Review on Mono and Hybrid Nanofluids: Preparation, Properties, Investigation, and Applications in IC Engines and Heat Transfer

Abstract

1. Introduction

1.1. Heat Exchanger

1.2. Hybrid Nanofluids

1.3. Secondary Refrigerant

1.4. Objectives

2. Preparation of Mono/Hybrid Nanofluids

3. Characterization and Stability of Mono/Hybrid Nanofluids

4. Thermo-Physical Properties of Mono/Hybrid Nanofluids

4.1. Density and Specific Heat of Mono/Hybrid Nanofluids

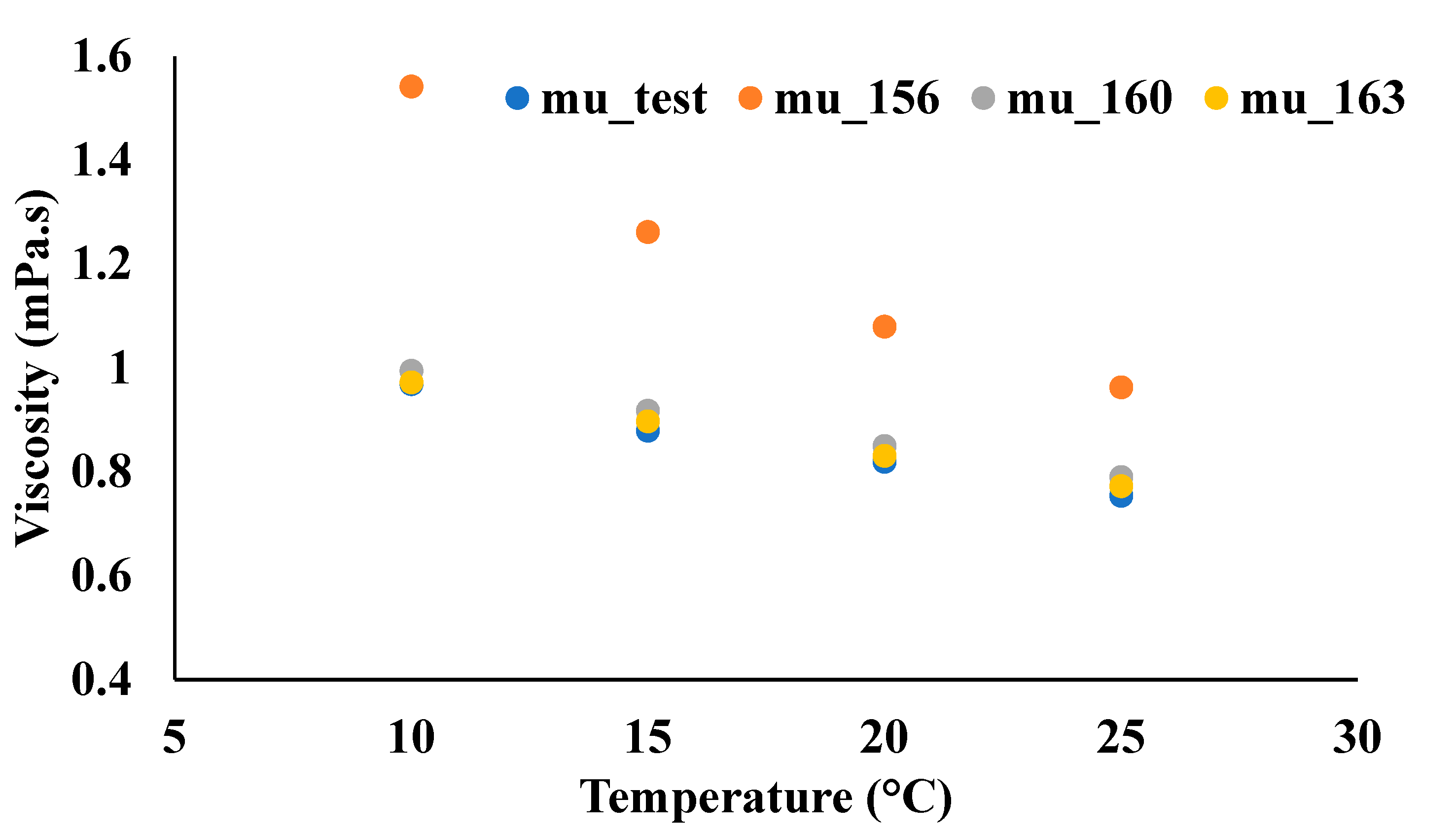

4.2. Viscosity of Mono/Hybrid Nanofluids

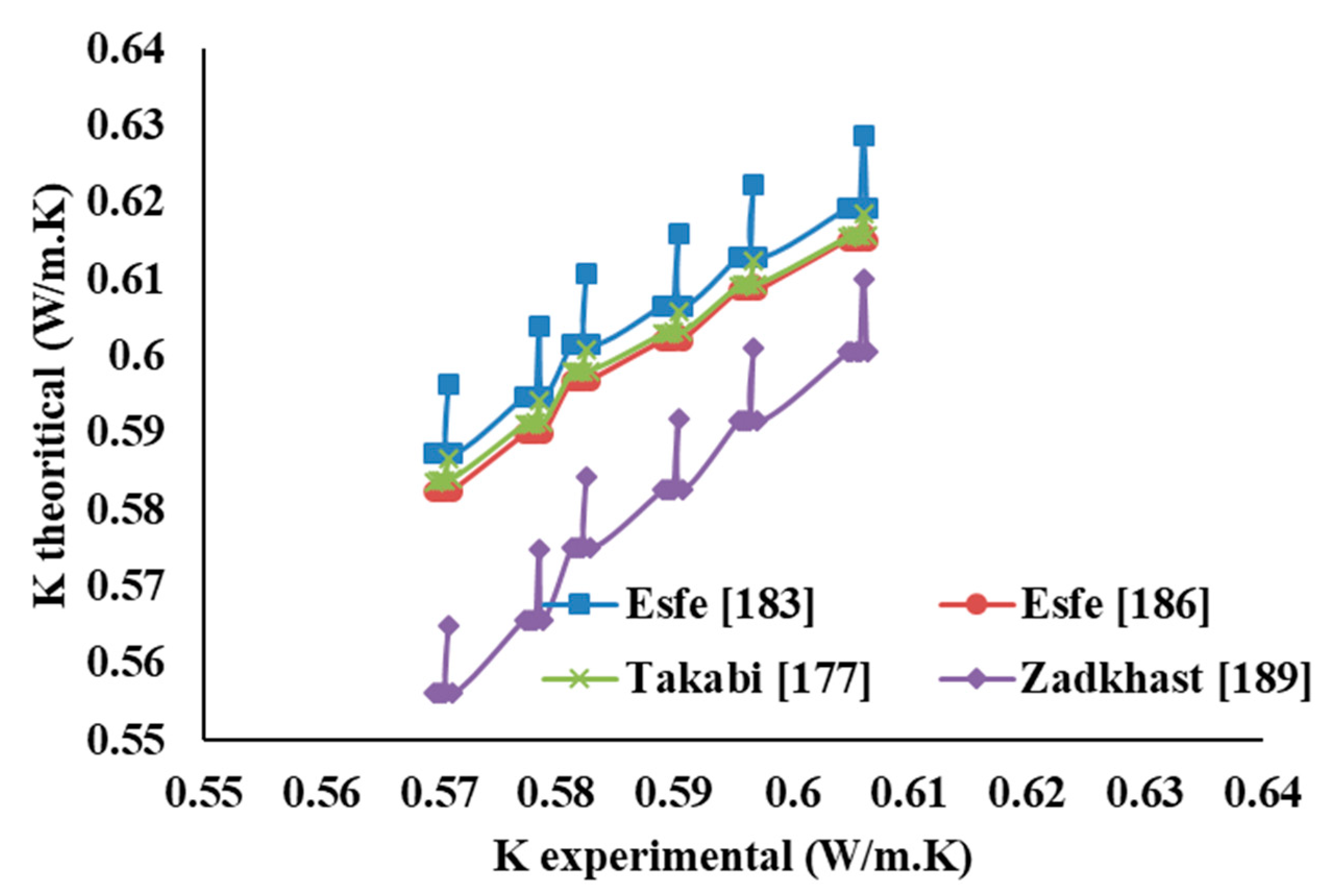

4.3. Thermal Conductivity of Mono/Hybrid Nanofluids

5. Hydrothermal Characteristics of Heat Exchanger

5.1. Experimental Studies on Heat Exchangers

5.2. Numerical Studies on the Heat Exchangers

6. Exergy Analysis of Mono/Hybrid Nanofluids

7. Applications of Mono/Hybrid Nanofluids

8. Conclusions

- There are limited studies on the heat transfer properties of hybrid nanofluid heat exchangers.

- The influence of individual particle proportions of hybrid nanofluids on the performance of heat exchangers is unknown.

- There is little experimental work and validation by CFD modeling of heat exchangers using hybrid nanofluids operating for low-temperature applications.

- Hybrid nanofluids can be used in biodiesel blends and as fuel additives to enhance the performance of IC engines.

- A single correlation containing the effect of temperature and particle size is needed to predict accurate thermal conductivity and viscosity of mono/hybrid nanofluids.

- Nanofluids with more thermal conductivity show better heat transfer characteristics, and nanofluids with more viscosity provide higher pressure drop and pump work. An increment in heat transfer is desirable, while an increment in pump work is undesirable; thus, another performance indicator must be determined, such as a performance index (ratio of heat transfer rate and pump work), to obtain a better nanofluid.

- Many empirical relations are available for calculating the Nusselt number on the basis of non-dimensional numbers, i.e., Reynolds and Prandtl numbers. However, the Nusselt number, by definition, depends on the thermal conductivity, geometric parameters, and heat transfer coefficient. Hence, it is suggested to validate the results in two ways. For this purpose, conducting the experiments and obtaining the required parameters are recommended.

- It can be observed that the thermal conductivity, density, and viscosity increase with the addition of nanoparticles in the base fluid. The fluid’s thermal conductivity increases with the temperature increase, whereas density and viscosity decrease. No change can be observed for the specific heat as the studied temperature range is small.

- Hybrid nanofluids can be used as a coolant in automobile radiators and ICEs.

- Few investigations are available for ternary hybrid nanofluids to analyze irreversibility, exergy, economic, and the second law of efficiency in air heat exchangers utilizing various turbulators.

- Studies were conducted primarily with water and EG/water brine as base fluids. Using different brines as primary and secondary cooling water should be explored.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| b | Plate spacing, mm |

| C | Specific heat, J/kg·K |

| K | Thermal conductivity, W/m·K |

| ṁ | Mass flow rate, kg/s |

| N | Shape factor |

| Pe | Pecklet number |

| Re | Reynolds number |

| T | Temperature, °C |

| V | Volume, m3 |

| Abbreviation | |

| COP | Coefficient of performance |

| CTAB | Cetyl trimethyl ammonium bromide |

| DI | Deionized water |

| DLS | Dynamic light scattering |

| EG | Ethylene glycol |

| F-CNF | Functionalized carbon nanofiber |

| FESEM | Field-emission scanning electron microscopy |

| GA | Gum Arabic |

| HCFC | Hydrochlorofluorocarbons |

| HEG | Hydrogen-induced exfoliated graphene |

| HEX | Heat exchanger |

| HTC | Heat transfer coefficient |

| HVAC | Heating, ventilation, and air conditioning |

| HyNf | Hybrid nanofluid |

| MCHS | Microchannel heat sink |

| MWCNT | Multiwalled carbon nanotube |

| PCM | Phase change material |

| PHE | Plate heat exchanger |

| PHP | Pulsating heat pipe |

| PVP | Polyvinyl pyrrolidone |

| PVA | Polyvinyl alcohol |

| rGO | Reduced graphene oxide |

| SDS | Sodium dodecyl sulfate |

| SDBS | Sodium dodecyl benzene sulfonate |

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscopy |

| VSM | Vibrating sample magnetometry |

| v% | Percentage volume concentration |

| XRD | X-ray diffraction |

| Greek symbols | |

| β | Chevron angle, ° |

| Ω | Discharge, lpm |

| µ | Dynamic viscosity, Pa·S |

| ρ | Density, kg/m3 |

| Φ | Volume concentration |

| Ψ | Coefficient |

| Subscript | |

| 1 | First |

| 2 | Second |

| bf | Base fluid |

| nf | Nanofluid |

| p | Nanoparticle |

| eff | Effective |

| h | Hot |

| c | Cold |

| i | Inlet |

References

- Rao, V.; Sankar, B. Heat transfer and friction factor investigations of CuO nanofluid flow in a double pipe U-bend heat exchanger. Mater. Today Proc. 2019, 18, 207–218. [Google Scholar]

- Omidi, M.; Farhadi, M.; Jafari, M. A comprehensive review on double pipe heat exchangers. Appl. Therm. Eng. 2017, 110, 1075–1090. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Han, Y.; Li, W.; Yang, L.; Guo, J.; Liu, Y.; Zhang, J.; Zhang, M.; Jiang, F. A comprehensive review of heat transfer enhancement and flow characteristics in the concentric pipe heat exchanger. Powder Technol. 2021, 397, 117037. [Google Scholar] [CrossRef]

- Ding, M.; Liu, C.; Rao, Z. Experimental investigation on heat transfer characteristic of TiO2-H2O nanofluid in microchannel for thermal energy storage. Appl. Therm. Eng. 2019, 160, 114024. [Google Scholar] [CrossRef]

- Alshukri, M.; Hussein, A.; Eidan, A.; Alsabery, A. A review on applications and techniques of improving the performance of heat pipe-solar collector systems. Sol. Energy 2022, 236, 417–433. [Google Scholar] [CrossRef]

- Cengel, Y. Heat and Mass Transfer. A Practical Approach, 3rd ed.; McGraw Hill/Interamericana Editores, S.A.: Mexico City, Mexico, 2013; pp. 1689–1699. [Google Scholar]

- Rostami, S.; Shahsavar, A.; Kefayati, G.; Goldanlou, A.S. Energy and exergy analysis of using turbulator in a parabolic trough solar collector filled with mesoporous silica modified with copper nanoparticles hybrid nanofluid. Energies 2020, 13, 2946. [Google Scholar] [CrossRef]

- Choi, S. Enhancing Thermal Conductivity of Fluids with Nanoparticles, Developments and Applications of Non-Newtonian Flows; ASME: New York, NY, USA, 1995; pp. 99–105. [Google Scholar]

- Kumar, P.M.; Palanisamy, K.; Vijayan, V. Stability analysis of heat transfer hybrid/water nanofluids. Mater. Today Proc. 2020, 21, 708–712. [Google Scholar] [CrossRef]

- Okonkwo, E.; Wole-Osho, I.; Almanassra, I.; Abdullatif, Y.; Al-Ansari, T. An updated review of nanofluids in various heat transfer devices. J. Therm. Anal. 2021, 145, 2817–2872. [Google Scholar] [CrossRef]

- Sarkar, J.; Ghosh, P.; Adil, A. A review on hybrid nanofluids: Recent research, development and applications. Renew. Sustain. Energy Rev. 2015, 43, 164–177. [Google Scholar] [CrossRef]

- Sahin, A. Performance enhancement of solar energy using nanofluids: An update review. Renew Energy 2020, 145, 1126–1148. [Google Scholar] [CrossRef]

- Zayed, M.; Du, Y.; Kabeel, A.; Shalaby, S. Factors affecting the thermal performance of the plate solar collector using nanofluids: A review. Sol. Energ. 2019, 182, 382–396. [Google Scholar] [CrossRef]

- Wahab, A.; Hassan, A.; Qasim, M.; Ali, H.; Babar, H.; Sajid, M. Solar energy systems—Potential of nanofluids. J. Mol. Liq. 2019, 289, 111049. [Google Scholar] [CrossRef]

- Pordanjani, A.; Aghakhani, S.; Afrand, M.; Mahmoudi, B.; Mahian, O.; Wongwises, S. An updated review on application of nanofluids in heat exchangers for saving energy. Energy Convers. Manag. 2019, 198, 111886. [Google Scholar] [CrossRef]

- Sajid, M.; Ali, H. Recent advances in application of nanofluids in heat transfer devices: A critical review. Renew. Sustain. Energy Rev. 2019, 103, 556–592. [Google Scholar] [CrossRef]

- Kumar, A.; Subudhi, S. Preparation, characterization and heat transfer analysis of nanofluids used for engine cooling. Appl. Therm. Eng. 2019, 160, 114092. [Google Scholar] [CrossRef]

- Rahman, S.; Ashraf, M.; Amin, A.; Bashar, M.; Ashik, M.; Kamruzzaman, M. Tuning nanofluids for improved lubrication performance in turning biomedical grade titanium alloy. J. Clean. Prod. 2019, 206, 180–196. [Google Scholar] [CrossRef]

- Panithasan, M.; Gopalakichenin, D.; Veeraraagavan, S. Impact of rice husk nanoparticle on the performance and emission aspect of a diesel engine running on blends on pine oildiesel. Env. Sci. Pollut. Res. 2019, 26, 282–291. [Google Scholar] [CrossRef]

- Pinto, R.; Fiorelli, F. Review of the mechanisms responsible for heat transfer enhancement using nanofluids. Appl. Therm. Eng. 2016, 108, 720–739. [Google Scholar] [CrossRef]

- Radomska, E.; Mika, L.; Sztekler, K. The impact of additives on the main properties of phase change materials. Energies 2020, 13, 3064. [Google Scholar] [CrossRef]

- Suhaimi, N.; Din, M.; Hamid, M.; Amin, N.; Zamri, W.; Wang, J. Optimum electrical and dielectric performance of multi-walled carbon nanotubes doped disposed transformer oil. Energies 2020, 13, 3181. [Google Scholar] [CrossRef]

- Sekar, A.; Jayabalan, T.; Muthukumar, H.; Chandrasekaran, N.; Mohamed, S.; Matheswaran, M. Enhancing power generation and treatment of dairy waste water in microbial fuel cell using Cu-doped iron oxide nanoparticles decorated anode. Energy 2019, 172, 173–180. [Google Scholar] [CrossRef]

- Said, Z.; Gupta, M.; Khan, A.; Jamil, M.; Bellos, E. A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int. J. Adv. Manuf. Technol. 2019, 105, 2057–2086. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A. The influence of hybrid nanofluids on the performances of elliptical tube: Recent research and numerical study. Int. J. Heat Mass Transf. 2019, 129, 132–143. [Google Scholar] [CrossRef]

- Elsaid, A. Experimental study on the heat transfer performance and friction factor characteristics of Co3O4 and Al2O3 based H2O/(CH2OH)2 nanofluids in a vehicle engine radiator. Int. Commun. Heat Mass Transf. 2019, 108, 104263. [Google Scholar] [CrossRef]

- Al-Shdaifat, M.; Zulkifli, R.; Sopian, K.; Salih, A. Thermal and hydraulic performance of CuO/water nanofluids: A review. Micromachines 2020, 11, 416. [Google Scholar] [CrossRef] [PubMed]

- Eshgarf, H.; Kalbasi, R.; Maleki, A.; Shadloo, M.; Karimipour, A. A review on the properties, preparation, models and stability of hybrid nanofluids to optimize energy consumption. J. Therm. Anal. Calorim. 2021, 144, 1959–1983. [Google Scholar] [CrossRef]

- Zainon, S.; Azmi, W. Recent progress on stability and thermo-physical properties of mono and hybrid towards green nanofluids. Micromachines 2021, 12, 176. [Google Scholar] [CrossRef] [PubMed]

- Pavia, M.; Alajami, K.; Estellé, P.; Vigolo, B. A critical review on thermal conductivity enhancement of graphene-based nanofluids. Adv. Colloid. Interface Sci. 2021, 294, 102452. [Google Scholar] [CrossRef] [PubMed]

- Inlow, S.; Groll, E. A performance comparison of secondary refrigerants. In Proceedings of the 1996 Purdue International Refrigeration Conference, West Lafayette, IN, USA, 23 July 1996; pp. 167–178. [Google Scholar]

- Wang, K.; Eisele, M.; Hwang, Y.; Radermacher, R. Review of secondary loop refrigeration systems. Int. J. Refrig. 2010, 33, 212–234. [Google Scholar] [CrossRef]

- Sreelakshmy, K.; Aswathy, S.; Vidhya, K.; Saranya, T.; Sreeja, C. An overview of recent nanofluid research. Int. Res. J. Pharm. 2014, 5, 239–243. [Google Scholar]

- Nor-Azwadi, C.; Adamu, I.; Jamil, M. Preparation methods and thermal performance of hybrid nanofluids. J. Adv. Rev. Sci. Res. 2016, 24, 13–23. [Google Scholar]

- Sidik, N.; Adamu, I.; Jamil, M.; Kefayati, G.; Mamat, R.; Najafi, G. Recent progress on hybrid nanofluids in heat transfer applications: A comprehensive review. Int. Commun. Heat Mass Transf. 2016, 78, 68–79. [Google Scholar] [CrossRef]

- Nabil, M.; Azmi, W.; Hamid, K.; Zawawi, N.; Priyandoko, G.; Mamat, R. Thermo-physical properties of hybrid nanofluids and hybrid nanolubricants: A comprehensive review on performance. Int. Commun. Heat Mass Transf. 2017, 83, 30–39. [Google Scholar] [CrossRef]

- Sundar, L.; Sharma, K.; Singh, M.; Sousa, A. Hybrid nanofluids preparation, thermal properties, heat transfer and friction factor–A review. Renew. Sustain. Energy Rev. 2017, 68, 185–198. [Google Scholar] [CrossRef]

- Babu, J.; Kumar, K.; Rao, S. State-of-art review on hybrid nanofluids. Renew. Sustain. Energy Rev. 2017, 77, 551–565. [Google Scholar] [CrossRef]

- Sidik, N.; Jamil, M.; Aziz-Japar, W.; Adamu, I. A review on preparation methods, stability and applications of hybrid nanofluids. Renew. Sustain. Energy Rev. 2017, 80, 1112–1122. [Google Scholar] [CrossRef]

- Kumar, D.; Arasu, A. A comprehensive review of preparation, characterization, properties and stability of hybrid nanofluids. Renew. Sustain. Energy Rev. 2018, 81, 1669–1689. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, V.; Kumar, S.; Said, Z. Up to date review on the synthesis and thermophysical properties of hybrid nanofluids. J. Clean. Prod. 2018, 190, 169–192. [Google Scholar] [CrossRef]

- Jamkhande, P.; Bamer, A.; Kalaskar, M. Metal nanoparticles synthesis: An overview on methods of preparation, advantages and disadvantages, and applications. J. Drug Deliv. Sci. Technol. 2019, 53, 101174. [Google Scholar] [CrossRef]

- Asadi, A.; Aberoumand, S.; Moradikazerouni, A.; Pourfattah, F.; Żyła, G.; Estellé, P.; Mahian, O.; Wongwises, S.; Nguyen, H.M.; Arabkoohsar, A. Recent advances in preparation methods and thermophysical properties of oil-based nanofluids: A state of the art review. Powder Technol. 2019, 352, 209–226. [Google Scholar] [CrossRef]

- Arshad, A.; Jabbal, M.; Yan, Y.; Reay, D. A review on graphene based nanofluids: Preparation, characterization and applications. J. Mol. Liq. 2019, 279, 444–484. [Google Scholar] [CrossRef]

- Mishra, P.; Sen, S.; Amin, R.; Biring, S. Effect of annealing on structure, optoelectronic and photoresponsivity properties of sol–gel prepared ZnO nanoparticles. Mater. Today Proc. 2019, 17, 261–265. [Google Scholar] [CrossRef]

- Esmaeili, E.; Rounaghi, S.; Gruner, W.; Eckert, J. The preparation of surfactant-free highly dispersed ethylene glycol-based aluminum nitride-carbon nanofluids for heat transfer application. Adv. Powder Technol. 2019, 30, 2032–2041. [Google Scholar] [CrossRef]

- Das, N.; Naik, P.; Reddy, D.; Mallik, B.; Bose, S.; Banerjee, T. Experimental and molecular dynamic insights on the thermophysical properties for MWCNT-Phosphonium based eutectic thermal media. J. Mol. Liq. 2022, 354, 118892. [Google Scholar]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Use of Hybrid Nanofluids in Plate Heat Exchanger for Low Temperature Applications. Ph.D. Thesis, Indian Institute of Technology Banaras Hindu University, Varanasi, Uttar Pradesh, India, 2019. [Google Scholar]

- Jana, S.; Khojin, A.; Zhong, W. Enhancement of fluid thermal conductivity by the addition of single and hybrid nano-additives. Thermochim. Acta 2007, 462, 45–55. [Google Scholar] [CrossRef]

- Han, Z.; Yang, B.; Kim, S.; Zachariah, M. Application of hybrid sphere/ carbon nanotube particles in nanofluids. Nanotechnology 2007, 18, 105701. [Google Scholar] [CrossRef]

- Turcu, R.; Pana, O.; Nan, A.; Craciunescu, I.; Chauvet, O.; Payen, C. Polypyrrole coated magnetite nanoparticles from water based nanofluids. J. Phys. Appl. Phys. 2008, 41, 245002. [Google Scholar] [CrossRef]

- Jha, N.; Ramaprabhu, S. Synthesis and thermal conductivity of copper nanoparticle decorated multiwalled carbon nanotubes based nanofluids. J. Phys. Chem. C 2008, 112, 9315–9319. [Google Scholar] [CrossRef]

- Han, W.; Rhi, S. Thermal characteristics of grooved heat pipe with hybrid nanofluids. Therm. Sci. 2011, 15, 195–206. [Google Scholar] [CrossRef]

- Baby, T.; Sundara, R. Synthesis and transport properties of metal oxide decorated graphene dispersed nanofluids. J. Phys. Chem. C 2011, 115, 8527–8533. [Google Scholar] [CrossRef]

- Paul, G.; Philip, J.; Raj, B.; Das, P.; Manna, I. Synthesis, characterization and thermal property measurement of nano-Al95Zn05 dispersed nanofluid prepared by a two-step process. Int. J. Heat Mass Transf. 2011, 54, 3783–3788. [Google Scholar] [CrossRef]

- Suresh, S.; Venkitaraj, K.; Selvakumar, P.; Chandrasekar, M. Synthesis of Al2O3-Cu/water hybrid nanofluids using two step method and its thermo physical properties. Colloids Surfaces A Physicochem. Eng. Asp. 2011, 388, 41–48. [Google Scholar] [CrossRef]

- Botha, S.S.; Ndungu, P.; Bladergroen, B.J. Physicochemical properties of oil-based nanofluids containing hybrid structures of silver nanoparticles supported on silica. Ind. Eng. Chem. Res. 2011, 50, 3071–3077. [Google Scholar] [CrossRef]

- Ho, C.; Huang, J.; Tsai, P.; Yang, Y. On laminar convective cooling performance of hybrid water-based suspensions of Al2O3 nanoparticles and MEPCM particles in a circular tube. Int. J. Heat Mass Transf. 2011, 54, 2397–2407. [Google Scholar] [CrossRef]

- Baby, T.; Sundara, R. Synthesis and nanofluid application of silver nanoparticles decorated graphene. J. Mater. Chem. 2011, 21, 9702–9709. [Google Scholar] [CrossRef]

- Amiri, A.; Shanbedi, M.; Eshghi, H.; Heris, S.; Baniadam, M. Highly dispersed multiwalled carbon nanotubes decorated with Ag nanoparticles in water and experimental investigation of the thermophysical properties. J. Phys. Chem. C 2012, 116, 3369–3375. [Google Scholar] [CrossRef]

- Chen, L.; Yu, W.; Xie, H. Enhanced thermal conductivity of nanofluids containing Ag/MWNT composites. Powder Technol. 2012, 231, 18–20. [Google Scholar] [CrossRef]

- Aravind, S.; Ramaprabhu, S. Graphene wrapped multiwalled carbon nanotubes dispersed nanofluids for heat transfer applications. J. Appl. Phys. 2012, 112, 124304–124309. [Google Scholar] [CrossRef]

- Bhosale, G.; Borse, S. Pool boiling CHF enhancement with Al2O3–CuO/H2O hybrid nanofluid. Int. J. Eng. Res. Technol. 2013, 2, 946–950. [Google Scholar]

- Balla, H.; Abdullah, S.; MohdFaizal, W.; Zulkifli, R.; Sopian, K. Numerical study of the enhancement of heat transfer for hybrid CuO-Cu nanofluids flowing in a circular pipe. J. Oleo Sci. 2013, 62, 533–539. [Google Scholar] [CrossRef]

- Abbasi, S.; Rashidi, A.; Nemati, A.; Arzani, K. The effect of functionalisation methodon the stability and the thermal conductivity of nanofluid hybrids of carbon nanotubes/gamma alumina. Ceram. Int. 2013, 39, 3885–3891. [Google Scholar] [CrossRef]

- Nine, M.; Munkhbayar, B.; Rahman, M.; Chung, H.; Jeong, H. Highly productive synthesis process of well dispersed Cu2O and Cu/Cu2O nanoparticles and its thermal characterization. Mater. Chem. Phys. 2013, 141, 636–642. [Google Scholar] [CrossRef]

- Munkhbayar, B.; Tanshen, M.; Jeoun, J.; Chung, H.; Jeong, H. Surfactant-free dispersion of silver nanoparticles into MWCNT-aqueous nanofluids prepared by one-step technique and their thermal characteristics. Ceram. Int. 2013, 39, 6415–6425. [Google Scholar] [CrossRef]

- Sundar, L.; Singh, M.; Ramana, E.; Sing, B.; Gracio, J.; Sousa, A. Enhanced thermal conductivity and viscosity of nanodiamond–nickel nanocomposite nanofluids. Sci. Rep. 2014, 4, 4039. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Deepak, K.; Saravanan, R.; Kalaiselvam, S. Preparation, thermal and rheological properties of hybrid nanocomposite phase change material for thermal energy storage. Appl. Energy 2014, 115, 320–330. [Google Scholar] [CrossRef]

- Batmunkh, M.; Tanshen, M.; Nine, M.; Myekhlai, M.; Choi, H.; Chung, H.; Jeong, H. Thermal conductivity of TiO2 nanoparticles based aqueous nanofluids with an addition of a modified silver particle. Ind. Eng. Chem. Res. 2014, 53, 8445–8451. [Google Scholar] [CrossRef]

- Madhesh, D.; Parameshwaran, R.; Kalaiselvam, S. Experimental investigation on convective heat transfer and rheological characteristics of Cu-TiO2 hybrid nanofluids. Exp. Therm. Fluid Sci. 2014, 52, 104–115. [Google Scholar] [CrossRef]

- Chen, L.; Cheng, M.; Yang, D.; Yang, L. Enhanced thermal conductivity of nanofluid by synergistic effect of multi-walled carbon nanotubes and Fe2O3 nanoparticles. Appl. Mech. Mater. 2014, 548, 118–123. [Google Scholar]

- Parekh, K. Thermo-magnetic properties of ternary polydispersed Mn0.5Zn0.5Fe2O4 ferrite magnetic fluid. Solid State Commun. 2014, 187, 33–37. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.; Zhao, H.; Cai, G.; Zheng, X. Tribology properties of Al2O3/TiO2 nanocomposites as lubricant additives. Ceram. Int. 2014, 40, 10103–10109. [Google Scholar] [CrossRef]

- Madhesh, D.; Kalaiselvam, S. Experimental study on heat transfer and rheological characteristics of hybrid nanofluids for cooling applications. J. Exp. Nanosci. 2015, 10, 1194–1213. [Google Scholar] [CrossRef]

- Zubir, M.; Badarudin, A.; Kazi, S.; Huang, N.; Misran, M.; Sadeghinezhad, E.; Mehrali, M.; Syuhada, N.; Gharehkhani, S. Experimental investigation on the use of reduced graphene oxide and its hybrid complexes in improving closed conduit turbulent forced convective heat transfer. Exp. Therm. Fluid Sci. 2015, 66, 290–303. [Google Scholar] [CrossRef]

- Qadri, M.; Chandra, R.; Ravindra, S.; Velmurugan, V. Synthesis and testing of graphene /cuprous oxide composite based nano fluids for engine coolants. Mater. Today Proc. 2015, 2, 4640–4645. [Google Scholar] [CrossRef]

- Karimi, A.; Sadatlu, M.; Saberi, B.; Shariatmadar, H. Experimental investigation on thermal conductivity of water based nickel ferrite nanofluids. Adv. Powder Technol. 2015, 26, 1529–1536. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sarkar, I.; Haldar, K.; Pal, S.; Chakraborty, S. Synthesis of Cu–Al layered double hydroxide nanofluid and characterization of its thermal properties. Appl. Clay Sci. 2015, 107, 98–108. [Google Scholar] [CrossRef]

- Megatif, L.; Ghozatloo, A.; Arimi, A.; Niasar, M. Investigation of laminar convective heat transfer of a novel TiO2-carbon nanotube hybrid water-based nanofluid. Exp. Heat Transf. 2015, 6152, 1–15. [Google Scholar] [CrossRef]

- Abbasi, S.; Zebarjad, S.; Baghban, S.; Youssefi, A.; Ekrami-Kakhki, M. Experimental investigation of the rheological behavior and viscosity of decorated multi-walled carbon nanotubes with TiO2 nanoparticles/water nanofluids. J. Therm. Anal. Calorim. 2016, 123, 81–89. [Google Scholar] [CrossRef]

- Toghraie, D.; Chaharsoghi, V.; Afrand, M. Measurement of thermal conductivity of ZnO–TiO2/EG hybrid nanofluid. J. Therm. Anal. Calorim. 2016, 125, 527–535. [Google Scholar] [CrossRef]

- Bhanvase, B.; Kamath, S.; Patil, U.; Patil, H.; Pandit, A.; Sonawane, S. Intensification of heat transfer using PANI nanoparticles and PANI-CuO nanocomposite based nanofluids. Chem. Eng. Process. 2016, 104, 172–180. [Google Scholar] [CrossRef]

- Asadi, A.; Alarifi, I.; Foong, L. An experimental study on characterization, stability and dynamic viscosity of CuO-TiO2/water hybrid nanofluid. J. Mol. Liq. 2020, 307, 112987. [Google Scholar] [CrossRef]

- Chen, Z.; Shahsavar, A.; Al-Rashed, A.; Afrand, M. The impact of sonication and stirring durations on the thermal conductivity of alumina-liquid paraffin nanofluid: An experimental assessment. Powder Technol. 2020, 360, 1134–1142. [Google Scholar] [CrossRef]

- Asadi, A.; Alarifid, I.; Ali, V.; Nguyen, H. An experimental investigation on the effects of ultrasonication time on stability and thermal conductivity of MWCNTwater nanofluid: Finding the optimum ultrasonication time. Ultrason. Sonochem. 2019, 58, 104639. [Google Scholar] [CrossRef]

- Gulzar, O.; Qayoum, A.; Gupta, R. Experimental study on stability and rheological behavior of hybrid Al2O3—TiO2 Therminol-55 nanofluids for concentrating solar collectors. Powder Technol. 2019, 352, 436–444. [Google Scholar] [CrossRef]

- Alarifi, I.; Alkouh, A.; Ali, V.; Nguyen, H.; Asadi, A. On the rheological properties of MWCNT-TiO2/oil hybrid nanofluid: An experimental investigation on the effects of shear rate, temperature, and solid concentration of nanoparticles. Powder Technol. 2019, 355, 157–162. [Google Scholar] [CrossRef]

- Akram, N.; Sadri, R.; Kazi, S.N.; Ahmed, S.M.; Zubir, M.N.M.; Ridha, M.; Soudagar, M.; Ahmed, W.; Arzpeyma, M.; Tong, G.B. An experimental investigation on the performance of a flat-plate solar collector using eco-friendly treated graphene nanoplatelets–water nanofluids. J. Therm. Anal. Calorim. 2019, 138, 609–621. [Google Scholar] [CrossRef]

- Sharafeldin, M.; Grof, G. Efficiency of evacuated tube solar collector using WO3/Water nanofluid. Renew. Energy 2019, 134, 453–460. [Google Scholar] [CrossRef]

- Chen, W.; Zou, C.; Li, X. Application of large-scale prepared MWCNTs nanofluids in solar energy system as volumetric solar absorber. Sol. Energy Mater. Sol. Cells 2019, 200, 109931. [Google Scholar] [CrossRef]

- Ali, N.; Teixeira, J.; Addali, A. Aluminum nanofluids stability: A comparison between the conventional two-step fabrication approach and the controlled sonication bath temperature method. J. Nanomater. 2019, 2019, 3930572. [Google Scholar] [CrossRef]

- Mahbubul, I.; Elcioglu, E.; Amalina, M.; Saidur, R. Stability, thermophysical properties and performance assessment of alumina–water nanofluid with emphasis on ultrasonication and storage period. Powder Technol. 2019, 345, 668–675. [Google Scholar] [CrossRef]

- Mahyari, A.; Karimipour, A.; Afrand, M. Effects of dispersed added Graphene Oxide-Silicon Carbide nanoparticles to present a statistical formulation for the mixture thermal properties. Phys. A Stat. Mech. Its Appl. 2019, 521, 98–112. [Google Scholar] [CrossRef]

- Chen, W.; Zou, C.; Li, X.; Liang, H. Application of recoverable carbon nanotube nanofluids in solar desalination system: An experimental investigation. Desalination 2019, 451, 92–101. [Google Scholar] [CrossRef]

- Okonkwo, E.; Wole-Osho, I.; Kavaz, D.; Abid, M. Comparison of experimental and theoretical methods of obtaining the thermal properties of alumina/iron mono and hybrid nanofluids. J. Mol. Liq. 2019, 292, 111377. [Google Scholar] [CrossRef]

- Teruel, M.; Aguilar, T.; Martínez-Merino, P.; Carrillo-Berdugo, I.; Gallardo-Bernal, J.J.; Gómez-Villarejo, R.; Alcántara, R.; Fernández-Lorenzo, C.; Navas, J. 2D MoSe2-based nanofluids prepared by liquid phase exfoliation for heat transfer applications in concentrating solar power. Sol. Energy Mater. Sol. Cells 2019, 200, 109972. [Google Scholar] [CrossRef]

- Li, Z.; Asadi, S.; Karimipour, A.; Abdollahi, A.; Tlili, I. Experimental study of temperature and mass fraction effects on thermal conductivity and dynamic viscosity of SiO2-oleic acid/ liquid paraffin nanofluid. Int. Commun. Heat Mass Transf. 2020, 110, 104436. [Google Scholar] [CrossRef]

- Geng, Y.; Al-Rashed, A.; Mahmoudi, B.; Alsagri, A.; Shahsavar, A.; Alebizadehsardari, P. Characterization of the nanoparticles, the stability analysis and the evaluation of a new hybrid nano-oil thermal conductivity. J. Therm. Anal. Calorim. 2020, 139, 1553–1564. [Google Scholar] [CrossRef]

- Li, Y.; Kalbasi, R.; Nguyen, Q.; Afrand, M. Effects of sonication duration and nanoparticles concentration on thermal conductivity of silica-ethylene glycol nanofluid under different temperatures: An experimental study. Powder Technol. 2020, 367, 464–473. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Experimentation on effect of particle ratio on hydrothermal performance of plate heat exchanger using hybrid nanofluid. Appl. Therm. Eng. 2019, 162, 114309. [Google Scholar] [CrossRef]

- Yang, L.; Ji, W.; Mao, M.; Huang, J. An updated review on the properties, fabrication and application of hybrid-nanofluids along with their environmental effects. J. Clean. Prod. 2020, 257, 120408. [Google Scholar] [CrossRef]

- Sezer, N.; Atieh, M.A.; Koç, M. A comprehensive review on synthesis, stability, thermophysical properties, and characterization of nanofluids. Powder Technol. 2019, 344, 404–431. [Google Scholar] [CrossRef]

- Asadi, A.; Pourfattah, F.; Szilágyi, I.; Afrand, M.; Żyła, G.; Ahn, H.; Wongwises, N.H.; Arabkoohsar, A.; Mahian, O. Effect of sonication characteristics on stability, thermophysical properties, and heat transfer of nanofluids: A comprehensive review. Ultrason. Sonochem. 2019, 58, 104701. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, X.; Mayers, B.; Herricks, T.; Xia, Y. Synthesis and characterization of magnetic Co nanoparticles: A comparison study of three different capping surfactants. J. Solid State Chem. 2008, 181, 1530–1538. [Google Scholar] [CrossRef]

- Saeedinia, M.; Akhavan-Behabadi, M.; Razi, P. Thermal and rheological characteristics of CuO-Base oil nanofluidflow inside a circular tube. Int. Commun. Heat Mass Tran. 2012, 39, 152–159. [Google Scholar] [CrossRef]

- Khan, A.; Arasu, A. A review of influence of nanoparticle synthesis and geometrical parameters on thermophysical properties and stability of nanofluids. Therm. Sci. Eng. Prog. 2019, 11, 334–364. [Google Scholar] [CrossRef]

- Singh, S. Review on the stability of the nanofluids. In Pipeline Engineering; Rushd, S., Ismail, M.A., Eds.; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Safiei, W.; Rahman, M.; Yusoff, A.; Radin, M. Preparation, stability and wettability of nanofluid: A review. J. Mech. Eng. Sci. 2020, 14, 7244–7257. [Google Scholar] [CrossRef]

- Amin, A.; Hamzah, W.; Oumer, A. Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review. Nanotechnol. Rev. 2021, 10, 1624–1661. [Google Scholar] [CrossRef]

- Malika, M.; Sonawane, S. Effect of nanoparticle mixed ratio on stability and thermo-physical properties of CuO-ZnO/water-based hybrid nanofluid. J. Indian Chem. Soc. 2020, 97, 414–419. [Google Scholar]

- Sahoo, R.; Kumar, V. Comparative analysis of Viscosity and Thermal Conductivity for Al2O3/CuO Hybrid Nanofluid in Binary Base Fluids. Nanotechnol. Mater. Sci. 2019, 6, 34–42. [Google Scholar]

- Ramadhan, A.; Azmi, W.; Mamat, R.; Hamid, K.; Norsakinah, S. Investigation on stability of tri-hybrid nanofluids in water- ethylene glycol mixture. IOP Conf. Ser. Mater. Sci. Eng. 2019, 469, 012068. [Google Scholar] [CrossRef]

- Afshari, F.; Manay, E.; Rahimpour, S.; Sahin, B.; Muratçobanoglu, B.; Teimuri-Mofrad, R. A review study on factors affecting the stability of nanofluids. Heat Transf. Res. 2022, 53, 77–91. [Google Scholar] [CrossRef]

- Arora, N.; Gupta, M. Stability Evaluation and Enhancement Methods in Nanofluids: A Review. AIP Conf. Proc. 2021, 2341, 040022. [Google Scholar] [CrossRef]

- Wcislik, S. Efficient stabilization of mono and hybrid nanofluids. Energies 2020, 13, 3793. [Google Scholar] [CrossRef]

- Bumataria, R.; Chavda, N.; Panchal, H. Current research aspects in mono and hybrid nanofluid based heat pipe technologies. Heliyon 2019, 5, e01627. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Salam, B. A review on nanofluid: Preparation, stability, thermophysical properties, heat transfer characteristics and application. SN Appl. Sci. 2020, 2, 1636. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, L.; Feng, J.; Qiao, L.; Yu, C.; Shi, W.; Ding, C.; Zang, Y.; Chang, C.; Xiong, Y.; et al. A comparative investigation on the effect of different nanofluids on the thermal performance of two-phase closed thermosiphon. Int. J. Heat Mass Transf. 2020, 149, 119189. [Google Scholar] [CrossRef]

- Said, Z.; Abdelkareem, M.; Rezk, H.; Nassef, A.; Atwany, H. Stability, thermophysical and electrical properties of synthesized carbon nanofiber and reduced-graphene oxidebased nanofluids and their hybrid along with fuzzy modeling approach. Powder Technol. 2020, 364, 795–809. [Google Scholar] [CrossRef]

- Muthoka, M.; Xuelai, Z.; Xioafeng, X. Experimental investigation on supercooling, thermal conductivity and stability of nanofluid based composite phase change material. J. Energy Storage 2018, 17, 47–55. [Google Scholar]

- Said, Z.; Allagui, A.; Abdelkareem, M.; Alawadhi, H.; Elsaid, K. Acid functionalized carbon nanofibers for high stability, thermoelectrical and electrochemical properties of nanofluids. J. Colloid Interface Sci. 2018, 18, 30190–30195. [Google Scholar] [CrossRef]

- Alawi, O.; Mallah, A.; Kazi, S.; Sidik, N.; Najafi, G. Thermophysical properties and stability of carbon nanostructures and metallic oxides nanofluids. J. Therm. Anal. Calor. 2019, 135, 1545–1562. [Google Scholar] [CrossRef]

- Akbari, A.; Saidi, M. Experimental investigation of nanofluid stability on thermal performance and flow regimes in pulsating heat pipe. J. Therm. Anal. Calor. 2019, 135, 1835–1847. [Google Scholar] [CrossRef]

- Boroomandpour, A.; Toghraie, D.; Hashemian, M. A comprehensive experimental investigation of thermal conductivity of a ternary hybrid nanofluid containing MWCNTs- titania zinc oxide/water water ethylene (80:20) as well as binary and mono nanofluids. Synth. Met. 2020, 268, 116501. [Google Scholar] [CrossRef]

- Uysal, A. Investigation of flank wear in MQL milling of ferritic stainless steel by using nano graphene reinforced vegetable cutting fluid. Ind. Lubr. Tribol. 2016, 68, 446–451. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Chaichan, M.T.; Kazem, H.A.; Sopian, K. Evaluation and analysis of nanofluid and surfactant impact on photovoltaic-thermal systems. Case Stud. Therm. Eng. 2019, 13, 100392. [Google Scholar] [CrossRef]

- Cacua, K.; Ordoñez, F.; Zapata, C.; Herrera, B.; Pabón, E.; Buitrago-Sierra, R. Surfactant concentration and pH effects on the zeta potential values of alumina nanofluids to inspect stability. Colloids Surf. A Physicochem. Eng. Asp. 2019, 583, 123960. [Google Scholar] [CrossRef]

- Kazemi, I.; Sefid, M.; Afrand, M. A novel comparative experimental study on rheological behavior of mono & hybrid nanofluids concerned graphene and silica nano-powders: Characterization, stability and viscosity measurements. Powder Technol. 2020, 366, 216–229. [Google Scholar]

- Xian, H.; Sidik, N.; Saidur, R. Impact of different surfactants and ultrasonication time on the Stability and thermophysical properties of hybrid nanofluids. Int. Commun. Heat Mass Transf. 2020, 110, 104389. [Google Scholar] [CrossRef]

- Almanassra, I.; Manasrah, A.; Al-Mubaiyedh, U.; Al-Ansari, T.; Malaibari, Z.; Atieh, M. An experimental study on stability and thermal conductivity of water/CNTs nanofluids using different surfactants: A comparison study. J. Mol. Liq. 2019, 19, 30396–30397. [Google Scholar] [CrossRef]

- Cacua, K.; Buitrago-Sierra, R.; Pabon, E.; Gallego, A.; Zapata, C.; Herrera, B. Nanofluids stability effect on a thermosyphon thermal performance. Int. J. Therm. Sci. 2020, 153, 106347. [Google Scholar] [CrossRef]

- Ouikhalfan, M.; Labihi, A.; Belaqziz, M.; Chehouani, H.; Benhamou, B.; Sarı, A.; Belfkira, A. Stability and thermal conductivity enhancement of aqueous nanofluid based on surfactant-modified TiO2. J. Dispers. Sci. Technol. 2020, 41, 374–382. [Google Scholar] [CrossRef]

- Siddiqui, F.; Tso, C.; Chan, K.; Fu, S.; Chao, C. On trade-off for dispersion stability and thermal transport of Cu-Al2O3 hybrid nanofluid for various mixing ratios. Int. J. Heat Mass Transf. 2019, 132, 1200–1216. [Google Scholar] [CrossRef]

- Etedali, S.; Afrand, M.; Abdollahi, A. Effect of different surfactants on the pool boiling heat transfer of SiO2/ deionized water nanofluid on a copper surface. Int. J. Therm. Sci. 2019, 145, 105977. [Google Scholar] [CrossRef]

- Giwa, S.; Sharifpur, M.; Goodarzi, M.; Alsulami, H.; Meyer, J. Influence of base fluid, temperature, and concentration on the thermophysical properties of hybrid nanofluids of alumina–ferrofluid: Experimental data, modeling through enhanced ANN, ANFIS, and curve fitting. J. Therm. Anal. Calorim. 2020, 6, 4149–4167. [Google Scholar] [CrossRef]

- Kazemi, I.; Sefid, M.; Afrand, M. Improving the thermal conductivity of water by adding mono & hybrid nanoadditives containing graphene and silica: A comparative experimental study. Int. Commun. Heat Mass Transf. 2020, 116, 104648. [Google Scholar]

- Gallego, A.; Cacua, K.; Herrera, B.; Cabaleiro, D.; Piñeiro, M.; Lugo, L. Experimental evaluation of the effect in the stability and thermophysical properties of water-Al2O3 based nanofluids using SDBS as dispersant agent. Adv. Powder Technol. 2020, 31, 560–570. [Google Scholar] [CrossRef]

- Shah, S.N.A.; Shahabuddin, S.; Sabri, M.F.M.; Salleh, M.F.M.; Ali, M.A.; Hayat, N.; Sidik, N.; Smykano, M.; Saidur, R. Experimental investigation on stability, thermal conductivity and rheological properties of rGO/ethylene glycol based nanofluids. Int. J. Heat Mass Transf. 2020, 150, 118981. [Google Scholar] [CrossRef]

- Ilyas, S.; Ridha, S.; Kareem, F. Dispersion stability and surface tension of SDS Stabilized saline nanofluids with graphene nanoplatelets. Colloids Surf. A Physicochem. Eng. Asp. 2020, 592, 124584. [Google Scholar] [CrossRef]

- Wu, S.; Ortiz, C. Experimental investigation of the effect of magnetic field on vapour absorption with LiBr-H2O nanofluid. Energy 2020, 193, 116640. [Google Scholar] [CrossRef]

- Xiao, X.; Jia, H.; Wen, D.; Zhao, X. Thermal performance analysis of a solar energy storage unit encapsulated with HITEC salt/copper foam/nanoparticles composite. Energy 2020, 192, 116593. [Google Scholar] [CrossRef]

- Lee, J.; Kang, Y. CO2 absorption enhancement by Al2O3 nanoparticles in NaCl aqueous solution. Energy 2020, 53, 206–211. [Google Scholar] [CrossRef]

- Vajjha, R.; Das, D. Experimental determination of thermal conductivity of three nanofluids and development of new correlations. Int. J. Heat Mass Transf. 2009, 52, 4675–4682. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, S. Multi-level uncertainty optimisation on phase change materials integrated renewable systems with hybrid ventilations and active cooling. Energy 2020, 202, 117747. [Google Scholar] [CrossRef]

- Khodadadi, H.; Aghakhani, S.; Majd, H.; Kalbasi, R.; Wongwises, S.; Afrand, M. A comprehensive review on rheological behavior of mono and hybrid nanofluids: Effective parameters and predictive correlations. Int. J. Heat Mass Transf. 2018, 127, 997–1012. [Google Scholar] [CrossRef]

- Sajid, M.; Ali, H. Thermal conductivity of hybrid nanofluids: A critical review. Int. J. Heat Mass Transf. 2018, 126, 211–234. [Google Scholar] [CrossRef]

- Askari, S.; Lotfi, R.; Rashidi, A.; Koolivand, H.; Koolivand-Salooki, M. Rheological and thermophysical properties of ultra-stable kerosene-based Fe3O4/Graphene nanofluids for energy conservation. Energy Convers. Manag. 2016, 128, 134–144. [Google Scholar] [CrossRef]

- Ho, C.; Huang, J.; Tsai, P.; Yang, Y. Preparation and properties of hybrid water-based suspension of Al2O3 nanoparticles and MEPCM particles as functional forced convection fluid. Int. Commun. Heat Mass Transf. 2010, 37, 490–494. [Google Scholar] [CrossRef]

- Baghbanzadeh, M.; Rashidi, A.; Rashtchian, D.; Lotfi, R.; Amrollahi, A. Synthesis of spherical silica/multiwall carbon nanotubes hybrid nanostructures and investigation of thermal conductivity of related nanofluids. Thermochim. Acta 2012, 549, 87–94. [Google Scholar] [CrossRef]

- Labib, M.; Nine, M.; Afrianto, H.; Chung, H.; Jeong, H. Numerical investigation on effect of base fluids and hybrid nanofluid in forced convective heat transfer. Int. J. Therm. Sci. 2013, 71, 163–171. [Google Scholar] [CrossRef]

- Nguyen, C.; Desgranges, F.; Galanis, N.; Roy, G.; Mare, T.; Boucher, S.; Mintsa, H. Viscosity data for Al2O3-water nanofluid-hysteresis: Is heat transfer enhancement using nanofluids reliable? Int. J. Therm. Sci. 2008, 47, 103–111. [Google Scholar] [CrossRef]

- Kishore, P.; Sireesha, V.; Harsha, V.; Rao, V.; Solomon, A. Preparation, characterization and thermo-physical properties of Cu-graphene nanoplatelets hybrid nanofluids. Mater. Today Proc. 2020, 27, 610–614. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H.; Chen, L.; Li, Y. Investigation of thermal conductivity and viscosity of ethylene glycol based ZnO nanofluid. Thermochim. Acta 2009, 491, 92–96. [Google Scholar] [CrossRef]

- Esfe, M.; Afrand, M.; Yan, W.; Yarmand, H.; Toghraie, D.; Dahari, M. Effects of temperature; concentration on rheological behavior of MWCNTs/SiO2 (20-80)-SAE40 hybrid nano-lubricant. Int. Commun. Heat Mass Transf. 2016, 76, 133–138. [Google Scholar] [CrossRef]

- Dardan, E.; Afrand, M.; Meghdadi-Isfahani, A. Effect of suspending hybrid nano-additives on rheological behavior of engine oil and pumping power. Appl. Therm. Eng. 2016, 109, 524–534. [Google Scholar] [CrossRef]

- Soltani, O.; Akbari, M. Effects of temperature and particles concentration on the dynamic viscosity of MgO-MWCNT/ethylene glycol hybrid nanofluid: Experimental study. Phys. E Low Dimens. Syst. Nanostructures 2016, 84, 564–570. [Google Scholar] [CrossRef]

- Esfe, M.; Raki, H.; Emami, M.; Afrand, M. Viscosity and rheological properties of antifreeze based nanofluid containing hybrid nano-powders of MWCNTs and TiO2 under different temperature conditions. Powder Technol. 2019, 342, 808–816. [Google Scholar] [CrossRef]

- Asadi, M.; Asadi, A. Dynamic viscosity of MWCNT/ZnO-engine oil hybrid nanofluid: An experimental investigation and new correlation in different temperatures and solid concentrations. Int. Commun. Heat Mass Transf. 2016, 76, 41–45. [Google Scholar] [CrossRef]

- Esfe, M.; Arani, A.; Rezaie, M.; Yan, W.; Karimipour, A. Experimental determination of thermal conductivity and dynamic viscosity of Ag-MgO/water hybrid nanofluid. Int. Commun. Heat Mass Transf. 2015, 66, 189–195. [Google Scholar] [CrossRef]

- Yarmand, H.; Gharehkhani, S.; Ahmadi, G.; Shirazi, S.; Baradaran, S.; Montazer, E.; Zubir, M.; Alehashem, M.; Kazi, S.; Dahari, M. Graphene nanoplatelets-silver hybrid nanofluids for enhanced heat transfer. Energy Convers. Manag. 2015, 100, 419–428. [Google Scholar] [CrossRef]

- Sundar, L.; Ramana, E.; Graça, M.; Singh, M.; Sousa, A. Nanodiamond-Fe3O4 nanofluids: Preparation and measurement of viscosity, electrical and thermal conductivities. Int. Commun. Heat Mass Transf. 2016, 73, 62–74. [Google Scholar] [CrossRef]

- Afrand, M.; Najafabadi, K.; Akbari, M. Effects of temperature and solid volume fraction on viscosity of SiO2-MWCNTs/SAE40 hybrid nanofluid as a coolant and lubricant in heat engines. Appl. Therm. Eng. 2016, 102, 45–54. [Google Scholar] [CrossRef]

- Esfe, M.; Afrand, M.; Rostamian, S.; Toghraie, D. Examination of rheological behavior of MWCNTs/ZnO-SAE40 hybrid nano-lubricants under various temperatures and solid volume fractions. Exp. Therm. Fluid Sci. 2017, 80, 384–390. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Shamlooei, M. Magnetic source influence on nanofluid flow in porous medium considering shape factor effect. Phys. Lett. A 2017, 381, 3071–3078. [Google Scholar] [CrossRef]

- Asadi, A.; Asadi, M.; Rezaei, M.; Siahmargoi, M.; Asadi, F. The effect of temperature and solid concentration on dynamic viscosity of MWCNT/MgO (20–80)–SAE50 hybrid nano-lubricant and proposing a new correlation: An experimental study. Int. Commun. Heat Mass Transf. 2016, 78, 48–53. [Google Scholar] [CrossRef]

- Riahi, A.; Khamlich, S.; Balghouthi, M.; Khamliche, T.; Doyle, T.; Dimassi, W.; Guizani, A.; Maaza, M. Study of thermal conductivity of synthesized Al2O3-water nanofluid by pulsed laser ablation in liquid. J. Mol. Liq. 2020, 304, 112694. [Google Scholar] [CrossRef]

- Hamze, S.; Berrada, N.; Cabaleiro, D.; Desforges, A.; Ghanbaja, J.; Gleize, J.; Bégin, D.; Michaux, F.; Maré, T.; Vigolo, B.; et al. Few-layer graphene-based nanofluids with enhanced thermal conductivity. Nanomaterials 2020, 10, 1258. [Google Scholar] [CrossRef] [PubMed]

- Hamze, S.; Cabaleiro, D.; Maré, T.; Vigolo, B.; Estellé, P. Shear flow behavior and dynamic viscosity of few-layer graphene nanofluids based on propylene glycol-water mixture. J. Mol. Liq. 2020, 316, 113875. [Google Scholar] [CrossRef]

- Charab, A.; Movahedirad, S.; Norouzbeigi, R. Thermal conductivity of Al2O3 + TiO2/water nanofluid: Model development and experimental validation. Appl. Therm. Eng. 2017, 119, 42–51. [Google Scholar] [CrossRef]

- Nine, M.; Batmunkh, M.; Kim, J.; Chung, H.; Jeong, H. Investigation of Al2O3-MWCNTs hybrid dispersion in water and their thermal characterization. J. Nanosci. Nanotechnol. 2012, 12, 4553–4559. [Google Scholar] [CrossRef] [PubMed]

- Shahsavar, A.; Salimpour, M.; Saghafian, M.; Shafii, M. An experimental study on the effect of ultrasonication on thermal conductivity of ferrofluid loaded with carbon nanotubes. Thermochim. Acta 2015, 617, 102–110. [Google Scholar] [CrossRef]

- Farbod, M.; Ahangarpour, A. Improved thermal conductivity of Ag decorated carbon nanotubes water based nanofluids. Phys. Lett. Sect. A 2016, 380, 4044–4048. [Google Scholar] [CrossRef]

- Harandi, S.; Karimipour, A.; Afrand, M.; Akbari, M.; D’Orazio, A. An experimental study on thermal conductivity of F-MWCNTs-Fe3O4/EG hybrid nanofluid: Effects of temperature and concentration. Int. Commun. Heat Mass Transf. 2016, 76, 171–177. [Google Scholar] [CrossRef]

- Yarmand, H.; Gharehkhani, S.; Shirazi, S.; Amiri, A.; Montazer, E.; Arzani, H.; Sadri, R.; Dahari, M.; Kazi, S. Nanofluid based on activated hybrid of biomass carbon/graphene oxide: Synthesis, thermo-physical and electrical properties. Int. Commun. Heat Mass Transf. 2016, 72, 10–15. [Google Scholar] [CrossRef]

- Chougule, S.; Sahu, S. Model of heat conduction in hybrid nanofluid. In Proceedings of the 2013 IEEE International Conference ON Emerging Trends in Computing, Communication and Nanotechnology (ICECCN), Tirunelveli, India, 25–26 March 2013; pp. 337–341. [Google Scholar]

- Takabi, B.; Salehi, S. Augmentation of the heat transfer performance of a sinusoidal corrugated enclosure by employing hybrid nanofluid. Adv. Mech. Eng. 2014, 2014, 147059. [Google Scholar] [CrossRef]

- Esfe, M.; Saedodin, S.; Biglari, M.; Rostamian, H. Experimental investigation of thermal conductivity of CNTs-Al2O3/water: A statistical approach. Int. Commun. Heat Mass Transf. 2015, 69, 29–33. [Google Scholar] [CrossRef]

- Esfe, M.; Wongwises, S.; Naderi, A.; Asadi, A.; Safaei, M.; Rostamian, H.; Dahari, M.; Karimipour, A. Thermal conductivity of Cu/TiO2-water/EG hybrid nanofluid: Experimental data and modeling using artificial neural network and correlation. Int. Commun. Heat Mass Transf. 2015, 66, 100–104. [Google Scholar] [CrossRef]

- Esfe, M.; Yan, W.; Akbari, M.; Karimipour, A.; Hassani, M. Experimental study on thermal conductivity of DWCNT-ZnO/water-EG nanofluids. Int. Commun. Heat Mass Transf. 2015, 68, 248–251. [Google Scholar] [CrossRef]

- Afrand, M. Experimental study on thermal conductivity of ethylene glycol containing hybrid nano-additives and development of a new correlation. Appl. Therm. Eng. 2017, 110, 1111–1119. [Google Scholar] [CrossRef]

- Vafaei, M.; Afrand, M.; Sina, N.; Kalbasi, R.; Sourani, F.; Teimouri, H. Evaluation of thermal conductivity of MgO-MWCNTs/EG hybrid nanofluids based on experimental data by selecting optimal artificial neural networks. Phys. E Low Dimens. Syst. Nanostructures 2017, 85, 90–96. [Google Scholar] [CrossRef]

- Esfe, M.; Alirezaie, A.; Rejvani, M. An applicable study on the thermal conductivity of SWCNT-MgO hybrid nanofluid and price-performance analysis for energy management. Appl. Therm. Eng. 2017, 111, 1202–1210. [Google Scholar] [CrossRef]

- Esfe, M.; Behbahani, P.; Arani, A.; Sarlak, M. Thermal conductivity enhancement of SiO2–MWCNT (85:15%)–EG hybrid nanofluids: ANN designing, experimental investigation, cost performance and sensitivity analysis. J. Therm. Anal. Calorim. 2017, 128, 249–258. [Google Scholar] [CrossRef]

- Esfe, M.; Esfandeh, S.; Rejvani, M. Modeling of thermal conductivity of MWCNT-SiO2 (30:70%)/EG hybrid nanofluid, sensitivity analyzing and cost performance for industrial applications. J. Therm. Anal. Calorim. 2018, 131, 1437–1447. [Google Scholar] [CrossRef]

- Esfe, H.M.; Arani, A.A.A.; Badi, S.R.; Rejvani, M. ANN modeling, cost performance and sensitivity analyzing of thermal conductivity of DWCNT–SiO2/EG hybrid nanofluid for higher heat transfer: An experimental study. J. Therm. Anal. Calorim. 2017, 131, 2381–2393. [Google Scholar] [CrossRef]

- Esfe, M.; Rejvani, M.; Karimpour, R.; Arani, A. Estimation of thermal conductivity of ethylene glycol-based nanofluid with hybrid suspensions of SWCNT–Al2O3 nanoparticles by correlation and ANN methods using experimental data. J. Therm. Anal. Calorim. 2017, 128, 1359–1371. [Google Scholar] [CrossRef]

- Rostamian, S.; Biglari, M.; Saedodin, S.; Esfe, M. An inspection of thermal conductivity of CuO-SWCNTs hybrid nanofluid versus temperature and concentration using experimental data, ANN modeling and new correlation. J. Mol. Liq. 2017, 231, 364–369. [Google Scholar] [CrossRef]

- Zadkhast, M.; Toghraie, D.; Karimipour, A. Developing a new correlation to estimate the thermal conductivity of MWCNT-CuO/water hybrid nanofluid via an experimental investigation. J. Therm. Anal. Calorim. 2017, 129, 859–867. [Google Scholar] [CrossRef]

- Elias, M.; Shahrul, I.; Mahbubul, I.; Saidur, R.; Rahim, N. Effect of different nanoparticle shapes on shell and tube heat exchanger using different baffle angles and operated with nanofluid. Int. J. Heat Mass Transf. 2014, 70, 289–297. [Google Scholar] [CrossRef]

- Vajjha, R.; Das, D.K. A review and analysis on influence of temperature and concentration of nanofluids on thermophysical properties, heat transfer and pumping power. Int. J. Heat Mass Transf. 2012, 55, 4063–4078. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A. Application of nanofluids in heat exchangers: A review. Renew. Sustain. Energy Rev. 2012, 16, 5625–5638. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A. Hybrid nanofluids for heat transfer applications—A state-of-the-art review. Int. J. Heat Mass Transf. 2018, 125, 82–103. [Google Scholar] [CrossRef]

- Anoop, K.; Cox, J.; Sadr, R. Thermal evaluation of nanofluids in heat exchangers. Int. Commun. Heat Mass Transf. 2013, 49, 5–9. [Google Scholar] [CrossRef]

- Kumar, V.; Tiwari, A.; Ghosh, S. Application of nanofluids in plate heat exchanger: A review. Energy Convers. Manag. 2015, 105, 1017–1036. [Google Scholar] [CrossRef]

- Azmi, W.; Hamid, K.; Usri, N.; Mamat, R.; Sharma, K. Heat transfer augmentation of ethylene glycol: Water nanofluids and applications—A review. Int. Commun. Heat Mass Transf. 2016, 75, 13–23. [Google Scholar] [CrossRef]

- Minea, A. Challenges in hybrid nanofluids behavior in turbulent flow: Recent resarch and numerical comparison. Renew. Sustain. Energy Rev. 2017, 71, 426–434. [Google Scholar] [CrossRef]

- Elmaaty, T.A.; Kabeel, A.; Mahgoub, M. Corrugated plate heat exchanger review. Renew. Sustain. Energy Rev. 2017, 70, 852–860. [Google Scholar] [CrossRef]

- Zheng, D.; Wang, J.; Pang, Y.; Chen, Z.; Sunden, B. Heat transfer performance and friction factor of various nanofluids in a double-tube counter flow heat exchanger. Therm. Sci. 2020, 24, 3601–3612. [Google Scholar] [CrossRef]

- Zheng, D.; Wang, J.; Chen, Z.; Baleta, J.; Sundén, B. Performance analysis of a plate heat exchanger using various nanofluids. Int. J. Heat Mass Transf. 2020, 158, 119993. [Google Scholar] [CrossRef]

- Babu, C.R.; Kumar, P.; Roy, S.; Ganesan, R. A comprehensive review on compound heat transfer enhancement using passive techniques in a heat exchanger. Mater. Today Proc. 2021, 54, 428–436. [Google Scholar]

- Bakthavatchalam, B.; Habib, K.; Saidur, R.; Saha, B.; Irshad, K. Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement: A review on current and future perspective. J. Mol. Liq. 2020, 305, 112787. [Google Scholar] [CrossRef]

- Pandey, S.; Nema, V. Experimental analysis of heat transfer and friction factor of nanofluid as a coolant in a corrugated plate heat exchanger. Exp. Therm. Fluid Sci. 2012, 38, 248–256. [Google Scholar] [CrossRef]

- Tiwari, A.; Ghosh, P.; Sarkar, J. Performance comparison of the plate heat exchanger using different nanofluids. Exp. Therm. Fluid Sci. 2013, 49, 141–151. [Google Scholar] [CrossRef]

- Tiwari, A.; Ghosh, P.; Sarkar, J. Particle concentration levels of various nanofluids in plate heat exchanger for best performance. Int. J. Heat Mass Transf. 2015, 89, 1110–1118. [Google Scholar] [CrossRef]

- Barzegarian, R.; Moraveji, M.; Aloueyan, A. Experimental investigation on heat transfer characteristics and pressure drop of BPHE (brazed plate heat exchanger) using TiO2-water nanofluid. Exp. Therm. Fluid Sci. 2016, 74, 11–18. [Google Scholar] [CrossRef]

- Tabari, Z.T.; Heris, S.Z.; Kahani, M. The study on application of TiO2/water nanofluid in plate heat exchanger of milk pasteurization industries. Renew. Sustain. Energy Rev. 2016, 58, 1318–1326. [Google Scholar] [CrossRef]

- Prashant, G.S.; Sarao, T. Experimental analysis of heat transfer and friction factor in plate heat exchanger with different orientations using Al2O3 nanofluids. Int. J. Eng. 2016, 29, 1450–1458. [Google Scholar]

- Huang, D.; Wu, Z.; Sunden, B. Pressure drop and convective heat transfer of Al2O3/water and MWCNT/water nanofluids in a chevron plate heat exchanger. Int. J. Heat Mass Transf. 2015, 89, 620–626. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Hydrothermal performance of different alumina hybrid nanofluid types in plate heat exchanger. J. Therm. Anal. Calorim. 2020, 139, 3777–3787. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Heat transfer characteristics of plate heat exchanger using hybrid nanofluids: Effect of nanoparticle mixture ratio. Heat Mass Transf. 2020, 56, 2457–2472. [Google Scholar] [CrossRef]

- Bhattad, A. Experimental investigation of Al2O3–MgO hot hybrid nanofluid in a plate heat exchanger. Heat Transf. 2020, 49, 2344–2354. [Google Scholar] [CrossRef]

- Bhattad, A. Exergy analysis of plate heat exchanger with graphene alumina hybrid nanofluid: Experimentation. Int. J. Exergy 2020, 33, 254–262. [Google Scholar] [CrossRef]

- Kavitha, R.; Algani, Y.; Kulkarni, K.; Gupta, M. Heat transfer enhancement in a double pipe heat exchanger with copper oxide nanofluid: An experimental study. Mater. Today Proc. 2021, 56, 3446–3449. [Google Scholar] [CrossRef]

- Jassim, E.; Ahmed, F. Assessment of nanofluid on the performance and energy-environment interaction of Plate-Type-Heat exchanger. Therm. Sci. Eng. Prog. 2021, 25, 100988. [Google Scholar] [CrossRef]

- Jassim, E.; Ahmed, F. Experimental assessment of Al2O3 and Cu nanofluids on the performance and heat leak of double pipe heat exchanger. Heat Mass Transf. 2020, 56, 1845–1858. [Google Scholar] [CrossRef]

- Mansoury, D.; Doshmanziari, F.; Kiani, A.; Chamkha, A.; Sharifpur, M. Heat transfer and flow characteristics of Al2O3/water nanofluid in various heat exchangers: Experiments on counter flow. Heat Transf. Eng. 2019, 41, 220–234. [Google Scholar] [CrossRef]

- Henein, S.; Abdel-Rehim, A. The performance response of a heat pipe evacuated tube solar collector using MgO/MWCNT hybrid nanofluid as a working fluid. Case Stud. Therm. Eng. 2022, 33, 101957. [Google Scholar] [CrossRef]

- Heyhat, M.; Abdi, A.; Jafarzad, A. Performance evaluation and exergy analysis of a double pipe heat exchanger under air bubble injection. Appl. Therm. Eng. 2018, 143, 582–593. [Google Scholar] [CrossRef]

- Hosseinian, A.; Isfahani, A. Experimental study of heat transfer enhancement due to the surface vibrations in a flexible double pipe heat exchanger. Heat Mass Transf. 2017, 54, 1113–1120. [Google Scholar] [CrossRef]

- Bezaatpour, M.; Goharkhah, M. Convective heat transfer enhancement in a double pipe mini heat exchanger by magnetic field induced swirling flow. Appl. Therm. Eng. 2020, 167, 114801. [Google Scholar] [CrossRef]

- Setareh, M.; Saffar-Avval, M.; Abdullah, A. Experimental and numerical study on heat transfer enhancement using ultrasonic vibration in a double-pipe heat exchanger. Appl. Therm. Eng. 2019, 159, 113867. [Google Scholar] [CrossRef]

- Akbarzadeh, M.; Rashidi, S.; Keshmiri, A.; Shokri, N. The optimum position of porous insert for a double-pipe heat exchanger based on entropy generation and thermal analysis. J. Therm. Anal. 2020, 139, 411–426. [Google Scholar] [CrossRef]

- Poongavanam, G.; Panchabikesan, K.; Murugesan, R.; Duraisamy, S.; Ramalingam, V. Experimental investigation on heat transfer and pressure drop of MWCNT-Solar glycol based nanofluids in shot peened double pipe heat exchanger. Powder Technol. 2019, 345, 815–824. [Google Scholar] [CrossRef]

- Arya, H.; Sarafraz, M.; Pourmehran, O.; Arjomandi, M. Performance index improvement of a double-pipe cooler with MgO/waterethylene glycol (50:50) nano-suspension. Propuls. Power Res. 2020, 9, 75–86. [Google Scholar] [CrossRef]

- Subramanian, R.; Kumar, A.S.; Vinayagar, K.; Muthusamy, S. Experimental analyses on heat transfer performance of TiO2–water nanofluid in double-pipe counter-flow heat exchanger for various flow regimes. J. Therm. Anal. 2020, 140, 603–612. [Google Scholar] [CrossRef]

- Dalkılıç, A.S.; Mercan, H.; Özçelik, G.; Wongwises, S. Optimization of the finned double-pipe heat exchanger using nanofluids as working fluids. J. Therm. Anal. 2021, 143, 859–878. [Google Scholar] [CrossRef]

- Bahmani, M.H.; Sheikhzadeh, G.; Zarringhalam, M.; Akbari, O.A.; Alrashed, A.A.; Shabani, G.A.S.; Goodarzi, M. Investigation of turbulent heat transfer and nanofluid flow in a double pipe heat exchanger. Adv. Powder Technol. 2018, 29, 273–282. [Google Scholar] [CrossRef]

- Bahmani, M.H.; Akbari, O.A.; Zarringhalam, M.; Shabani, G.A.S.; Goodarzi, M. Forced convection in a double tube heat exchanger using nanofluids with constant and variable thermophysical properties. Int. J. Numer. Methods Heat Fluid Flow 2019, 30, 3247–3265. [Google Scholar] [CrossRef]

- Kristiawan, B.; Rifa, A.; Enoki, K.; Wijayanta, A.; Miyazaki, T. Enhancing the thermal performance of TiO2/water nanofluids flowing in a helical microfin tube. Powder Technol. 2020, 376, 254–262. [Google Scholar] [CrossRef]

- Akachi, H. Structure of a Heat Pipe. U.S. Patent 4921041; Scientific research an academic publisher, 1990. [Google Scholar]

- Singh, U.; Kumar, N. Stability issues and operating limitations of nanofluid filled heat pipe: A critical review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Karthikeyan, V.K.; Ramachandran, K.; Pillai, B.C.; Solomon, A.B. Effect of nanofluids on thermal performance of closed loop pulsating heat pipe. Exp. Therm. Fluid Sci. 2014, 54, 171–178. [Google Scholar] [CrossRef]

- Goshayeshi, H.R.; Safaei, M.R.; Goodarzi, M.; Dahari, M. Particle size and type effects on heat transfer enhancement of ferro-nanofluids in a pulsating heat pipe. Powder Technol. 2016, 301, 1218–1226. [Google Scholar] [CrossRef]

- Li, Z. Operation analysis, response and performance evaluation of a pulsating heat pipe for low temperature heat recovery. Energy Convers. Manag. 2020, 222, 113230. [Google Scholar] [CrossRef]

- Kim, H.-T.; Bang, K.-H. Heat transfer enhancement of nanofluids in a pulsating heat pipe for heat dissipation of led lighting. J. Korean Soc. Manuf. Process Eng. 2014, 38, 1200–1205. [Google Scholar] [CrossRef]

- Kang, S.W.; Wang, Y.C.; Liu, Y.C.; Lo, H.M. Visualization and thermal resistance measurements for a magnetic nanofluid pulsating heat pipe. Appl. Therm. Eng. 2017, 126, 1044–1050. [Google Scholar] [CrossRef]

- Wu, H. Thermal performance comparison of oscillating heat pipes with SiO2/water and Al2O3/water nanofluids. Int. J. Therm. Sci. 2011, 50, 1954–1962. [Google Scholar]

- Goshayeshi, H.R.; Izadi, F.; Bashirnezhad, K. Comparison of heat transfer performance on closed pulsating heat pipe for Fe3O4 and ɤFe2O3 for achieving an empirical correlation. Phys. E Low Dimens. Syst. Nanostruct. 2017, 89, 43–49. [Google Scholar] [CrossRef]

- Xu, R.; Wang, R.; Li, Y. Effect of C60 nanofluid on the thermal performance of a flat-plate pulsating heat pipe. Int. J. Heat Mass Transf. 2016, 100, 892–898. [Google Scholar]

- Xue, Y.; Qi, H.; Cai, W. Experimental study on heat transfer performance of pulsating heat pipes with hybrid working fluids. Int. J. Heat Mass Transf. 2020, 157, 119727. [Google Scholar] [CrossRef]

- Zufar, G.P.; Kumar, H.M.; Ng, K.C. Numerical and experimental investigations of hybrid nanofluids on pulsating heat pipe performance. Int. J. Heat Mass Transf. 2020, 146, 118887. [Google Scholar] [CrossRef]

- Khodami, R.; Nejad, A.A.; Khabbaz, M.R.A. Experimental investigation of energy and exergy efficiency of a pulsating heat pipe for chimney heat recovery. Sustain. Energy Technol. Assess. 2016, 16, 11–17. [Google Scholar] [CrossRef]

- Jahani, M.M.; Shafii, M.B.; Shiee, Z. Promising technology for electronic cooling: Nanofluidic micro pulsating heat pipes. J. Electron. Packag. 2013, 135, 021005. [Google Scholar] [CrossRef]

- Zhang, M.; Han, W.; Guo, X. Enhancement of heat transport in oscillating heat pipe with ternary fluid. Int. J. Heat Mass Transf. 2015, 87, 258–264. [Google Scholar]

- Babar, H.; Ali, H. Towards hybrid nanofluids: Preparation, thermophysical properties, applications, and challenges. J. Mol. Liq. 2019, 281, 598–633. [Google Scholar] [CrossRef]

- Selvakumar, P.; Suresh, S. Use of Al2O3–Cu/water hybrid nanofluid in an electronic heat sink. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 1600–1607. [Google Scholar] [CrossRef]

- Ahammed, N.; Asirvatham, L.; Wongwises, S. Entropy generation analysis of graphene–alumina hybrid nanofluid in multiport mini channel heat exchanger coupled with thermoelectric cooler. Int. J. Heat Mass Tran. 2016, 103, 1084–1097. [Google Scholar] [CrossRef]

- Nimmagadda, R.; Venkatasubbaiah, K. Experimental and multiphase analysis of nanofluids on the conjugate performance of micro-channel at low Reynolds numbers. Heat Mass Tran. 2017, 53, 2099–2115. [Google Scholar] [CrossRef]

- Ho, C.; Liu, Y.; Ghalambaz, M.; Yan, W. Forced convection heat transfer of Nano-Encapsulated Phase Change Material (NEPCM) suspension in a mini-channel heatsink. Int. J. Heat Mass Tran. 2020, 155, 119858. [Google Scholar] [CrossRef]

- Kumar, V.; Sarkar, J. Effect of different nanoparticles mixture dispersed nanofluids on hydrothermal characteristics in mini channel heat sink. Adv. Powder Technol. 2020, 31, 621–631. [Google Scholar] [CrossRef]

- Nimmagadda, R.; Venkatasubbaiah, K. Two-phase analysis on the conjugate heat transfer performance of microchannel with Cu, Al, SWCNT, and hybrid nanofluids. J. Therm. Sci. Eng. Appl. 2017, 9, 041011. [Google Scholar] [CrossRef]

- Bahiraei, M.; Berahmand, M.; Shahsavar, A. Irreversibility analysis for flow of a non Newtonian hybrid nanofluid containing coated CNT/Fe3O4 nanoparticles in a mini channel heat exchanger. Appl. Therm. Eng. 2017, 125, 1083–1093. [Google Scholar] [CrossRef]

- Mashayekhi, R.; Khodabandeh, E.; Akbari, O.; Toghraie, D.; Bahiraei, M.; Gholami, M. CFD analysis of thermal and hydrodynamic characteristics of hybrid nanofluid in a new designed sinusoidal double-layered microchannel heat sink. J. Therm. Anal. Calorim. 2018, 134, 2305–2315. [Google Scholar] [CrossRef]

- Bahiraei, M.; Jamshidmofid, M.; Dahari, M. Second law analysis of hybrid nanofluid flow in a microchannel heat sink integrated with ribs and secondary channels for utilization in miniature thermal devices. Chem. Eng. Process 2020, 153, 107963. [Google Scholar] [CrossRef]

- Ho, C.; Guo, Y.; Yang, T.; Rashidi, S.; Yan, W. Numerical study on forced convection of water-based suspensions of nanoencapsulated PCM particles/Al2O3 nanoparticles in a mini-channel heat sink. Int. J. Heat Mass Tran. 2020, 157, 119965. [Google Scholar] [CrossRef]

- Uysal, C.; Gedik, E.; Chamkha, A. A Numerical analysis of laminar forced convection and entropy generation of a diamond-Fe3O4/water hybrid nanofluid in a rectangular mini channel. J. Appl. Fluid Mech. 2019, 12, 391–402. [Google Scholar] [CrossRef]

- Shahsavar, A.; Godini, A.; Sardari, P.; Toghraie, D.; Salehipour, H. Impact of variable fluid properties on forced convection of Fe3O4/CNT/water hybrid nanofluid in a double-pipe mini-channel heat exchanger. J. Therm. Anal. Calorim. 2019, 137, 1031–1043. [Google Scholar] [CrossRef]

- He, W.; Mashayekhi, R.; Toghraie, D.; Akbari, O.; Li, Z.; Tlili, I. Hydrothermal performance of nanofluid flow in a sinusoidal double layer microchannel in order to geometric optimization. Int. Commun. Heat Mass Tran. 2020, 117, 104700. [Google Scholar] [CrossRef]

- Pantzali, M.N.; Kanaris, A.G.; Antoniadis, K.D.; Mouza, A.A.; Paras, S.V. Effect of nanofluids on the performance of a miniature plate heat exchanger with modulatedsurface. Int. J. Heat Fluid Flow 2009, 30, 691–699. [Google Scholar] [CrossRef]

- Gherasim, I.; Galanis, N.; Nguyen, C.T. Numerical study of nanofluid flow and heat transfer in a plate heat exchanger. Comput. Therm. 2013, 5, 317–332. [Google Scholar] [CrossRef]

- Ray, D.R.; Das, D.K.; Vajjha, R.S. Experimental and numerical investigations of nanofluids performance in a compact minichannel plate heat exchanger. Int. J. Heat Mass Transf. 2014, 71, 732–746. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Ghosh, P.; Sarkar, J.; Dahiya, H.; Parekh, J. Numerical investigation of heat transfer and fluid flow in plate heat exchanger using nanofluids. Int. J. Therm. Sci. 2014, 85, 93–103. [Google Scholar] [CrossRef]

- Stogiannis, I.A.; Mouza, A.A.; Paras, S.V. Efficacy of SiO2 nanofluids in a miniature plate heat exchanger with undulated surface. Int. J. Therm. Sci. 2015, 92, 230–238. [Google Scholar] [CrossRef]

- Jokar, A.; O’Halloran, S.P. Heat transfer and fluid flow analysis of nanofluids in corrugated plate heat exchangers using computational fluid dynamics simulation. J. Therm. Sci. Eng. Appl. 2013, 5, 011002. [Google Scholar] [CrossRef]

- Goodarzi, M.; Amiri, A.; Goodarzi, M.S.; Safaei, M.R.; Karimipour, A.; Languri, E.M.; Dahari, M. Investigation of heat transfer and pressure drop of a counter flow corrugated plate heat exchanger using MWCNT based nanofluids. Int. Commun. Heat Mass Transf. 2015, 66, 172–179. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Discrete phase numerical model and experimental study of hybrid nanofluid heat transfer and pressure drop in plate heat exchanger. Int. Commun. Heat Mass Transf. 2018, 91, 262–273. [Google Scholar] [CrossRef]

- Ding, Z.; Qi, C.; Luo, T.; Wang, Y.; Tu, J.; Wang, C. Numerical simulation of nanofluids forced convection in a corrugated double-pipe heat exchanger. Can. J. Chem. Eng. 2021, 100, 1954–1964. [Google Scholar] [CrossRef]

- Bhattad, A.; Babu, S.S. Thermal analysis of shell and tube type heat exchanger using hybrid nanofluid. Trends Sci. 2022, 19, 2890. [Google Scholar] [CrossRef]

- Jafarmadar, S.; Azizinia, N.; Razmara, N.; Mobadersani, F. Thermal analysis and entropy generation of pulsating heat pipes using nanofluids. Appl. Therm. Eng. 2016, 103, 356–364. [Google Scholar] [CrossRef]

- Yan, H.; Yang, J.; Zhang, W. Numerical study of enhanced heat transfer of microchannel heat sink with nanofluids. IOP Conf. Ser. Mater. Sci. Eng. 2020, 721, 012052. [Google Scholar]

- Khetib, Y.; Abo-Dief, H.M.; Alanazi, A.K.; Sajadi, S.M.; Sharifpur, M.; Meyer, J.P. A computational fluid dynamic study on efficiency of a wavy microchannel/heat sink containing various nanoparticles. Micromachines 2021, 12, 1192. [Google Scholar] [CrossRef]

- Kalteh, M.; Kouhikamali, R.; Akbari, S. Numerical simulation of nanofluid heat transfer in a double-layered microchannel heat sink using two phase mixture model. J. Nanofluids 2016, 5, 139–147. [Google Scholar] [CrossRef]

- Pantzali, M.N.; Mouza, A.A.; Paras, S.V. Investigating the efficacy of nanofluids as coolants in plate heat exchangers (PHE). Chem. Eng. Sci. 2009, 64, 3290–3300. [Google Scholar] [CrossRef]

- Zamzamian, A.; Oskouie, S.N.; Doosthoseini, A.; Joneidi, A.; Pazouki, M. Experimental investigation of forced convective heat transfer coefficient in nanofluids of Al2O3/EG and CuO/EG in a double pipe and plate heat exchangers under turbulent flow. Exp. Therm. Fluid Sci. 2011, 35, 495–502. [Google Scholar] [CrossRef]

- Kabeel, A.E.; El-Maaty, T.M.A.; El-Samadony, Y. The effect of using nano-particles on corrugated plate heat exchanger performance. Appl. Therm. Eng. 2013, 52, 221–229. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Ghosh, P.; Sarkar, J. Heat transfer and pressure drop characteristics of CeO2/water nanofluid in plate heat exchanger. Appl. Therm. Eng. 2013, 57, 24–32. [Google Scholar] [CrossRef]

- Khairul, M.A.; Alim, M.A.; Mahbubul, I.M.; Saidur, R.; Hepbasli, A.; Hossain, A. Heat transfer performance and exergy analyses of a corrugated plate heat exchanger using metal oxide nanofluids. Int. Commun. Heat Mass Transf. 2014, 50, 8–14. [Google Scholar] [CrossRef]

- Huang, D.; Wu, Z.; Sunden, B. Effects of hybrid nanofluid mixture in plate heat exchangers. Exp. Therm. Fluid Sci. 2016, 72, 190–196. [Google Scholar] [CrossRef]

- Tabari, Z.T.; Heris, S.Z. Heat Transfer Performance of Milk Pasteurization Plate Heat Exchangers Using MWCNT/Water Nanofluid. J. Dispers. Sci. Technol. 2015, 36, 196–204. [Google Scholar] [CrossRef]

- Abed, A.M.; Alghoul, M.A.; Sopian, K.; Mohammed, H.A.; Al-Shamani, A.N. Design characteristics of corrugated trapezoidal plate heat exchangers using nanofluids. Chem. Eng. Process. Process Intensif. 2015, 87, 88–103. [Google Scholar] [CrossRef]

- Behrangzade, A.; Heyhat, M.M. The effect of using nano-silver dispersed water based nanofluid as a passive method for energy efficiency enhancement in a plate heat exchanger. Appl. Therm. Eng. 2016, 102, 311–317. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Hormozi, F.J.E.T. Heat transfer, pressure drop and fouling studies of multi-walled carbon nanotube nanofluids inside a plate heat exchanger. Exp. Therm. Fluid Sci. 2016, 72, 1–11. [Google Scholar] [CrossRef]

- Sun, P.; Zuo, Y. Investigation on the flow and convective heat transfer characteristics of nanofluids in the plate heat exchanger. Exp. Therm. Fluid Sci. 2016, 76, 75–86. [Google Scholar] [CrossRef]

- Kumar, V.; Tiwari, A.K.; Ghosh, S.K. Effect of chevron angle on heat transfer performance in plate heat exchanger using ZnO/water nanofluid. Energy Convers. Manag. 2016, 118, 142–154. [Google Scholar] [CrossRef]

- Kumar, V.; Tiwari, A.K.; Ghosh, S.K. Effect of variable spacing on performance of plate heat exchanger using nanofluids. Energy 2016, 114, 1107–1119. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Ahmed, M.I.; Seder, I.M.; Salman, B.H. Experimental investigation for sequential triangular double-layered microchannel heat sink with nanofluids. Int. Commun. Heat Mass Transf. 2016, 77, 104–115. [Google Scholar] [CrossRef]

- Sarvar-Ardeh, S.; Rafee, R.; Rashidi, S. Hybrid nanofluids with temperature-dependent properties for use in double-layered microchannel heat sink; hydrothermal investigation. J. Taiwan Inst. Chem. Eng. 2021, 124, 53–62. [Google Scholar] [CrossRef]

- Wang, J.; Yu, K.; Ye, M.; Wang, E.; Wang, W.; Sundén, B. Effects of pin fins; vortex generators on thermal performance in a microchannel with Al2O3 nanofluids. Energy 2022, 239, 122606. [Google Scholar] [CrossRef]

- Adio, S.A.; Alo, T.A.; Olagoke, R.O.; Olalere, A.E.; Veeredhi, V.R.; Ewim, D.R. Thermohydraulic and entropy characteristics of Al2O3-water nanofluid in a ribbed interrupted microchannel heat exchanger. Heat Transf. 2021, 50, 1951–1984. [Google Scholar] [CrossRef]

- Adio, A.S.; Olalere, A.E.; Olagoke, R.O.; Alo, T.A.; Veeredhi, V.R.; Ewim, D.R.; Olakoyejo, O.T. Thermal and entropy analysis of a manifold microchannel heat sink operating on CuO–water nanofluid. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–15. [Google Scholar] [CrossRef]

- Ali, M.A.; Angelino, M.; Rona, A. Numerical analysis on the thermal performance of microchannel heat sinks with Al2O3 nanofluid and various fins. Appl. Therm. Eng. 2021, 198, 117458. [Google Scholar] [CrossRef]

- Kumar, M.P.; Kumar, C.A. Numerical study on heat transfer performance using Al2O3/water nanofluids in six circular channel heat sink for electronic chip. Mater. Today Proc. 2020, 21, 194–201. [Google Scholar] [CrossRef]

- Elbadawy, I.; Fayed, M. Reliability of Al2O3 nanofluid concentration on the heat transfer augmentation and resizing for single and double stack mi-crochannels. Alex. Eng. J. 2020, 59, 1771–1785. [Google Scholar] [CrossRef]

- Mostafa, K. Simulation of nanofluid flow through rectangular microchannel by modified thermal dispersion model. Heat Transf. Eng. 2020, 41, 377–392. [Google Scholar]

- Pourfattah, F.; Arani, A.A.A.; Babaie, M.R.; Nguyen, H.M.; Asadi, A. On the thermal characteristics of a manifold microchannel heat sink subjected to nanofluid using two-phase flow simulation. Int. J. Heat Mass Transf. 2019, 143, 118518. [Google Scholar] [CrossRef]

- Kumar, A.; Nath, S.; Bhanja, D. Effect of nanofluid on thermo hydraulic performance of double layer tapered microchannel heat sink used for electronic chip cooling. Numer. Heat Transf. Part A Appl. 2018, 73, 429–445. [Google Scholar] [CrossRef]

- Arjun, K.S.; Rakesh, K. CFD analysis of thermal performance of microchannel nanofluid flow at different Reynolds numbers. Songklanakarin J. Sci. Technol. 2019, 41, 109–116. [Google Scholar]

- Madhava Reddy, H.; Venu Vinod, A. CFD simulation of the heat transfer using nanofluids in microchannel with dimple and protrusion. Indian Chem. Eng. 2019, 61, 40–51. [Google Scholar] [CrossRef]

- Darzi, A.A.R.; Farhadi, M.; Sedighi, K. Heat transfer and flow characteristics of Al2O3–water nanofluid in a double tube heat exchanger. Int. Commun. Heat Mass Transf. 2013, 47, 105–112. [Google Scholar] [CrossRef]

- Maddah, H.; Alizadeh, M.; Ghasemi, N.; Alwi, S.R.W. Experimental study of Al2O3/water nanofluid turbulent heat transfer enhancement in the horizontal double pipes fitted with modified twisted tapes. Int. J. Heat Mass Transf. 2014, 78, 1042–1054. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Hormozi, F. Intensification of forced convection heat transfer using biological nanofluid in a double-pipe heat exchanger. Exp. Therm. Fluid Sci. 2015, 66, 279–289. [Google Scholar] [CrossRef]

- Jafarimoghaddam, A.; Aberoumand, S.; Aberoumand, H.; Javaherdeh, K. Experimental study on Cu/Oil nanofluids through concentric annular tube: A correlation. Heat Tran. Asian Res. 2017, 46, 251–260. [Google Scholar] [CrossRef]

- Shirvan, K.M.; Mamourian, M.; Mirzakhanlari, S.; Ellahi, R. Numerical investigation of heat exchanger effectiveness in a double pipe heat exchanger filled with nanofluid: A sensitivity analysis by response surface methodology. Powder Technol. 2017, 313, 99–111. [Google Scholar] [CrossRef]

- Akyurek, E.F.; Gelis, K.; Sahin, B.; Many, E. Experimental analysis for heat transfer of nanofluid with wire coil turbulators in a concentric tube heat exchanger. Results Phys. 2018, 9, 376–389. [Google Scholar] [CrossRef]

- Albadr, J.; Tayal, S.; Alasadi, M. Heat transfer through heat exchanger using Al2O3 nanofluid at different concentrations. Case Stud. Therm. Eng. 2013, 1, 38–44. [Google Scholar] [CrossRef]

- Godson, L.; Deepak, K.; Enoch, C.; Jefferson, B.; Raja, B. Heat transfer characteristics of silver/water nanofluids in a shell and tube heat exchanger. Arch. Civ. Mech. Eng. 2014, 14, 489–496. [Google Scholar] [CrossRef]

- Dharmalingam, R.; Sivagnanaprabhu, K.K.; Yogaraja, J.; Gunasekaran, S.; Mohan, R. Experimental investigation of heat transfer characteristics of nanofluid using parallel flow, counter flow and shell and tube heat exchanger. Arch. Mech. Eng. 2015, LXII, 509–522. [Google Scholar] [CrossRef]

- Aghabozorg, M.H.; Rashidi, A.; Mohammadi, S. Experimental investigation of heat transfer enhancement of Fe2O3-CNT/water magnetic nanofluids under laminar, transient and turbulent flow inside a horizontal shell and tube heat exchanger. Exp. Therm. Fluid Sci. 2016, 72, 182–189. [Google Scholar] [CrossRef]

- Tan, Y.; He, Z.; Xu, T.; Fang, X.; Gao, X.; Zhang, Z. Experimental investigation of heat transfer and pressure drop characteristics of non-Newtonian nanofluids flowing in the shell-side of a helical baffle heat exchanger with low-finned tubes. Heat Mass Transf. 2017, 53, 2813–2827. [Google Scholar] [CrossRef]

- Naik, B.A.K.; Vinod, A.V. Heat transfer enhancement using non Newtonian nanofluids in a shell and helical coil heat exchanger. Exp. Therm. Fluid Sci. 2018, 90, 132–142. [Google Scholar] [CrossRef]

- Said, Z.; Rahman, S.M.A.; Assad, M.E.H.; Alami, A.H. Heat transfer enhancement and life cycle analysis of a Shell-and-Tube Heat Exchanger using stable CuO/water nanofluid. Sustain. Energy Technol. Assessm. 2019, 31, 306–317. [Google Scholar] [CrossRef]

- Arshad, M.; Hussain, A.; Hassan, A.; Wro, P.; Elfasakhany, A.; Elkotb, M.; Abdelmohimen, M.; Galal, A. Thermal energy investigation of magnetohydrodynamic nano-material liquid flow over a stretching sheet: Comparison of single and composite particles. Alex. Eng. J. 2022, 61, 10453–10462. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Exergetic analysis of plate evaporator using hybrid nanofluids as secondary refrigerant for low temperature applications. Int. J. Exergy 2017, 24, 1–20. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Energetic and exergetic performances of plate heat exchanger using brine based hybrid nanofluid for milk chilling application. Heat Transf. Eng. 2020, 41, 522–535. [Google Scholar] [CrossRef]

- Mishra, R.; Das, P.K.; Sarangi, S. Second law based optimisation of crossflow plate-fin heat exchanger design using genetic algorithm. Appl. Therm. Eng. 2009, 29, 2983–2989. [Google Scholar] [CrossRef]