Characterization of Thermophysical and Electrical Properties of SiC and BN Nanofluids

Abstract

1. Introduction

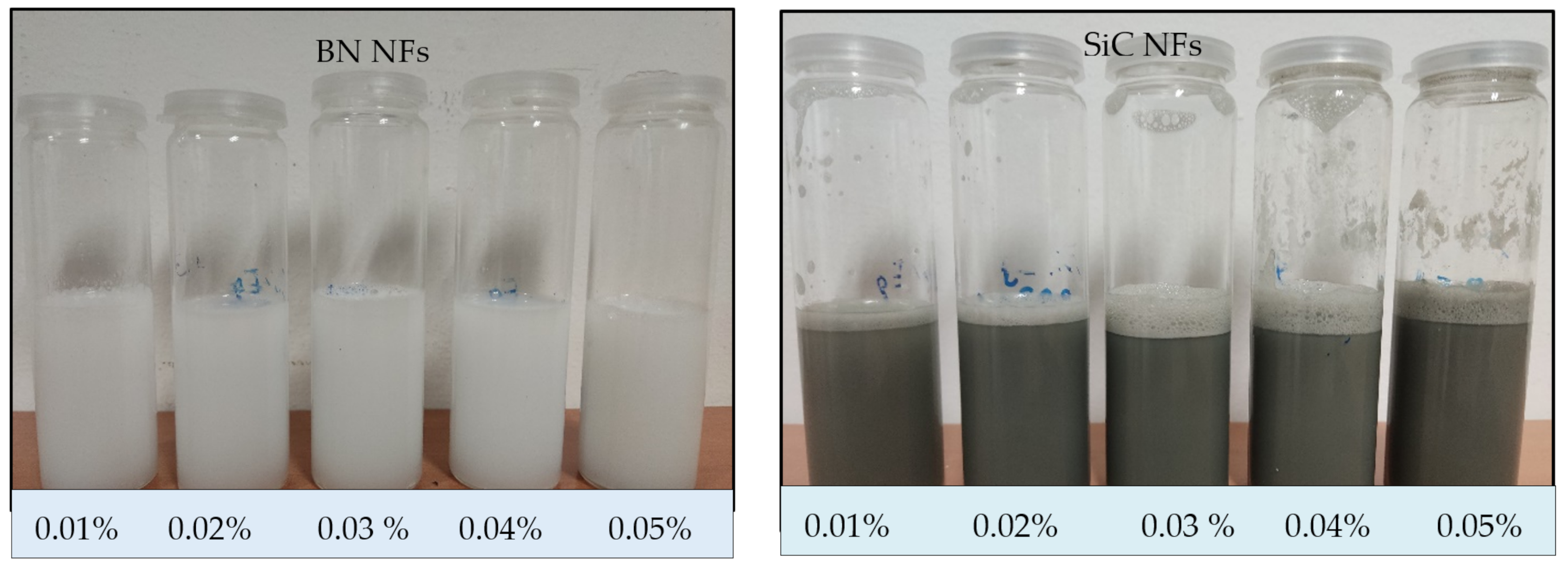

2. Nanofluids Preparation and Experimental Procedures

3. Results and Discussion

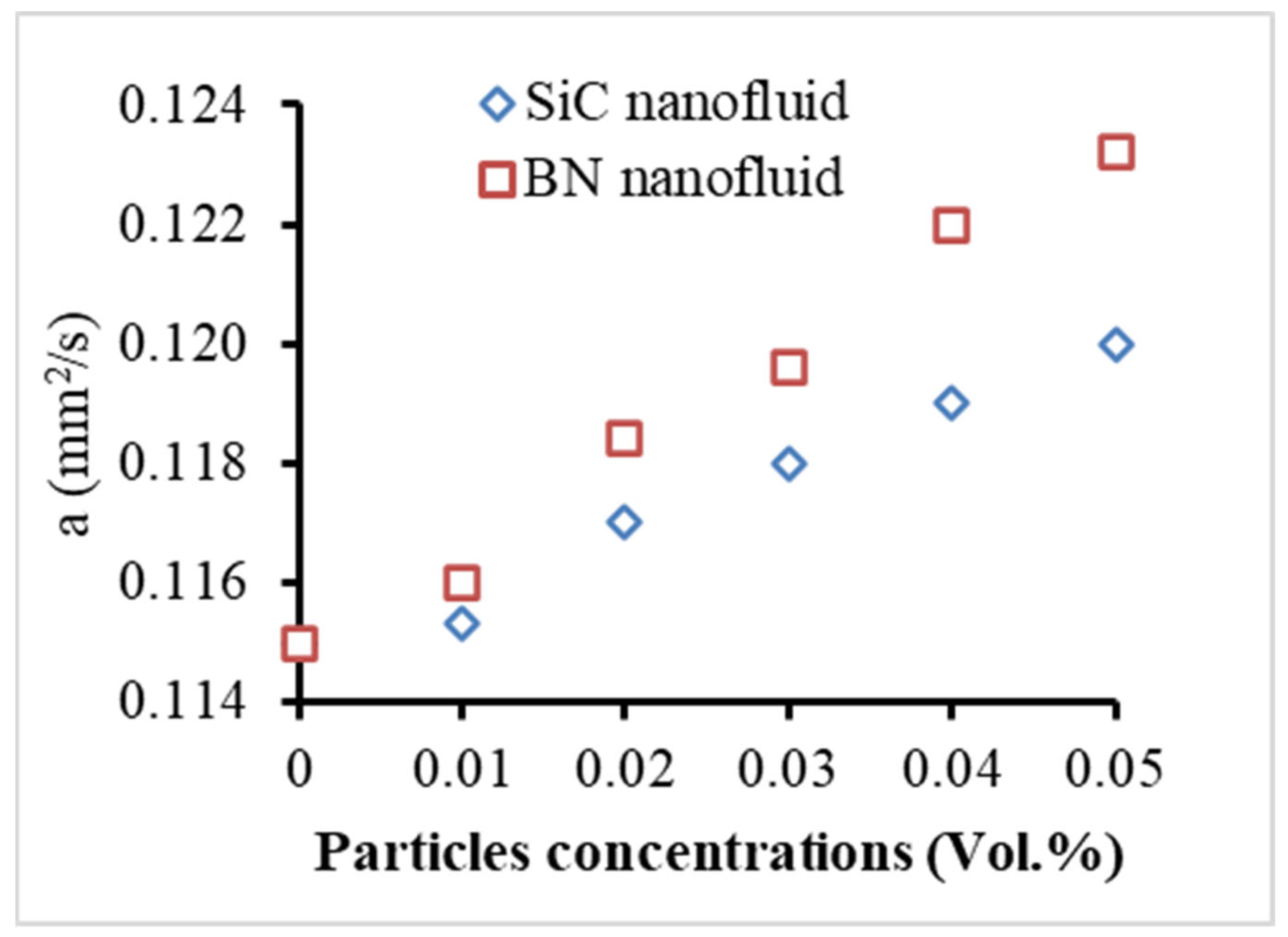

3.1. Thermal Properties

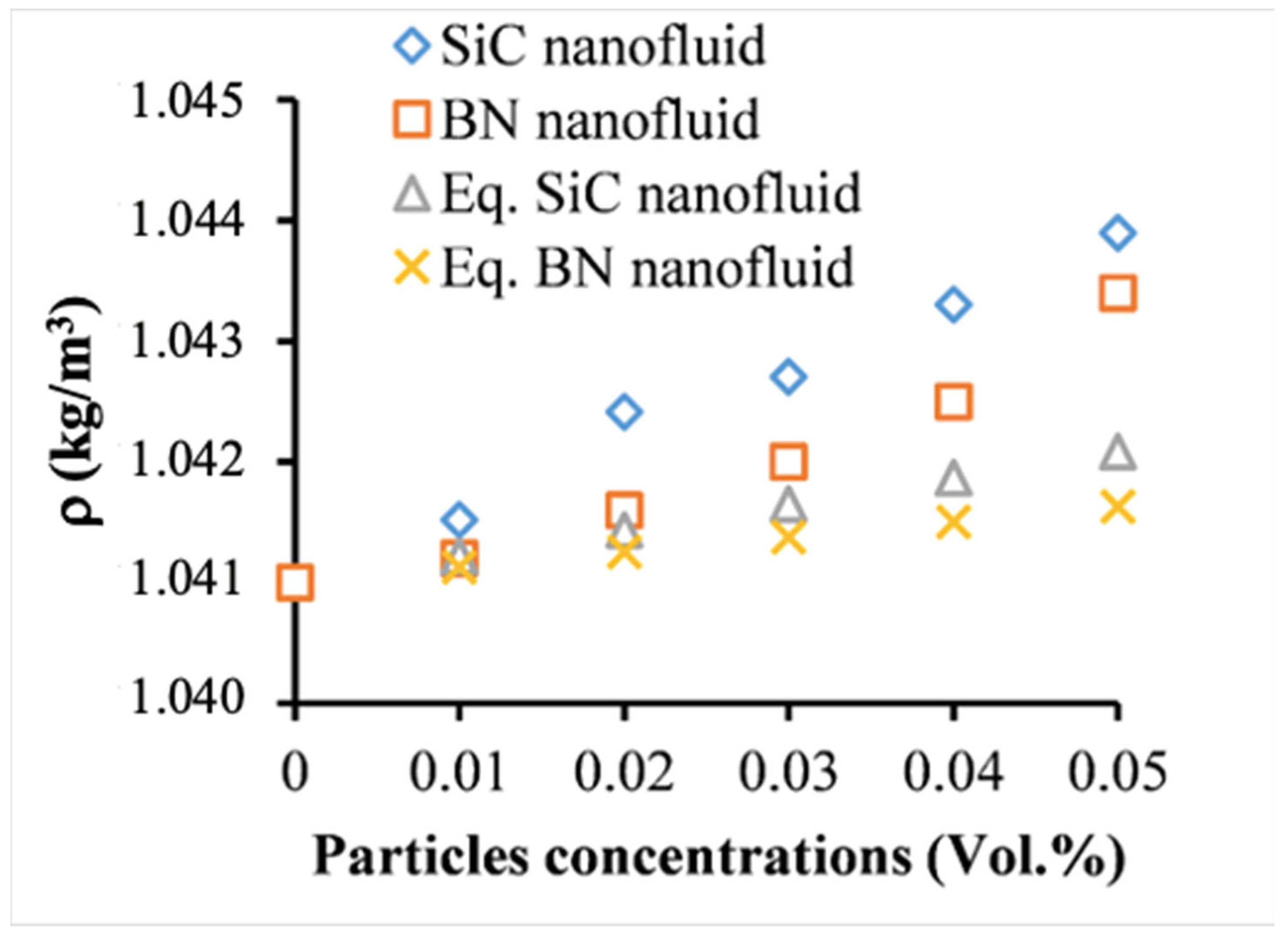

3.2. Density

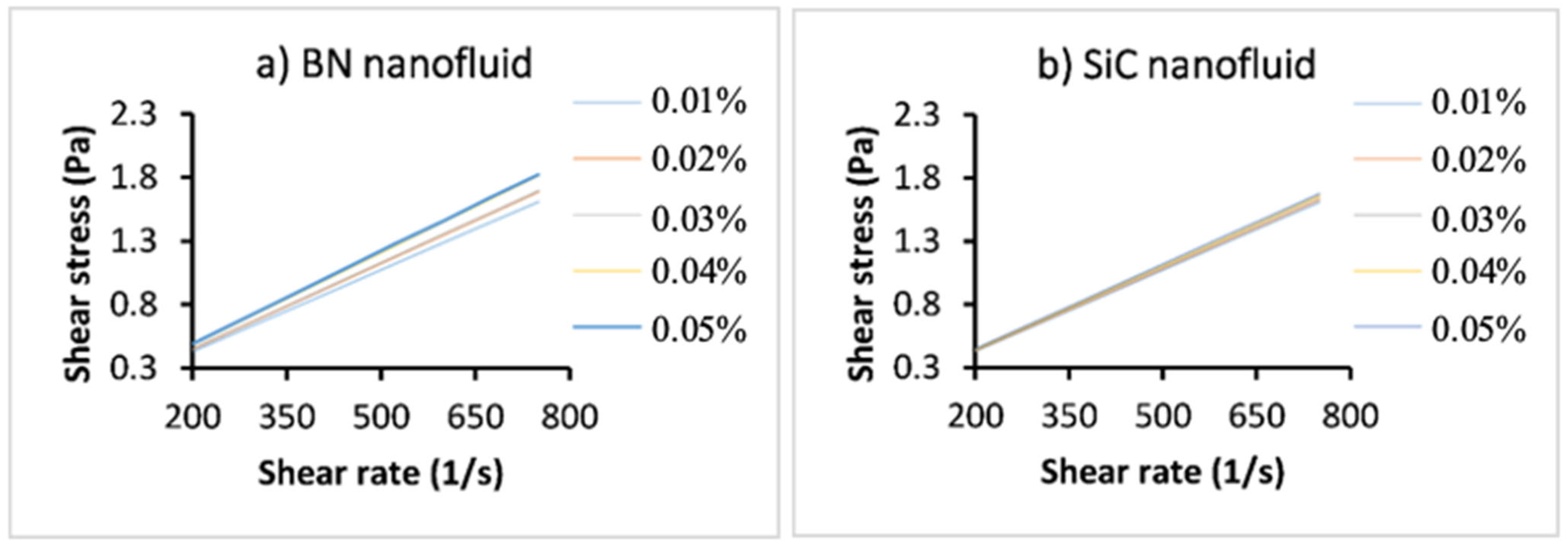

3.3. Viscosity and Rheological Characteristics

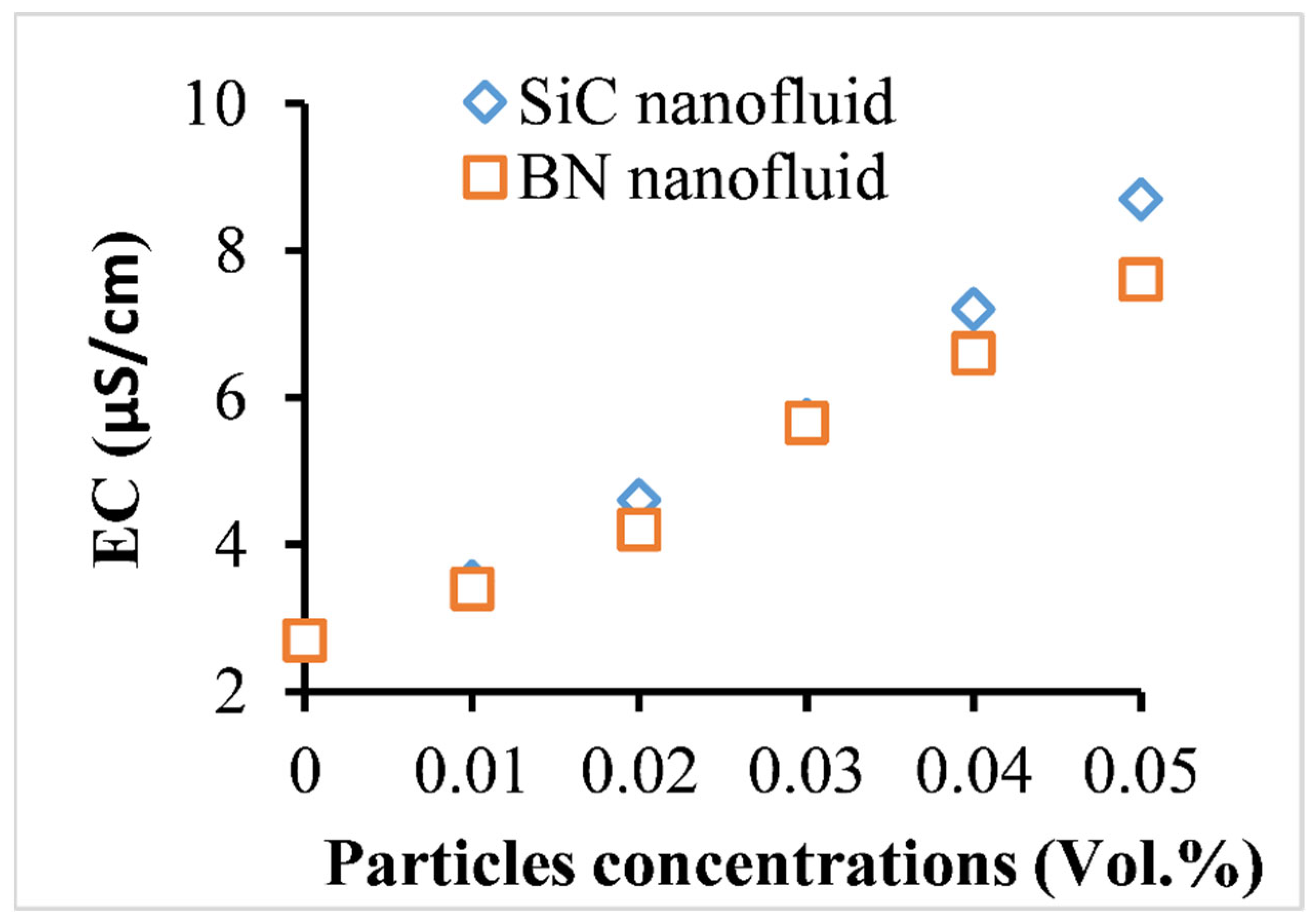

3.4. Electrical Conductivity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| BF | Base fluid |

| BN | Boron nitride |

| DW | Distilled water |

| EG | Ethylene glycol |

| NFs | Nanofluids |

| NP | Nanoparticles |

| SiC | Silicon carbide |

| TC | Thermal conductivity |

| TPs | Thermal properties |

| TPPs | Thermophysical properties |

References

- Pathak, S.K.; Kumar, R.; Goel, V.; Pandey, A.; Tyagi, V. Recent advancements in thermal performance of nano-fluids charged heat pipes used for thermal management applications: A comprehensive review. Appl. Therm. Eng. 2022, 216, 119023. [Google Scholar] [CrossRef]

- Murshed, S.M.S. Advanced Cooling Technologies and Applications; IntechOpen: London, UK, 2019. [Google Scholar]

- Vallejo, J.P.; Prado, J.I.; Lugo, L. Hybrid or mono nanofluids for convective heat transfer applications. A critical review of experimental research. Appl. Therm. Eng. 2021, 203, 117926. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, V.; Kumar, R.; Said, Z. A review on thermophysical properties of nanofluids and heat transfer applications. Renew. Sustain. Energy Rev. 2017, 74, 638–670. [Google Scholar] [CrossRef]

- Ajeeb, W.; da Silva, R.R.T.; Murshed, S.M.S. Experimental investigation of heat transfer performance of Al2O3 nanofluids in a compact plate heat exchanger. Appl. Therm. Eng. 2023, 218, 119321. [Google Scholar] [CrossRef]

- Ajeeb, W.; Roque, D.; Murshed, S.M.S. Thermal-hydraulic performance of Al2O3 nanofluids under laminar flow in a minitube. Int. J. Energy Clean Environ. 2022, 23, 39–59. [Google Scholar] [CrossRef]

- Ajeeb, W.; Murshed, S.M.S. Nanofluids in compact heat exchangers for thermal applications: A State-of-the-art review. Therm. Sci. Eng. Prog. 2022, 30, 101276. [Google Scholar] [CrossRef]

- Ajeeb, W.; Murshed, S.M.S. Numerical Study of Convective Heat Transfer Performance, Entropy Generation and Energy Efficiency of Al and Al2O3 Nanofluids in Minichannel. J. Nanofluids 2023, 12, 18–28. [Google Scholar] [CrossRef]

- Trisaksri, V.; Wongwises, S. Critical review of heat transfer characteristics of nanofluids. Renew. Sustain. Energy Rev. 2007, 11, 512–523. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Zhang, Z.G.; Yu, W.; Lockwood, F.E.; Grulke, E.A. Anomalous thermal conductivity enhancement in nanotube suspensions. Appl. Phys. Lett. 2001, 79, 2252–2254. [Google Scholar] [CrossRef]

- Eastman, J.A.; Choi, S.U.S.; Li, S.; Yu, W.; Thompson, L.J. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl. Phys. Lett. 2001, 78, 718–720. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Enhanced thermal conductivity of TiO2—Water based nanofluids. Int. J. Therm. Sci. 2005, 44, 367–373. [Google Scholar] [CrossRef]

- Liu, M.; Lin, M.C.; Wang, C. Enhancements of thermal conductivities with Cu, CuO, and carbon nanotube nanofluids and application of MWNT/water nanofluid on a water chiller system. Nanoscale Res. Lett. 2011, 6, 297. [Google Scholar] [CrossRef] [PubMed]

- Murshed, S.M.S. Correction and comment on “thermal conductance of nanofluids: Is the controversy over?”. J. Nanopart. Res. 2008, 11, 511–512. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Routbort, J.L.; Singh, D. Particle shape effects on thermophysical properties of alumina nanofluids. J. Appl. Phys. 2009, 106, 014304. [Google Scholar] [CrossRef]

- Nan, C.-W.; Liu, G.; Lin, Y.; Li, M. Interface effect on thermal conductivity of carbon nanotube composites. Appl. Phys. Lett. 2004, 85, 3549–3551. [Google Scholar] [CrossRef]

- Murshed, S.; Leong, K.; Yang, C. A combined model for the effective thermal conductivity of nanofluids. Appl. Therm. Eng. 2009, 29, 2477–2483. [Google Scholar] [CrossRef]

- Yang, L.; Xu, J.; Du, K.; Zhang, X. Recent developments on viscosity and thermal conductivity of nanofluids. Powder Technol. 2017, 317, 348–369. [Google Scholar] [CrossRef]

- Khoshvaght-Aliabadi, M.; Hosseinirad, E.; Farsi, M.; Hormozi, F. Heat transfer and flow characteristics of novel patterns of chevron minichannel heat sink: An insight into thermal management of microelectronic devices. Int. Commun. Heat Mass Transf. 2021, 122, 105044. [Google Scholar] [CrossRef]

- Mohammed, H.; Bhaskaran, G.; Shuaib, N.; Saidur, R. Heat transfer and fluid flow characteristics in microchannels heat exchanger using nanofluids: A review. Renew. Sustain. Energy Rev. 2011, 15, 1502–1512. [Google Scholar] [CrossRef]

- Wen, D.; Lin, G.; Vafaei, S.; Zhang, K. Review of nanofluids for heat transfer applications. Particuology 2009, 7, 141–150. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Aghakhani, S.; Afrand, M.; Mahmoudi, B.; Mahian, O.; Wongwises, S. An updated review on application of nanofluids in heat exchangers for saving energy. Energy Convers. Manag. 2019, 198, 111886. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Estellé, P. A state of the art review on viscosity of nanofluids. Renew. Sustain. Energy Rev. 2017, 76, 1134–1152. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Z.; Han, F.; Wadsö, L.; Sundén, B. Experimental comparative evaluation of a graphene nanofluid coolant in miniature plate heat exchanger. Int. J. Therm. Sci. 2018, 130, 148–156. [Google Scholar] [CrossRef]

- Ajeeb, W. Convective Heat Transfer of Non-Newtonian Nanofluids in Micro Heat Exchanger. Ph.D. Thesis, Universidade de Aveiro, Aveiro, Portugal, 2019. [Google Scholar]

- Ashrae. ASHRAE Handbook: Fundamentals; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Peachtree Corners, GA, USA, 2005. [Google Scholar]

- Herwig, H.; Hausner, O. Critical view on “new results in micro-fluid mechanics”: An example. Int. J. Heat Mass Transf. 2003, 46, 935–937. [Google Scholar] [CrossRef]

- Chiu, H.-C.; Jang, J.-H.; Yeh, H.-W.; Wu, M.-S. The heat transfer characteristics of liquid cooling heatsink containing microchannels. Int. J. Heat Mass Transf. 2011, 54, 34–42. [Google Scholar] [CrossRef]

- Hooman, K.; Ejlali, A. Effects of viscous heating, fluid property variation, velocity slip, and temperature jump on convection through parallel plate and circular microchannels. Int. Commun. Heat Mass Transf. 2010, 37, 34–38. [Google Scholar] [CrossRef]

- Ajeeb, W.; Zhang, J.Z.; Wu, Z.; Murshed, S.M.S.; Sundén, B. Numerical development of the thermal convection characteristics of nanofluids. In Fundamentals and Transport Properties of Nanofluids; Murshed, S.M.S., Ed.; The Royal Society of Chemistry: London, UK, 2022; pp. 335–365. [Google Scholar] [CrossRef]

- Ajeeb, W.; Oliveira, M.S.A.; Martins, N.; Abreu, B. Experimental and numerical study of convective heat transfer and laminar flow of a MWCNTs nanofluid in a horizontal tube. J. Nanofluids 2019, 8, 132–142. [Google Scholar] [CrossRef]

- Ajeeb, W.; Oliveira, M.S.; Martins, N.; Murshed, S.M.S. Forced convection heat transfer of non-Newtonian MWCNTs nanofluids in microchannels under laminar flow. Int. Commun. Heat Mass Transf. 2021, 127, 105495. [Google Scholar] [CrossRef]

- Ajeeb, W.; Oliveira, M.S.; Martins, N.; Murshed, S.M.S. Performance evaluation of convective heat transfer and laminar flow of non-Newtonian MWCNTs in a circular tube. Therm. Sci. Eng. Prog. 2021, 25, 101029. [Google Scholar] [CrossRef]

- Chen, X.; Chen, M.; Zhou, P. Solar-thermal conversion performance of heterogeneous nanofluids. Renew. Energy 2022, 198, 1307–1317. [Google Scholar] [CrossRef]

- Mahian, O.; Kolsi, L.; Amani, M.; Estellé, P.; Ahmadi, G.; Kleinstreuer, C.; Marshall, J.S.; Taylor, R.A.; Abu-Nada, E.; Rashidi, S.; et al. Recent advances in modeling and simulation of nanofluid flows—Part II: Applications. Phys. Rep. 2018, 791, 1–59. [Google Scholar] [CrossRef]

- Arjun, K.S.; Rakesh, K. Heat transfer enhancement using alumina nanofluid in circular micro channel. J. Eng. Sci. Technol. 2017, 12, 265–279. [Google Scholar]

- Nojoomizadeh, M.; Karimipour, A. The effects of porosity and permeability on fluid flow and heat transfer of multi walled carbon nano-tubes suspended in oil (MWCNT/Oil nano-fluid) in a microchannel filled with a porous medium. Phys. E Low-Dimens. Syst. Nanostruct. 2016, 84, 423–433. [Google Scholar] [CrossRef]

- Kamali, R.; Jalali, Y.; Binesh, A.R. Investigation of multiwall carbon nanotube-based nanofluid advantages in microchannel heat sinks. Micro Nano Lett. 2013, 8, 319–323. [Google Scholar] [CrossRef]

- Arani, A.A.A.; Akbari, O.A.; Safaei, M.R.; Marzban, A.; Alrashed, A.A.; Ahmadi, G.R.; Nguyen, T.K. Heat transfer improvement of water/single-wall carbon nanotubes (SWCNT) nanofluid in a novel design of a truncated double-layered microchannel heat sink. Int. J. Heat Mass Transf. 2017, 113, 780–795. [Google Scholar] [CrossRef]

- Yasmin, H.; Giwa, S.O.; Noor, S.; Aybar, H. Reproduction of nanofluid synthesis, thermal properties and experiments in engineering: A research paradigm shift. Energies 2023, 16, 1145. [Google Scholar] [CrossRef]

- Mohammadi, M.; Taheri, A.; Passandideh-Fard, M.; Sardarabadi, M. Electronic chipset thermal management using a nanofluid-based mini-channel heat sink: An experimental study. Int. Commun. Heat Mass Transf. 2020, 118, 104836. [Google Scholar] [CrossRef]

- Chen, W.; Zou, C.; Li, X. An investigation into the thermophysical and optical properties of SiC/ionic liquid nanofluid for direct absorption solar collector. Sol. Energy Mater. Sol. Cells 2017, 163, 157–163. [Google Scholar] [CrossRef]

- Li, X.; Zou, C.; Lei, X.; Li, W. Stability and enhanced thermal conductivity of ethylene glycol-based SiC nanofluids. Int. J. Heat Mass Transf. 2015, 89, 613–619. [Google Scholar] [CrossRef]

- Li, X.; Zou, C. Thermo-physical properties of water and ethylene glycol mixture based SiC nanofluids: An experimental investigation. Int. J. Heat Mass Transf. 2016, 101, 412–417. [Google Scholar] [CrossRef]

- Song, S.L.; Lee, J.H.; Chang, S.H. CHF enhancement of SiC nanofluid in pool boiling experiment. Exp. Therm. Fluid Sci. 2014, 52, 12–18. [Google Scholar] [CrossRef]

- Gómez-Villarejo, R.; Aguilar, T.; Hamze, S.; Estellé, P.; Navas, J. Experimental analysis of water-based nanofluids using boron nitride nanotubes with improved thermal properties. J. Mol. Liq. 2019, 277, 93–103. [Google Scholar] [CrossRef]

- Gómez-Villarejo, R.; Estellé, P.; Navas, J. Boron nitride nanotubes-based nanofluids with enhanced thermal properties for use as heat transfer fluids in solar thermal applications. Sol. Energy Mater. Sol. Cells 2019, 205, 110266. [Google Scholar] [CrossRef]

- Krishnam, M.; Bose, S.; Das, C. Boron nitride (BN) nanofluids as cooling agent in thermal management system (TMS). Appl. Therm. Eng. 2016, 106, 951–958. [Google Scholar] [CrossRef]

- Younes, H.; Mao, M.; Murshed, S.M.S.; Lou, D.; Hong, H.; Peterson, G. Nanofluids: Key parameters to enhance thermal conductivity and its applications. Appl. Therm. Eng. 2022, 207, 118202. [Google Scholar] [CrossRef]

- Sharifpur, M.; Yousefi, S.; Meyer, J.P. A new model for density of nanofluids including nanolayer. Int. Commun. Heat Mass Transf. 2016, 78, 168–174. [Google Scholar] [CrossRef]

- Shoghl, S.N.; Jamali, J.; Moraveji, M.K. Electrical conductivity, viscosity, and density of different nanofluids: An experimental study. Exp. Therm. Fluid Sci. 2016, 74, 339–346. [Google Scholar] [CrossRef]

- Khan, S.A.; Tariq, M.; Khan, A.A.; Urooj, S.; Mihet-Popa, L. An Experimental Study and Statistical Analysis on the Electrical Properties of Synthetic Ester-Based Nanofluids. Energies 2022, 15, 9127. [Google Scholar] [CrossRef]

- Islam, R.; Shabani, B. Prediction of electrical conductivity of TiO2 water and ethylene glycol-based nanofluids for cooling application in low temperature PEM fuel cells. Energy Procedia 2019, 160, 550–557. [Google Scholar] [CrossRef]

- Luo, Z.-Z.; Cai, S.; Hao, S.; Bailey, T.P.; Luo, Y.; Luo, W.; Yu, Y.; Uher, C.; Wolverton, C.; Dravid, V.P.; et al. Extraordinary role of Zn in enhancing thermoelectric performance of Ga-doped n-type PbTe. Energy Environ. Sci. 2021, 15, 368–375. [Google Scholar] [CrossRef]

- Shit, S.P.; Pal, S.; Ghosh, N.; Sau, K. Thermophysical properties of graphene and hexagonal boron nitride nanofluids: A comparative study by molecular dynamics. J. Mol. Struct. 2021, 1239, 130525. [Google Scholar] [CrossRef]

- Żyła, G.; Fal, J.; Traciak, J.; Gizowska, M.; Perkowski, K. Huge thermal conductivity enhancement in boron nitride—Ethylene glycol nanofluids. Mater. Chem. Phys. 2016, 180, 250–255. [Google Scholar] [CrossRef]

- Shamsuddin, H.S.; Estellé, P.; Navas, J.; Mohd-Ghazali, N.; Mohamad, M. Effects of surfactant and nanofluid on the performance and optimization of a microchannel heat sink. Int. J. Heat Mass Transf. 2021, 175, 121336. [Google Scholar] [CrossRef]

- Oster, K.; Hardacre, C.; Jacquemin, J.; Ribeiro, A.P.C.; Elsinawi, A. Ionic liquid-based nanofluids (ionanofluids) for thermal applications: An experimental thermophysical characterization. Pure Appl. Chem. 2019, 91, 1309–1340. [Google Scholar] [CrossRef]

- Oster, K.; Hardacre, C.; Jacquemin, J.; Ribeiro, A.; Elsinawi, A. Understanding the heat capacity enhancement in ionic liquid-based nanofluids (ionanofluids). J. Mol. Liq. 2018, 253, 326–339. [Google Scholar] [CrossRef]

- Azmi, W.; Hamid, K.A.; Mamat, R.; Sharma, K.; Mohamad, M. Effects of working temperature on thermo-physical properties and forced convection heat transfer of TiO2 nanofluids in water—Ethylene glycol mixture. Appl. Therm. Eng. 2016, 106, 1190–1199. [Google Scholar] [CrossRef]

- Wen, T.; Lu, L.; Zhang, S.; Zhong, H. Experimental study and CFD modelling on the thermal and flow behavior of EG/water ZnO nanofluid in multiport mini channels. Appl. Therm. Eng. 2020, 182, 116089. [Google Scholar] [CrossRef]

- Ajeeb, W.; Murshed, S.M.S. Pool boiling heat transfer characteristics of new and recycled alumina nanofluids. Nanomaterials 2023, 13, 1040. [Google Scholar] [CrossRef]

- Nithiyanantham, U.; Zaki, A.; Grosu, Y.; González-Fernández, L.; Anagnostopoulos, A.; Navarro, M.; Ding, Y.; Igartua, J.M.; Faik, A. Effect of silica nanoparticle size on the stability and thermophysical properties of molten salts based nanofluids for thermal energy storage applications at concentrated solar power plants. J. Energy Storage 2022, 51, 104276. [Google Scholar] [CrossRef]

- Senthilkumar, D.; Jumpholkul, C.; Wongwises, S. Enhancing thermal behavior of SiC nanopowder and SiC/Water nanofluid by using cryogenic treatment. Adv. Mat. Proce. Technol. 2018, 4, 402–415. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A.; Fleaca, C.; Dumitrache, F.; Morjan, I. Thermo-physical properties of water based SiC nanofluids for heat transfer applications. Int. Commun. Heat Mass Transf. 2017, 84, 94–101. [Google Scholar] [CrossRef]

- Bakthavatchalam, B.; Habib, K.; Saidur, R.; Saha, B.B.; Irshad, K. Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement: A review on current and future perspective. J. Mol. Liq. 2020, 305, 112787. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; De Castro, C.A.N. Predicting the thermal conductivity of nanofluids—effect of brownian motion of nanoparticles. J. Nanofluids 2012, 1, 180–185. [Google Scholar] [CrossRef]

- Ajeeb, W.; Oliveira, A.M.S.; Martins, N.; Murshed, S.M.S. Numerical approach for fluids flow and thermal convection in microchannels. J. Phys. Conf. Ser. 2021, 2116, 012049. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y.I. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transf. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Xuan, Y.; Roetzel, W. Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Santos, F.; De Castro, C.A.N. Investigations of viscosity of silicone oil-based semiconductor nanofluids. J. Nanofluids 2013, 2, 261–266. [Google Scholar] [CrossRef]

- Abdullah, A.M.; Chowdhury, A.R.; Yang, Y.; Vasquez, H.; Moore, H.J.; Parsons, J.G.; Lozano, K.; Gutierrez, J.J.; Martirosyan, K.S.; Uddin, M.J. Tailoring the viscosity of water and ethylene glycol based TiO2 nanofluids. J. Mol. Liq. 2020, 297, 111982. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Santos, F.J.V.; de Castro, C.A.N. Rheology of nanofluids containing TiO2 and SiO2 nanoparticles. In Proceedings of the 8th World Conference on Experimental Heat Transfer, Fluid Mechanics, and Thermodynamics, Lisbon, Portugal, 16–20 June 2013. [Google Scholar]

- Murshed, S.M.S. Simultaneous measurement of thermal conductivity, thermal diffusivity, and specific heat of nanofluids. Heat Transf. Eng. 2012, 33, 722–731. [Google Scholar] [CrossRef]

- Martínez-Cuenca, R.; Mondragón, R.; Hernández, L.; Segarra, C.; Jarque, J.; Hibiki, T.; Juliá, J. Forced-convective heat-transfer coefficient and pressure drop of water-based nanofluids in a horizontal pipe. Appl. Therm. Eng. 2016, 98, 841–849. [Google Scholar] [CrossRef]

- Fal, J.; Sobczak, J.; Stagraczyński, R.; Estellé, P.; Żyła, G. Electrical conductivity of titanium dioxide ethylene glycol-based nanofluids: Impact of nanoparticles phase and concentration. Powder Technol. 2022, 404, 117423. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ajeeb, W.; Murshed, S.M.S. Characterization of Thermophysical and Electrical Properties of SiC and BN Nanofluids. Energies 2023, 16, 3768. https://doi.org/10.3390/en16093768

Ajeeb W, Murshed SMS. Characterization of Thermophysical and Electrical Properties of SiC and BN Nanofluids. Energies. 2023; 16(9):3768. https://doi.org/10.3390/en16093768

Chicago/Turabian StyleAjeeb, Wagd, and S. M. Sohel Murshed. 2023. "Characterization of Thermophysical and Electrical Properties of SiC and BN Nanofluids" Energies 16, no. 9: 3768. https://doi.org/10.3390/en16093768

APA StyleAjeeb, W., & Murshed, S. M. S. (2023). Characterization of Thermophysical and Electrical Properties of SiC and BN Nanofluids. Energies, 16(9), 3768. https://doi.org/10.3390/en16093768