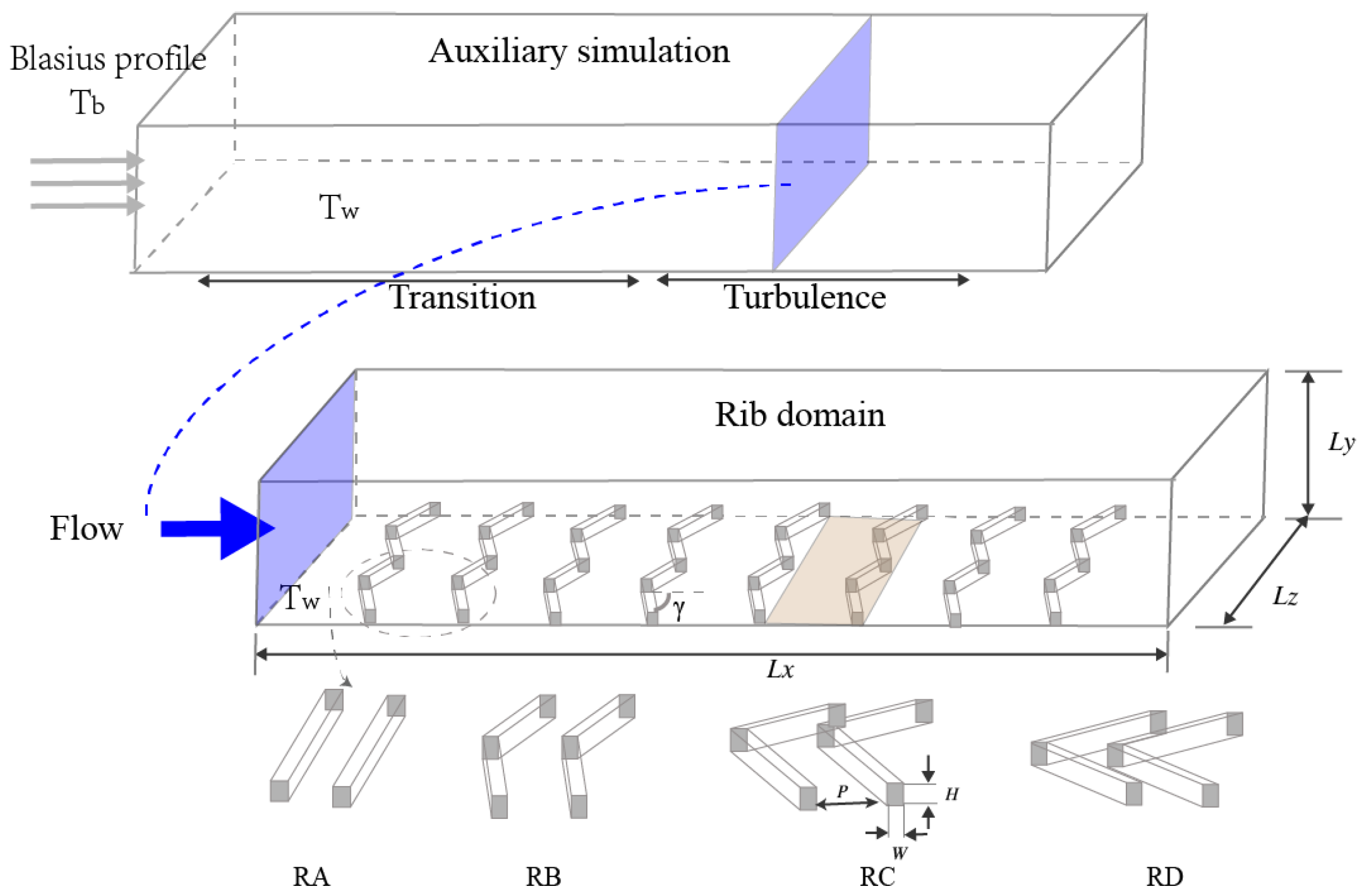

The impact of the rib angle upon turbulence and heat transfer performance is examined, based on global properties and first-order statistics. Next, the characteristics of turbulent momentum and heat transfer are discussed in detail by analyzing the shear stress and heat flux in the cross-sectional plane and decomposing the drag coefficient and Stanton number. Finally, the Reynolds analogy is analyzed to evaluate the heat augmentation performance of different surface regions.

3.1. Mean Statistics

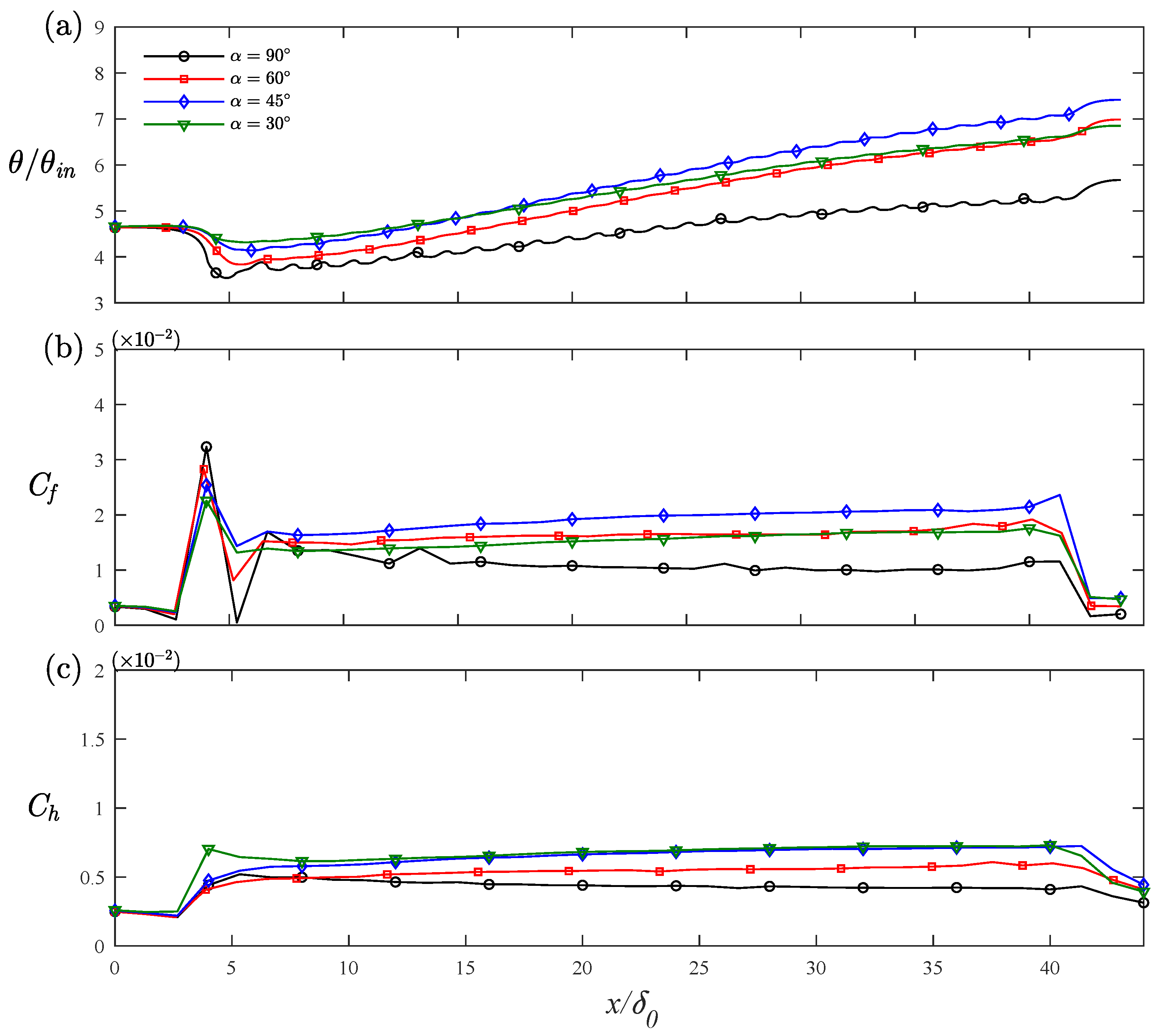

The influence of angled ribs on the overlying flow was assessed by evaluating the evolution of boundary layer momentum thickness

, drag coefficient

, and Stanton number

along the streamwise direction in the rib domain. as shown in

Figure 4. Compared to the transverse rib case, all quantities in the V-shaped rib cases substantially increased. The growth rate of momentum thickness increased and then decreased when the rib angle became smaller. A similar trend was also observed for

and

. The drag coefficient and Stanton number reached peak values of approximately 0.021 and 0.0073, respectively, in the

rib case. This non-monotonic behavior may be attributed to reduced pressure, or drag formed and the presence of secondary flows as the rib angle decreased. While similar trends were observed, significant differences existed between the momentum and heat transport. For instance, approximately the same drag coefficients were obtained in cases RB and RD, whereas better heat transfer performance was observed in RD. In order to further illustrate the changes in drag and heat transfer coefficients,

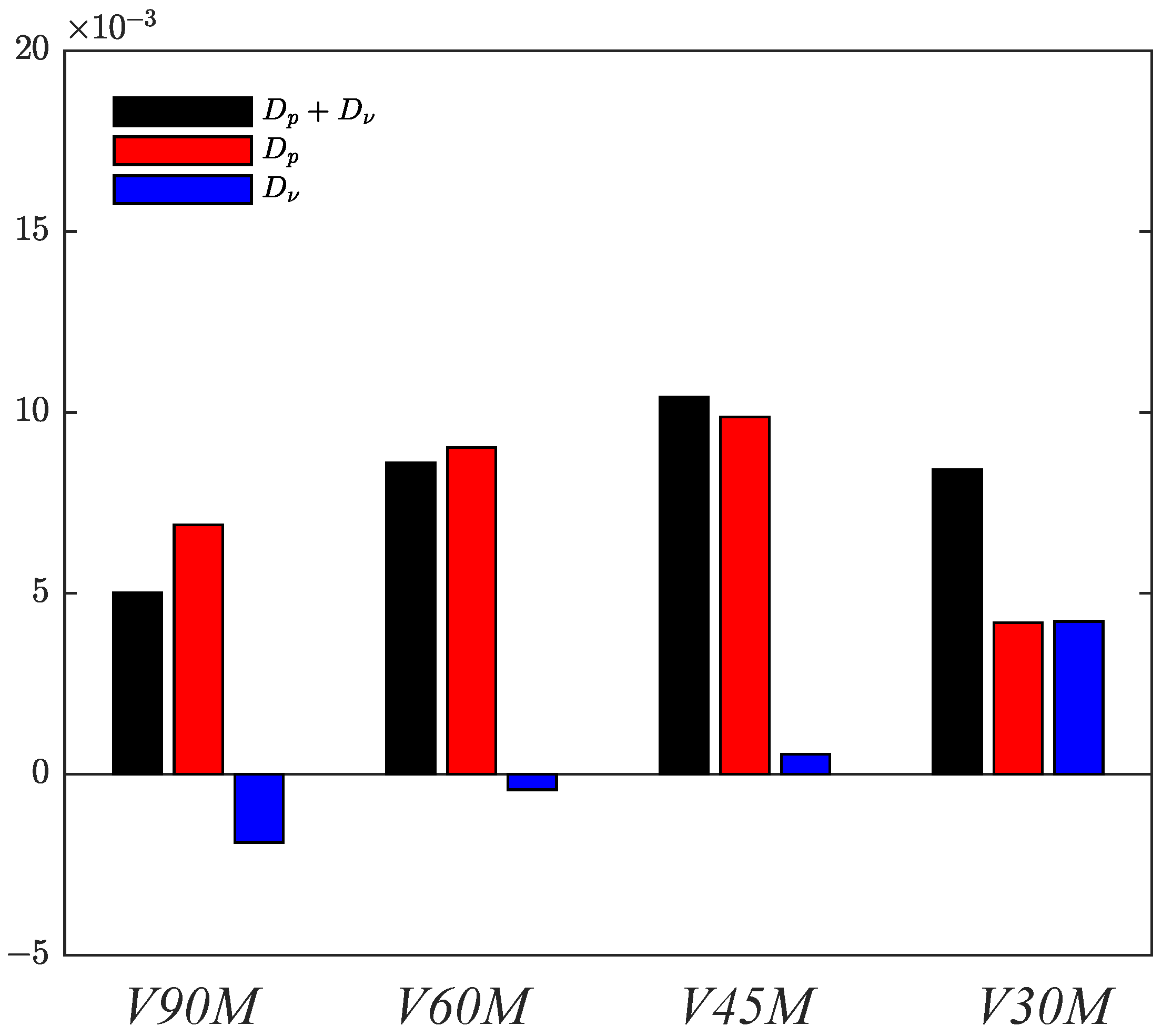

Figure 5 was constructed show the comparison between pressure drag

and frictional drag

. For the transverse rib case, drag mainly came from the pressure difference between the windward and leeward walls of the rib. Due to the formation of stable recirculation opposite the mainstream flow direction in the cavity, the drag at the bottom wall was negative, that is, opposite to the direction of the total drag. As the angle decreased, the contribution of pressure drag gradually decreased, and the contribution of viscous drag gradually increased. The variation in viscous drag was nonlinear and changed rapidly when approaching

and

. Furthermore, the decrease of drag accelerated when exceeding

. The decrease in drag from case RC to RD was primarily attributed to the decrease in pressure drag, which greatly exceeded the increase in viscous drag. Heat transfer was not affected by a pressure penalty and was greatly influenced by the mean velocity gradient. As the angle decreased, mean flow velocity increased, leading to an increase in

from case RA to RC, but when the angle exceeded

, mean streamwise velocity had no evident change in the near wall region, and, consequently, no significant change was found in

from case RC to RD.

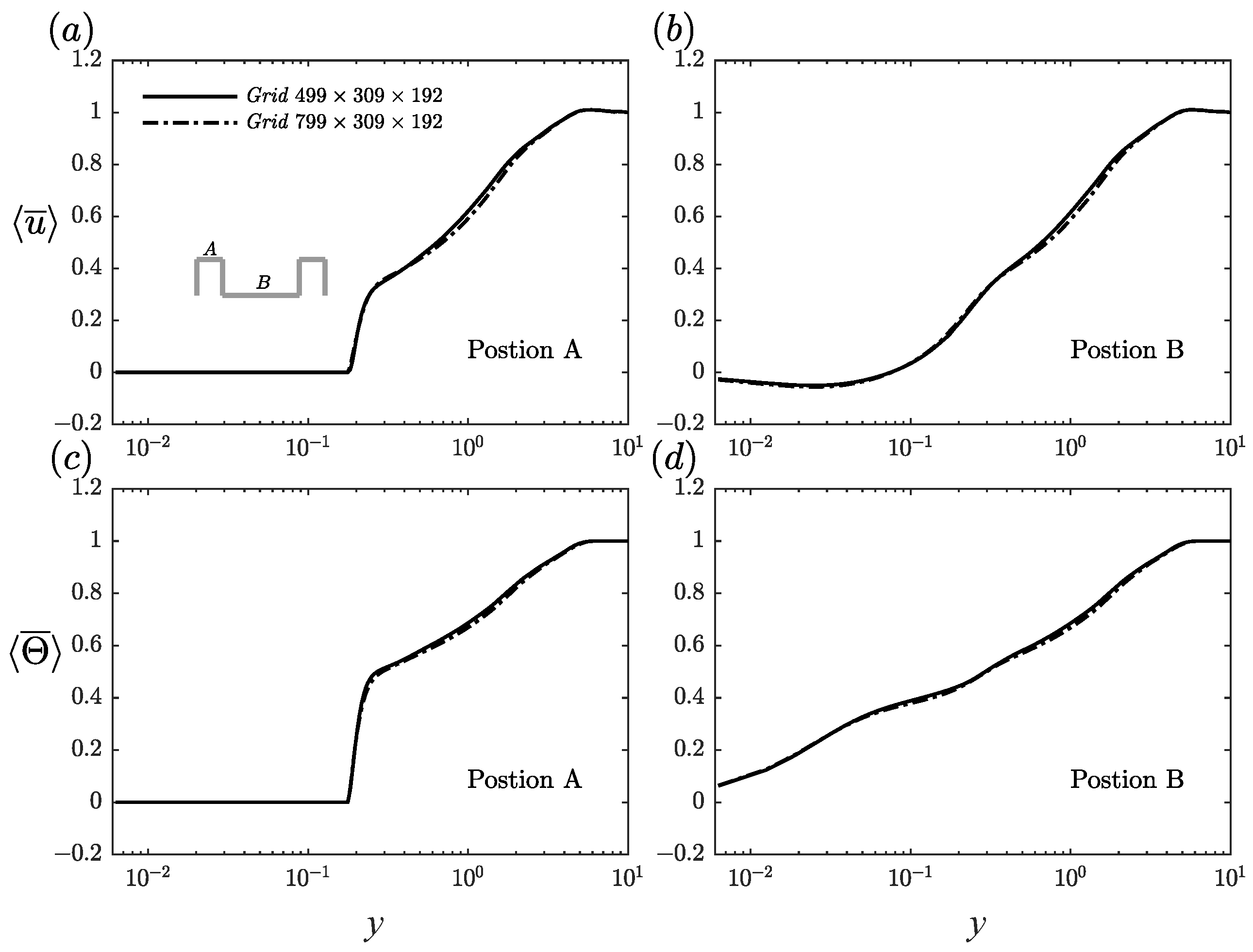

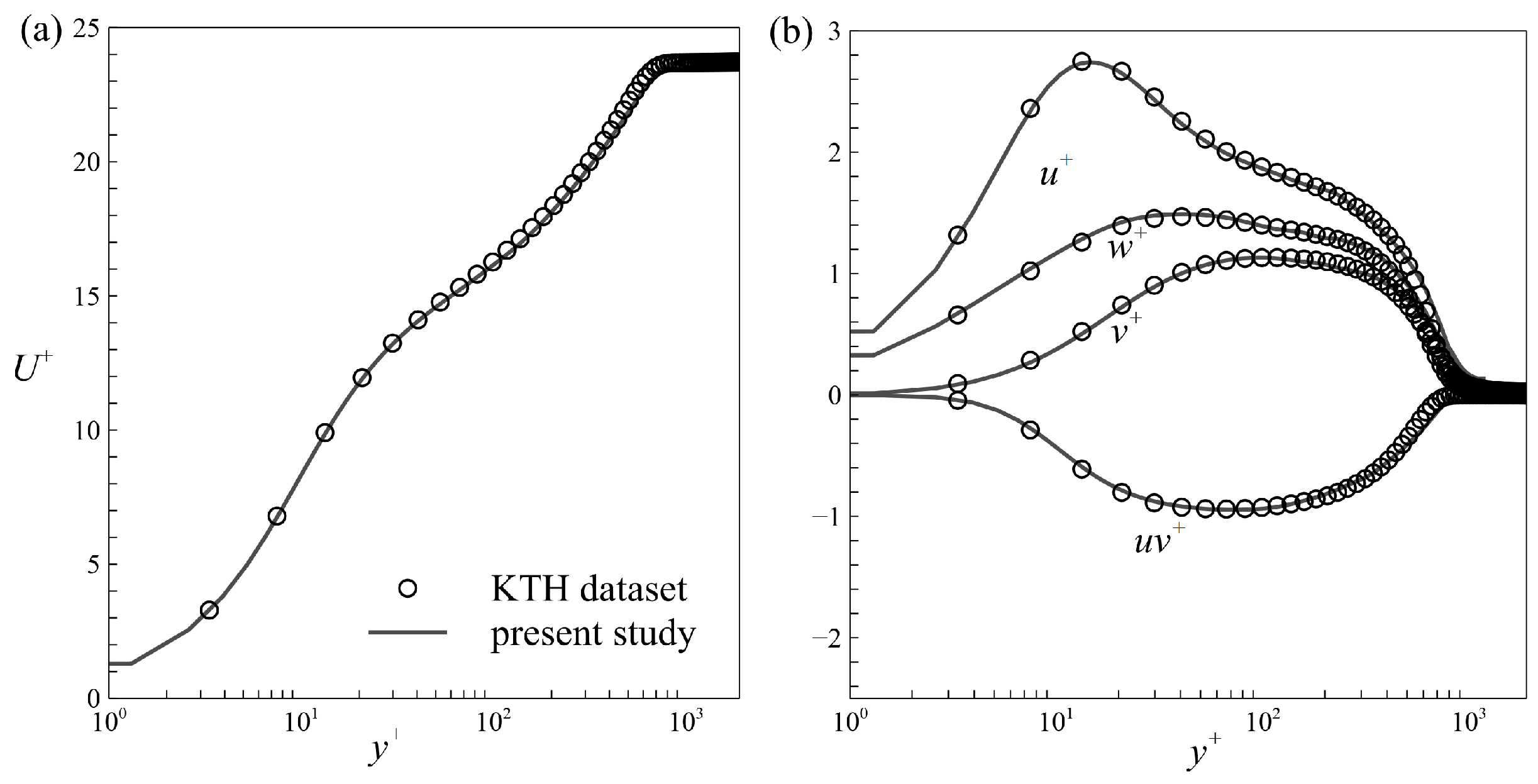

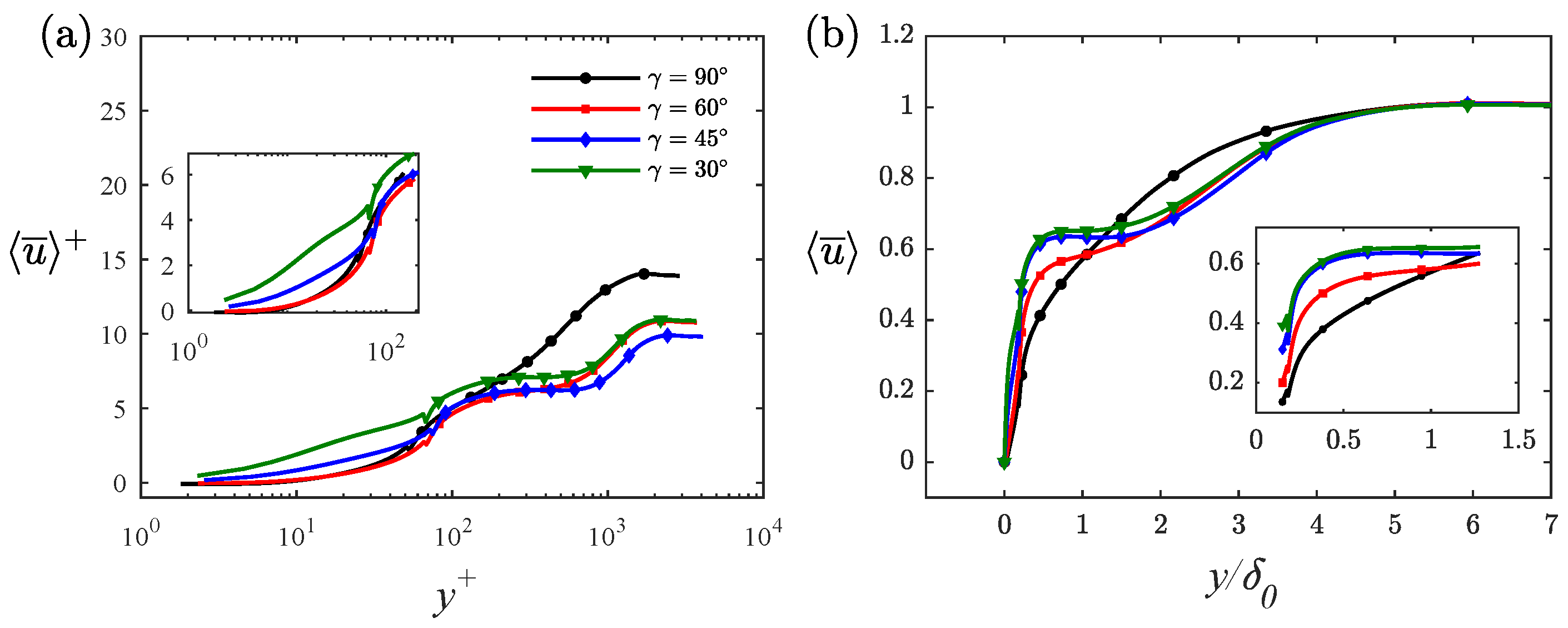

Figure 6 and

Figure 7 demonstrate the mean streamwise velocity and temperature profiles in the inner and outer coordinates, respectively. The velocities in

Figure 6a were non-dimensionalizedy friction velocity

, and showed evident downward shifts, known as momentum defects, due to hindrance from the rough elements. Under the crest of ribs, the maximal streamwise velocity occurred in RD as the rib obstruction reduced with decreasing rib angle. Close above the crest of the ribs,

, reflected significant improvement for all V-shaped cases relative to that in the transverse rib case. In the plots shown in the small box in

Figure 6b, the velocity prominence above the rib gradually increased as the rib angle decreased. The peak occurred in the

rib case, reaching the value

at

. Fang reported similar velocity bulges in their study on duct channel flow over aibbed surface. This non-typical behavior indicated the break of wall-similarity under the influence of angled ribs, which was preserved in the transverse rib case and smooth wall turbulence. The enhancement of double-averaged streamwise velocity just above and under the crest of ribs indicated that ribs with sharper angles effectively reduced the obstruction in the near wall regions. The coverage of this region expanded from the wall to approximately

, above which

was conversely suppressed up to the boundary layer edge. Therefore, we concluded that angled ribs influenced the flow across the boundary layer and that the area of influence could be classified into two regions, depending on whether

was enhanced or suppressed. We further plotted the mean streamwise velocity differences between V-shaped and transverse rib cases in

Figure 8a to highlight the two regions. The enhanced region ranged, approximately, from the wall to

, which was nearly equal to seven times the height of the ribs, and the suppressed region extended from this position to the edge of the boundary layer. The maximal positive velocity difference occurred closely above the rib crests, whereas the maximal negative velocity was positioned at

. We explain the underlying mechanism leading to these differences in the streamwise velocity when we discuss the flow structure.

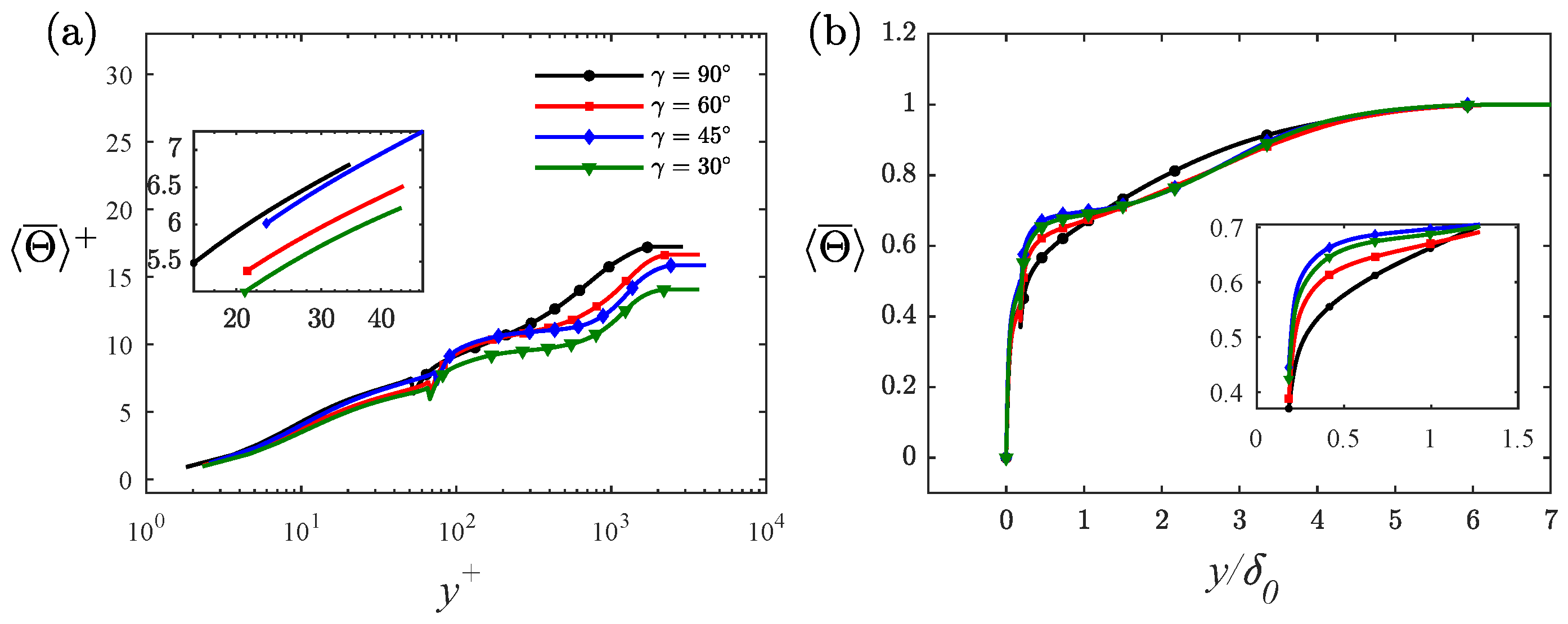

Similarly, we present the dimensionless temperature, normalized by

, in

Figure 7. The maximum value at the edge of the boundary layer is indicative of the heat transfer efficiency for each case, due to the inherent definition of

, which takes into account both friction velocity and temperature. RD exhibited the highest heat transfer efficiency, while RC had the largest

, as shown in

Figure 4c. As discussed in the velocity flow section, enhanced and suppressed regions were also observed in

Figure 8b. The temperature differences were overall smaller compared to streamwise velocity, with a larger difference observed in RC at the crest of the ribs than that in RD,nd the maximal negative difference in RD was significantly larger than that in RC. In regard to the velocity pattern, differences in RD were slightly smaller than those in RC. Moreover, the demarcation points of the positive and negative temperature differences were closer to the wall and located at

, equating to a smaller enhanced region in the temperature field. Thus, the larger suppressed region demonstrated the discrepancy in the vertical transport of momentum and heat in the thermal turbulent boundary layer flow over the ribbed surface.

3.2. Secondary Motion

In this section, we present the flow structures and temperature spatial distributions to understand how angled ribs alter flow dynamics.

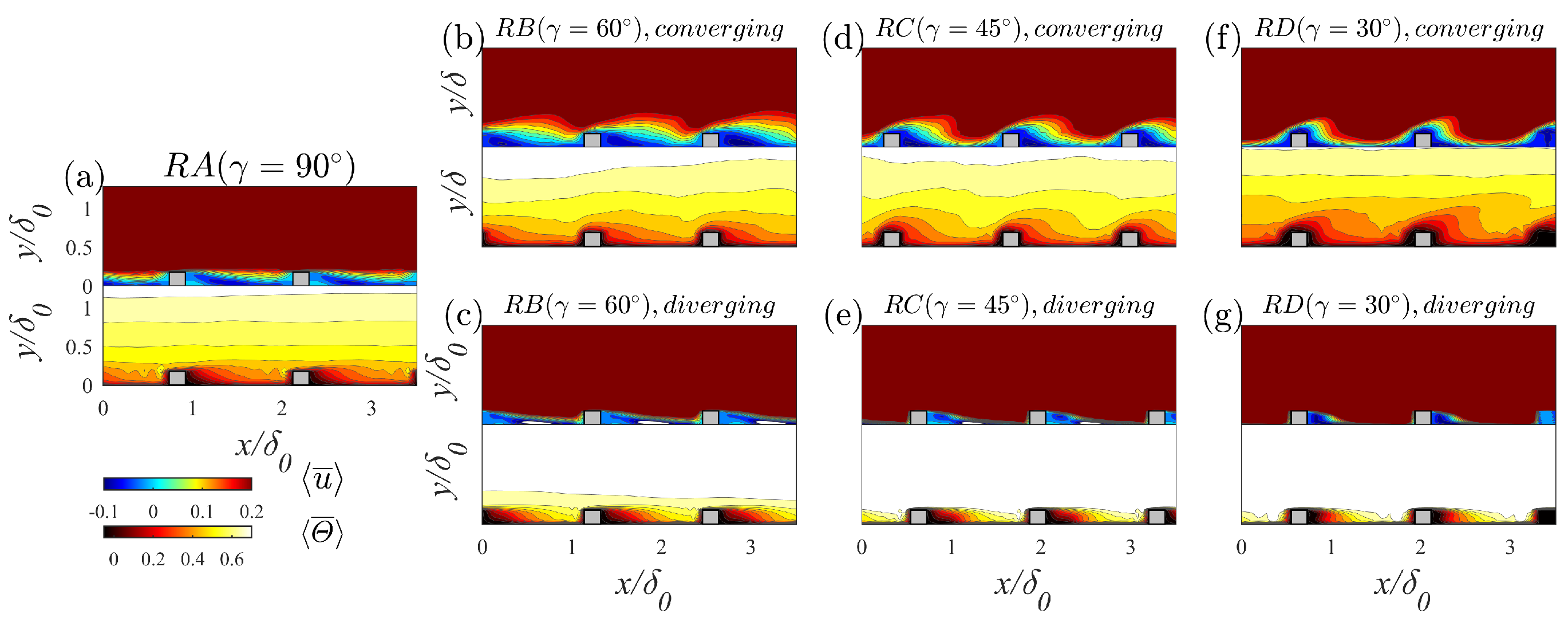

Figure 9 presents a comparison of the mean streamwise velocity and temperature in the

planes of both converging and diverging areas. These measurements were taken at spanwise coordinates

and

. In the transverse rib case, a shear layer was present n the crests of the ribs and recirculation occurred in the cavity between the two ribs, consistent with findings in previous studies [

15]. For the V-shaped rib cases in the converging area (

Figure 9b,d,f), the strength of the recirculated flow in the cavity under the crests of the ribs became weaker as the incoming flow was drawn into the sidewalls by the angled ribs, attenuating the streamwise impinging effect. In diverging slices displayed in

Figure 9c, for example, as the rib angle decreased, the recirculation size became smaller, while strength was augmented. Reattachment points moved closer to the leeward sides of the ribs and the outer flow, with higher velocity, occupied a considerable space underneath the crests of the ribs. Thus, in the sharper angle case (RD), the velocity under the crests of the ribs was higher, as mentioned in

Figure 6b. In regard to temperature, heat accumulated, due to the recirculated flow near the leeward surfaces of the ribs, resulting in low-temperature areas forming near the windward surfaces under the crest of the ribs, in both the diverging and converging slices. As rib angle decreased, the high-temperature fluid from the outer region had more opportunities to attach to the wall and then to enhance the heat transfer.

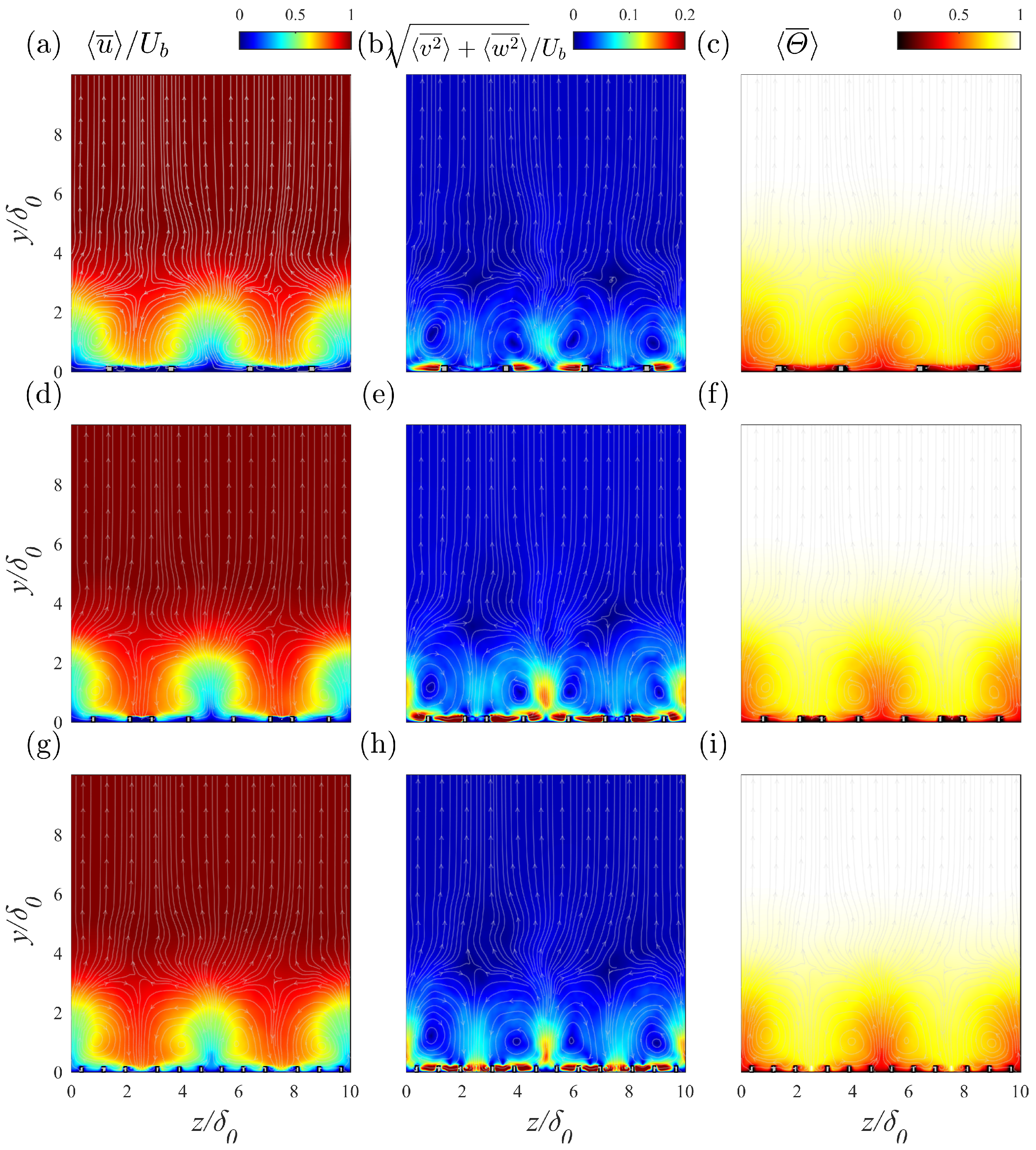

Contours of time-averaged normalized streamwise velocity, normalized strength of the secondary flow, and dimensionless temperature in the cross-stream plane, superimposed with the streamlines of secondary flows, are plotted in

Figure 10. The magnitude of the secondary flow is defined as

. The first row of the figure highlights strong flow disturbances in the spanwise direction induced by the ribs. Secondary flows appear as LPMs and HPMs located above the diverging and converging regions of the ribs, respectively. The streamlines and secondary motion strengths in the second row clearly indicate that LMPs were flanked by a pair of counter-rotating vortices aligned in the flow direction. These vortices carried the high-velocity fluid in the domain center downward to the sidewalls, forming a relatively high velocity region above the windward angle of the ribs, as depicted in

Figure 6.

As the rib angle decreased, the vortex edges extended further away from the wall (highest position

for RD), while the strongest secondary motion intensity was observed in the

rib case RC. Thus, it was not possible to simply conclude which case was most affected by secondary flow. The overall impact is discussed in detail in

Section 3.3 and

Section 3.4. An analogous phenomenon is presented in the third column of

Figure 10, where rotating vortices drove fluid with high dimensionless temperature to the lower region, enhancing heat exchange between the wall and the bulk flow.

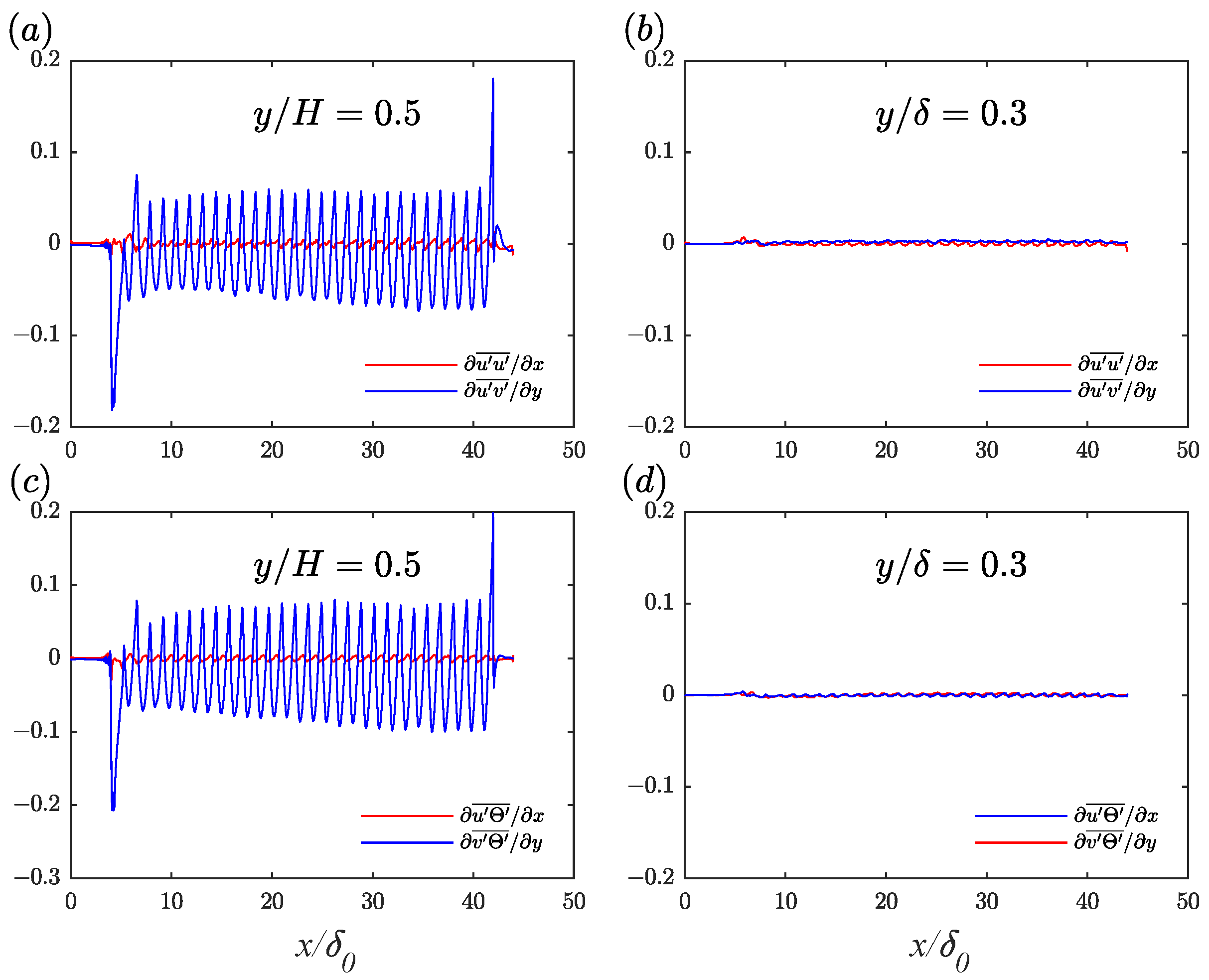

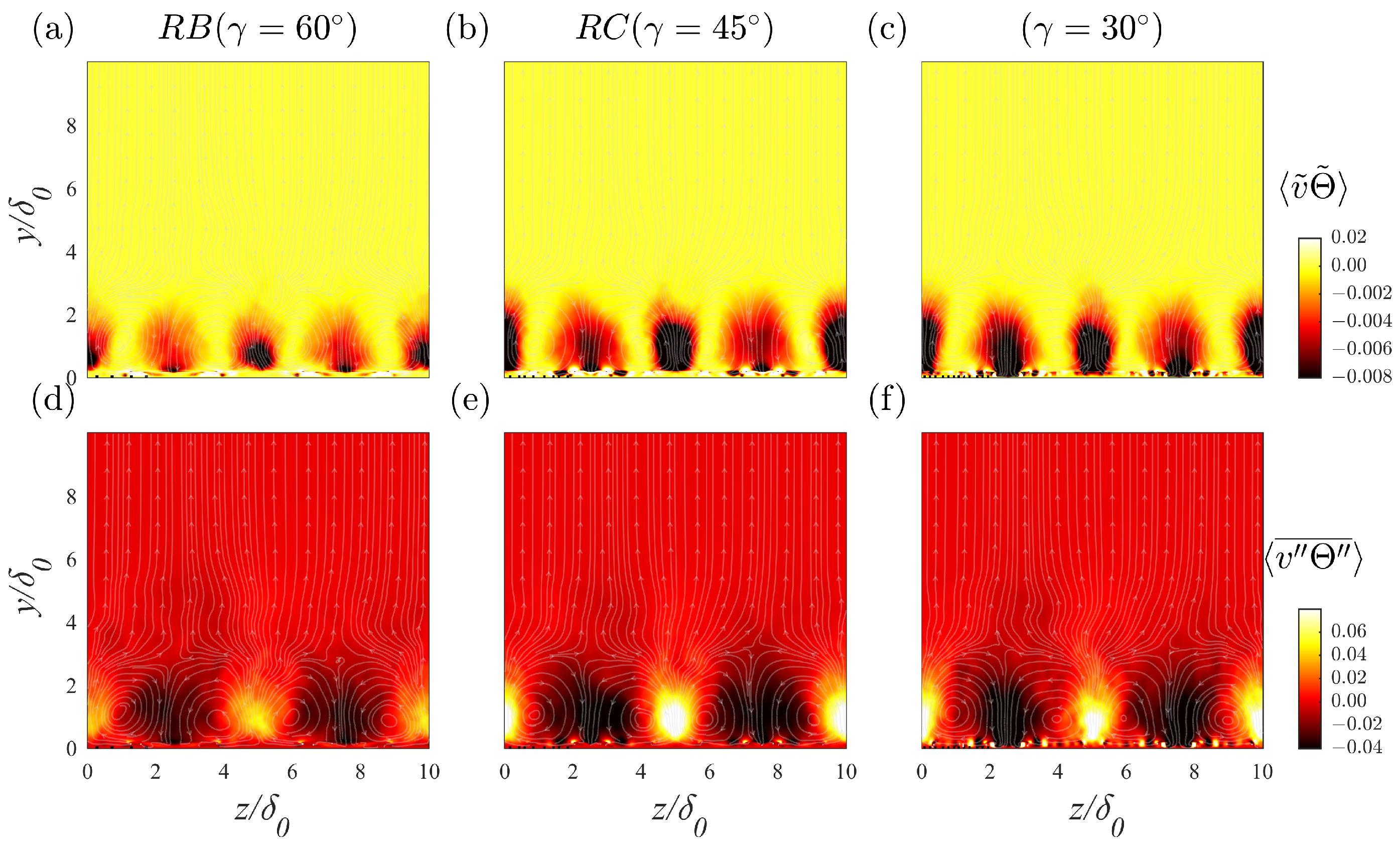

3.3. Characteristics of Shear Stress and Heat Flux

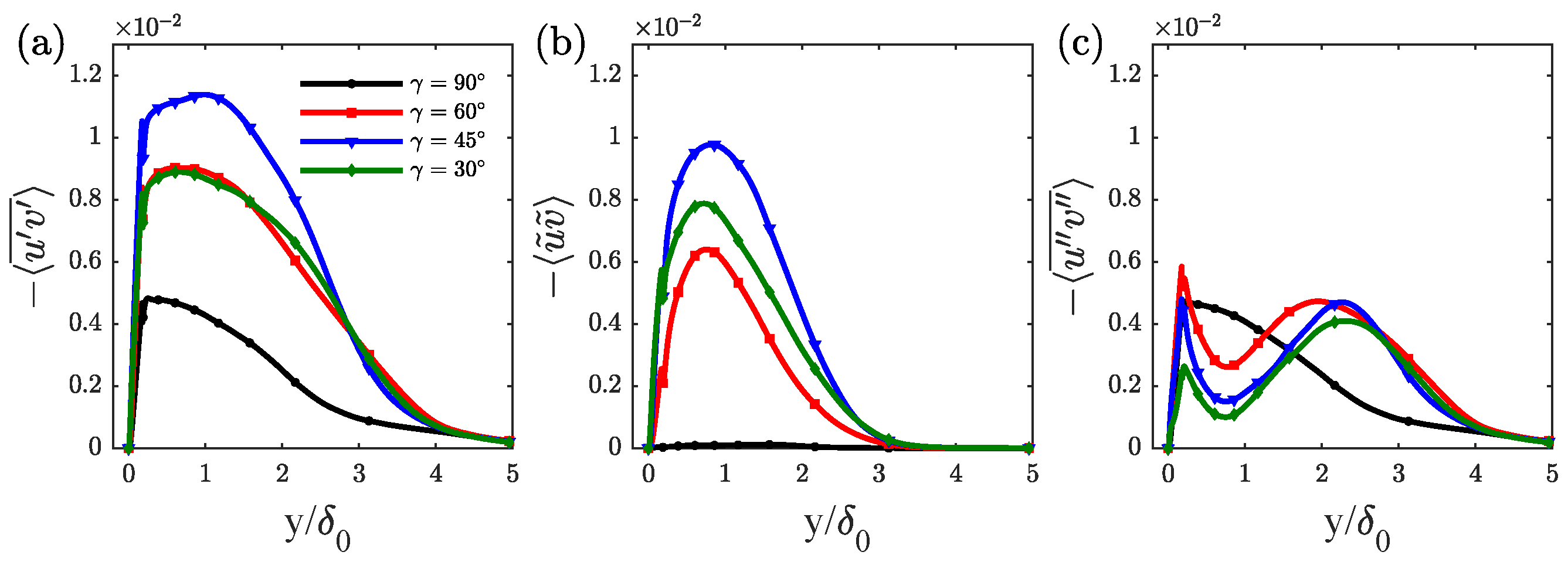

Understanding the total wall stress and heat flux modifications can provide insight into ow the angled ribs change the integral properties.

Figure 11a presents he total shear stress along the wall-normal direction in the outer coordinate at the matched Reynolds number. The vertical position of the peak value for all cases occurred at

, which was nearly four times the height of the ribs, while, for the transverse rib case, the peak value was found closely above the ribs. Maximal total stress was obtained in RC, while the peak value of shear stress was roughly equal in RB and RD. However, the extent of stress in the outer region increase, with decreasing rib angle. The dispersive and turbulent components are depicted in

Figure 12 to further investigate the distinct features of shear stress and their spatial distribution in the cross-stream plane. The results, illustrated in

Figure 11b, show that the magnitude rank of dispersive stress was RC > RD > RB. Moreover, no stress contribution came from the dispersive component in the transverse rib case due tots homogeneity in the spanwise direction. In the first row of

Figure 9, negative

occupied both the diverging and converging regions and the intensity of

above the converging region first increased and then decreased. Furthermore, the strength of the secondary motion in the diverging region grew consistently with decreasing rib angle, leading to a higher magnitude of

in RD than that in RB. Turbulent stresses for all V-shaped cases, displayed in

Figure 11c, showed double peaks, including an inner and an outer peak. The inner peak occurred in the vicinity of the rib crest, while the outer peak was further away from the wall. The emergence of double peaks resulted from turbulent shear stress with opposite signs forming above the diverging and converging regions. In the second row, the negative turbulent shear stress played a dominant role under the rib crest, while more positive spots appeared in the adjacent two sides of the ribs as the rib angle decreased, consistent with the decreasing inner peak values shown in

Figure 9a. Above the crest of ribs, alternating positive and negative turbulent shear stress formed in the LMPs and HMPs, that is, converging and diverging regions, respectively, creating a defect between two peaks. Additionally, due to the faster attenuation of positive shear stress, the second peak formed vertically away from the ribs. The distance of extent in the wall-normal direction of the two components was consistent with that in the total shear stress.

Contrary to the shear stress profiles, both RC and RD displayed relatively high total heat flux, as illustrated in

Figure 13. This was primarily due to the nearly equal dispersive components in both cases. This behavior differed from the stress pattern, where the secondary motion contributed the most in the middle angle case (RC). By comparing

Figure 12 and

Figure 14b, a change in the intensity of the dispersive component in the diverging region was evident. For RD, a strong negative

was found in the diverging regions, while the approximately equivalent strength of

, relative to RC, is shown in

Figure 12. This significant difference offers new insights into the underlying dissimilarity mechanisms in the turbulent transport of momentum and heat over ribbed surfaces.

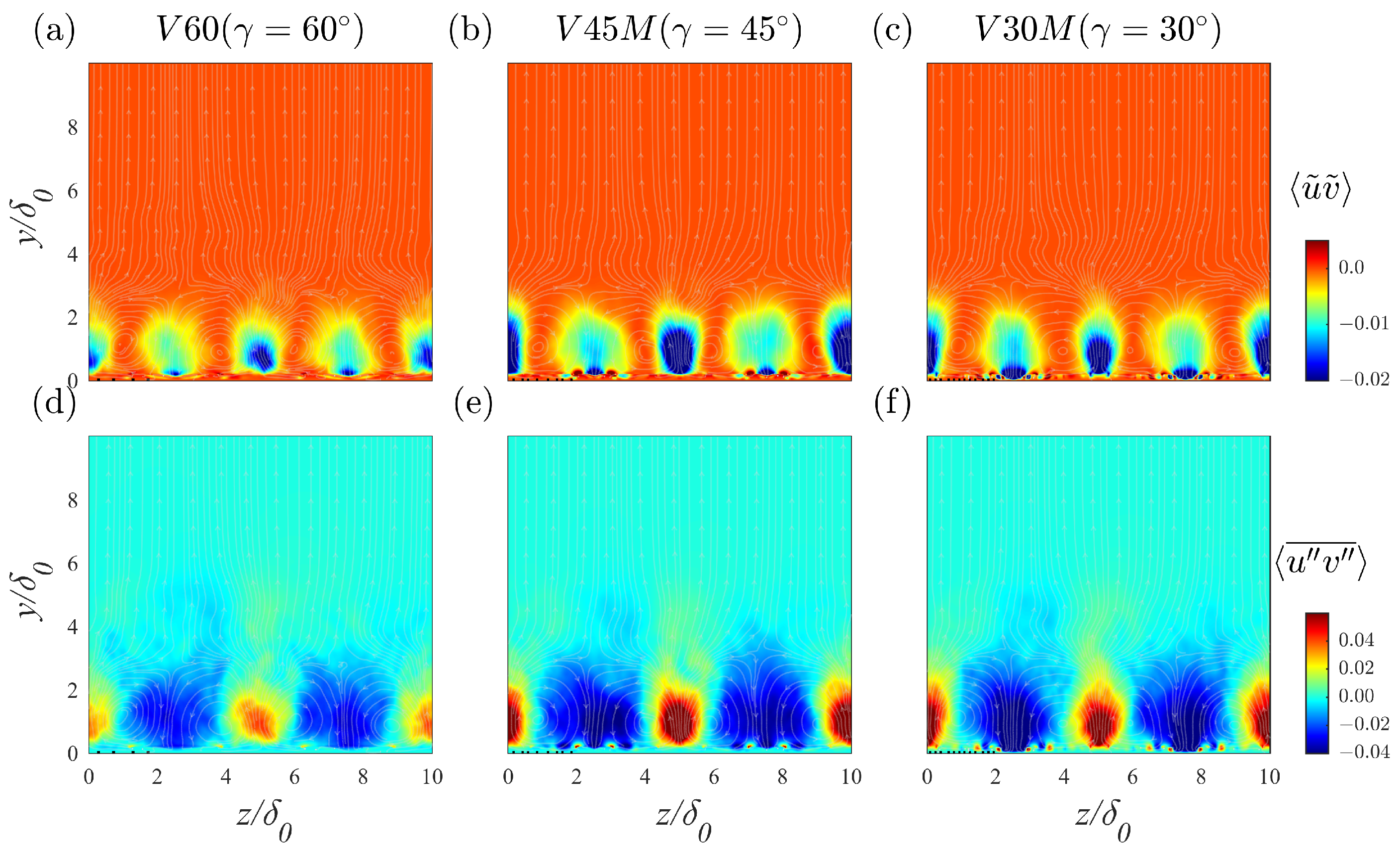

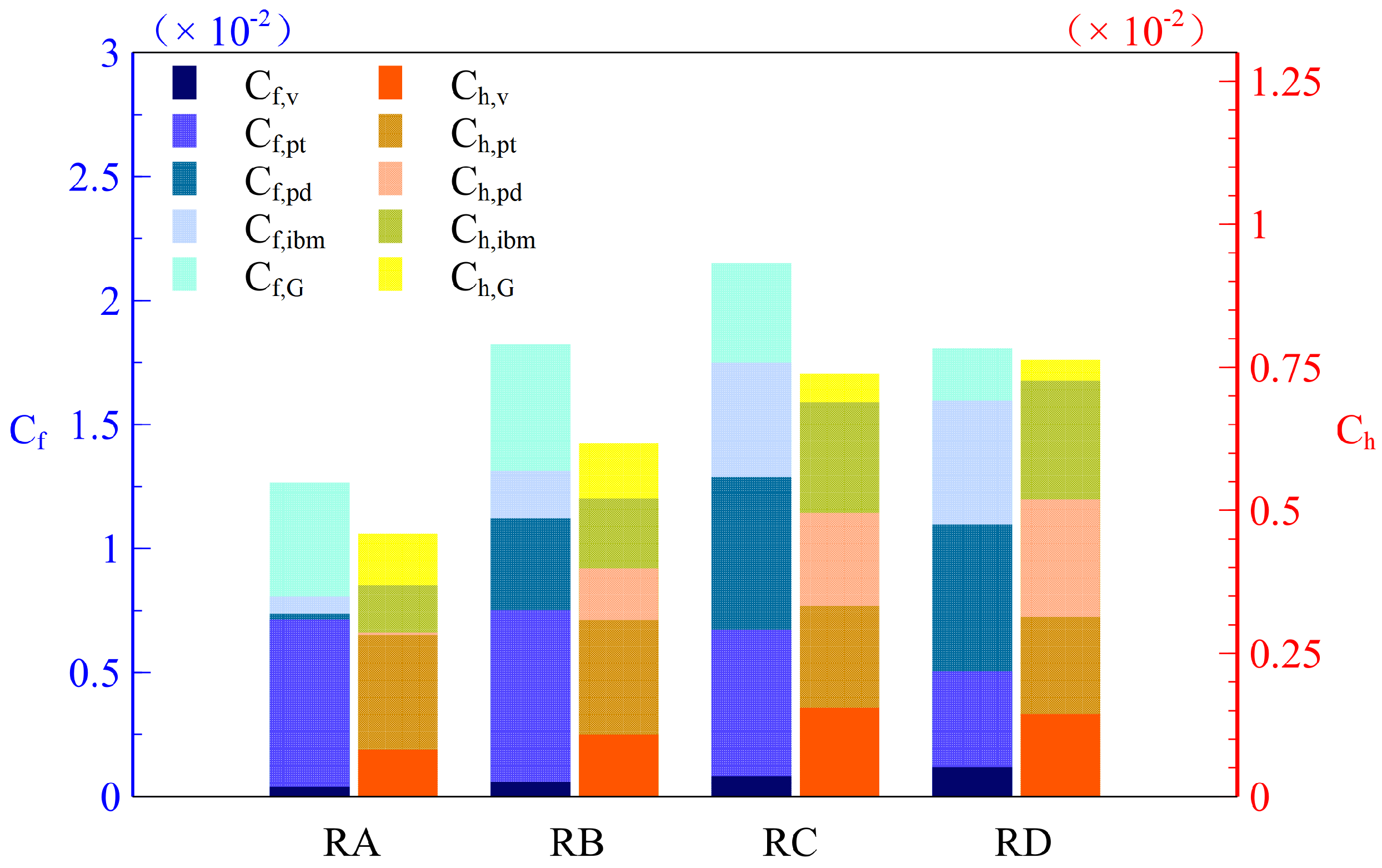

3.4. Decomposition of Velocity and Thermal Field

The contributions of constituents of

and

were examined to determine the effect of the secondary flow on the drag and heat transfer efficiency. The terms presented in Equation (

12) were derived from the RD identity by performing triple decomposition of the mean transport equation of TKE and, subsequently, integrating from the wall to bulk flow as follows:

where

,

,

and

on the right-hand side of Equation (

12) are the laminar term, total production term, IBM forcing term and spatial growth term, respectively. The detailed process of derivation is presented in

Appendix A. Based on Equation (

6),

can be further divided into the dispersive production term,

, and turbulent production term,

The decomposition of

and terms with analogous physical meanings are obtained in a similar manner

The contributions of these terms are shown in

Figure 15. As expected, the dispersive constituent was absent in the transverse rib case.

increased as the rib angle decreased due to the reduction in impingement of the incoming flow, resulting in higher

underneath the crests of ribs and generating large laminar effects. Conversely, turbulent shear stress was suppressed in the presence of the angled ribs, thereby decreasing the contribution of

. Although the dispersive component in the RC case was significantly higher than that in the RB case, no notable difference was observed when compared to that in the RD case. For heat transfer patterns, the laminar component

accounts for a considerable portion in the Stanton number and presents a different trend from the drag pattern. RC had the largest laminar contribution in

, indicating limited temperature gradient improvement when the rib angle exceeded

. The contributions of dispersive and turbulent components were similar to that of drag patterns. A remarkable difference was the increased

in RD relative to that in RC, which differed from that in

. Since nearly the same magnitude of dispersive flux was observed, as seen in

Figure 13b, we concluded that the excess of dispersive production in RD resulted from a higher temperature gradient in the near wall region. The IBM-related terms,

and

, contributed more as the angle decreased. According to Fan’s research [

21], boundary layer growth is strongly related to the pressure gradient. Although the total mean pressure gradient was zero in the cases presented, the appearance of ribs induced local non-equilibrium pressure in the streamwise direction. As shown in

Figure 5, the influence of pressure decreased rapidly with a decreasing rib angle, exceeding

. Therefore, the growth terms,

and

, contributed less as the angle decreased in the V-shaped cases.

3.5. Global and Local Reynolds Analogy

From the view of energy saving, the goal is for the ribbed wall to enhance heat transfer performance without generating excessive additional drag. The Reynolds analogy was used here as an indicator of heat transfer augmentation capacity under this criterion. The Reynolds analogy was plotted globally and locally, in

Figure 16 and

Figure 17, for each case to investigate the performance of ribbed walls at different angles.

The Reynolds analogy factor s is defined as the ratio between the Stanton number and drag coefficient and can be expressed as [

20]

where

and

are evaluated at matched Reynolds number. Value

for smooth wall boundary layer flow indicates the similarity in turbulent transport momentum and heat evident in the present study without rough elements. In this study,

and

correspond to the four cases, as shown in the

Figure 16. According to the definition, a surface transports heat from wall to fluid more efficiently when s is large. Therefore, in the present study, the largest Reynolds analogy was obtained in RD, indicating that, among the angled ribs researched, ribs with

angle were favorable for heat transfer augmentation.

For clear visualization, the Reynolds analogy is shown in the

coordinate in

Figure 16b, based on Rouhi [

29], where

and

correspond to the skin friction coefficient and Stanton number of the smooth surface at matched Reynolds numbers. In general, the point located at the top left corner represents high heat transfer efficiency, and the grey line denotes the smooth wall case. As shown in

Figure 16b, RD generated a much higher heat transfer coefficient than the transverse rib case, while producing less drag than RC and, therefore, achieved the highest heat transfer efficiency.

The local distribution of Reynolds analogy factor in the

plane is presented in

Figure 17. The Reynolds analogy values at points sampled from diverging region to converging region (marked with point

and

, respectively) were plotted in

Figure 17a,c,e,g for each case. The spatial distribution of

and

were contoured in the second and third columns of the figure. In the diverging region, both positive and negative drag existed in the cavity. As discussed in

Section 3.1, steady recirculated flow formed near the leeward faces, and the reattachment point moved towards the leeward face with a decreasing rib angle, resulting in an increase in the area of contact between the wall and high-speed fluid. This is reflected in the second column of

Figure 17, where the blue area, representing negative drag in the diverging region, decreased with decreasing angle. In the ribbed area of the diverging region, the pressure difference between the windward and leeward walls was the primary source of drag. As observed in

Figure 17, as the angle decreased, the formed drag became increasingly concentrated on the ribs at the windward angle as the angle decreased. This phenomenon is primarily attributed to the stronger secondary flow in cases with sharper angles. In terms of the Stanton number in the diverging region, cases with sharper ribs’ angles exhibited better heat transfer performance, due to the smaller size of the recirculation zone in the cavity, which led to accumulation of heat. Consistent with the above analysis,

, which represents the

s in the diverging region in

Figure 17c,e,g, gradually became close to the “smooth wall line” as the rib angle decreased, indicating higher heat transfer efficiency. RD showed the best heat transfer efficiency in the diverging region, due to its greatest heat transfer gain.

In the transition region, which ranged from point to , many points were distributed near the “smooth wall line” for all V-shaped rib cases, indicating enhancement in heat transfer efficiency in this region. This was mainly due to the fact that decreased faster than from to , in other words, from the diverging region to the converging region, for the V-shaped rib cases. This trend was more pronounced at smaller angles. When decreased to around 5, the points were densely distributed near the line in RD, indicating a relatively high heat transfer efficiency region near . However, in this region, both and were low and showed less effect on total shear stress and heat flux.

Additionally, the Reynolds analogy in the windward angle (marked with ) became larger with decreasing rib angle, due to the higher , and was almost unchanged, indicating that the heat transfer efficiency gradually improved from to in the diverging regions. In the converging area, marked with , lower streamwise fluid velocity led to the accumulation of heat and generated a smaller temperature gradient. Thus, low heat transfer efficiency was obtained in this area, especially in the central line of the V-shaped ribs. Differing from the diverging region, values of s within the converging area were distributed around the reference line with no significant difference found for all cases, suggesting that this area played no dominant role in changing the heat transfer efficiency. The heat transfer performance in immediate areas, ranging from to , varied significantly among the three V-shaped cases. In this area, the Reynolds analogy consistently changed from the value of to the value of in a convex form, with some points exceeding the diagonal line. The curvature of the convex line was linked with the rib angle, with more points above the reference line in the rib case than in other cases. This indicated that most RD regions were heat-transfer friendly. Based on the above discussion, the immediate region with high heat transfer originated from the more rapid decline of than from to , and the increasing width of this region contributed more to heat transfer efficiency when the rib angle decreased.