1. Introduction

The geopolitical upheavals of the year 2022 demonstrated quite dramatically the dependency of developed society on the availability of fossil energy. Especially in Europe, the market price for natural gas showed unknown and unpredictable fluctuations, with extensive impact on national economies. In order to partly compensate the lack of affordable gas, and to reduce the subjection from unreliable sources, an increased use of coal was one of the measures taken by several countries all over the world. This was one of the reasons why the global coal demand reached a new record of more than 8 billion tons in 2022 [

1]. For the sake of security of supply, the increased use of coal might be necessary in the short-term. On the other hand, these turbulences in the global energy markets elucidate the undeniable need for renewable and locally available energy sources.

Solar energy technologies already play a substantial role by contributing to the required transformation of the global energy supply system. The worldwide photovoltaic (PV) market revealed a growth of 25% from 2020 to 2021, reaching an installed capacity of 942 GW

el by the end of 2021 [

2], and the milestone of 1 TW

el installed PV-power in May 2022 [

3]. The global market for solar thermal (ST) systems showed a growth rate of 3% from 2020 to 2021, prolonging the positive trend from the year before. The globally installed solar thermal capacity by the end of 2021 amounted to 522 GW

th [

4]. The combination of PV and ST into a hybrid solar system (PVT) is currently a young variant of solar energy harvesting, although it exhibits promising market development. The totally installed capacity (combined electrical and thermal power) was around 1 GW

el+th in 2021, corresponding to a growth rate of 13% [

4]. The PVT technology provides some benefits compared to separated solar systems if it is deployed for suitable applications. Mostly constructed for providing heat in the temperature range below 60 °C, PVT collectors show an increased annual yield of electrical energy up to 4% compared to PV-only installations, caused by the reduced cell temperatures due to permanent heat extraction [

5]. Furthermore, combined thermal and electrical energy generation by one component significantly raises the surface-related efficiency from around 21% of PV-only systems up to 80% in PVT installations [

5]. For achieving these benefits, PVT collectors are usually designed for maximizing the heat transfer between the electrical and the thermal part, thus enabling efficient heat extraction from PV cells. However, thermal coupling between the PV part and the heat transfer fluid limits the applicability of the PVT collectors regarding the possible outlet temperature, caused by the specified temperature limit of the PV laminate. This is the main reason why conventional PVT collectors are mostly utilized for low-temperature applications such as swimming pool heating, pre-heating of domestic hot water generation or space heating support [

6].

Nevertheless, if the challenging task of transforming the world’s energy supply system towards renewable sources shall be successful, emission-free heat is also needed in the higher temperature range. In 2015, 16% of the total final energy consumption in the EU28 was caused by industrial process heating, whereby 72% of these processes required temperatures above 100 °C [

7]. The provision of solar heat greater than 100 °C is possible with conventional collector technologies such as flat plate collectors or evacuated tube collectors, but only with reduced efficiency [

8,

9]. By contrast, concentrating solar systems can supply heat at temperatures between 100 °C and 1000 °C, depending on the specific technology [

10].

The combination of a concentrating thermal collector with PV results in a concentrating PVT (CPVT) collector, offering some benefits as already mentioned above. On the one hand, the surface-related efficiency can be distinctly increased and the costly mechanical construction for focusing is used twice, both for electrical and thermal energy generation. On the other hand, the required PV surface made of semiconductor material can be reduced by the concentration factor, which has a positive impact on the economic and ecologic effort for such solar systems. Finally, the generation of both forms of solar energy out of one system provides high flexibility to react to fluctuating demands within the operating industrial plant. Although there is the need for both mid-temperature solar heat and renewable electricity in the industrial sector, CPVT collectors are still a niche technology [

4], because their construction shows a similar challenge to non-concentrating PVT collectors. The thermal part of the collector respectively the receiver shall provide temperatures as high as possible, while the PV part must not exceed the specified temperature limits of the cells, or should even be kept as cold as possible in order to work with the highest efficiency.

One possible approach to solving this discrepancy is known as spectral splitting and has already been investigated for several years [

11]. The main intention of this method is to divide the incident solar spectrum into several wavelength ranges by different means of optical filtering. The PV part of such a CPVT receiver with integrated spectral splitting is only impinged with the spectrum range where the applied PV cells provide maximum spectral response, whereas all other domains of the solar spectrum are directly converted into heat within the thermal part of the receiver.

Figure 1 illustrates this approach for the example of crystalline silicon (c-Si) cells with a maximum spectral response at around 900 nm (black line). Therefore, the spectral splitting configuration is chosen in a way that only concentrated solar light in the wavelength range between 700 nm and 1100 nm reaches the PV cells, where the conversion efficiency reaches a maximum (blue area). The shorter wavelengths below 700 nm are less suitable for electricity generation, because the high energetic photons cause thermalization losses within the semiconductor and lead to additional heat dissipation. Furthermore, wavelengths above 1100 nm do not contribute to electricity generation, because the corresponding photons do not carry enough energy to lift electrons beyond the bandgap. Therefore, these spectral ranges between 280 nm and 700 nm as well as the remaining spectrum beyond 1100 nm (red areas) are not guided to the PV cells, but are directly transformed into accessible heat. Depending on the constructive implementation of the spectral splitting approach, the threshold wavelengths of the blue area can be varied, and therefore the configuration can be adapted to the specific PV technology in use.

The main benefits of spectral splitting integrated in a CPVT receiver can be summarized in the following way:

The electrical conversion efficiency is increased compared to full spectrum operation, because less suitable wavelengths are not directed to the PV cells.

The PV cell temperature can be kept low, even if operated under concentrated light, on the one hand, because the cells do not receive the full irradiance, and on the other hand, because waste heat dissipation within the cells is reduced by the optimized spectrum.

A large part of the solar spectrum, which would be radiated as waste heat in a concentrated PV system, becomes accessible as solar heat in a temperature range above 100 °C.

The implementation of spectral splitting in a CPVT receiver can be done in different ways based on various physical and optical effects. As thoroughly described in review articles over the past few years, splitting up the solar spectrum as explained above is possible by selective reflection, selective absorption, interference filters, glass prisms and other mechanisms [

11,

13,

14,

15]. According to the opinion of the authors, the constructive design of a spectral splitting CPVT receiver should not be too complex, because if this technology shall overcome its niche status on the long-term perspective, it must also be economically viable in the future. Therefore, the research work of the authors focusses on spectral splitting by selective absorption, because this approach appears to be promising for developing compact CPVT receivers with a high probability of being experimentally feasible [

12,

16,

17,

18,

19,

20,

21].

The main purpose of this paper is to provide an updated review on the latest developments in the research sector of spectral splitting by selective absorption. Therefore, two sub-categories are considered separately:

CPVT receiver concepts mainly published within the last three years are presented and discussed. Furthermore, the latest CPVT receiver design of the authors and significant simulation results for showing possible increase of conversion efficiency is included in this paper. An outlook for potential improvements in receiver construction concludes this review.

2. Spectral Splitting by Selective Absorption Using Liquid Filters

Within this sub-category of spectral splitting by selective absorption, the required filtering of wavelengths takes place by the heat transfer fluid (HTF), which has the main purpose of transporting the heat generated in the receiver to the connected heat sink to thermal storage. If the HTF also works as an optical filter, no additional component is needed to realize spectral splitting, which supports the aim of keeping the CPVT receiver designs as simple as possible.

One of the latest examples for such a CPVT receiver design using a liquid filter was presented by Huang et al. [

22].

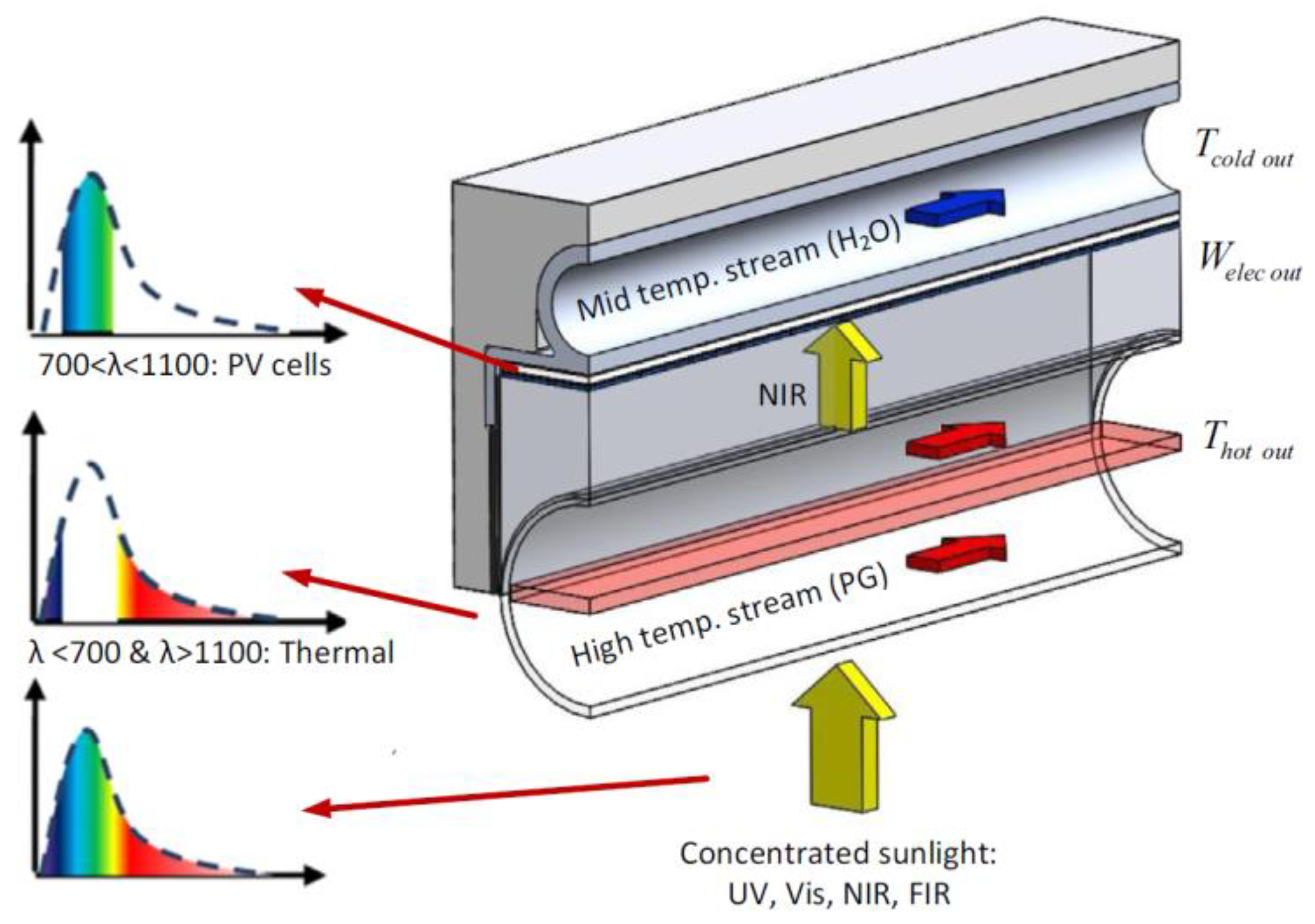

Figure 2 displays the arrangement of the CPVT receiver in the focus of a parabolic trough concentrator (left) as well as the detailed construction of the receiver itself (right), but with a horizontally mirrored view. The centerpiece of this design is the flowing optical filter fluid, which acts as HTF for the high-temperature circuit and as a spectrum-splitting optical filter. This fluid channel is surrounded by vacuum gaps for minimizing the heat loss to ambient air and undesired heat transfer to the adjacent PV module. In this configuration, the concentrated solar light enters the CPVT receiver from the bottom side, passes the first vacuum gap and penetrates the liquid filter HTF, which absorbs domains of long and short wavelengths that are unsuitable for conversion into electricity. The remaining spectral band passes the second vacuum gap and impinges the PV module, where it is converted into electricity with maximum efficiency. This receiver design offers another cooling channel at the backside of the PV module for extracting remaining waste heat that occurs within the semiconductor. In this way, high-temperature heat is provided by the optical filter fluid due to the absorption of selected wavelengths, while low-temperature heat is extracted from the PV modules by the backside cooling channel. The length of the proposed receiver is defined by 1 m, while the thickness of fluid channels and vacuum gaps is assumed to be 10 mm.

Huang et al. [

22] performed comprehensive optical, electrical and thermal modelling of their receiver design, investigated different upper and lower thresholds for the optical filter fluid, and considered two different kinds of PV technologies (Si and CdTe). Their simulations resulted in a possible output of high-temperature heat with 400 °C at a thermal efficiency of 19.5%, low-temperature heat at 70 °C with 49.5% efficiency and electrical output with an efficiency of 17.5%. The temperature of the PV module remained below 100 °C. These investigations were performed under the assumption that an optical filter fluid is available with ideal optical, hydraulic and thermal properties. This premise could be appraised as quite optimistic for the perspective of real feasibility, as experimental research has already shown [

21,

23]. Furthermore, the implementation of vacuum gaps formed by glass channels with rectangular cross-section could be challenging in terms of mechanical stability. The output temperature of 400 °C could only be reached within the simulations by setting the mass flow to a very low value of 7 kg/h. For possible future implementation in a real application, such a low mass flow rate is disadvantageous for the further transfer of the gained heat, as heat transfer coefficients in heat exchangers will be very low.

Adjustability of spectral splitting behavior is crucial for the development of such CPVT receivers, because this offers a possible adaption to different kinds of PV technologies and various demands from the application side. Han et al. [

24] concentrated their research work on the optical filter itself by investigating a hybrid base fluid consisting of CoSO

4 and propylene glycol (PG). Silver (Ag) nanoparticles in different concentrations between 5.3 ppm and 84.7 ppm were added to the base fluid, which affected the transmissivity of the liquid filter.

Figure 3 schematically illustrates the arrangement of this CPVT receiver configuration. The concentrated incident solar light penetrates the liquid filter, where a certain part of the spectrum is absorbed and converted into heat. The remaining wavelengths are transmitted to the PV cells where they generate electricity. In this case, the PV technologies Si and GaAs were considered.

The investigation of five different Ag concentrations in the nanofluid was done with comprehensive experiments on stagnant fluid within a glass container. This fluid filter with a thickness of 10 mm was arranged above the PV cells and exposed to an irradiance of 1000 W/m2 within a sun simulator. The results yielded clear coherence between the Ag particle concentration and the electrical and thermal performance of the CPVT configuration. With increasing Ag concentration, the electrical efficiency was reduced, while the thermal efficiency was rising. The maximum electrical output could be achieved with the hybrid base fluid only, without Ag nanoparticles, where the efficiency resulted in 9.74% for GaAs cells. On the other hand, the maximum thermal efficiency of 79.4% was measured with the highest concentration of Ag particles of 84.7 ppm. Although the maximum measured temperature of 61.7 °C was not yet in the range of industrial process heat, these experiments demonstrated the possibility of adapting the performance of a liquid filter according to the needs of the specific application. Furthermore, it would be recommendable to analyze the thermal and optical stability of the considered nanofluid by performing a long-term stress test at temperatures above 100 °C in order to evaluate its suitability for the industrial temperature range.

A similar approach was chosen by Huaxu et al. [

25], who investigated a liquid filter consisting of a nanofluid on a glycol basis combined with ZnO nanoparticles. The chosen PV cell technology was monocrystalline silicon with a bandgap at around 1100 nm. Therefore, the liquid filter should basically absorb the wavelengths above 1100 nm and transmit the lower domain of the spectrum (300 nm to 1100 nm) to the PV cells.

Figure 4 depicts this configuration in a schematic way.

Experimental analysis of different fluid configurations was performed by varying the concentration of ZnO nanoparticles between 11.2 ppm and 89.2 ppm. The nanofluid was tested on a 2-axis tracking solar collector with a Fresnel lens concentrator. The resulting tendencies of the performance measurements correlated to the ones from Han et al. [

24], as rising ZnO concentration led to reduced electrical output but increased thermal output of the CPVT system. While the electrical efficiency decreased from 14.49% to 13.1%, the thermal efficiency could be raised from 7.4% to 10.97% with adding more ZnO to the nanofluid. However, the absolute numbers of thermal efficiency would require further investigation. Besides technical performance evaluation, Huaxu et al. [

25] also compared the ZnO nanofluid with other fluids in terms of costs. At the time of publication at the beginning of 2020, the price for ZnO nanoparticles was 0.285 USD/g, whereas Ag nanoparticles utilized by Han et al. [

24] as mentioned above had a price of 37.5 USD/g. This difference in costs corresponds to a factor of 132, which illustrates clearly that ZnO nanoparticles can contribute to lowering the overall costs for CPVT receivers using liquid optical filters.

3. Spectral Splitting by Selective Absorption Using Combined Liquid and Solid Filters

Selective absorption by liquid filters only, as described above, provides the advantage that just one component, namely the fluid, is required to achieve the desired splitting of the spectrum. This approach supports the general aim to keep the complexity of such CPVT systems low, which is important to be competitive to other renewable energy technologies. However, the simplification of the spectral splitting mechanism to only one filter element is linked with a reduced degree of freedom in terms of wavelength selection. Applicable fluids usually have a characteristic decrease of transmittance for long wavelengths, which meets the exact requirements for the spectral splitting approach (see

Figure 1), but the desired absorption of short wavelengths by the fluid is mostly not provided, as experimental transmissivity investigations have shown [

16,

17,

21,

23].

By contrast, the implementation of a solid absorption filter in combination with the filtering fluid offers the additional possibility to clearly define the transmission characteristic of the filter configuration also in the range of short wavelengths.

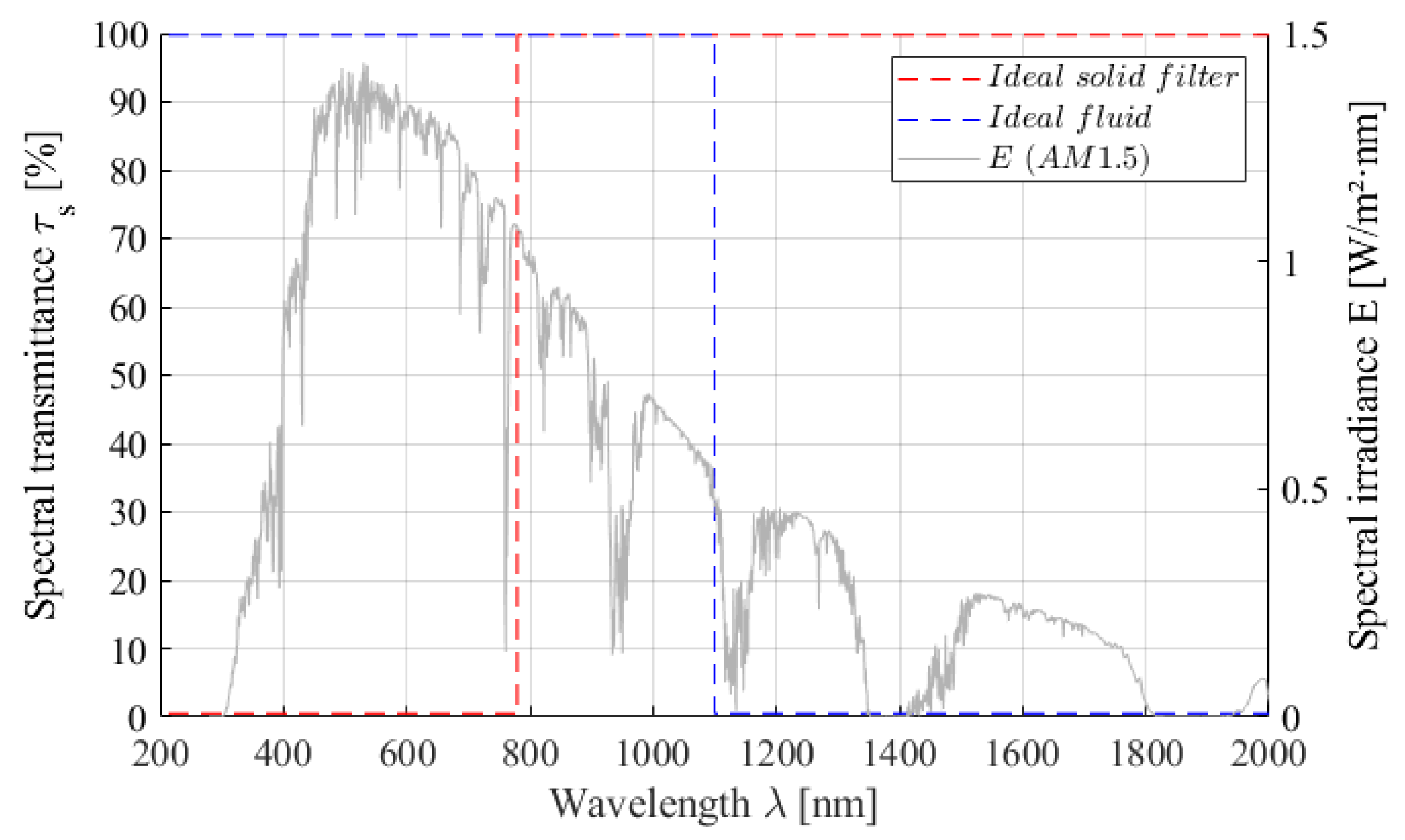

Figure 5 shows that the spectral transmittance of the combination of ideal solid and liquid filters overlapped with the AM1.5 spectrum [

26]. The red dashed line describes the transmission characteristic of the solid filter, providing full absorption of the short wavelengths up to a selectable threshold, which is at 780 nm in this exemplary case. Above this threshold wavelength, the remaining spectrum is ideally transmitted without any losses. The transmissivity of the ideal fluid, illustrated as a blue dashed line, shows the opposite behavior by transmitting the short wavelengths and absorbing the long ones. The threshold wavelength at 1100 nm corresponds to the results of experimental measurements. If both filter elements are combined, only the spectral band between the two threshold wavelengths is transmitted to the PV cells, which is between 780 nm and 1100 nm in this illustrated case, whereas all other domains of the spectrum are absorbed either by the solid or the liquid filter and directly converted into accessible heat.

Compared to approaches with liquid filters only, the combination with a solid filter element reveals the advantage that the lower threshold wavelength with a sharp rising edge of transmissivity can be selected by the specific type of filter. In this way, the entire filter characteristic can be adjusted to different PV technologies to support varying spectral requirements. On the other hand, this adjustability provides the option to choose the fractioning between electrical and thermal output of the CPVT system, which can make it possible to configure the CPVT collector according to the customers’ needs [

12].

Stanley et al. [

27] presented such a CPVT receiver design including the combination of solid and liquid filter elements; see

Figure 6. The solid filter (visualized in red) is made of semiconductor-doped glass (SDG) and is implemented in a glass tube filled with propylene glycol (PG) which serves both as HTF and liquid filter. This thermal part of the receiver absorbs wavelengths below 700 nm and above 1100 nm, according to the chosen kind of SDG filter and the transmissivity characteristic of PG. The near-infrared (NIR) range of the spectrum (700 nm to 1100 nm) is directed to the crystalline silicon cells mounted in an aluminum profile for being converted into electricity with maximum efficiency. The remaining waste heat of the PV cells is extracted by an additional cooling channel at the back, which is driven with water. The resulting gap between the tubular thermal part and the planar electrical part of the receiver is filled with transparent silicone, serving as optical coupling by reducing reflection losses on the boundary layers. Thermal insulation of the entire receiver decreases heat losses due to convection and radiation. Stanley et al. implemented the CPVT receiver concept as a prototype and conducted performance measurements on a parabolic trough concentrator. The high temperature circuit provided a maximum temperature of 120 °C with a thermal efficiency of 31%, concurrently with an electrical power output of 85 W

el and an efficiency of 3.8% related to total incident irradiance. The backside cooling of the PV cells appeared to work well, as the cell temperature could be limited to 29 °C during the measurements. At the measurement point of maximum output temperature, the thermal power of the high temperature part was 500 W

th, while the PV cooling channel gained a thermal power of 595 W

th. Therefore, Stanley et al. concluded that filling the gap between the two receiver parts with silicone caused an undesired heat transfer to the PV cells, which resulted in an exergy loss. Furthermore, the introduction of an enveloping glass tube around the thermal receiver part was recommended for reducing the influence of wind speed on the thermal performance.

Another receiver design with combined solid and liquid filter elements was developed by Han et al. [

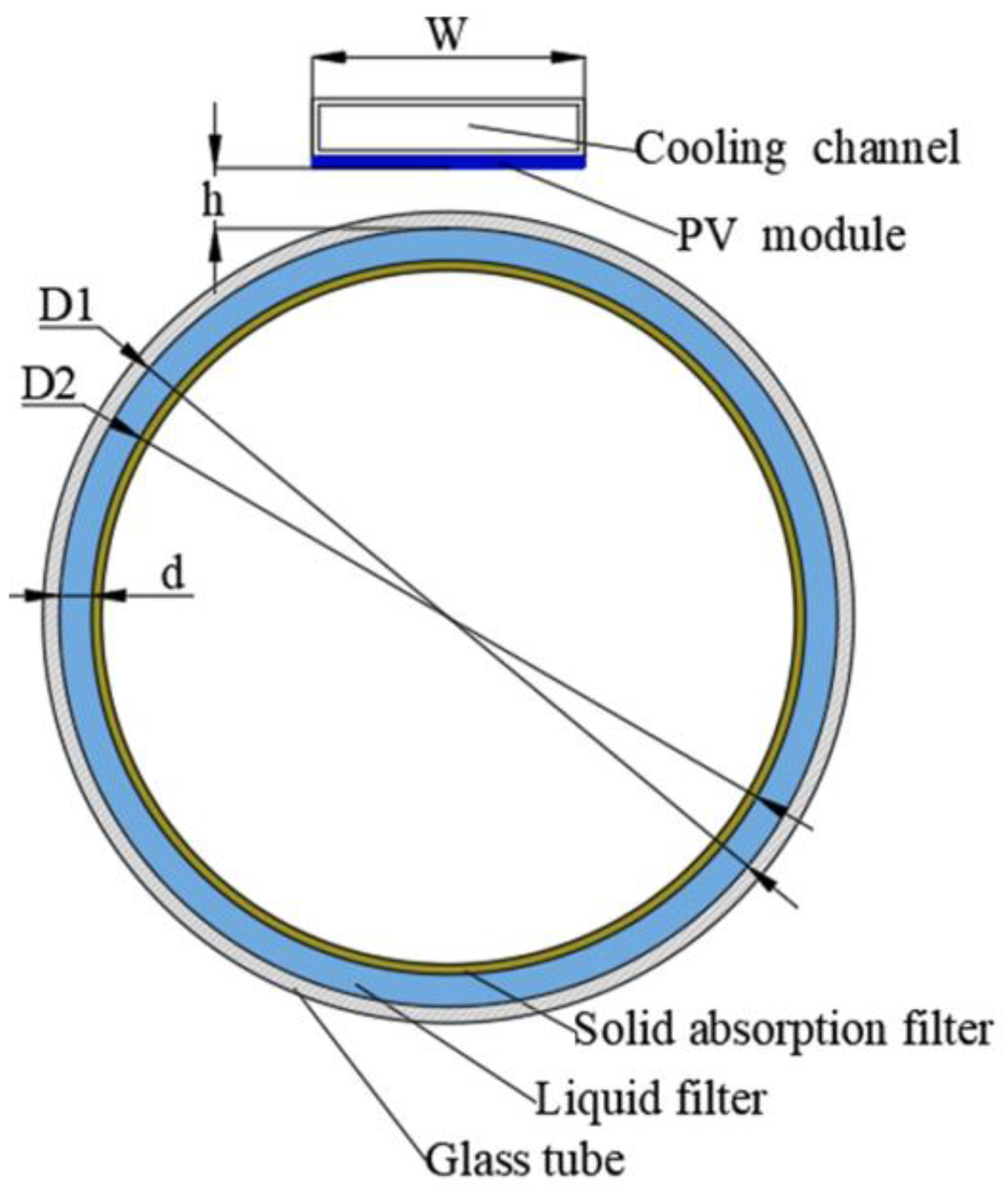

28] (see

Figure 7) for a possible implementation on a linear Fresnel concentrator. The novelty of this proposal can be seen in the tubular shape of the solid absorption filter made of semiconductor-doped glass. Together with the outer glass tube, an annular clearance is formed, which is filled with PG, serving both as a liquid filter and HTF. The inner volume of the thermal receiver part is air. The electrical part of the CPVT receiver consists of mono-crystalline silicon cells, equipped with a backside cooling channel for taking the remaining waste heat from the semiconductor. The dimensions of this tubular receiver concept are declared to be adjustable according to the respective Fresnel mirror field applied. An optical modelling of this configuration was done by using the ray-tracing software LightTools. However, an incident angle of 0° was considered, meaning that the optical simulation was restricted to vertical rays only. For experimental measurements, a simplified receiver configuration was used, consisting of an SDG filter with a threshold wavelength of 650 nm, but in a planar design. The incident irradiance was provided by a non-concentrating sun simulator and reached a maximum value of 1000 W/m

2. The thermal performance of this arrangement resulted in an efficiency of 40.74% at a maximum fluid temperature of 48.9 °C, whereas an electrical efficiency of 6.03% was achieved. Furthermore, the combined filter configuration was compared to PG-only as the liquid filter, which obtained a much lower thermal efficiency of 13.73%. Although the proposed CPVT receiver design appears to be unique, the availability of a tubular-shaped SDG filter could be challenging to implement as a full prototype.

By contrast, technical feasibility was a major aspect during the developing phase of a novel CPVT receiver design proposed by Resch and Höller [

12].

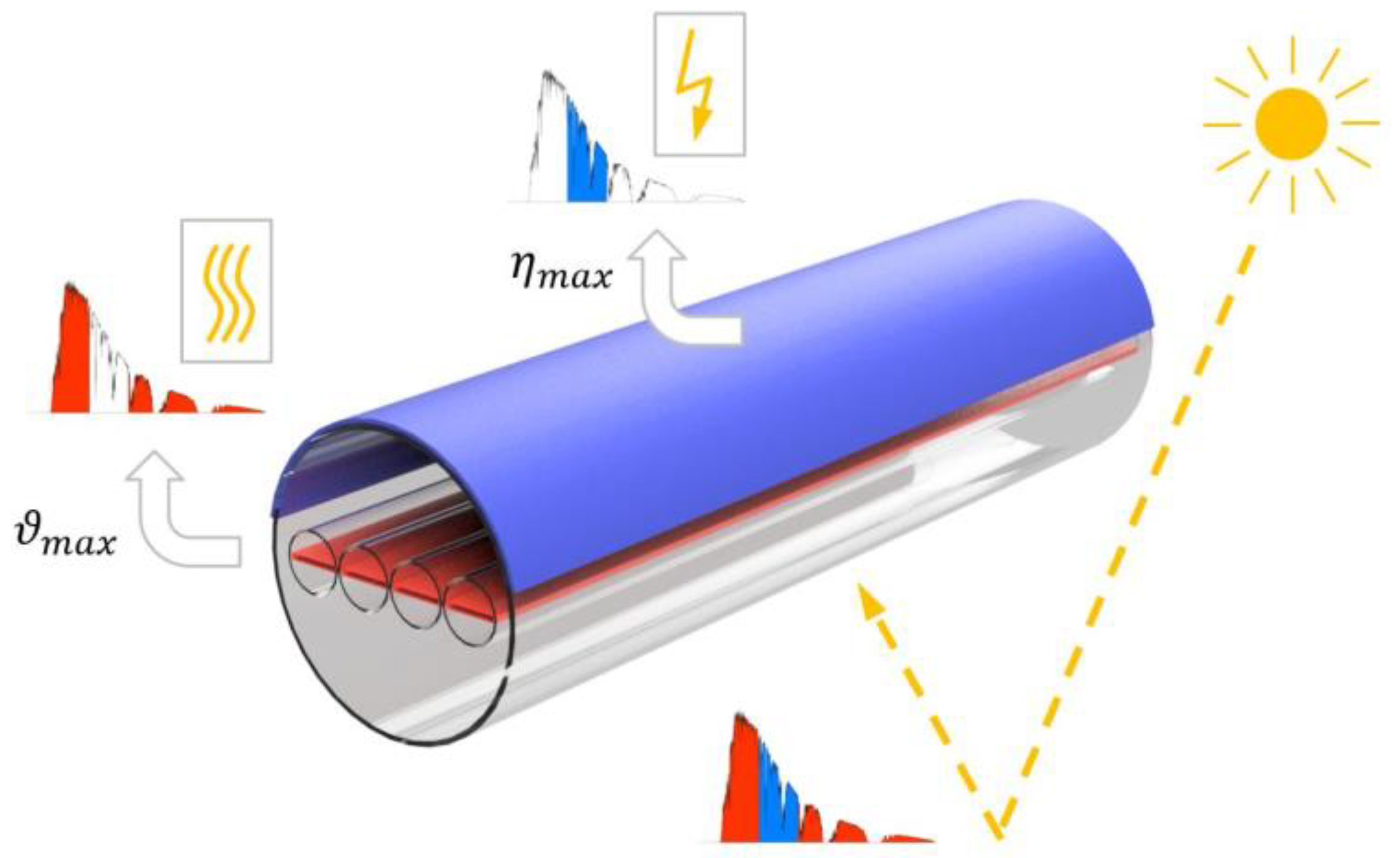

Figure 8 provides the cross-section of the proposed concept, whereas

Figure 9 presents the rendering of a 3D visualization of the receiver. All dimensions are given in mm. The thermal part of the receiver consists of four glass tubes, each hosting an SDG filter with a threshold wavelength of 780 nm. A novel heat transfer fluid named triethylenglycol was considered for this concept and was already successfully tested with respect to its optical, thermal and hydraulic properties, also including long-term stress tests [

21]. This combination of solid and liquid filters results in a wavelength band of 780 nm to 1100 nm that is directed to the PV cells, based on CIGS technology. The implementation of bendable thin-film PV is another novelty of this CPVT receiver concept, which supports the aim of keeping material costs low. Any flexible CIGS PV module from mass production can be used for this purpose, as it is superimposed to the outer glass tube and mechanically fixed. However, the required bending radius of 70 mm must be supported by the PV module. Due to the application of bendable PV modules, the realization of a very compact receiver cross-section becomes possible. The main purpose of the enveloping glass tube is to reduce the heat transfer of the thermal receiver part towards both directions, to ambient air as well as to the PV part. Furthermore, the influence of wind speed on the thermal performance can be minimized by this outer glass tube. The number of four inner glass tubes was chosen with regard to the Fresnel mirror field serving as concentrator for this developed receiver. Simulations and experimental optimization of the mirror field resulted in a focus image width of 80 mm in the expected receiver input plane [

29]. Therefore, the total width of the required SDG filter was defined by 100 mm in order to have some tolerance for inaccurate focusing. As realizing this filter width in one piece is hardly feasible, the illustrated approach of four adjacent glass tubes with implemented SDG filters was chosen.

For reasons of clarity, the hydraulic connections of the inner glass tubes, the end cap of the outer glass tube and the Fresnel concentrator are not displayed in

Figure 9. Depending on the corresponding application and the hydraulic boundary conditions, the connection of the inner glass tubes can either be done in series or in parallel, resulting in more temperature gain or in less pressure drop, respectively.

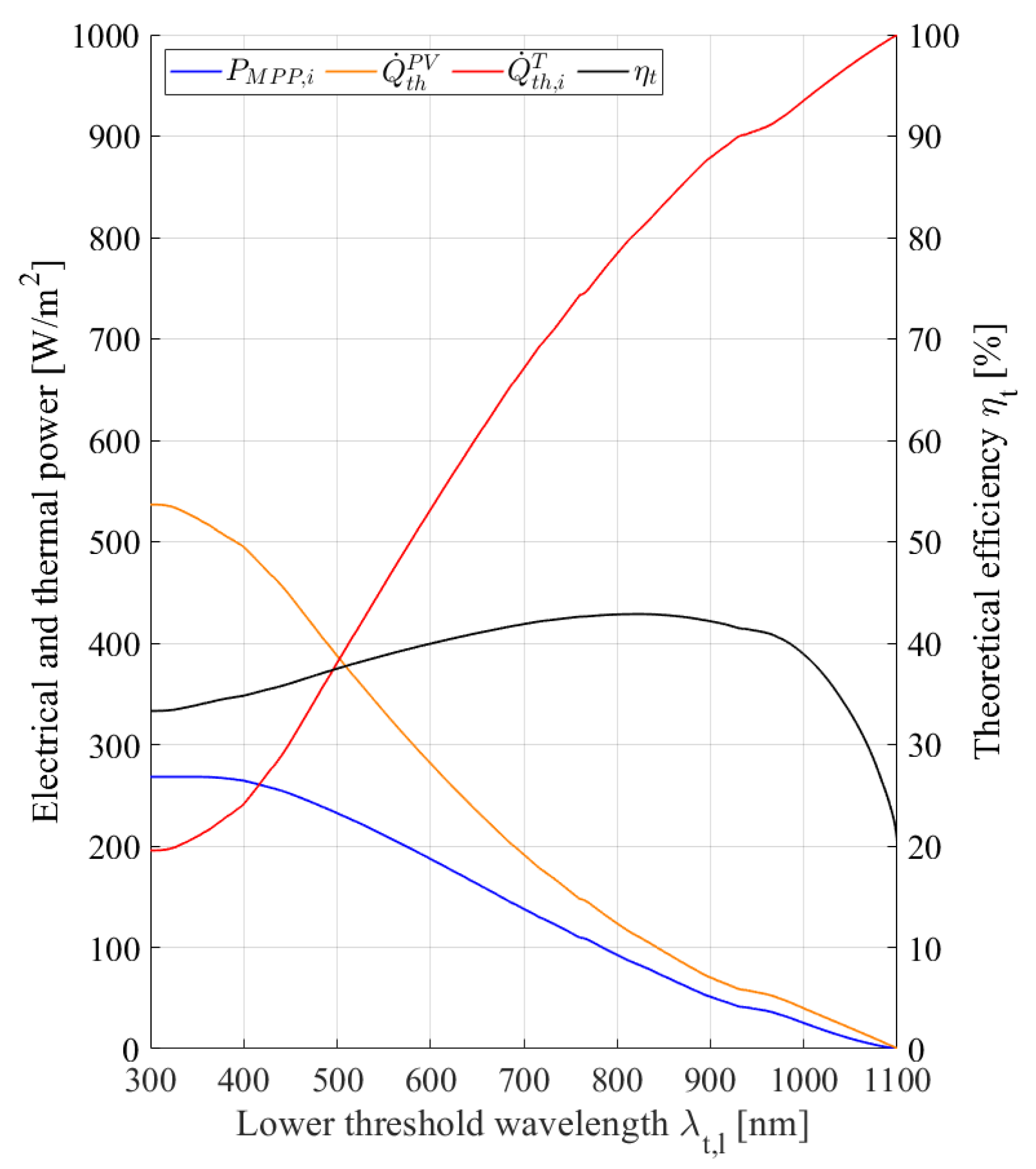

4. Simulations of Potential Increase in Electrical Efficiency by Spectral Splitting with Combined Solid and Liquid Filters

The CPVT receiver design of Resch and Höller, as described in

Section 3, was analyzed by comprehensive modelling using MATLAB™. One of the major results is the potential increase of electrical conversion efficiency due to the applied approach of spectral splitting using a combination of solid and liquid filter elements. These simulations were done for the three PV technologies c-Si, CIGS and CdTe, whereas

Figure 10 only depicts the results for CIGS. The

x-axis corresponds to the lower threshold wavelength

given by the transmissivity characteristic of the SDG filter, which is assumed to be steplessly selectable in the range between 300 nm and 1100 nm by choosing different filter types. By contrast, the upper threshold wavelength is kept constant at 1100 nm, because it is defined by the fluid triethylenglycol. The illustrated results were calculated based on an irradiance of 1000 W/m

2, as the impacts of concentration factor and cell temperature were investigated separately. The blue curve in

Figure 10 represents the electrical power output

, which is decreasing with rising

, because the irradiance directed to the PV cells is reduced. However, the ideal thermal power

(red line) is ramping up for the same reason. The spectral splitting effect becomes obvious by decreasing waste heat dissipation

within the PV cells (orange curve) and by the black line representing the theoretical efficiency

, which shows a maximum of 42.9% for the case of using a solid filter with a

of 823 nm. Compared to the conventional full spectrum operation of CIGS cells, where a theoretical efficiency of 28% is reported [

30,

31,

32], the relative increase of conversion efficiency due to the application of spectral splitting amounts to 53.2%.

5. Potential Further Improvements

Research results with different spectral splitting approaches are promising for raising the conversion efficiency of CPVT receivers, as described in

Section 2,

Section 3 and

Section 4, thus revealing potential for further improvement.

Investigations of nanofluids acting as liquid filters confirmed their feasibility for achieving the required splitting of wavelength ranges and proved the possibility of influencing the transmissivity behavior by changing the concentration of dispersed nanoparticles [

22,

24,

25]. The spectral splitting effect using liquid filters could only be further improved if the upper threshold wavelength, which is currently around 1100 nm for most of the investigated fluids, could be actively modified by adding nanoparticles. This would help to raise the flexibility of adapting the filter characteristic towards the specific needs, depending on the PV technology or the application requirements. The current lack of adaptability caused by the fixed upper threshold wavelength of the fluids also appeared to be disadvantageous during simulations of the CPVT receiver concept of Resch and Höller. The analyzed CdTe PV cells cannot convert wavelengths above 900 nm, caused by the particular bandgap energy. Therefore, the spectrum range between 900 nm and the fluid’s upper threshold wavelength of 1100 nm is fully dissipated as heat within the cells, and thus reduces the total conversion efficiency [

12].

The CPVT receiver design proposals using combined liquid and solid filters generally provide higher flexibility for adapting the spectral splitting configuration, compared to liquid filters only, as the lower threshold wavelength can be chosen accurately by the implemented type of SDG filter. However, these solid filters are originally produced for the optics industry with very high requirements in terms of quality and filtering accuracy, resulting in high material costs. Moreover, the available size of SDG filters is limited, requiring further effort to join several pieces of filter elements for producing a strip-type filter with an according length to be implemented in a CPVT receiver [

27]. Potential for improvement in this regard could be seen in researching solid filters based on simpler materials, e.g., colored glass, which provide sufficient filtering quality for significantly reduced costs.

For the specific receiver design of Resch and Höller (see

Figure 8 and

Figure 9), a possible enhancement is discovered by optimizing the size of the PV modules attached to the enveloping glass tube on top. Simplified optical calculations resulted in the assumption that the width of the PV surface can be reduced, as the concentrated beams reflected by the Fresnel mirror field are more centered above the thermal receiver part than expected. A detailed optical investigation by ray-tracing methods will obtain reliable results and will therefore contribute to further improving the receiver concept by reducing the required PV surface.