To Charge or to Sell? EV Pack Useful Life Estimation via LSTMs, CNNs, and Autoencoders

Abstract

1. Introduction and Background

- We propose a novel RUL definition in the machine learning context, based on ampere-hours, to push forward the applicability to real cases. The first application of deep learning techniques on an RUL that is not based on the simplified concept of cycles is also provided.

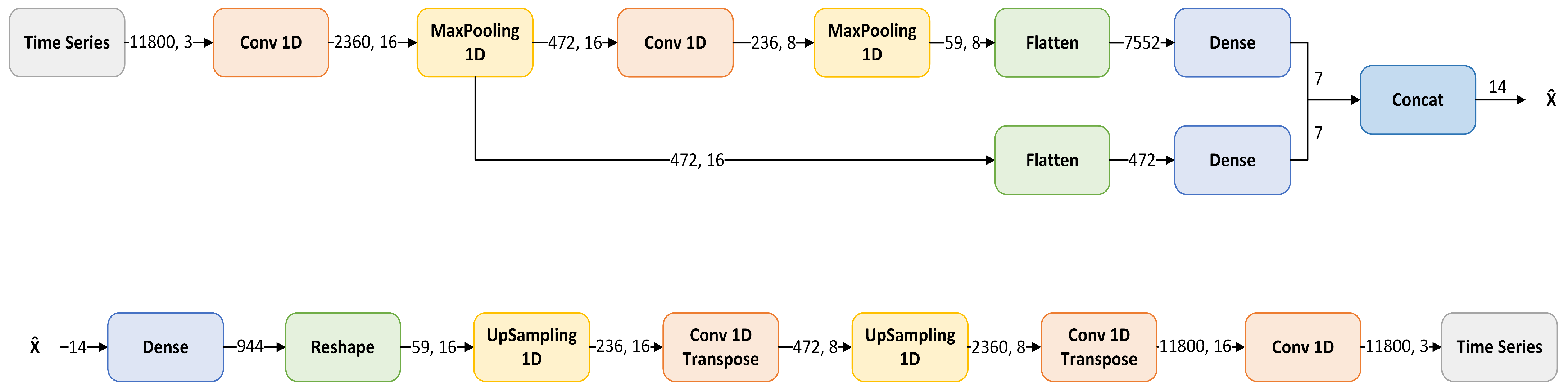

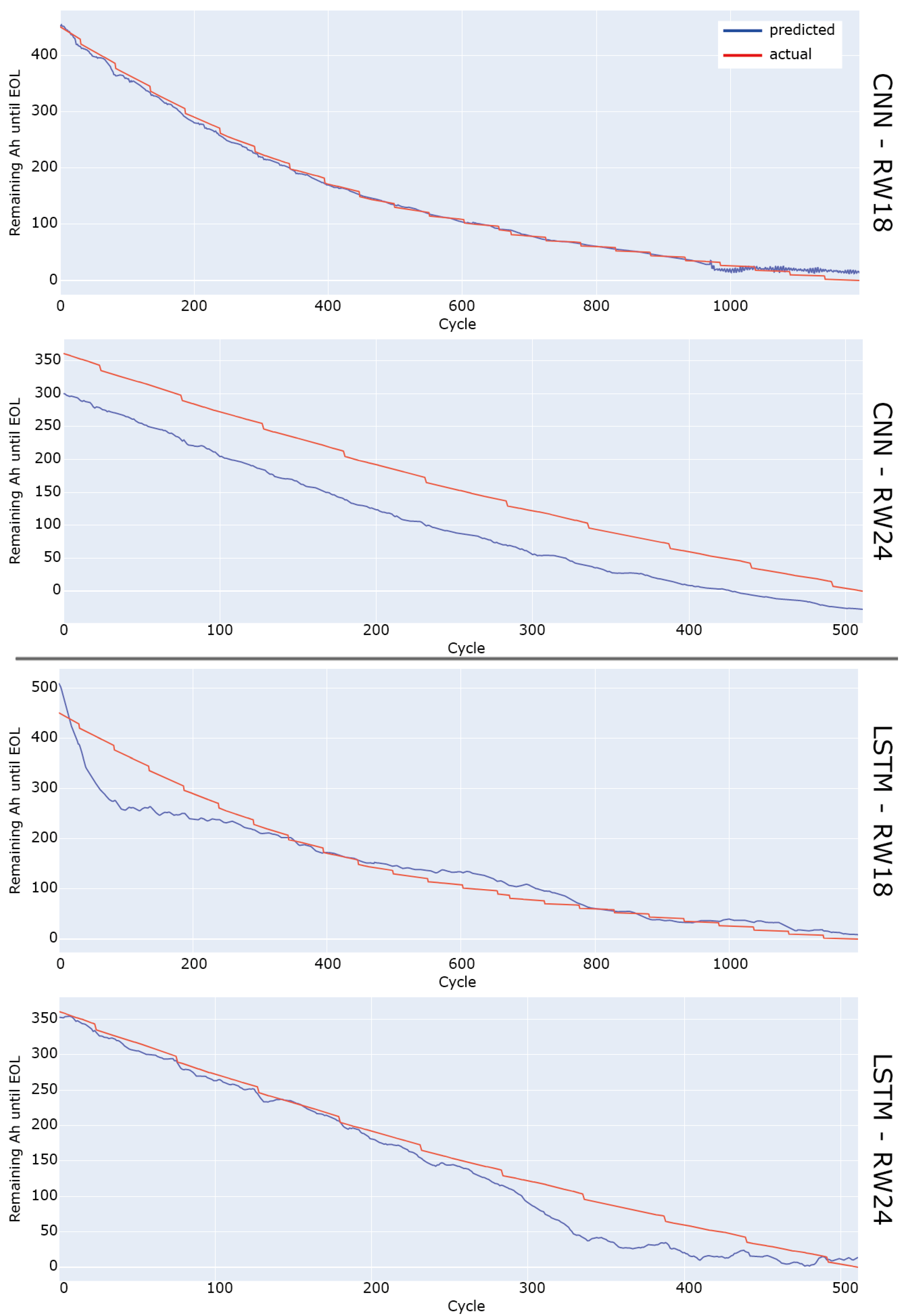

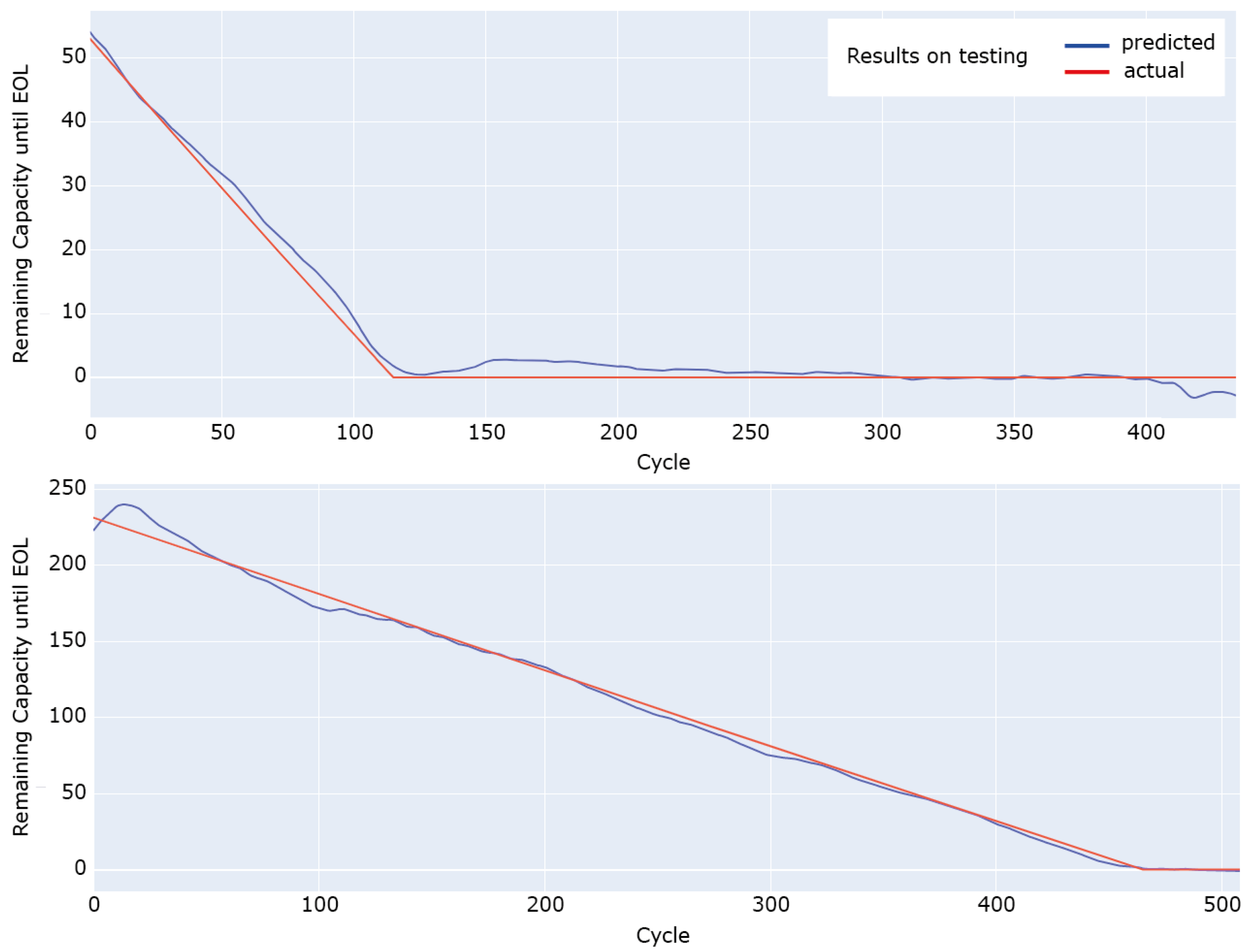

- Two models for RUL estimation are presented and compared on the NASA Randomized dataset: autoencoder plus CNN and autoencoder plus LSTM. In addition, an LSTM is proposed to predict the RUL in the UNIBO Powertools dataset. The results show that the particular autoencoder can effectively extract the relevant features of the cycle curves, while the CNNs and the LSTMs can be used to estimate the RUL.

- Two vast datasets containing batteries cycled with an extensive set of different conditions and variables are used in the experiments to ensure generalization. Compared to the data used in the literature so far (with a limited amount of batteries typically discharged under constant current), the examples used in this paper present many more batteries and conditions that are more challenging to predict. All the relevant details about the data selection and splitting are detailed, ensuring transparency in the results.

2. Related Works

3. Experiments

- Input: The only information used is voltage (V), current (I), and temperature (T), as using only measurable variables boosts applicability. The data are taken from the discharge cycles and are organized in time series, in the format . As explained in Section 3.2, at each cycle n, the input given to the network is based solely on the cycle n and the previous ones (; where N is the history length), i.e., no information from the future is used.

- Output—RUL definition: As detailed in Section 2, defining the RUL as the number of remaining cycles has no practical meaning. Here, instead, the RUL is defined as the normalized remaining ampere-hour (Ah) that the battery can deliver before reaching EOL.

3.1. Datasets

3.1.1. NASA Randomized Battery Usage Dataset

- RW1, RW2, RW7, RW8 batteries are repeatedly charged for a random duration between 0.5 and 3 h, then discharged to 3.2 V using a randomized sequence of currents between 0.5 A and 4 A. The discharge random profile is the RW. The setpoint is loaded every 5 min. Operated at room temperature.

- RW3, RW4, RW5, RW6 batteries are repeatedly charged to 4.2 V and then discharged to 3.2 V using a randomized sequence of currents between 0.5 A and 4 A. The discharge random profile is the RW. The setpoint is loaded every 5 min. Operated at room temperature.

- RW9, RW10, RW11, RW12 batteries are repeatedly charged and then discharged using a randomized sequence of currents between −4.5 A and 4.5 A. The charge and discharge random profile is the RW. The setpoint is loaded every 5 min. Operated at room temperature.

- RW13, RW14, RW15, RW16 batteries are repeatedly charged to 4.2 V and then discharged to 3.2 V using a randomized sequence of currents between 0.5 A and 5 A. The random profile is the skewed high RW. The setpoint is loaded every 1 min. Operated at room temperature.

- RW17, RW18, RW19, RW20 batteries are repeatedly charged to 4.2 V and then discharged to 3.2 V using a randomized sequence of currents between 0.5 A and 5 A. The random profile is the skewed low RW. The setpoint is loaded every 1 min. Operated at room temperature.

- RW21, RW22, RW23, RW24 batteries are repeatedly charged to 4.2 V and then discharged to 3.2 V using a randomized sequence of currents between 0.5 A and 5 A. The random profile is the skewed low RW. The setpoint is loaded every 1 min. Operated at 40 C temperature.

- RW25, RW26, RW27, RW28 batteries are repeatedly charged to 4.2 V and then discharged to 3.2 V using a randomized sequence of currents between 0.5 A and 5 A. The random profile is the skewed high RW. The setpoint is loaded every 1 min. Operated at 40 C temperature.

3.1.2. UNIBO Powertools Dataset

- DM-3.0-4019-S 4 cells: 000, 001, 002, 003.

- DM-3.0-4019-H 3 cells: 009, 010, 011.

- DM-3.0-4019-P 7 cells: 013, 014, 015, 016, 017, 047, 049.

- EE-2.85-0820-S 4 cells: 006, 007, 008, 042.

- EE-2.85-0820-H 2 cells: 043, 044.

- DP-2.00-1320-S 8 cells: 018, 019, 036, 037, 038, 039, 050, 051 (039 has date 2420).

- DM-4.00-2320-S 2 cells: 040, 041.

3.2. Models

3.2.1. NASA Randomized: AE-LSTM vs. AE-CNN

3.2.2. UNIBO Powertools: LSTM

4. Results

4.1. NASA Randomized

4.2. UNIBO Powertools

5. Conclusions and Future Works

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hofmann, J.; Guan, D.; Chalvatzis, K.; Huo, H. Assessment of electrical vehicles as a successful driver for reducing CO2 emissions in China. Appl. Energy 2016, 184, 995–1003. [Google Scholar] [CrossRef]

- Zou, Y.; Wei, S.; Sun, F.; Hu, X.; Shiao, Y. Large-scale deployment of electric taxis in Beijing: A real-world analysis. Energy 2016, 100, 25–39. [Google Scholar] [CrossRef]

- US Environmental Protection Agency (EPA). Global Greenhouse Gas Emissions Data. 2014. Available online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed on 3 May 2021).

- European Commission. Air Pollution from the Main Sources—Air Emissions from Road Vehicles. 2012. Available online: https://ec.europa.eu/environment/air/sources/road.htm (accessed on 3 May 2021).

- Kleeman, M.J.; Schauer, J.J.; Cass, G.R. Size and Composition Distribution of Fine Particulate Matter Emitted from Motor Vehicles. Environ. Sci. Technol. 2000, 34, 1132–1142. [Google Scholar] [CrossRef]

- Kheirbek, I.; Haney, J.; Douglas, S.; Ito, K.; Matte, T. The contribution of motor vehicle emissions to ambient fine particulate matter public health impacts in New York City: A health burden assessment. Environ. Health 2016, 15, 89. [Google Scholar] [CrossRef]

- Koolen, C.D.; Rothenberg, G. Air pollution in Europe. ChemSusChem 2019, 12, 164–172. [Google Scholar] [CrossRef]

- Anderson, H.R.; Atkinson, R.W.; Peacock, J.L.; Sweeting, M.J.; Marston, L. Ambient particulate matter and health effects: Publication bias in studies of short-term associations. Epidemiology 2005, 16, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Brunekreef, B.; Forsberg, B. Epidemiological evidence of effects of coarse airborne particles on health. Eur. Respir. J. 2005, 26, 309–318. [Google Scholar] [CrossRef]

- Opitz, A.; Badami, P.; Shen, L.; Vignarooban, K.; Kannan, A. Can Li-Ion batteries be the panacea for automotive applications? Renew. Sustain. Energy Rev. 2017, 68, 685–692. [Google Scholar] [CrossRef]

- Manzetti, S.; Mariasiu, F. Electric vehicle battery technologies: From present state to future systems. Renew. Sustain. Energy Rev. 2015, 51, 1004–1012. [Google Scholar] [CrossRef]

- Hannan, M.; Lipu, M.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Zhang, S.; Zhai, B.; Guo, X.; Wang, K.; Peng, N.; Zhang, X. Synchronous estimation of state of health and remaining useful lifetime for lithium-ion battery using the incremental capacity and artificial neural networks. J. Energy Storage 2019, 26, 100951. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, J.; Peng, Y. Data-driven prognostics and remaining useful life estimation for lithium-ion battery: A review. Instrumentation 2014, 1, 59–70. [Google Scholar]

- Hu, X.; Cao, D.; Egardt, B. Condition monitoring in advanced battery management systems: Moving horizon estimation using a reduced electrochemical model. IEEE/ASME Trans. Mechatronics 2017, 23, 167–178. [Google Scholar] [CrossRef]

- Williard, N.; He, W.; Hendricks, C.; Pecht, M. Lessons Learned from the 787 Dreamliner Issue on Lithium-Ion Battery Reliability. Energies 2013, 6, 4682–4695. [Google Scholar] [CrossRef]

- NASA. Mars Global Surveyor (MGS) Spacecraft Loss of Contact; NASA: Washington, DC, USA, 2007.

- Isidore, C.; Valdes-Dapena, P. Hyundai’s Recall of 82,000 Electric Cars is One of the Most Expensive in History. 2021. Available online: https://edition.cnn.com/2021/02/25/tech/hyundai-ev-recall/index.html (accessed on 3 May 2021).

- Hawkins, A.J. GM Recalls 68,000 Electric Chevy Bolts over Battery Fire Concerns. Verge 2020. Available online: https://www.theverge.com/2020/11/13/21564217/gm-chevy-bolt-recall-battery-fire-lg-chem (accessed on 15 March 2023).

- Bilgin, B.; Magne, P.; Malysz, P.; Yang, Y.; Pantelic, V.; Preindl, M.; Korobkine, A.; Jiang, W.; Lawford, M.; Emadi, A. Making the Case for Electrified Transportation. IEEE Trans. Transp. Electrif. 2015, 1, 4–17. [Google Scholar] [CrossRef]

- Mahmoudzadeh Andwari, A.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Wu, Y.; Xue, Q.; Shen, J.; Lei, Z.; Chen, Z.; Liu, Y. State of Health Estimation for Lithium-Ion Batteries Based on Healthy Features and Long Short-Term Memory. IEEE Access 2020, 8, 28533–28547. [Google Scholar] [CrossRef]

- Johnson, N. 19—Battery technology for CO2 reduction. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance; Folkson, R., Ed.; Woodhead Publishing: Sawston, UK, 2014; pp. 582–631. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Fan, Y.; Xiao, F.; Li, C.; Yang, G.; Tang, X. A novel deep learning framework for state of health estimation of lithium-ion battery. J. Energy Storage 2020, 32, 101741. [Google Scholar] [CrossRef]

- Vidal, C.; Malysz, P.; Kollmeyer, P.; Emadi, A. Machine Learning Applied to Electrified Vehicle Battery State of Charge and State of Health Estimation: State-of-the-Art. IEEE Access 2020, 8, 52796–52814. [Google Scholar] [CrossRef]

- IEC-62660-2; Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles—Part 2: Reliability and Abuse Testing 2018. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- ISO 12405-3; ISO Electrically Propelled Road Vehicles—Test Specification for Lithium-Ion Traction Battery Packs and Systems— Part 3: Safety Performance Requirements. ISO: Geneva, Switzerland, 2018.

- IEEE Std 450-2020 (Revision IEEE Std 450-2010); IEEE Recommended Practice for Maintenance, Testing, and Replacement of Vented Lead-Acid Batteries for Stationary Applications. IEEE: New York, NY, USA, 2021; pp. 1–71.

- Duong, T.Q. USABC and PNGV test procedures. J. Power Sources 2000, 89, 244–248. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.W.; Tsui, K.L.; Pecht, M. An ensemble model for predicting the remaining useful performance of lithium-ion batteries. Microelectron. Reliab. 2013, 53, 811–820. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K. Battery Data Set. NASA Ames Prognostics Data Repository. 2007. Available online: https://www.nasa.gov/content/prognostics-center-of-excellence-data-set-repository (accessed on 15 March 2023).

- Chen, Y.; He, Y.; Li, Z.; Chen, L.; Zhang, C. Remaining Useful Life Prediction and State of Health Diagnosis of Lithium-Ion Battery Based on Second-Order Central Difference Particle Filter. IEEE Access 2020, 8, 37305–37313. [Google Scholar] [CrossRef]

- Li, X.; Shu, X.; Shen, J.; Xiao, R.; Yan, W.; Chen, Z. An On-Board Remaining Useful Life Estimation Algorithm for Lithium-Ion Batteries of Electric Vehicles. Energies 2017, 10, 691. [Google Scholar] [CrossRef]

- Ng, S.S.; Xing, Y.; Tsui, K.L. A naive Bayes model for robust remaining useful life prediction of lithium-ion battery. Appl. Energy 2014, 118, 114–123. [Google Scholar] [CrossRef]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

- Song, L.; Zhang, K.; Liang, T.; Han, X.; Zhang, Y. Intelligent state of health estimation for lithium-ion battery pack based on big data analysis. J. Energy Storage 2020, 32, 101836. [Google Scholar] [CrossRef]

- Venugopal, P.; Vigneswaran, T. State-of-Health Estimation of Li-ion Batteries in Electric Vehicle Using IndRNN under Variable Load Condition. Energies 2019, 12, 4338. [Google Scholar] [CrossRef]

- Ahmadi, L.; Yip, A.; Fowler, M.; Young, S.B.; Fraser, R.A. Environmental feasibility of re-use of electric vehicle batteries. Sustain. Energy Technol. Assess. 2014, 6, 64–74. [Google Scholar] [CrossRef]

- Shen, S.; Sadoughi, M.; Chen, X.; Hong, M.; Hu, C. A deep learning method for online capacity estimation of lithium-ion batteries. J. Energy Storage 2019, 25, 100817. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Pražanová, A.; Knap, V.; Stroe, D.-I. Literature Review, Recycling of Lithium-Ion Batteries from Electric Vehicles, Part II: Environmental and Economic Perspective. Energies 2022, 15, 7356. [Google Scholar] [CrossRef]

- Lipu, M.H.; Hannan, M.; Hussain, A.; Hoque, M.; Ker, P.J.; Saad, M.; Ayob, A. A review of state of health and remaining useful life estimation methods for lithium-ion battery in electric vehicles: Challenges and recommendations. J. Clean. Prod. 2018, 205, 115–133. [Google Scholar] [CrossRef]

- Dai, H.; Zhao, G.; Lin, M.; Wu, J.; Zheng, G. A Novel Estimation Method for the State of Health of Lithium-Ion Battery Using Prior Knowledge-Based Neural Network and Markov Chain. IEEE Trans. Ind. Electron. 2019, 66, 7706–7716. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet Classification with Deep Convolutional Neural Networks. In Advances in Neural Information Processing Systems 25; Pereira, F., Burges, C.J.C., Bottou, L., Weinberger, K.Q., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2012; pp. 1097–1105. [Google Scholar]

- Hametner, C.; Jakubek, S.; Prochazka, W. Data-driven design of a cascaded observer for battery state of health estimation. In Proceedings of the 2016 IEEE International Conference on Sustainable Energy Technologies (ICSET), Hanoi, Vietnam, 14–16 November 2016; pp. 180–185. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Dos Reis, G.; Strange, C.; Yadav, M.; Li, S. Lithium-ion battery data and where to find it. Energy AI 2021, 5, 100081. [Google Scholar] [CrossRef]

- Bole, B.; Kulkarni, C.; Daigle, M. Randomized Battery Usage Data Set. NASA Ames Prognostics Data Repository. 2014. Available online: https://www.nasa.gov/content/prognostics-center-of-excellence-data-set-repository (accessed on 15 March 2023).

- Ungurean, L.; Micea, M.V.; Cârstoiu, G. Online state of health prediction method for lithium-ion batteries, based on gated recurrent unit neural networks. Int. J. Energy Res. 2020, 44, 6767–6777. [Google Scholar] [CrossRef]

- Zhou, D.; Li, Z.; Zhu, J.; Zhang, H.; Hou, L. State of Health Monitoring and Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Temporal Convolutional Network. IEEE Access 2020, 8, 53307–53320. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Liu, Z. A LSTM-RNN method for the lithuim-ion battery remaining useful life prediction. In Proceedings of the 2017 Prognostics and System Health Management Conference (PHM-Harbin), Harbin, China, 9–12 July 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Li, X. Deep learning-based prognostic approach for lithium-ion batteries with adaptive time-series prediction and on-line validation. Measurement 2020, 164, 108052. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Z.; Xiong, Q.; Ding, B.; Hou, J.; Luo, D.; Rong, Y.; Li, S. State-of-health estimation and remaining useful life prediction for the lithium-ion battery based on a variant long short term memory neural network. J. Power Sources 2020, 459, 228069. [Google Scholar] [CrossRef]

- Ren, L.; Zhao, L.; Hong, S.; Zhao, S.; Wang, H.; Zhang, L. Remaining Useful Life Prediction for Lithium-Ion Battery: A Deep Learning Approach. IEEE Access 2018, 6, 50587–50598. [Google Scholar] [CrossRef]

- Ren, L.; Dong, J.; Wang, X.; Meng, Z.; Zhao, L.; Deen, M.J. A Data-Driven Auto-CNN-LSTM Prediction Model for Lithium-Ion Battery Remaining Useful Life. IEEE Trans. Ind. Inform. 2021, 17, 3478–3487. [Google Scholar] [CrossRef]

- Wong, K.L.; Bosello, M.; Tse, R.; Falcomer, C.; Rossi, C.; Pau, G. Li-Ion Batteries State-of-Charge Estimation Using Deep LSTM at Various Battery Specifications and Discharge Cycles. In Proceedings of the Conference on Information Technology for Social Good, GoodIT ’21, Rome, Italy, 9–11 September 2021; Association for Computing Machinery: New York, NY, USA, 2021; pp. 85–90. [Google Scholar] [CrossRef]

- Maggipinto, M.; Masiero, C.; Beghi, A.; Susto, G.A. A Convolutional Autoencoder Approach for Feature Extraction in Virtual Metrology. Procedia Manuf. 2018, 17, 126–133. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, L.; Polosukhin, I. Attention Is All You Need. arXiv 2017, arXiv:1706.03762. [Google Scholar]

- Tang, Y.; Zhang, Q.; Li, Y.; Wang, G.; Li, Y. Recycling mechanisms and policy suggestions for spent electric vehicles’ power battery—A case of Beijing. J. Clean. Prod. 2018, 186, 388–406. [Google Scholar] [CrossRef]

- Hao, H.; Xu, W.; Wei, F.; Wu, C.; Xu, Z. Reward-Penalty vs. Deposit-Refund: Government Incentive Mechanisms for EV Battery Recycling. Energies 2022, 15, 6885. [Google Scholar] [CrossRef]

| Method | Input | Output | Dataset | Performances | Issues |

|---|---|---|---|---|---|

| TCN [53] | History of SOH | RUL | NASA, 3 CC batteries (#5, #6, #18) CALCE, 2 CC batteries (#CS_34, #CS_35) | RMSE up to 0.048 |

|

| LSTM network [54] | History of SOH | RUL | Panasonic 18,650 (1 CC battery) | - |

|

| LSTM network [55] | History of SOH | K-step ahead SOH | NASA, 4 CC batteries (#5, #6, #7, #18) | MAE 1.92 (on battery #5) |

|

| Variant of LSTM. SOH is estimated and then used to predict RUL [56] | V, I, T, sampling time (discharge) | SOH+RUL | NASA (12 batteries) | SOH: RMSE up to 0.059 RUL: RMSE up to 0.026 (on battery #5) |

|

| Features are extracted from the IC discharge curve and given as input to two NNs [13] | V, I, sampling time (discharge) | SOH+RUL | NASA, 4 CC batteries (#5, #6, #7, #18) | SOH: MRER up to 1.25% RUL: RMSE up to 5.41 |

|

| Feature extraction with autoencoder followed by a DNN [57] | V, I, T, sampling time (charge + discharge), capacity, i.e., SOH (discharge) | RUL | NASA, 3 CC batteries (#5, #6, #7) | RMSE up to 13.2% (on battery #7) |

|

| Auto-CNN-LSTM: data augmentation with autoencoder followed by CNN+LSTM extractor [58] | V, I, T, sampling time (charge + discharge) | RUL | NASA, 6 CC batteries (#5, #6, #7 #25, #27, #28) | RMSE up to 5.03% (on battery #7 and #28) |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bosello, M.; Falcomer, C.; Rossi, C.; Pau, G. To Charge or to Sell? EV Pack Useful Life Estimation via LSTMs, CNNs, and Autoencoders. Energies 2023, 16, 2837. https://doi.org/10.3390/en16062837

Bosello M, Falcomer C, Rossi C, Pau G. To Charge or to Sell? EV Pack Useful Life Estimation via LSTMs, CNNs, and Autoencoders. Energies. 2023; 16(6):2837. https://doi.org/10.3390/en16062837

Chicago/Turabian StyleBosello, Michael, Carlo Falcomer, Claudio Rossi, and Giovanni Pau. 2023. "To Charge or to Sell? EV Pack Useful Life Estimation via LSTMs, CNNs, and Autoencoders" Energies 16, no. 6: 2837. https://doi.org/10.3390/en16062837

APA StyleBosello, M., Falcomer, C., Rossi, C., & Pau, G. (2023). To Charge or to Sell? EV Pack Useful Life Estimation via LSTMs, CNNs, and Autoencoders. Energies, 16(6), 2837. https://doi.org/10.3390/en16062837