Energy Performance and Control Strategy for Dynamic Façade with Perovskite PV Panels—Technical Analysis and Case Study

Abstract

1. Introduction

1.1. State of the Art, Related Work

- First generation, with single-crystal and monocrystalline silicon as well as polycrystalline and multicrystalline silicon—classic PV panels, generally not flexible;

- Second generation, with amorphous silicon, cadmium telluride, and copper indium gallium selenide—flexible;

- Third generation, with a very wide spectrum of materials such as organic solar cells, nanocrystal solar cells, and perovskite solar cells (PSCs)—flexible, thinner, and semi-transparent.

1.2. Contributions

- Detailed technical analysis of a pilot installation with PPV panels for a specific location in Central and Eastern Europe—a real case study;

- An original set of measurement data of the most important parameters that have a direct impact on the energy efficiency of the dynamic building façade with PPV panels (short measurement periods for different seasons, conditioned by the availability of a pilot installation);

- Multi-faceted analysis of power effectiveness and performance of PPV panels, considering trends of changes in the operating conditions of the pilot installation, along with a discussion of the results;

- New strategy for control of the dynamic building façade to improve its energy efficiency and ensure the comfort of use of the rooms behind it.

2. Methods and Tools

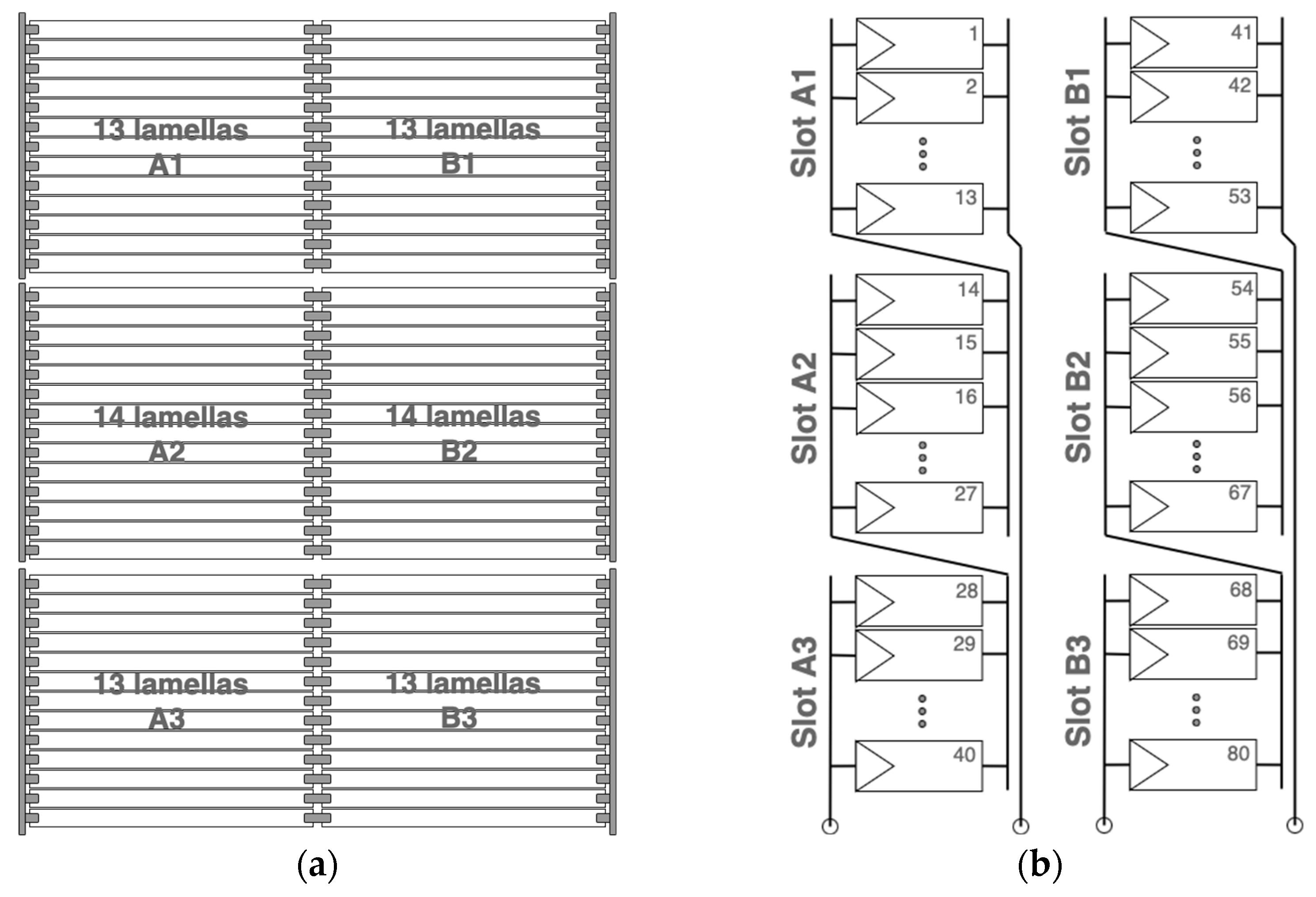

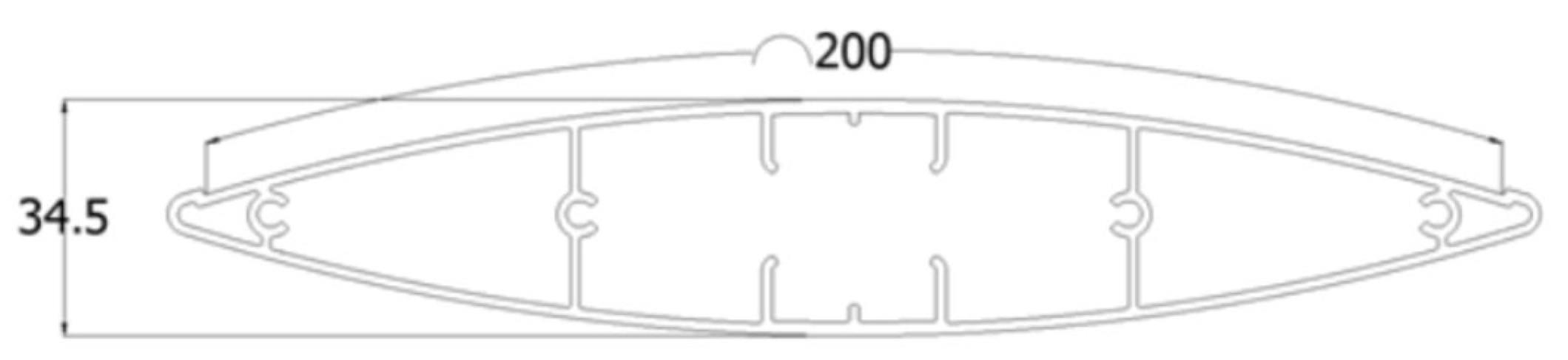

2.1. Perovskite PV Pilot Façade

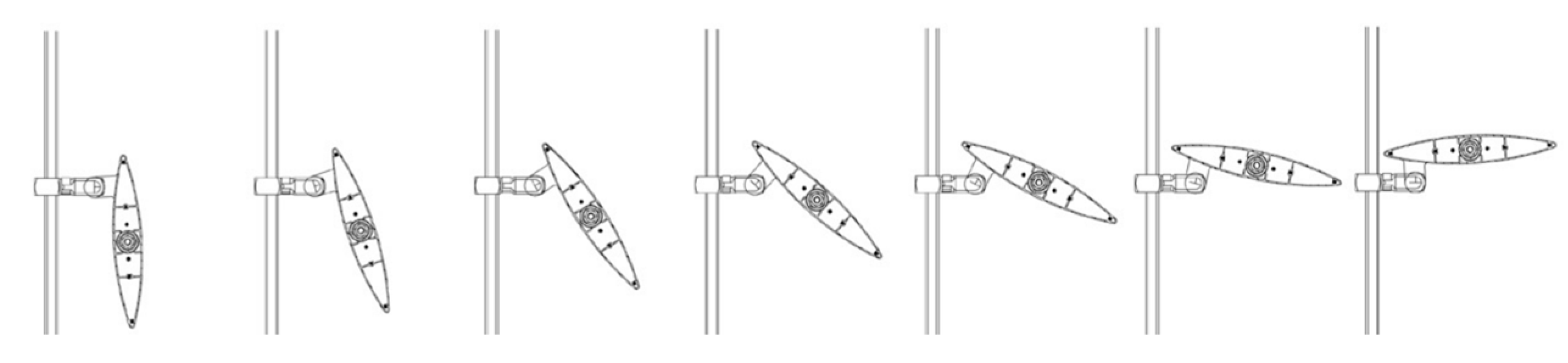

2.1.1. Moving PPV Slats with Motors

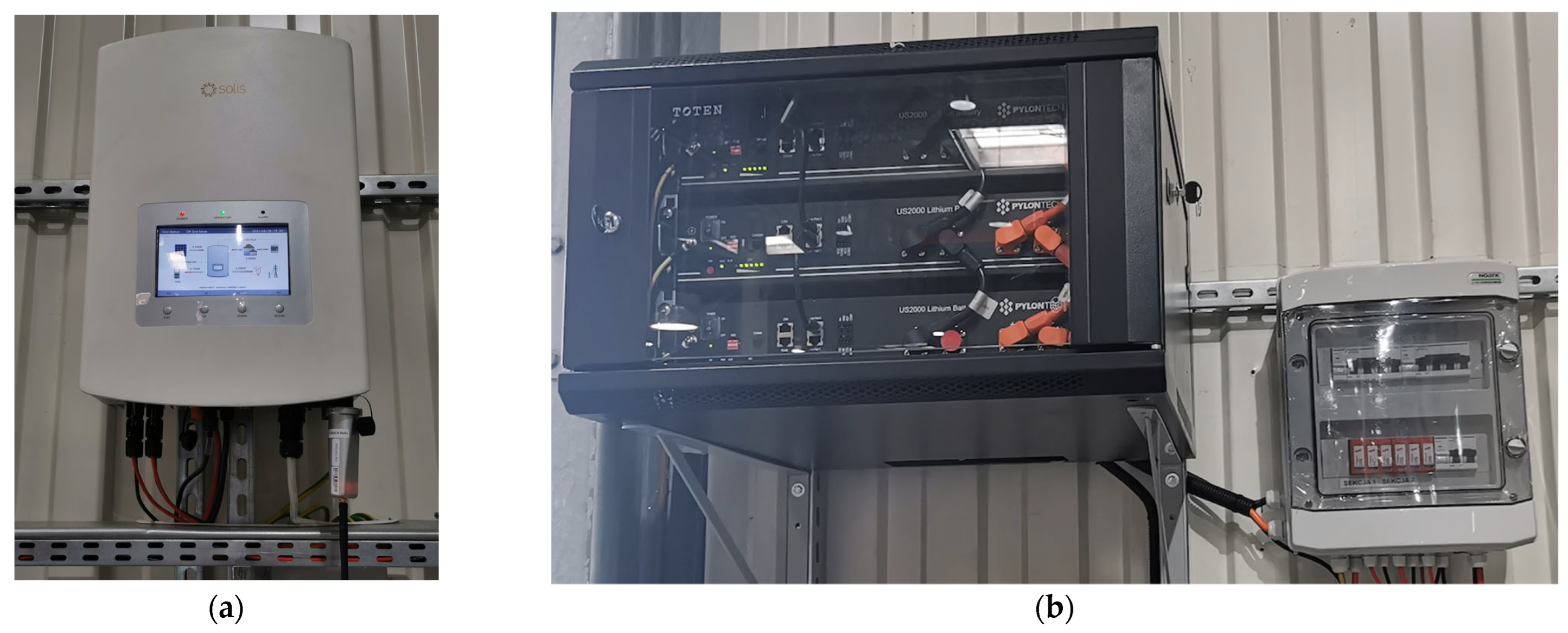

2.1.2. Inverter and Batteries

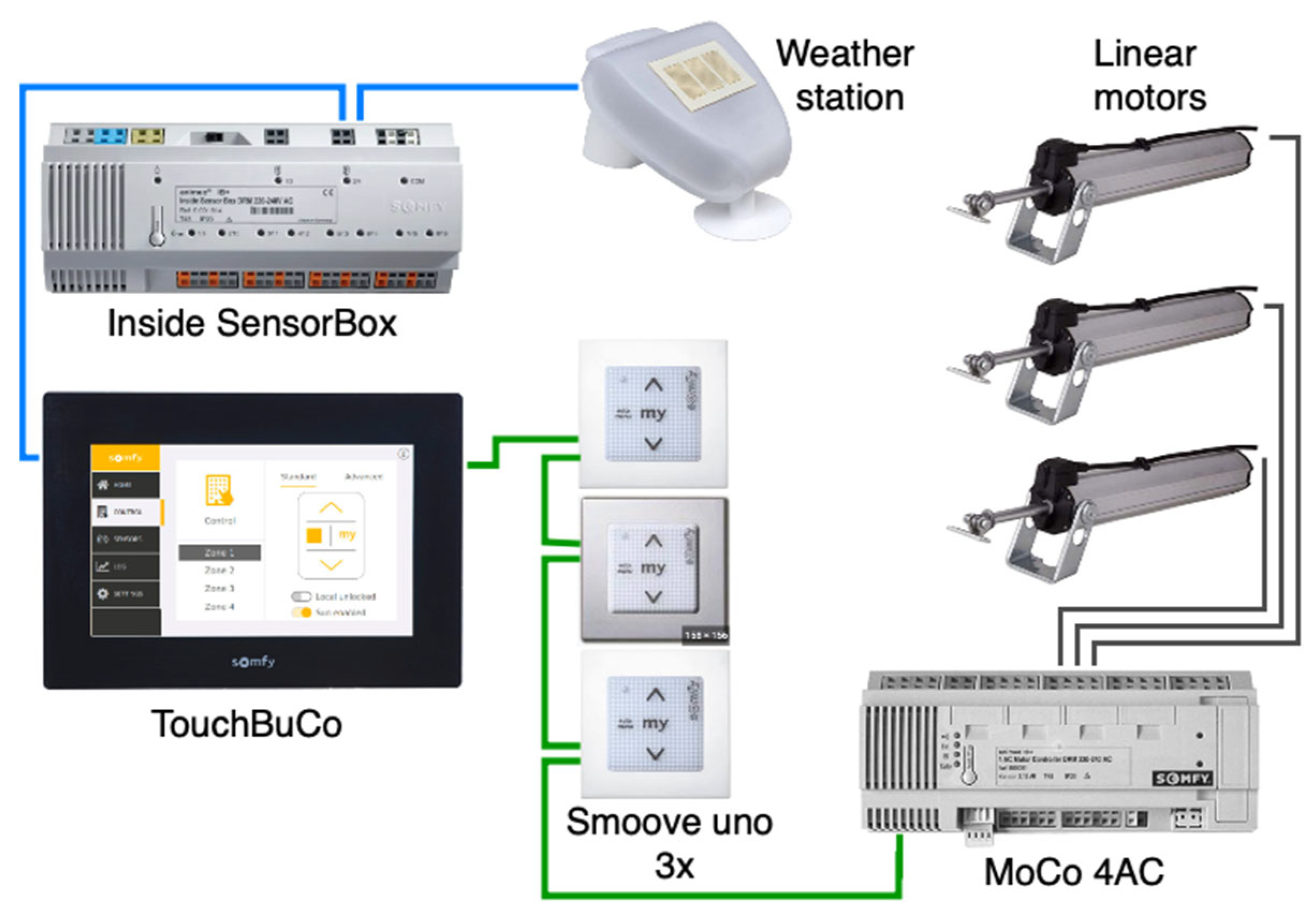

2.2. Automation System Devices and Configuration

2.3. Measurement Stand and Procedures

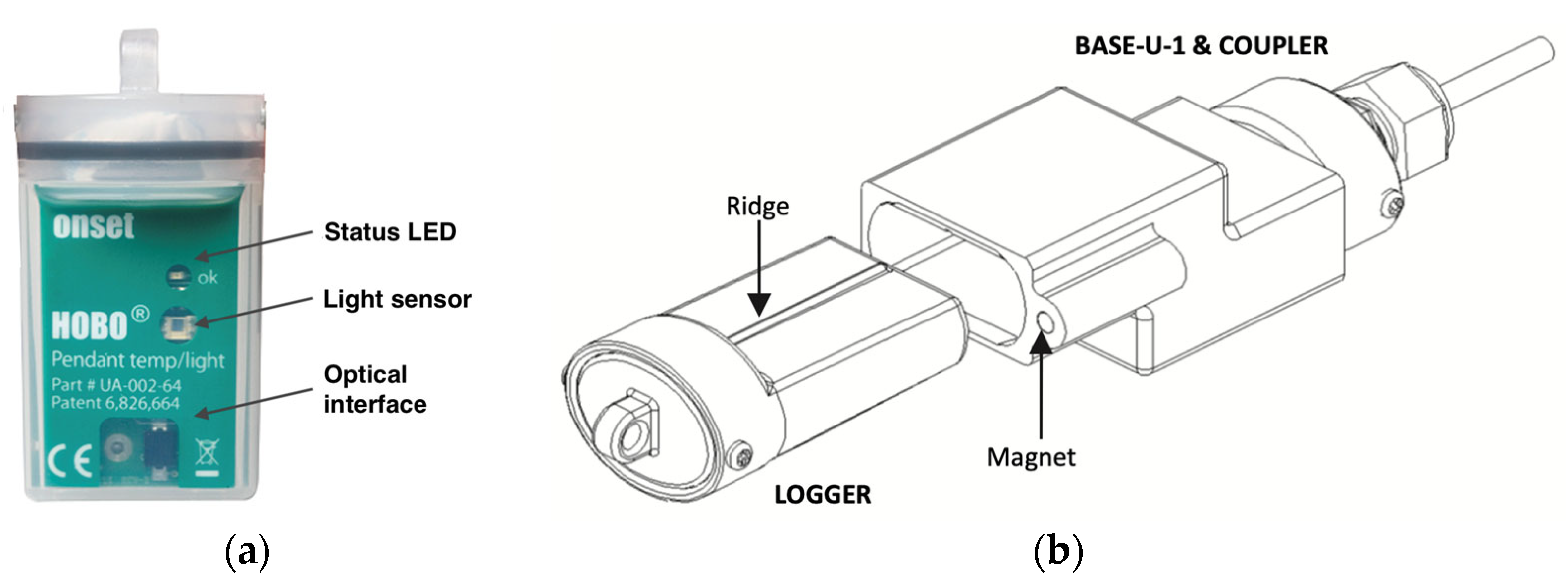

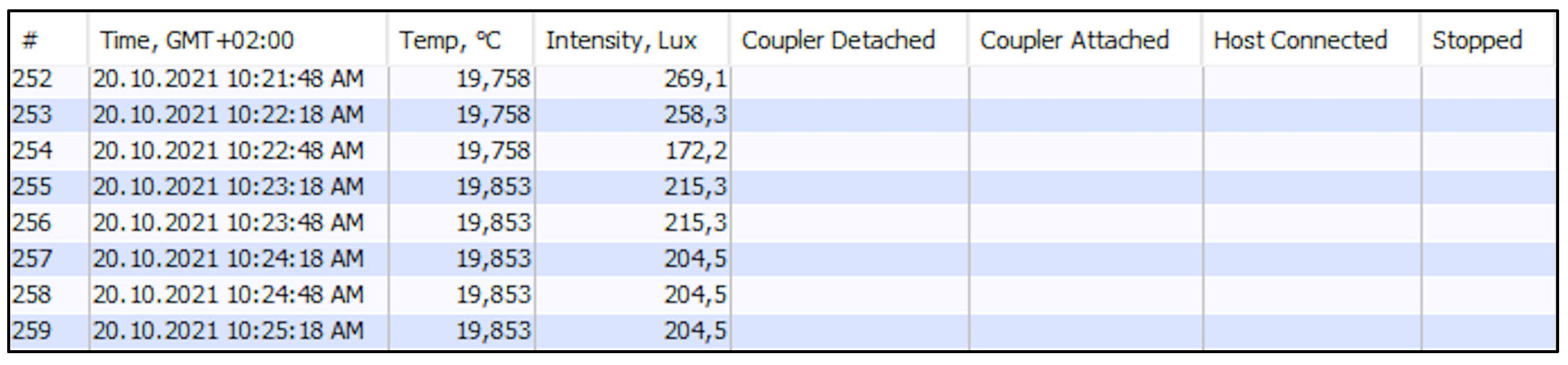

2.3.1. Sunlight Illuminance and Temperature Sensor

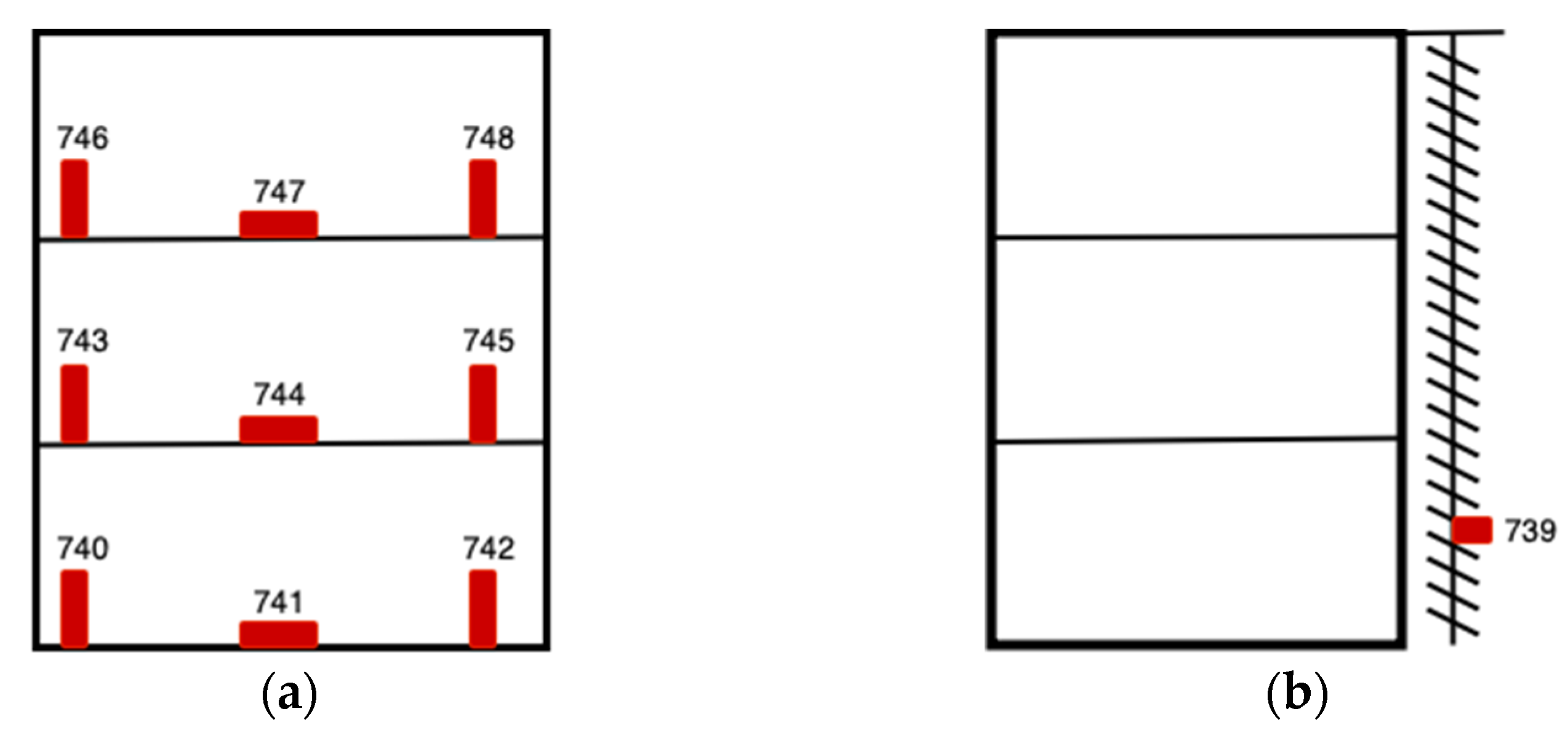

2.3.2. Measurement Stand and Infrastructure

3. Experimental Results, Analysis, and Discussion

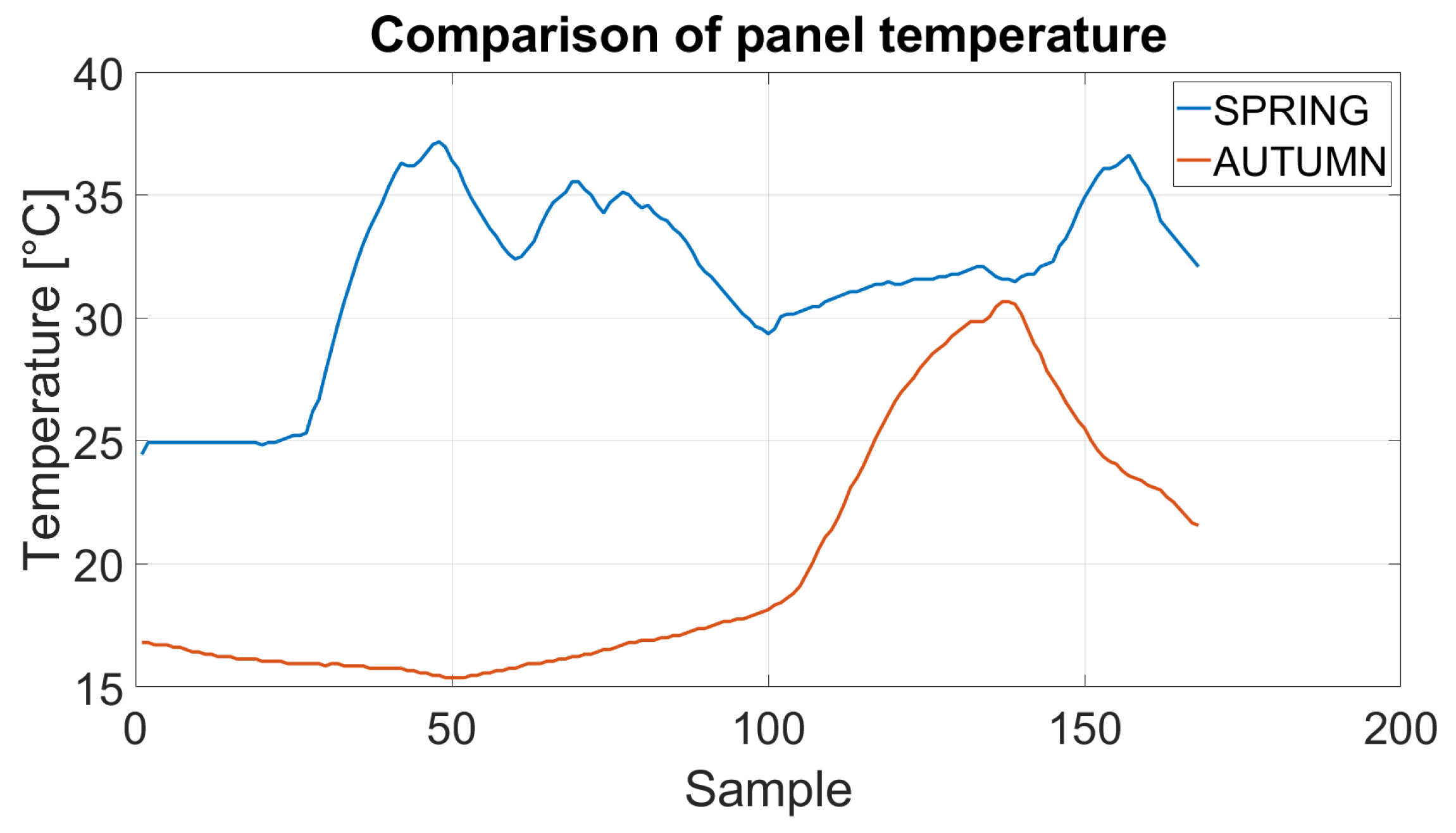

3.1. First Measurement Session—Autumn

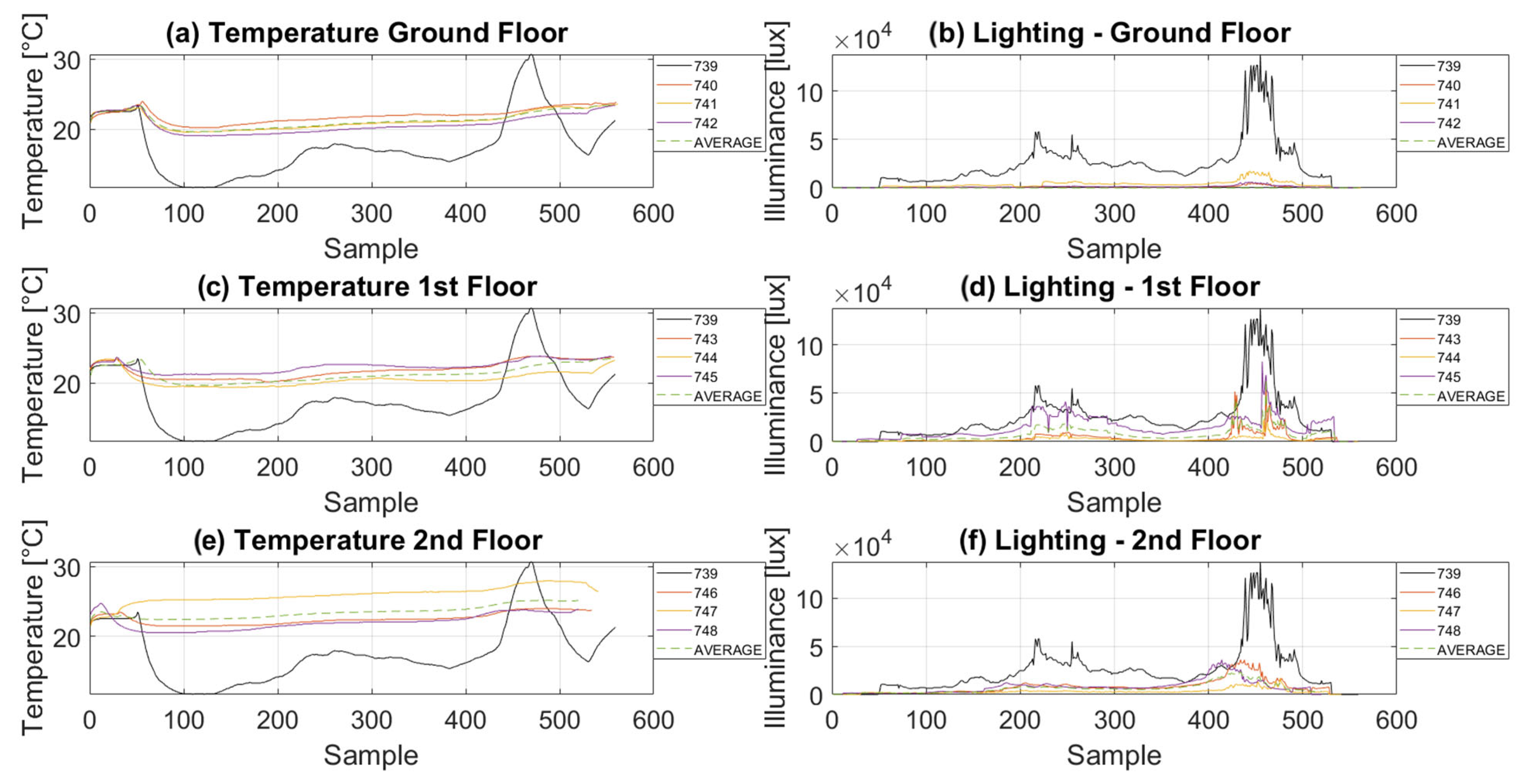

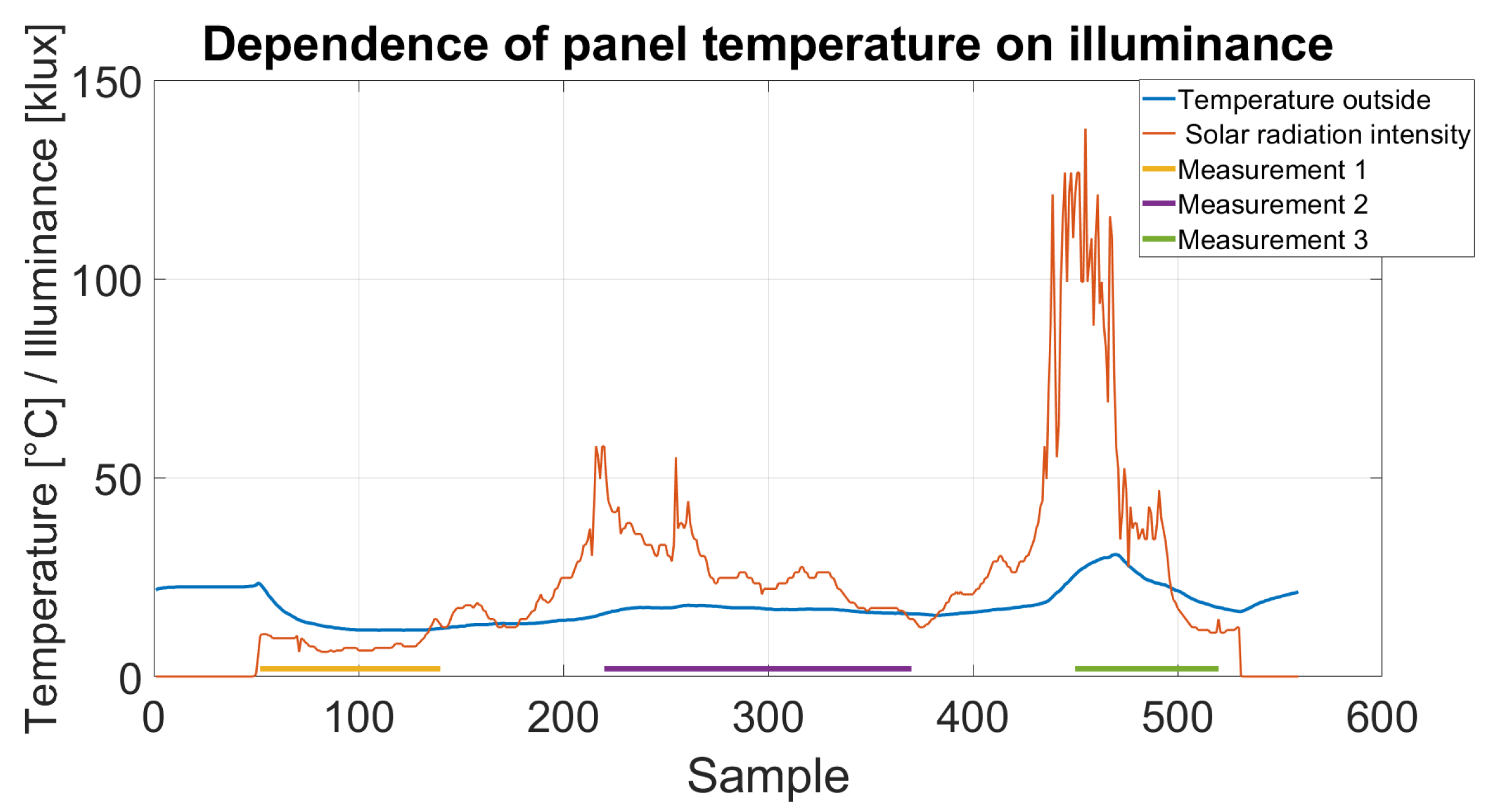

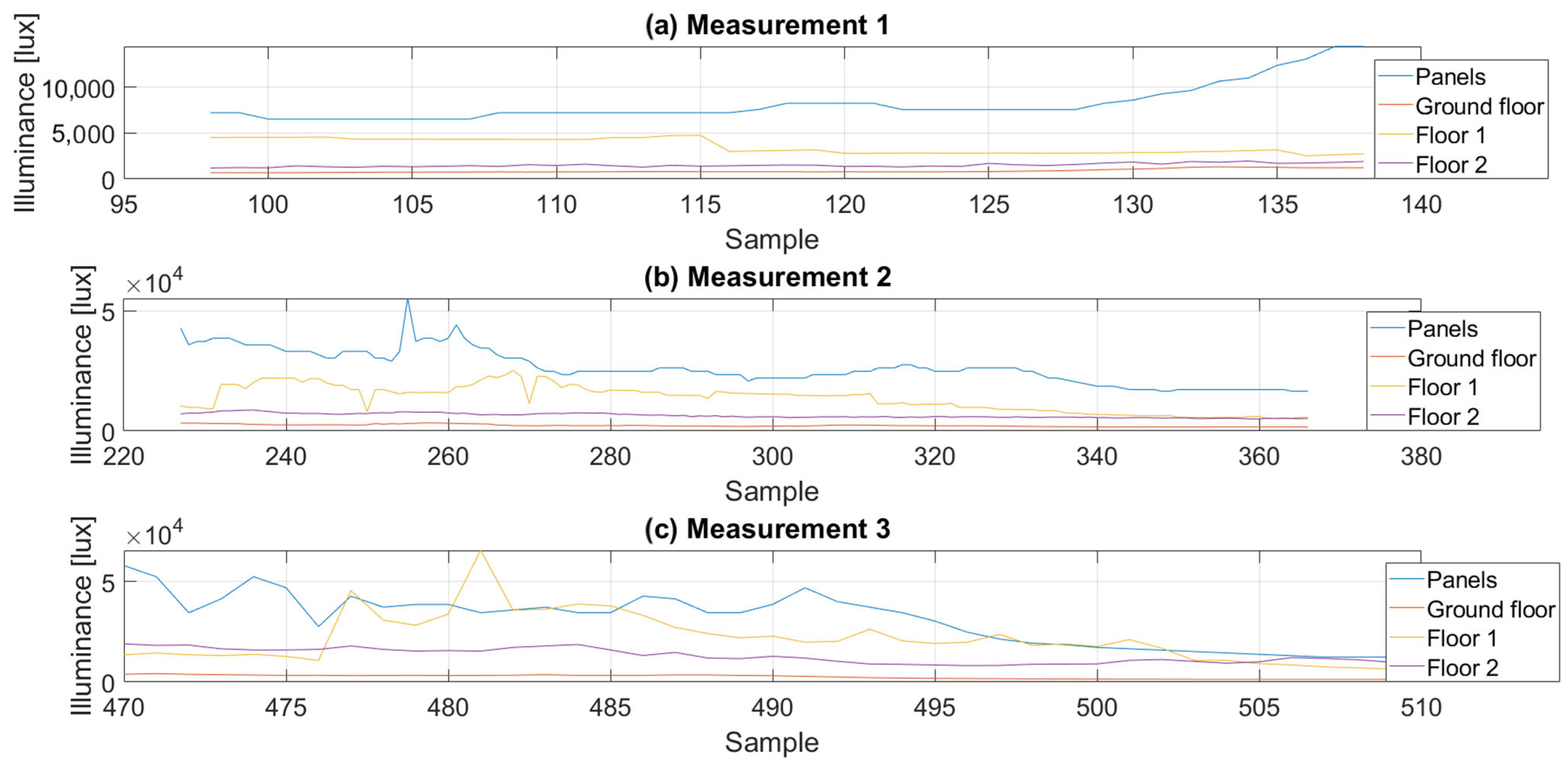

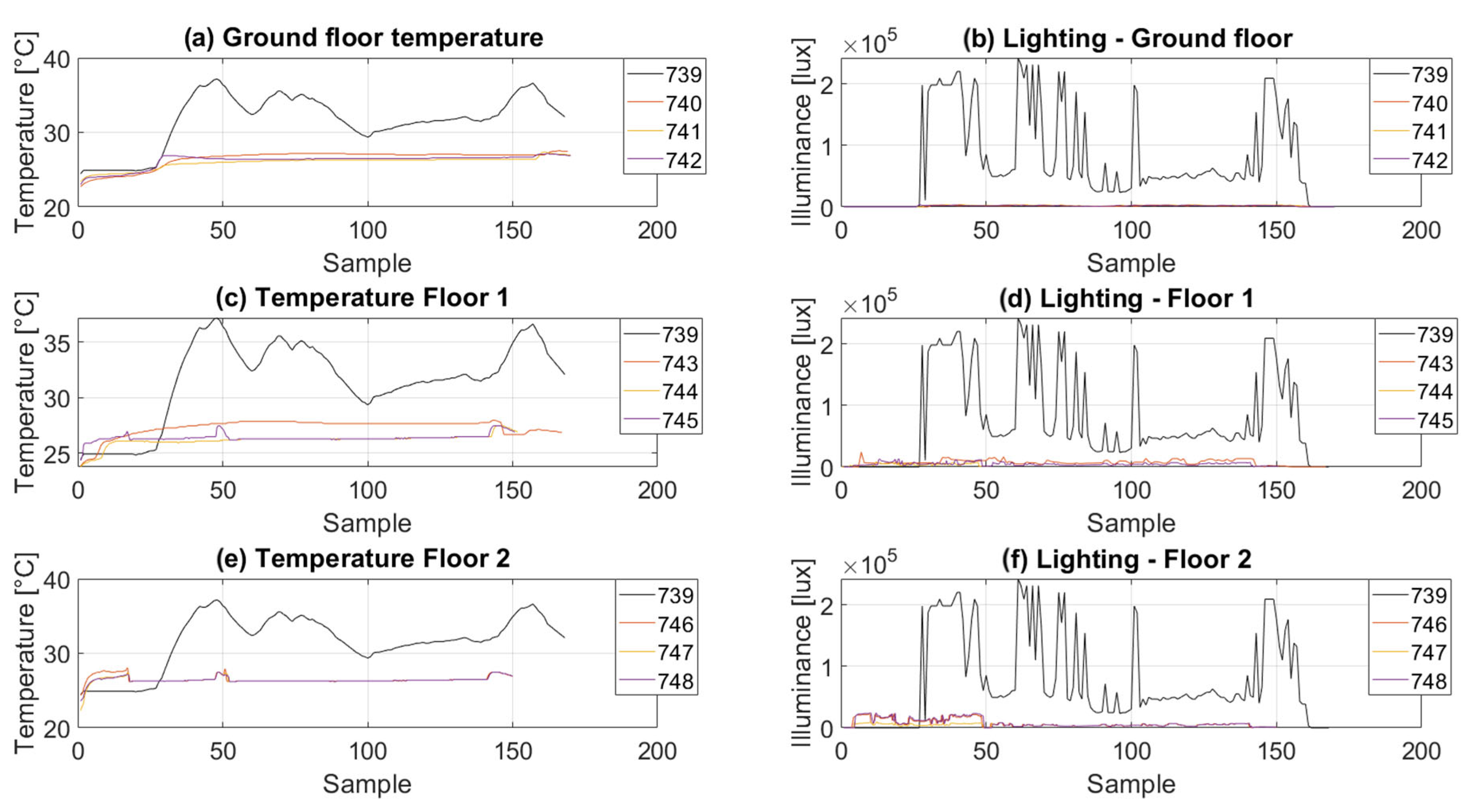

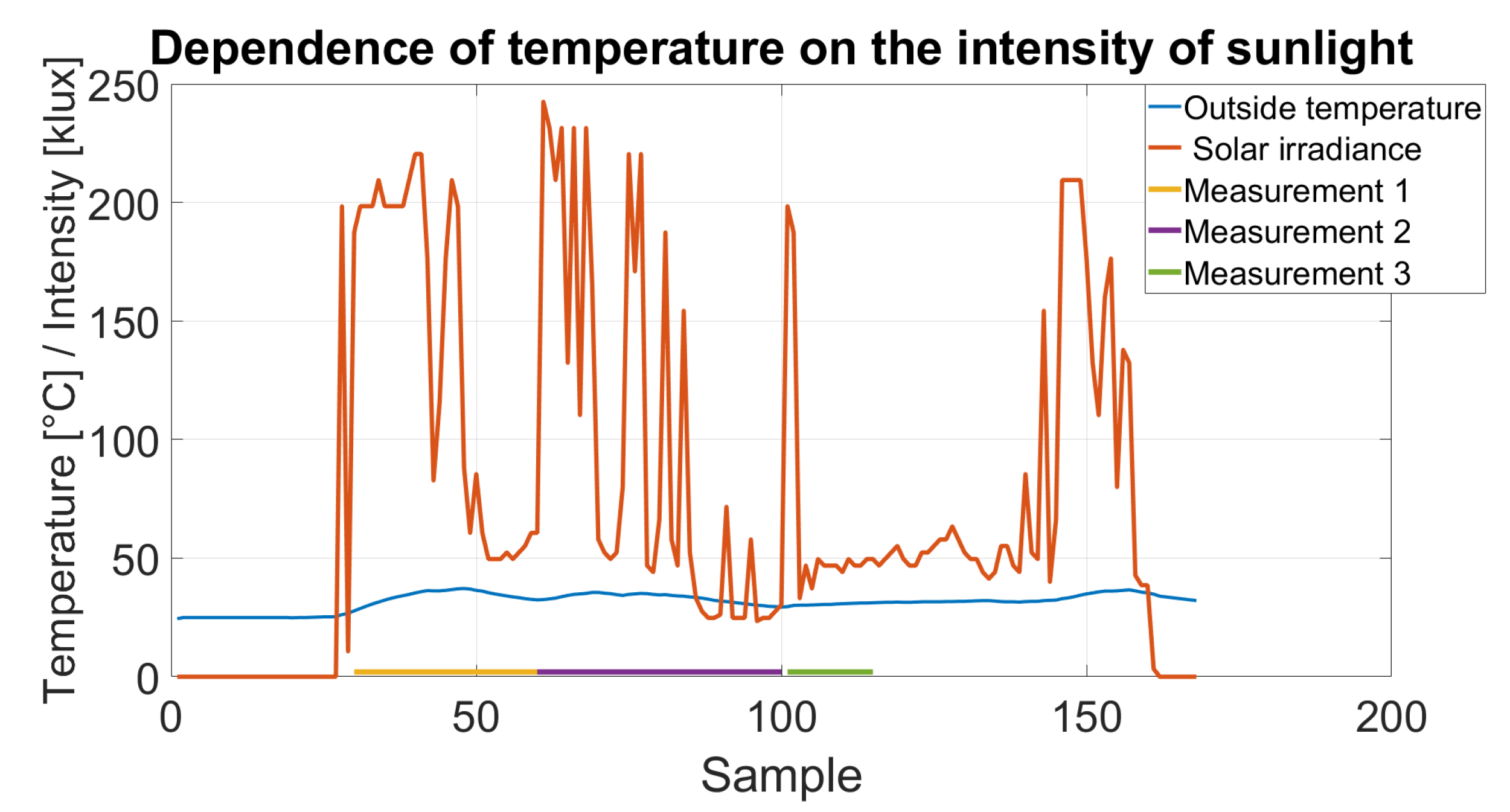

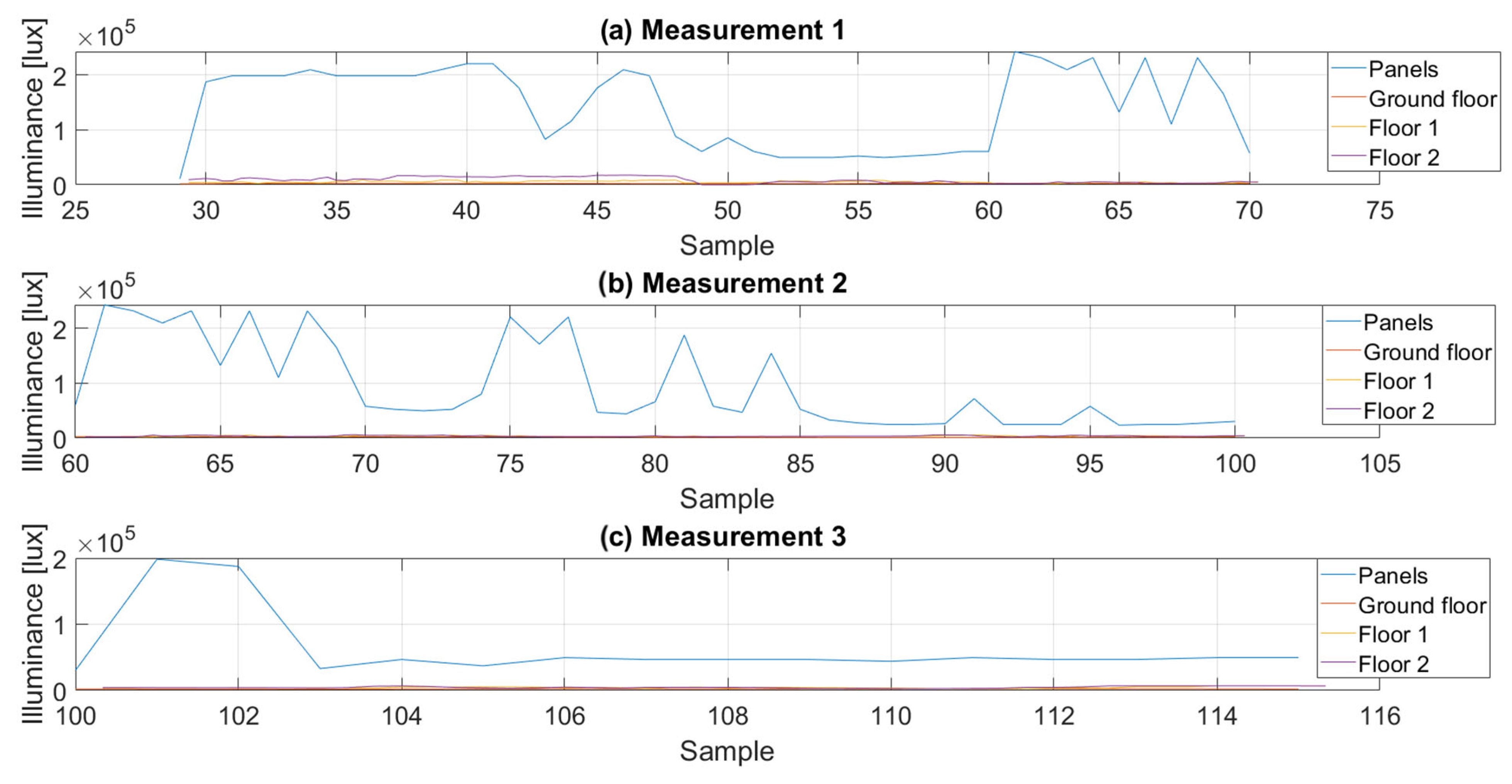

3.1.1. Dynamic Façade Measurements

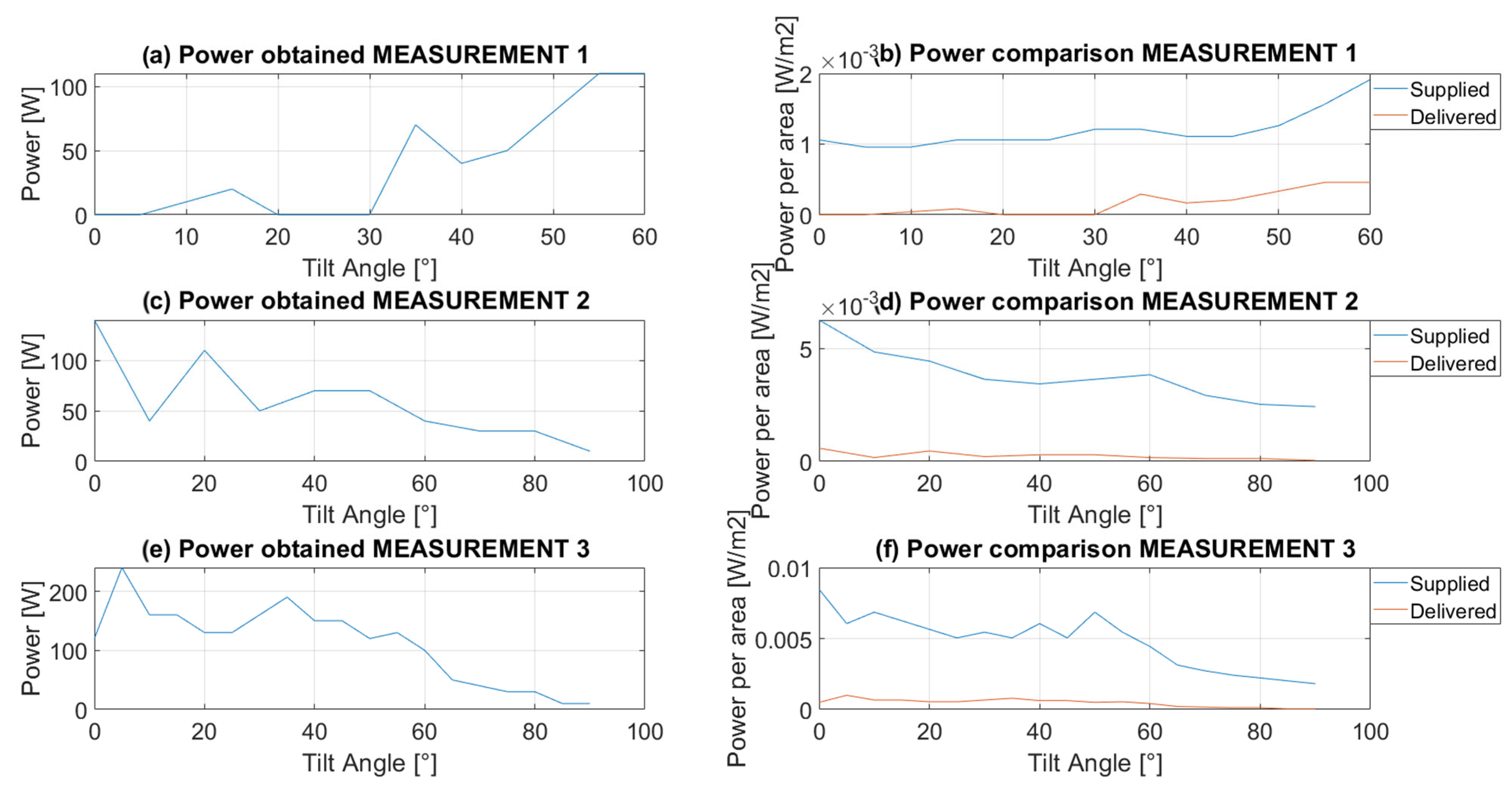

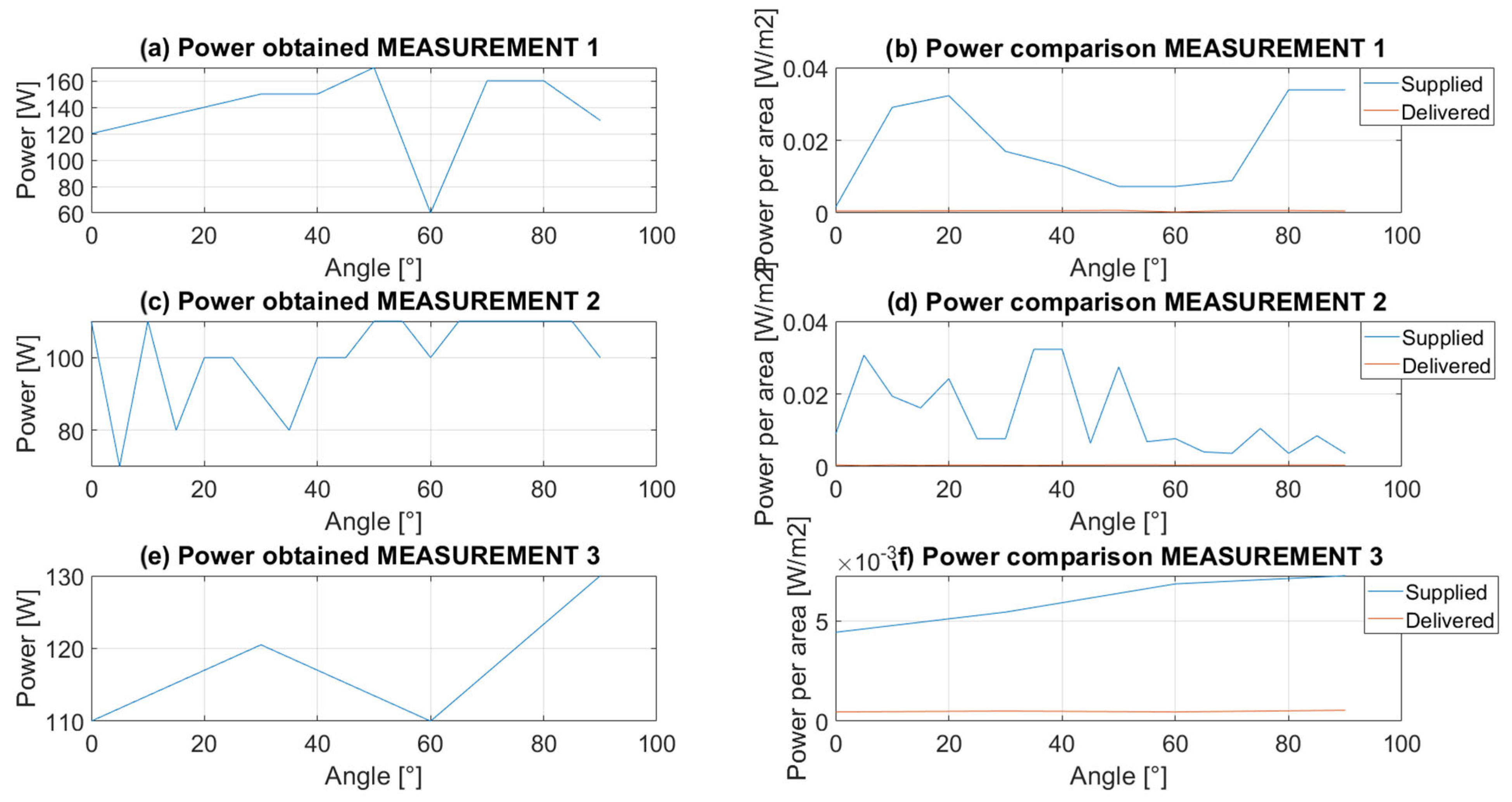

3.1.2. Power Effectiveness Measurements

3.2. Second Measurement Session—Spring

3.2.1. Dynamic Façade Measurements

3.2.2. Power Effectiveness Measurements

3.3. Discussion

4. Dynamic Façade—Energy Efficiency and Control Strategy

Energy Performance Analysis

- Each movement of the slats is a load of 100.5 W (3 motors of 30 W each + 7 W inverter + 3.5 W controller);

- In the standard (default) control scenario, the Somfy BMS platform checks and corrects the position of the slats every two minutes (maximum 720 correction movements per day), and one corrective movement lasts 10 s;

- The façade and its slats are set in a safe position during the night and remain in it for 12 h, which means that the number of corrective movements is halved (360);

- By analyzing the sun’s position changes during the day, it was initially assumed that the standard control scenario for the dynamic façade (sun-tracking) is not optimal, and the correction of the position of the slats every two minutes is too frequent.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BACS | Building Automation and Control Systems |

| BIPV | Building-integrated Photovoltaic |

| BMS | Building Management System |

| DC | Direct Current |

| EPBD | Energy Performance of Buildings Directive |

| FF | Fill Factor |

| IEA | International Energy Agency |

| MPPT | Maximum Power Point Tracking |

| PPV | Perovskite Photovoltaic |

| PSCs | Perovskite Solar Cells |

| PV | Photovoltaic |

| RES | Renewable Energy Sources |

| SRI | Smart Readiness Indicator |

References

- IEA Buildings. A Source of Enormous Untapped Efficiency Potential. Available online: https://www.iea.org/topics/buildings (accessed on 24 January 2023).

- Kaminska, A.; Ożadowicz, A. Lighting Control Including Daylight and Energy Efficiency Improvements Analysis. Energies 2018, 11, 2166. [Google Scholar] [CrossRef]

- Shin, W.-G.; Shin, J.-Y.; Hwang, H.-M.; Park, C.-H.; Ko, S.-W. Power Generation Prediction of Building-Integrated Photovoltaic System with Colored Modules Using Machine Learning. Energies 2022, 15, 2589. [Google Scholar] [CrossRef]

- IEA Renewables 2022; International Energy Agency: Paris, France, 2022.

- Basher, M.K.; Nur-E-Alam, M.; Rahman, M.M.; Hinckley, S.; Alameh, K. Design, Development, and Characterization of Highly Efficient Colored Photovoltaic Module for Sustainable Buildings Applications. Sustainability 2022, 14, 4278. [Google Scholar] [CrossRef]

- European Parliament Directive (EU) 2018/844 of the European Parliament and the Council on the Energy Performance of Buildings. Off. J. Eur. Union 2018, 156, 75–91.

- Vassiliades, C.; Agathokleous, R.; Barone, G.; Forzano, C.; Giuzio, G.F.; Palombo, A.; Buonomano, A.; Kalogirou, S. Building Integration of Active Solar Energy Systems: A Review of Geometrical and Architectural Characteristics. Renew. Sustain. Energy Rev. 2022, 164, 112482. [Google Scholar] [CrossRef]

- Kiehbadroudinezhad, M.; Merabet, A.; Abo-Khalil, A.G.; Salameh, T.; Ghenai, C. Intelligent and Optimized Microgrids for Future Supply Power from Renewable Energy Resources: A Review. Energies 2022, 15, 3359. [Google Scholar] [CrossRef]

- Shayeghi, H.; Shahryari, E.; Moradzadeh, M.; Siano, P. A Survey on Microgrid Energy Management Considering Flexible Energy Sources. Energies 2019, 12, 2156. [Google Scholar] [CrossRef]

- Sierla, S.; Pourakbari-Kasmaei, M.; Vyatkin, V. A Taxonomy of Machine Learning Applications for Virtual Power Plants and Home/Building Energy Management Systems. Autom. Constr. 2022, 136, 104174. [Google Scholar] [CrossRef]

- Gul, M.; Kotak, Y.; Muneer, T. Review on Recent Trend of Solar Photovoltaic Technology. Energy Explor. Exploit. 2016, 34, 485–526. [Google Scholar] [CrossRef]

- Marques Lameirinhas, R.A.; Torres, J.P.N.; de Melo Cunha, J.P. A Photovoltaic Technology Review: History, Fundamentals and Applications. Energies 2022, 15, 1823. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A Review of Solar Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, M.; Yang, H. A Review of the Energy Performance and Life-Cycle Assessment of Building-Integrated Photovoltaic (BIPV) Systems. Energies 2018, 11, 3157. [Google Scholar] [CrossRef]

- Sabu, T.; Aparna, T. Perovskite Photovoltaics; Elsevier: Chennai, India, 2018; ISBN 978-0-12-812915-9. [Google Scholar]

- Romaní, J.; Ramos, A.; Salom, J. Review of Transparent and Semi-Transparent Building-Integrated Photovoltaics for Fenestration Application Modeling in Building Simulations. Energies 2022, 15, 3286. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Han, J. Investigation on the Annual Thermal Performance of a Photovoltaic Wall Mounted on a Multi-Layer Façade. Appl. Energy 2013, 112, 646–656. [Google Scholar] [CrossRef]

- Olivieri, L.; Caamaño-Martín, E.; Moralejo-Vázquez, F.J.; Martín-Chivelet, N.; Olivieri, F.; Neila-Gonzalez, F.J. Energy Saving Potential of Semi-Transparent Photovoltaic Elements for Building Integration. Energy 2014, 76, 572–583. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Lu, L.; Ma, T.; Yang, H. Assessment of Energy Performance of Semi-Transparent PV Insulating Glass Units Using a Validated Simulation Model. Energy 2016, 112, 538–548. [Google Scholar] [CrossRef]

- Senkus, P.; Glabiszewski, W.; Wysokińska-Senkus, A.; Cyfert, S.; Batko, R. The Potential of Ecological Distributed Energy Generation Systems, Situation, and Perspective for Poland. Energies 2021, 14, 7966. [Google Scholar] [CrossRef]

- Zsiborács, H.; Pintér, G.; Vincze, A.; Baranyai, N.H.; Mayer, M.J. The Reliability of Photovoltaic Power Generation Scheduling in Seventeen European Countries. Energy Convers. Manag. 2022, 260, 115641. [Google Scholar] [CrossRef]

- Zhou, Y.; Herr, C.M. A Review of Advanced Façade System Technologies to Support Net-Zero Carbon High-Rise Building Design in Subtropical China. Sustainability 2023, 15, 2913. [Google Scholar] [CrossRef]

- Akram, M.; Ullah, K.; Pamucar, D. Performance Evaluation of Solar Energy Cells Using the Interval-Valued T-Spherical Fuzzy Bonferroni Mean Operators. Energies 2022, 15, 292. [Google Scholar] [CrossRef]

- Unger, E.; Paramasivam, G.; Abate, A. Perovskite Solar Cell Performance Assessment. J. Phys. Energy 2020, 2, 044002. [Google Scholar] [CrossRef]

- Subramanya, R.; Yli-Ojanperä, M.; Sierla, S.; Hölttä, T.; Valtakari, J.; Vyatkin, V. A Virtual Power Plant Solution for Aggregating Photovoltaic Systems and Other Distributed Energy Resources for Northern European Primary Frequency Reserves. Energies 2021, 14, 1242. [Google Scholar] [CrossRef]

- Attoye, D.E.; Hassan, A. A Review on Building Integrated Photovoltaic Façade Customization Potentials. Sustainability 2017, 9, 2287. [Google Scholar] [CrossRef]

- Bonomo, P.; Chatzipanagi, A.; Frontini, F. Overview and Analysis of Current BIPV Products: New Criteria for Supporting the Technological Transfer in the Building Sector. VITRUVIO—Int. J. Archit. Technol. Sustain. 2015, 67, 67–85. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C. State-of-the-Art Building Integrated Photovoltaics. Energy Procedia 2012, 20, 68–77. [Google Scholar] [CrossRef]

- Juarez-Perez, E.J.; Ono, L.K.; Qi, Y. Thermal Degradation of Formamidinium Based Lead Halide Perovskites into Sym-Triazine and Hydrogen Cyanide Observed by Coupled Thermogravimetry-Mass Spectrometry Analysis. J. Mater. Chem. A Mater. 2019, 7, 16912–16919. [Google Scholar] [CrossRef]

- Guo, Y.; Jia, Y.; Li, N.; Chen, M.; Hu, S.; Liu, C.; Zhao, N. Degradation Mechanism of Perovskite Light-Emitting Diodes: An In Situ Investigation via Electroabsorption Spectroscopy and Device Modelling. Adv. Funct. Mater. 2020, 30, 1910464. [Google Scholar] [CrossRef]

- Hui, Y.; Tan, Y.; Chen, L.; Nan, Z.; Zhou, J.; Yan, J.; Mao, B. Stability of Perovskite Thin Films under Working Condition: Bias-Dependent Degradation and Grain Boundary Effects. Adv. Funct. Mater. 2021, 31, 2103894. [Google Scholar] [CrossRef]

- Finkenauer, B.P.; Akriti; Ma, K.; Dou, L. Degradation and Self-Healing in Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2022, 14, 24073–24088. [Google Scholar] [CrossRef]

- Zhang, D.; Li, D.; Hu, Y.; Mei, A.; Han, H. Degradation Pathways in Perovskite Solar Cells and How to Meet International Standards. Commun. Mater. 2022, 3, 58. [Google Scholar] [CrossRef]

- Jung, S.; Han, S.; Lee, M.-G.; Lee, H. Development of a Solar Tracking-Based Movable Louver System to Save Lighting Energy and Create a Comfortable Light Environment. Buildings 2022, 12, 2017. [Google Scholar] [CrossRef]

- Chi, F.; Wang, R.; Li, G.; Xu, L.; Wang, Y.; Peng, C. Integration of Sun-Tracking Shading Panels into Window System towards Maximum Energy Saving and Non-Glare Daylighting. Appl. Energy 2020, 260, 114304. [Google Scholar] [CrossRef]

- Kang, H.; Hong, T.; Lee, M. A New Approach for Developing a Hybrid Sun-Tracking Method of the Intelligent Photovoltaic Blinds Considering the Weather Condition Using Data Mining Technique. Energy Build 2020, 209, 109708. [Google Scholar] [CrossRef]

- Brzezicki, M.; Regucki, P.; Kasperski, J. Optimization of Useful Daylight Illuminance for Vertical Shading Fins Covered by Photovoltaic Panels for a Case Study of an Office Room in the City of Wroclaw, Poland. Buildings 2021, 11, 637. [Google Scholar] [CrossRef]

- Al-Saadi, M.; Al-Greer, M.; Short, M. Reinforcement Learning-Based Intelligent Control Strategies for Optimal Power Management in Advanced Power Distribution Systems: A Survey. Energies 2023, 16, 1608. [Google Scholar] [CrossRef]

- Ożadowicz, A. A New Concept of Active Demand Side Management for Energy Efficient Prosumer Microgrids with Smart Building Technologies. Energies 2017, 10, 1771. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Liu, Z.; Cui, J.; Osmani, M.; Demian, P. Exploring Building Information Modeling (BIM) and Internet of Things (IoT) Integration for Sustainable Building. Buildings 2023, 13, 288. [Google Scholar] [CrossRef]

- European Parliament Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency. Off. J. Eur. Union Dir. 2012, 55, 1–56. [CrossRef]

- Ożadowicz, A. A Hybrid Approach in Design of Building Energy Management System with Smart Readiness Indicator and Building as a Service Concept. Energies 2022, 15, 1432. [Google Scholar] [CrossRef]

- Märzinger, T.; Österreicher, D. Extending the Application of the Smart Readiness Indicator—A Methodology for the Quantitative Assessment of the Load Shifting Potential of Smart Districts. Energies 2020, 13, 3507. [Google Scholar] [CrossRef]

- Vigna, I.; Pernetti, R.; Pernigotto, G.; Gasparella, A. Analysis of the Building Smart Readiness Indicator Calculation: A Comparative Case-Study with Two Panels of Experts. Energies 2020, 13, 2796. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Y.; Xu, X. Towards Transactive Energy: An Analysis of Information-related Practical Issues. Energy Convers. Econ. 2022, 3, 112–121. [Google Scholar] [CrossRef]

- Hou, P.; Yang, G.; Hu, J.; Douglass, P.J.; Xue, Y. A Distributed Transactive Energy Mechanism for Integrating PV and Storage Prosumers in Market Operation. Engineering 2022, 12, 171–182. [Google Scholar] [CrossRef]

- Babar, M.; Grela, J.; Ożadowicz, A.; Nguyen, P.; Hanzelka, Z.; Kamphuis, I. Energy Flexometer: Transactive Energy-Based Internet of Things Technology. Energies 2018, 11, 568. [Google Scholar] [CrossRef]

- Saule Technologies Saule Technologies Products. Available online: https://sauletech.com/product/ (accessed on 10 January 2023).

- Somfy Systems Inc. Available online: https://www.somfy.com/en-en/ (accessed on 17 January 2023).

- Somfy, P.L. Available online: https://www.somfy.pl (accessed on 17 January 2023).

- OneTemp—Trading as HOBO Data Loggers Australia. Available online: https://www.hobodataloggers.com.au/hobo-pendant-ua-002-64-temperaturelight-data-logger-64k (accessed on 19 January 2023).

- Ryer, A. Light Measurement Handbook; International Light Inc.: Newburyport, MA, USA, 1997; ISBN 0-9658356-9-3. [Google Scholar]

- Michael, P.R.; Johnston, D.E.; Moreno, W. A Conversion Guide: Solar Irradiance and Lux Illuminance. J. Meas. Eng. 2020, 8, 153–166. [Google Scholar] [CrossRef]

- Karabulut, M.; Kusetogullari, H.; Kivrak, S. Outdoor Performance Assessment of New and Old Photovoltaic Panel Technologies Using a Designed Multi-Photovoltaic Panel Power Measurement System. Int. J. Photoenergy 2020, 2020, 8866412. [Google Scholar] [CrossRef]

- Arkar, C.; Žižak, T.; Domjan, S.; Medved, S. Dynamic Parametric Models for the Holistic Evaluation of Semi-Transparent Photovoltaic/Thermal Façade with Latent Storage Inserts. Appl. Energy 2020, 280, 115994. [Google Scholar] [CrossRef]

- Lee, K.; Han, K.; Lee, J. The Impact of Shading Type and Azimuth Orientation on the Daylighting in a Classroom–Focusing on Effectiveness of Façade Shading, Comparing the Results of DA and UDI. Energies 2017, 10, 635. [Google Scholar] [CrossRef]

- Liu, H.; Xiang, L.; Gao, P.; Wang, D.; Yang, J.; Chen, X.; Li, S.; Shi, Y.; Gao, F.; Zhang, Y. Improvement Strategies for Stability and Efficiency of Perovskite Solar Cells. Nanomaterials 2022, 12, 3295. [Google Scholar] [CrossRef]

- Wu, T.; Qin, Z.; Wang, Y.; Wu, Y.; Chen, W.; Zhang, S.; Cai, M.; Dai, S.; Zhang, J.; Liu, J.; et al. The Main Progress of Perovskite Solar Cells in 2020–2021. Nano-Micro Lett. 2021, 13, 152. [Google Scholar] [CrossRef]

- Sharma, D.K.; Purohit, G. Analysis on the Efficiency of Solar PV System for Improved Design of MPPT. In Proceedings of the 6th World Conference on Photovoltaic Energy Conversion, Kyoto, Japan, 23–27 November 2014; pp. 1281–1282. [Google Scholar]

- Kanareykin, A.I. On the Correctness of Calculating the Fill Factor of the Solar Module. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Hangzhou, China, 1 July 2021; IOP Publishing Ltd.: Bristol, UK, 2021; Volume 808, p. 012018. [Google Scholar]

- Ma, C.; Park, N.-G. A Realistic Methodology for 30% Efficient Perovskite Solar Cells. Chem 2020, 6, 1254–1264. [Google Scholar] [CrossRef]

- Hu, D.; Yang, Q.; Chen, H.; Wobben, F.; Le Corre, V.M.; Singh, R.; Liu, T.; Ma, R.; Tang, H.; Koster, L.J.A.; et al. 15.34% Efficiency All-Small-Molecule Organic Solar Cells with an Improved Fill Factor Enabled by a Fullerene Additive. Energy Environ. Sci. 2020, 13, 2134–2141. [Google Scholar] [CrossRef]

- Cao, Q.; Li, Y.; Zhang, H.; Yang, J.; Han, J.; Xu, T.; Wang, S.; Wang, Z.; Gao, B.; Zhao, J.; et al. Efficient and Stable Inverted Perovskite Solar Cells with Very High Fill Factors via Incorporation of Star-Shaped Polymer. Sci. Adv. 2021, 7, 633–640. [Google Scholar] [CrossRef] [PubMed]

- Atsu, D.; Seres, I.; Farkas, I. The State of Solar PV and Performance Analysis of Different PV Technologies Grid-Connected Installations in Hungary. Renew. Sustain. Energy Rev. 2021, 141, 110808. [Google Scholar] [CrossRef]

- Gulkowski, S. Specific Yield Analysis of the Rooftop PV Systems Located in South-Eastern Poland. Energies 2022, 15, 3666. [Google Scholar] [CrossRef]

- Kräuchi, P.; Dahinden, C.; Jurt, D.; Wouters, V.; Menti, U.-P.; Steiger, O. Electricity Consumption of Building Automation. Energy Procedia 2017, 122, 295–300. [Google Scholar] [CrossRef]

- Iváncsy, T.; Tamus, Z.Á. Analysis of the Energy Consumption of Building Automation Systems. In Sustainability Through Innovation in Product Life Cycle Design; Springer: Singapore, 2017; pp. 871–881. ISBN 978-981-10-0471-1. [Google Scholar]

| Period of Measurements | Efficiency of the Installation |

|---|---|

| 1 | 13.1442% |

| 2 | 6.4822% |

| 3 | 9.6635% |

| Average | 9.7633% |

| Period of Measurements | Efficiency of the Installation |

|---|---|

| 1 | 3.1036% |

| 2 | 3.0441% |

| 3 | 8.1666% |

| Average | 4.7714% |

| Description | Each 2 min Movements | Each 10 min Movements |

|---|---|---|

| Energy consumption for 10 s slats movement | 1005 Ws, i.e., 0.28 Wh | 1005 Ws, i.e., 0.28 Wh |

| Energy consumption for 360 movements during the day | 100.5 Wh i.e., 0.1005 kWh | 20.1 Wh i.e., 0.0201 kWh |

| Annual energy consumption (365 days) for sun-tracking | 36.68 kWh | 7.34 kWh |

| Description | Each 2 min Movements | Each 10 min Movements |

|---|---|---|

| Ratio of energy consumed for sun-tracking to produced (autumn 1 day) | 5.03% | 1.01% |

| Ratio of energy consumed for sun-tracking to produced (spring 1 day) | 3.17% | 0.63% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ożadowicz, A.; Walczyk, G. Energy Performance and Control Strategy for Dynamic Façade with Perovskite PV Panels—Technical Analysis and Case Study. Energies 2023, 16, 3793. https://doi.org/10.3390/en16093793

Ożadowicz A, Walczyk G. Energy Performance and Control Strategy for Dynamic Façade with Perovskite PV Panels—Technical Analysis and Case Study. Energies. 2023; 16(9):3793. https://doi.org/10.3390/en16093793

Chicago/Turabian StyleOżadowicz, Andrzej, and Gabriela Walczyk. 2023. "Energy Performance and Control Strategy for Dynamic Façade with Perovskite PV Panels—Technical Analysis and Case Study" Energies 16, no. 9: 3793. https://doi.org/10.3390/en16093793

APA StyleOżadowicz, A., & Walczyk, G. (2023). Energy Performance and Control Strategy for Dynamic Façade with Perovskite PV Panels—Technical Analysis and Case Study. Energies, 16(9), 3793. https://doi.org/10.3390/en16093793