Circular Economy in Wastewater Treatment Plant—Water, Energy and Raw Materials Recovery

Abstract

1. Introduction

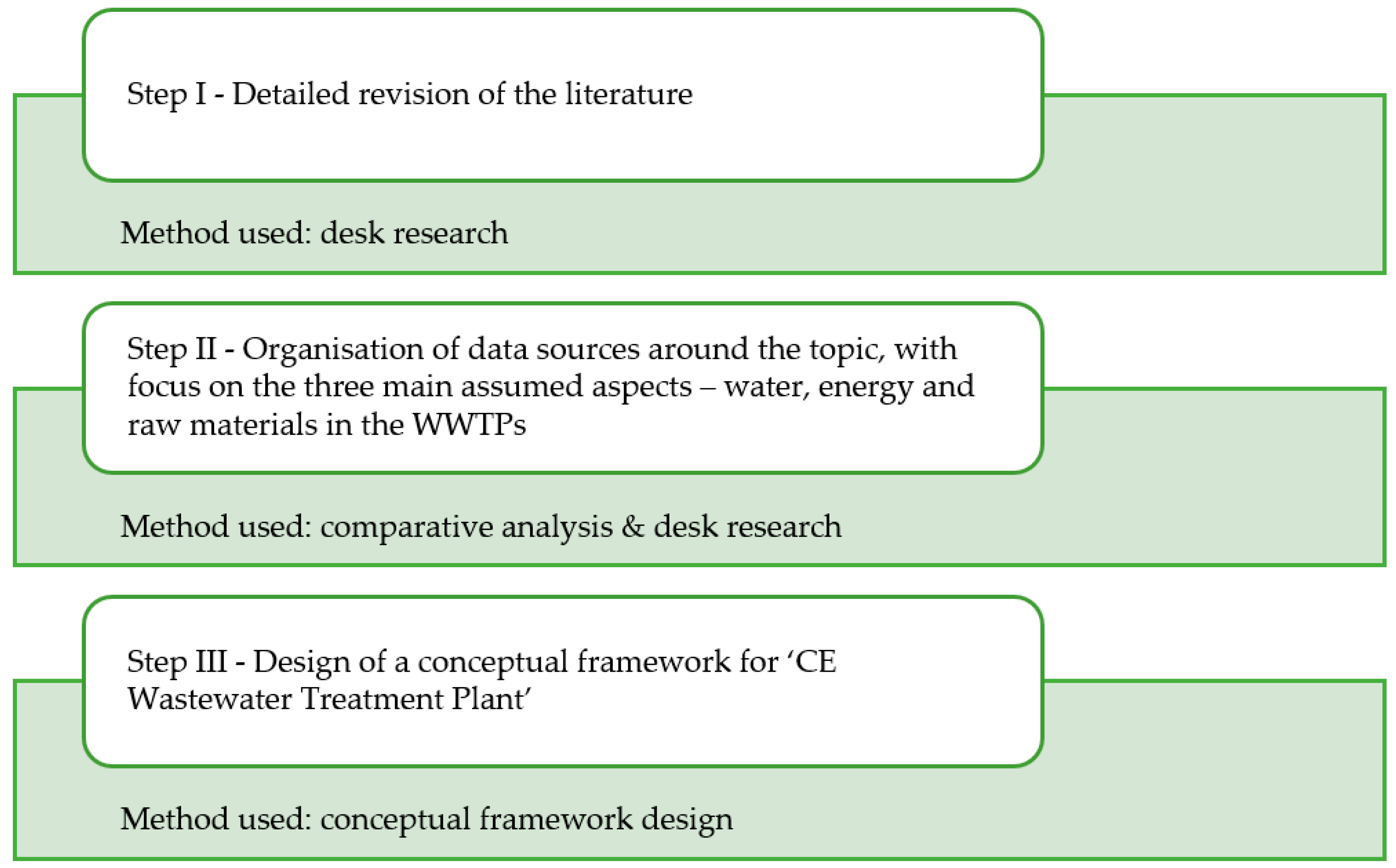

2. Materials and Methods

3. Results

3.1. Importance of Water, Energy and Raw Materials in CE

3.2. Wastewater Treatment Plants

- Modernization of water supply systems and devices guaranteeing the water quality required by law, intended for supplying the population;

- Construction, extension and modernization of sewage systems and WWTPs in areas with concentrated buildings and urbanized areas;

- Improving the efficiency of removing harmful substances from wastewater discharged into surface waters;

- Preventing eutrophication of waters under the influence of pollution, including from diffuse sources.

- Municipal wastewater treatment plants;

- Industrial wastewater treatment plants;

- Special-purpose wastewater treatment plants.

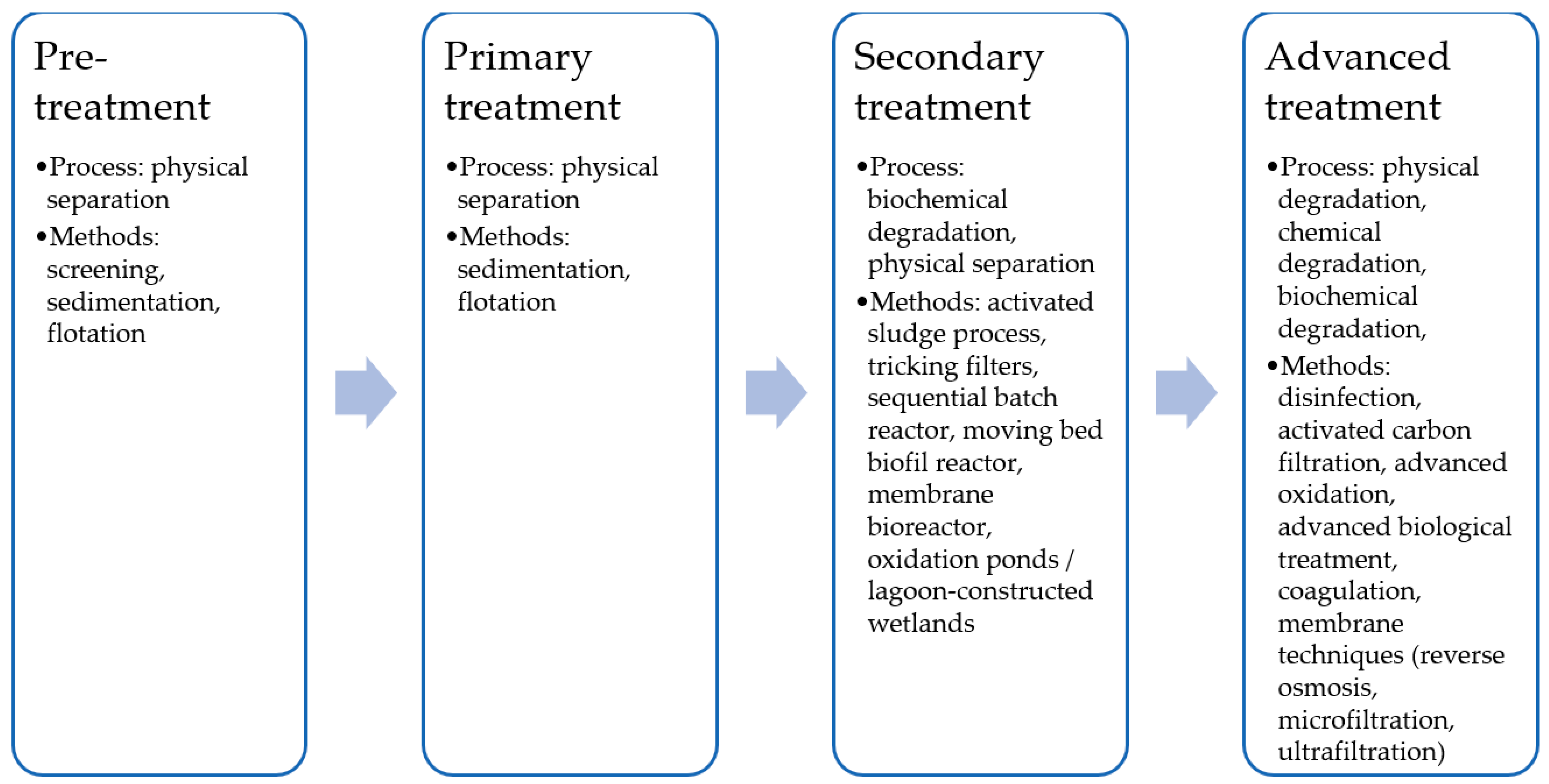

- Pre-treatment, which includes physical removal of large objects (e.g., rags and plastics) and smaller objects (e.g., grit from the wastewater);

- Primary treatment, which includes removal of fine particles; wastewater is kept in a dedicated tank where heavier solids fall to the bottom, and lighter solids or fat float to the surface; settled and floating solids are separated; remaining liquid is directed to secondary treatment or discharged to the natural reservoir;

- Secondary treatment (biological treatment),which removes all remaining organic matter, suspended solids, selected viruses, bacteria and parasites; it could also remove nutrients or chemical substances to some extent;

- Advanced treatment (more stringent treatment), which is applied for the removal of the remaining nutrients before discharge into sensitive waters (e.g., through disinfection that can be used for further removal of viruses, bacteria and parasites, or other remaining chemicals and harmful substances).

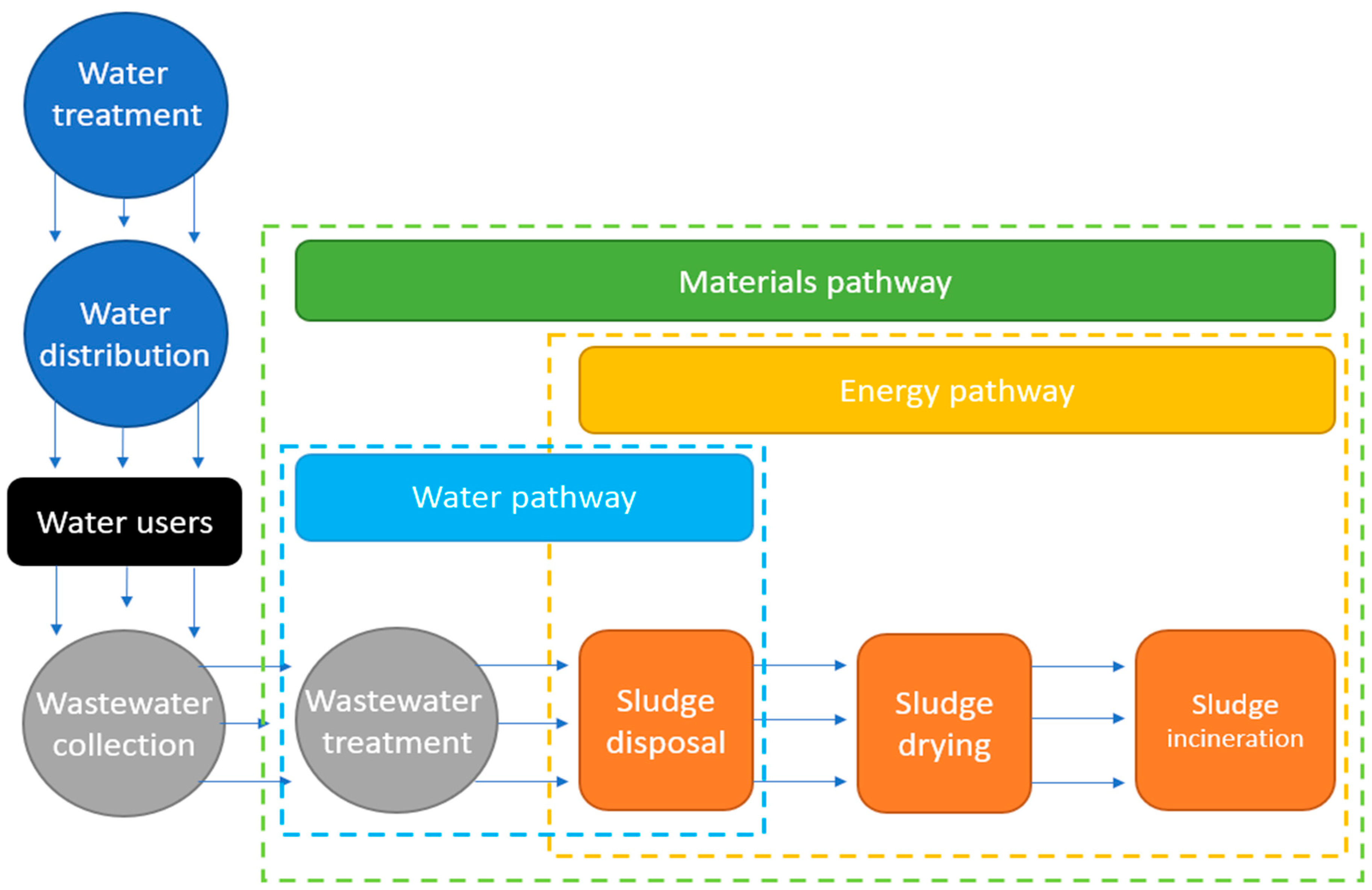

3.3. Wastewater Treatment Plant of the Future

- Water pathway;

- Energy pathway;

- Materials pathway.

- Cogeneration and/or biogas combustion systems;

- Thermal transformation of sewage sludge;

- Chemical oxidation of sewage sludge;

- Heat of treated sewage;

- Other additional installations, such as ground heat pumps and/or photovoltaic panels.

- Technological needs: improvement of the efficiency of the wastewater treatment process through modern solutions allowing for a better quality of treated wastewater, reduction in operating costs through the development of technologies for energy recovery and reduction in energy consumption of technological processes and devices, comprehensive approach to wastewater treatment as an opportunity to obtain renewable raw materials, e.g., production of organic fertilizers;

- Social needs: improvement of society’s living conditions due to the developed water and sewage management system, much less nuisance in WWTP operation in relation to the immediate surroundings, creation of modern infrastructure, generation of new specialized jobs, creation of new raw materials for use by society;

- Ecological needs: reducing GHG emissions, reducing the amount of energy used from non-renewable sources, minimizing the amount of waste by reusing recovered raw materials, saving drinking water resources, limiting the emission of micropollutants to the aquatic environment;

- Research, development and commercial potential: development of national contractors from the construction sector and increasing export opportunities of the developed technology understood as a product, as well as possible export of economic solutions regarding wastewater treatment installations.

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | anaerobic digestion |

| BREFs | Best Available Techniques reference documents |

| CE | circular economy |

| CRM | critical raw material |

| EGD | European Green Deal |

| EPS | extracellular polymeric substance |

| ESPP | European Sustainable Phosphorus Platform |

| GHG | greenhouse gas |

| INMAP | Integrated Nutrient Management Action Plan |

| NEW | nutrients–energy–water |

| NF | nanofiltration |

| P | phosphorus |

| RO | reverse osmosis |

| SD | sustainable development |

| SS | sewage sludge |

| SSA | sewage sludge ash |

| UF | ultrafiltration |

| UWWTD | urban waste water treatment |

| WW | wastewater |

| WWTP | wastewater treatment plant |

References

- Sikosana, M.L.; Sikhwivhilu, K.; Moutloali, R.; Madyira, D.M. Municipal Wastewater Treatment Technologies: A Review. Procedia Manuf. 2019, 35, 1018–1024. [Google Scholar] [CrossRef]

- European Commission Communication from the Commission: The European Green Deal; COM no. 640; European Commission: Brussels, Belgium, 2019.

- Preisner, M.; Smol, M.; Horttanainen, M.; Deviatkin, I.; Havukainen, J.; Klavins, M.; Ozola-Davidane, R.; Kruopienė, J.; Szatkowska, B.; Appels, L.; et al. Indicators for Resource Recovery Monitoring within the Circular Economy Model Implementation in the Wastewater Sector. J. Environ. Manag. 2022, 304, 114261. [Google Scholar] [CrossRef]

- Ramm, K. Considerations Related to the Application of the EU Water Reuse Regulation to the Production of Snow from Reclaimed Water. Circ. Econ. Sustain. 2021, 2, 569–587. [Google Scholar] [CrossRef]

- Sikdar, S. Circular Economy: Is There Anything New in This Concept? Clean Technol. Environ. Policy 2019, 21, 1173–1175. [Google Scholar] [CrossRef]

- European Commission Communication from the Commission: Closing the Loop—An EU Action Plan for the Circular Economy; COM no. 614; European Commission: Brussels, Belgium, 2015.

- European Commission Communication from the Commission: Circular Economy Action Plan for a Cleaner and More Competitive Europe; COM no. 98; European Commission: Brussels, Belgium, 2020.

- Werle, S.; Sobek, S. Gasification of Sewage Sludge within a Circular Economy Perspective: A Polish Case Study. Environ. Sci. Pollut. Res. 2019, 26, 35422–35432. [Google Scholar] [CrossRef]

- Peterson, H.M.; Baker, L.A.; Aggarwal, R.M.; Boyer, T.H.; Chan, N.I. A Transition Management Framework to Stimulate a Circular Phosphorus System. Environ. Dev. Sustain. 2022, 24, 1713–1737. [Google Scholar] [CrossRef]

- Smol, M.; Adam, C.; Kugler, S.A. Inventory of Polish Municipal Sewage Sludge Ash (SSA)—Mass Flows, Chemical Composition, and Phosphorus Recovery Potential. Waste Manag. 2020, 116, 31–39. [Google Scholar] [CrossRef] [PubMed]

- Hosomi, M. New Challenges on Wastewater Treatment. Clean Technol. Environ. Policy 2016, 18, 627–628. [Google Scholar] [CrossRef]

- Terada, A. Lessons from a Simple Ecological Wastewater Treatment Technology for Scientific Research and Advanced Engineering. Clean Technol. Environ. Policy 2019, 21, 717–718. [Google Scholar] [CrossRef]

- Morris, L.; Colombo, V.; Hassell, K.; Kellar, C.; Leahy, P.; Long, S.M.; Myers, J.H.; Pettigrove, V. Municipal Wastewater Effluent Licensing: A Global Perspective and Recommendations for Best Practice. Sci. Total Environ. 2017, 580, 1327–1339. [Google Scholar] [CrossRef]

- Kosek, K.; Luczkiewicz, A.; Fudala-Książek, S.; Jankowska, K.; Szopińska, M.; Svahn, O.; Tränckner, J.; Kaiser, A.; Langas, V.; Björklund, E. Implementation of Advanced Micropollutants Removal Technologies in Wastewater Treatment Plants (WWTPs)—Examples and Challenges Based on Selected EU Countries. Environ. Sci. Policy 2020, 112, 213–226. [Google Scholar] [CrossRef]

- Preisner, M.; Smol, M.; Szołdrowska, D. Trends, Insights and Effects of the Urban Wastewater Treatment Directive (91/271/EEC) Implementation in the Light of the Polish Coastal Zone Eutrophication. Environ. Manag. 2021, 67, 342–354. [Google Scholar] [CrossRef]

- European Commission Urban Wastewater; European Commission: Brussels, Belgium, 2023.

- Beyond Water Quality-Sewage Treatment in a Circular Economy; European Environment Agency: Copenhagen, Denmark, 2022; ISBN 9789294804785.

- European Commission Communication from the Commission: Towards a Circular Economy: A Zero Waste Programme for Europe; COM no. 398; European Commission: Brussels, Belgium, 2014.

- European Commission Regulation (EU). 2019/1009 Fertilizer Products. Off. J. Eur. Union 2019, 2019, 1–114. [Google Scholar]

- The European Parliament and the Council Regulation EU 2020/741, Minimum Requirements for Water Reuse; EU 2020/741; European Commission: Brussels, Belgium, 2020.

- European Commission Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability; COM no. 474; European Commission: Brussels, Belgium, 2020.

- Marcinek, P.; Smol, M. Bioeconomy as One of the Key Areas of Implementing a Circular Economy (CE) in Poland. Environ. Res. Eng. Manag. 2020, 76, 20–31. [Google Scholar] [CrossRef]

- European Commission Proposal for a Regulation on the Making Available on the Market of CE Marked Fertilising Products and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 Annexes 1 to 5; Regulation of the European Parliament and of the Council; COM no. 157; European Commission: Brussels, Belgium, 2016.

- Smol, M. Transition to Circular Economy in the Fertilizer Sector—Analysis of Recommended Directions and End-Users’ Perception of Waste-Based Products in Poland. Energies 2021, 14, 4312. [Google Scholar] [CrossRef]

- Smol, M.; Marcinek, P.; Koda, E. Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector. Energies 2021, 14, 2219. [Google Scholar] [CrossRef]

- Chin, H.H.; Varbanov, P.S.; Klemeš, J.J.; Kravanja, Z. Novel Circularity and Sustainability Assessment of Symbiosis Networks through the Energy Quality Pinch Concept. Energy 2023, 266, 126271. [Google Scholar] [CrossRef]

- Nikolaou, I.E.; Tsagarakis, K.P. An Introduction to Circular Economy and Sustainability: Some Existing Lessons and Future Directions. Sustain. Prod. Consum. 2021, 28, 600–609. [Google Scholar] [CrossRef]

- Havukainen, J.; Nguyen, M.T.; Hermann, L.; Horttanainen, M.; Mikkilä, M.; Deviatkin, I.; Linnanen, L. Potential of Phosphorus Recovery from Sewage Sludge and Manure Ash by Thermochemical Treatment. Waste Manag. 2016, 49, 221–229. [Google Scholar] [CrossRef] [PubMed]

- Lipińska, D. The Water-Wastewater-Sludge Sector and the Circular Economy. Comp. Econ. Res. 2018, 21, 121–137. [Google Scholar] [CrossRef]

- Hreiz, R.; Latifi, M.A.; Roche, N. Optimal Design and Operation of Activated Sludge Processes: State-of-the-Art. Chem. Eng. J. 2015, 281, 900–920. [Google Scholar] [CrossRef]

- Benedetti, L.; Dirckx, G.; Bixio, D.; Thoeye, C.; Vanrolleghem, P.A. Environmental and Economic Performance Assessment of the Integrated Urban Wastewater System. J. Environ. Manag. 2008, 88, 1262–1272. [Google Scholar] [CrossRef] [PubMed]

- Zaharia, C. Wastewater Treatment Systems: Characteristics, Performances. In Proceedings of the 21st International Conference of Inventics—“INVENTICA 2017”, Iasi, Romania, 28–30 June 2017. [Google Scholar]

- Wang, B.; Baleta, J.; Mikul, H.; Sabev, P. Cleaner Energy for Sustainable Circular Economy Implementations: Integrated Energy, Water and Environment Systems. Clean. Energy Syst. 2023, 4, 100056. [Google Scholar] [CrossRef]

- Smol, M.; Adam, C.; Preisner, M. Circular Economy Model Framework in the European Water and Wastewater Sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef]

- International Water Association Water Utility Pathways in a Circular Economy. 2016. Available online: https://iwa-network.org/water-utility-pathways-cir (accessed on 10 April 2023).

- Wang, H.; Xiao, K.; Yang, J.; Yu, Z.; Yu, W.; Xu, Q.; Wu, Q.; Liang, S.; Hu, J.; Hou, H.; et al. Phosphorus Recovery from the Liquid Phase of Anaerobic Digestate Using Biochar Derived from Iron−rich Sludge: A Potential Phosphorus Fertilizer. Water Res. 2020, 174, 115629. [Google Scholar] [CrossRef] [PubMed]

- Cornel, P.; Schaum, C. Phosphorus Recovery from Wastewater: Needs, Technologies and Costs. Water Sci. Technol. 2009, 59, 1069–1076. [Google Scholar] [CrossRef] [PubMed]

- Cichy, B.; Kużdżał, E.; Krztoń, H. Phosphorus Recovery from Acidic Wastewater by Hydroxyapatite Precipitation. J. Environ. Manag. 2019, 232, 421–427. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Y. Simultaneous Nitrogen and Phosphorus Recovery from Sludge-Fermentation Liquid Mixture and Application of the Fermentation Liquid to Enhance Municipal Wastewater Biological Nutrient Removal. Environ. Sci. Technol. 2009, 43, 6164–6170. [Google Scholar] [CrossRef]

- Saktaywin, W.; Tsuno, H.; Nagare, H.; Soyama, T.; Weerapakkaroon, J. Advanced Sewage Treatment Process with Excess Sludge Reduction and Phosphorus Recovery. Water Res. 2005, 39, 902–910. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, Q.; Li, D.; Li, J.; Guo, W. Performance Comparison of Phosphorus Recovery from Different Sludges in Sewage Treatment Plants through Pyrolysis. J. Clean. Prod. 2022, 372, 133728. [Google Scholar] [CrossRef]

- Guedes, P.; Couto, N.; Ottosen, L.M.; Ribeiro, A.B. Phosphorus Recovery from Sewage Sludge Ash through an Electrodialytic Process. Waste Manag. 2014, 34, 886–892. [Google Scholar] [CrossRef] [PubMed]

- Adam, C.; Peplinski, B.; Michaelis, M.; Kley, G.; Simon, F.G. Thermochemical Treatment of Sewage Sludge Ashes for Phosphorus Recovery. Waste Manag. 2009, 29, 1122–1128. [Google Scholar] [CrossRef] [PubMed]

- Smol, M.; Adam, C.; Kugler, S.A. Thermochemical Treatment of Sewage Sludge Ash (SSA)-Potential and Perspective in Poland. Energies 2020, 13, 5461. [Google Scholar] [CrossRef]

- Hermann, L.; Schaaf, T. Outotec (AshDec®) Process for P Fertilizers from Sludge Ash. Phosphorus Recover. Recycl. 2018, 15, 221–233. [Google Scholar] [CrossRef]

- Szołdrowska, D.; Smol, M. Phosphorus raw materials in sustainable agriculture. In Sustainable and Circular Management of Resources and Waste Towards a Green Deal; Elsevier: Amsterdam, The Netherlands, 2023; pp. 247–255. [Google Scholar]

- van der Hoek, J.P.; Duijff, R.; Reinstra, O. Nitrogen Recovery from Wastewater: Possibilities, Competition with Other Resources, and Adaptation Pathways. Sustainability 2018, 10, 4605. [Google Scholar] [CrossRef]

- Han, F.; Zhou, W. Nitrogen Recovery from Wastewater by Microbial Assimilation—A Review. Bioresour. Technol. 2022, 363, 127933. [Google Scholar] [CrossRef]

- Xiao, Y.; Zheng, Y.; Wu, S.; Yang, Z.H.; Zhao, F. Nitrogen Recovery from Wastewater Using Microbial Fuel Cells. Front. Environ. Sci. Eng. 2016, 10, 185–191. [Google Scholar] [CrossRef]

- Wan, C.; Ding, S.; Zhang, C.; Tan, X.; Zou, W.; Liu, X.; Yang, X. Simultaneous Recovery of Nitrogen and Phosphorus from Sludge Fermentation Liquid by Zeolite Adsorption: Mechanism and Application. Sep. Purif. Technol. 2017, 180, 1–12. [Google Scholar] [CrossRef]

- Chojnacka, K.; Skrzypczak, D.; Szopa, D.; Izydorczyk, G.; Moustakas, K.; Witek-Krowiak, A. Management of Biological Sewage Sludge: Fertilizer Nitrogen Recovery as the Solution to Fertilizer Crisis. J. Environ. Manag. 2023, 326, 116602. [Google Scholar] [CrossRef]

- Munasinghe-Arachchige, S.P.; Nirmalakhandan, N. Nitrogen-Fertilizer Recovery from the Centrate of Anaerobically Digested Sludge. Environ. Sci. Technol. Lett. 2020, 7, 450–459. [Google Scholar] [CrossRef]

- Koskue, V.; Freguia, S.; Ledezma, P.; Kokko, M. Efficient Nitrogen Removal and Recovery from Real Digested Sewage Sludge Reject Water through Electroconcentration. J. Environ. Chem. Eng. 2021, 9, 106286. [Google Scholar] [CrossRef]

- Horttanainen, M.; Deviatkin, I.; Havukainen, J. Nitrogen Release from Mechanically Dewatered Sewage Sludge during Thermal Drying and Potential for Recovery. J. Clean. Prod. 2017, 142, 1819–1826. [Google Scholar] [CrossRef]

- Munasinghe-Arachchige, S.P.; Cooke, P.; Nirmalakhandan, N. Recovery of Nitrogen-Fertilizer from Centrate of Anaerobically Digested Sewage Sludge via Gas-Permeable Membranes. J. Water Process Eng. 2020, 38, 101630. [Google Scholar] [CrossRef]

- Rastetter, N.; Gerhardt, A. Toxic Potential of Different Types of Sewage Sludge as Fertiliser in Agriculture: Ecotoxicological Effects on Aquatic, Sediment and Soil Indicator Species. J. Soils Sediments 2017, 17, 106–121. [Google Scholar] [CrossRef]

- Jensen, J.; Jepsen, S.E. The Production, Use and Quality of Sewage Sludge in Denmark. Waste Manag. 2005, 25, 239–247. [Google Scholar] [CrossRef] [PubMed]

- Černý, J.; Balík, J.; Kulhánek, M.; Vašák, F.; Peklová, L.; Sedlář, O. The Effect of Mineral n Fertiliser and Sewage Sludge on Yield and Nitrogen Efficiency of Silage Maize. Plant Soil Environ. 2012, 58, 76–83. [Google Scholar] [CrossRef]

- Lamastra, L.; Suciu, N.A.; Trevisan, M. Sewage Sludge for Sustainable Agriculture: Contaminants’ Contents and Potential Use as Fertilizer. Chem. Biol. Technol. Agric. 2018, 5, 10. [Google Scholar] [CrossRef]

- Buta, M.; Hubeny, J.; Zieliński, W.; Harnisz, M.; Korzeniewska, E. Sewage Sludge in Agriculture—The Effects of Selected Chemical Pollutants and Emerging Genetic Resistance Determinants on the Quality of Soil and Crops—A Review. Ecotoxicol. Environ. Saf. 2021, 214, 112070. [Google Scholar] [CrossRef]

- Duan, B.; Feng, Q. Comparison of the Potential Ecological and Human Health Risks of Heavy Metals from Sewage Sludge and Livestock Manure for Agricultural Use. Toxics 2021, 9, 145. [Google Scholar] [CrossRef]

- Iticescu, C.; Georgescu, P.L.; Arseni, M.; Rosu, A.; Timofti, M.; Carp, G.; Cioca, L.I. Optimal Solutions for the Use of Sewage Sludge on Agricultural Lands. Water 2020, 13, 585. [Google Scholar] [CrossRef]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of Sewage Sludge in the Fabrication of Construction and Building Materials: A Review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Wu, K.; Hu, Y.; Zhang, L.; Xu, L.; Yang, Z. Promoting the Sustainable Fabrication of Bricks from Municipal Sewage Sludge through Modifying Calcination: Microstructure and Performance Characterization. Constr. Build. Mater. 2022, 324, 126401. [Google Scholar] [CrossRef]

- Li, X.; He, C.; Lv, Y.; Jian, S.; Liu, G.; Jiang, W.; Jiang, D. Utilization of Municipal Sewage Sludge and Waste Glass Powder in Production of Lightweight Aggregates. Constr. Build. Mater. 2020, 256, 119413. [Google Scholar] [CrossRef]

- Areias, I.O.R.; Vieira, C.M.F.; Colorado, H.A.; Delaqua, G.C.G.; Monteiro, S.N.; Azevedo, A.R.G. Could City Sewage Sludge Be Directly Used into Clay Bricks for Building Construction? A Comprehensive Case Study from Brazil. J. Build. Eng. 2020, 31, 101374. [Google Scholar] [CrossRef]

- Taki, K.; Gahlot, R.; Kumar, M. Utilization of Fly Ash Amended Sewage Sludge as Brick for Sustainable Building Material with Special Emphasis on Dimensional Effect. J. Clean. Prod. 2020, 275, 123942. [Google Scholar] [CrossRef]

- Świerczek, L.; Cieślik, B.M.; Konieczka, P. Challenges and Opportunities Related to the Use of Sewage Sludge Ash in Cement-Based Building Materials—A Review. J. Clean. Prod. 2021, 287, 125054. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The Possible Use of Sewage Sludge Ash (SSA) in the Construction Industry as a Way towards a Circular Economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- Ducoli, S.; Zacco, A.; Bontempi, E. Incineration of Sewage Sludge and Recovery of Residue Ash as Building Material: A Valuable Option as a Consequence of the COVID-19 Pandemic. J. Environ. Manag. 2021, 282, 111966. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Bertelsen, I.M.G.; Jensen, P.E.; Kirkelund, G.M. Sewage Sludge Ash as Resource for Phosphorous and Material for Clay Brick Manufacturing. Constr. Build. Mater. 2020, 249, 118684. [Google Scholar] [CrossRef]

- Mannina, G.; Presti, D.; Montiel-Jarillo, G.; Suárez-Ojeda, M.E. Bioplastic Recovery from Wastewater: A New Protocol for Polyhydroxyalkanoates (PHA) Extraction from Mixed Microbial Cultures. Bioresour. Technol. 2019, 282, 361–369. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Otari, S.V.; Jeon, J.M.; Gurav, R.; Choi, Y.K.; Bhatia, R.K.; Pugazhendhi, A.; Kumar, V.; Rajesh Banu, J.; Yoon, J.J.; et al. Biowaste-to-Bioplastic (Polyhydroxyalkanoates): Conversion Technologies, Strategies, Challenges, and Perspective. Bioresour. Technol. 2021, 326, 124733. [Google Scholar] [CrossRef]

- Roibás-Rozas, A.; Mosquera-Corral, A.; Hospido, A. Environmental Assessment of Complex Wastewater Valorisation by Polyhydroxyalkanoates Production. Sci. Total Environ. 2020, 744, 140893. [Google Scholar] [CrossRef] [PubMed]

- Van Der Hoek, J.P.; De Fooij, H.; Struker, A. Wastewater as a Resource: Strategies to Recover Resources from Amsterdam’s Wastewater. Resour. Conserv. Recycl. 2016, 113, 53–64. [Google Scholar] [CrossRef]

- Akyol, Ç.; Eusebi, A.L.; Cipolletta, G.; Bruni, C.; Foglia, A.; Giosuè, C.; Frison, N.; Tittarelli, F.; Canestrari, F.; Fatone, F. Cellulosic Materials Recovery from Municipal Wastewater: From Treatment Plants to the Market. In Clean Energy and Resource Recovery; Elsevier: Amsterdam, The Netherlands, 2022; pp. 125–136. [Google Scholar]

- Ezziat, L.; Elabed, A.; Ibnsouda, S.; El Abed, S. Challenges of Microbial Fuel Cell Architecture on Heavy Metal Recovery and Removal from Wastewater. Front. Energy Res. 2019, 7, 1. [Google Scholar] [CrossRef]

- Wang, F.; Lu, X.; Li, X.Y. Selective Removals of Heavy Metals (Pb2+, Cu2+, and Cd2+) from Wastewater by Gelation with Alginate for Effective Metal Recovery. J. Hazard. Mater. 2016, 308, 75–83. [Google Scholar] [CrossRef]

- Westerhoff, P.; Lee, S.; Yang, Y.; Gordon, G.W.; Hristovski, K.; Halden, R.U.; Herckes, P. Characterization, Recovery Opportunities, and Valuation of Metals in Municipal Sludges from U.S. Wastewater Treatment Plants Nationwide. Environ. Sci. Technol. 2015, 49, 9479–9488. [Google Scholar] [CrossRef]

- Perwitasari, D.S.; Muryanto, S.; Jamari, J.; Bayuseno, A.P. Optimization of Struvite Crystallization and Heavy Metal Recovery in Wastewater Using Response Surface Methodology. Orient. J. Chem. 2018, 34, 336–345. [Google Scholar] [CrossRef]

- Djukic, M.; Jovanoski, I.; Ivanovic, O.M.; Lazic, M.; Bodroza, D. Cost-Benefit Analysis of an Infrastructure Project and a Cost-Reflective Tariff: A Case Study for Investment in Wastewater Treatment Plant in Serbia. Renew. Sustain. Energy Rev. 2016, 59, 1419–1425. [Google Scholar] [CrossRef]

- Guven, H.; Tanik, A. Water-Energy Nexus: Sustainable Water Management and Energy Recovery from Wastewater in Eco-Cities. Smart Sustain. Built Environ. 2020, 9, 54–57. [Google Scholar] [CrossRef]

- Jaramillo, M.F.; Restrepo, I. Wastewater Reuse in Agriculture: A Review about Its Limitations and Benefits. Sustainability 2017, 9, 1734. [Google Scholar] [CrossRef]

- Libutti, A.; Gatta, G.; Gagliardi, A.; Vergine, P.; Pollice, A.; Beneduce, L.; Disciglio, G.; Tarantino, E. Agro-Industrial Wastewater Reuse for Irrigation of a Vegetable Crop Succession under Mediterranean Conditions. Agric. Water Manag. 2018, 196, 1–14. [Google Scholar] [CrossRef]

- Vergine, P.; Salerno, C.; Libutti, A.; Beneduce, L.; Gatta, G.; Berardi, G.; Pollice, A. Closing the Water Cycle in the Agro-Industrial Sector by Reusing Treated Wastewater for Irrigation. J. Clean. Prod. 2017, 164, 587–596. [Google Scholar] [CrossRef]

- Quist-Jensen, C.A.; Macedonio, F.; Drioli, E. Membrane Technology for Water Production in Agriculture: Desalination and Wastewater Reuse. Desalination 2015, 364, 17–32. [Google Scholar] [CrossRef]

- Bunani, S.; Yörükoğlu, E.; Yüksel, Ü.; Kabay, N.; Yüksel, M.; Sert, G. Application of Reverse Osmosis for Reuse of Secondary Treated Urban Wastewater in Agricultural Irrigation. Desalination 2015, 364, 68–74. [Google Scholar] [CrossRef]

- Tran, Q.K.; Schwabe, K.A.; Jassby, D. Wastewater Reuse for Agriculture: Development of a Regional Water Reuse Decision-Support Model (RWRM) for Cost-Effective Irrigation Sources. Environ. Sci. Technol. 2016, 50, 9390–9399. [Google Scholar] [CrossRef]

- Szendera, M.; Turek-Szytow, J. The Use of Sorption Properties of Selected Sorbents for the Removal of Organic Compounds on the Example of Catechol. In Contemporary Problems of Environmental Protection and Energy; Department of Waste Management Technologies and Devices, Silesian University of Technology: Gliwice, Poland, 2020; pp. 225–266. ISBN 9788395008771. [Google Scholar]

- Nzila, A.; Razzak, S.A.; Zhu, J. Bioaugmentation: An Emerging Strategy of Industrial Wastewater Treatment for Reuse and Discharge. Int. J. Environ. Res. Public Health 2016, 13, 846. [Google Scholar] [CrossRef] [PubMed]

- Cristóvaõ, R.O.; Botelho, C.M.; Martins, R.J.E.; Loureiro, J.M.; Boaventura, R.A.R. Fish Canning Industry Wastewater Treatment for Water Reuse—A Case Study. J. Clean. Prod. 2015, 87, 603–612. [Google Scholar] [CrossRef]

- Barbera, M.; Giovanni, G. Wastewater Treatment and Reuse in the Food Industry; Springer International Publishing: Cham, Switzerland, 2018; ISBN 9783319684413. [Google Scholar]

- Panepinto, D.; Fiore, S.; Zappone, M.; Genon, G.; Meucci, L. Evaluation of the Energy Efficiency of a Large Wastewater Treatment Plant in Italy. Appl. Energy 2016, 161, 404–411. [Google Scholar] [CrossRef]

- Gandiglio, M.; Lanzini, A.; Soto, A.; Leone, P.; Santarelli, M. Enhancing the Energy Efficiency of Wastewater Treatment Plants through Co-Digestion and Fuel Cell Systems. Front. Environ. Sci. 2017, 5, 1–21. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Wang, X.; Wu, J.; Li, F. Energy Self-Sufficient Wastewater Treatment Plants: Feasibilities and Challenges. Energy Procedia 2017, 105, 3741–3751. [Google Scholar] [CrossRef]

- Durdević, D.; Blecich, P.; Jurić, Ž. Energy Recovery from Sewage Sludge: The Case Case Study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef]

- Abuşoğlu, A.; Özahi, E.; İhsan Kutlar, A.; Al-jaf, H. Life Cycle Assessment (LCA) of Digested Sewage Sludge Incineration for Heat and Power Production. J. Clean. Prod. 2017, 142, 1684–1692. [Google Scholar] [CrossRef]

- Bianchini, A.; Bonfiglioli, L.; Pellegrini, M.; Saccani, C. Sewage Sludge Drying Process Integration with a Waste-to-Energy Power Plant. Waste Manag. 2015, 42, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Naqvi, S.R.; Tariq, R.; Hameed, Z.; Ali, I.; Naqvi, M.; Chen, W.H.; Ceylan, S.; Rashid, H.; Ahmad, J.; Taqvi, S.A.; et al. Pyrolysis of High Ash Sewage Sludge: Kinetics and Thermodynamic Analysis Using Coats-Redfern Method. Renew. Energy 2019, 131, 854–860. [Google Scholar] [CrossRef]

- Praspaliauskas, M.; Pedišius, N. A Review of Sludge Characteristics in Lithuania’s Wastewater Treatment Plants and Perspectives of Its Usage in Thermal Processes. Renew. Sustain. Energy Rev. 2017, 67, 899–907. [Google Scholar] [CrossRef]

- Campello, L.D.; Barros, R.M.; Tiago Filho, G.L.; dos Santos, I.F.S. Analysis of the Economic Viability of the Use of Biogas Produced in Wastewater Treatment Plants to Generate Electrical Energy. Environ. Dev. Sustain. 2021, 23, 2614–2629. [Google Scholar] [CrossRef]

- Shen, Y.; Linville, J.L.; Urgun-Demirtas, M.; Mintz, M.M.; Snyder, S.W. An Overview of Biogas Production and Utilization at Full-Scale Wastewater Treatment Plants (WWTPs) in the United States: Challenges and Opportunities towards Energy-Neutral WWTPs. Renew. Sustain. Energy Rev. 2015, 50, 346–362. [Google Scholar] [CrossRef]

- Budych-Gorzna, M.; Smoczynski, M.; Oleskowicz-Popiel, P. Enhancement of Biogas Production at the Municipal Wastewater Treatment Plant by Co-Digestion with Poultry Industry Waste. Appl. Energy 2016, 161, 387–394. [Google Scholar] [CrossRef]

- Asadi, M.; Guo, H.; McPhedran, K. Biogas Production Estimation Using Data-Driven Approaches for Cold Region Municipal Wastewater Anaerobic Digestion. J. Environ. Manag. 2020, 253, 109708. [Google Scholar] [CrossRef]

- Mirmasoumi, S.; Ebrahimi, S.; Saray, R.K. Enhancement of Biogas Production from Sewage Sludge in a Wastewater Treatment Plant: Evaluation of Pretreatment Techniques and Co-Digestion under Mesophilic and Thermophilic Conditions. Energy 2018, 157, 707–717. [Google Scholar] [CrossRef]

- Zubaidi, S.L.; Ortega-Martorell, S.; Al-Bugharbee, H.; Olier, I.; Hashim, K.S.; Gharghan, S.K.; Kot, P.; Al-Khaddar, R. Urban Water Demand Prediction for a City That Suffers from Climate Change and Population Growth: Gauteng Province Case Study. Water 2020, 12, 1885. [Google Scholar] [CrossRef]

- Zarei, N.; Azari, A.; Heidari, M.M. Improvement of the Performance of NSGA-II and MOPSO Algorithms in Multi-Objective Optimization of Urban Water Distribution Networks Based on Modification of Decision Space. Appl. Water Sci. 2022, 12, 133. [Google Scholar] [CrossRef]

- AL-Washali, T.; Sharma, S.; Kennedy, M. Methods of Assessment of Water Losses in Water Supply Systems: A Review. Water Resour. Manag. 2016, 30, 4985–5001. [Google Scholar] [CrossRef]

- Button, C.; Ng, J.L.; Burnay, C.; van Duijn, T. Application of Ecological Dynamics Principles to Drowning Prevention. Asian J. Sport Exerc. Psychol. 2022, 2, 59–66. [Google Scholar] [CrossRef]

- European Commission Communication from Commission: An EU Strategy to Harness the Potential of Offshore Renewable Energy for a Climate Neutral Future; COM no. 741; European Commission: Brussels, Belgium, 2020.

- Azis Aziz, N.F.; Ramli, N.A.; Hamid, M.F.A. Energy Efficiency of Wastewater Treatment Plant through Aeration System. Desalin. Water Treat. 2019, 156, 38–45. [Google Scholar] [CrossRef]

- Luna, T.; Ribau, J.; Figueiredo, D.; Alves, R. Improving Energy Efficiency in Water Supply Systems with Pump Scheduling Optimization. J. Clean. Prod. 2019, 213, 342–356. [Google Scholar] [CrossRef]

- Feng, L.; Chen, B. Energy-Water Nexus of Wastewater Treatment System: Conceptual Model and Framework. Energy Procedia 2016, 104, 141–145. [Google Scholar] [CrossRef]

- Kacprzak, M.J.; Kupich, I. The Specificities of the Circular Economy (CE) in the Municipal Wastewater and Sewage Sludge Sector—Local Circumstances in Poland. Clean Technol. Environ. Policy 2021, 25, 519–535. [Google Scholar] [CrossRef]

- Anielak, A.M.; Kłeczek, A. Innovative Method of Extraction of Humic Substances from Digested Sludge and Assessment of the Impact of Their on the Growth of Selected Plants. Energies 2023, 16, 1283. [Google Scholar] [CrossRef]

- Chrispim, M.C.; Scholz, M.; Nolasco, M.A. Biogas Recovery for Sustainable Cities: A Critical Review of Enhancement Techniques and Key Local Conditions for Implementation. Sustain. Cities Soc. 2021, 72, 103033. [Google Scholar] [CrossRef]

- Som Gupta, A. Feasibility Study for Production of Biogas from Wastewater and Sewage Sludge-Development of a Sustainability Assessment Framework and Its Application. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2020. [Google Scholar]

- Neczaj, E.; Grosser, A. Circular Economy in Wastewater Treatment Plant–Challenges and Barriers. In Proceedings of the 3rd EWaS International Conference on “Insights on the Water-Energy-Food Nexus”, Lefkada Island, Greece, 27–30 June 2018. [Google Scholar] [CrossRef]

- Krüger, O.; Adam, C. Recovery Potential of German Sewage Sludge Ash. Waste Manag. 2015, 45, 400–406. [Google Scholar] [CrossRef] [PubMed]

- Smol, M. Inventory of Wastes Generated in Polish Sewage Sludge Incineration Plants and Their Possible Circular Management Directions. Resources 2020, 9, 91. [Google Scholar] [CrossRef]

- Power, C.; McNabola, A.; Coughlan, P. Development of an Evaluation Method for Hydropower Energy Recovery in Wastewater Treatment Plants: Case Studies in Ireland and the UK. Sustain. Energy Technol. Assess. 2014, 7, 166–177. [Google Scholar] [CrossRef]

- Foglia, A.; Bruni, C.; Cipolletta, G.; Eusebi, A.L.; Frison, N.; Katsou, E.; Akyol, Ç.; Fatone, F. Assessing Socio-Economic Value of Innovative Materials Recovery Solutions Validated in Existing Wastewater Treatment Plants. J. Clean. Prod. 2021, 322, 129048. [Google Scholar] [CrossRef]

- Wiśniowska, E.; Kowalczyk, M. Recovery of Cellulose, Extracellular Polymeric Substances and Microplastics from Sewage Sludge: A Review. Energies 2022, 15, 7744. [Google Scholar] [CrossRef]

- European Commission Consultative Communication on the Sustainable Use of Phosphorus; COM no. 517 Final; European Commission: Brussels, Belgium, 2013.

- Smol, M.; Preisner, M.; Bianchini, A.; Rossi, J.; Hermann, L.; Schaaf, T.; Kruopiene, J.; Pamakštys, K.; Klavins, M.; Ozola-Davidane, R.; et al. Strategies for Sustainable and Circular Management of Phosphorus in the Baltic Sea Region: The Holistic Approach of the InPhos Project. Sustainability 2020, 12, 2567. [Google Scholar] [CrossRef]

- Herzel, H.; Krüger, O.; Hermann, L.; Adam, C. Sewage Sludge Ash—A Promising Secondary Phosphorus Source for Fertilizer Production. Sci. Total Environ. 2016, 542, 1136–1143. [Google Scholar] [CrossRef]

- Smol, M. Phosphorus Extraction and Sludge Dissolution; Butterworth-Heinemann: Oxford, UK, 2019; ISBN 9780128159071. [Google Scholar]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage Sludge Disposal Strategies for Sustainable Development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- National Center for Research and Development Regulations for the Conduct of Procedure No. 92/20/PU/P88 for the Award of a Contract for Research and Development Services under the Project: “Oczyszczalnia Przyszłości”; National Center for Research and Development Regulations: Warsaw, Poland, 2020.

- United Nations Resolution Adopted by the General Assembly on 25 September 2015. Transforming Our World: The 2030 Agenda for Sustainable Development; A/RES/70/1; United Nations General Assembly: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

| Policy Area | Law Document | Recommendations and Objectives |

|---|---|---|

| Circular Economy | Zero-waste program for Europe (COM no. 398, 2014) [18] |

|

| First CE Action Plan (COM no. 614, 2015) [6] |

| |

| Second CE Action Plan (COM no. 98, 2020) [7] |

| |

| Fertilizers | Regulation on EU fertilizing products (EU 2019/2019) [19] |

|

| Water | Regulation on EU water reuse (EU 2020/741) [20] |

|

| No. | Country | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Austria | n.d. | 93.90 | n.d. | 94.50 | n.d. | 95.00 | n.d. | 95.20 | n.d. | 95.95 | 95.95 | 96.04 |

| 2 | Belgium | 88.50 | 82.20 | 84.40 | 86.71 | 87.21 | 87.48 | 87.79 | 87.96 | 88.08 | 87.22 | 86.88 | 87.52 |

| 3 | Bulgaria | 70.40 | 70.62 | 74.09 | 74.33 | 74.70 | 74.88 | 75.50 | 75.69 | 76.03 | 76.19 | 76.42 | 76.25 |

| 4 | Czechia | 81.10 | 82.30 | 83.40 | 83.00 | 84.70 | 83.90 | 84.20 | 84.70 | 85.50 | 85.50 | 85.50 | 86.10 |

| 5 | Denmark | 89.80 | 90.00 | 90.30 | 90.50 | 90.60 | 90.70 | 90.90 | 91.40 | 91.60 | 91.70 | 91.80 | 92.00 |

| 6 | Germany | n.d. | 95.70 | 95.90 | 96.01 | 96.16 | 96.48 | 96.80 | 97.12 | n.d. | n.d. | n.d. | n.d. |

| 7 | Estonia | 81.00 | 82.00 | 82.00 | 82.00 | 82.00 | 82.00 | 83.00 | 83.00 | 83.00 | 83.00 | 83.00 | 83.00 |

| 8 | Finland | 83.00 | 83.00 | 83.00 | 83.00 | 83.00 | 85.00 | 84.00 | 84.00 | 85.00 | 85.00 | 85.00 | 85.00 |

| 9 | Ireland | 77.00 | n.d. | 63.80 | 63.89 | 63.97 | 64.06 | 64.14 | 64.22 | 64.22 | 64.22 | 64.22 | n.d. |

| 10 | Greece | 87.30 | 87.30 | 88.10 | 92.04 | 92.80 | 92.80 | 93.40 | 93.40 | 94.80 | 94.80 | 94.20 | n.d. |

| 11 | Spain | n.d. | 98.00 | n.d. | 95.58 | n.d. | 96.39 | n.d. | 96.52 | n.d. | 96.52 | n.d. | n.d. |

| 12 | France | n.d. | 82.00 | 82.00 | 82.00 | 82.00 | 82.00 | 82.00 | 82.00 | 82.00 | 82.00 | 82.00 | 82.00 |

| 13 | Croatia | n.d. | n.d. | 54.60 | 54.60 | 54.60 | 54.60 | 54.60 | 54.60 | 54.60 | 54.60 | 54.60 | 54.60 |

| 14 | Italy | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | 87.80 | n.d. | n.d. |

| 15 | Cyprus | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | 82.65 | n.d. | n.d. |

| 16 | Latvia | 65.71 | 65.22 | 71.41 | 72.58 | 73.34 | 73.12 | 74.81 | 72.99 | 77.75 | 75.78 | 80.91 | 80.11 |

| 17 | Lithuania | n.d. | 63.77 | 65.12 | 67.00 | 67.00 | 69.61 | 72.45 | 73.67 | 73.91 | 75.88 | 76.64 | 77.08 |

| 18 | Luxembourg | n.d. | 97.10 | 99.00 | 99.00 | 99.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| 19 | Hungary | 72.00 | 72.30 | 72.70 | 74.00 | 74.99 | 76.64 | 78.56 | 80.65 | 81.37 | 82.00 | 82.57 | 82.78 |

| 20 | Malta | 98.32 | 98.34 | 98.37 | 98.39 | 98.43 | 98.47 | 98.51 | 98.53 | 98.81 | 98.85 | 98.90 | 98.92 |

| 21 | The Netherlands | n.d. | 99.30 | 99.40 | 99.40 | 99.40 | 99.40 | 99.43 | 99.45 | 99.50 | 99.50 | 99.50 | 99.52 |

| 22 | Poland | 64.20 | 64.60 | 65.60 | 68.70 | 70.30 | 71.40 | 72.60 | 73.59 | 73.67 | 74.12 | 75.00 | 75.38 |

| 23 | Portugal | 81.30 | n.d. | 80.00 | 81.00 | 82.00 | 82.00 | 83.00 | 84.00 | 85.82 | 85.00 | n.d. | n.d. |

| 24 | Romania | 43.10 | 43.50 | 43.50 | 46.90 | 46.70 | 47.20 | 47.80 | 49.20 | 50.90 | 52.90 | 54.30 | 56.00 |

| 25 | Slovenia | 62.60 | 62.60 | 62.60 | 62.60 | 62.60 | 62.60 | 62.60 | 63.53 | 66.51 | 67.78 | 68.02 | 67.43 |

| 26 | Slovakia | 59.50 | 60.40 | 61.60 | 62.40 | 63.60 | 64.70 | 65.20 | 66.40 | 67.70 | 68.40 | 69.13 | 69.70 |

| 27 | Sweden | 86.00 | 86.00 | 86.00 | 87.00 | 87.00 | 87.00 | 87.00 | 87.00 | 87.00 | 88.00 | 88.00 | n.d. |

| EU average | 75.93 | 80.01 | 77.69 | 79.89 | 78.96 | 80.70 | 79.93 | 81.55 | 80.35 | 82.13 | 81.48 | 81.55 | |

| Pathway | Example | References |

|---|---|---|

| Materials pathway | Phosphorus recovery from liquid phase | [36,37,38,39] |

| Phosphorus recovery from sewage sludge | [40,41] | |

| Phosphorus recovery from sewage sludge ash | [42,43,44,45,46] | |

| Nitrogen recovery from liquid phase | [39,47,48,49,50] | |

| Nitrogen recovery sewage sludge | [51,52,53,54,55] | |

| Sewage sludge as fertilizer | [56,57,58,59,60,61,62] | |

| Sewage sludge as building | [63,64,65,66] | |

| Sewage sludge ash as building materials | [67,68,69,70,71] | |

| Bioplastics from liquid phase | [72,73,74] | |

| Paper/cellulose recovery | [75,76] | |

| Metal and mineral recovery | [77,78,79,80] | |

| Water pathway | Rainwater harvesting | [81,82] |

| Reused for agriculture and aquaculture | [83,84,85,86,87,88] | |

| Reused water for industry | [89,90,91,92] | |

| Energy pathway | Energy saving at WWTP and distribution systems | [93,94,95,96] |

| Biosolid to energy production (gas, electricity and heat) | [97,98,99,100,101] | |

| Renewable energy | [102,103,104,105,106] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smol, M. Circular Economy in Wastewater Treatment Plant—Water, Energy and Raw Materials Recovery. Energies 2023, 16, 3911. https://doi.org/10.3390/en16093911

Smol M. Circular Economy in Wastewater Treatment Plant—Water, Energy and Raw Materials Recovery. Energies. 2023; 16(9):3911. https://doi.org/10.3390/en16093911

Chicago/Turabian StyleSmol, Marzena. 2023. "Circular Economy in Wastewater Treatment Plant—Water, Energy and Raw Materials Recovery" Energies 16, no. 9: 3911. https://doi.org/10.3390/en16093911

APA StyleSmol, M. (2023). Circular Economy in Wastewater Treatment Plant—Water, Energy and Raw Materials Recovery. Energies, 16(9), 3911. https://doi.org/10.3390/en16093911