A Study on Creep-Fatigue Evaluation of Nuclear Cladded Components by ASME-III Division 5

Abstract

1. Introduction

- Stress cycle types and number of combined cycles;

- Equivalent strain range corresponding to stress cycle type;

- Creep strain increments that should be included in the total strain range for each type of stress cycle;

- Enveloped stress relaxation time history including all stress cycle types;

- Metal temperature required for each application procedure.

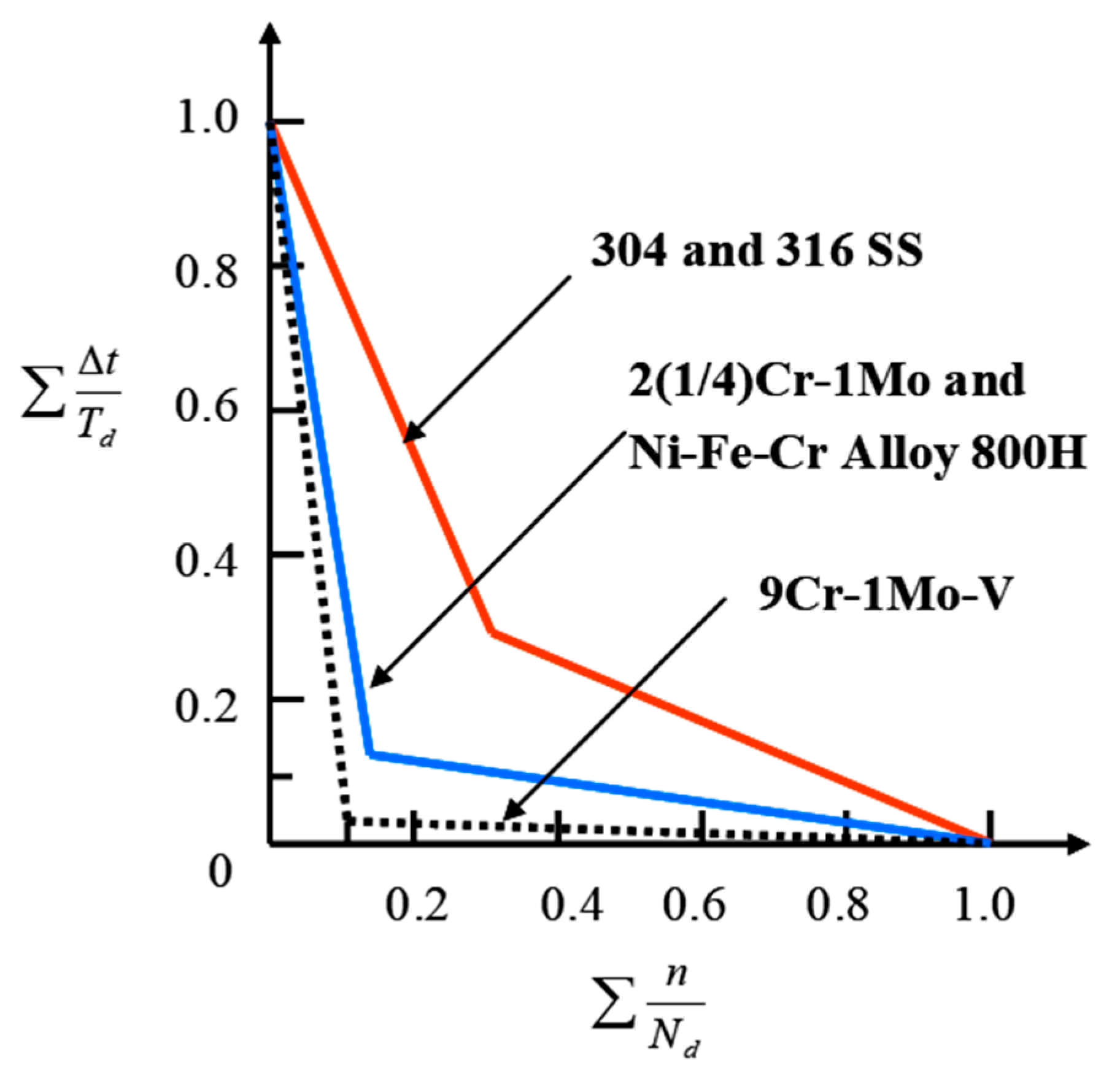

2. Review of the Creep-Fatigue Evaluation Procedure of ASME-III Division 5

- D = allowable value for total creep-fatigue damage

- p = total number of stress cycle types

- (n)j = number of combining cycles for j-th stress cycle type

- (Nd)j = allowable number of cycles for j-th stress cycle type

- q = total number of time intervals for enveloped stress relaxation time history

- (Δt)k = duration of the k-th time interval

- (Td)k = allowable time duration for k-th time interval

2.1. Procedure of Fatigue Evaluation

- -

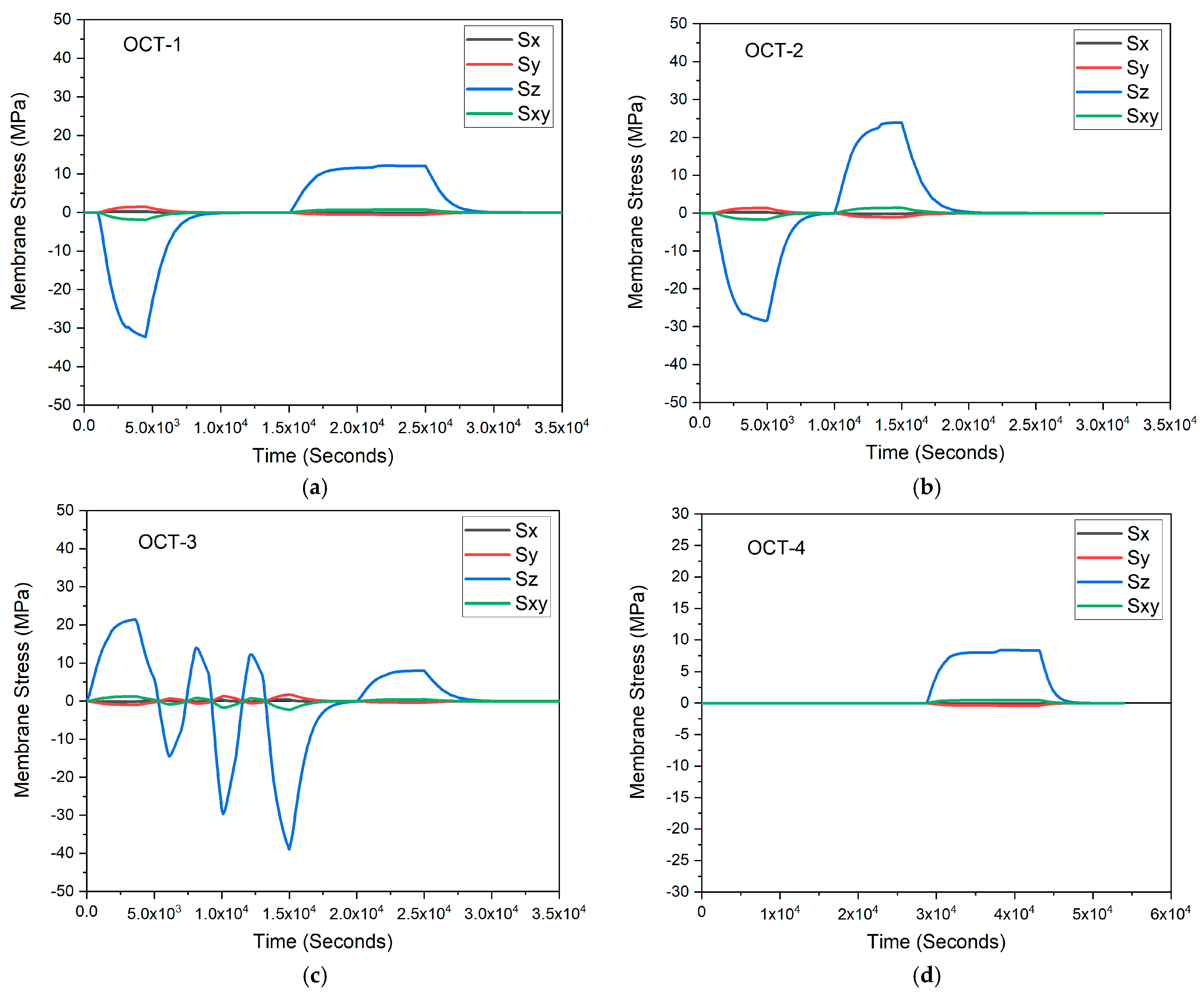

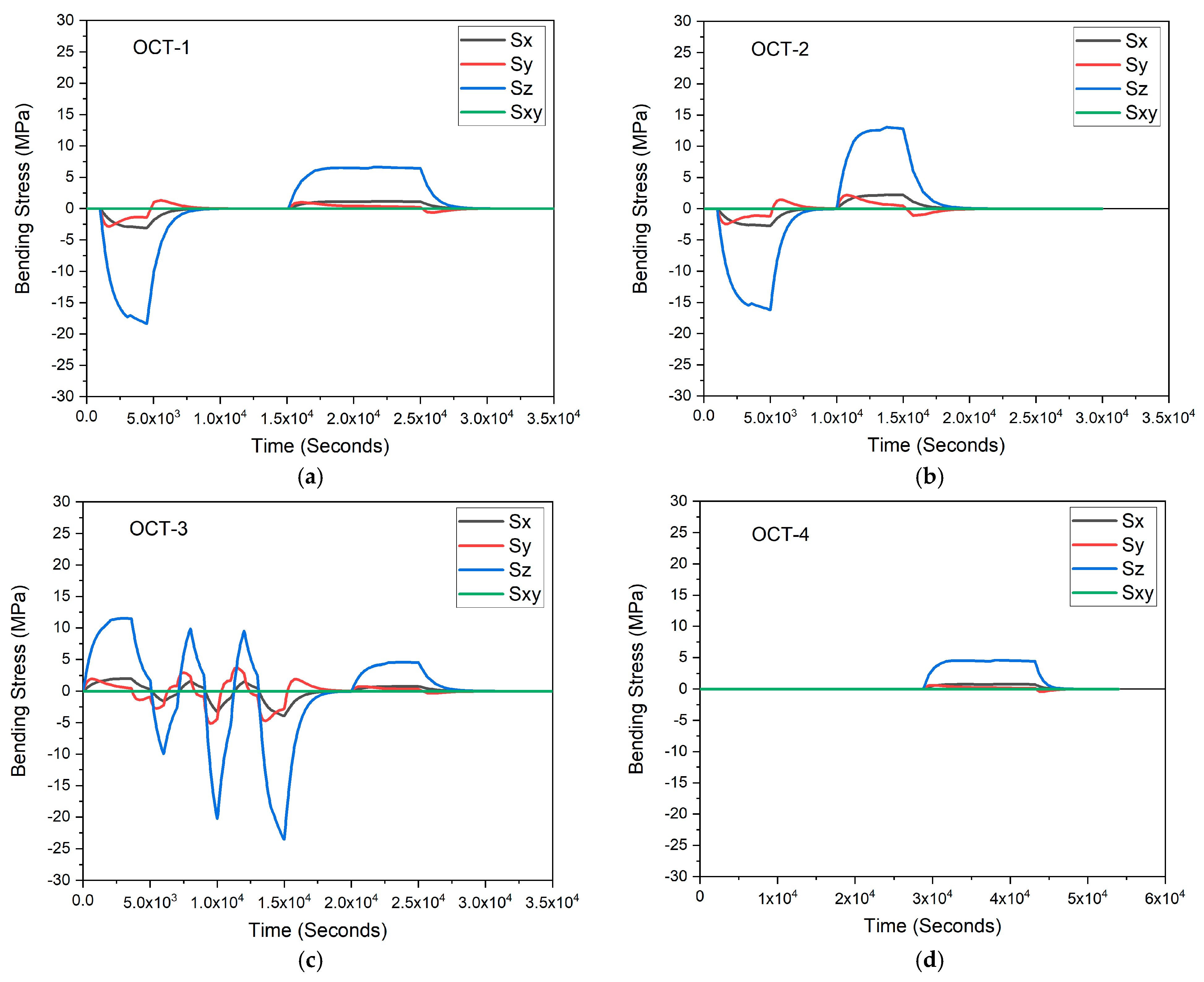

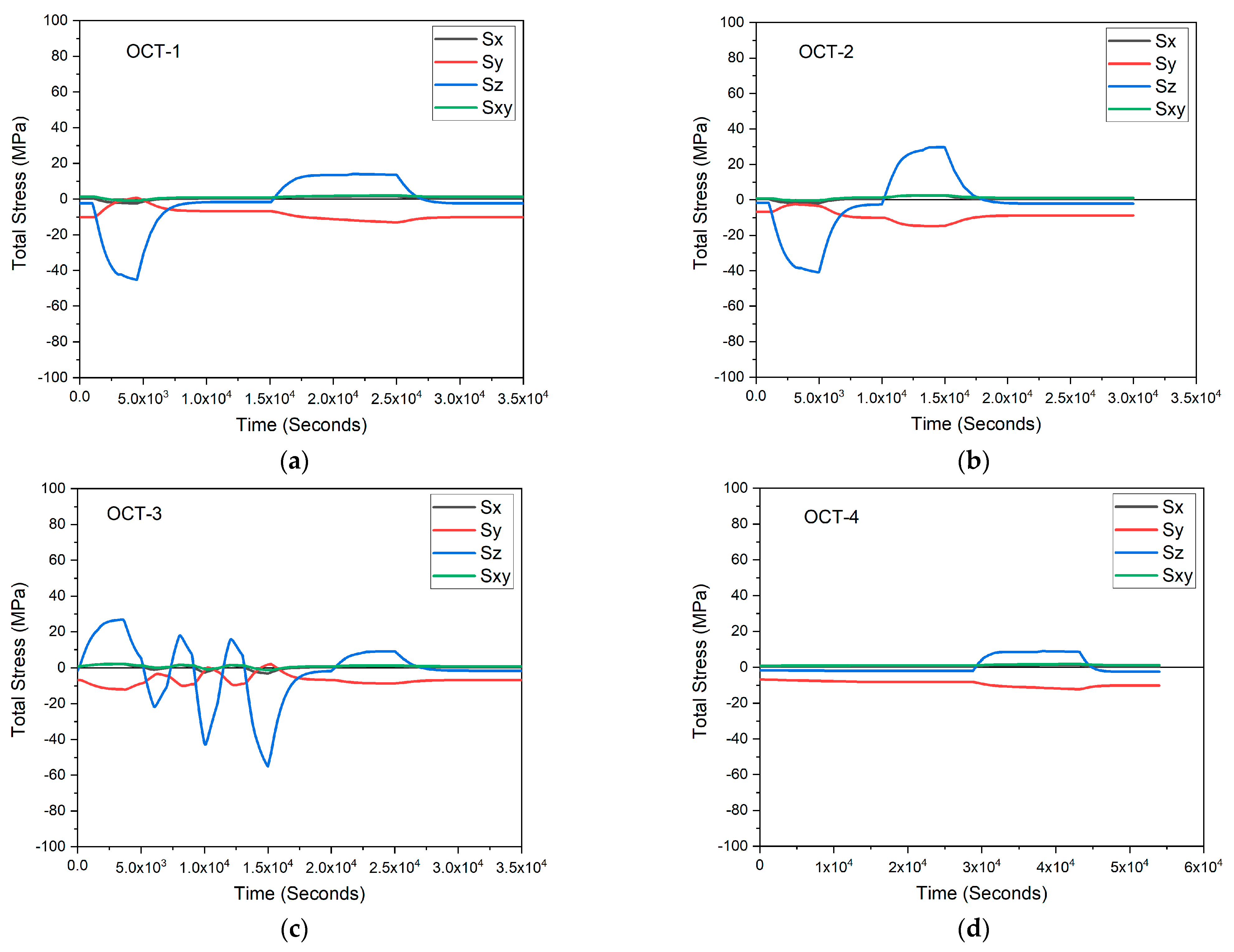

- Time points of stress extreme for each OCT;

- -

- Directional stress components of membrane, bending, and peak stress at stress extremes for each OCT;

- -

- Maximum metal temperature at stress extremes.

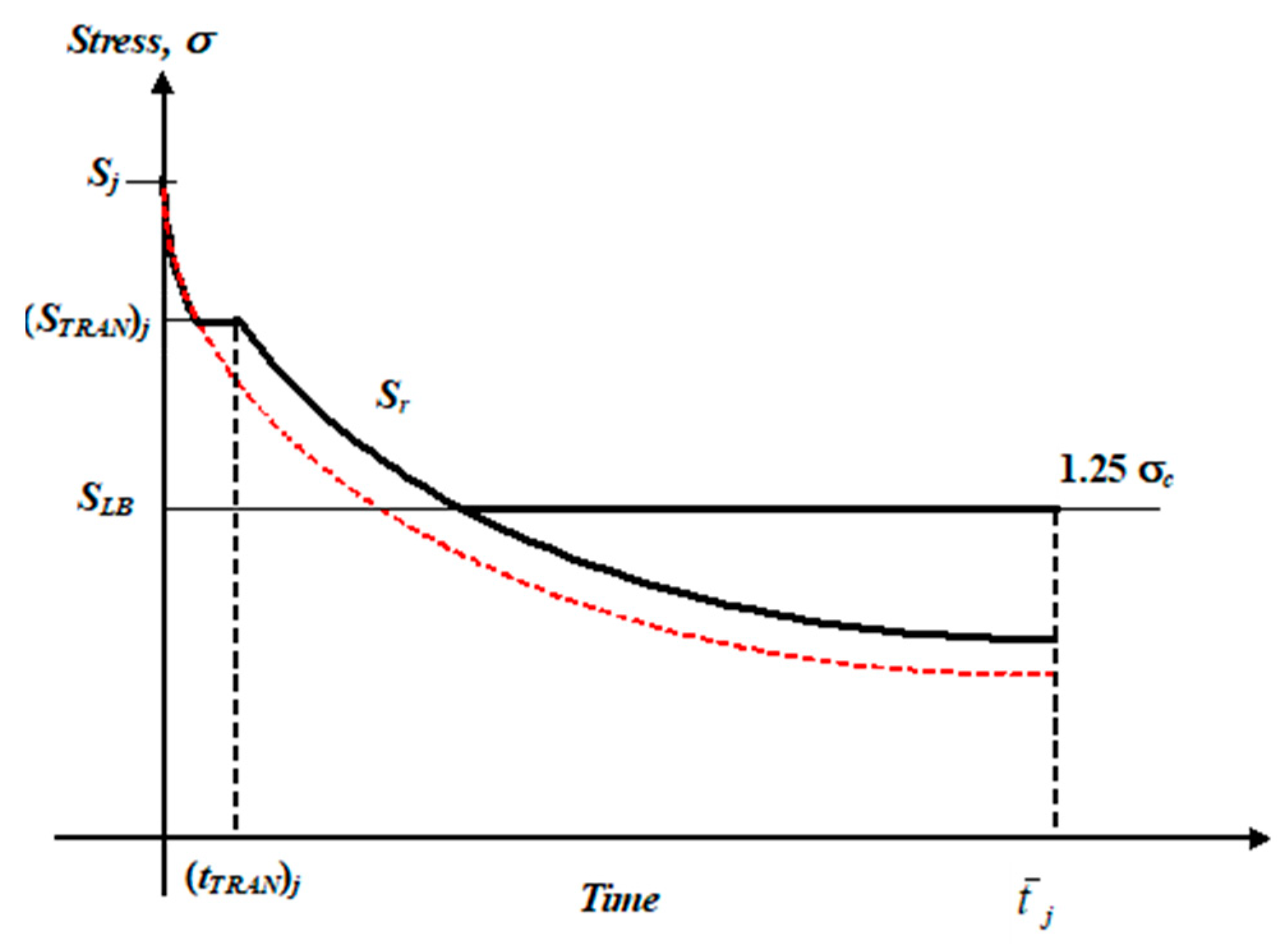

2.2. Procedure of Creep Evaluation

- -

- Transient duration (tTRAN)j during average cycle time;

- -

- Load-controlled stress intensity (STRAN)j;

- -

- Transient temperature of j-th SCT;

- -

- Lower bound stress level (SLB).

- -

- Time interval, (Δt)k;

- -

- Stress value at k-th time interval, (S)k.

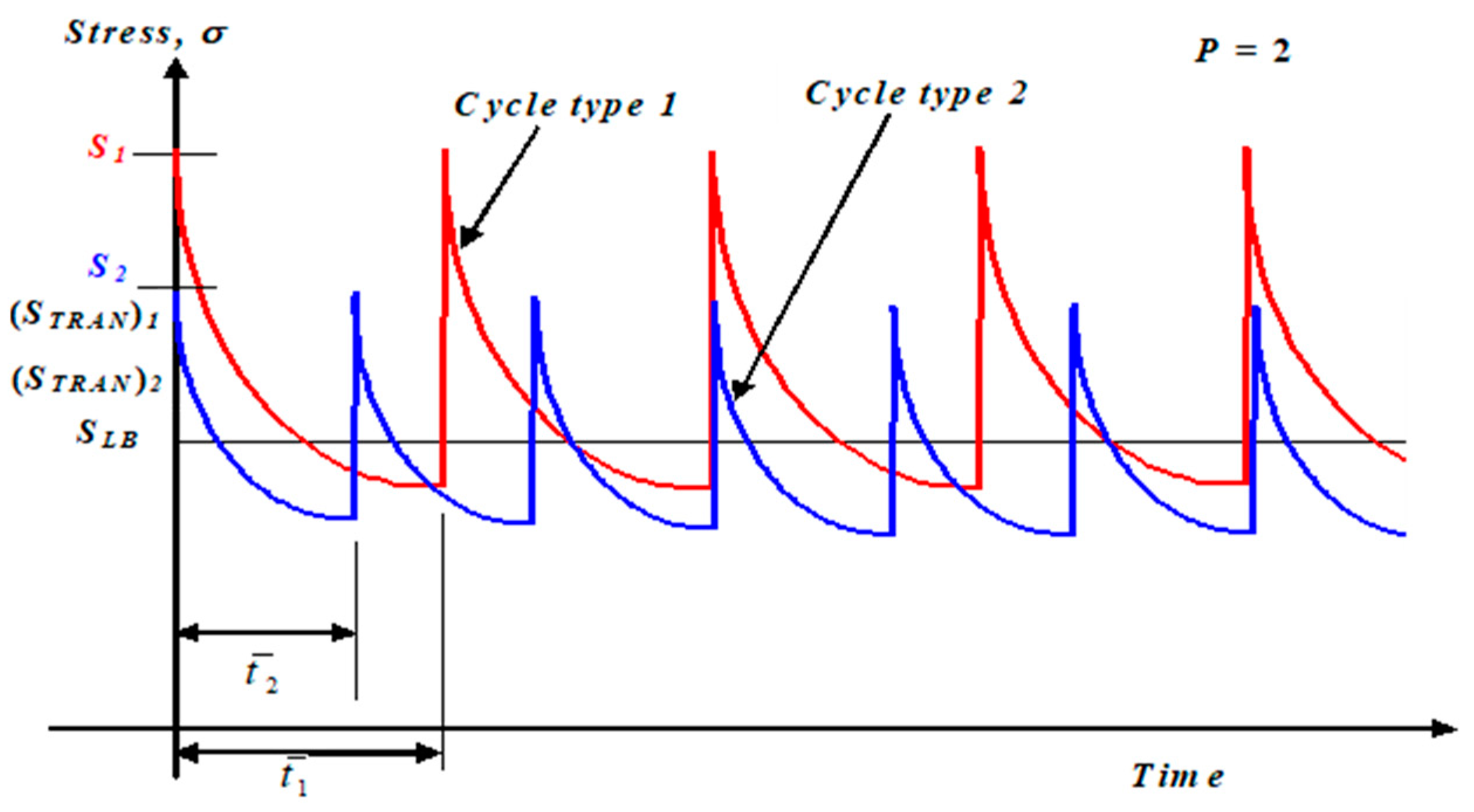

3. Exampled Nuclear Component and Operation Cycle Types

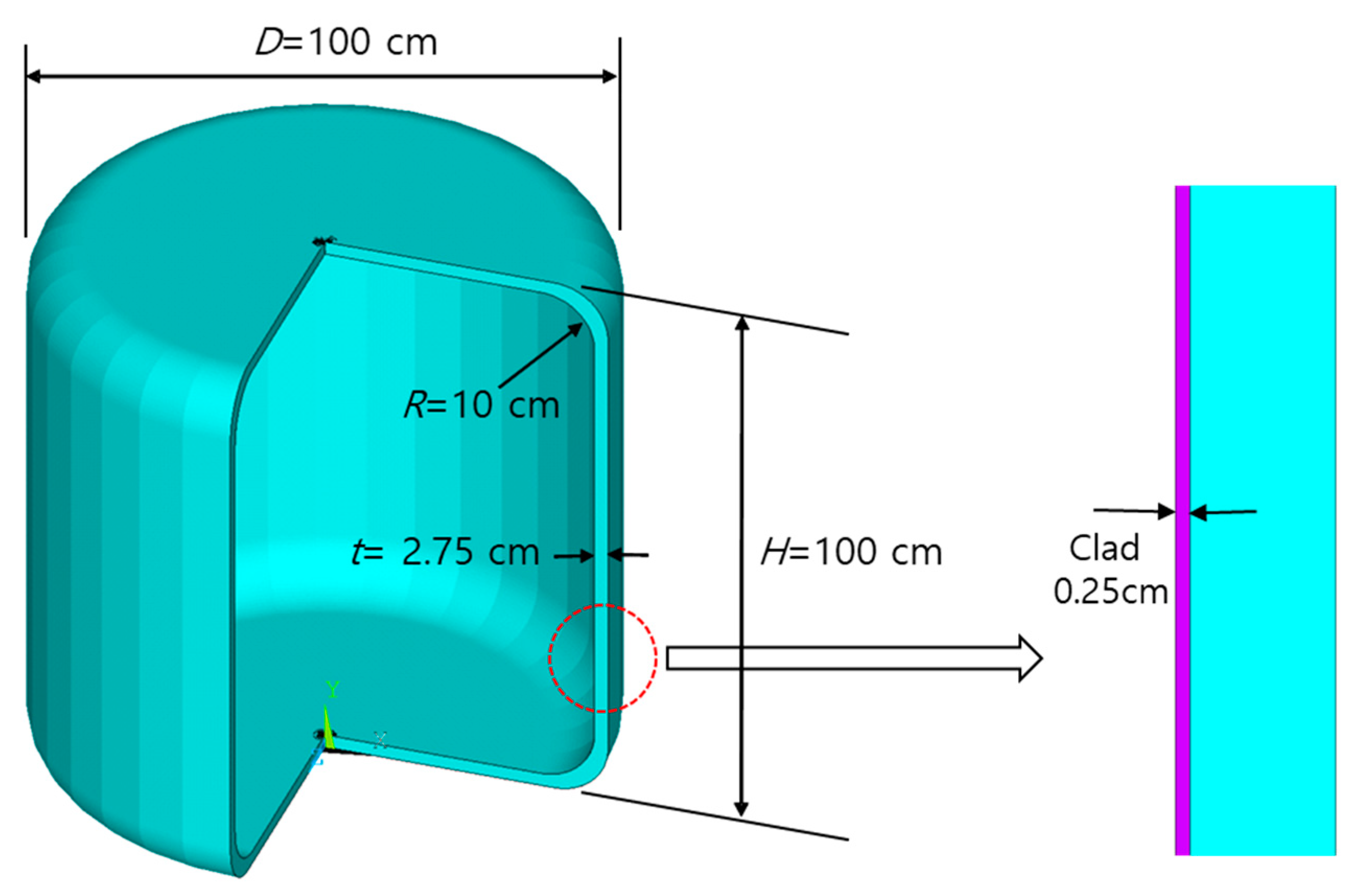

3.1. Geometric Shapes and Cladding

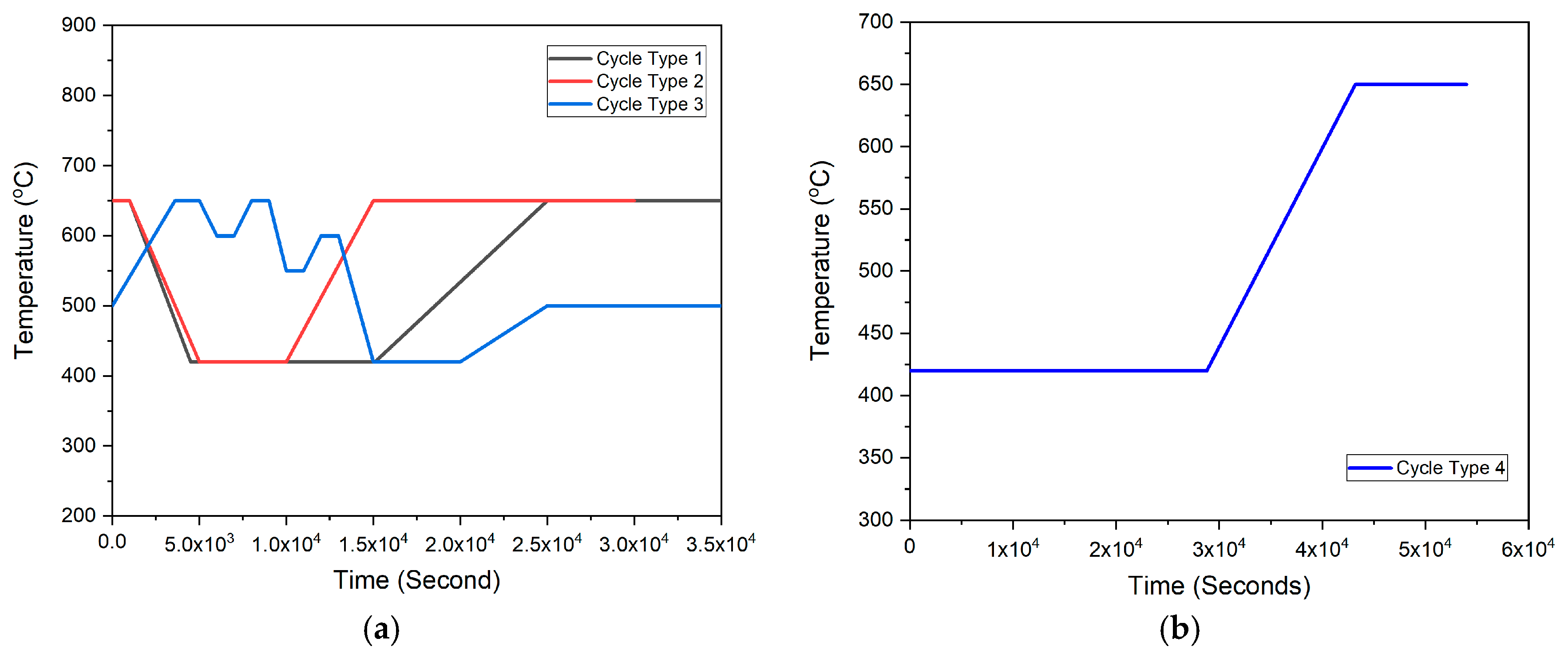

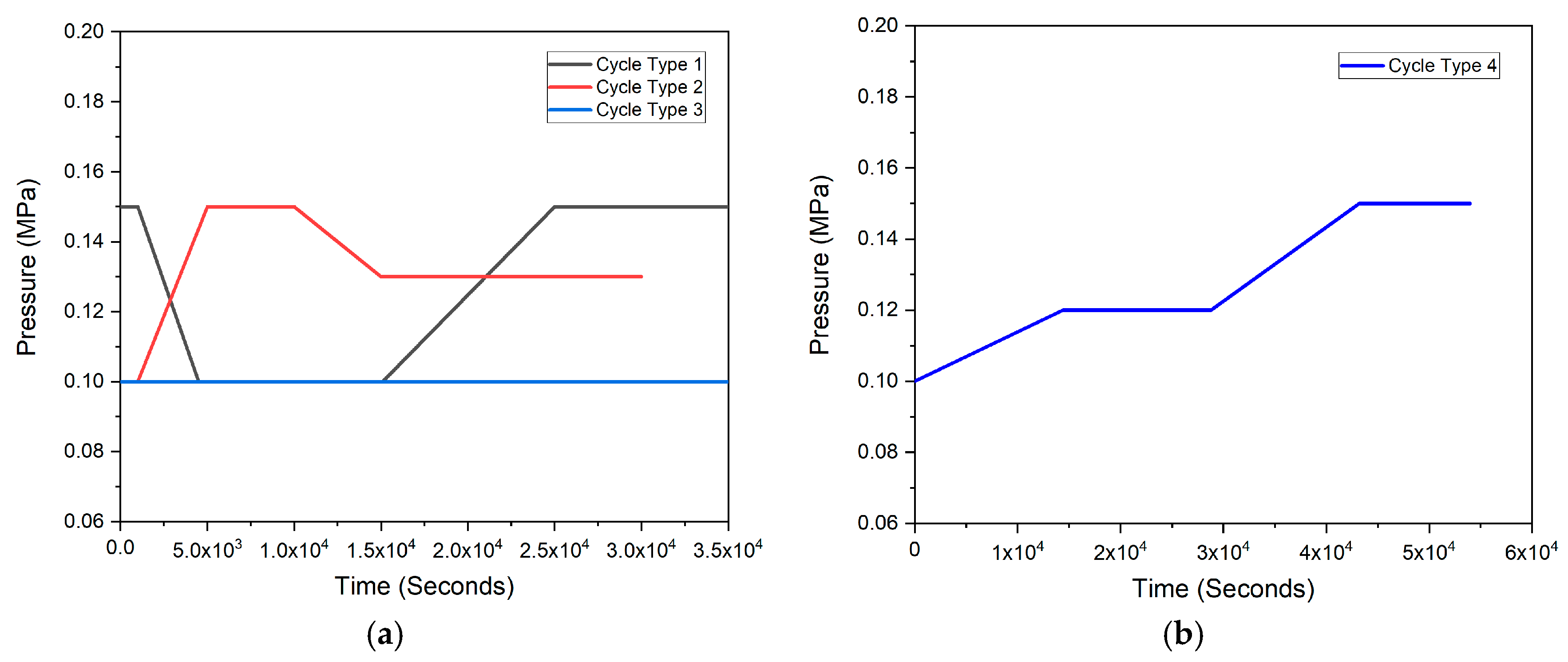

3.2. Operation Cycle Types

4. Finite Element Analysis

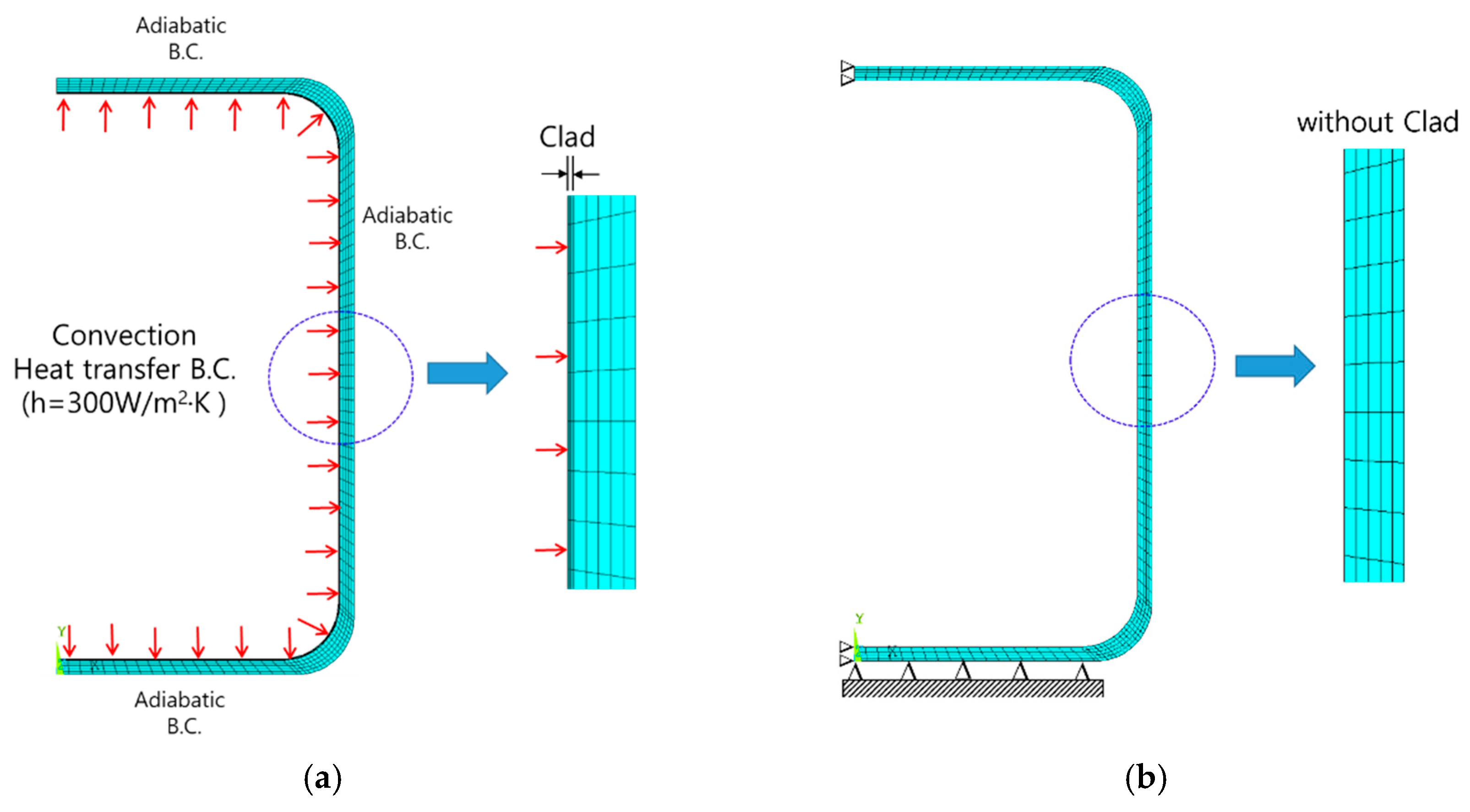

4.1. Analysis Modeling and Material Properties

- -

- Heat conduction = 60.7 W/(m·°C);

- -

- Specific heat = 460 J/(kg·°C);

- -

- Density = 8900 kg/m3.

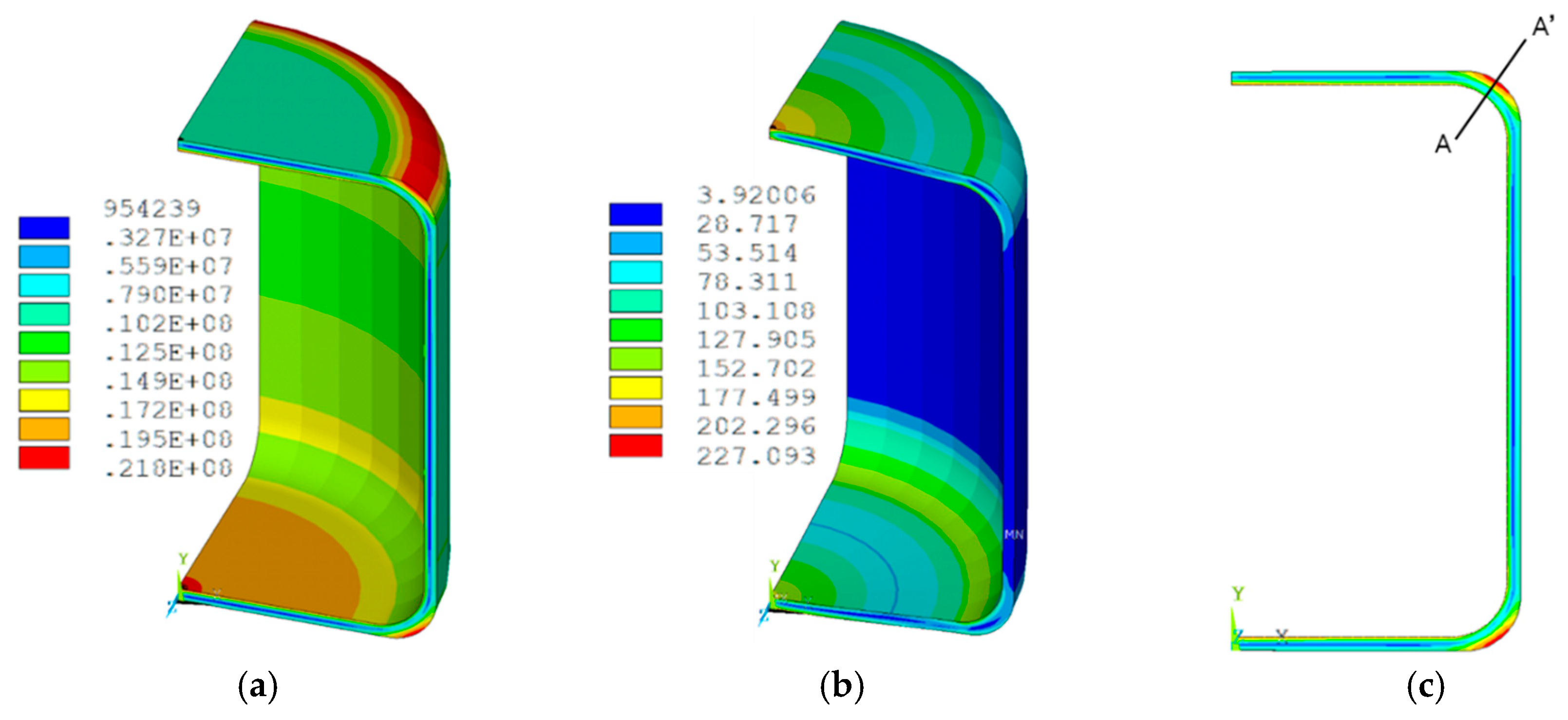

4.2. Stress Analyses

5. Creep-Fatigue Evaluation

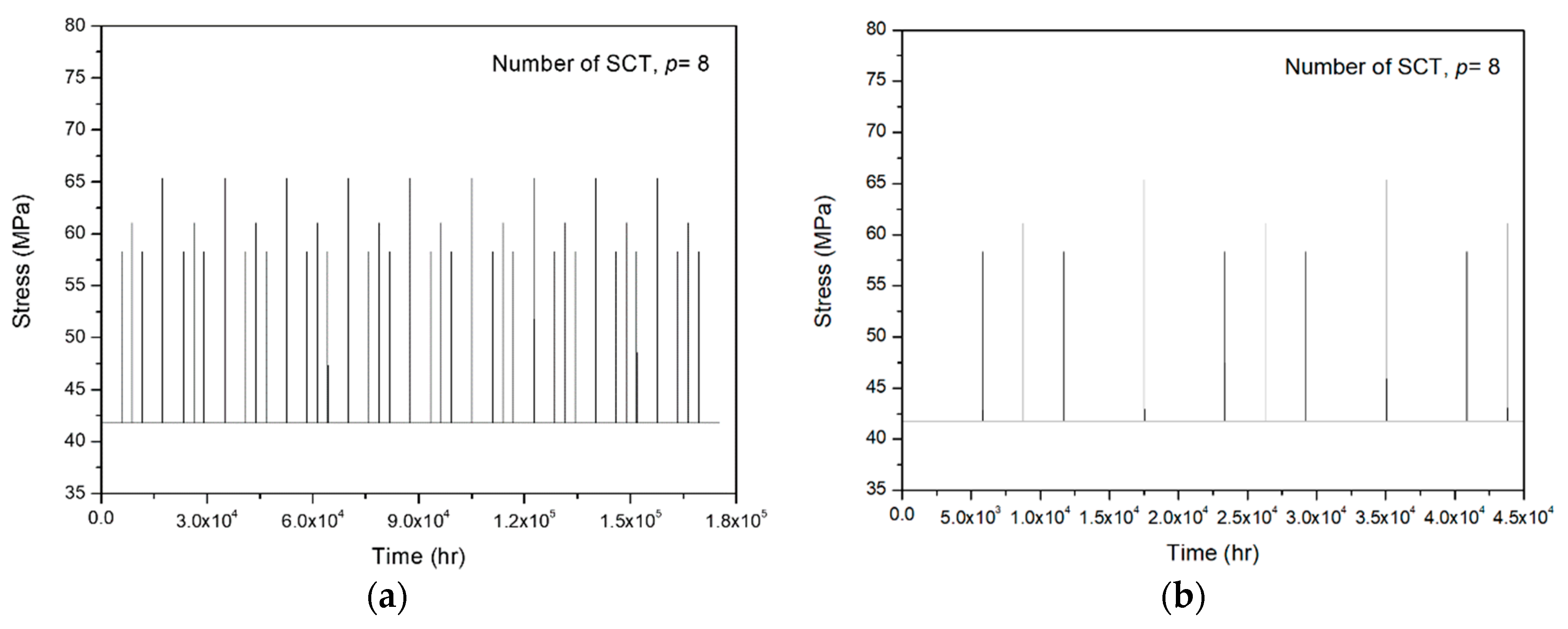

5.1. Determination of Stress Cycle Types and Combining Cycles

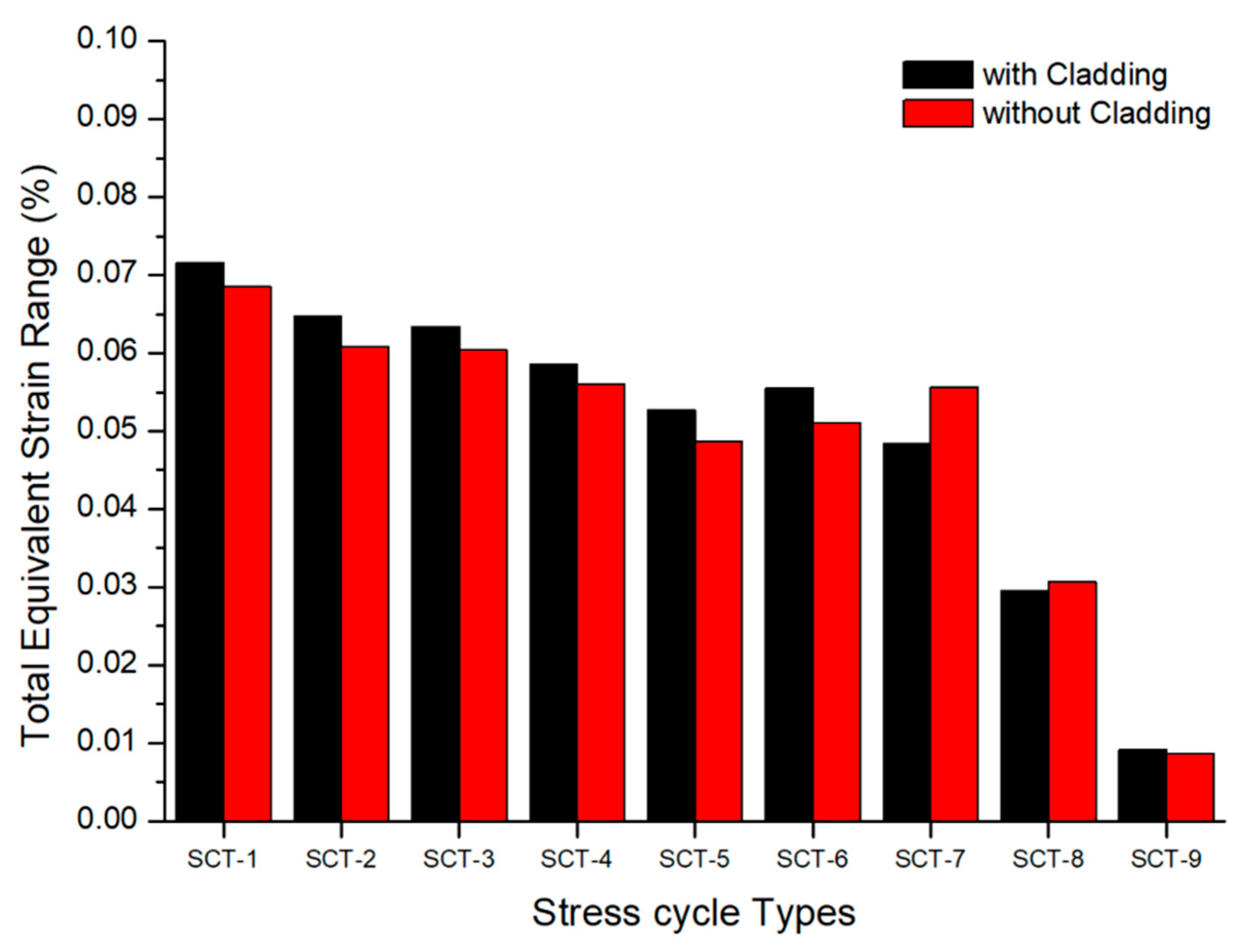

5.2. Fatigue Damage Evaluation

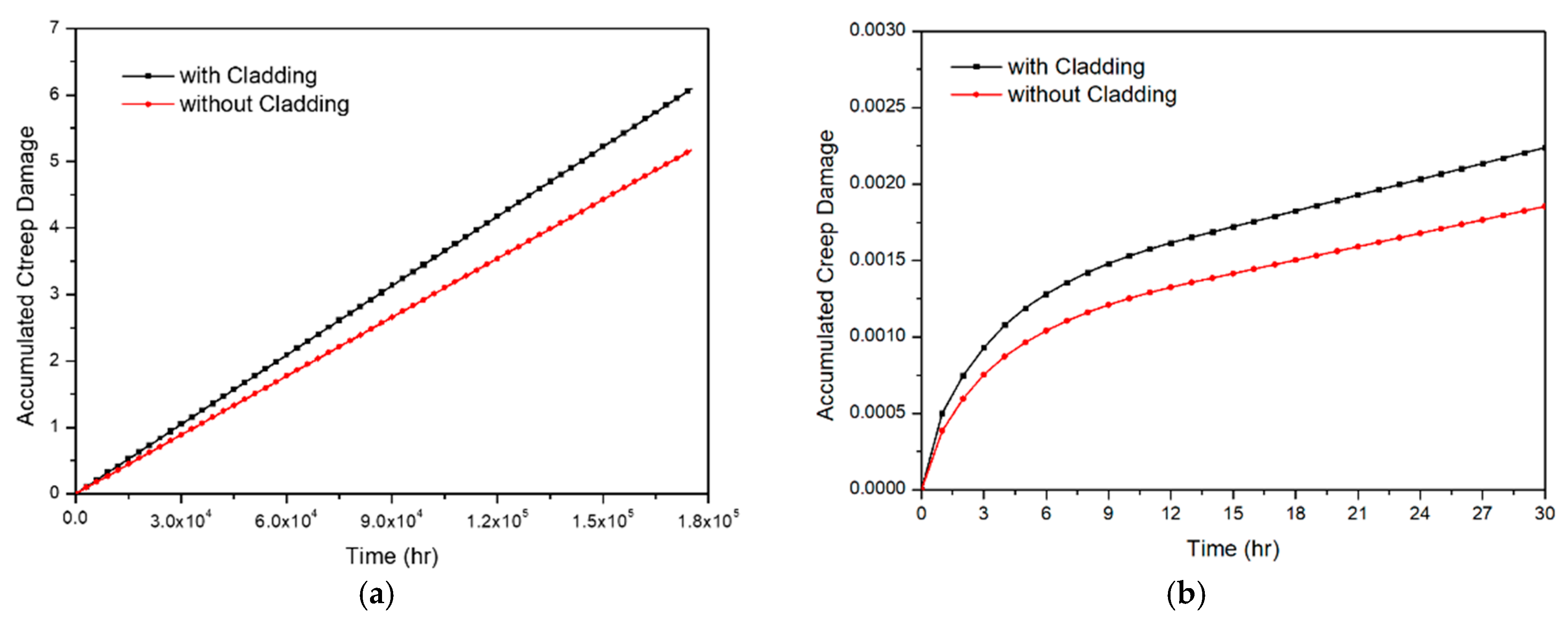

5.3. Creep Damage Evaluation

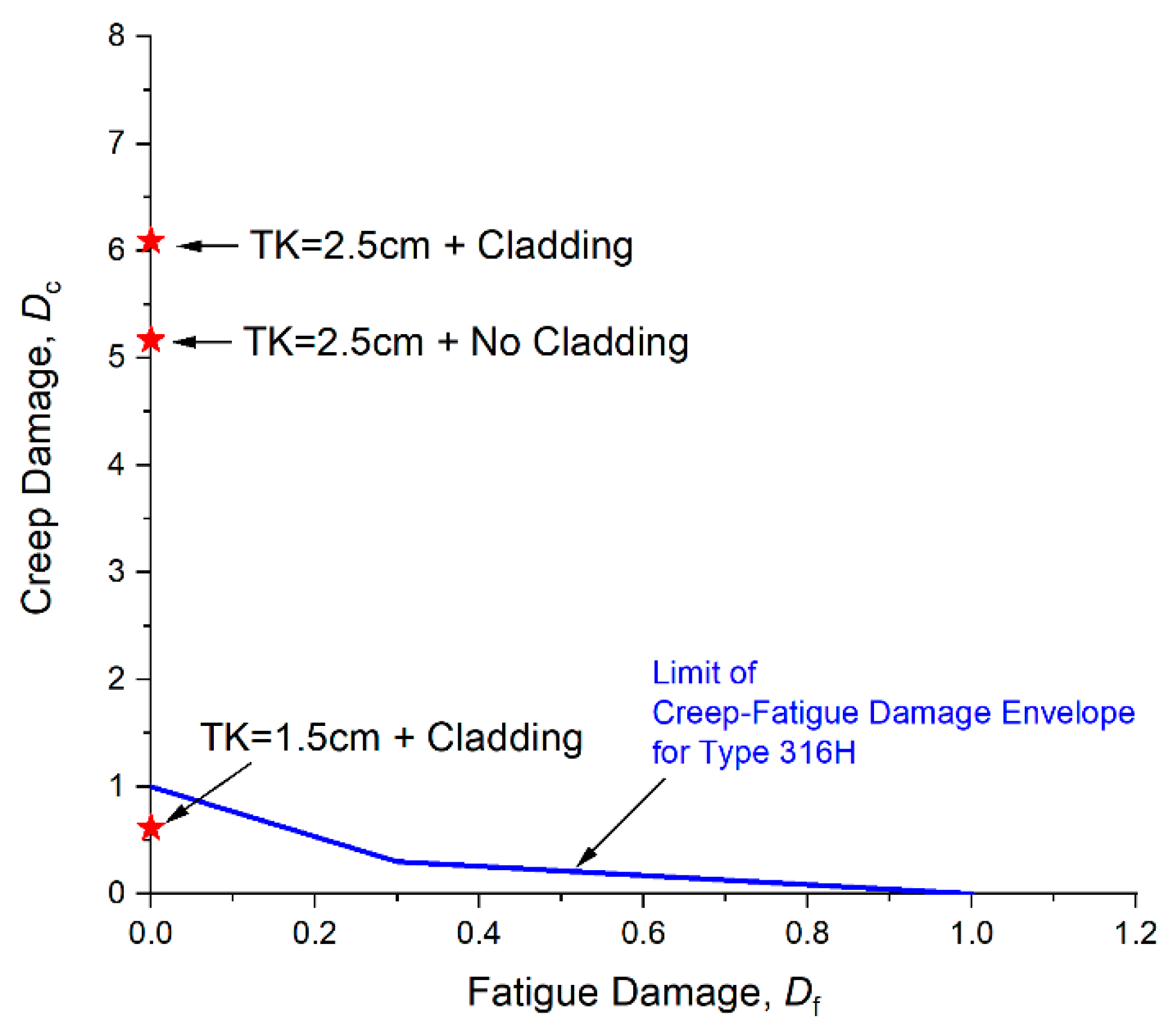

5.4. Reduction of Creep Damage

- -

- Fatigue damage (Df) = 0.1568 × 10−6 < Allowable value = 0.1654: Satisfy;

- -

- Creep Damage (Dc) = 0.6141 < Allowable value = 1.0: Satisfy.

6. Conclusions

- -

- In this study, a practical creep-fatigue evaluation procedure and its application example are described step by step in detail complying with the ASME-III Division 5 rules.

- -

- When applying the ASME-III Division 5 rules for creep-fatigue evaluation, it is very important to determine the stress cycle types and their number of combining cycles from the combination of operation cycle types.

- -

- The corrosion resistance cladding material applying to the nuclear components affects the temperature distribution through the vessel wall thickness and can increase creep-fatigue damage value by thermal stress increment. Therefore, the cladding material in the nuclear cladded components needs to be carefully considered for creep-fatigue evaluation.

- -

- The creep-fatigue evaluations for the nuclear components operating at low pressure and high temperature conditions, such as molten salt reactor, sodium-cooled reactor, and so on, are dominated by the thermal stresses in design by the elastic analysis method of the ASME-III Division 5. Therefore, the structural design minimizing the thermal stresses is important for the structural integrity of high temperature reactors.

- -

- In conclusion, the described creep-fatigue evaluation procedure and application example in this study can be practically used for the structural integrity evaluation of high-temperature reactors.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Serp, J.; Allibert, M.; Benes, O.; Delpech, S.; Feynberg, O.; Ghetta, V.; Heuer, D.; Holcomb, D.; Ignatiev, V.; Kloosterman, J.L.; et al. The molten salt reactor (MSR) in generation IV: Overview and perspectives. Prog. Nucl. Energy 2014, 77, 308–319. [Google Scholar] [CrossRef]

- ORNL/SPR-2019/1089; Technical Gap Assessment for Materials and Component Integrity Issues for Molten Salt Reactors. Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2019.

- ANL/EXT-18-45171; Status of Metallic Structural Materials for Molten Salt Reactors; Revision 0. Argonne National Laboratory: Lemont, IL, USA, May 2018.

- Barua, B.; Messner, M.C.; Jetter, R.I.; Sham, T.-L. Selection Criteria for Clad Materials to Use with a 316H Base Material for High Temperature Nuclear Reactor Cladded Components. In Proceedings of the ASME 2020 Pressure Vessels & Piping Division Conference PVP2020, Minneapolis, MN, USA, 19–24 July 2020. PVP2020-21493. [Google Scholar]

- ASME. ASME Boiler and Pressure Vessel Code Section III; Division 5; ASME: New York, NY, USA, 2021. [Google Scholar]

- ANL-21/11; Design Rules for 316H Nuclear Components Cladded with Nickel or Tungsten. Argonne National Laboratory: Lemont, IL, USA, March 2021.

- Barua, B.; Jetter, R.I.; Messner, M.C.; Sham, T.-L. Simplified Criteria with Reduced Testing Effort for Selecting Clad Materials for High Temperature Reactor Structural Components. In Proceedings of the ASME 2021, Pressure Vessels & Piping Division Conference, PVP2021, Virtual, 12–16 July 2021; p. 2021. [Google Scholar]

- Messner, M.C.; Phan, V.-T.; Jetter, R.I.; Sham, T.-L. The Mechanical Interaction of Clad and Base Metal for Molten Salt Reactor Structural Components. In Proceedings of the ASME 2018 Pressure Vessels and Piping Conference PVP2018, Prague, Czech Republic, 15–20 July 2018. [Google Scholar]

- ANL-ART-134; Finite Element Analysis of Compliant Cladding and Base Metal Systems. Argonne National Laboratory: Lemont, IL, USA, July 2018.

- Mariappan, K.; Nagesha, A. Creep-fatigue interaction behavior of simulated microstructures and the actual weldment of P91 steel. Mater. Sci. Eng. A 2023, 866, 144695. [Google Scholar] [CrossRef]

- Shanyavskiy, A.; Shlyannikov, V.; Soldatenkov, A.; Rubtsov, V. Micromechanics of fatigue, creep-fatigue interaction and thermomechanical crack growth of XH73M nickel alloy. Struct. Integr. Procedia 2023, 43, 215–220. [Google Scholar] [CrossRef]

- Alsmadi, Z.T.; Abouelella, H.; Alomari, A.S.; Murty, K.L. Stress-Controlled Creep–Fatigue of an Advanced Austenitic Stainless Steel at Elevated Temperatures. Materials 2022, 15, 3984. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Dai, H.; Xu, L.; Tang, Z.; Li, C.; Zhang, J.; Lin, J. Modeling and effect analysis on crack growth behavior of Hastelloy X under high temperature creep-fatigue interaction. Int. J. Mech. Sci. 2021, 195, 106219. [Google Scholar] [CrossRef]

- Jadon, J.K.S.; Singh, R.; Mahato, J.K. Creep-fatigue interaction behavior of high temperature alloys: A review. Mater. Today: Proc. 2022, 62, 5351–5357. [Google Scholar]

- Rao, G.V.S.N.; Kumar, P.A.; Kannan, R.; Nagesha, A. Influence of Temperature and Strain Amplitude on Low Cycle Fatigue and Creep–Fatigue Interaction Behaviour of Alloy 617 M. Trans. Indian Natl. Acad. Eng. 2022, 7, 509–517. [Google Scholar]

- Alsmadi, Z.Y.; Murty, K.L. High-temperature effects on creep-fatigue interaction of the Alloy 709 austenitic stainless steel. Int. J. Fatigue 2021, 143, 105987. [Google Scholar]

- Takahashi, Y. Creep-fatigue interaction: Its mechanism and predictability. In Proceedings of the Asian Pacific Conference for Materials and Mechanics 2009, Yokohama, Japan, 13–16 November 2009. [Google Scholar]

- Barbera, D.; Chen, H.; Liu, Y. On Creep Fatigue Interaction of Components at Elevated Temperature. J. Press. Vessel. Technol. 2016, 138, 041403. [Google Scholar] [CrossRef]

- Yokobori, T.; Yokobori, A.T., Jr. High temperature creep, fatigue and creep-fatigue interaction in engineering materials. Int. J. Press. Vessel. Pip. 2001, 78, 903–908. [Google Scholar] [CrossRef]

- AFCEN. RCC-MRx: Design and Construction Rules for Mechanical Components in High-Temperature Structures, Experimental Reactors, Fusion Reactor; AFCEN: Lyon, France, 2015. [Google Scholar]

- British Energy Generation Ltd. Assessment Procedure for the High Temperature Response of Structures (R5); British Energy Generation Ltd.: Gloucester, UK, 2003. [Google Scholar]

- PNC. Elevated Temperature Structural Design Guide for Class 1 Components of Prototype Fast Breeder Reactor; PNC N241-84-08; PNC: Yokohama, Japan, 1984. [Google Scholar]

- Koo, G.H.; Lee, J.H. Development of an ASME-NH program for nuclear component design at elevated temperatures. Int. J. Press. Vessel. Pip. 2008, 85, 385–393. [Google Scholar] [CrossRef]

- Koo, G.H.; Lee, J.H. Elevated Temperature Design of KALIMER Reactor Internals Accounting for Creep and Stress-Rupture Effects. J. Korean Nucl. Soc. 2000, 32, 566–594. [Google Scholar]

- Koo, G.H.; Yoo, B. Evaluation of Creep-Fatigue Damage of KALIMER Reactor Internals Using the Elastic Analysis Method in RCC-MR. J. Korean Nucl. Soc. 2001, 33, 566–584. [Google Scholar]

- ASME. ASME Boiler and Pressure Vessel Code Section III, Mandatory Appendix XIII; ASME: New York, NY, USA, 2021. [Google Scholar]

- ANSYS Mechanical APDL Release 15.0; ANSYS, Inc.: Canonsburg, PA, USA, 2013.

- ASME. ASME Boiler and Pressure Vessel Code Section II, Part D; ASME: New York, NY, USA, 2021. [Google Scholar]

| OSTs | Design No. of Cycles | Transient Duration (h) |

|---|---|---|

| OCT-1 | 200 | 7.0 |

| OCT-2 | 50 | 4.2 |

| OCT-3 | 30 | 7.0 |

| OCT-4 | 30 | 12.0 |

| Properties | Temperature (°C) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 100 | 200 | 300 | 400 | 450 | 500 | 550 | 600 | 650 | |

| Heat conduction (W/m2·°C) | 14.1 | 15.4 | 16.8 | 18.3 | 19.7 | 20.5 | 21.2 | 21.9 | 22.6 | 23.2 |

| Specific heat [J/(kg·°C)] | 491.9 | 511.4 | 525.7 | 540.0 | 552.5 | 561.1 | 566.5 | 570.6 | 574.4 | 576.7 |

| Density (kg/m3) | 8030 | 8030 | 8030 | 8030 | 8030 | 8030 | 8030 | 8030 | 8030 | 8030 |

| Thermal expansion (10−6/°C) | 15.3 | 17.0 | 18.4 | 19.1 | 19.5 | 19.8 | 20.2 | 20.6 | 21.1 | 21.6 |

| Elastic modulus (GPa) | 209 | 189 | 183 | 176 | 169 | 165 | 160 | 156 | 151 | 146 |

| Poisson’s ratio | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 |

| OCT No. | Stress Extreme Time Points (s) (Metal Temperature, °C) | |||||

|---|---|---|---|---|---|---|

| TP1 | TP2 | TP3 | TP4 | TP5 | TP6 | |

| OCT-1 | 4500 (468) | 25,000 (633) | ||||

| OCT-2 | 4870 (469) | 14,250 (582) | ||||

| OCT-3 | 3600 (620) | 6050 (625) | 8100 (627) | 10,100 (597) | 12,100 (579) | 15,000 (478) |

| OCT-4 | 43,200 (638) | 54,000 (650) | ||||

| SCT No. | TP1 | TP2 | Combined Cycles | Metal Temp (°C) | ||

|---|---|---|---|---|---|---|

| OCT No. | Time (s) | OCT No. | Time (s) | |||

| SCT-1 | 3 | 15,000 | 2 | 14,250 | 30 | 582 |

| SCT-2 | 1 | 4500 | 2 | 14,500 | 20 | 582 |

| SCT-3 | 1 | 4500 | 3 | 3600 | 30 | 620 |

| SCT-4 | 1 | 4500 | 3 | 8100 | 30 | 627 |

| SCT-5 | 1 | 4500 | 1 | 25,000 | 120 | 633 |

| SCT-6 | 3 | 10,100 | 1 | 25,000 | 30 | 633 |

| SCT-7 | 2 | 4870 | 1 | 25,000 | 50 | 633 |

| SCT-8 | 3 | 12,100 | 3 | 6050 | 30 | 625 |

| SCT-9 | 4 | 43,200 | 4 | 54,000 | 30 | 650 |

| SCT No. | Salt (MPa) | E (GPa) | Δϵmax (%) |

|---|---|---|---|

| SCT-1 | 51.06 | 152.80 | 0.0668 |

| SCT-2 | 45.56 | 152.80 | 0.0596 |

| SCT-3 | 42.69 | 149.02 | 0.0573 |

| SCT-4 | 37.03 | 148.27 | 0.0499 |

| SCT-5 | 36.62 | 147.70 | 0.0496 |

| SCT-6 | 34.72 | 147.70 | 0.0470 |

| SCT-7 | 32.28 | 147.70 | 0.0437 |

| SCT-8 | 21.45 | 148.53 | 0.0289 |

| SCT-9 | 6.57 | 146.00 | 0.0090 |

| SCT No. | X | Y | Z | 1.25σc (MPa) | (%) |

|---|---|---|---|---|---|

| SCT-1 | 0.3855 | 0.2889 | 0.4425 | 63.45 | 0.4757 × 10−2 |

| SCT-2 | 0.3221 | 0.2556 | 0.3693 | 52.96 | 0.5082 × 10−2 |

| SCT-3 | 0.3287 | 0.2488 | 0.3750 | 52.69 | 0.6052 × 10−2 |

| SCT-4 | 0.3305 | 0.2198 | 0.3714 | 51.91 | 0.8454 × 10−2 |

| SCT-5 | 0.3319 | 0.2079 | 0.3706 | 51.59 | 0.3141 × 10−2 |

| SCT-6 | 0.3060 | 0.1989 | 0.3420 | 47.61 | 0.8457 × 10−2 |

| SCT-7 | 0.3025 | 0.1895 | 0.3367 | 46.87 | 0.4714 × 10−2 |

| SCT-8 | 0.1539 | 0.1364 | 0.1745 | 24.43 | 0.6009 × 10−3 |

| SCT-9 | 0.0611 | 0.0386 | 0.0663 | 9.12 | 0.2168 × 10−3 |

| j | SCT No. | nj | (Nd)j | (Df)j = (n/Nd)j | |

|---|---|---|---|---|---|

| 1 | SCT-1 | 0.0716 | 30 | 0.8971 × 107 | 0.3344 × 10−5 |

| 2 | SCT-2 | 0.0647 | 20 | 0.1892 × 108 | 0.1057 × 10−5 |

| 3 | SCT-3 | 0.0634 | 30 | 0.2214 × 108 | 0.1355 × 10−5 |

| 4 | SCT-4 | 0.0585 | 30 | 0.3995 × 108 | 0.7508 × 10−6 |

| 5 | SCT-5 | 0.0527 | 120 | 0.8614 × 108 | 0.1393 × 10−5 |

| 6 | SCT-6 | 0.0555 | 30 | 0.5911 × 108 | 0.5076 × 10−6 |

| 7 | SCT-7 | 0.0484 | 50 | 0.1615 × 109 | 0.3096 × 10−6 |

| 8 | SCT-8 | 0.0295 | 30 | 0.6336 × 1010 | 0.4735 × 10−8 |

| 9 | SCT-9 | 0.0092 | 30 | 0.3465 × 1014 | 0.8658 × 10−12 |

| SCT No. | tH (h) | THT (°C) | nj | Sj (MPa) | |

|---|---|---|---|---|---|

| SCT-1 | 175,200 | 650 | 30 | 5840 | 103.20 |

| SCT-2 | 175,200 | 650 | 20 | 7760 | 93.32 |

| SCT-3 | 175,200 | 650 | 30 | 5840 | 91.36 |

| SCT-4 | 175,200 | 650 | 30 | 5.840 | 84.35 |

| SCT-5 | 175,200 | 650 | 120 | 1460 | 76.03 |

| SCT-6 | 175,200 | 650 | 30 | 5840 | 80.00 |

| SCT-7 | 175,200 | 650 | 50 | 3504 | 69.84 |

| SCT-8 | 175,200 | 650 | 30 | 5840 | 42.52 |

| SCT-9 | 175,200 | 650 | 30 | 5840 | 13.29 |

| SCT No. | SLB (MPa) | (TTRAN)j (h) | (TTRAN)j (°C) | (Pm + Pb)TRAN (MPa) |

|---|---|---|---|---|

| SCT-1 | 63.45 | 11.2 | 650 | 8.57 |

| SCT-2 | 63.45 | 11.2 | 650 | 8.57 |

| SCT-3 | 63.45 | 14.0 | 650 | 8.57 |

| SCT-4 | 63.45 | 14.0 | 650 | 8.57 |

| SCT-5 | 63.45 | 14.0 | 650 | 8.57 |

| SCT-6 | 63.45 | 14.0 | 650 | 8.57 |

| SCT-7 | 63.45 | 11.2 | 650 | 12.72 |

| SCT-8 | 63.45 | 14.0 | 650 | 8.57 |

| SCT-9 | 63.45 | 24.0 | 650 | 12.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koo, G.-H.; Lee, S.-Y.; Seo, J.-H.; Song, K.-H.; Choi, G.-S.; Sohn, M.-S. A Study on Creep-Fatigue Evaluation of Nuclear Cladded Components by ASME-III Division 5. Energies 2023, 16, 2898. https://doi.org/10.3390/en16062898

Koo G-H, Lee S-Y, Seo J-H, Song K-H, Choi G-S, Sohn M-S. A Study on Creep-Fatigue Evaluation of Nuclear Cladded Components by ASME-III Division 5. Energies. 2023; 16(6):2898. https://doi.org/10.3390/en16062898

Chicago/Turabian StyleKoo, Gyeong-Hoi, Sang-Yun Lee, Joo-Hwan Seo, Kang-Hyun Song, Geun-Suk Choi, and Myong-Sung Sohn. 2023. "A Study on Creep-Fatigue Evaluation of Nuclear Cladded Components by ASME-III Division 5" Energies 16, no. 6: 2898. https://doi.org/10.3390/en16062898

APA StyleKoo, G.-H., Lee, S.-Y., Seo, J.-H., Song, K.-H., Choi, G.-S., & Sohn, M.-S. (2023). A Study on Creep-Fatigue Evaluation of Nuclear Cladded Components by ASME-III Division 5. Energies, 16(6), 2898. https://doi.org/10.3390/en16062898