Innovative Method of Extraction of Humic Substances from Digested Sludge and Assessment of the Impact of Their on the Growth of Selected Plants

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Procedure of HS Extraction and Analytics

2.3. Phytotestkit Procedure

3. Results and Discussion

3.1. Characteristics of Digested Sludge

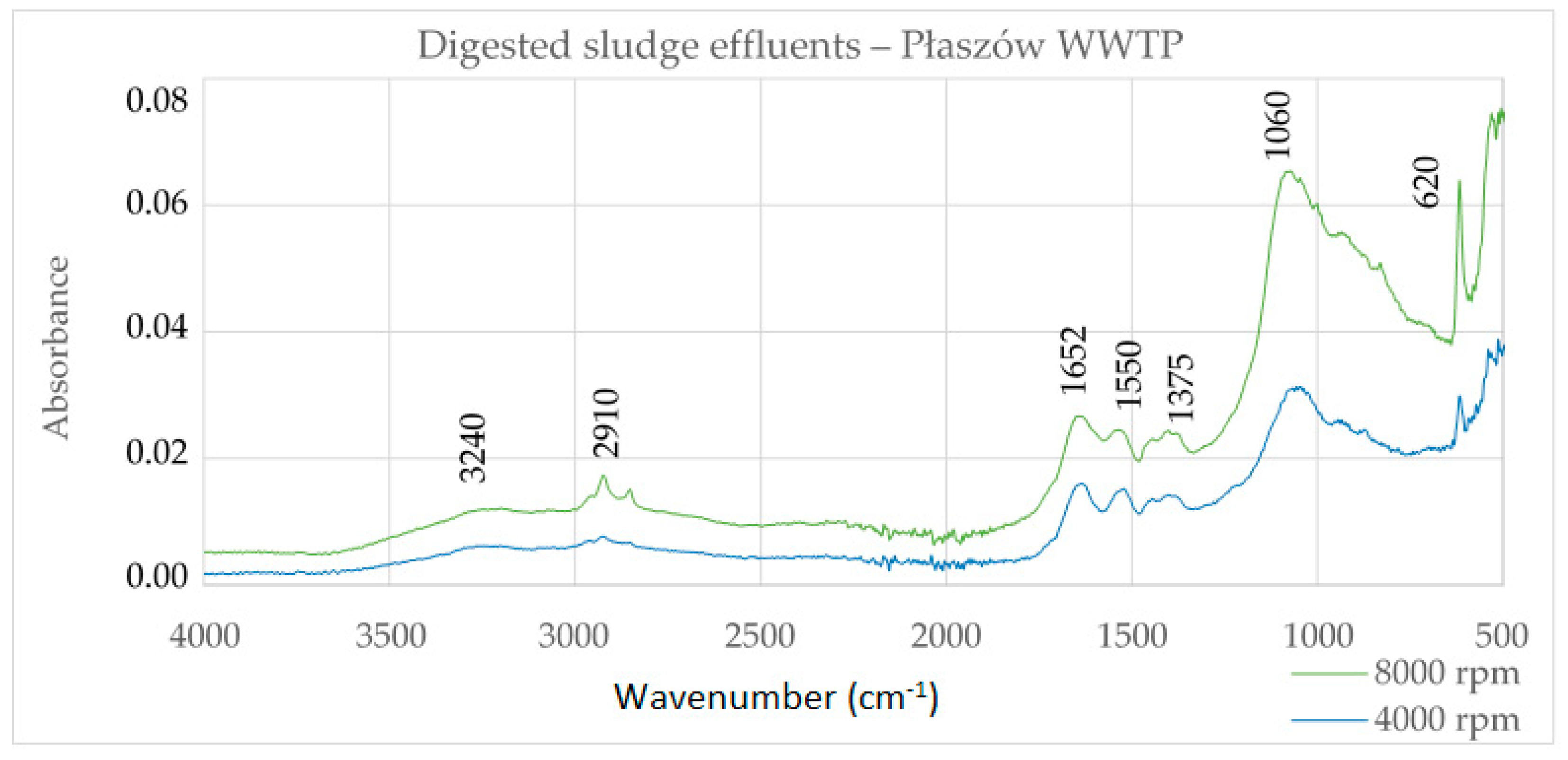

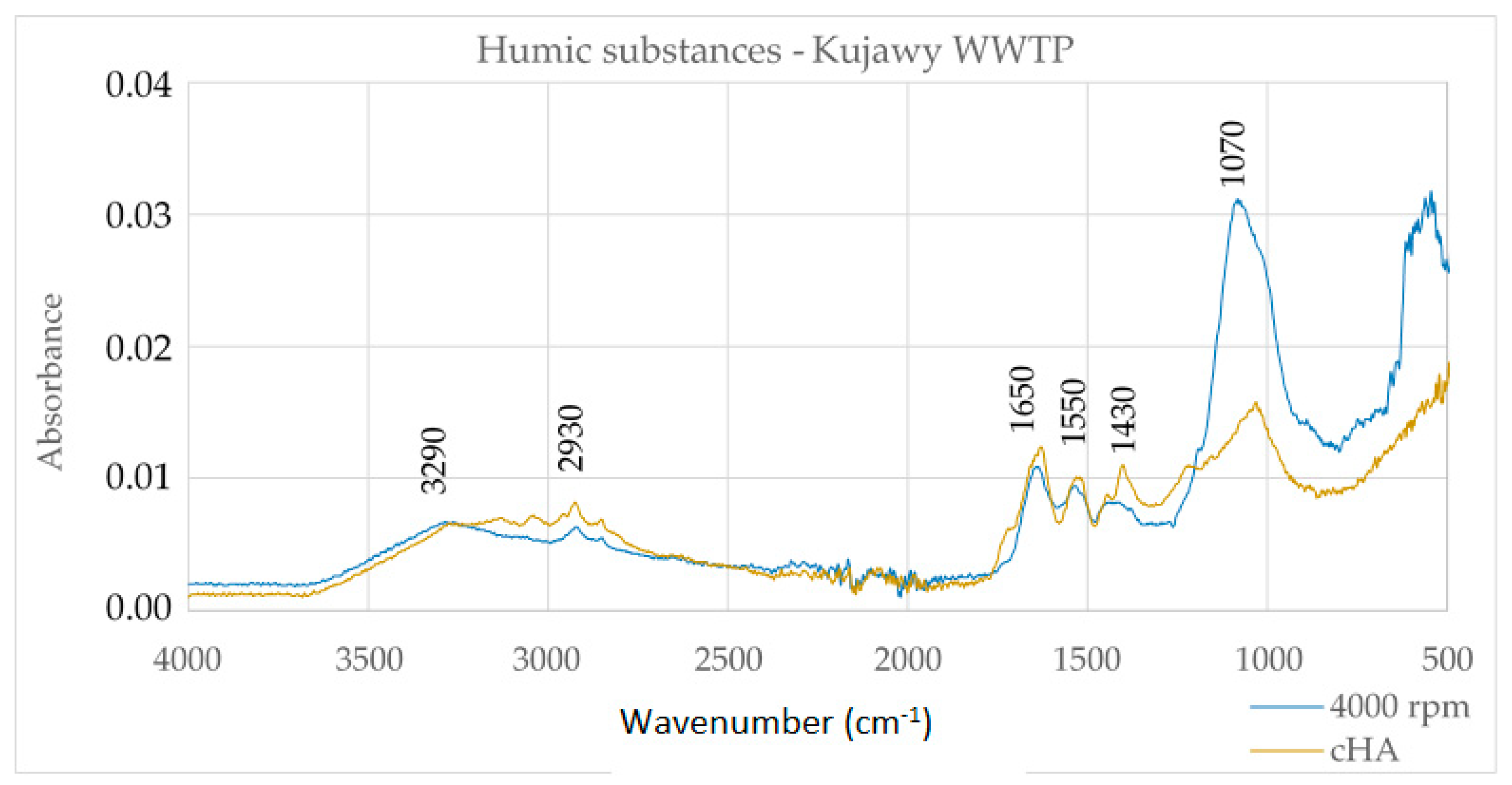

3.2. Characteristics of HS Extracted by an Innovative Method Developed by the Authors

3.3. Microbiological Testing

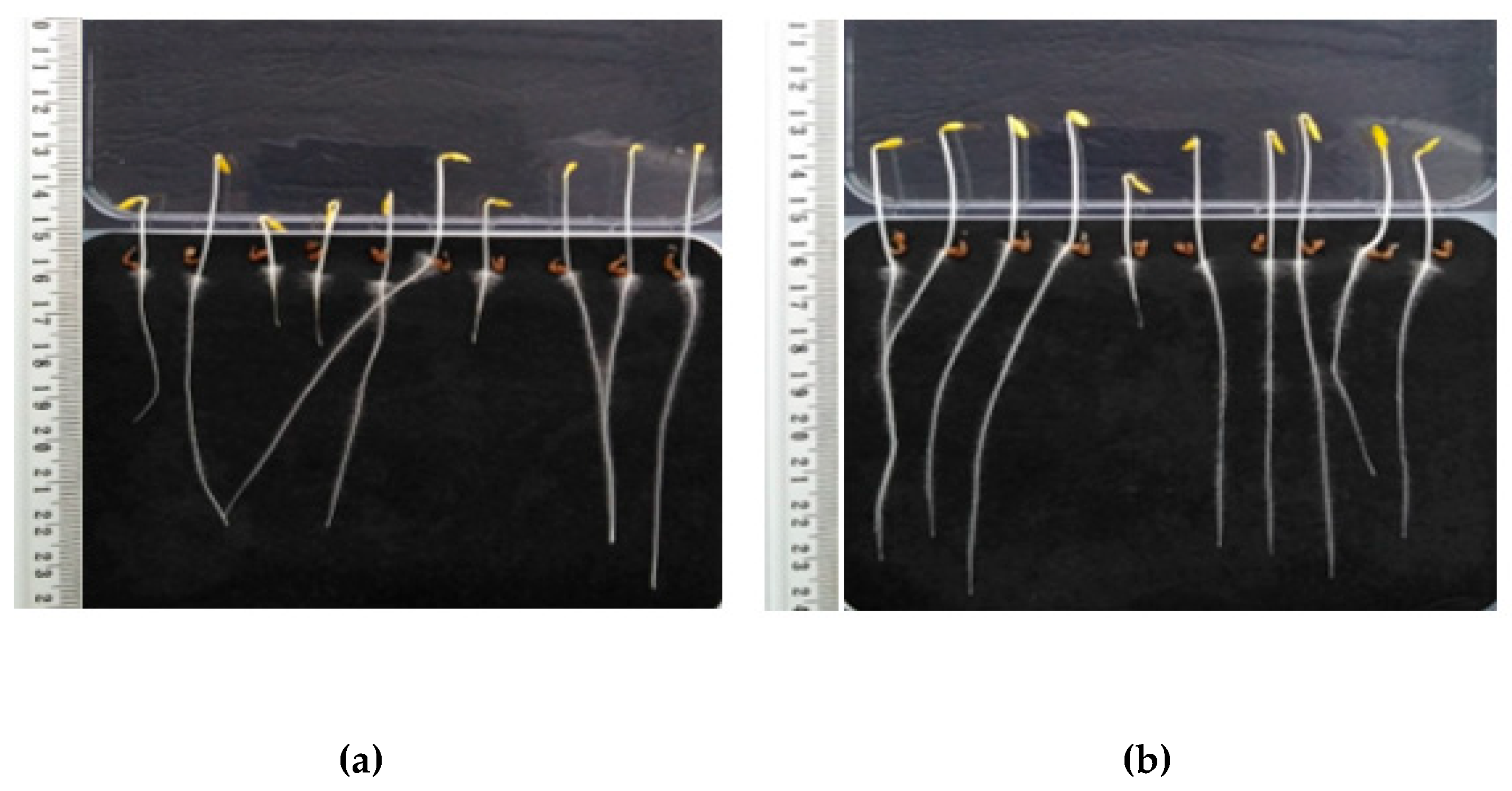

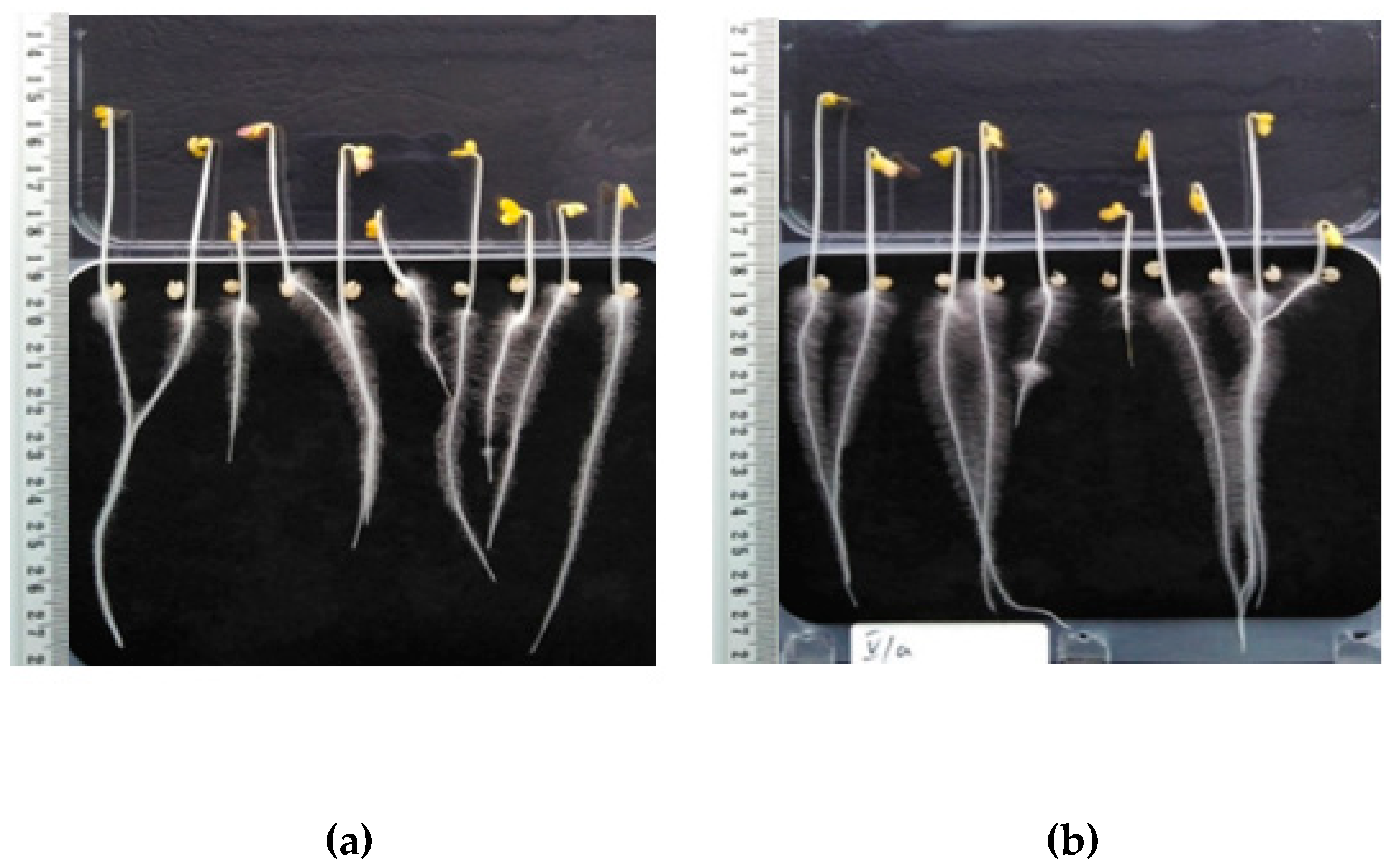

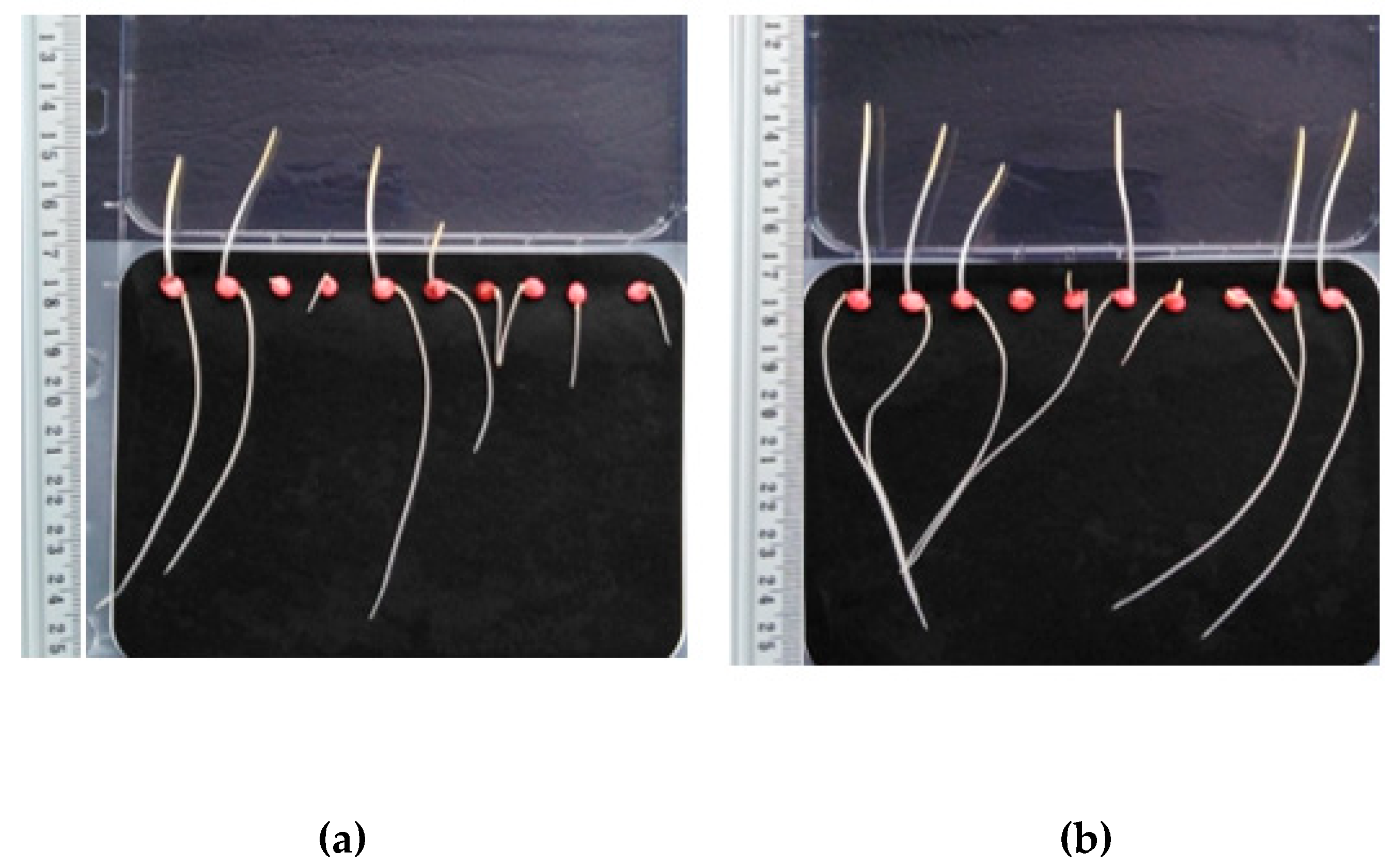

3.4. Effect of Extracted HS on the Growth of Selected Plants—Phytotestkit

3.5. Advantages of the Author’s Method

4. Conclusions

- The presented author’s method of obtaining HS from digested sewage sludge is a simple and economically justified extraction method that can be used on an industrial scale. A centrifugation speed of 4000 rpm can be used in the extraction process.

- As a result of extraction using the author’s method, the number of inorganic micropollutants in HS was reduced in relation to the initial digested sewage sludge.

- HS isolated from digested sewage sludge does not contain Salmonella Sp. and live ATT parasites.

- For the tested plants, positive effects of using HS extracted from digested sewage sludge were obtained in comparison with traditional NP fertilization.

- The results of the Phytotestkit studies may indicate that HS isolated from digested sewage sludge, containing relatively high amounts of nutrients necessary for plants (including N and P), are a good component of a fertilizing/biostimulating substance. Positive effects may also be influenced by the property of HS, which increases the bioavailability of nutrients for plants.

- The use of biostimulants derived from biowaste, especially HS, can contribute to reducing the use of chemical synthetic fertilizers.

- There are no legal grounds for the use of the described HS in agriculture (possible organic contamination, e.g., pharmaceuticals), but the prospect of using the obtained HS in soil reclamation is promising.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, L.; Geelen, D. Developing biostimulants from agro-food and industrial by-products. Front. Plant Sci. 2018, 9, 1567. [Google Scholar] [CrossRef] [PubMed]

- Canellas, L.P.; Canellas, N.O.; da Irineu, L.E.S.; Olivares, F.L.; Piccolo, A. Plant chemical priming by humic acids. Chem. Biol. Technol. Agric. 2020, 7, 1–17. [Google Scholar] [CrossRef]

- Jindo, K.; Martim, S.A.; Navarro, E.C.; Pérez-Alfocea, F.; Hernandez, T.; Garcia, C.; Canellas, L.P. Root growth promotion by humic acids from composted and non-composted urban organic wastes. Plant Soil 2012, 353, 209–220. [Google Scholar] [CrossRef]

- Palumbo, G.; Schiavon, M.; Nardi, S.; Ertani, A.; Celano, G.; Colombo, C.M. Biostimulant potential of humic acids extracted from an amendment obtained via combination of olive mill wastewaters (OMW) and a pre-treated organic material derived from municipal solid waste (MSW). Front. Plant Sci. 2018, 9, 1028. [Google Scholar] [CrossRef] [PubMed]

- Qi, G.; Yue, D.; Nie, Y. Characterization of humic substances in bio-treated municipal solid waste landfill leachate. Front. Environ. Sci. Eng. 2012, 6, 711–716. [Google Scholar] [CrossRef]

- Xiaoli, C.; Guixiang, L.; Xin, Z.; Yongxia, H.; Youcai, Z. Fluorescence excitation–emission matrix combined with regional integration analysis to characterize the composition and transformation of humic and fulvic acids from landfill at different stabilization stages. Waste Manag. 2012, 32, 438–447. [Google Scholar] [CrossRef] [PubMed]

- Orliński, T.; Anielak, A.M. Characteristics of fulvic acids generated in communes waste landfills. Arch. Environ. Prot. 2021, 47, 41–52. [Google Scholar]

- Gu, N.; Liu, J.; Ye, J.; Chang, N.; Li, Y.Y. Bioenergy, ammonia and humic substances recovery from municipal solid waste leachate: A review and process integration. Bioresour. Technol. 2019, 293, 122159. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, C.; Li, X.; Lin, J.; Liao, Y.; Jin, Z. Recovery of humic substances from leachate nanofiltration concentrate by a two-stage process of tight ultrafiltration membrane. J. Clean. Prod. 2017, 161, 84–94. [Google Scholar] [CrossRef]

- Ye, W.; Liu, H.; Jiang, M.; Lin, J.; Ye, K.; Fang, S.; He, Z. Sustainable management of landfill leachate concentrate through recovering humic substance as liquid fertilizer by loose nanofiltration. Water Res. 2019, 157, 555–563. [Google Scholar] [CrossRef]

- Kulikowska, D.; Bernat, K.; Wojnowska-Baryła, I.; Klik, B.; Michałowska, S.; Kasiński, S. Stabilizate from autoclaved municipal solid waste as a source of valuable humic substances in a waste circular economy. Waste Biomass Valorization 2020, 11, 6147–6157. [Google Scholar] [CrossRef]

- Kulikowska, D.; Gusiatin, Z.M.; Bułkowska, K.; Kierklo, K. Humic substances from sewage sludge compost as washing agent effectively remove Cu and Cd from soil. Chemosphere 2015, 136, 42–49. [Google Scholar] [CrossRef] [PubMed]

- Angelova, V.R.; Akova, V.I.; Artinova, N.S.; Ivanov, K.I. The effect of organic amendments on soil chemical characteristics. Bulg. J. Agric. Sci. 2013, 19, 958–971. [Google Scholar]

- Ayuso, M.; Hernández, T.; García, C.; Pascual, J.A. A comparative study of the effect on barley growth of humic substances extracted from municipal wastes and from traditional organic materials. J. Sci. Food Agric. 1996, 72, 493–500. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Jin, Y.; Zou, S.; Li, C. Recovery of sludge humic acids with alkaline pretreatment and its impact on subsequent anaerobic digestion. J. Chem. Technol. Biotechnol. 2014, 89, 707–713. [Google Scholar] [CrossRef]

- Cristina, G.; Camelin, E.; Ottone, C.; Garofalo, S.F.; Jorquera, L.; Castro, M.; Tommasi, T. Recovery of humic acids from anaerobic sewage sludge: Extraction, characterization and encapsulation in alginate beads. Int. J. Biol. Macromol. 2020, 164, 277–285. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Zou, S.; Li, C. Extracting humic acids from digested sludge by alkaline treatment and ultrafiltration. J. Mater. Cycles Waste Manag. 2014, 16, 93–100. [Google Scholar] [CrossRef]

- Chen, Y.O.N.A.; Clapp, C.E.; Magen, H. Mechanisms of plant growth stimulation by humic substances: The role of organo-iron complexes. Soil Sci. Plant Nutr. 2004, 50, 1089–1095. [Google Scholar] [CrossRef]

- Rose, M.T.; Patti, A.F.; Little, K.R.; Brown, A.L.; Jackson, W.R.; Cavagnaro, T.R. A meta-analysis and review of plant-growth response to humic substances: Practical implications for agriculture. Adv. Agron. 2014, 124, 37–89. [Google Scholar]

- Nardi, S.; Schiavon, M.; Francioso, O. Chemical structure and biological activity of humic substances define their role as plant growth promoters. Molecules 2021, 26, 2256. [Google Scholar] [CrossRef] [PubMed]

- Rouphael, Y.; Colla, G. Synergistic biostimulatory action: Designing the next generation of plant biostimulants for sustainable agriculture. Front. Plant Sci. 2018, 9, 1655. [Google Scholar] [CrossRef] [PubMed]

- Canellas, L.P.; Olivares, F.L.; Okorokova-Façanha, A.L.; Façanha, A.R. Humic acids isolated from earthworm compost enhance root elongation, lateral root emergence, and plasma membrane H+-ATPase activity in maize roots. Plant Physiol. 2002, 130, 1951–1957. [Google Scholar] [CrossRef] [PubMed]

- Bento, L.R.; Melo, C.A.; Ferreira, O.P.; Moreira, A.B.; Mounier, S.; Piccolo, A.; Spaccini, R.; Bisinoti, M.C. Humic extracts of hydrochar and Amazonian Dark Earth: Molecular characteristics and effects on maize seed germination. Sci. Total Environ. 2020, 708, 135000. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.Y.A.; Ibrahim, M.E.H.; Zhou, G.; Nimir, N.E.A.; Elsiddig, A.M.I.; Jiao, X.; Zhu, G.; Salih, E.G.I.; Suliman, M.S.E.; Elradi, S.B.M. Gibberellic acid and nitrogen efficiently protect early seedlings growth stage from salt stress damage in Sorghum. Sci. Rep. 2021, 11, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.Y.A.; Ibrahim, M.E.H.; Zhou, G.; Nimir, N.E.A.; Jiao, X.; Zhu, G.; Elsiddig, A.M.I.; Suliman, M.S.E.; Elradi, S.B.M.; Yue, W. Exogenous jasmonic acid and humic acid increased salinity tolerance of sorghum. Agron. J. 2020, 112, 871–884. [Google Scholar] [CrossRef]

- Anielak, A.M.; Świderska, R. The influence of the adsorbents’ electrokinetic potential on the adsorption process of humic substances. Environ. Prot. Eng. 2001, 27, 23–34. [Google Scholar]

- Tsinghua University. Method for Extracting Humic Acid Substances from Methane Fluid. CN102146101, 10 August 2011. [Google Scholar]

- Gyo, H. Extacting Method for Humic Acid and Fulvic Acid from Humic Substances. KR20120108816, 5 October 2012. [Google Scholar]

- Dong, S.H. Manufacturing Method of Liqufied Activated Humic Substances. KR20040008104, 28 January 2004. [Google Scholar]

- Qingdao Laoxiang Tea Product, Mountain tea tree biological fertilizer. CN103708941, 9 April 2014.

- Bowen, Y. Preparation method of antibacterial and corrosion-free type air conditioner cleaning agent. CN106753829, 31 May 2017. [Google Scholar]

- Gyo, H. Bacterial Enrichment Method of Using Bacterial Enrichment Composition Comprising Humic Acid. KR20120108795, 5 October 2012. [Google Scholar]

- Depuracque. Process for recovering humic substances from percolate originating from urban solid refuse dumps or the like, and humic substance obtained by the process. IT2012VE0013, 11 October 2013. [Google Scholar]

- Depuraque. Process for Recovering Humic Substances from Percolate Originating from Urban Solid Refuse Dumps or the Like and Humic Substances Obtained by Said Process. RO-130328, 30 June 2015. [Google Scholar]

- Luo, I. Sewage Factory Sludge Produced Organic Acid Fertilizer and its Product. CN1966474, 23 May 2007. [Google Scholar]

- Gyo, H. Bacterial Reduction Compostion Comprising Fulvic Acid. KR20120108820, 5 October 2012. [Google Scholar]

- Beijing Goldenway Bio Tech. Biochemical Humic Acid Product Prepared from Kitchen Waste and the Method of Preparing the Same. CN101941851, 12 January 2011. [Google Scholar]

- Xingyi, F. Hua Humic Acid. CN104072378, 1 October 2014. [Google Scholar]

- Xi An Lanxin Organic Fertilizer. High-Activity Composite Humic Acid and Preparation Process Thereof. CN106396762, 15 February 2017. [Google Scholar]

- Oktaba, W. Elementy Statystyki Matematycznej i Metodyka Doświadczalnictwa, 4th ed.; Państwowe Wydawnictwo Naukowe: Warsaw, Poland, 1976. [Google Scholar]

- Anielak, A.M.; Kłeczek, A. Humic acids in the digested sludge and their properties. Materials 2022, 15, 1475. [Google Scholar] [CrossRef]

| Kujawy WWTP, mg/kg DM 1 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mn | Ba | K | Ag | Mg | Ca | As | Cr | Cd | Cu | Ni | Pb | Hg | Zn |

| 203.3 | 232.7 | 10,349 | <10 | 14.96 | 63.50 | <10 | 312.0 | <10 | 232.7 | 34.4 | 16.9 | 0.85 | 1182 |

| Płaszów WWTP, mg/kg DM | |||||||||||||

| Mn | Ba | K | Ag | Mg | Ca | As | Cr | Cd | Cu | Ni | Pb | Hg | Zn |

| 230.0 | 242.3 | 13,183 | <10 | 24.30 | 44.60 | <10 | 158.0 | <10 | 274.3 | 68.5 | 33.6 | 0.54 | 1279 |

| DR (%) | ROI (%) | LOI (%) | TOC (mg/kg DM) | |

|---|---|---|---|---|

| Number of measurements, n | 51 | 51 | 51 | 3 |

| Year 2020 | 3.0 | 42.8 | 57.2 | 58.719 |

| Year 2019 | 3.0 | 41.8 | 58.2 | – |

| Kujawy WWTP, mg/kg Effluents | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mn | Ba | K | Ag | Mg | Ca | As | Cr | Cd | Cu | Ni | Pb | Zn | Fe | Al | TOC | |

| 0.07 | <0.05 | 168.7 | <0.05 | 7.6 | 42.0 | <0.05 | <0.05 | <0.05 | <0.05 | 0.14 | 0.12 | 0.11 | 1.86 | 0.51 | 218 | |

| Płaszów WWTP, mg/kg effluents | ||||||||||||||||

| Mn | Ba | K | Ag | Mg | Ca | As | Cr | Cd | Cu | Ni | Pb | Hg | Zn | Fe | Al | TOC |

| 0.065 | 0.105 | 343.0 | <0.05 | 8.0 | 72.0 | <0.05 | <0.05 | <0.05 | <0.05 | 0.12 | <0.05 | <0.0004 | 0.127 | 8.70 | 0.68 | 240 |

| Centrifuge Speed (rpm) | Sample | Elementals Content of Ash-Free Mass (%) | Atomic Ratios (–) | Ash Content (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | O | O/C | H/C | C/N | O/H | |||

| Płaszów WWTP | ||||||||||

| 10,000 | cFA1 * | 44.83 | 6.47 | 5.23 | 43.47 | 0.73 | 1.73 | 10.08 | 0.42 | 14.66 |

| 8000 | HS1 | 49.28 | 7.52 | 10.18 | 33.02 | 0.50 | 1.83 | 5.63 | 0.27 | 24.33 |

| 4000 | HS2 | 48.02 | 7.37 | 9.56 | 35.05 | 0.55 | 1.84 | 5.88 | 0.30 | 22.83 |

| Kujawy WWTP | ||||||||||

| 10,000 | cFA2 * | 43.33 | 6.31 | 4.71 | 45.65 | 0.79 | 1.75 | 10.62 | 0.45 | 15.64 |

| cHA ** | 55.40 | 7.36 | 8.08 | 29.16 | 0.39 | 1.59 | 7.97 | 0.24 | 14.09 | |

| 4000 | HS3 | 50.06 | 7.92 | 8.53 | 33.49 | 0.50 | 1.90 | 6.84 | 0.26 | 27.31 |

| Centrifuge Speed (rpm) | Sample | Elementals Content of Ash-Free Mass (%) | Ash Content (%) | |||

|---|---|---|---|---|---|---|

| C | H | N | O | |||

| Płaszów WWTP | ||||||

| 8000 | DS1 * | 46.85 | 7.69 | 8.47 | 36.99 | 50.74 |

| 4000 | DS2 | 46.83 | 7.36 | 8.69 | 37.12 | 41.00 |

| Kujawy WWTP | ||||||

| 4000 | DS3 | 51.07 | 7.00 | 8.54 | 33.39 | 46.15 |

| Denisty (g/cm3) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | K | Ca | Mg | P | B | Sr | Al | Ba | Heavy Metals (ρ > 4.5 g/cm3) | Ash [%] | ||||||

| Zn | Cr | Mn | Fe | Ni | Cu | Pb | ||||||||||

| 0.89 | 1.55 | 1.738 | 1.823 | 2.34 | 2.64 | 2.70 | 3.51 | 7.14 | 7.15 | 7.21 | 7.874 | 8.908 | 8.96 | 11.34 | ||

| Płaszów WWTP, mg/kg DM | ||||||||||||||||

| HS1 | – | – | – | – | 28.0 | 14.0 | 1907 | 16.0 | 294.0 | 19.0 | 15.0 | 2163 | 38.0 | 61.0 | 5.0 | 24.33 |

| HS2 | – | – | – | – | 13.0 | 41.0 | 2431 | 36.0 | 402.0 | 25.0 | 29.0 | 3049 | 31.0 | 69.0 | 8.0 | 22.83 |

| Kujawy WWTP, mg/kg DM | ||||||||||||||||

| HS3 | 36,559 | 5133 | 524.0 | 29,222 | – | 31.0 | 2221 | 25.0 | 415.0 | 51.0 | 21.0 | 6761 | 32.0 | 53.0 | – | 27.31 |

| Denisty (g/cm3) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | K | Ca | Mg | P | B | Sr | Al | Ba | Heavy Metals (ρ > 4.5 g/cm3) | Ash [%] | ||||||

| Zn | Cr | Mn | Fe | Ni | Cu | Pb | ||||||||||

| 0.89 | 1.55 | 1.738 | 1.823 | 2.34 | 2.64 | 2.70 | 3.51 | 7.14 | 7.15 | 7.21 | 7.874 | 8.908 | 8.96 | 11.34 | ||

| Płaszów WWTP, mg/kg DM | ||||||||||||||||

| DS1 8000 rpm | – | – | – | – | 19.0 | 28.0 | 515.0 | 13.0 | 116.0 | 10.0 | 13.0 | 1145 | 18.0 | 31.0 | 5.0 | 50.74 |

| DS2 4000 rpm | – | – | – | – | 26.0 | 48.0 | 1899 | 37.0 | 269.0 | 23.0 | 30.0 | 2449 | 19.0 | 54.0 | 8.0 | 41.00 |

| Kujawy WWTP, mg/kg DM | ||||||||||||||||

| DS3 4000 rpm | 57,709 | 18,656 | 3560 | 42,078 | – | 65.0 | 1376 | 30.0 | 247.0 | 47.0 | 33.0 | 5436 | 8.0 | 48.0 | – | 46.15 |

| Combination Number | Presence of Factor | Dosage (g/L) | ||||

|---|---|---|---|---|---|---|

| a | b | c | a | b | c | |

| 1–I | − | − | − | 0.0 | 0.0 | 0.0 |

| 2–a | + | − | − | 0.27 | 0.0 | 0.0 |

| 3–b | − | + | − | 0.0 | 2.75 | 0.0 |

| 4–ab | + | + | − | 0.27 | 2.75 | 0.0 |

| 5–c | − | − | + | 0.0 | 0.0 | 2.75 |

| 6–ac | + | − | + | 0.27 | 0.0 | 2.75 |

| 7–bc | − | + | + | 0.0 | 2.75 | 2.75 |

| 8–abc | + | + | + | 0.27 | 2.75 | 2.75 |

| Percentage Effect of Testing Agents on Root Growth (%) | ||||

|---|---|---|---|---|

| Combination | Lepidium sativum | Sinapis alba | Sorghum saccharatum | |

| 2–a | HS | 51.79 | 32.83 | 60.68 |

| 3–b | N | 13.32 | −0.81 | −16.44 |

| 4–ab | HS + N | 21.29 | 15.96 | 41.53 |

| 5–c | P | 40.80 | 35.05 | −14.41 |

| 6–ac | HS + P | 49.45 | 32.32 | 42.71 |

| 7–bc | N + P | 41.21 | 3.94 | 38.47 |

| 8–abc | HS + N + P | 22.25 | 8.89 | −14.58 |

| Percentage effect of testing agents on shoot growth (%) | ||||

| Combination | Lepidium sativum | Sinapis alba | Sorghum saccharatum | |

| 2–a | HS | 12.0 | 0.0 | 31.91 |

| 3–b | N | −4.0 | 15.38 | 17.02 |

| 4–ab | HS + N | 8.0 | 24.62 | 42.55 |

| 5–c | P | 1.8 | 1.54 | 29.79 |

| 6–ac | HS + P | 1.4 | 18.46 | 27.66 |

| 7–bc | N + P | −8.0 | 12.31 | 38.30 |

| 8–abc | HS + N + P | 6.0 | 20.0 | 2.13 |

| Lepidium sativum | Limit Values for F0 | |||||

|---|---|---|---|---|---|---|

| Main Factors | Average Root Length (mm) | Average Main Factorial Effects | Main Effects | Test Function F0 | F 0.05 | F 0.01 |

| 69 | 180 | 5.63 | 4.89 | 4.04 | 7.18 | |

| 52 | −160 | −5.00 | 3.86 | |||

| 64 | 245 | 7.66 | 9.06 | |||

| Interactions | Average root length (mm) | Average interactions | Interactions | Test function F0 | ||

| 55 | −260 | −8.13 | 10.21 | |||

| 68 | −255 | −7.97 | 9.82 | |||

| 64 | −35 | −1.09 | + | |||

| 56 | 59 | 1.84 | + | |||

| Sinapis alba | Limit Values for F0 | |||||

|---|---|---|---|---|---|---|

| Main Factors | Average Root Length (mm) | Average Main Factorial Effects | Main Effects | Test Function F0 | F 0.05 | F 0.01 |

| 82 | 256.5 | 8.02 | 20.91 | 4.04 | 7.18 | |

| 61 | −357.5 | −11.17 | 40.63 | |||

| 84 | 159.5 | 4.98 | 8.09 | |||

| Interactions | Average root length (mm) | Average interactions | Interactions | Test function F0 | ||

| 72 | −41.5 | −1.30 | + | |||

| 82 | −234.5 | −7.33 | 17.48 | |||

| 64 | −182.5 | −5.70 | 10.59 | |||

| 67 | 117.5 | 3.67 | 4.39 | |||

| Sorghum saccharatum | Limit Values for F0 | |||||

|---|---|---|---|---|---|---|

| Main Factors | Average Root Length (mm) | Average Main Factorial Effects | Main Effects | Test Function F0 | F 0.05 | F 0.01 |

| 59 | 11.31 | 362 | 11.53 | 4.04 | 7.18 | |

| 31 | −3.69 | −118 | 1.22 | |||

| 32 | −3.09 | −99 | + | |||

| Interactions | Average root length (mm) | Average interactions | Interactions | Test function F0 | ||

| 52 | −10.41 | −333 | 9.75 | |||

| 53 | −10.56 | −338 | 10.05 | |||

| 51 | 2.88 | 92 | + | |||

| 32 | −9.91 | −317 | 8.84 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anielak, A.M.; Kłeczek, A.; Łuszczek, B. Innovative Method of Extraction of Humic Substances from Digested Sludge and Assessment of the Impact of Their on the Growth of Selected Plants. Energies 2023, 16, 1283. https://doi.org/10.3390/en16031283

Anielak AM, Kłeczek A, Łuszczek B. Innovative Method of Extraction of Humic Substances from Digested Sludge and Assessment of the Impact of Their on the Growth of Selected Plants. Energies. 2023; 16(3):1283. https://doi.org/10.3390/en16031283

Chicago/Turabian StyleAnielak, Anna M., Aneta Kłeczek, and Bartosz Łuszczek. 2023. "Innovative Method of Extraction of Humic Substances from Digested Sludge and Assessment of the Impact of Their on the Growth of Selected Plants" Energies 16, no. 3: 1283. https://doi.org/10.3390/en16031283

APA StyleAnielak, A. M., Kłeczek, A., & Łuszczek, B. (2023). Innovative Method of Extraction of Humic Substances from Digested Sludge and Assessment of the Impact of Their on the Growth of Selected Plants. Energies, 16(3), 1283. https://doi.org/10.3390/en16031283