A Comprehensive Review of Fracture Characterization and Its Impact on Oil Production in Naturally Fractured Reservoirs

Abstract

1. Introduction

2. Fracture Characterization

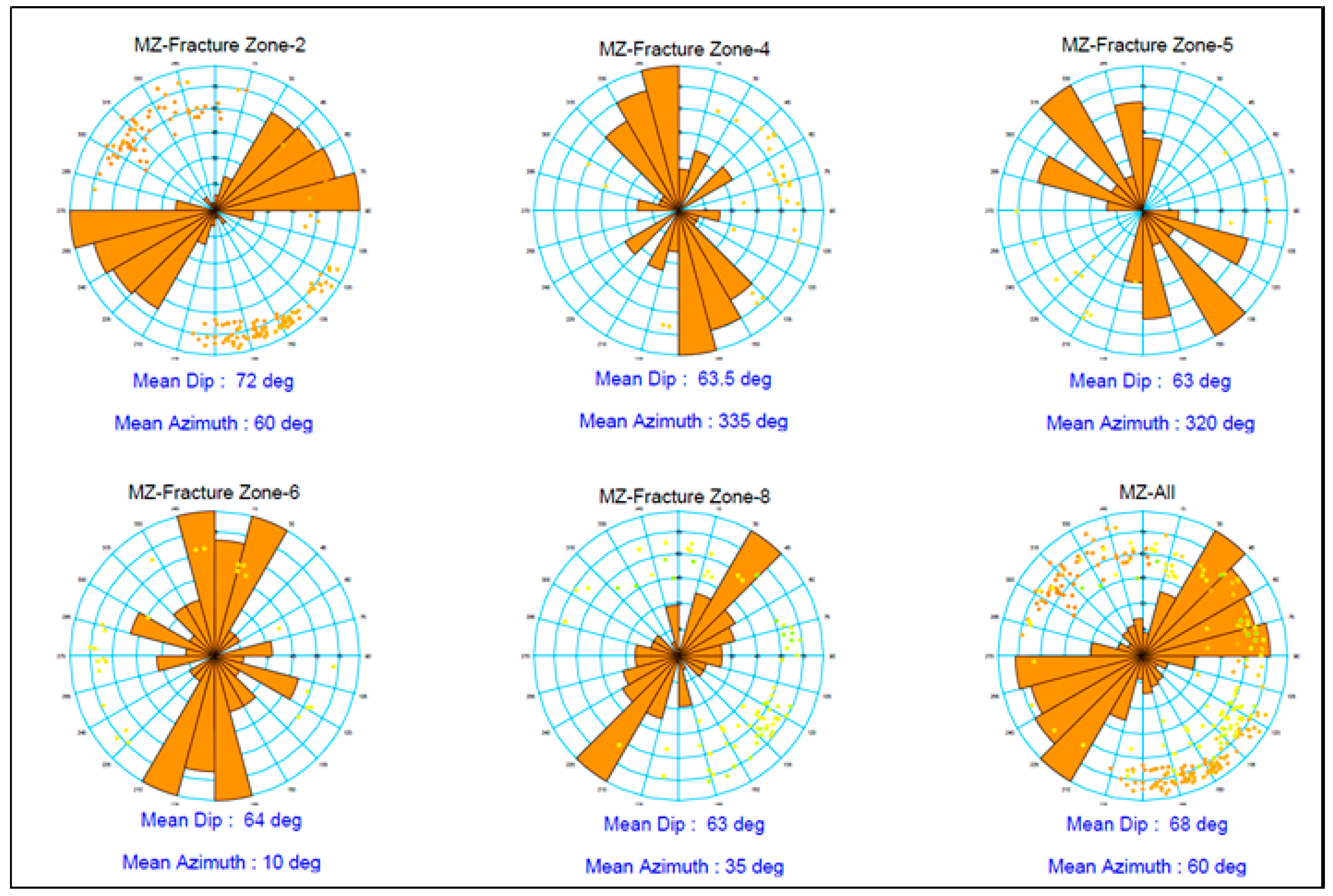

2.1. Fractures Characteristics, Parameters, and Fracture Types

2.2. Matrix–Fracture Interaction

2.3. Modeling and Workflow for Data Integration

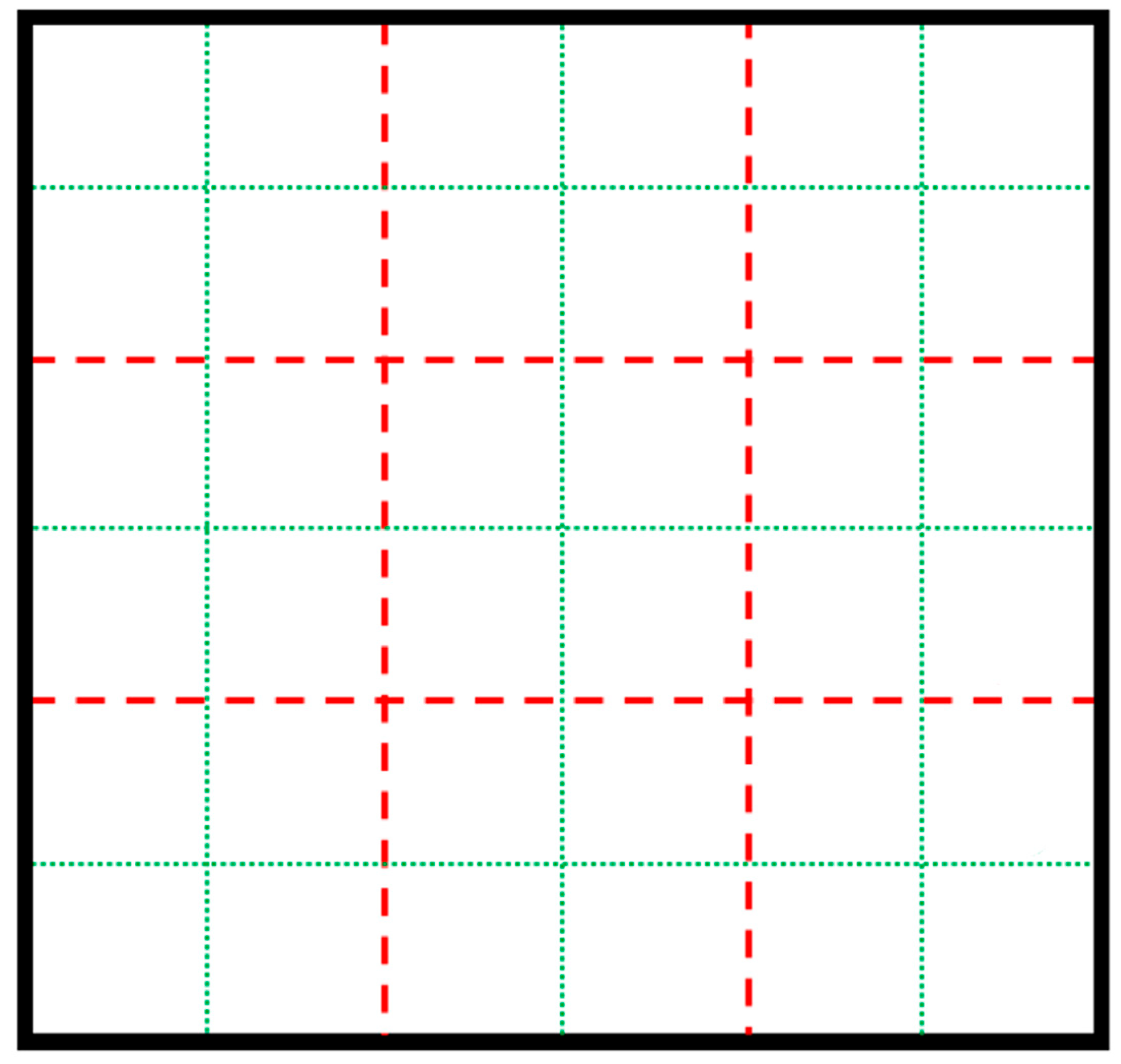

2.3.1. Continuum Approach

2.3.2. Discrete Fractures Approach

2.3.3. Hybrid Approach

3. Impact of Fractures on Recovery Processes

3.1. Primary Recovery

3.2. Secondary Recovery

3.3. Enhanced Oil Recovery

4. Summary and Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thuwaini, J.S.; Alwan, A.K.; Ranjan, A. Uncertainty Analysis of a Fractured Carbonate Reservoir. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 15–18 March 2009; p. SPE-120722-MS. [Google Scholar]

- Khosravi, M.; Rostami, B.; Fatemi, S. Uncertainty Analysis of a Fractured Reservoir’s Performance: A Case Study. Oil Gas Sci. Technol.-Rev. d’IFP 2012, 67, 423–433. [Google Scholar] [CrossRef]

- Kharrat, R.; Mahdavi, S.; Ghorbani, D. A Comprehensive EOR Study of a Highly Fractured matured field-Case Study, SPE 153311. In Proceedings of the 74th EAGE Conference and Exhibition incorporating EUROPEC 2012, Copenhagen, Denmark, 4–7 June 2012. [Google Scholar]

- Demyanov, V.; Gopa, K.; Arnold, D.; Elfeel, M.A. Production Optimisation under Uncertainty in Fractured Reservoirs. In Proceedings of the ECMOR 2014, 14th European Conference on the Mathematics of Oil Recovery, Catania, Italy, 8–11 September 2014. [Google Scholar]

- Kharrat, R.; Zallaghi, M.; Ott, H. Performance Quantification of Enhanced Oil Recovery Methods in Fractured Reservoirs. Energies 2021, 14, 4739. [Google Scholar] [CrossRef]

- De Hoop, S.; Voskov, D.V.; Bertotti, G.; Barnhoorn, A. An Advanced Discrete Fracture Methodology for Fast, Robust, and Accurate Simulation of Energy Production From Complex Fracture Networks. Water Resour. Res. 2022, 58, e2021WR030743. [Google Scholar] [CrossRef]

- Guerriero, V.; Mazzoli, S.; Iannace, A.; Vitale, S.; Carravetta, A.; Strauss, C. A permeability model for naturally fractured carbonate reservoirs. Mar. Pet. Geol. 2013, 40, 115–134. [Google Scholar] [CrossRef]

- Tiab, D.; Donalson, C. Petrophysics (Fourth Edition) Theory and Practice of Measuring Reservoir Rock and Fluid Transport Properties, Chapter 8—Naturally Fractured Reservoirs; Gulf Professional Publishing: Oxford, UK, 2016; pp. 415–448. [Google Scholar]

- Lei, Q.; Latham, J.-P.; Tsang, C.-F. The use of discrete fracture networks for modeling coupled geomechanical and hydrological behavior of fractured rocks. Comput. Geotech. 2017, 85, 151–176. [Google Scholar] [CrossRef]

- Ukar, E.; Laubach, S.E.; Hooker, J.N. Outcrops as guides to subsurface natural fractures: Example from the Nikanassin Formation tight-gas sandstone, Grande Cache, Alberta foothills, Canada. Mar. Pet. Geol. 2019, 103, 255–275. [Google Scholar] [CrossRef]

- Aghli, G.; Mossavi-Harami, R.; Mohammadian, R. Reservoir heterogeneity and fracture parameter determination using electrical image logs and petrophysical data (a case study, carbonate Asmari Formation, Zagros Basin, SW Iran). Pet. Sci. 2020, 17, 51–69. [Google Scholar] [CrossRef]

- Aljuboori, F.A.; Lee, J.H.; Elraies, K.A.; Stephen, K.D. Effect of fracture characteristics on history matching in the Qamchuqa reservoir: A case study from Iraq. Carbonates Evaporites 2020, 35, 87. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Kadkhodaie, A.; Reazaee, R.; Kadkhodaie, R. Discrete fracture modeling by integrating image logs, seismic attributes, and production data: A case study from Ilam and Sarvak Formations, Danan Oilfield, southwest of Iran. J. Pet. Explor. Prod. Technol. 2022, 13, 1053–1083. [Google Scholar] [CrossRef]

- Pejic, M.; Kharrat, R.; Kadkhodaaie, A.; Azizmohammadi, S.; Ott, H. Impact of fracture types on the oil recovery in naturally fractured reservoirs. Energies 2022, 15, 7321. [Google Scholar] [CrossRef]

- Kolapo, P.; Ogunsola, N.O.; Munemo, P.; Alewi, D.; Komolafe, K.; Giwa-Bioku, A. DFN: An Emerging Tool for Stochastic Modelling and Geomechanical Design. Eng 2023, 4, 174–205. [Google Scholar] [CrossRef]

- Moreno, M.J.; Gurpinar, O.; Liu, Y. A Holistic Approach to EOR Screening in Dual-Porosity Naturally Fractured Reservoirs. In Proceedings of the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 11–13 August 2015. SPE-174577-Ms. [Google Scholar]

- Delamaide, E.; Batôt, G.; Alshaqsi, A.; Alkindy, A.; Al-Mejni, R. Enhanced Oil Recovery in Naturally Fractured Reservoirs: State of the Art and Future Perspectives. In Proceedings of the SPE Conference at Oman Petroleum & Energy Show, Muscat, Oman, 21–23 March 2022. SPE-200076-MS. [Google Scholar]

- Zuo, L.; Tan, X.; Yu, W.; Hu, X. Fracture Detection and Numerical Modeling for Fractured Reservoirs. Energies 2019, 386, 15. [Google Scholar] [CrossRef]

- Chesnaux, R.; Allen, D.M.; Jenni, S. Regional fracture network permeability using outcrop scale measurements. Eng. Geol. 2009, 108, 259–271. [Google Scholar] [CrossRef]

- Li, J.; Pei, Y.; Jiang, H.; Zhao, L.; Li, L.; Zhou, H.; Zhao, Y.; Zhang, Z. Tracer Flowback Based Fracture Network Characterization in Hydraulic Fracturing. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 7–10 November 2016. SPE-183444-MS. [Google Scholar]

- Li, L.; Pinprayong, V.; Meng, F.; Jiang, H.; Li, J. Fracture Network Evaluation Using Tracer Flowback: A Case Study. In Proceedings of the SPE Symposium: Production Enhancement and Cost Optimisation, Kuala Lumpur, Malaysia, 7–8 November 2017. SPE-189273-MS. [Google Scholar]

- Gong, J.; Rossen, W. Shape factor for dual-permeability fractured reservoir simulation: Effect of non-uniform flow in 2D fracture network. Fuel 2016, 184, 81–88. [Google Scholar] [CrossRef]

- Wenli, Y.; Sharifzadeh, M.; Yang, Z.; Xu, G.; Fang, Z. Assessment of fracture characteristics controlling fluid flow performance in discrete fracture networks (DFN). J. Pet. Sci. Eng. 2019, 178, 1104–1111. [Google Scholar] [CrossRef]

- Zimmerman, R.; Bodvarsson, G. Hydraulic Conductivity of Rock Fractures. Transp. Porous Media 1996, 23, 1–30. [Google Scholar] [CrossRef]

- Gilman, J.R.; Kazemi, H. Improvements in Simulation of Naturally Fractured Reservoirs. SPE J. 1983, 23, 695–707. [Google Scholar] [CrossRef]

- Pejic, M. Mechanistic Study of Fracture Types Effect on Oil Production. Master’s Thesis, Montanuniversität Leoben, Leoben, Austria, 2021. [Google Scholar]

- Pooladi-Darvish, M.; Firoozabadi, A. Cocurrent and Counter-current Imbibition in a Water-Wet Matrix Block. SPE J. 2000, 5, 3–11. [Google Scholar] [CrossRef]

- Moghaddam, M.B.; Rasaei, M.R. Experimental Study of the Fracture and Matrix Effects on Free-Fall Gravity Drainage with Micromodels. SPE J. 2014, 20, 324–336. [Google Scholar] [CrossRef]

- Agada, S.; Geiger, S.; Doster, F. Wettability, hysteresis, and fracture–matrix interaction during CO2 EOR and storage in fractured carbonate reservoirs. Int. J. Greenh. Gas Control. 2016, 46, 57–75. [Google Scholar] [CrossRef]

- Zobeidi, K.; Shafie, M.M. Ganjeh-Ghazvini M, The effect of gravity drainage mechanism on oil recovery by reservoir simulation; a case study in an Iranian highly fractured reservoir. J. Pet. Explor. Prod. Technol. 2022, 12, 1633–1647. [Google Scholar] [CrossRef]

- Gugl, R.; Kharrat, R.; Shariat, A.; Ott, H. Evaluation of Gas-based EOR Methods in Gas Invaded Zones of Fractured Carbonate Reservoir. Energies 2022, 15, 4921. [Google Scholar] [CrossRef]

- Harimi, B.; Masihi, M.; Ghazanfari, M.H. An insight into the formation of liquid bridge and its role on fracture capillary pressure during gravity drainage in fractured porous media. Can. J. Chem. Eng. 2021, 99, S212–S231. [Google Scholar] [CrossRef]

- Maerten, L.; Gillespie, P.A.; Daniel, J.M. Three-dimensional geomechanical modeling for constraint of sub seismic fault simulation. AAPG Bull. 2006, 90, 1337–1358. [Google Scholar] [CrossRef]

- Gong, J.; Rossen, W. Modeling flow in naturally fractured reservoirs: Effect of fracture aperture distribution on dominant sub-network for flow. Pet. Sci. 2017, 14, 138–154. [Google Scholar] [CrossRef]

- Gong, J.; Rossen, W. Characteristic fracture spacing in primary and secondary recovery for naturally fractured reservoirs. Fuel 2018, 2213, 470–485. [Google Scholar] [CrossRef]

- Heel, A.P.G.V.; Boerrigter, P.M.; Dorp, J.J.V. Thermal and Hydraulic Matrix-Fracture Interaction in Dual-Permeability Simulation. SPE Res. Eval. Eng. 2008, 11, 735–749. [Google Scholar] [CrossRef]

- Warren, J.E.; Root, P.J. The Behavior of Naturally Fractured Reservoirs. SPE J. 1963, 3, 245–255. [Google Scholar] [CrossRef]

- Quandalle, P.; Sabathier, J.C. Typical features of a multipurpose reservoir simulator. SPE Reserv. Eng. 1989, 4, 475–480. [Google Scholar] [CrossRef]

- Ghaedi, M.; Masihi, M.; Heinemann, Z.E.; Ghazanfari, M.H. History matching of naturally fractured reservoirs based on the recovery curve method. J. Pet. Sci. Eng. 2015, 126, 211–221. [Google Scholar] [CrossRef]

- Wong, D.L.Y.; Doster, F.; Geiger, S.; Francot, E.; Gouth, F. Fluid Flow Characterization Framework for Naturally Fractured Reservoirs Using Small-Scale Fully Explicit Models. Transp. Porous Media 2020, 134, 399–434. [Google Scholar] [CrossRef]

- Xu, Y.; Sepehrnoori, K. Development of an Embedded Discrete Fracture Model for Field-Scale Reservoir Simulation with Complex Corner-Point Grids. SPE J. 2019, 24, 1552–1575. [Google Scholar] [CrossRef]

- Bosma, S.; Hajibeygi, H.; Tene, M.; Tchelepi, H.A. Multiscale finite volume method for discrete fracture modeling on unstructured grids (MS-DFM). J. Comput. Phys. 2017, 351, 145–164. [Google Scholar] [CrossRef]

- Yan, X.; Huang, Z.; Yao, J.; Li, Y.; Fan, D. An efficient embedded discrete fracture model based on mimetic finite difference method. J. Pet. Sci. Eng. 2016, 145, 11–21. [Google Scholar] [CrossRef]

- CMG Webinar- Advances in Fractured Reservoir Modelling Using DFN. 2021. Available online: https://www.youtube.com/watch?v=h9h9Ou6BP4E (accessed on 9 February 2023).

- Kleppe, J.; Morse, R. Oil Production from Fractured Reservoirs by Water Displacement. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Houston, TX, USA, 6–9 October 1974. SPE-5084-MS. [Google Scholar]

- Xu, Z.-X.; Li, S.-Y.; Li, B.-F.; Chen, D.-Q.; Liu, Z.-Y.; Li, Z.-M. A review of development methods and EOR technologies for carbonate reservoirs. Pet. Sci. 2020, 17, 990–1013. [Google Scholar] [CrossRef]

- Khelifa, C.; Zeddouri, A.; Djabes, F. Influence of natural fractures on oil production of unconventional reservoirs. Energy Procedia 2014, 50, 360–367. [Google Scholar] [CrossRef]

- Mi, L.; An, C.; Cao, Y.; Yan, B.; Jiang, H.; Pei, Y.; Killough, J. A Guideline on Optimizing Fracture Modeling for Fractured Reservoir Simulation. In Proceedings of the SPE Asia Pacific Hydraulic Fracturing Conference, Beijing, China, 24–26 August 2016. SPE-181814-MS. [Google Scholar]

- Bahrami, H.; Rezaee, R.; Hossain, M. Characterizing natural fractures in tight gas reservoirs. J. Pet. Explor. Prod. Technol. 2012, 2, 107–115. [Google Scholar] [CrossRef]

- Doe, T.; Lacazette, A.; Dershowitz, W.; Knitter, C. Evaluating the Effect of Natural Fractures on Production from Hydraulically Fractured Wells Using Discrete Fracture Network Models. In Proceedings of the Unconventional Resources Technology Conference URTeC, Denver, CO, USA, 12–14 August 2013; p. 10. [Google Scholar]

- Wei, Y.; Xiaohu, H.; Malin, L.; Weihong, W. Investigation of the Effect of Natural Fractures on Multiple Shale-Gas Well Performance Using Non-Intrusive EDFM Technology. Energies 2019, 12, 16. [Google Scholar]

- Erfani, H.; Malekabadi, A.K.; Ghazanfari, M.H.; Rostami, B. Experimental and Modelling Study of Gravity Drainage in a Three-Block System. Transp. Porous Media 2021, 136, 471–494. [Google Scholar] [CrossRef]

- Nouri, A. Impact of Fractures Networks on Gas-Based EOR Methods. Ph.D. Thesis, University of Leoben, Leoben, Austria, 2022. [Google Scholar]

- Berkowitz, B. Characterizing flow and transport in fractured geological media: A review. Adv. Water Res. 2002, 25, 861–884. [Google Scholar] [CrossRef]

- Tong, K.; Liu, H.; Zhang, Y. Three-dimensional physical modeling of waterflooding in metamorphic fractured reservoirs. Pet. Explor. Dev. 2015, 42, 538–544. [Google Scholar] [CrossRef]

- Rezaveisi, M.; Ayatollahi, S.; Rostami, B. Experimental Investigation of Matrix Wettability Effects on Water Imbibition in Fractured Artificial Porous Media. J. Pet. Sci. Eng. 2012, 86, 165–171. [Google Scholar] [CrossRef]

- Udoh, F.D.; Igbafe, A.I.; Okon, A.N. Gas-Oil Gravity Drainage and Reinfiltration in Naturally Fractured Reservoirs. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 4–6 August 2015. SPE-178271-MS. [Google Scholar]

- Silva, R.; Maini, B. Evaluation of Gas-Assisted Gravity Drainage GAGD in Naturally Fractured Reservoirs NFR. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016; SPE-179585-MS. p. 17. [Google Scholar]

- Saidi, M.A. Simulation of Naturally Fractured Reservoirs. In Proceedings of the 1983 SPE Symposium on Reservoir Simulation, San Francisco, CA, USA, 15–18 November 1983. SPE-12270-MS. [Google Scholar]

- Meng, Q.; Liu, H.; Wang, J. A critical review on fundamental mechanisms of spontaneous imbibition and the impact of boundary condition, fluid viscosity and wettability. Adv. Geo-Energy Res. 2017, 1, 1–17. [Google Scholar] [CrossRef]

- Hamidpour, E.; Mirzaei-Paiaman, A.; Masihi, M. Experimental study of some important factors on non-wetting phase recovery by cocurrent spontaneous imbibition. J. Nat. Gas Sci. Eng. 2015, 27, 1213–1228. [Google Scholar] [CrossRef]

- Hatiboglu, C.U.; Babadagli, T. Experimental and visual analysis of co- and counter-current spontaneous imbibition for different viscosity ratios, interfacial tensions, and wettabilities. J. Pet. Sci. Eng. 2010, 70, 214–228. [Google Scholar] [CrossRef]

- Karpyn, Z.T.; Halleck, P.M.; Grader, A.S. An experimental study of spontaneous imbibition in fractured sandstone with contrasting sedimentary layers. J. Pet. Sci. Eng. 2009, 67, 48–56. [Google Scholar] [CrossRef]

- Mason, G.; Morrow, N.R. Developments in spontaneous imbibition and possibilities for future work. J. Pet. Sci. Eng. 2013, 110, 268–293. [Google Scholar] [CrossRef]

- Mogensen, K.; Masalmeh, S.H. A review of EOR techniques for carbonate reservoirs in challenging geological settings. J. Pet. Sci. Eng. 2020, 195, 107889. [Google Scholar] [CrossRef]

- Aghabarari, A.; Ghaedi, M.; Riazi, M. Prediction of oil recovery in naturally fractured reservoirs subjected to reinfiltration during gravity drainage using a new scaling equation. Pet. Explor. Dev. 2020, 47, 1307–1315. [Google Scholar] [CrossRef]

- Fatemi, S.; Kharrat, R.; Vossoughi, S. Investigation of Steam Assisted Gravity Drainage (SAGD) and Expanding Solvent-SAGD (ES-SAGD) Process in Complex Fractured Models: Effects of Fractures’ Geometrical Properties. In Proceedings of the SPE Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 12–14 December 2011. SPE-150082-MS. [Google Scholar]

- Fatemi, R.; Kharrat, R.; Ghotbi, S. Toe-to-Heel Air Injection (THAI): Investigation of the Effect of Fractures Geometrical Properties on Process Performance. Energy Sources Part A Recovery Util. Environ. Eff. 2012, 33, 2067–2077. [Google Scholar] [CrossRef]

- Fatemi, S.; Kharrat, R.; Vossoughi, S. Investigation of Top-Down In-Situ Combustion Process in Complex Fractured Carbonate Models: Effects of Fractures’ Geometrical Properties. In Proceedings of the Canadian Unconventional Resources Conference, Calgary, AB, Canada, 15–17 November 2014. CSUG/SPE 149314. [Google Scholar]

- Fatemi, S.M.; Kharrat, R.; Vossoughi, S.; Ghotbi, C. Macroscopic Recovery Mechanisms of In-Situ Combustion Process in Heavy Oil Fractured Systems: Effect of Fractures Geometrical Properties and Operational Parameters. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. SPE-154839-MS. [Google Scholar]

- Shojaiepour, A.; Kharrat, R.; Hashemi, A. Experimental and simulation of In situ combustion process in carbonated fractured porous media. J. Jpn. Pet. Inst. 2014, 57, 208–215. [Google Scholar] [CrossRef]

- Fatemi, S.M.; Kharrat, R. Assessment of Vapor Extraction (VAPEX) process performance in naturally fractured reservoirs. J. Pet. Sci. Eng. 2011, 75, 260–273. [Google Scholar] [CrossRef]

- Azin, R.; Kharrat, R.; Vossoughi, S.; Ghotbi, C. Study of The VAPEX Process in Fractured Physical Systems Using Different Solvent Mixtures. Oil Gas Sci. Technol. 2008, 63, 219–227. [Google Scholar] [CrossRef]

- Azin, R.; Kharrat, R.; Rostami, B.; Vossoughi, S. Theoretical Investigation of the VAPEX Process in Fractured Heavy Oil System at Reservoir Conditions. J. Pet. Sci. Eng. 2008, 60, 51–66. [Google Scholar] [CrossRef]

- Heeremans, J.; Esmaiel, T.; Kruijsdijk, C.V. Feasibility Study of WAG Injection in Naturally Fractured Reservoirs. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2006; SPE-100034-MS. p. 10. [Google Scholar]

- Haugen, A.; Fernø, M.A.; Graue, A. Experimental Study of Foam Flow in Fractured Oil-Wet Limestone for Enhanced Oil Recovery. SPE Reserv. Eval. Eng. 2012, 15, 218–228. [Google Scholar] [CrossRef]

- Luo, H.; Mohanty, K.K. Modeling Near-Miscible Gas Foam Injection in Fractured Tight Rocks and Its Challenges. Energies 2021, 14, 1998. [Google Scholar] [CrossRef]

- Ocampo, A.; Restrepo, A.; Clavijo, J.; Mejia, J. Successful Foams EOR Field Pilot in a Naturally Fractured Reservoir by the Injection of the Foaming Agent Dispersed in the Gas Stream. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 31 August–4 September 2020; SPE-200377-MS. p. 7. [Google Scholar]

- Ocampo, A.; Restrepo, A.; Lopera, S.; Mejia, J. Creation of Insitu EOR Foams by the Injection of Surfactant in Gas Dispersions-Lab Confirmation and Field Application. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018; SPE-190219-MS. p. 8. [Google Scholar]

- Yadali, J. Chemical Flooding in Naturally Fractured Reservoirs: Fundamental Aspects and Field-Scale Practices. Oil Gas Sci. Technol. Rev. d’IFP Energ. Nouv. 2011, 66, 991–1004. [Google Scholar] [CrossRef]

- Cheng, X.; Kleppe, J.; Torsæter, O. Simulation Study of Surfactant Imbibition Mechanisms in Naturally Fractured Reservoirs. In Proceedings of the SPE Norway One Day Seminar, Bergen, Norway, 18 April 2018; SPE-191309-MS. p. 13. [Google Scholar]

- Akbar, M.I.; Agenet, N.; Kamp, A.M.; Gosselin, O.R. Evaluation and Optimisation of Smart Water Injection for Fractured Reservoir. In Proceedings of the SPE Europec featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018. SPE-190854-MS. [Google Scholar]

- Bakhshi, P.; Kharrat, R.; Hashemi, A.; Zallaghi, M. Experimental evaluation of carbonated waterflooding: A practical process for enhanced oil recovery and geological CO2 storage. Greenh. Gases Sci. Technol. 2018, 8, 238–256. [Google Scholar] [CrossRef]

- Al Karfy, L.; Kharrat, R.; Ott, H. Mechanistic study of the carbonated smart water in carbonate reservoirs. Greenh. Gases Sci. Technol. 2021, 11, 661–681. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kharrat, R.; Ott, H. A Comprehensive Review of Fracture Characterization and Its Impact on Oil Production in Naturally Fractured Reservoirs. Energies 2023, 16, 3437. https://doi.org/10.3390/en16083437

Kharrat R, Ott H. A Comprehensive Review of Fracture Characterization and Its Impact on Oil Production in Naturally Fractured Reservoirs. Energies. 2023; 16(8):3437. https://doi.org/10.3390/en16083437

Chicago/Turabian StyleKharrat, Riyaz, and Holger Ott. 2023. "A Comprehensive Review of Fracture Characterization and Its Impact on Oil Production in Naturally Fractured Reservoirs" Energies 16, no. 8: 3437. https://doi.org/10.3390/en16083437

APA StyleKharrat, R., & Ott, H. (2023). A Comprehensive Review of Fracture Characterization and Its Impact on Oil Production in Naturally Fractured Reservoirs. Energies, 16(8), 3437. https://doi.org/10.3390/en16083437