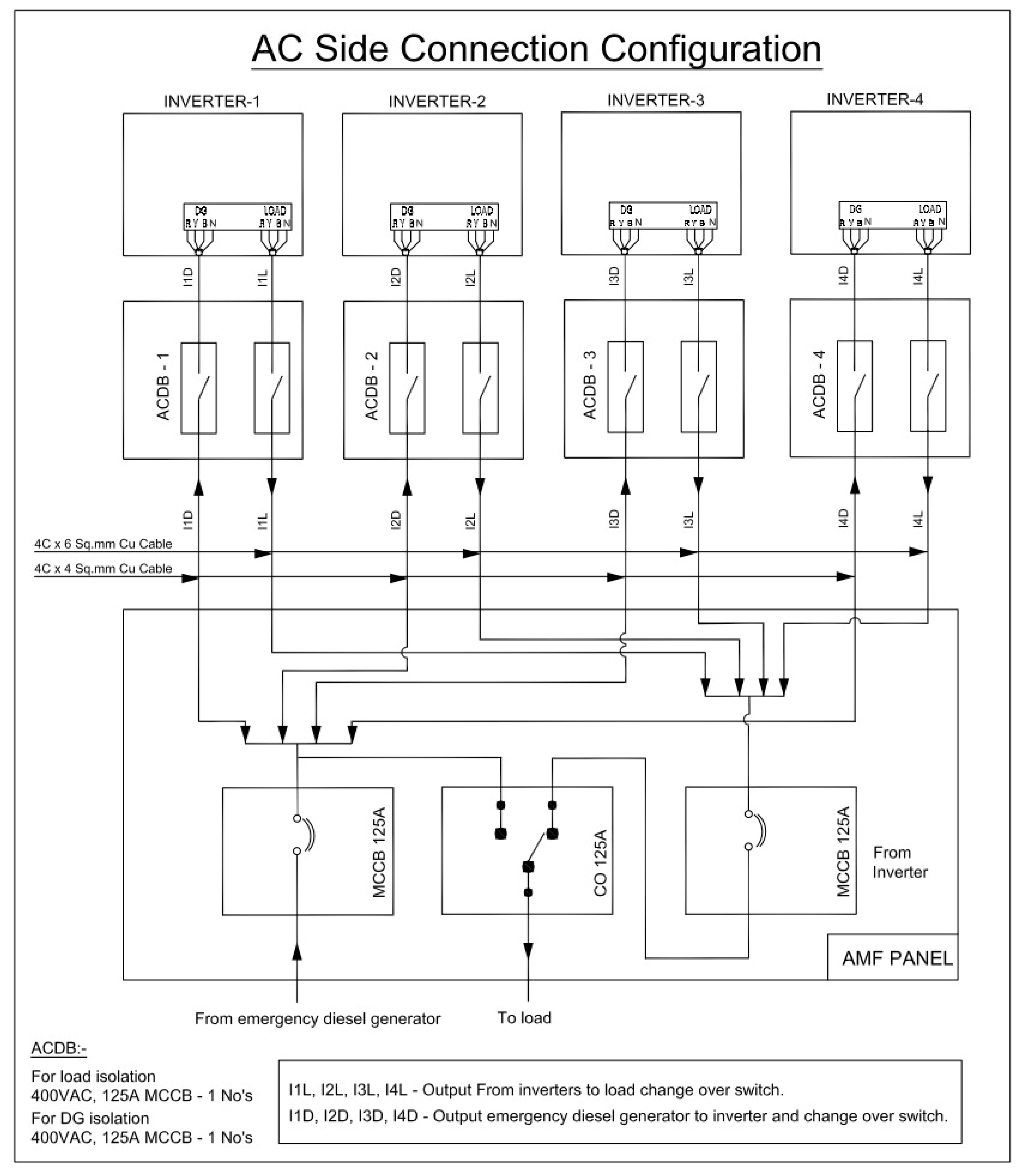

Figure 8,

Figure 9 and

Figure 10 shows schematics of the connection diagram for several hybrid stand-alone microgrid components, including the configurations for the DC distribution box, inverter, AC distribution box, BESS, load, and EDG of the proposed hybrid stand-alone microgrid network.

Figure 8 represents the schematics of DCDBs and inverters’ connection configuration,

Figure 9 represents the schematics of BESS and inverters’ connection configuration, and

Figure 10 represents the schematics of AC side connection configuration.

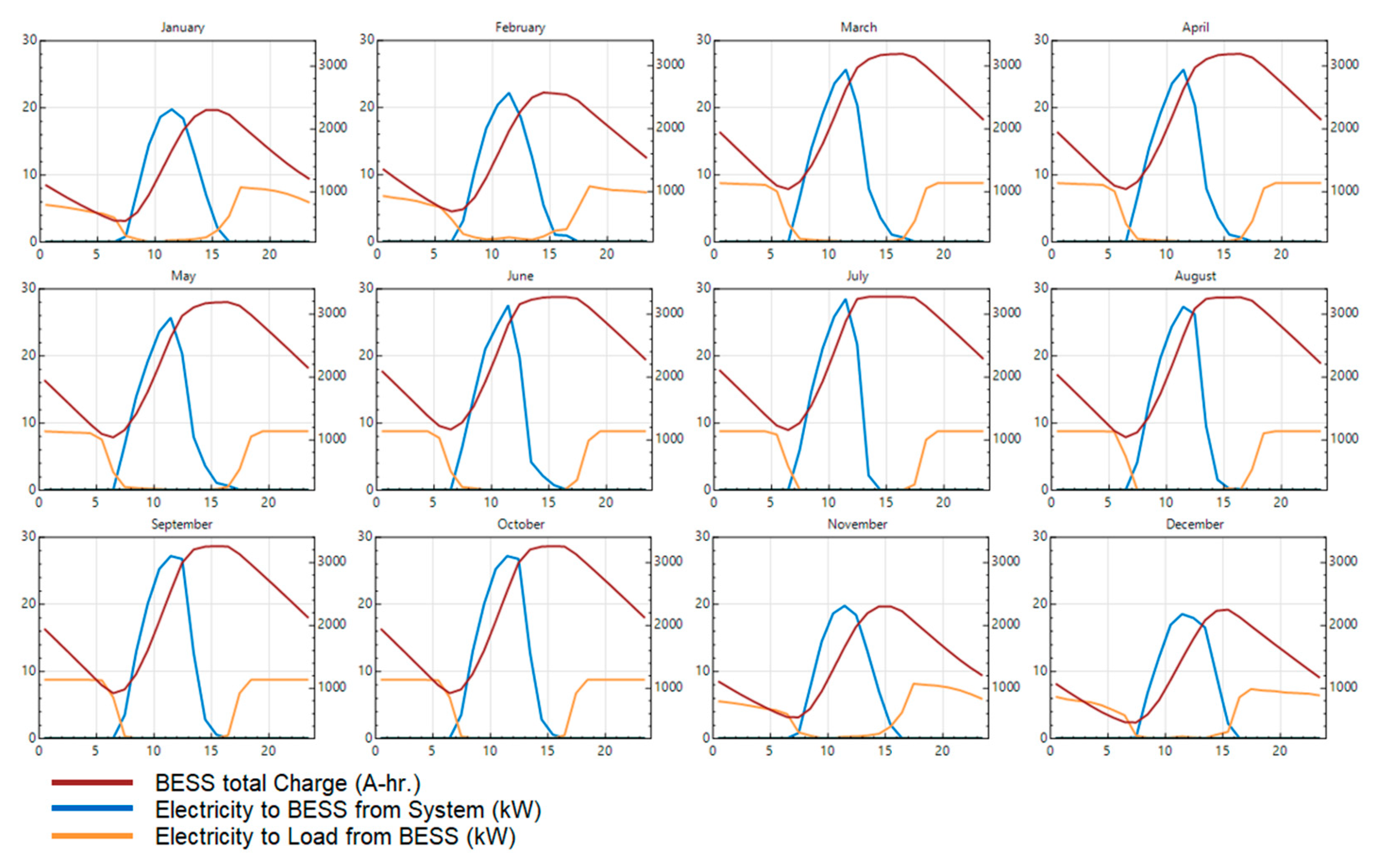

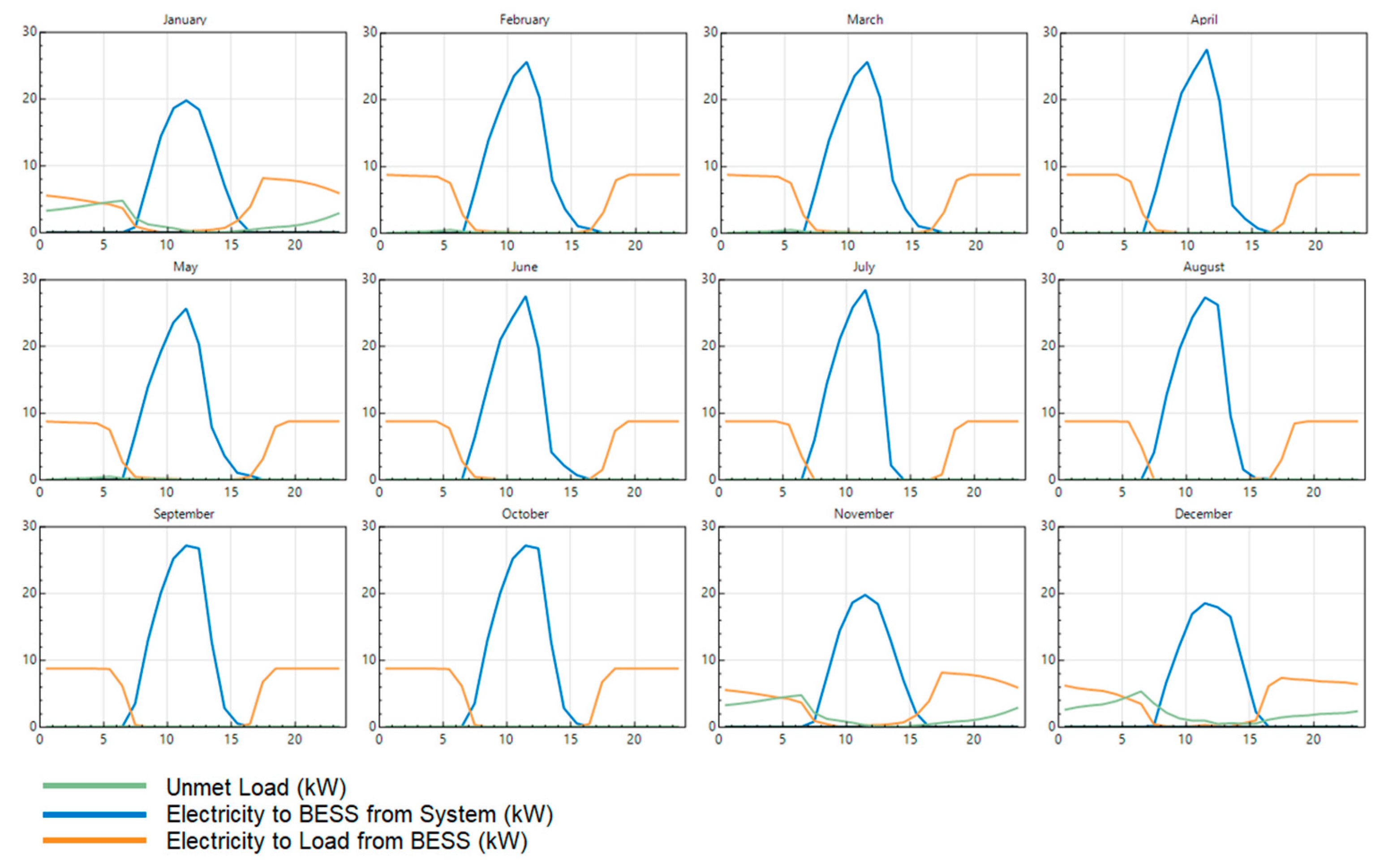

2.5. Performance Analysis of Hybrid Stand-Alone Microgrid

SAM (System Advisor Model) version 2020.11.21 software is used to analyze proposed hybrid stand-alone microgrid’s performance. SAM software offers detailed insights into the energy production, consumption, and storage within the microgrid system. SAM is used to assess the proposed hybrid stand-alone microgrid system’s overall effectiveness, viability, and reliability. For the performance analysis of the microgrid in this study, SAM (System Advisor Model) software is used.

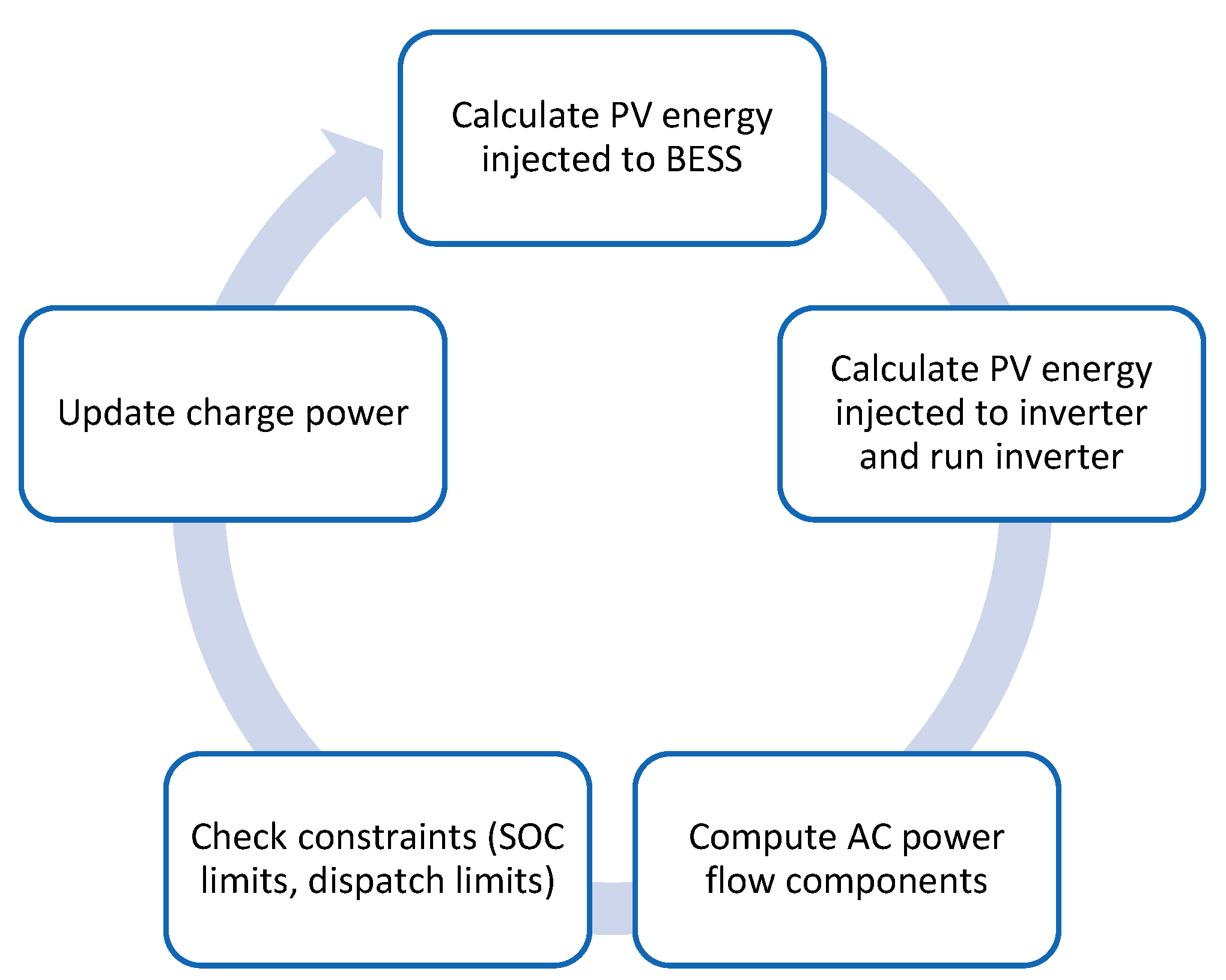

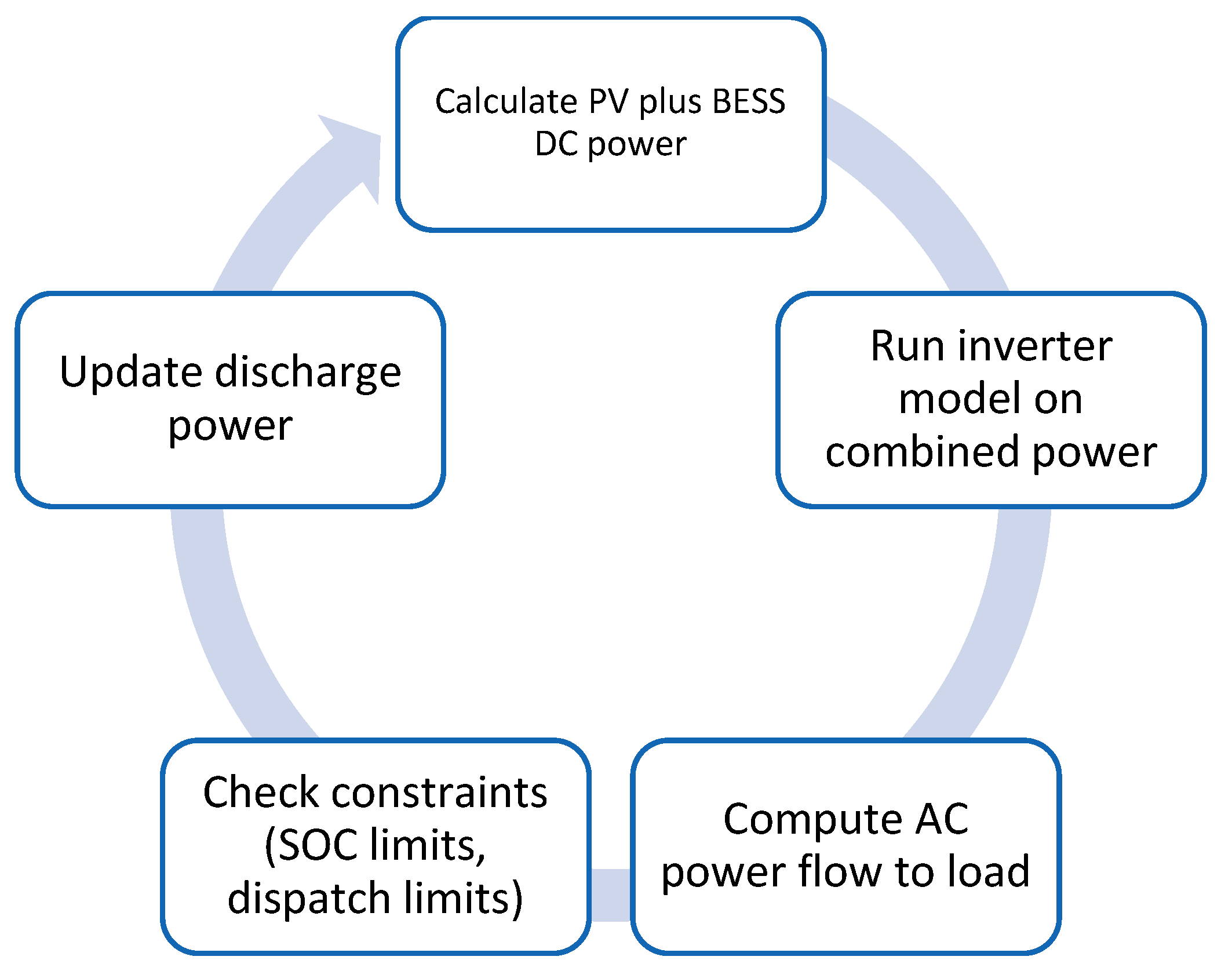

Figure 11 depicts a flowchart for BESS charging, and

Figure 12 depicts a flowchart for BESS charging using SAM software.

4. Conclusions

This research article comprehensively analyzes a hybrid stand-alone microgrid system comprising PV modules, inverters, a battery storage system, a generator, and an AC load. Integrating PVsyst, HOMER Pro, and SAM software tools allowed for a thorough design, optimization, and performance evaluation of the hybrid stand-alone microgrid. The findings reveal increasing ground clearance results in uniform backside irradiance, which amplifies bifacial power gain to an optimal level, and increasing ground albedo also results in bifacial power gain. For monofacial power generation there was a promising normalized production of 4.53 kWh/kWp/day with a performance ratio of 0.815 and annual energy production estimates of 84.31 MWh (P50), 79.57 MWh (P90), and 78.24 MWh (P95). Notably, this study highlights the operational challenges faced during the winter months, necessitating generator support for load fulfillment. Moreover, the hybrid stand-alone microgrid is shown to be environmentally beneficial, saving approximately 1811.6 tons of CO2 emissions over a 30-year period, emphasizing its positive impact on sustainability and clean energy initiatives. Furthermore, the successful installation and validation of the hybrid stand-alone microgrid through experimental testing underscore its practical applicability. This research contributes valuable insights to the field of hybrid stand-alone microgrid design and underscores the importance of hybrid energy solutions to ensure a reliable power supply under varying conditions while simultaneously mitigating greenhouse gas emissions. This research will assist researchers/engineers/designers in optimizing, modeling, performance evaluating, designing, and implementing microgrid components while taking into account various parameters.