Extensive Experimental Characterization with Kinetic Data for the Gasification Simulation of Solid Biofuels

Abstract

1. Introduction

- drying (evaporation of humidity water);

- pyrolysis (further devolatilizing to char, tar, water, and gas);

- tar cracking (secondary tar reactions);

- homogeneous reactions;

- -

- water–gas shift reaction;

- -

- combustion of H2, CO, gaseous hydrocarbons (e.g., mainly CH4) and tars;

- heterogeneous reactions;

- -

- char combustion;

- -

- Boudouard reaction;

- -

- steam gasification.

2. Materials and Methods

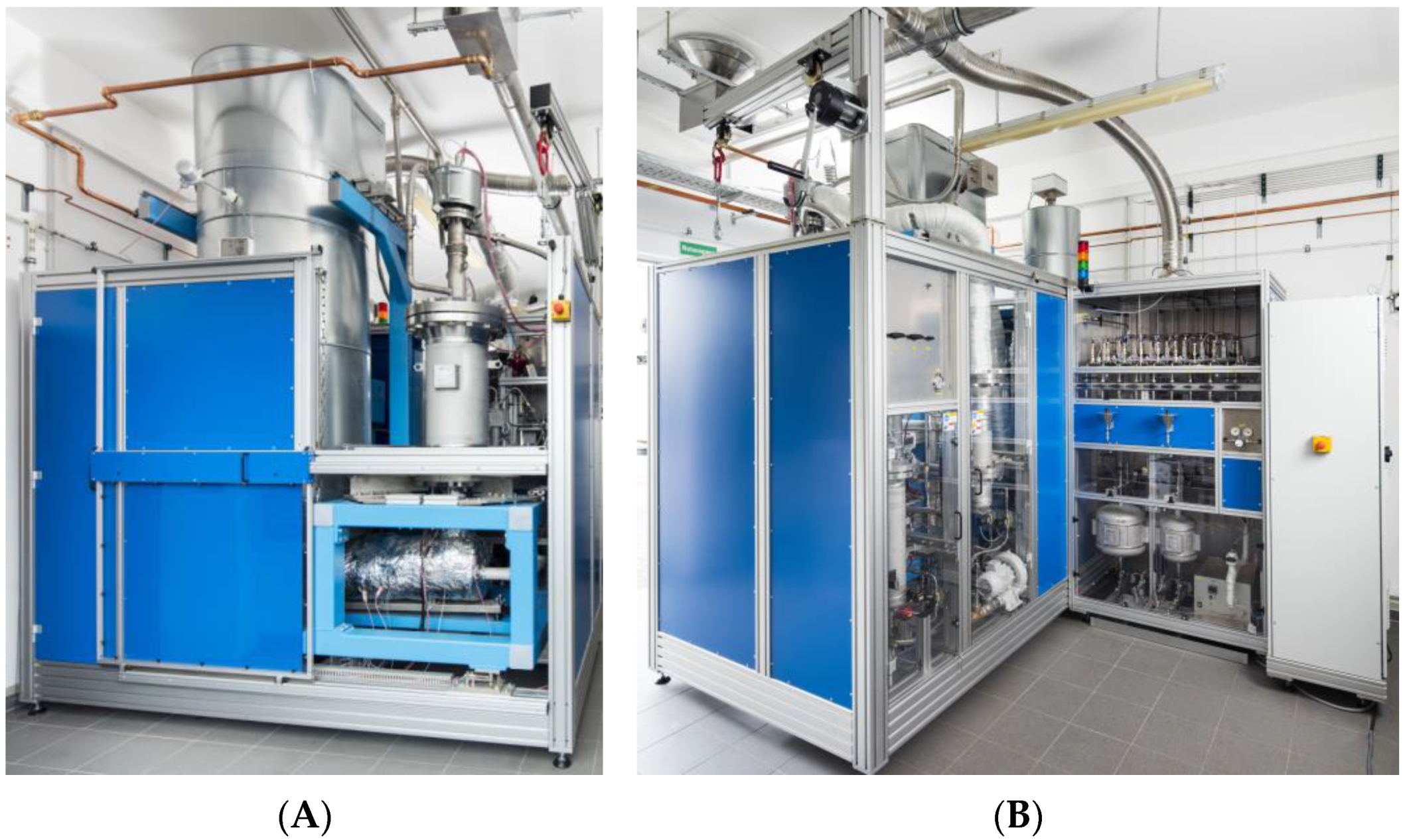

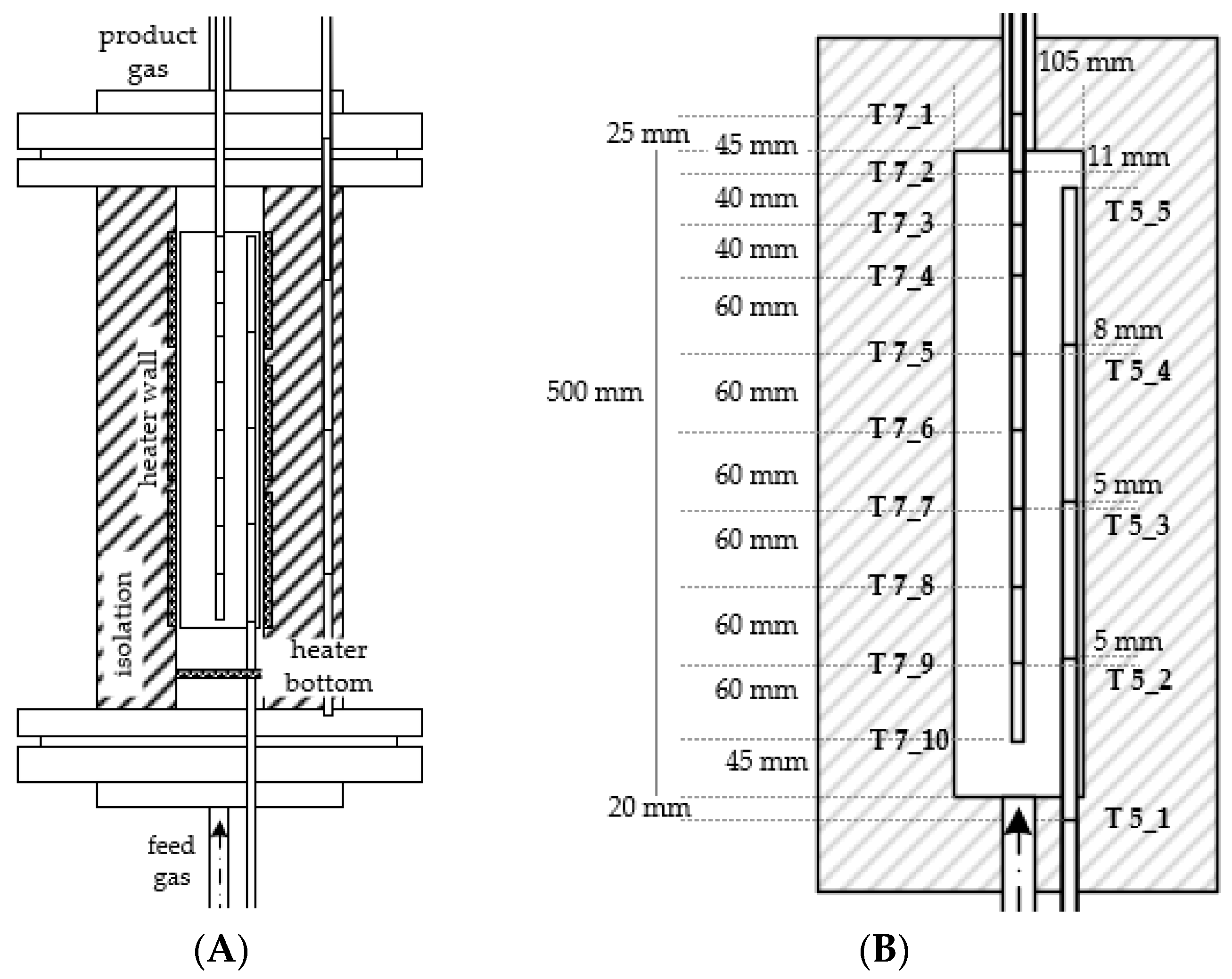

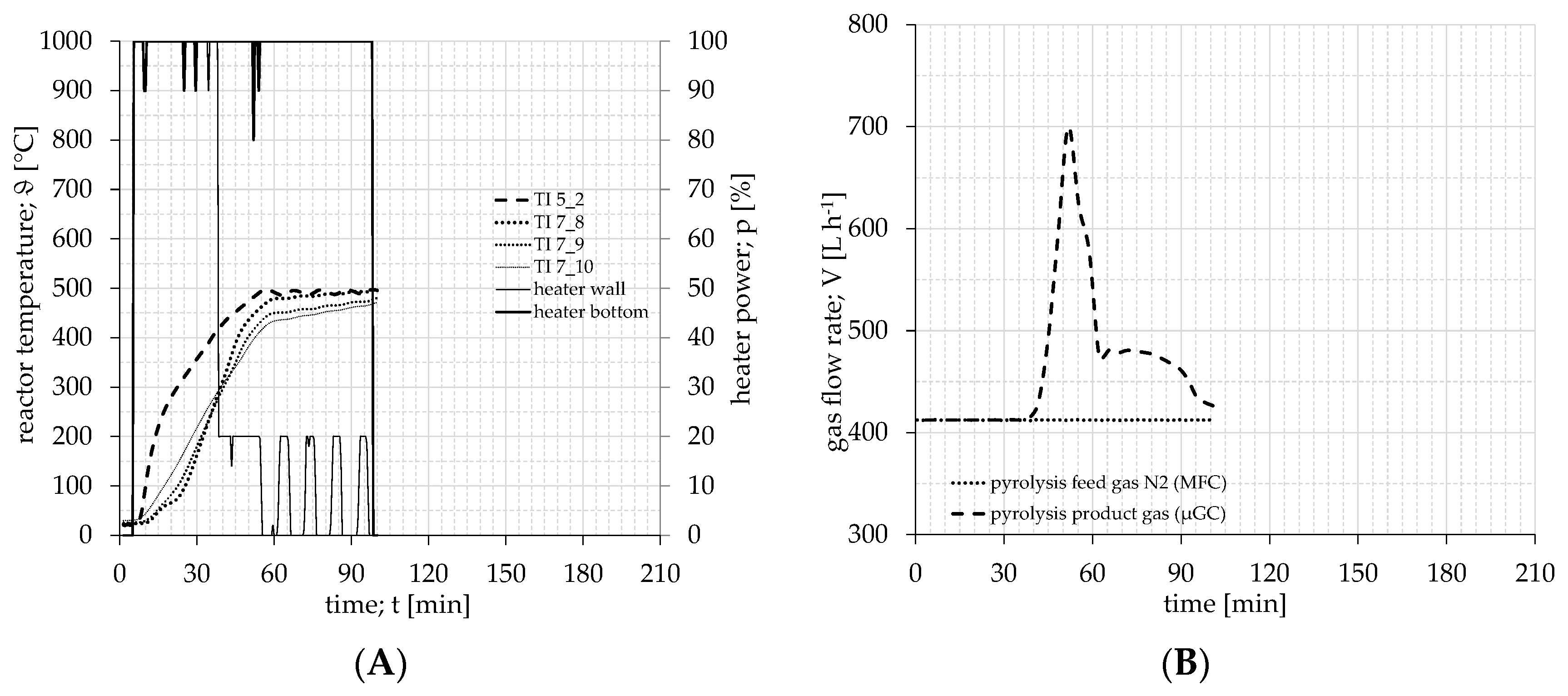

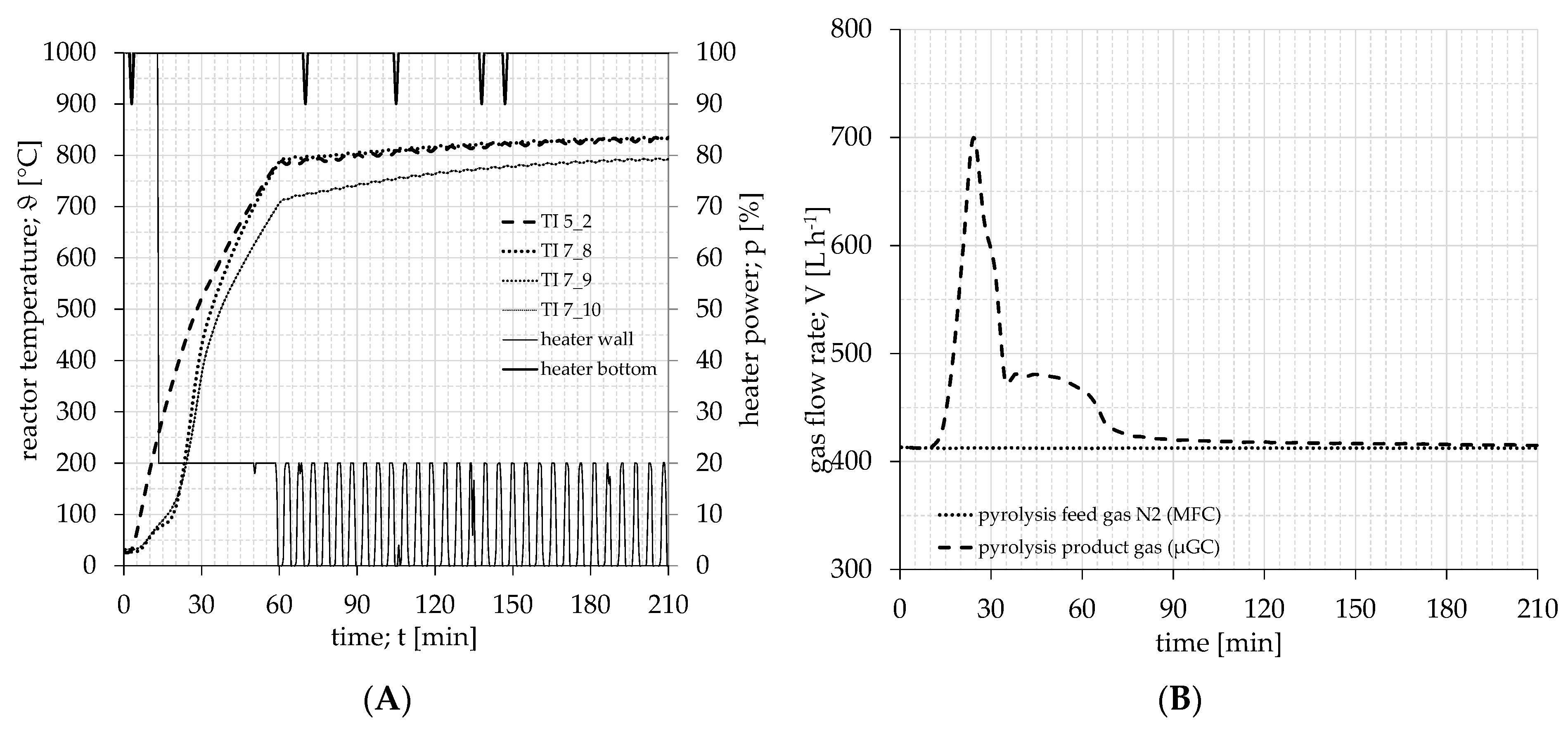

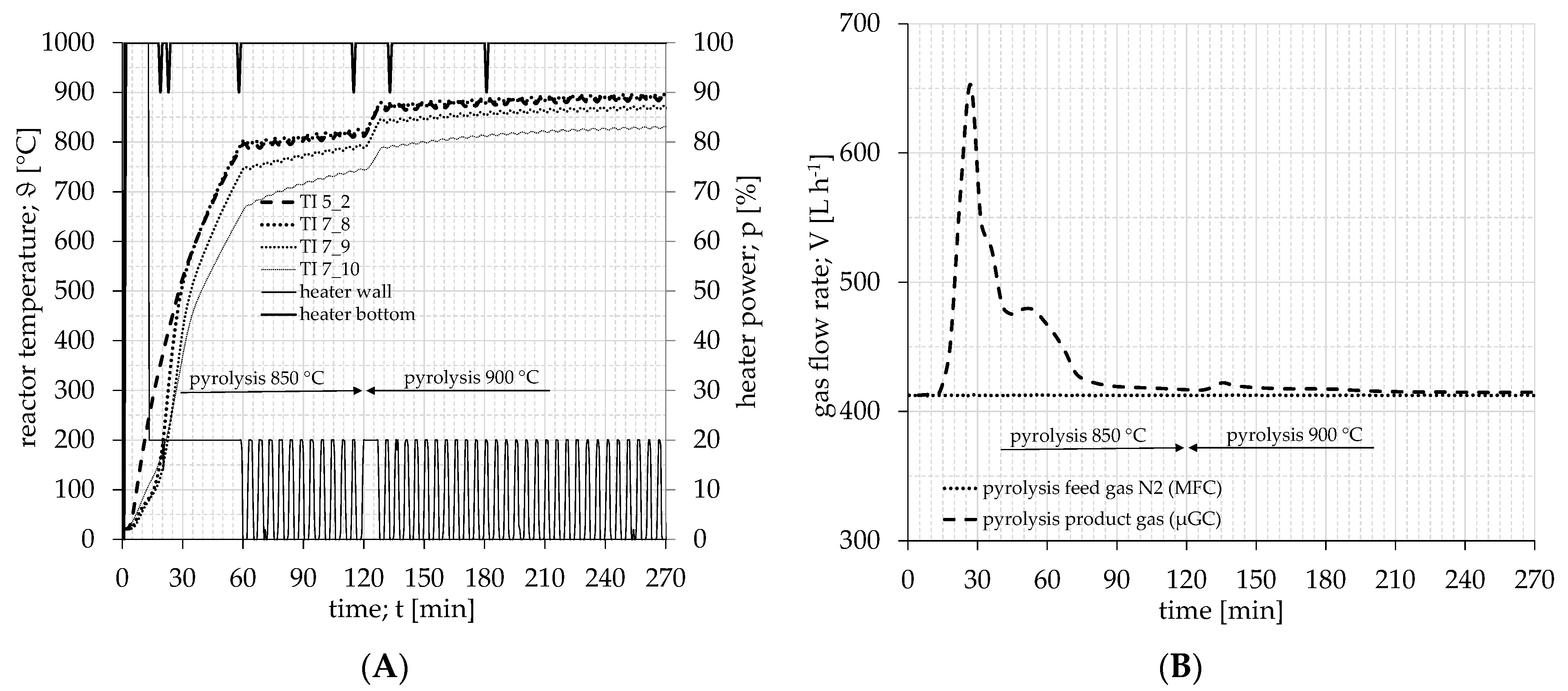

2.1. Fixed–Bed Batch Reactor Wood Chip Pyrolysis

2.2. Char Powder Gasification

2.3. Single Particle Char Gasification

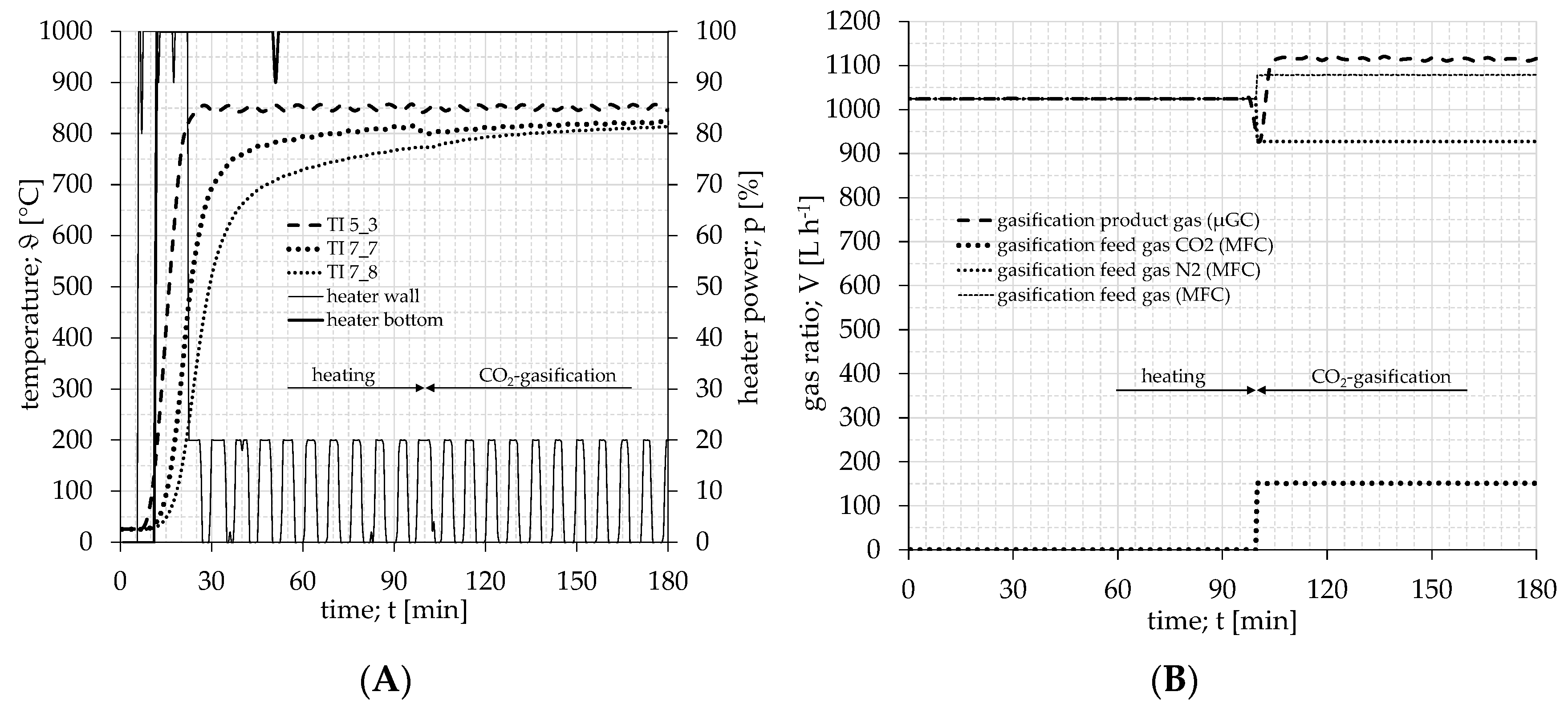

2.4. Fixed–Bed Batch Char Gasification

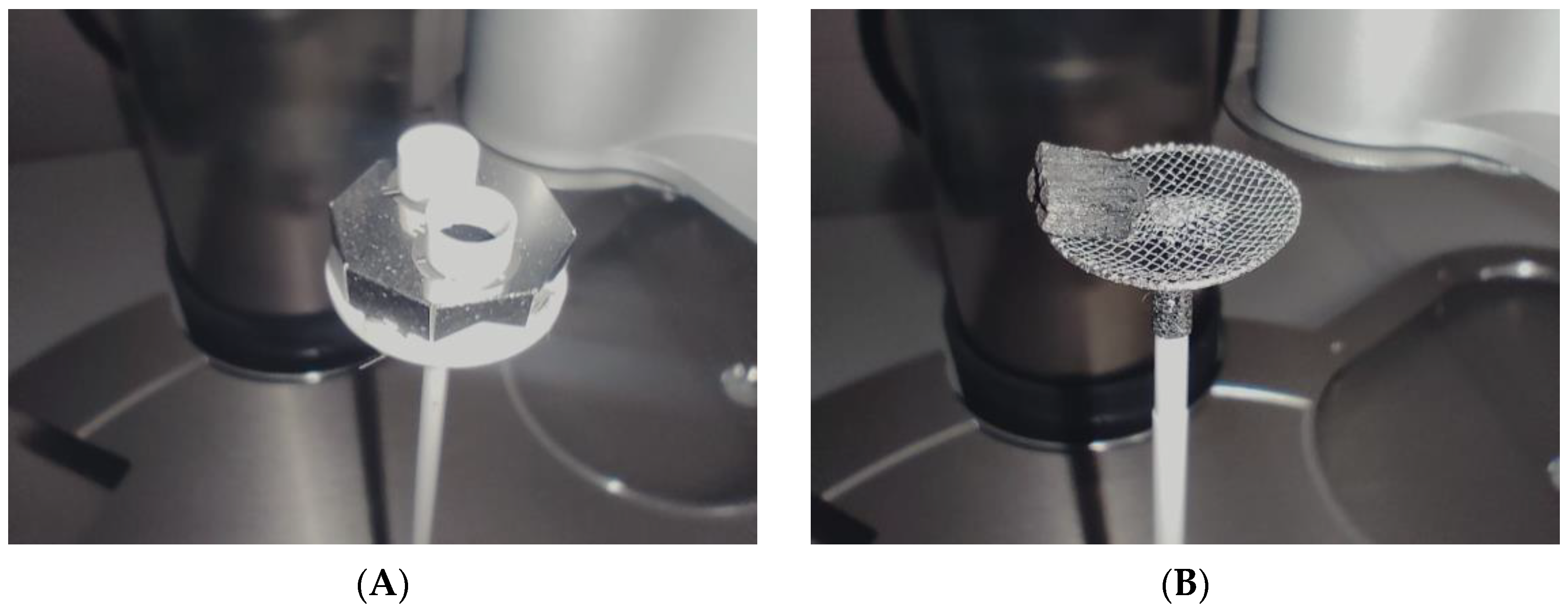

2.5. Model for Laboratory Reactor

| Description | Original | Ref. | Adaption for Laboratory Reactor | Equation No. | ||

|---|---|---|---|---|---|---|

| transport of solids and change of solid mass | [4] | (1a) | (1b) | |||

| gas transport and | [4] | (2a) | (2b) | |||

| gas velocity | not explicitly described in reference | (-) | (3) | |||

| energy and heat transport | [4] | (4) | (5) | |||

| (6) | ||||||

| (7) | ||||||

| = −2.0448 × 10−14 = 5.5397 × 10−10 = −4.9341 × 10−6 = 2.2135 × 10−2 = 7.6942 × 102 | = −6.1077 × 10−7 = 7.1354 × 10−3 = 8.0184 × 102 | (8) | (-) | |||

| wall heater | [4] | not applied | (9) | (-) | ||

| particle porosity | [4] | (10a) | (10b) | |||

| water evaporation | [33] | not applied | (11) | (-) | ||

| pyrolysis | [4] | not applied | (12) | (-) | ||

| mass transport coefficient | [32] | applied | (13) | (-) | ||

| Sherwood–number | [32] | applied | (14) | (-) | ||

| binary diffusion coefficient | [34] | applied | (15) | (-) | ||

| effective diffusion coefficient | with and | [32] | applied | (16) | (-) | |

| modified Thiele–modulus | [32] | (17a) | (17b) | |||

| effectiveness factor | [32] | applied | (18) | (-) | ||

| effective reaction rate | [35] | applied | (19) | (-) | ||

3. Results and Discussion

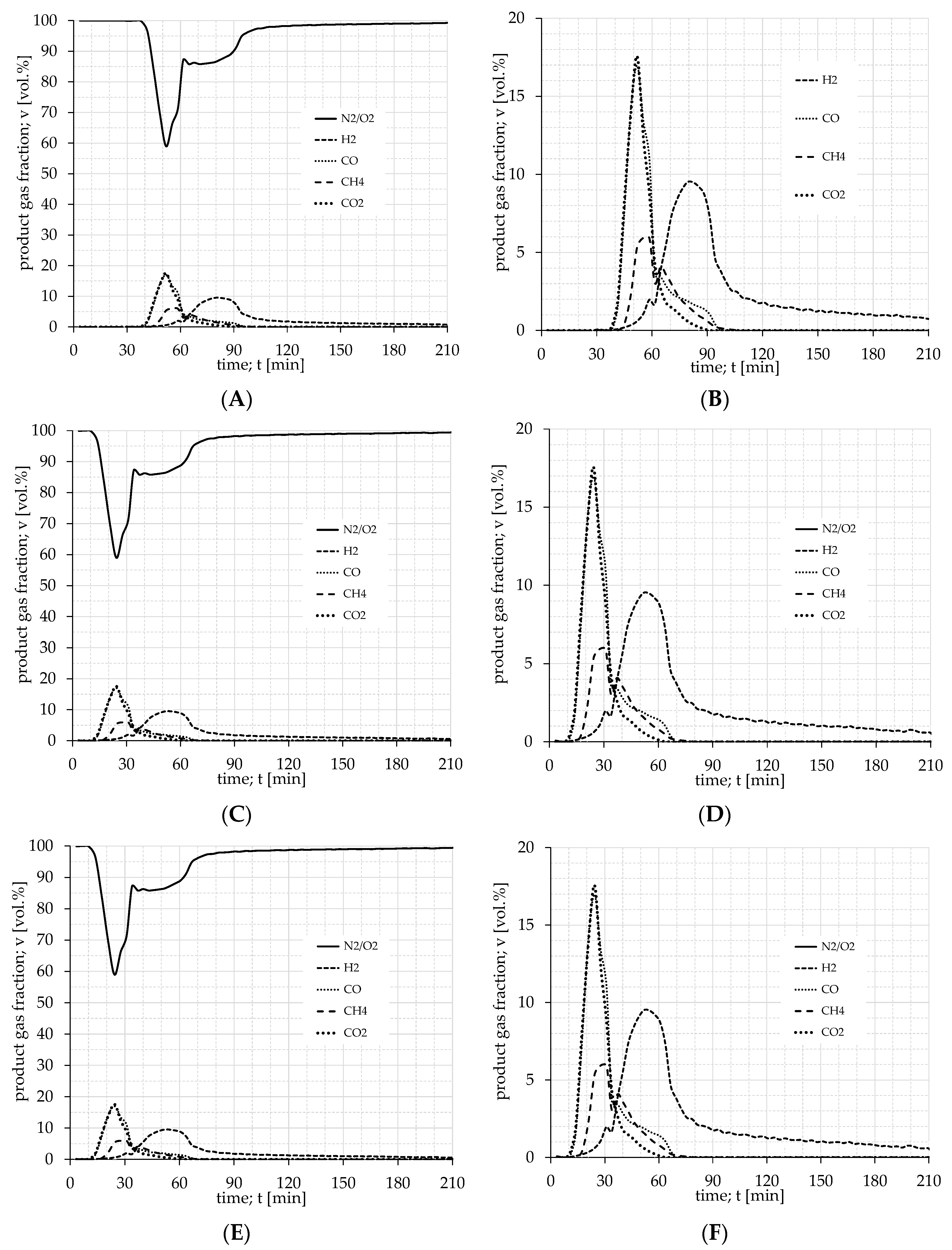

3.1. Pyrolysis

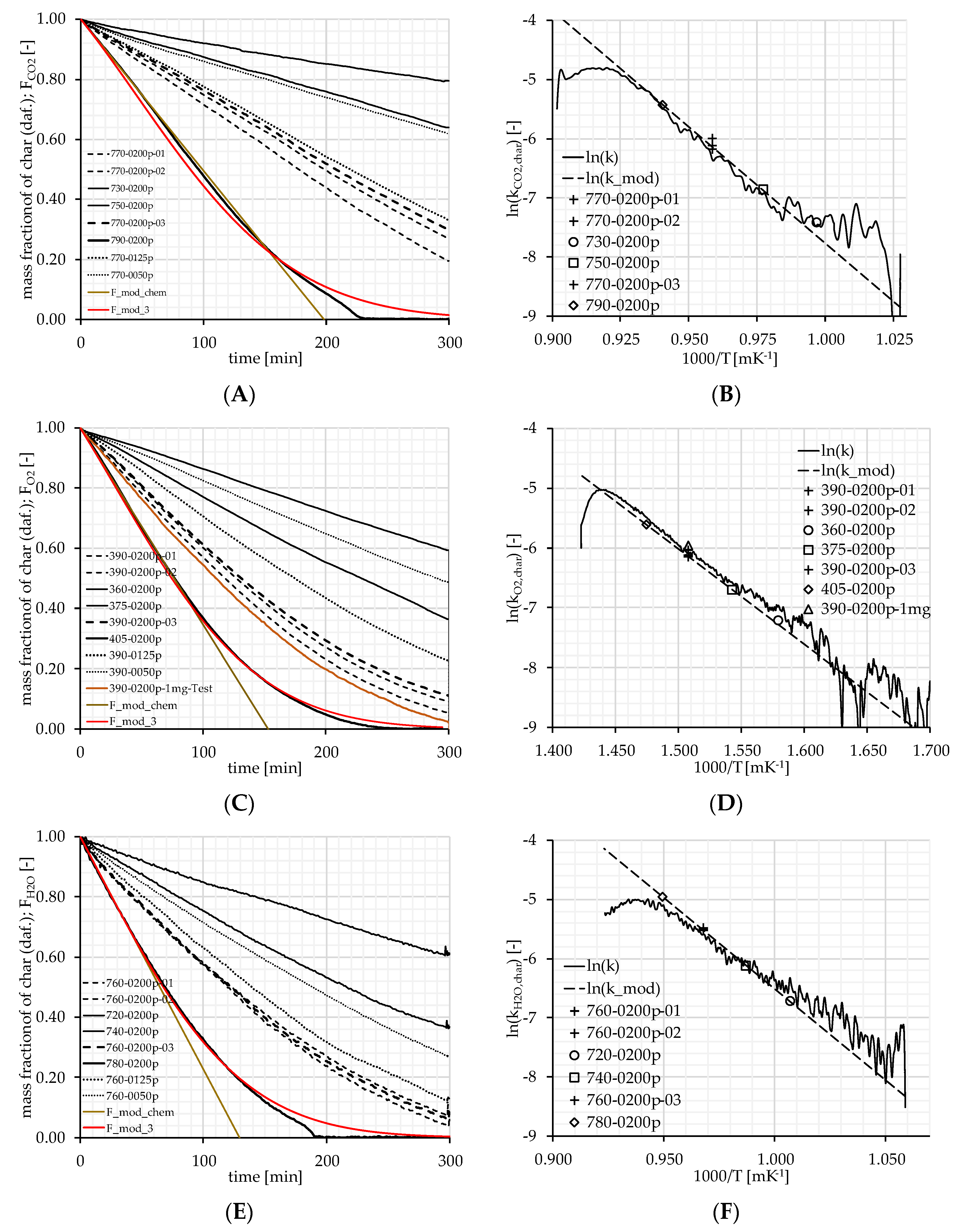

3.2. Char Powder Gasification

- the dependence on actual mass is of order zero in the first 25% of conversion;

- the reaction rate is chemically controlled without diffusion effects;

- a simple power law applies with respect to the reactive gas concentration;

- is a hypothetical molar mass based on an ultimate analysis;

- is dry and ash free (daf).

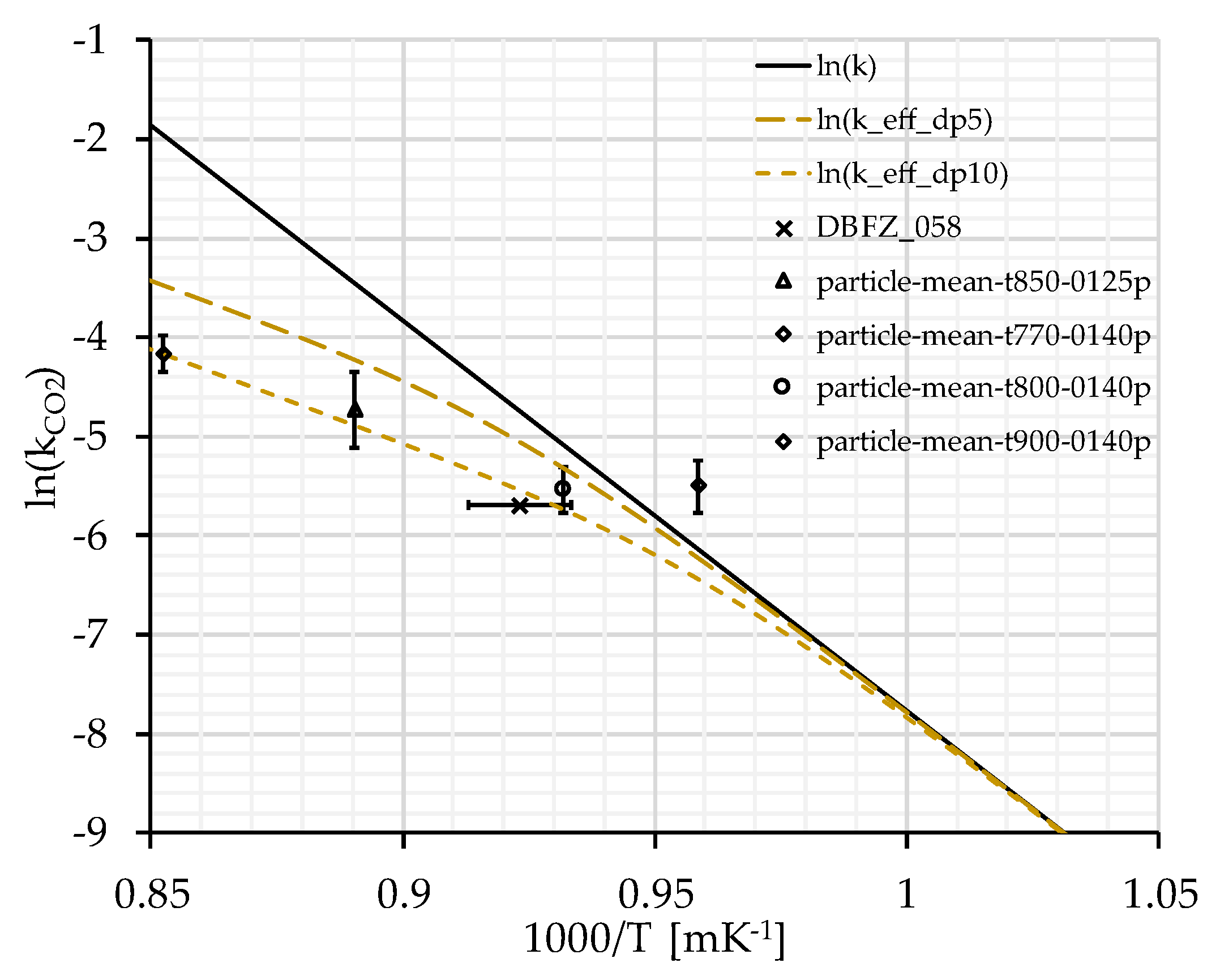

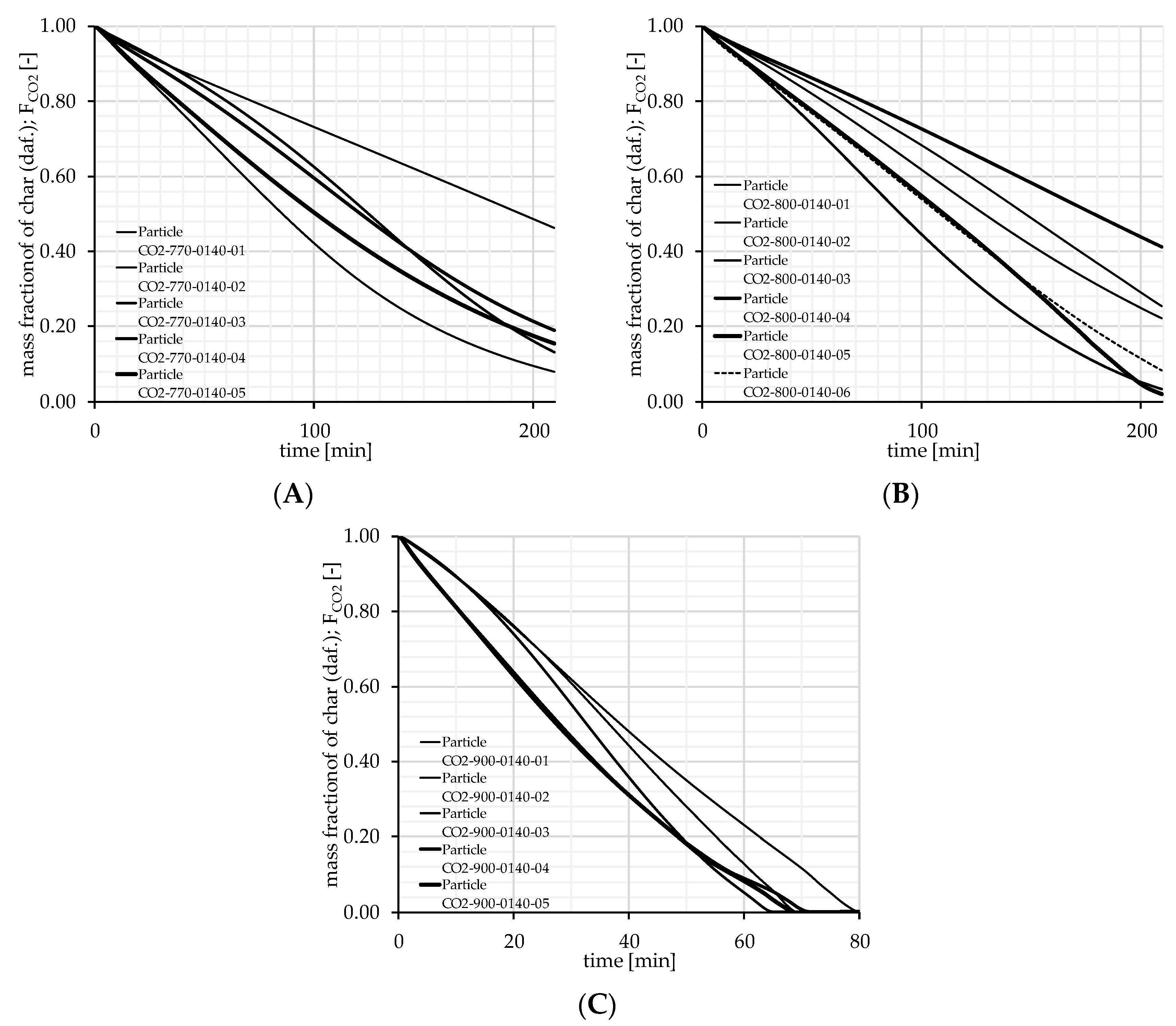

3.3. Single Particle Char Gasification

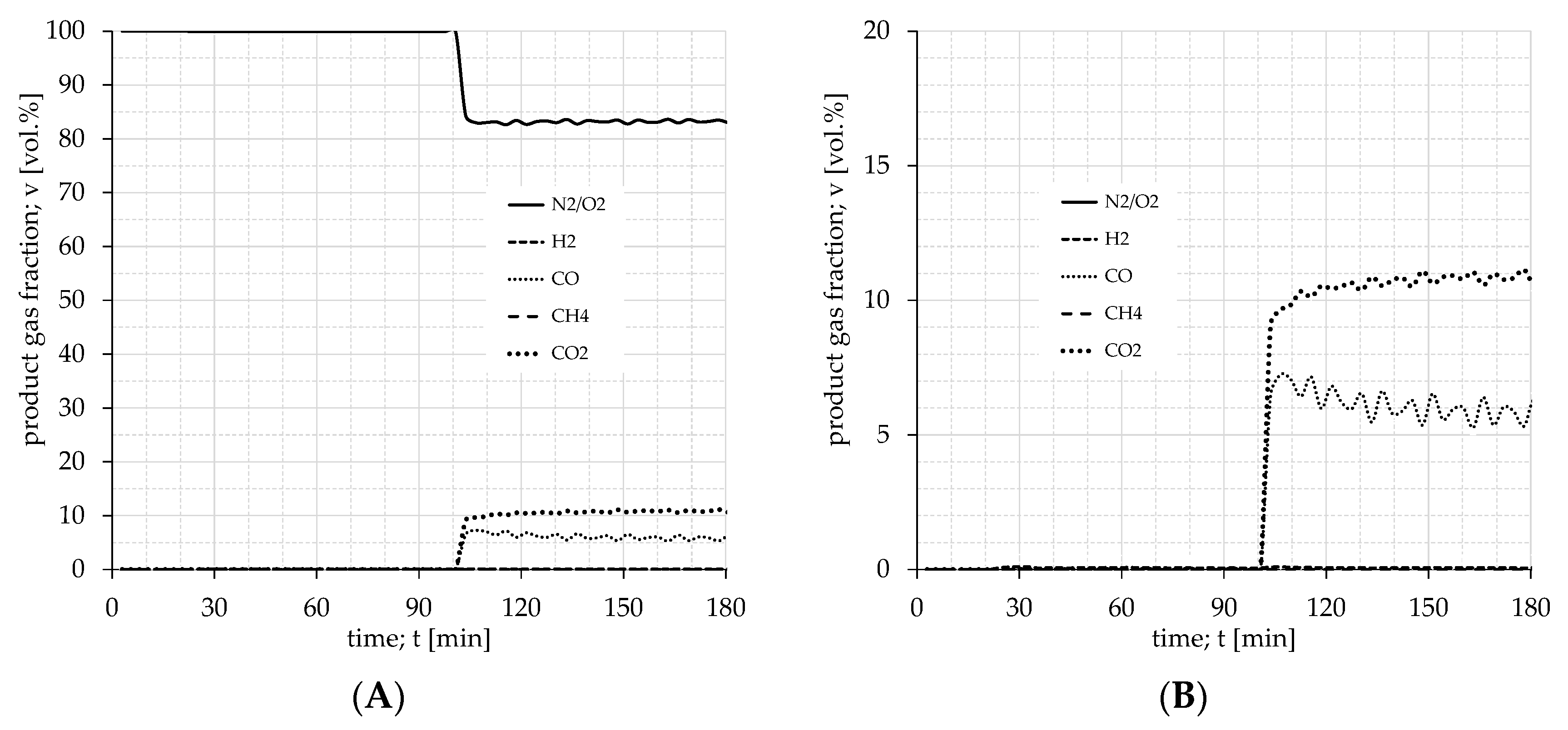

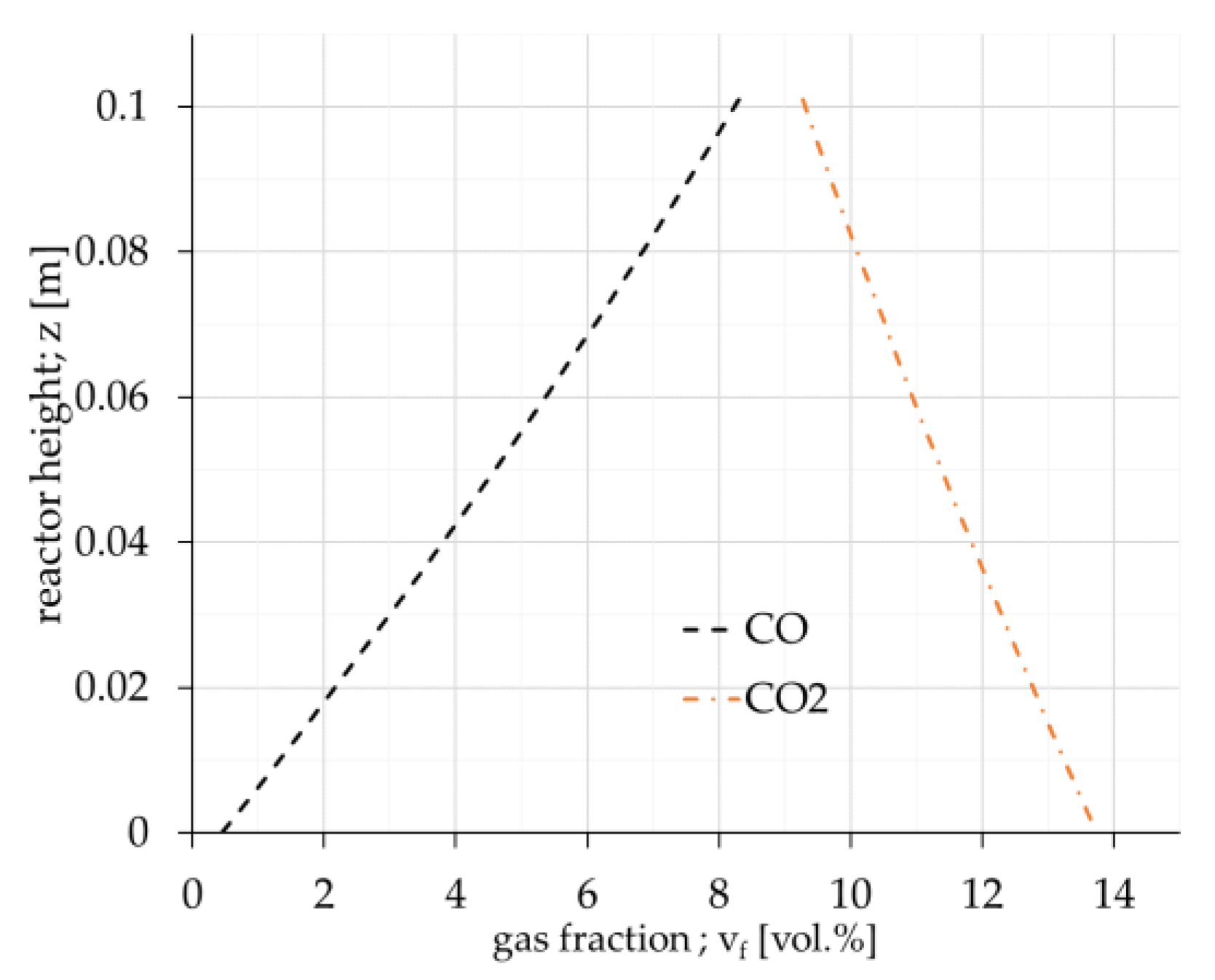

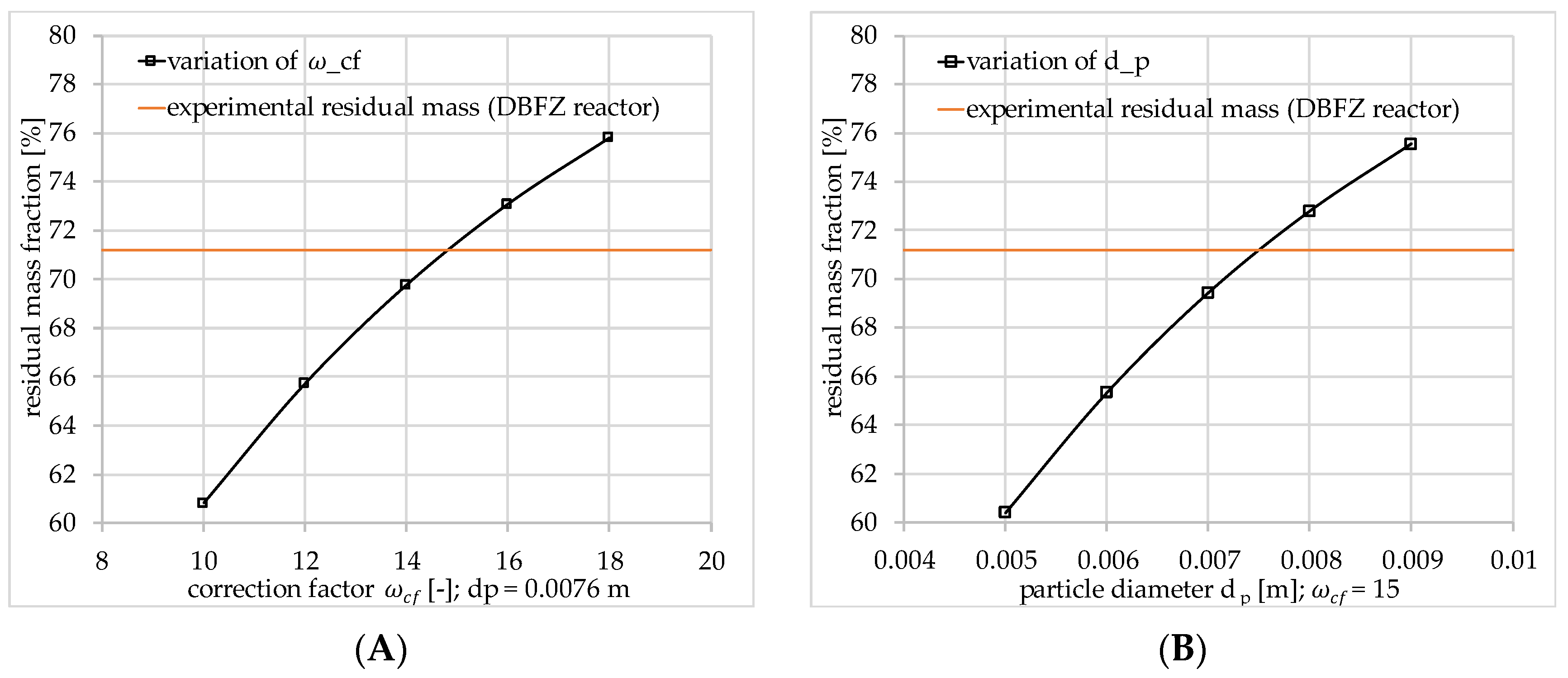

3.4. Fixed–Bed Batch Char Gasification and Model Comparison

3.5. Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols Used | Unit | |

| A0 | preexponential factor | m3 kg−1 |

| c | molar concentration | mol m−3 |

| cp | heat capacity | J kg−1 K−1 |

| d, di | diameter, inner diameter | M |

| D | diffusion coefficient | m2 s−1 |

| EA | activation energy | kJ mol−1 |

| F | residual mass fraction | - |

| h | height | m |

| H | reaction enthalpy | J mol−1 |

| l | length | m |

| L0 | total length of overlapped system per unit volume | cm cm3 |

| M | molar mass | kg mol−1 |

| n | number | |

| Nu | Nusselt number | - |

| p0 | atmospheric pressure | kg m−1 s−2 |

| Q | heat flow | - |

| r | reaction rate | mol s−1 m−3 |

| R | gas constant | J kg−1 mol−1 |

| Re | Reynolds number | - |

| S | surface area | m2 |

| S0 | inner surface area per unit volume at t=0 | cm2 cm3 |

| Sp,o | outer surface area per unit mass of particle | m² kg−1 |

| Sc | Schmidt number | - |

| Sh | Sherwood number | - |

| t | time | s |

| T | absolute temperature | K |

| U | velocity | m s−1 |

| vf | volume fraction | - |

| w | mass fraction | - |

| Sauter diameter | m | |

| X | conversion | - |

| z | coordinate | m |

| Sub– and Superscripts | Unit | |

| 0 | at the beginning | |

| bm | biomass | |

| chem | chemically | |

| char | investigated char | |

| eff | effective | |

| g | gas | |

| i | indicator solid species; numerical time step | |

| j | indicator gaseous species | |

| n | numerical element step | |

| p | particle | |

| pyr | pyrolysis | |

| s | solid | |

| t | time dependent | |

| TC | thermocouple | |

| total | e.g., total porosity | |

| w | wall | |

| Greek Letters | ||

| mass transfer coefficient | m s−1 | |

| mass concentration | kg m−3 | |

| porosity | mg3 m−3 | |

| structure factor | - | |

| Thiele modulus | - | |

| reaction order | - | |

| density | kg m−3 | |

| tortuosity | - | |

| heat conductivity | W m−1 K−1 | |

| effectiveness factor | - | |

| temperature | °C | |

| structural factor | - | |

| correction factor | - | |

| Abbreviations | ||

| n.d. | not detectable | |

| ASC | automatic sample changer | |

| DSC | differential scanning calorimetry | |

| DWC | defined wooden chips | |

| daf | dry ash free | |

| FTIR | Fourier-transform infrared spectroscopy | |

| ICP-OES | inductively coupled plasma optical emission spectrometry | |

| µGC | micro gas chromatography | |

| MFC | mass flow controller | |

| SD | standard deviation | |

| TGA | thermogravimetric analysis |

Appendix A

| Amount [mg kg−1(Dry)] | ||

|---|---|---|

| Element | Spruce | Char |

| Aluminum | 4.35 | 34 |

| Barium | 27.6 | 86.2 |

| Cadmium | 0.375 | n.d. |

| Calcium | 1150 | 3060 |

| Chrome | 0.642 | 3.88 |

| Cobalt | 0.399 | 0.202 |

| Copper | 0.904 | 3.27 |

| Iron | 15.1 | 49.6 |

| Lead | n.d. | n.d. |

| Lithium | n.d. | n.d. |

| Magnesium | 160 | 480 |

| Mangan | 350 | 603 |

| Molybdenum | n.d. | n.d. |

| Nickel | 0.662 | 5.53 |

| Phosphorus | 48.5 | 192 |

| Potassium | 260 | 1570 |

| Silicon | 48.2 | n.d. |

| Sodium | n.d. | 41.3 |

| Strontium | 7.17 | 20.3 |

| Sulfur | 84.4 | 94.9 |

| Thallium | n.d. | n.d. |

| Titanium | 0.881 | 8.95 |

| Tungsten | n.d. | n.d. |

| Zinc | 16.8 | 37.5 |

References

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- Anca-Couce, A. Reaction mechanisms and multi-scale modelling of lignocellulosic biomass pyrolysis. Prog. Energy Combust. Sci. 2016, 53, 41–79. [Google Scholar] [CrossRef]

- Di Blasi, C. Heat, momentum and mass transport through a shrinking biomass particle exposed to thermal radiation. Chem. Eng. Sci. 1996, 51, 1121–1132. [Google Scholar] [CrossRef]

- Gradel, A.; Honke, R.; Wünning, J.A.; Plessing, T.; Jess, A. Modeling of Biomass Gasification in a Downdraft Gasifier with Integrated Tar Adsorption. Chem. Eng. Technol. 2019, 42, 1895–1906. [Google Scholar] [CrossRef]

- Kaltschmitt, M.; Hartmann, H.; Hofbauer, H. Energie aus Biomasse: Grundlagen Techniken und Verfahren, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-662-47437-2. [Google Scholar]

- Basu, P. Gasification Theory. In Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory, 3rd ed.; Basu, P., Ed.; Academic Press: London, UK, 2018; pp. 211–262. ISBN 9780128129920. [Google Scholar]

- Neves, D.; Thunman, H.; Matos, A.; Tarelho, L.; Gómez-Barea, A. Characterization and prediction of biomass pyrolysis products. Prog. Energy Combust. Sci. 2011, 37, 611–630. [Google Scholar] [CrossRef]

- Morin, M.; Pécate, S.; Masi, E.; Hémati, M. Kinetic study and modelling of char combustion in TGA in isothermal conditions. Fuel 2017, 203, 522–536. [Google Scholar] [CrossRef]

- Guerrero, M.; Ruiz, M.P.; Alzueta, M.U.; Bilbao, R.; Millera, A. Pyrolysis of eucalyptus at different heating rates: Studies of char characterization and oxidative reactivity. J. Anal. Appl. Pyrolysis 2005, 74, 307–314. [Google Scholar] [CrossRef]

- Cetin, E.; Moghtaderi, B.; Gupta, R.; Wall, T. Influence of pyrolysis conditions on the structure and gasification reactivity of biomass chars. Fuel 2004, 83, 2139–2150. [Google Scholar] [CrossRef]

- Kumar, M.; Gupta, R.C. Influence of carbonization conditions on the gasification of acacia and eucalyptus wood chars by carbon dioxide. Fuel 1994, 73, 1922–1925. [Google Scholar] [CrossRef]

- Fushimi, C.; Araki, K.; Yamaguchi, Y.; Tsutsumi, A. Effect of Heating Rate on Steam Gasification of Biomass. 1. Reactivity of Char. Ind. Eng. Chem. Res. 2003, 42, 3922–3928. [Google Scholar] [CrossRef]

- Mermoud, F.; Salvador, S.; Vandesteene, L.; Golfier, F. Influence of the pyrolysis heating rate on the steam gasification rate of large wood char particles. Fuel 2006, 85, 1473–1482. [Google Scholar] [CrossRef]

- Okumura, Y.; Hanaoka, T.; Sakanishi, K. Effect of pyrolysis conditions on gasification reactivity of woody biomass-derived char. Proc. Combust. Inst. 2009, 32, 2013–2020. [Google Scholar] [CrossRef]

- Zanzi, R.; Sjöström, K.; Björnbom, E. Rapid high-temperature pyrolysis of biomass in a free-fall reactor. Fuel 1996, 75, 545–550. [Google Scholar] [CrossRef]

- Morin, M.; Pécate, S.; Hémati, M.; Kara, Y. Pyrolysis of biomass in a batch fluidized bed reactor: Effect of the pyrolysis conditions and the nature of the biomass on the physicochemical properties and the reactivity of char. J. Anal. Appl. Pyrolysis 2016, 122, 511–523. [Google Scholar] [CrossRef]

- Irfan, M.F.; Usman, M.R.; Kusakabe, K. Coal gasification in CO2 atmosphere and its kinetics since 1948: A brief review. Energy 2011, 36, 12–40. [Google Scholar] [CrossRef]

- Federal Ministry of Food and Agriculture. Holzmarktbericht 2021: Abschlussergebnisse für die Forst- und Holzwirtschaft des Wirtschaftsjahres. 2021. Available online: https://www.bmel-statistik.de/forst-holz/holzmarkt/holzmarktberichte (accessed on 7 March 2023).

- ICS 75.160.40 (DIN EN ISO 16948); Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2015.

- ICS 75.160.40 (DIN EN ISO 16967:2015); Solid Biofuels—Determination of Major Elements. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2015.

- ICS 75.160.40 (DIN EN ISO 16968); Solid Biofuels—Determination of Minor Elements. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2015.

- ICS 75.160.40 (DIN EN 14775); Solid Biofuels—Determination of Ash Content. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2012.

- ICS 75.160.10 (DIN 51719); Testing of Solid Fuels—Solid Mineral Fuels—Determination of Ash Content. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 1997.

- ICS 75.160.40 (DIN EN 14774-2); Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2010.

- ICS 75.160.40 (DIN EN ISO 18123); Solid Biofuels—Determination of the Content of Volatile Matter. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2016.

- Dufourny, A.; van de Steene, L.; Humbert, G.; Guibal, D.; Martin, L.; Blin, J. Influence of pyrolysis conditions and the nature of the wood on the quality of charcoal as a reducing agent. J. Anal. Appl. Pyrolysis 2019, 137, 1–13. [Google Scholar] [CrossRef]

- ICS 19.120 (DIN ISO 9276-2); Representation of Results of Particle Size Analysis—Part 2: Calculation of Average Particle Sizes/Diameters and Moments from Particle Size Distributions. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2006.

- ICS 75.160.40 (DIN EN 15149-1); Solid Biofuels—Determination of Particle Size Distribution—Part 1: Oscillating Screen Method Using Sieve Apertures of 1 Mm and Above. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2011.

- ICS 75.160.40 (DIN EN ISO 18125:2017-08); Solid Biofuels—Determination of Calorific Value. Beuth Verlag GmbH: Berlin/Heidelberg, Germany, 2017.

- Magnaterra, M.; Fusco, J.R.; Ochoa, J.; Cukierman, A.L. Kinetic Study of the Reaction of Different Hardwood Sawdust Chars with Oxygen. Chemical and Structural Characterization of the Samples. In Advances in Thermochemical Biomass Conversion; Bridgwater, A.V., Ed.; Springer: Dordrecht, The Netherlands, 1993; pp. 116–130. ISBN 978-94-010-4582-7. [Google Scholar]

- Benson, B.B.; Krause, D. The Concentration and Isotopic Fractionation of Gases Dissolved in Freshwater in Equilibrium with the Atmosphere. 1. Oxygen. Available online: http://www.jstor.org/stable/2835754 (accessed on 6 August 2021).

- Jess, A.; Wasserscheid, P. Chemical Technology: An Integral Textbook; Wiley-VCH: Weinheim, Germany, 2013; ISBN 978-3-527-30446-2. [Google Scholar]

- Baehr, H.D.; Stephan, K. Wärme- und Stoffübertragung, 9th ed.; aktualisierte Auflage; Springer Vieweg: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-662-49676-3. [Google Scholar]

- Fuller, E.N.; Schettler, P.D.; Giddings, J.C. New method for prediction of binary gas-phase diffusion coefficients. Ind. Eng. Chem. 1966, 58, 18–27. [Google Scholar] [CrossRef]

- Gradel, A. Gleichstromvergasung von Holzpellets mit integrierter Adsorption von Teerkomponenten. Ph.D. Thesis, Universität Bayreuth, Bayreuth, Germany, 2020. [Google Scholar]

- Kashiwagi, T.; Nambu, H. Global kinetic constants for thermal oxidative degradation of a cellulosic paper. Combust. Flame 1992, 88, 345–368. [Google Scholar] [CrossRef]

- Várhegyi, G.; Sebestyén, Z.; Czégény, Z.; Lezsovits, F.; Könczöl, S. Combustion Kinetics of Biomass Materials in the Kinetic Regime. Energy Fuels 2012, 26, 1323–1335. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Perlmutter, D.D. A random pore model for fluid-solid reactions: I. Isothermal, kinetic control. AIChE J. 1980, 26, 379–386. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Perlmutter, D.D. A random pore model for fluid-solid reactions: II. Diffusion and transport effects. AIChE J. 1981, 27, 247–254. [Google Scholar] [CrossRef]

- Anca-Couce, A.; Sommersacher, P.; Scharler, R. Online experiments and modelling with a detailed reaction scheme of single particle biomass pyrolysis. J. Anal. Appl. Pyrolysis 2017, 127, 411–425. [Google Scholar] [CrossRef]

- Grieco, E.; Baldi, G. Analysis and modelling of wood pyrolysis. Chem. Eng. Sci. 2011, 66, 650–660. [Google Scholar] [CrossRef]

- Di Blasi, C. Combustion and gasification rates of lignocellulosic chars. Prog. Energy Combust. Sci. 2009, 35, 121–140. [Google Scholar] [CrossRef]

- Schneider, C.; Zeller, M.; Böhm, D.; Kolb, T. Influence of pressure on the gasification kinetics of two high-temperature beech wood chars with CO2, H2O and its mixture. Fuel 2021, 299, 120523. [Google Scholar] [CrossRef]

- Trubetskaya, A. Reactivity Effects of Inorganic Content in Biomass Gasification: A Review. Energies 2022, 15, 3137. [Google Scholar] [CrossRef]

- Wu, R.; Beutler, J.; Price, C.; Baxter, L.L. Biomass char particle surface area and porosity dynamics during gasification. Fuel 2020, 264, 116833. [Google Scholar] [CrossRef]

- Liang, D.; Singer, S. Pore-resolving simulations to study the impacts of char morphology on zone II combustion and effectiveness factor models. Combust. Flame 2021, 229, 111405. [Google Scholar] [CrossRef]

- Nguyen, C.B.; Scherer, J.; Hartwich, M.; Richter, A. The morphology evolution of char particles during conversion processes. Combust. Flame 2021, 226, 117–128. [Google Scholar] [CrossRef]

| Description and Properties | Values | Unit | Comments | ||

|---|---|---|---|---|---|

| Wood | Char | ||||

| type | spruce | - | - | not further specified | |

| origin | calamity wood germany | - | - | - | |

| particle size | >1 mm | 0.1 wt.% | - | - | DIN EN 15149-1 [28] |

| >3.15 mm | 1.7 wt.% | - | - | - | |

| >8 mm | 96.9 wt.% | - | - | - | |

| >16 mm | 1.3 wt.% | - | - | - | |

| average dimensions | 16 × 11 × 4 | 11 × 8 × 3 | mm | statistical ( = 30) | |

| Sauter diameter, | 0.0105 | 0.0076 | m | DIN EN ISO 9276-2 [27] | |

| bulk density | 178.4 | 118.8 | kg m−3 | statistical ( = 10) | |

| true density | - | 1850 | kg m−3 | [26] | |

| apparent density | 405 | 221 | kg m−3 | [26] | |

| particle porosity | - | 0.88 | - | [26] | |

| HHV | 20,080 | 32,500 | kJ kg−1 | DIN EN ISO 18125 [29] | |

| LHV | 18,790 | 31,830 | kJ kg−1 | DIN EN ISO 18125 [29] | |

| bark fraction | <1 | <1 | wt.% | - | |

| ash content at 550 °C | 0.38 | 1.5 | wt.% (dry) | DIN EN 14775 [22] | |

| ash content at 855 °C | - | 1.55 | wt.% (dry) | DIN 51719 [23] | |

| water content | 15.2 | 2.6 | wt.% | DIN EN 14774-2 [24] | |

| volatile matter | 84.5 | - | wt.% | DIN EN ISO 18123 [25] | |

| ultimate analysis | DIN EN ISO 16948 [19] | ||||

| C | 51 | 85.9 | wt.% (dry) | - | |

| H | 6.09 | 2.93 | wt.% (dry) | - | |

| S | n.d. | n.d. | wt.% (dry) | not detectable (below detection limit) | |

| O | 42.91 | 10.84 | wt.% (dry) | calculated residual | |

| N | n.d. | n.d. | wt.% (dry) | - | |

| ICP–OES Total analysis | 24 elements | 24 elements | mg kg−1 | DIN EN ISO 16967 [20] DIN EN ISO 16968 [21] results in Appendix A | |

| Step | Mode | Temperature [°C] | Heating Rate [K min−1] | Duration [min] | Gas Flowrate [mL min−1] | Comments |

|---|---|---|---|---|---|---|

| #1 | start | 40 | - | - | 200 N2 | - |

| #2 | heating 1 | to 130 | 20 | - | 200 N2 | - |

| #3 | isothermal | at 130 | - | 30 | 200 N2 | to fully evaporate the humidity and inertiziation |

| #4 | heating 2 | Ttarget−15 | 20 | - | 200 N2 | fast heating to approximate Ttarget |

| #5 | heating 3 | Ttarget | 5 | 3 | 200 N2 | slow heating to acquire Ttarget |

| #6 | isothermal | Ttarget | - | 40 | 200 N2 | time to stabilize after heating |

| #7 | isothermal | Ttarget | - | 300 | switch to reactive gas mixture with total flowrate of 200 | heterogeneous reaction |

| #8 | end | - | - | - | - | - |

| Gas | V01 | V02 | V03 | V04 | V05 | V06 | V07 | V08 | |

|---|---|---|---|---|---|---|---|---|---|

| CO2 | Ttarget,CO2 [°C] | 770 | 770 | 730 | 750 | 770 | 790 | 770 | 770 |

| [vol.%] | 20 | 20 | 20 | 20 | 20 | 20 | 12.5 | 5 | |

| O2 | Ttarget,O2 [°C] | 390 | 390 | 360 | 375 | 390 | 405 | 390 | 390 |

| [vol.%] | 20 | 20 | 20 | 20 | 20 | 20 | 12.5 | 5 | |

| H2O | Ttarget,H2O [°C] | 760 | 760 | 720 | 740 | 760 | 780 | 760 | 760 |

| [vol.%] | 20 | 20 | 20 | 20 | 20 | 20 | 12.5 | 5 |

| Experiment Number | Pyrolysis Temperature [°C] | Heating Ratio [K min−1] | Input | Output | |||||

|---|---|---|---|---|---|---|---|---|---|

| Fuel Mass [g] | Char Mass (Reactor) | Gas (Dry, STP) | Condensate (Calculated) | ||||||

| [g] | [%] | [g] | [%] | [g] | [%] | ||||

| 2021-00078 | 500 | 7–10 | 470.3 | 120.7 | 25.7 | 71.5 | 15.2 | 278.0 | 59.1 |

| 2021-00079 | 490.1 | 126.6 | 25.8 | 74.5 | 15.2 | 289.1 | 59.0 | ||

| 2021-00084 | 458.8 | 118.3 | 25.8 | 65.9 | 14.4 | 274.6 | 59.9 | ||

| 2021-00108 | 480.5 | 124.2 | 25.8 | 65.2 | 13.6 | 291.1 | 60.6 | ||

| 2021-00122 | 485.6 | 127.5 | 26.3 | 70.2 | 14.4 | 288.0 | 59.3 | ||

| 2021-00210 | 490.2 | 122.6 | 25.0 | 71.3 | 14.5 | 296.3 | 60.4 | ||

| 2021-00213 | 476.9 | 124.7 | 26.1 | 67.4 | 14.1 | 284.8 | 59.7 | ||

| 2022-00027 | 850 | 12–13 | 481.3 | 105.4 | 21.9 | 93.6. | 19.4 | 282.3 | 58.6 |

| 2022-00028 | 463.5 | 101.2 | 21.8 | 89.8 | 19.4 | 272.6 | 58.8 | ||

| 2022-00040 | 461.1 | 101.3 | 22.0 | 93.0 | 20.2 | 266.8 | 57.9 | ||

| 2022-00041 | 475.2 | 104.6 | 22.0 | 98.3 | 20.7 | 272.3 | 57.3 | ||

| 2022-00057 | 850/900 | 481.2 | 101.6 | 21.1 | 88.0 | 18.3 | 291.6 | 60.6 | |

| 2022-00065 | 470.1 | 101.9 | 21.7 | 84.0 | 17.9 | 284.2 | 60.5 | ||

| 2022-00134 | 466.7 | 98.1 | 21.0 | 84.1 | 18.0 | 284.5 | 61.0 | ||

| 2022-00138 | 463.3 | 101.4 | 21.9 | 85.0 | 18.3 | 276.9 | 59.8 | ||

| Gas | Volume Fraction [vol.%] | Maximum Error [vol.%]?? |

|---|---|---|

| H2 | 38.7 | ±3.5 |

| CO | 26.6 | ±3.0 |

| CH4 | 22.1 | ±3.4 |

| CO2 | 11.9 | ±0.1 |

| C2H4 | 0.1 | ±2.4 |

| C2H6 | 0.6 | ±0.7 |

| Gas | Ash–Content [wt.%] | SD [wt.%] | Estimated Possible dF/dt Error [%] |

|---|---|---|---|

| CO2 | 2.48 | 0.47 | 1.5 |

| O2 | 4.14 | 0.97 | 2.5 |

| H2O | 5.28 | 2.63 | 6 |

| Gas, j | |||

|---|---|---|---|

| CO2 | 5.30 × 1013 | 3.27 × 102 | 0.41 |

| O2 | 5.79 × 107 | 1.32 × 102 | 0.61 |

| H2O | 3.8 × 1010 | 2.57 × 102 | 0.34 |

| Particle | Approx. Size [mm] | Volume [mm³] | Weight [mg] | [×10−5 s−1] | Approx. [kg m−3] | ||

|---|---|---|---|---|---|---|---|

| L | W | H | |||||

| 01 | 7 | 7 | 3.2 | 156.8 | 29.5 | 4.57 | 245 |

| 02 | 8.9 | 5.9 | 4.2 | 220.5 | 36.6 | 9.75 | 151 |

| 03 | 9.2 | 7.8 | 2.9 | 208.1 | 23.9 | 5.89 | 102 |

| 04 | 9.7 | 7.5 | 3 | 218.3 | 33.1 | 6.56 | 395 |

| 05 | 12.7 | 7 | 3.5 | 311.2 | 58.8 | 8.44 | 198 |

| Avg. | 9.5 | 7.0 | 3.4 | 223.0 | 36.4 | 7.04 | 162 |

| Std.dev. | 1.8 | 0.7 | 0.5 | 49.8 | 12.0 | 1.84 | 27 |

| Particle | Approx. Size [mm] | Volume [mm³] | Weight [mg] | [×10−5 s−1] | Approx. [kg m−3] | ||

|---|---|---|---|---|---|---|---|

| L | W | H | |||||

| 01 | 6.9 | 5.3 | 3.3 | 120.7 | 29.6 | 5.17 | 245 |

| 02 | 10.5 | 7.1 | 2.7 | 201.3 | 30.4 | 6.18 | 151 |

| 03 | 10 | 7.5 | 5.5 | 412.5 | 41.9 | 8.68 | 102 |

| 04 | 7.2 | 7 | 2.4 | 121.0 | 47.8 | 4.56 | 395 |

| 05 | 9 | 8.2 | 3.5 | 258.3 | 51.2 | 7.19 | 198 |

| 06 | 7.1 | 6.8 | 4.1 | 198.0 | 47.1 | 8.02 | 238 |

| Avg. | 8.5 | 7.0 | 3.6 | 218.6 | 41.3 | 6.63 | 222 |

| Std.dev. | 1.5 | 0.9 | 1.0 | 99.2 | 8.5 | 1.47 | 92 |

| Particle | Approx. Size [mm] | Volume [mm³] | Weight [mg] | [×10−5 s−1] | Approx. [kg m−3] | ||

|---|---|---|---|---|---|---|---|

| L | W | H | |||||

| 01 | 8.5 | 6.2 | 2.8 | 147.6 | 28.7 | 20.7 | 195 |

| 02 | 6.7 | 6.6 | 3.2 | 141.5 | 28.3 | 20.6 | 200 |

| 03 | 8 | 6.1 | 3.9 | 190.3 | 25.1 | 22.9 | 132 |

| 04 | 6.9 | 5.4 | 3.5 | 130.4 | 21.6 | 30.4 | 166 |

| 05 | 5.5 | 5.1 | 2.8 | 79.5 | 15.4 | 31.0 | 196 |

| Avg. | 7.1 | 5.9 | 3.2 | 137.7 | 23.8 | 25.1 | 178 |

| Std.dev. | 1.1 | 0.6 | 0.4 | 36.9 | 4.9 | 4.65 | 26 |

| Experiment Number | Pyrolysis Temperature [°C] | Heating Ratio [K min−1] | Input | Output | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Mass (Reactor) | Gasification Agent | ∑in | ∑out | Char Mass (Reactor) | Gas (Dry, STP) | |||||

| [g] | [g] | [g] | [g] | [g] | [%] | [g] | [%] | |||

| 2022-00047 | 850 | 31–34 | 102.6 (2022-00041) | 431.2 | 533.8 | 529.6 | 66.4 | 64.7 | 463.2 | 35.3 |

| 2022-00048 | 99.4 (2022-00040) | 419.1 | 518.5 | 513.3 | 67.2 | 67.6 | 446.1 | 32.8 | ||

| 2022-00058 | 101.1 (2022-00057 | 428.8 | 529.9 | 529.9 | 72.0 | 71.2 | 457.9 | 28.8 | ||

| 2022-00126 | 99.0 (2022-00065) | 446.1 | 545.1 | 542.8 | 70.9 | 71.6 | 471.9 | 28.4 | ||

| Input Mass | Min [g] | Measurement Amount [g] | Max [g] | ||

|---|---|---|---|---|---|

| Material | Measurement Error | ||||

| fuel | ±0.1% | 101.01 | 101.11 | 101.21 | |

| feed gas CO2 | ±0.23 L h−1 at 100 L h−1 STP | 428.15 | 428.81 | 429.46 | |

| feed gas N2 | ±10.83 L h−1 at 1000 L h−1 STP | 1643.67 | 1663.08 | 1682.51 | |

| ∑ input | 2172.83 | 2193.00 | 2213.18 | ||

| ∑ input without N2 | 529.16 | 529.92 | 530.67 | ||

| output mass | |||||

| char | ± 2% | 70.55 | 71.99 | 73.43 | |

| product gas | 2028.70 | 2124.56 | 2227.15 | ||

| product gas without N2 | 439.56 | 457.92 | 483.01 | ||

| condensate (tar, water) | - | not measured | not measured | not measured | |

| ∑output | 2099.25 | 2196.55 | 2300.58 | ||

| ∑output without N2 | 510.11 | 529.91 | 556.44 | ||

| balance | |||||

| output − input | −73.58 | 3.55 | 87.40 | ||

| −3.39%of input mass | 0.16%of input mass | 3.95%of input mass | |||

| output − input (without N2) | −19.05 | −0.01 | 25.77 | ||

| 3.60%of input mass | <0.002%of input mass | 4.86%of input mass | |||

| Measured CO2 Gasification Reaction | ||||||

|---|---|---|---|---|---|---|

| C | + | CO2 | <-> | 2 CO | ||

| 1 mol | + | 1 mol | 2 mol | ∑input | ||

| 29.12 g | 93.32 g | 122.33 g | 122.44 g | |||

| −0.11 g (0.37%C-reaction) | ||||||

| mass calculation | ||||||

| 101.01 g char input | - | 71.99 g char output | = | 29.12 g C reaction | ||

| 428.80 g CO2 feed gas | - | 335.48 CO2 product gas | = | 93.32 g CO2 reaction | ||

| Component | Mass Fraction [wt.% to Fuel] | |||

|---|---|---|---|---|

| This Study | 650 °C [40] | 750 °C [40] | 703 °C Pine [41] | |

| char | 21.5 | 15.6 | 15.0 | 27 |

| condensate | 58.9 | 61.5 | 48.9 | 54 |

| thereof H2O | - | 19.2 | 15.9 | 20 |

| total gas | 19.3 | 22.1 | 34.6 | 21 |

| H2 | 0.87 | - | - | 0.2 |

| CO | 8.34 | 7.7 | 20.3 | 6.0 |

| CH4 | 3.96 | 1.6 | 3.8 | 2.3 |

| CO2 | 5.60 | 12.3 | 9.3 | 11.5 |

| C2H4 | 0.03 | 0.5 | 1.2 | - |

| C2H6 | 0.20 | - | - | - |

| Parameter | This Study | Various Research Reviewed by Di Blasi [42] | Schneider et al. [43] | Unit |

|---|---|---|---|---|

| 3.27 | 0.88–2.50 | 3.0–3.1 | [×102 kJ/mol] | |

| 5.30 × 1013 | 3.1 × 106–2.59 × 108 | 5.68 × 109–1.02 × 1010 | varying | |

| 0.41 | 0.4–0.6 | 0.19–0.21 | - | |

| 1.32 | 0.76–2.29 | - | [×102 kJ/mol] | |

| 5.79 × 107 | 5.3 × 105–4.5 × 108 | - | varying | |

| 0.61 | 0.5–1 | - | - | |

| 2.57 | 1.43–2.37 | 2.35–2.64 | [×102 kJ/mol] | |

| 3.8 × 1010 | 1.7 × 105–2.62 × 108 | 1.55 × 106–5.7 × 108 | varying | |

| 0.34 | 0.4–1 | 0.45–0.47 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heinrich, M.R.; Herrmann, A.; Gradel, A.; Klemm, M.; Plessing, T. Extensive Experimental Characterization with Kinetic Data for the Gasification Simulation of Solid Biofuels. Energies 2023, 16, 2888. https://doi.org/10.3390/en16062888

Heinrich MR, Herrmann A, Gradel A, Klemm M, Plessing T. Extensive Experimental Characterization with Kinetic Data for the Gasification Simulation of Solid Biofuels. Energies. 2023; 16(6):2888. https://doi.org/10.3390/en16062888

Chicago/Turabian StyleHeinrich, Maximilian Robert, André Herrmann, Andy Gradel, Marco Klemm, and Tobias Plessing. 2023. "Extensive Experimental Characterization with Kinetic Data for the Gasification Simulation of Solid Biofuels" Energies 16, no. 6: 2888. https://doi.org/10.3390/en16062888

APA StyleHeinrich, M. R., Herrmann, A., Gradel, A., Klemm, M., & Plessing, T. (2023). Extensive Experimental Characterization with Kinetic Data for the Gasification Simulation of Solid Biofuels. Energies, 16(6), 2888. https://doi.org/10.3390/en16062888