Abstract

Increased effectiveness of methane drainage from sealed post-mining goaves in hard coal mines contributes to reduced methane emission from goaves into the mine ventilation system. This paper focuses on issues concerning the assessment of the additional amount of methane released from the goaf into mine workings during periods of atmospheric pressure drops, which can be captured with a methane drainage system. Thanks to the solutions presented in the paper, it is possible to control the efficiency of the goaf drainage system, which in turn leads to the reduction of methane emission from the mine ventilation air into Earth’s atmosphere. These solutions are of great added value for both the environment and coal mines as they reduce the costs arising from greenhouse gas emissions that are incurred by mining companies, increasing the efficiency of methane capture and its use in gas engines or district heating systems. The paper uses relationships relating to the influence of atmospheric pressure changes on the process of gas release from the goaf according to the hysteresis loop of methane release during atmospheric pressure changes, which was developed based on conducted research. The analysis and conclusions presented in this paper may facilitate the development of strategies aimed at reducing methane emissions from a mine’s ventilated air into Earth’s atmosphere.

Keywords:

greenhouse gas; methane; hysteresis loop; longwall; coal; goaf; pressure; mine; seam; environment 1. Introduction

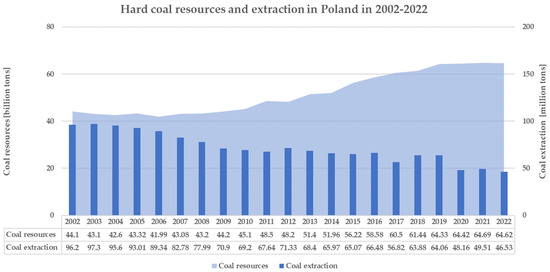

The efficient utilization of recoverable methane resources emitted into sealed post-mining goaves is of great importance to mining companies pursuing strategies to capture methane by means of various methane drainage systems [1,2,3,4]. The impact of atmospheric pressure changes on methane emission in operating and decommissioned mines, as well as other places of its possible occurrence, e.g., landfills, is becoming an increasingly relevant area of concern [5,6,7,8,9,10,11,12,13]. In ventilated mine workings, the inflow of methane into the mine’s air from sealed goaves significantly affects the safety of miners. To ensure worker safety, technological processes in which the release of methane into mine air is recorded are analyzed, and a ventilation and methane balance is carried out [14,15,16,17,18,19,20,21,22,23,24]. It should be mentioned that changes in atmospheric pressure and their impact on the content of methane and other gases in mine air are controlled by monitoring systems and analyzed by the supervisory services of mine ventilation departments. Methane is captured with mine drainage systems and then used to produce combined heat and power through use in gas engines or as a fuel for heat production in district heating systems [2,3,25,26,27]. Ensuring the best possible efficiency of the above-mentioned methane utilization systems depends on the effectiveness of methane drainage systems. The volume of methane captured with this system and then utilized is inextricably linked with reductions in its emission into the atmosphere. This is a particularly important task for the Polish hard coal mining sector. Poland is the main hard coal producer in the European Union (approx. 96%), although the current level of extraction is far from the level of 1990 (151.3 million tons), and in 2022 it amounted to 43.53 million tons (Figure 1) [28].

Figure 1.

Graphic presentation of coal balance resources and coal production from 2002 to 2022 in Poland [28].

Considering the coal balance resources and further exploitation, the economical use of methane to produce combined energy (electricity and heat) should be developed to the greatest possible extent and is regarded as a goal of the coal mine strategy aimed at the maximum reduction of methane emission to the atmosphere. To achieve this, solutions must be sought to increase the effectiveness of methane drainage systems in operating areas and sealed post-mining goaves.

The volume of methane released into longwall goaves and sealed post-mining goaves in hard coal mines constitutes the main source of its subsequent emission. The release of methane into sealed post-mining goaves after the completion of exploitation in methane seams is a result of the degassing of distressed underworked and overworked seams, which are within the stress-relief range of an operated longwall.

The volume of coal, its methane-bearing capacity, and the time that has elapsed since the completion of longwall extraction from the coal seam determines the volume of the methane flow into the sealed goaf space. Sealed post-mining goaves located in the vicinity of distressed unextracted under- and overworked seams with a primary methane-bearing capacity of more than 2.5 m3 CH4/Mgcsw contribute to methane inflow over approximately 15 years after the completion of longwall extraction [21,29]. Forecast volumes of methane released into goaves are correlated with the absolute total volume of methane during longwall extraction and the time that has elapsed after sealing the area after the longwall extraction was completed. Sealed post-mining goaves can be described as those connected to the mine ventilation system or those cut off from it. Goaves that are connected to the ventilation system are also connected to the stress-relief zones of the currently operating longwall, while goaves that are cut off have no ventilation dependence on the longwall currently in operation.

2. Materials and Methods

Studies aimed at estimating the value of methane inflow to sealed post-mining goaves after the completion of longwall extraction carried out between 1998 and 2000 allowed for the development of a simplified model of methane release into sealed goaves [29]. The model of methane release into sealed goaves is determined using Equation (1).

where:

- —is the average absolute methane emission throughout the life of a longwall during the mining operation period in m3 CH4/min,

- U—is the number of years after mining operations ceased.

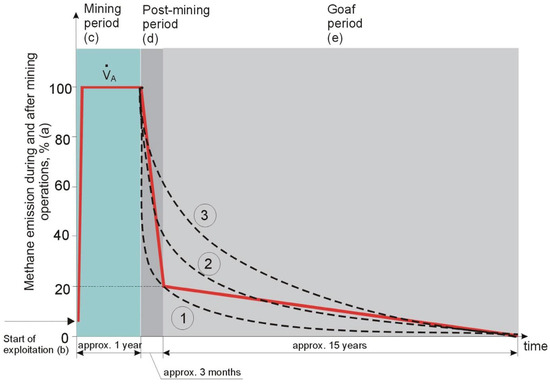

A graphical illustration of the release of methane into the longwall environment during its exploitation and then into the goaf after its completion over the next 15 years is presented in Figure 2. The red line represents the model, and Curves 1, 2, and 3 reflect the methane quantities emitted into the goaves of mined seams, depending on the different contributions of undermined as well as overmined seams.

Figure 2.

Release of methane into the longwall environment during its exploitation, and then into the goaf after its completion over the next 15 years [10].

Using Equation (1), it is possible to assess the volume of methane released into the sealed post-mining goaf in subsequent years after the completion of longwall extraction.

Draining methane from the goaves that are both connected to and cut off from the longwalls in operation reduces their volumetric methane potential. In the case of post-mining goaves that are connected to the environment of the longwalls under operation, their drainage often reduces the value of methane released into the workings of the longwall being extracted.

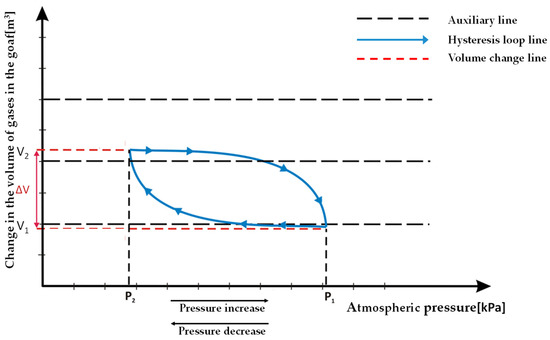

Draining methane from the post-mining goaves that are cut off from the longwalls in operation increases the total volume of methane captured from mine goaves, at the same time reducing the methane emission from the environment of sealed goaves into ventilated mine workings. The volume of methane flow released from the sealed post-mining goaf is influenced by atmospheric pressure changes [5,6,7]. Hysteresis is the phenomenon of the dependence of the current state of a system on states in preceding moments. In this paper, the phenomenon of hysteresis relates to the change in the composition of gas in mine workings as a result of changes in atmospheric pressure—the existence of a pressure difference is a direct factor influencing the flow rates and quantities of gas flowing out of the goaf into the mine air. On a graph of two dependent quantities, the phenomenon of hysteresis is usually shown as a hysteresis loop. Figure 3 uses a hysteresis loop to illustrate the change in the volume of gases in goaves, including methane released from post-mining goaves into the workings during atmospheric pressure changes.

Figure 3.

Hysteresis loop of the change in the volume of mine gases in the goaf with changes in atmospheric pressure.

A decrease in atmospheric pressure from P1 to P2 results in an increase in the volume of goaf gases from V1 to V2. The increase in the goaf gas pressure triggers the process of migration of goaf gases together with methane into ventilated mine workings. During the period of increasing atmospheric pressure, the reverse process occurs, in which air migrates from ventilated mine workings into the goaves. The volume of methane additionally released from the goaf will be significantly influenced by the course and duration of the decreasing atmospheric pressure period.

The impact of atmospheric pressure changes on the additional volume of methane flow that can be captured with the methane drainage system during an atmospheric pressure drop is important in the way it affects the reduction of methane migration into the mine ventilation system. When longwalls are operated in seams of high methane concentration, the percentage of methane released into the goaf is between 60 and 80% of the total amount of methane released into the longwall environment.

The level of methane released from the goaf into ventilated workings of the longwall environment causes a change in the methane concentration in the air in the longwall ventilation path and in the paths of air discharge from the longwall.

When the atmospheric pressure changes, i.e., from a higher-pressure value to a lower one, the increase in the volume of gases in the longwall goaf results in its migration to the lower-pressure areas in ventilated workings of the longwall area. This change in atmospheric pressure periodically contributes to:

- increased migration of methane from the goaf into ventilated mine workings, resulting in an increase in methane concentration in the ventilation air,

- increased efficiency of the longwall goaf methane drainage system,

- increased release of methane from goaves that are connected to and cut off from the environment of currently operated longwalls as well as to mine workings located in the vicinity of sealed post-mining goaves of previously extracted longwalls.

Methane concentration in the goaf atmosphere depends on the following factors:

- the volume of methane flowing into the goaf as a result of degassing of distressed over- and underworked currently exploited or abandoned seams,

- the tightness of the sealing of post-mining goaves isolated from ventilated mine workings,

- the longwall ventilation method and its location in the ventilation subsystem,

- the development of the field of aerodynamic potentials in the junctions of the ventilation system surrounding the goaf.

The above-mentioned factors have an impact on both the distribution of methane concentration in post-mining goaves and methane volumetric flows coming from goaves to adjacent ventilated workings. Frequent changes in the values of methane concentration recorded by the sensors of automatic methanometry are regarded as confirmation of upcoming atmospheric pressure changes.

The coefficient of irregularity of methane release into currently excavated longwalls is 1.55 [21,29]. It means that due to technological operations in the longwall and decreasing atmospheric pressure, the volume of methane released into the longwall area may increase by 55% compared to the total methane average value. When operating longwalls with a high concentration of extraction, ventilated by the “U” method along a coal face, the coefficient of irregularity of methane release is often higher than 1.55, which is the value adopted at the stage of designing the longwall. This is mainly caused by significant atmospheric pressure drops. The volume of goaf gas with methane released during changes in atmospheric pressure can be estimated based on Clapeyron’s equation describing the ideal gas law. Clapeyron’s equation is applicable to the ideal gas; however, it can be used for real gases that exhibit small deviations.

For the fixed quantity of gas, all the parameters describing its state (volume, pressure, and temperature) can be related by the following equation.

Regardless of the atmospheric pressure changes occurring over a period of time (working shift, day, or longer), the volume of the goaf should be considered to be a constant value. The volume of free space in the goaf of a longwall being extracted is assumed to be 30% of the volume of the coal extracted in the longwall parcel. One year after the completion of the longwall plot extraction, the volume of free space in the goaf is assumed to be 10% of the total volume of coal extracted by longwall mining.

During atmospheric pressure changes, the goaf gas with methane changes from the first state to the second state, which is characterized by a different volume, pressure, and temperature. With a constant volume of goaf gas with methane, the existence of two states can be represented by the following Equation (3):

Assuming that T1 = T2 = const. despite the distribution of temperature values along the goaf border, Equation (3) can be multiplied by the temperature T on both sides, obtaining (4):

where:

- V1—absolute methane volume in the goaf is the product of the actual goaf volume and the average methane concentration in the goaf (in state 1) Figure 3,

- V2—absolute methane volume in the goaf after an atmospheric pressure change from p1 to p2 (to state 2) Figure 3,

- p1—atmospheric pressure (in state 1) before its decrease or increase (from state 1 to state 2) Figure 3,

- p2—atmospheric pressure (in state 2).

Equation (4) expresses the Boyle-Mariotte law, i.e., at constant temperature, the product of volume and pressure is a constant quantity—an isothermal transformation. During atmospheric pressure changes, p1 (state 1) changes to p2 (state 2) Figure 3. The amount of methane released from the goaf during atmospheric pressure changes is influenced by the pressure gradient ranging from p1 (state 1) to p2 (state 2) over a given time interval. The maximum actual pressure gradient over 1 h is 4 hPa, while over 24 h, it is 24 hPa, i.e., an average of 1 hPa per hour. The release of methane from the longwall goaf into the workings of the longwall environment during atmospheric pressure drops is illustrated by examples later in this paper (Results).

3. Results

3.1. Additional Methane Volumetric Flow Released from the Goaf of an Operating Longwall to Mine Workings in Its Area during an Atmospheric Pressure Drop

Longwall 4, with a panel length of 1400 m, has reached the longwall face advance of 1200 m. The parameters of the longwall are as follows: height of the mining gate 2.5 m, longwall length 200 m. The volume of the post-mining goaf, taking into account a reconsolidation coefficient of 0.3, is 180,000 m3. Calculations were carried out for three average values of methane concentrations in the goaf of Longwall 4, which are 20%, 30%, and 40%. The absolute volumes of methane in the goaf are:

- at 20% CH4; volume of methane in the goaf is 36,000 m3 CH4,

- at 30% CH4; volume of methane in the goaf is 54,000 m3 CH4,

- at 40% CH4; volume of methane in the goaf is 72,000 m3 CH4.

Three pressure drop variants over a period of 10 h were adopted, respectively:

- Variant I—25 hPa over 10 h, i.e., 2.5 hPa/1 h,

- Variant II—20 hPa over 10 h, i.e., 2.0 hPa/1 h,

- Variant III—12 hPa over 10 h, i.e., 1.2 hPa/1 h,

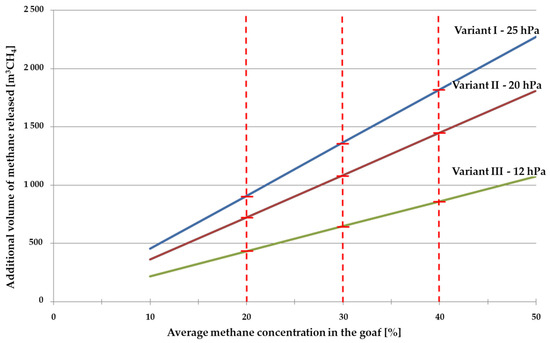

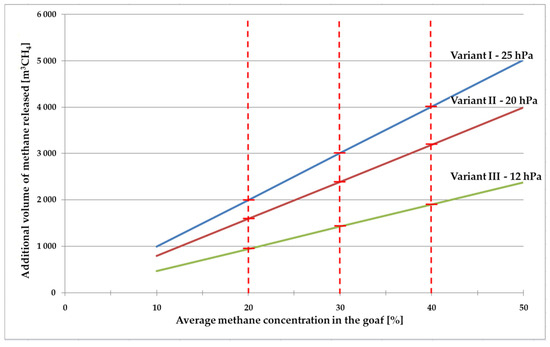

- An initial atmospheric pressure value of P1, i.e., 1,015,000 Pa, was adopted for three pressure drop variants from which a pressure drop of the values corresponding to the three variants occurs over 10 h. Calculation of the emitted methane volume for respective pressure drop variants and calculation of the additional averaged emitted methane flow per minute over 10 h are summarized in Table 1 and graphically illustrated in Figure 4.

Table 1. Summary of amounts calculated for additional methane emitted over the duration of the atmospheric pressure drop with values of 25 hPa, 20 hPa, and 12 hPa over 10 h for Longwall 4.

Table 1. Summary of amounts calculated for additional methane emitted over the duration of the atmospheric pressure drop with values of 25 hPa, 20 hPa, and 12 hPa over 10 h for Longwall 4. Figure 4. Nomogram of the additional volume of methane released from the goaf of Longwall 4 during a 10-h atmospheric pressure drop in three variants: 25 hPa, 20 hPa, and 12 hPa.

Figure 4. Nomogram of the additional volume of methane released from the goaf of Longwall 4 during a 10-h atmospheric pressure drop in three variants: 25 hPa, 20 hPa, and 12 hPa.

3.2. Additional Methane Volumetric Flow from Longwall Goafs (4 Longwalls) to the Workings in Their Area during Pressure Drops

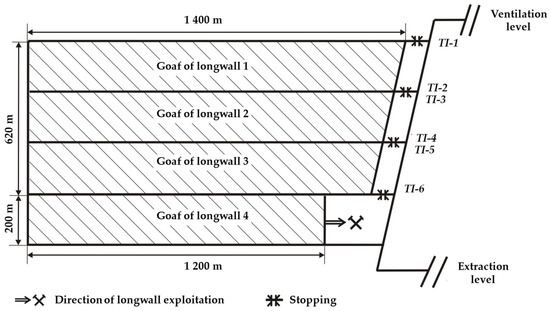

The above calculations (Section 3.1) of methane release from goaves to mine workings during the period of atmospheric pressure drop include the goaf in the plot of the currently operating longwall. Usually, this goaf is connected to the goaves of previously extracted longwalls; therefore, while maintaining the assumptions made for Longwall 4, this longwall was additionally situated in the vicinity of post-mining goaves of three previously extracted longwalls (1, 2, and 3), as presented in Figure 5.

Figure 5.

Illustration of connected to the ventilation system post-mining goaves of three extracted.

With the height of 2.5 m, the volume of free space in post-mining goaves of Longwalls 1, 2, and 3 is 217,000 m3 after their reconsolidation given a coefficient of 0.1, and 180,000 m3 of Longwall 4 given a coefficient of 0.3.

The total volume of free space connected to the ventilation system post-mining goaf in the seam mined by Longwall 4 is 397,000 m3.

For calculations, as before, three variants of the atmospheric pressure drop were adopted for the longwall over a period of 10 h, i.e., 25 hPa, 20 hPa, and 12 hPa. For each of these variants, average values of methane concentration in the goaf were adopted, i.e., 20%, 30%, and 40%.

Column 5 of Table 2 shows the additional total volume of methane released during 10 h from the goaf of operating Longwall 4 and from the post-mining goaves of previously extracted Longwalls 1, 2, and 3. Calculation results are presented in Table 2 and graphically in Figure 6.

Table 2.

Comparison of calculation results of additional volumes of methane released during the atmospheric pressure drop of 25 hPa, 20 hPa, and 12 hPa over a 10-h period for Longwall 4, with consideration of the impact of previously extracted Longwalls 1, 2 and 3.

Figure 6.

Nomogram of the additional volume of released methane during a 10-h atmospheric pressure drop in three variants of 25 hPa, 20 hPa, and 12 hPa for Longwall 4, with the impact of previously mined Longwalls 1, 2 and 3 taken into account.

During the atmospheric pressure drop, methane from the vicinity of currently extracted longwall 4 and from connected goaves of previously extracted Longwalls 1, 2, and 3 forms an additional volume that will be released into the goaf of the operating longwall environment and from behind the stopping systems of the goaves of previously extracted three Longwalls.

A comparative analysis of the volume of methane released from the post-mining goaf of a single longwall (Table 1) and that of the same longwall surrounded by the post-mining goaves of previously extracted three longwalls (Table 2) indicates that the vicinity of the additional goaf volume of the previously extracted longwall has a significant influence on the additional volume of methane released from the goaf into mine workings.

3.3. Methane Release from Sealed Goaf of Four Extracted Longwalls to Ventilated Mine Workings

After the completion of longwall operations, the post-mining goaf is sealed. Most often, the plot of the next longwall extracted in the seam has a direct or indirect goaf contact with the goaf of the previously extracted longwall or is separated by a narrow coal pillar. Regardless of the existing goaf connections, the currently operated longwall is sealed with explosion-proof stoppings from ventilated mine workings. Over a long period of about 15 years after the completion of longwall extraction, methane flows into the goaf as a result of degasification of distressed under- and overworked seams located within the zone of operational stress relief. The forecast of methane release to post-mining goaves in subsequent years after the exploitation is completed is calculated based on Formula/Equation (1) presented in this paper. The above-mentioned model of forecasting methane release refers to unflooded goaves. A model of methane release forecast to flooded goaves, developed at the Central Mining Institute, is presented in publication [21]. The above-mentioned forecasting model takes into account the influence of the water column hydrostatic pressure in the goaf, bearing in mind the surface area of the flooded goaf, on the development of the forecast volume of released methane flow in subsequent years after completion of the longwall operation.

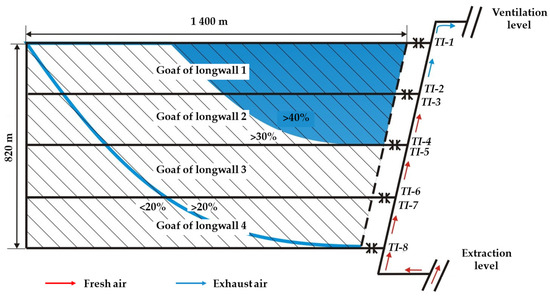

In this part of the paper, data for the calculations come from post-mining goaves of four extracted longwalls in the seam section identified in Figure 5. However, after the extraction of Longwall 4 is completed and it is sealed with TI-7 and TI-8 sealing walls, data for the analysis will come from the complex of post-mining goaves cut off from the ventilation system.

The goaf area of extracted longwalls in the seam section under operation is 1,148,000 m2, and the volume of extracted coal with an average longwall face height of 2.5 m is 2,870,000 m3. Adopting a goaf consolidation coefficient of 0.1, the volume of free space in the reconsolidated goaves of four extracted longwalls is 287,000 m3. Post-mining goaves are separated from the ramp, connecting the mining level with the ventilation level with explosion-proof stoppings.

Methane migrates from the goaf into mine workings surrounded by (explosion-proof) stoppings and then to the interlevel ramp in the seam to be discharged into the mine’s return shaft. Both the tightness of stoppings and the amount of methane flowing into the goaf after being released in the process of degassing the distressed coal seam influence the distribution of methane concentrations in sealed goaves.

In Figure 7, out of eight stoppings, TI-1, TI-2, and TI-3 are very likely to function as return systems, while TI-8, TI-7, and TI-6 are likely to function as intake systems.

Figure 7.

Drawing of sealed post-mining goaves cut off from the ventilation system in a seam section.

The functions of these stoppings separating post-mining goaves will determine the possible outflow of methane in their vicinity to the interlevel ramp.

During atmospheric pressure drops, stoppings for returns will be characterized by a positive difference in aerodynamic potential values in front of and behind the stopping system. Stoppings with ±0 mm water column (inert) may change from intake to return ones. In the case of intake-stopping systems, the negative potential difference in front of and behind the stoppings decreases during atmospheric pressure drops.

An increase in the volume of goaf gases in a tightly sealed goaf space may make all stoppings function as return systems. Table 3 presents the results of calculations of the additional volume of methane released from the goaf into ventilated mine workings for three values of methane concentration in the goaf, i.e., 20%, 30%, and 40%. As before, the calculations were made for 3 variants of atmospheric pressure drop. The last column of Table 3 lists the calculated absolute volumes of additional methane released in the vicinity of stopping systems during periods of atmospheric pressure drops.

Table 3.

Summary of calculated volumes of additional methane released from sealed post-mining goaves into ventilated mine workings over 10 h of atmospheric pressure drops of 25 hPa, 20 hPa, and 12 hPa.

4. Discussion

4.1. Additional Methane Volumetric Flow Released from the Goaf of Longwall 4 to the Workings in Its Vicinity during Atmospheric Pressure Drops

Calculations made for Longwall 4 indicate that average methane concentrations in the post-mining goaf of Longwall 4 and adopted values of atmospheric pressure drop over 10 h result in an additional inflow of methane migrating from the goaf to the workings of the Longwall environment. Three variants of atmospheric pressure drop during ten hours adopted for calculations are 25 hPa, 20 hPa, and 12 hPa.

In column 2 of Table 1, three average methane concentration values in the goaf were adopted for each variant of pressure drop, namely 20%, 30%, and 40%. Column 5 of Table 1 lists additional volumes of methane released from the goaf into mine workings during atmospheric pressure drops. Column 6 of Table 1 lists average methane volumes additionally released per minute over 10 h. Calculations are made based on data coming from the goaf of one longwall that is not connected with adjacent goaves within this seam or connected with other seams by means of a stress-relief zone.

Graphical interpretation of additional volume of methane released from the post-mining goaf of a single longwall for 3 variants of atmospheric pressure drops of 25 hPa, 20 hPa, and 12 hPa over 10 h presented with nomograms in Figure 4 allows for two main conclusions to be drawn:

- For an adopted value of atmospheric pressure drop in the longwall goaf, during the adopted 10-h period, an increase in average methane concentration in longwall goaf leads to a linear growth of the volume of methane additionally released to the workings of the longwall environment,

- The rising pressure gradient of a pressure drop over the time interval causes an increase in the volume of methane additionally released from the goaf into the workings of the longwall environment.

4.2. Additional Methane Volumetric Flow Released from Goafs (of Four Longwalls) to the Longwall Area Workings during Atmospheric Pressure Drops

Results of calculations presented in column 6 of Table 2 prove that the additional methane volumetric flow released from connected goaves of previously extracted Longwalls 1, 2, and 3 with the goaf of the operating Longwall 4 represents a significant value. The increase in methane outflow from the longwall goaf of approximately 5 m3 CH4/min will create a significant methane hazard in the area of the junction of the longwall and the ventilating roadway. Longwall 4 is ventilated using the “U” method along the coal face. During the atmospheric pressure drop, methane concentration in Longwall 4, in the area of the goaf of the ventilating roadway of this longwall that is being decommissioned, may exceed the regulatory limit for ventilating roadways.

When a drop in atmospheric pressure is anticipated, measures should be taken to increase the effectiveness of operational methane draining of Longwall 4 and TI-1 stopping, which definitely functions as the main return way for post-mining goaves of extracted Longwalls 1, 2, and 3. After the completion of operations with Longwall 4, Figure 5, and after the goaf sealing, the post-mining goaves will be cut off from the ventilation system with an inflow of recoverable methane resources to their space.

4.3. Methane Release from Sealed Goafs of Four Selected Longwalls to the Workings in the Mine Ventilation System

If no methane drainage of post-mining goaves is carried out, an additional volume of methane migrates surrounded by (explosion-proof) stoppings into ventilated mine workings.

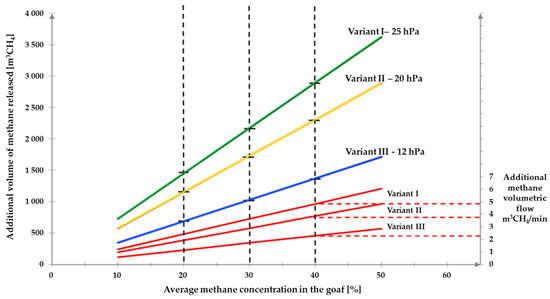

Nomograms in Figure 8 refer to 3 variants of atmospheric pressure drop and provide a graphical representation of the following:

Figure 8.

Nomogram of the additional volume of methane released from sealed goaves into ventilated mine workings during a 10-h atmospheric pressure drop for three variants of the pressure drop: 25 hPa, 20 hPa, and 12 hPa.

- The additional volume of methane produced in post-mining goaves as a result of atmospheric pressure drop in m3 CH4,

- The additional methane flow in m3 CH4/min that can be captured by the goaf drainage system, reducing its emission to the workings and, at the same time, the amount of methane emitted to the atmosphere through ventilation shafts.

The last column of Table 3 lists additional methane volumetric flows that can be captured with drainage systems from post-mining goaves during periods of atmospheric pressure drops, converted into m3 CH4/min. Nomograms in Figure 8 provide a graphical interpretation of the presented results of calculations.

Two axes of ordinates refer, respectively, to the additional methane volume in the goaf for three variants of the atmospheric pressure drop and to the additional methane volumetric flow that can be captured during the period of the atmospheric pressure drop.

The pressure gradient over 10 h of the pressure drop for Variants I, II, and III, respectively, made it possible to calculate the value of the additional methane flow that could be captured with the drainage system.

Red nomograms presented in Figure 8 allow the assessment of additional methane volume that can be captured by draining post-mining goaves.

5. Conclusions

Methane volumetric flow released into sealed post-mining goaves comes second only to the release of methane into the longwall environment in coal mines with high methane concentrations. The new strategy for reducing methane emissions into the mine environment aims to increase the efficiency of post-mining goaf methane drainage systems. The discussed issue of increasing the efficiency of post-mining goaf methane drainage systems during atmospheric pressure drops should be included in the developed program of the future mining strategy aimed at reducing methane emissions to the atmosphere.

Calculations presented in this paper facilitate the identification and assessment of the additional volume of methane that is released from goaves of operating longwalls and sealed post-mining goaves.

In the case of multi-seam mining with connected goaves, post-mining goaves are connected by the stress-relief zones of extracted longwalls in adjacent seams. Thanks to the connection of the stress-relief zones caused by the exploitation of multiple seams, a complex of post-mining goaves is formed, which in turn leads to the creation of conditions for methane migration both along the post-mining goaf elevation and spatially. Methane migration takes different directions induced by differences in the values of the aerodynamic potential field within one ventilation subsystem. The diagonal nature of the post-mining goaf complex may be influenced by the parameters of the main fans at the return shafts. During changes in atmospheric pressure, the spatial location of goaves in the mine’s ventilation sub-networks has a great impact on the directions of methane migration in goaves.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the author.

Conflicts of Interest

The author declares no conflict of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

References

- Szlazak, N.; Obracaj, D.; Swolkień, J. Methane Drainage from Roof Strata Using an Overlying Drainage Gallery. Int. J. Coal Geol. 2014, 136, 99–115. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Q.; Cheng, Y.; Ge, C.; Chen, J. Methane Drainage and Utilization in Coal Mines with Strong Coal and Gas Outburst Dangers: A Case Study in Luling Mine, China. J. Nat. Gas Sci. Eng. 2014, 20, 357–365. [Google Scholar] [CrossRef]

- Shang, H.; Bai, H.; Li, X.; Li, J.; Yang, J. Site Trials of Methane Capture from Low-Concentration Coalbed Methane Drainage Wells Using a Mobile Skid-Mounted Vacuum Pressure Swing Adsorption System. Sep. Purif. Technol. 2022, 295, 121271. [Google Scholar] [CrossRef]

- Huo, B.; Jing, X.; Fan, C.; Han, Y. Numerical Investigation of Flue Gas Injection Enhanced Underground Coal Seam Gas Drainage. Energy Sci. Eng. 2019, 7, 3204–3219. [Google Scholar] [CrossRef]

- Zapletal, P.; Pach, G.; Kosowski, M. The Influence of Atmospheric Pressure on Methane Drainage from Mines in the Upper Silesian Coal Basin. Int. J. Oil Gas Coal Technol. 2022, 30, 97–108. [Google Scholar] [CrossRef]

- Myszor, H.; Gruszka, A. O Zależności Wydzielania Metanu Do Kopalń Od Ciśnienia Atmosferycznego. Arch. Gór. 1996, 41, 2. [Google Scholar]

- Wasilewski, S. Influence of Barometric Pressure Changes on Ventilation Conditions in Deep Mines. Arch. Min. Sci. 2014, 59, 621–639. [Google Scholar] [CrossRef]

- Lolon, S.; Gilmore, R.; Brune, J.; Bogin, G.; Grubb, J.; Zipf, R.; Juganda, A.; Saki, S. Effect of Decreasing Barometric Pressure on Explosive Gas Zones in Bleeder Ventilated Longwall Gobs. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VI, USA, 20–25 June 2015. [Google Scholar]

- Wu, T.; Zhan, L.T. Influence of Atmospheric Pressure on Methane Emissions from Earthen Landfill Covers. In Proceedings of the 8th International Congress on Environmental Geotechnics, Hangzhou, China, 28 October–1 November 2018; pp. 85–92. [Google Scholar]

- Duda, A.; Krzemień, A. Forecast of Methane Emission from Closed Underground Coal Mines Exploited by Longwall Mining—A Case Study of Anna Coal Mine. J. Sustain. Min. 2018, 17, 184–194. [Google Scholar] [CrossRef]

- Gavrylenko, Y.N.; Ermakov, V.N.; Krenid, Y.F.; Ulitskiy, O.A. Technogenic Impact of Mining Site Closure in Ukraine; Nord-Press Publishing: Donetsk, Ukraine, 2004; Volume 632. [Google Scholar]

- Duda, A.; Valverde, G.F. Environmental and Safety Risks Related to Methane Emissions in Underground Coal Mine Closure Processes. Energies 2020, 13, 6312. [Google Scholar] [CrossRef]

- Sułkowski, J.; Drenda, J.; Różański, Z.; Wrona, P. Noticed in Mining Areas, Environmental Hazard Connected with Outflow of Gases from Abandoned Mines and with Spontaneous Ignition of Coal Waste Dumps. Gospod. Surowcami Miner. 2008, 24, 319–333. [Google Scholar]

- Gilman, A.; Beckie, R. Flow of Coal-Bed Methane to a Gallery. Transp. Porous Media 2000, 41, 1–16. [Google Scholar] [CrossRef]

- Valliappan, S.; Numerical, Z.W.-I.J. Numerical Modelling of Methane Gas Migration in Dry Coal Seams. Int. J. Numer. Anal. Methods Geomech. 1996, 20, 571–593. [Google Scholar] [CrossRef]

- Bertard, C.; Bruyet, B.; Gunther, J. Determination of Desorbable Gas Concentration of Coal (Direct Method). Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1970, 7, 43–65. [Google Scholar] [CrossRef]

- Barker-Read, G.R.; Radchenko, S.A. Methane Emission from Coal and Associated Strata Samples. Int. J. Min. Geol. Eng. 1989, 7, 101–126. [Google Scholar] [CrossRef]

- Wrona, P.; Król, A.; Król, M. Gas Outflow from an Underground Site—Numerical Simulations into Baric Tendency and Airflow Rate Relationship. Arch. Min. Sci. 2018, 63, 251–268. [Google Scholar] [CrossRef]

- Dziurzynski, W.; Krach, A.; Pałka, T. A Reliable Method of Completing and Compensating the Results of Measurements of Flow Parameters in a Network of Headings. Arch. Min. Sci. 2015, 60, 3–24. [Google Scholar] [CrossRef]

- Babets, D.; Sdvyzhkova, O.; Gapieiev, S.; Shashenko, O.; Prykhodchenko, V. Multifactorial Analysis of a Gateroad Stability at Goaf Interface during Longwall Coal Mining—A Case Study. Min. Miner. Depos. 2023, 17, 9–19. [Google Scholar] [CrossRef]

- Krause, E.; Karbownik, M. Tests of Methane Desorption and Emission from Samples of Hard Coal in the Context of Mine Closures through Flooding. J. Sustain. Min. 2019, 18, 127–133. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J.; Szurgacz, D.; Sobik, L.; Zhironkin, S. The Impact of the Ventilation System on the Methane Release Hazard and Spontaneous Combustion of Coal in the Area of Exploitation—A Case Study. Energies 2020, 13, 4891. [Google Scholar] [CrossRef]

- Batugin, A.; Kobylkin, A.; Kolikov, K.; Ivannikov, A.; Musina, V.; Khotchenkov, E.; Zunduijamts, B.; Ertuganova, E.; Krasnoshtanov, D. Study of the Migrating Mine Gas Piston Effect during Reactivation of Tectonic Faults. Appl. Sci. 2023, 13, 12041. [Google Scholar] [CrossRef]

- Dreger, M.; Kędzior, S. Methane Emissions against the Background of Natural and Mining Conditions in the Budryk and Pniówek Mines in the Upper Silesian Coal Basin (Poland). Environ. Earth Sci. 2021, 80, 746. [Google Scholar] [CrossRef]

- Su, S.; Agnew, J. Catalytic Combustion of Coal Mine Ventilation Air Methane. Fuel 2006, 85, 1201–1210. [Google Scholar] [CrossRef]

- Karakurt, I.; Aydin, G.; Aydiner, K. Mine Ventilation Air Methane as a Sustainable Energy Source. Renew. Sustain. Energy Rev. 2011, 15, 1042–1049. [Google Scholar] [CrossRef]

- Li, Q.; Lin, B.; Yuan, D.; Chen, G. Demonstration and Its Validation for Ventilation Air Methane (VAM) Thermal Oxidation and Energy Recovery Project. Appl. Therm. Eng. 2015, 90, 75–85. [Google Scholar] [CrossRef]

- Węgiel Kamienny—Państwowy Instytut Geologiczny—PIB. Available online: https://www.pgi.gov.pl/surowce/energetyczne/13937-wegiel_kamienny.html (accessed on 9 December 2023).

- Krause, E.; Pokryszka, Z. Investigations on Methane Emission from Flooded Workings of Closed Coal Mines. J. Sustain. Min. 2013, 12, 40–45. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).