A Maximum Power Point Tracking Technique for a Wind Power System Based on the Trapezoidal Rule

Abstract

1. Introduction

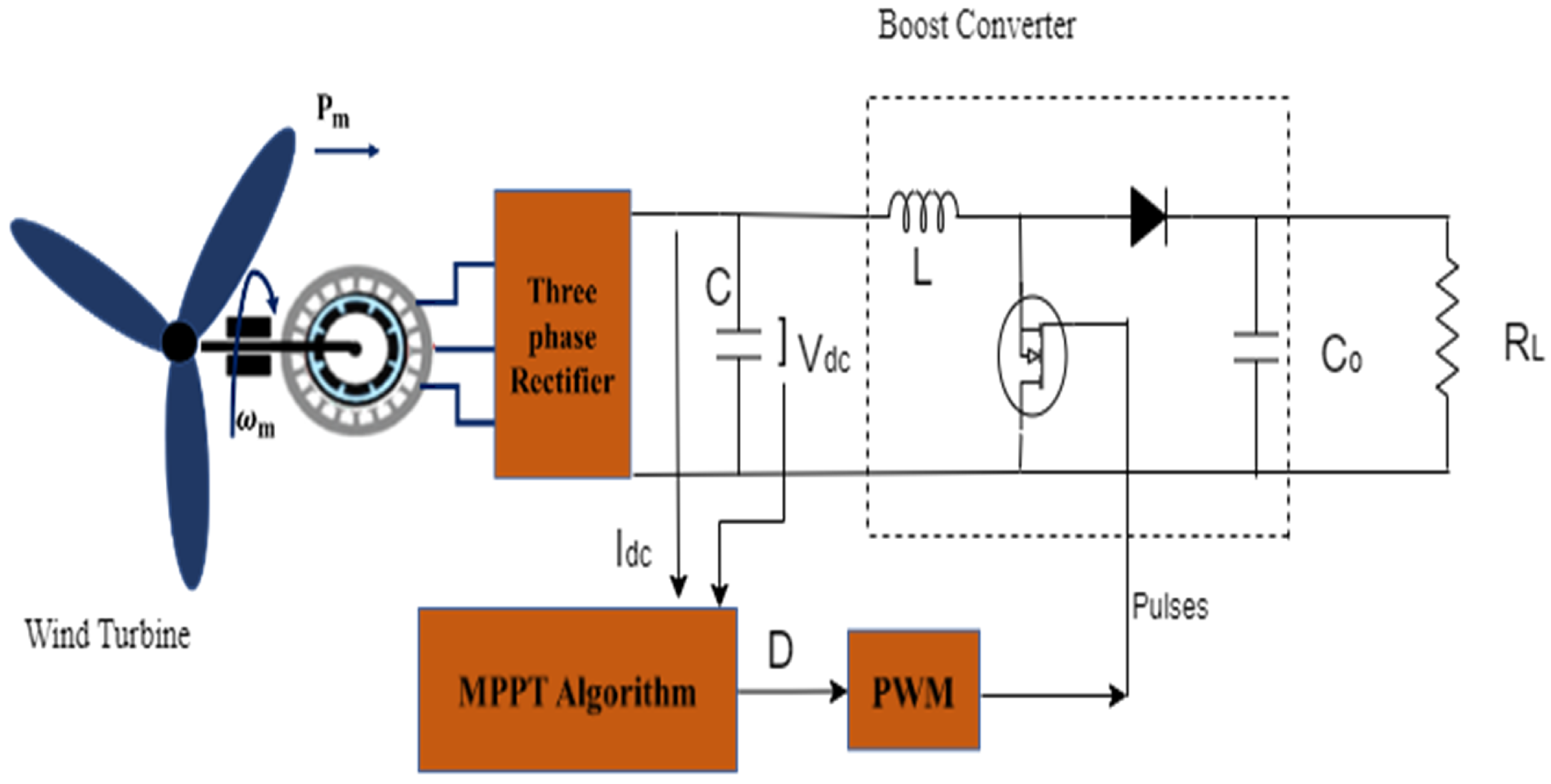

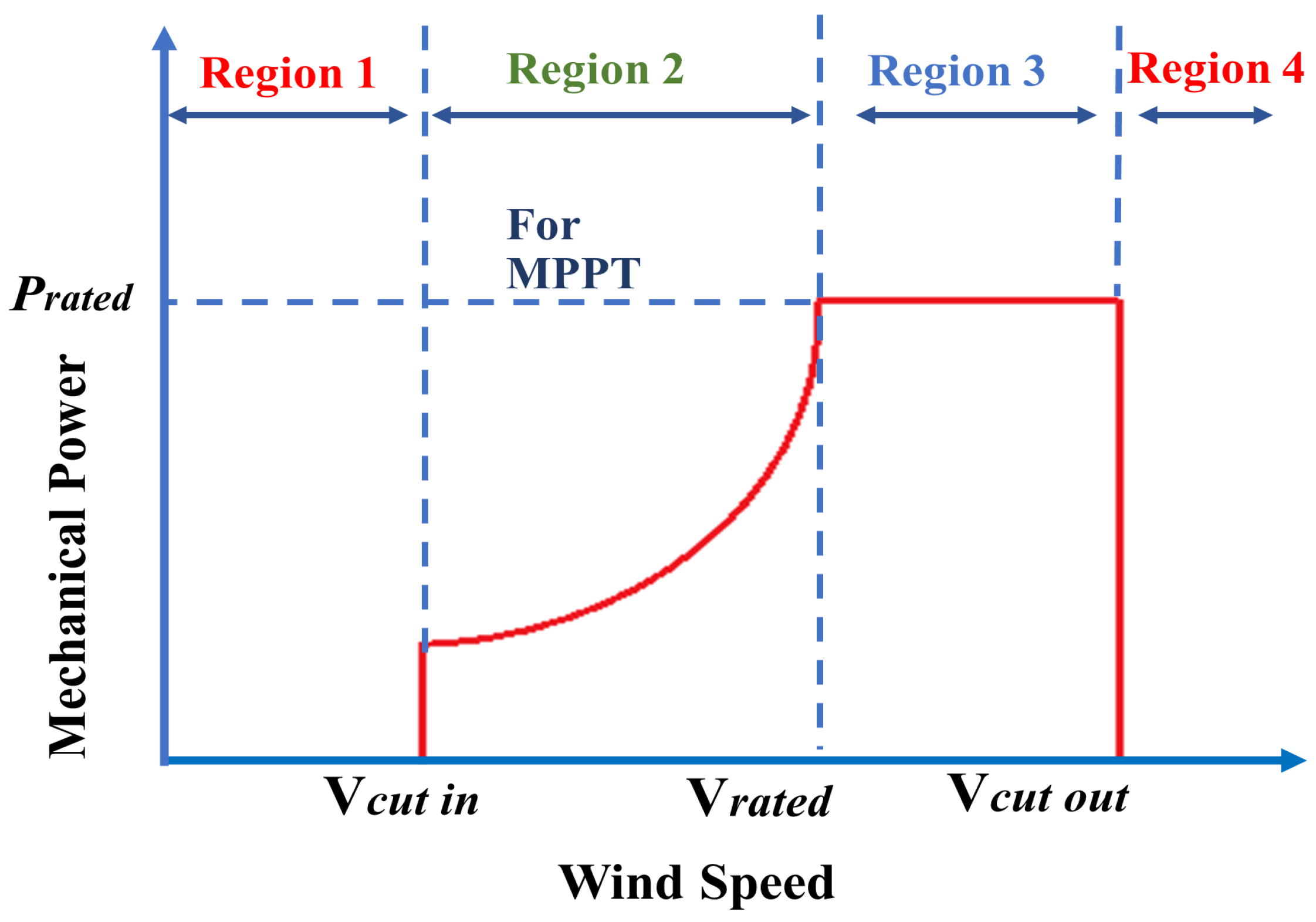

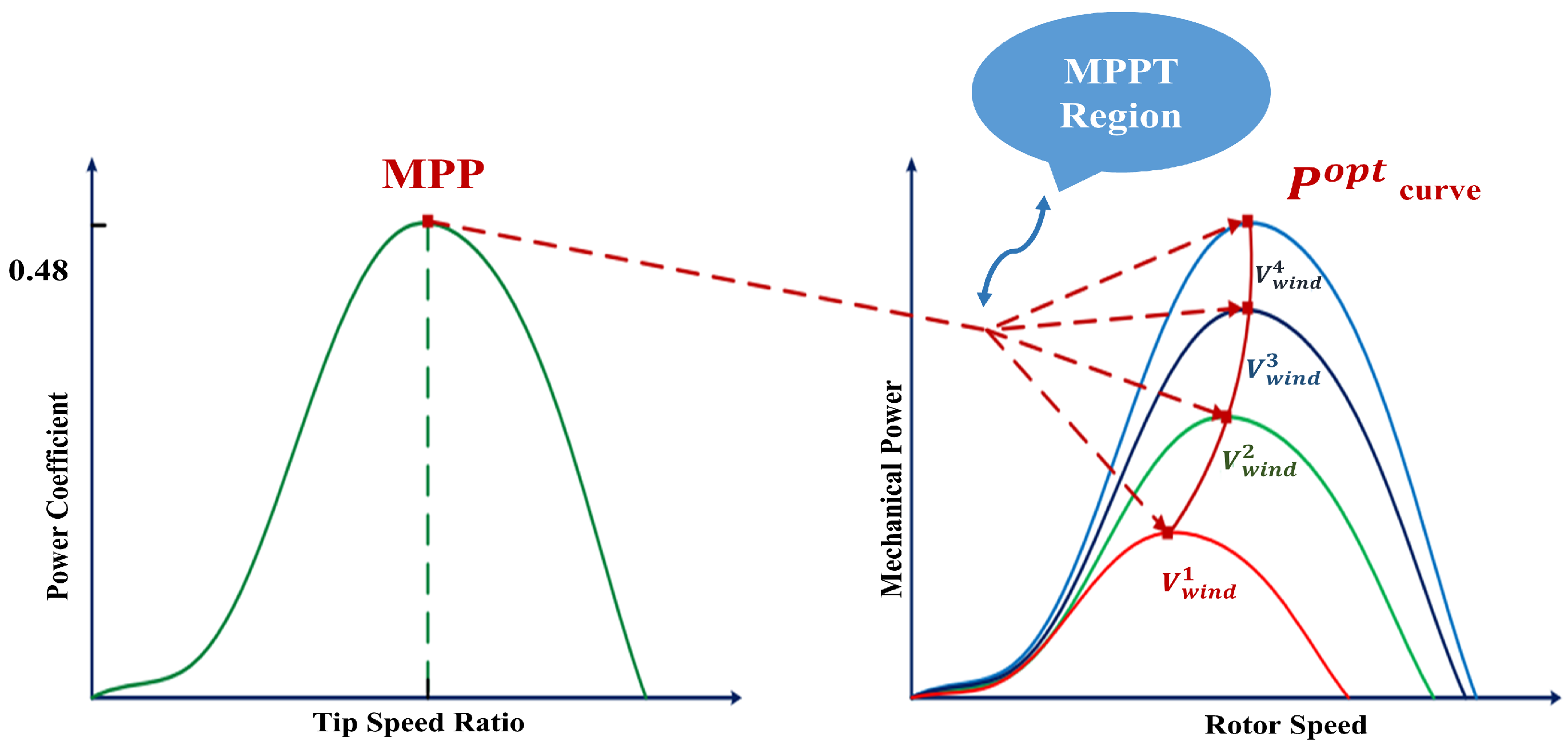

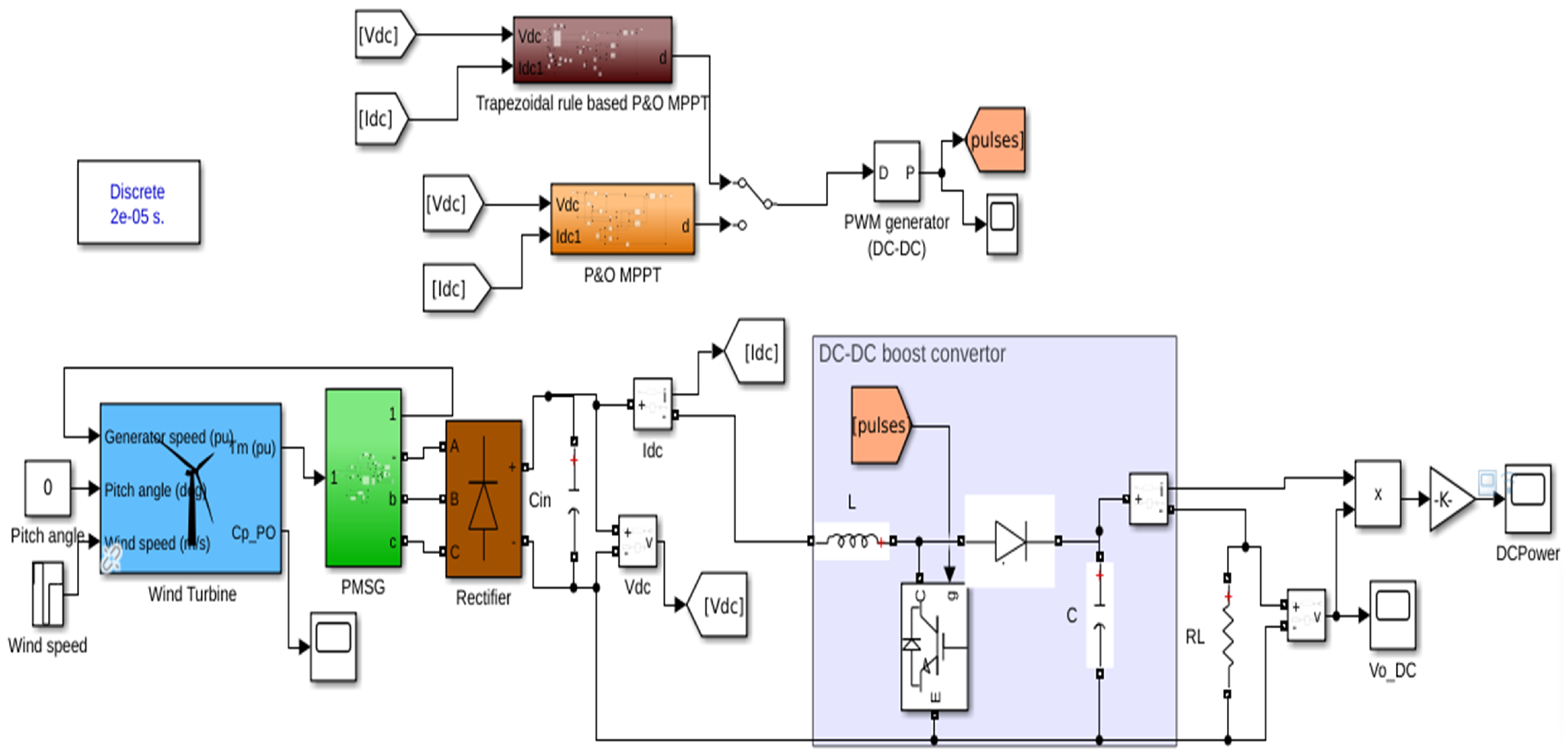

2. Overall Power System with MPPT Algorithm

Concept of MPPT and Related Terminologies

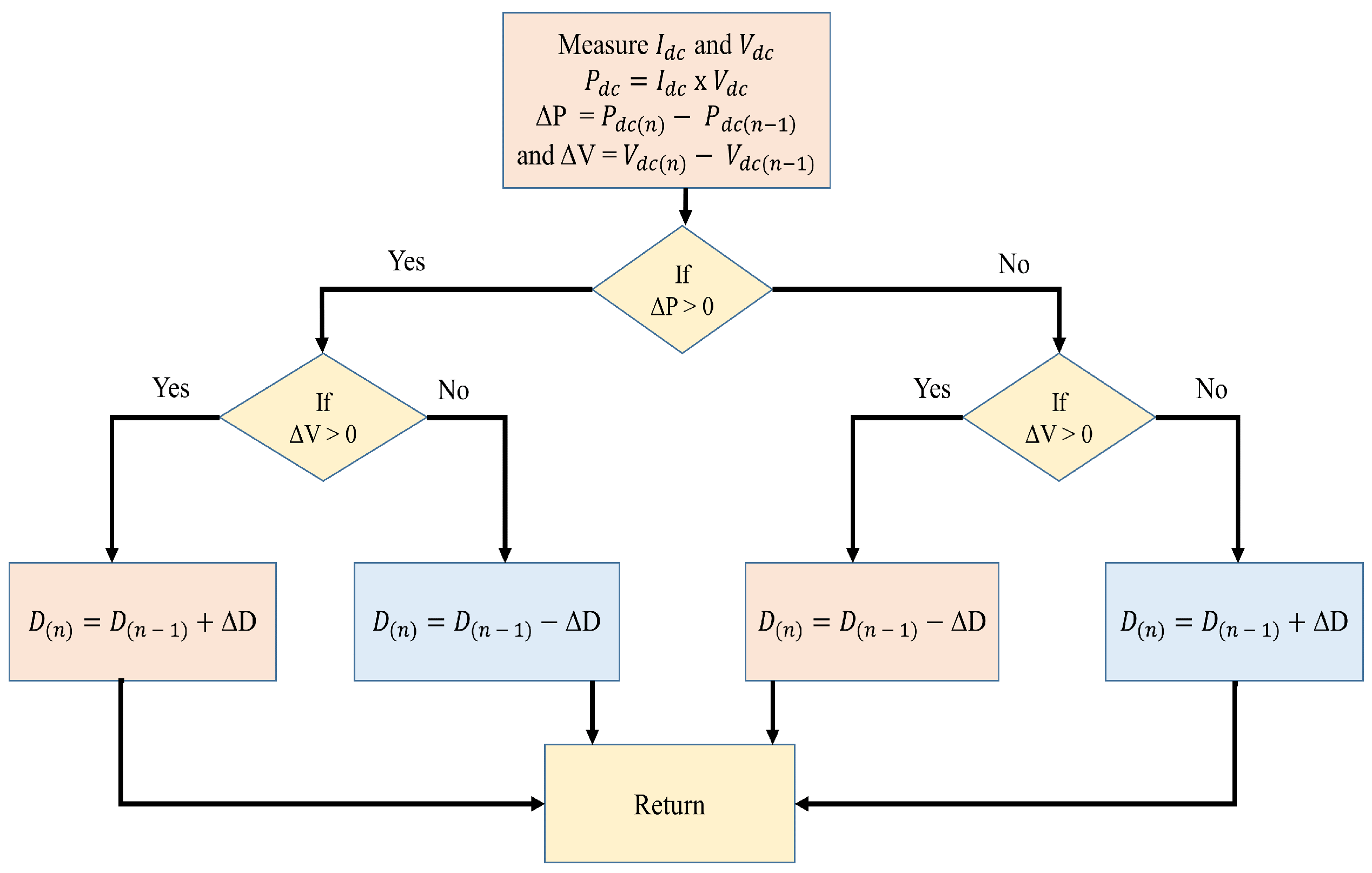

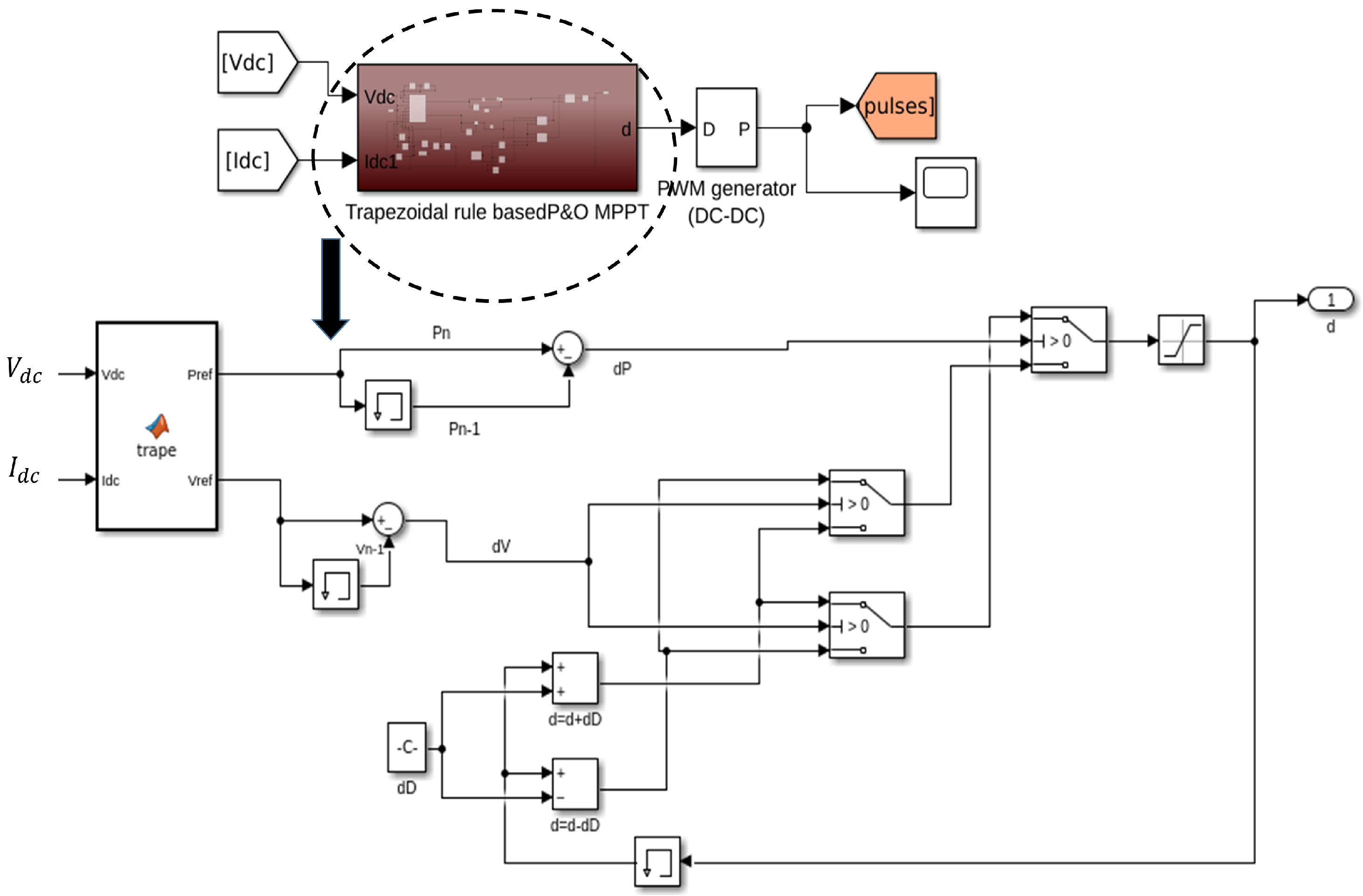

3. Proposed Algorithm

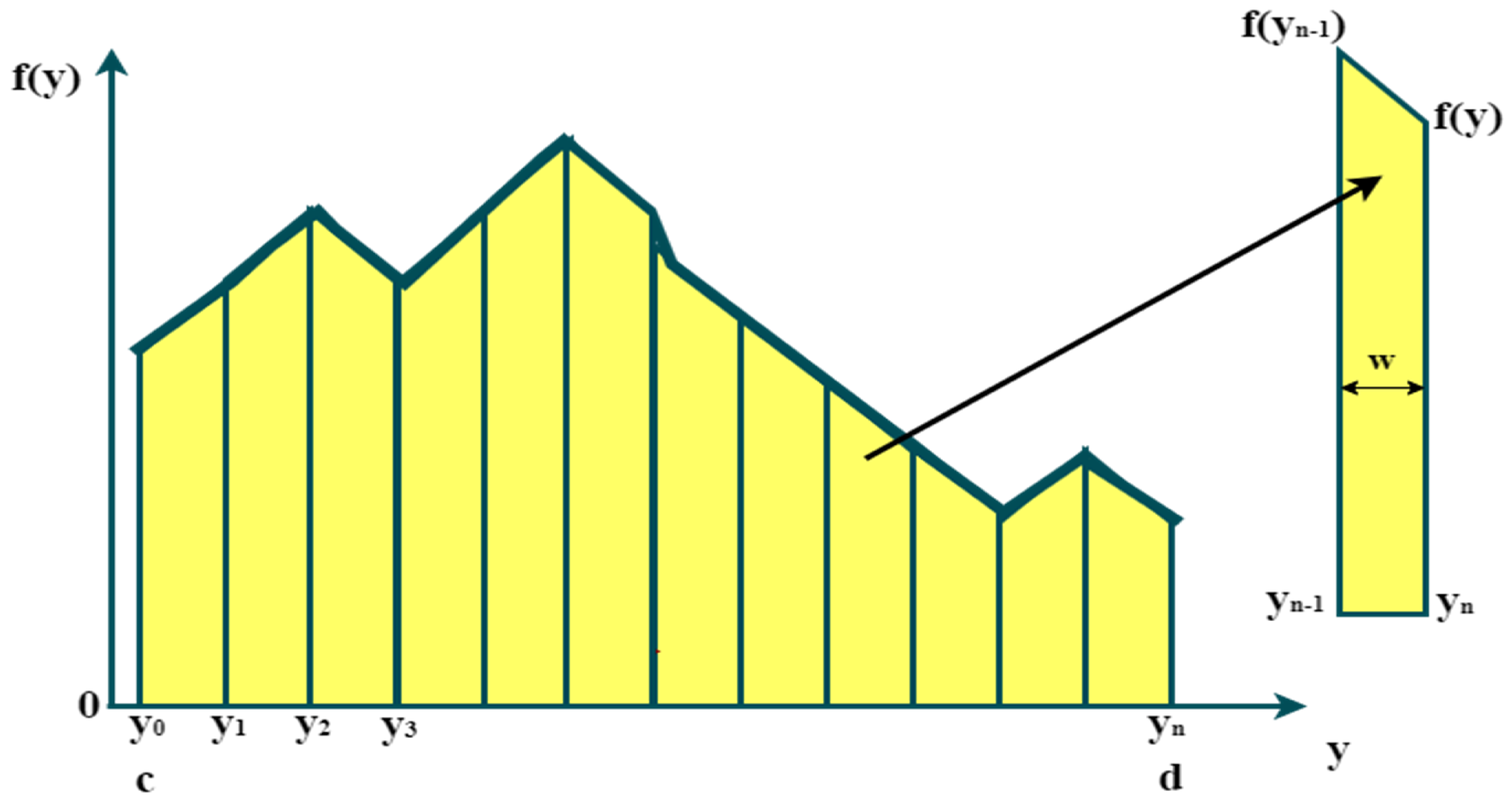

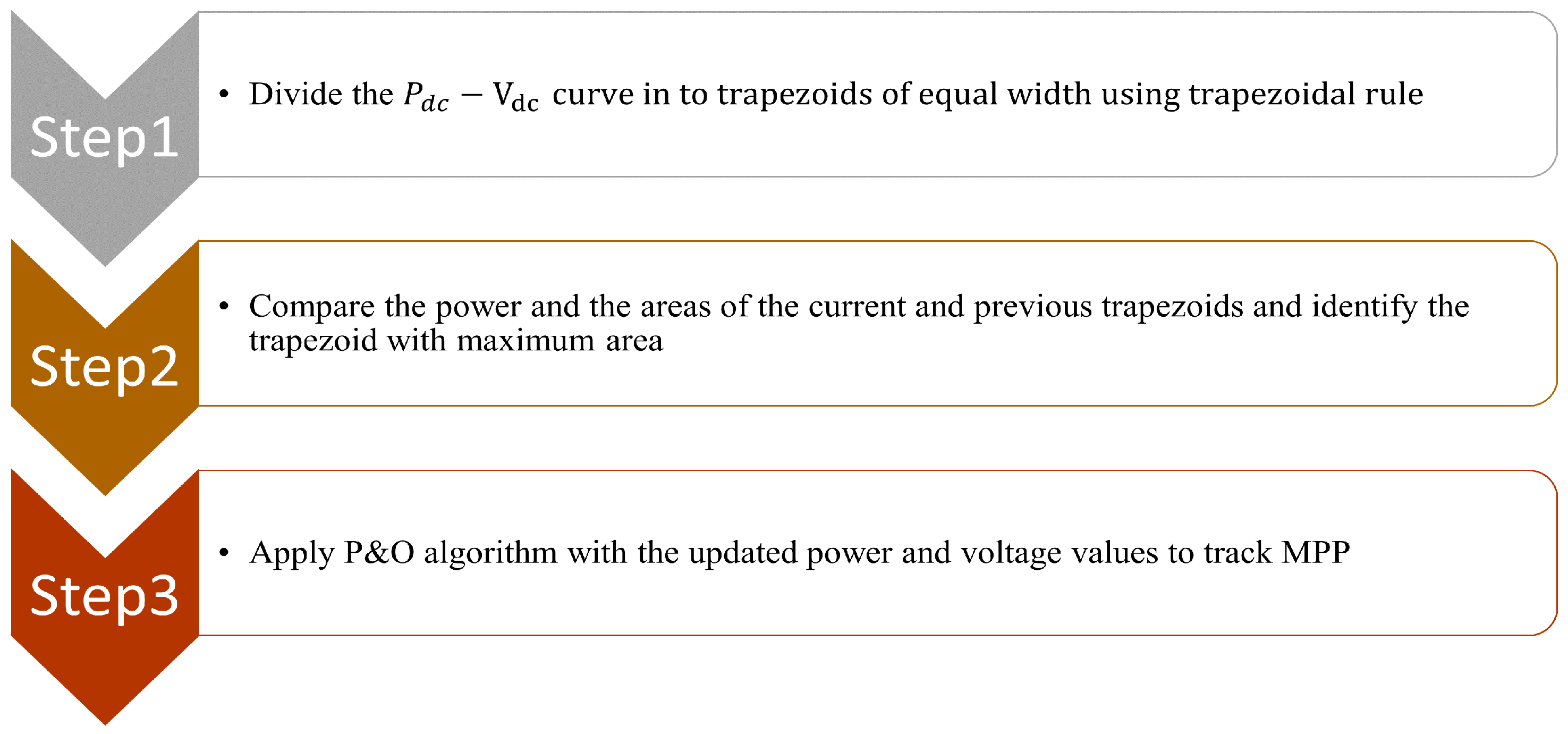

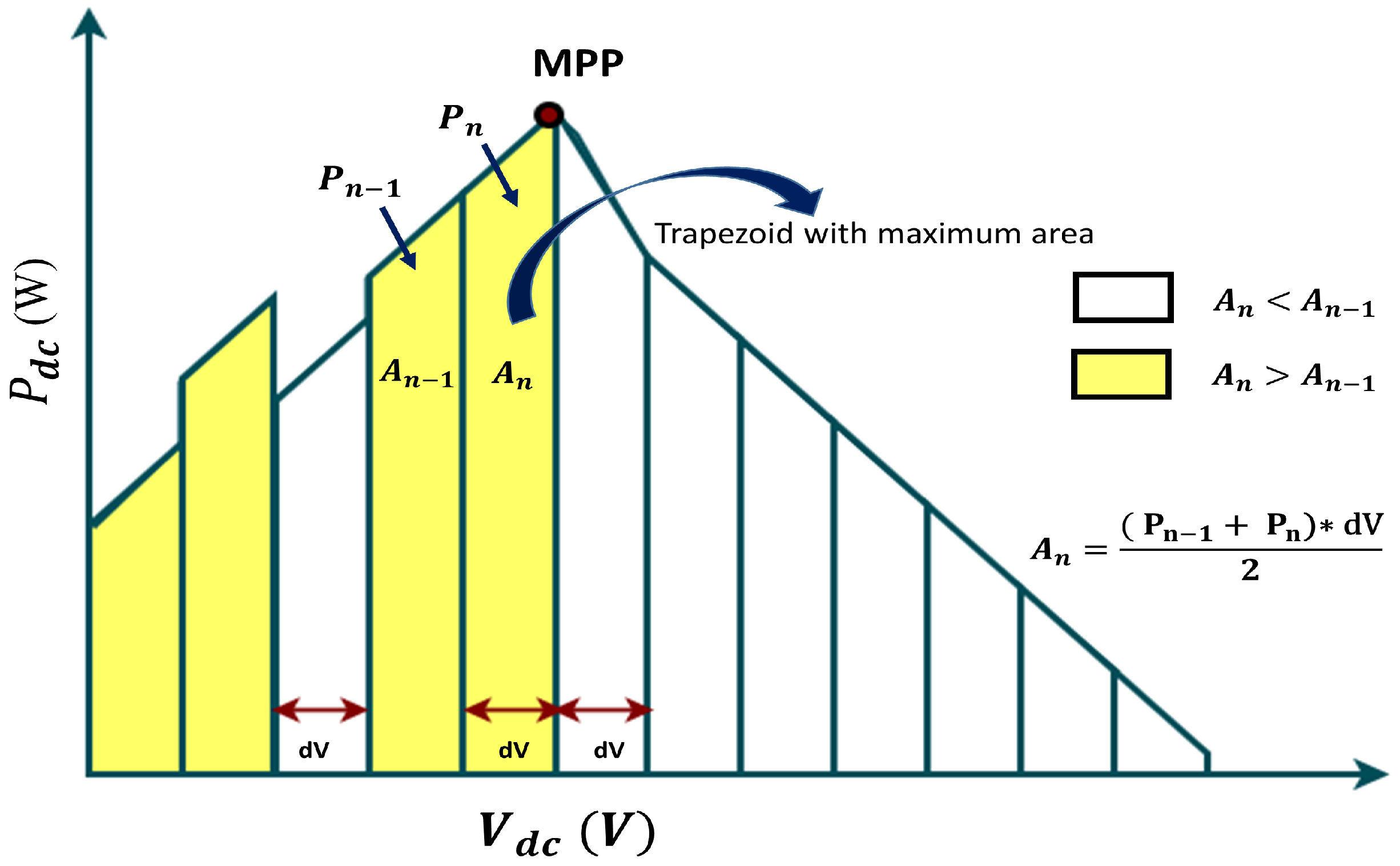

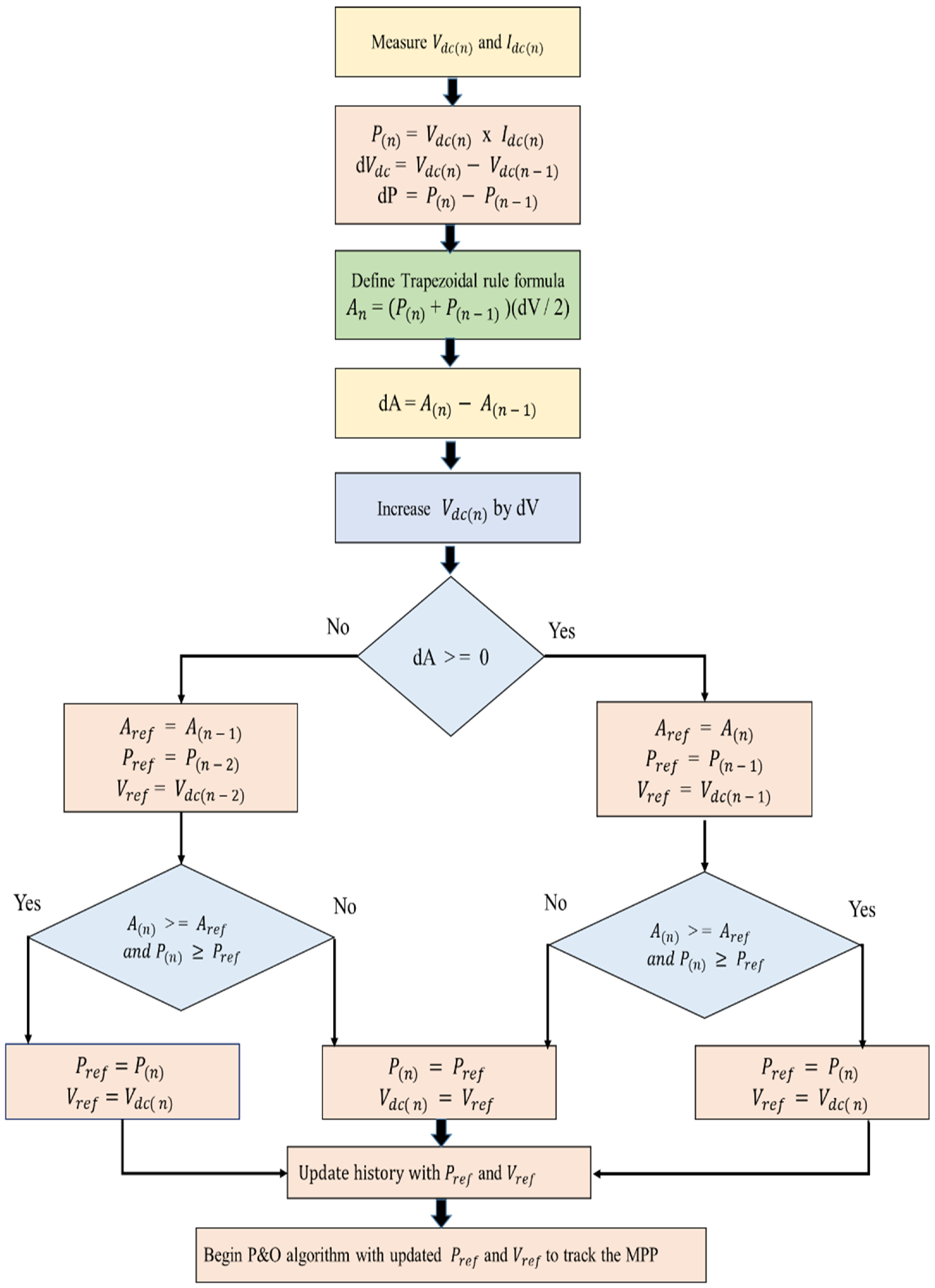

- Step 1 The first step of the algorithm employs the trapezoidal rule and divides the – curve into trapezoids of equal width using the formula for the trapezoidal rule.

- Step 2 In the second stage, the adjacent trapezoids are compared with respect to area, and the trapezoid with the maximum area (and hence power) is identified.

- Step 3 In the third and last step of the algorithm, the values of voltage () and power () from this identified trapezoid are updated, and based on these updated values, the P&O technique is employed for tracking the MPP.

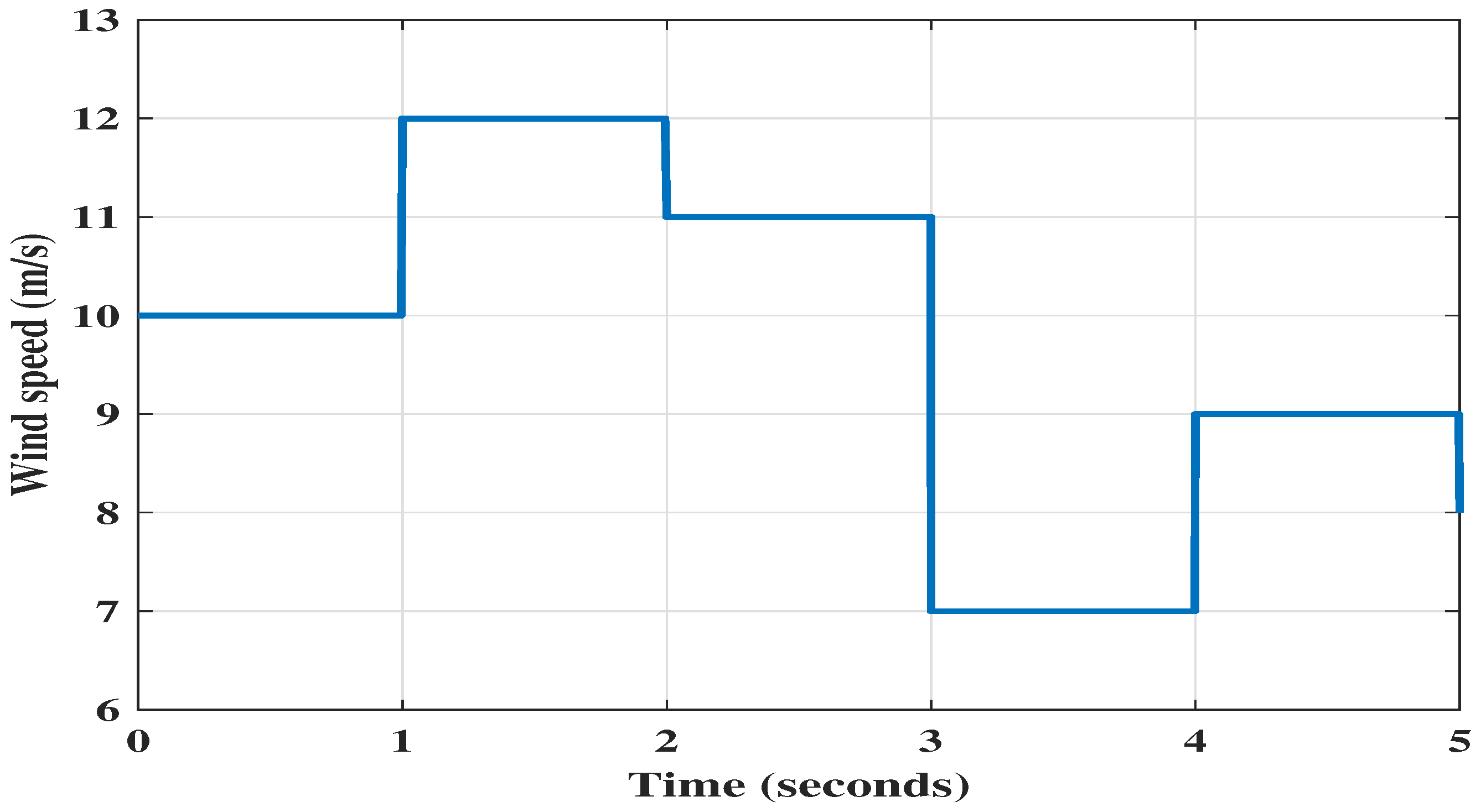

4. Simulation of the Proposed Algorithm

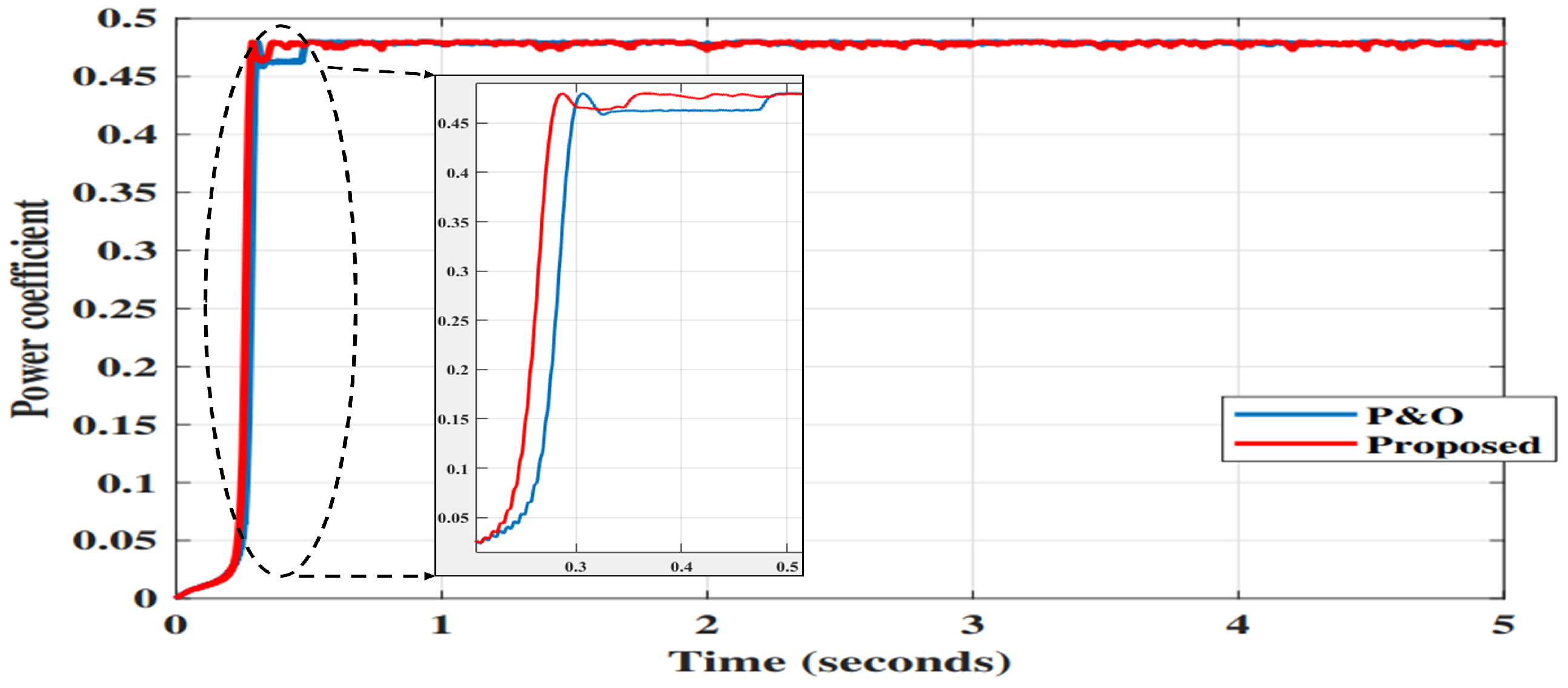

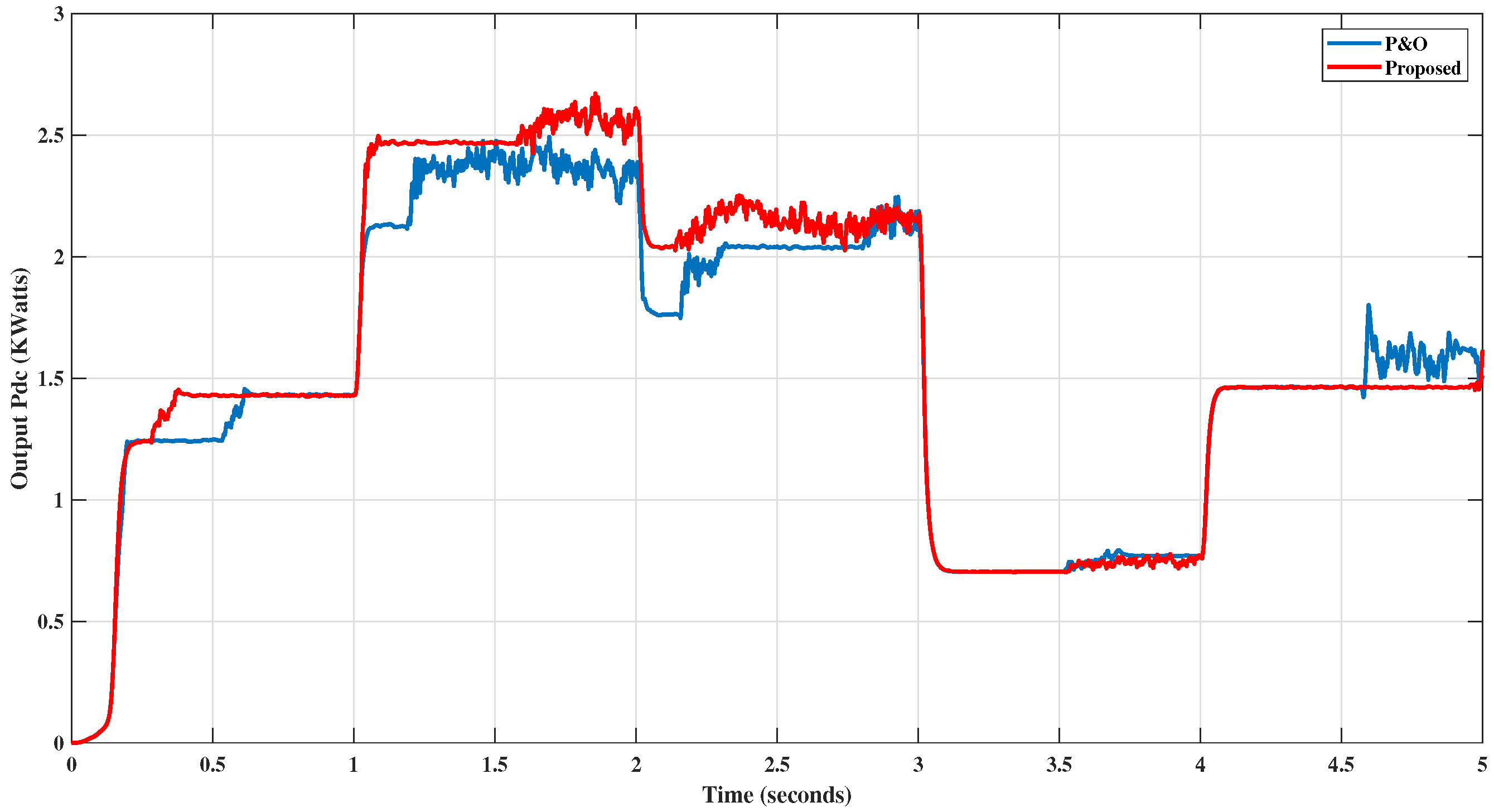

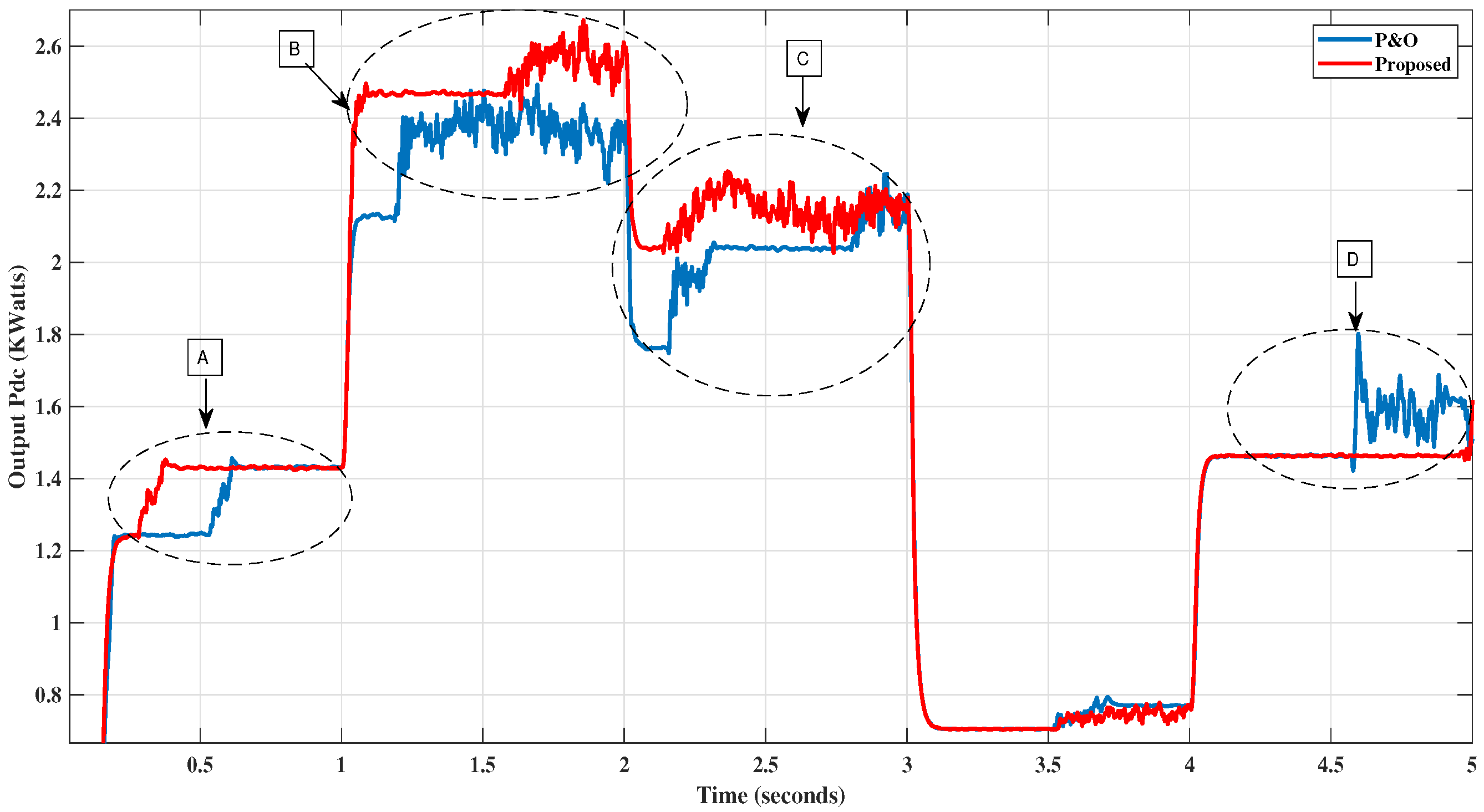

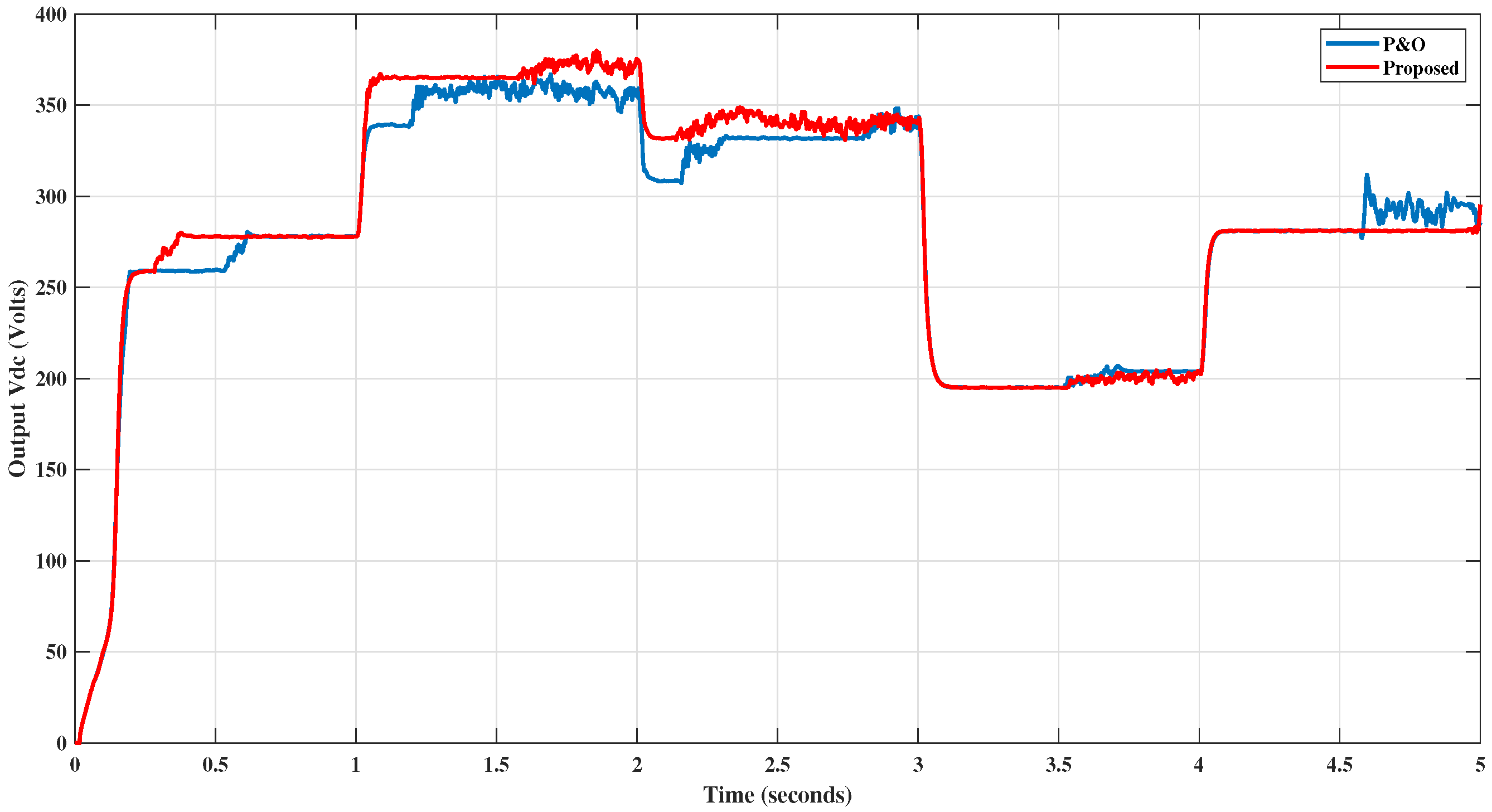

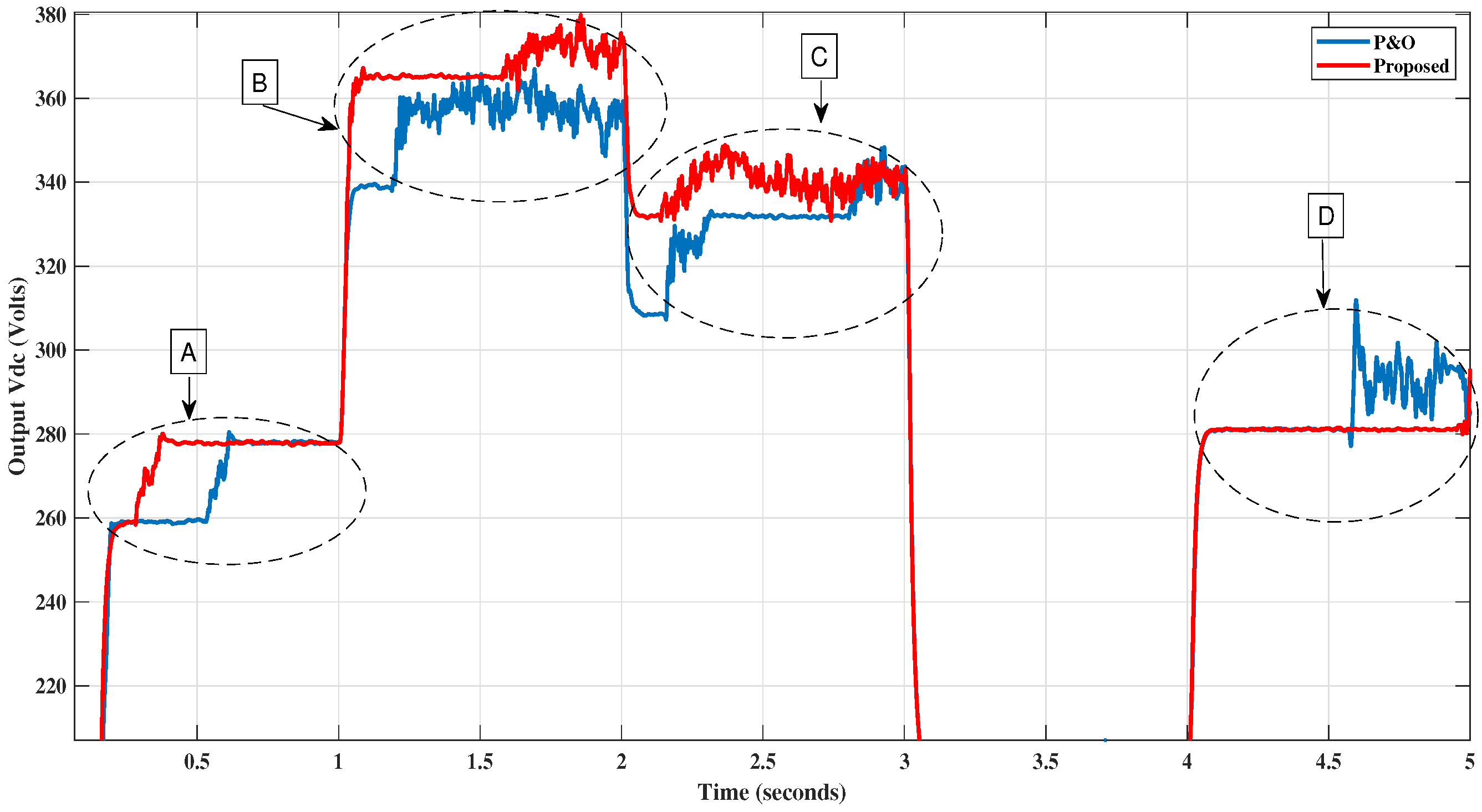

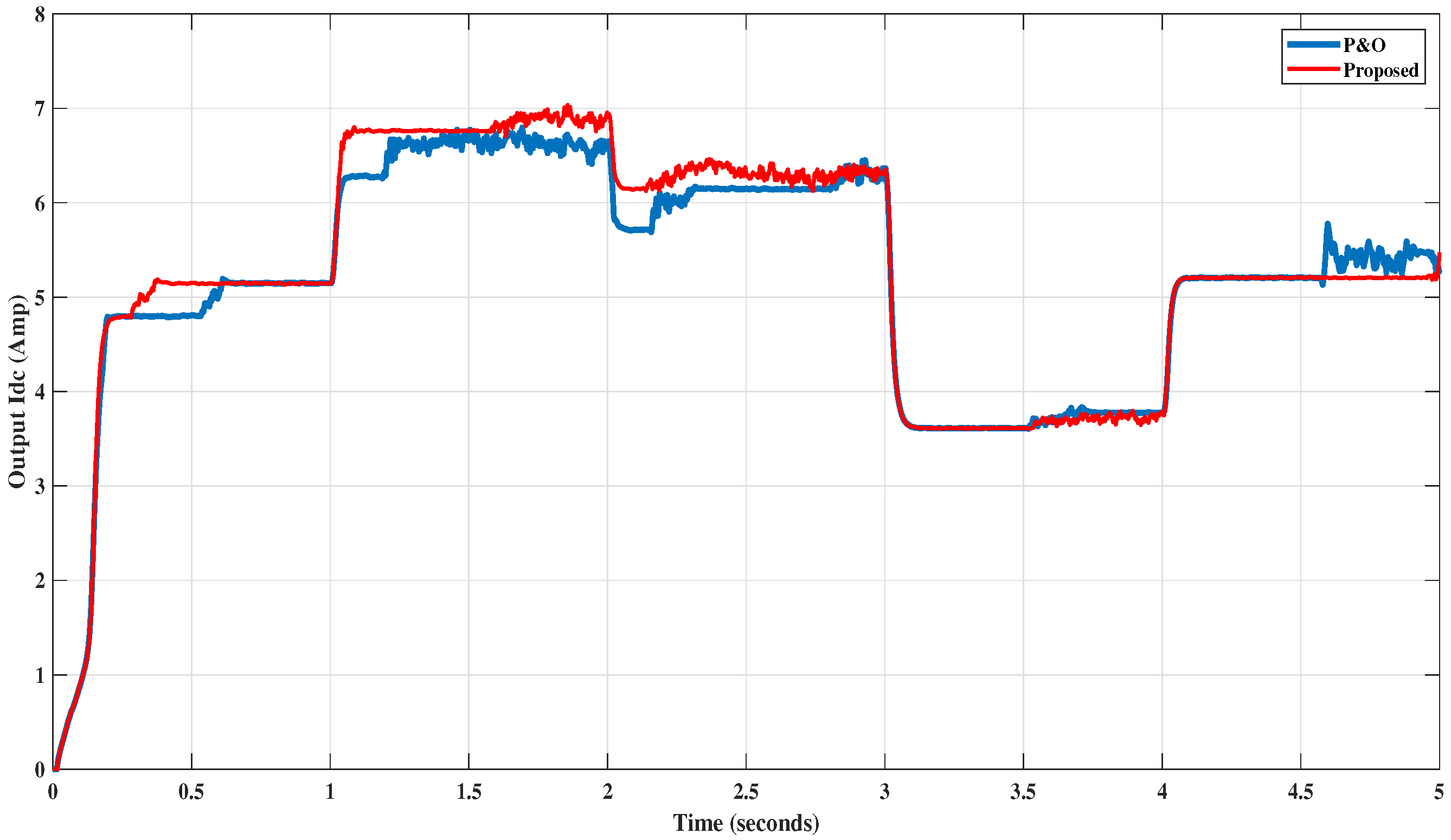

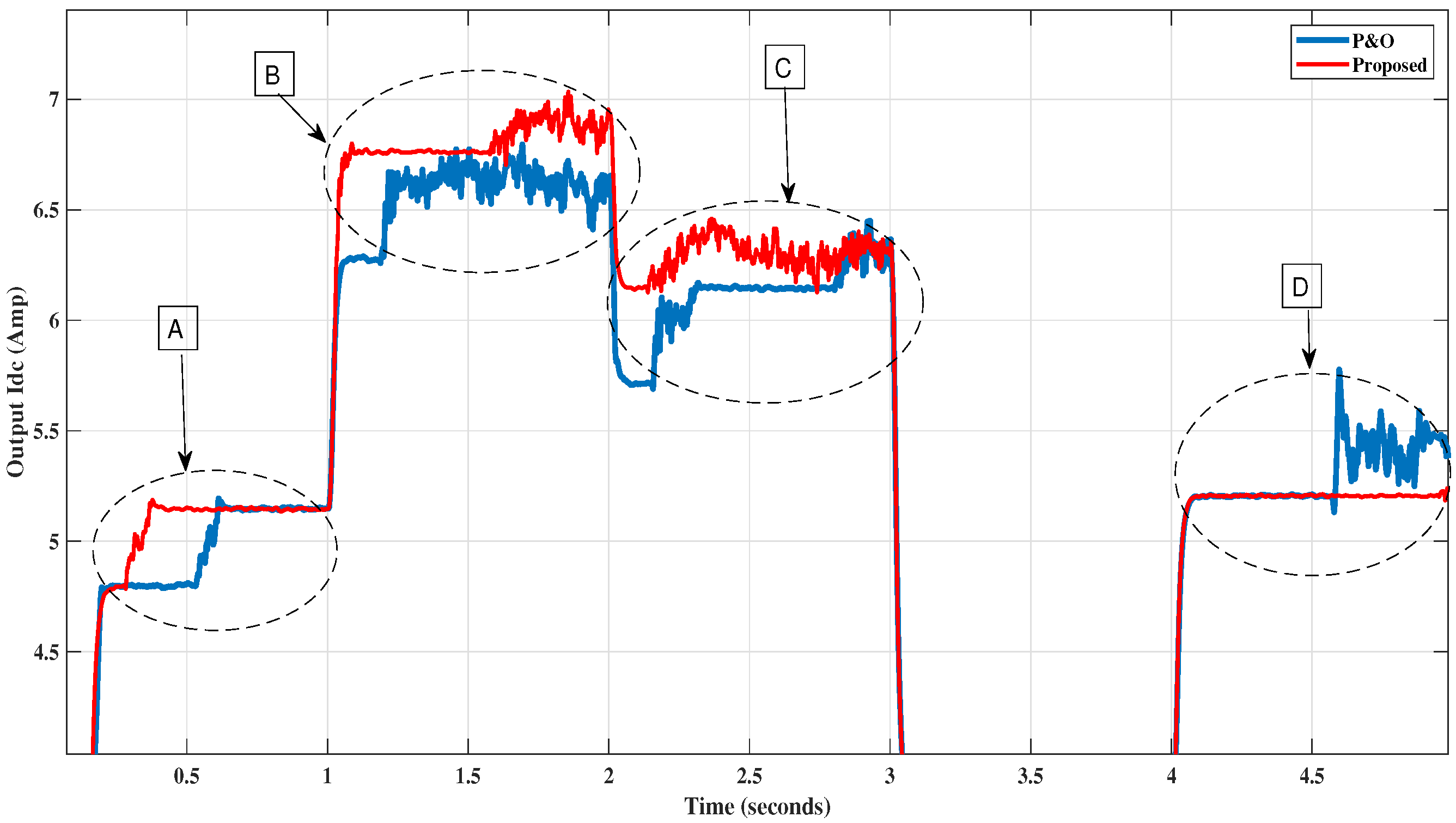

5. Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WT | Wind turbine |

| WECS | Wind energy conversion system |

| MPP | Maximum power point |

| MPPT | Maximum power point tracking |

| P&O | Perturb and observe |

| VAWT | Vertical axis wind turbine |

| HAWT | Horizontal axis wind turbine |

| VSWT | Variable speed wind turbine |

| FSWT | Fixed speed wind turbine |

| SCIG | Squirrel cage induction generator |

| DFIG | Doubly fed induction generator |

| PMSG | Permanent magnet synchronous generator |

| FRT | Fault ride through |

| IPC | Indirect power control |

| DPC | Direct power control |

| TSR | Tip speed ratio |

| PSF | Power signal flow |

| OT | Optimal torque |

| INC | Incremental conductance |

| ORB | Optimal-relation-based |

| NN | Neural network |

| ANN | Artificial neural network |

| FLC | Fuzzy logic control |

| PID | Proportional integral derivative |

| MVPO | Multivariable perturb and observe |

| CPO | Conventional perturb and observe |

| MPO | Modified perturb and observe |

| CS | Cuckoo search |

| PSO | Particle swarm optimization |

| ACO | Ant colony optimization |

| TLBO | Teaching learning based optimization |

References

- Kaldellis, J.K.; Apostolou, D. Life cycle energy and carbon footprint of offshore wind energy. Comparison with onshore counterpart. Renew. Energy 2017, 108, 72–84. [Google Scholar] [CrossRef]

- Aliyu, A.K.; Modu, B.; Tan, C.W. A review of renewable energy development in Africa: A focus in South Africa, Egypt and Nigeria. Renew. Sustain. Energy Rev. 2018, 81, 2502–2518. [Google Scholar] [CrossRef]

- Egea-Alvarez, A.; Junyent-Ferre, A.; Bergas-Jané, J.; Bianchi, F.D.; Gomis-Bellmunt, O. Control of a wind turbine cluster based on squirrel cage induction generators connected to a single VSC power converter. Int. J. Electr. Power Energy Syst. 2014, 61, 523–530. [Google Scholar] [CrossRef]

- Rajaei, A.; Mohamadian, M.; Yazdian Varjani, A. Vienna-rectifier-based direct torque control of PMSG for wind energy application. IEEE Trans. Ind. Electron. 2013, 60, 2919–2929. [Google Scholar] [CrossRef]

- Singh, M.; Chandra, A. Application of adaptive network-based fuzzy inference system for sensorless control of PMSG-based wind turbine with nonlinear-load-compensation capabilities. IEEE Trans. Power Electron. 2011, 26, 165–175. [Google Scholar] [CrossRef]

- Chen, Z.; Guerrero, J.M.; Blaabjerg, F. A review of the state of the art of power electronics for wind turbines. IEEE Trans. Power Electron. 2009, 24, 1859–1875. [Google Scholar] [CrossRef]

- Linus, R.M.; Damodharan, P. Maximum power point tracking and grid feeding of permanent magnet synchronous generator based wind energy conversion system using modified hill climb searching algorithm. In Proceedings of the India International Conference on Power Electronics, IICPE, Delhi, India, 6–8 December 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.; Qiao, W.; Qu, L. A space-vector-modulated sensorless direct-torque control for direct-drive PMSG wind turbines. IEEE Trans. Ind. Appl. 2014, 50, 2331–2341. [Google Scholar] [CrossRef]

- Xie, D.; Lu, Y.; Sun, J.; Gu, C. Small signal stability analysis for different types of PMSGs connected to the grid. Renew. Energy 2017, 106, 149–164. [Google Scholar] [CrossRef]

- Uehara, A.; Pratap, A.; Goya, T.; Senjyu, T.; Yona, A.; Urasaki, N.; Funabashi, T. A coordinated control method to smooth wind power fluctuations of a PMSG-Based WECS. IEEE Trans. Energy Convers. 2011, 26, 550–558. [Google Scholar] [CrossRef]

- Duran, M.J.; Barrero, F.; Pozo-Ruz, A.; Guzman, F.; Fernandez, J.; Guzman, H. Understanding power electronics and electrical machines in multidisciplinary wind energy conversion system courses. IEEE Trans. Educ. 2013, 56, 174–182. [Google Scholar] [CrossRef]

- Cheng, M.; Zhu, Y. The state of the art of wind energy conversion systems and technologies: A review. Energy Convers. Manag. 2014, 88, 332–347. [Google Scholar] [CrossRef]

- Singh, G.K. Self-excited induction generator research—A survey. Electr. Power Syst. Res. 2004, 69, 107–114. [Google Scholar] [CrossRef]

- Patel, M.R. Wind and solar power systems: Design, analysis, and operation, second edition. J. Environ. Energy 2005, 35, 692. [Google Scholar] [CrossRef]

- Kumar, D.; Chatterjee, K. Artificial bee colony based MPPT algorithm for wind energy conversion system. In Proceedings of the 2016 IEEE 6th International Conference on Power Systems, ICPS 2016, New Delhi, India, 4–6 March 2016. [Google Scholar] [CrossRef]

- Mittal, R.; Sandhu, K.; Jain, D. An Overview of Some Important Issues Related to Wind Energy Conversion System (WECS). Int. J. Environ. Sci. Dev. 2010, 1, 351–363. [Google Scholar] [CrossRef]

- Aslam Bhutta, M.M.; Hayat, N.; Farooq, A.U.; Ali, Z.; Jamil, S.R.; Hussain, Z. Vertical axis wind turbine—A review of various configurations and design techniques. Renew. Sustain. Energy Rev. 2012, 16, 1926–1939. [Google Scholar] [CrossRef]

- Njiri, J.G.; Söffker, D. State-of-the-art in wind turbine control: Trends and challenges. Renew. Sustain. Energy Rev. 2016, 60, 377–393. [Google Scholar] [CrossRef]

- Pao, L.Y.; Johnson, K.E. Control of Wind Turbines: Approaches, challenges, and recent developments. IEEE Control Syst. 2011, 31, 44–62. [Google Scholar] [CrossRef]

- Castelló, J.; Espí, J.M.; García-Gil, R. Development details and performance assessment of a Wind Turbine Emulator. Renew. Energy 2016, 86, 848–857. [Google Scholar] [CrossRef]

- Ghaffari, A.; Krstić, M.; Seshagiri, S. Power optimization and control in wind energy conversion systems using extremum seeking. IEEE Trans. Control Syst. Technol. 2014, 22, 1684–1695. [Google Scholar] [CrossRef]

- Taveiros, F.E.; Barros, L.S.; Costa, F.B. Back-to-back converter state-feedback control of DFIG (doubly-fed induction generator)-based wind turbines. Energy 2015, 89, 896–906. [Google Scholar] [CrossRef]

- Abdullah, M.A.; Yatim, A.H.; Tan, C.W.; Saidur, R. A review of maximum power point tracking algorithms for wind energy systems. Renew. Sustain. Energy Rev. 2012, 16, 3220–3227. [Google Scholar] [CrossRef]

- Youssef, A.R.; Mousa, H.H.; Mohamed, E.E. Development of self-adaptive P&O MPPT algorithm for wind generation systems with concentrated search area. Renew. Energy 2020, 154, 875–893. [Google Scholar] [CrossRef]

- Mei, Q.; Shan, M.; Liu, L.; Guerrero, J.M. A novel improved variable step-size incremental-resistance MPPT method for PV systems. IEEE Trans. Ind. Electron. 2011, 58, 2427–2434. [Google Scholar] [CrossRef]

- Lahfaoui, B.; Zouggar, S.; Mohammed, B.; Elhafyani, M.L. Real Time Study of P&O MPPT Control for Small Wind PMSG Turbine Systems Using Arduino Microcontroller. Energy Procedia 2017, 111, 1000–1009. [Google Scholar] [CrossRef]

- Kazmi, S.M.R.; Goto, H.; Guo, H.J.; Ichinokura, O. A novel algorithm for fast and efficient speed-sensorless maximum power point tracking in wind energy conversion systems. IEEE Trans. Ind. Electron. 2011, 58, 29–36. [Google Scholar] [CrossRef]

- Chen, J.; Lin, T.; Wen, C.; Song, Y. Design of a Unified Power Controller for Variable-Speed Fixed-Pitch Wind Energy Conversion System. IEEE Trans. Ind. Electron. 2016, 63, 4899–4908. [Google Scholar] [CrossRef]

- Ahmed, S.; Rashid, M.A.; Mohamed, S.B.; Yaakob, S.B. A Novel Maximum Power Point Tracking Algorithm for Wind Energy Conversion System. Eng. Lett. 2019, 27, 822–830. [Google Scholar]

- Mousa, H.H.; Youssef, A.R.; Mohamed, E.E. Variable step size P&O MPPT algorithm for optimal power extraction of multi-phase PMSG based wind generation system. Int. J. Electr. Power Energy Syst. 2019, 108, 218–231. [Google Scholar] [CrossRef]

- Ali, M.M.; Youssef, A.R.; Ali, A.S.; Abdel-Jaber, G.T. Variable step size PO MPPT algorithm using model reference adaptive control for optimal power extraction. Int. Trans. Electr. Energy Syst. 2020, 30, 1–21. [Google Scholar] [CrossRef]

- Mozafarpoor-Khoshrodi, S.H.; Shahgholian, G. Improvement of perturb and observe method for maximum power point tracking in wind energy conversion system using fuzzy controller. Energy Equip. Syst. 2016, 4, 111–122. [Google Scholar] [CrossRef]

- Mousa, H.H.; Youssef, A.R.; Mohamed, E.E. Adaptive P&O MPPT algorithm based wind generation system using realistic wind fluctuations. Int. J. Electr. Power Energy Syst. 2019, 112, 294–308. [Google Scholar] [CrossRef]

- Youssef, A.R.; Ali, A.I.; Saeed, M.S.; Mohamed, E.E. Advanced multi-sector P&O maximum power point tracking technique for wind energy conversion system. Int. J. Electr. Power Energy Syst. 2019, 107, 89–97. [Google Scholar] [CrossRef]

- Hassan Abdou, E.; Youssef, A.R.; Kamel, S.; Aly, M. Sensor Less Proposed Multi Sector Perturb and Observe Maximum Power Tracking for 1.5 MW Based on DFIG. J. Control. Instrum. Eng. 2020, 6, 1–13. [Google Scholar] [CrossRef]

- Chaicharoenaudomrung, K.; Areerak, K.; Areerak, K.; Bozhko, S.; Hill, C.I. Maximum Power Point Tracking for Stand-Alone Wind Energy Conversion System Using FLC-P&O Method. IEEJ Trans. Electr. Electron. Eng. 2020, 15, 1723–1733. [Google Scholar] [CrossRef]

- Mousa, H.H.; Youssef, A.R.; Mohamed, E.E. Hybrid and adaptive sectors P&O MPPT algorithm based wind generation system. Renew. Energy 2020, 145, 1412–1429. [Google Scholar] [CrossRef]

- Watil, A.; El Magri, A.; Raihani, A.; Lajouad, R.; Giri, F. Multi-objective output feedback control strategy for a variable speed wind energy conversion system. Int. J. Electr. Power Energy Syst. 2020, 121, 106081. [Google Scholar] [CrossRef]

- Errami, Y.; Ouassaid, M.; Maaroufi, M. A performance comparison of a nonlinear and a linear control for grid connected PMSG wind energy conversion system. Int. J. Electr. Power Energy Syst. 2015, 68, 180–194. [Google Scholar] [CrossRef]

- Jadhav, H.T.; Roy, R. A comprehensive review on the grid integration of doubly fed induction generator. Int. J. Electr. Power Energy Syst. 2013, 49, 8–18. [Google Scholar] [CrossRef]

- Pande, J.; Nasikkar, P.; Kotecha, K. A Review of Maximum Power Point Tracking Algorithms for Wind Energy Conversion Systems. J. Mar. Sci. Eng. 2021, 9, 1187. [Google Scholar] [CrossRef]

- Priyadarshi, N.; Ramachandaramurthy, V.K.; Padmanaban, S.; Azam, F. An ant colony optimized mppt for standalone hybrid pv-wind power system with single cuk converter. Energies 2019, 12, 167. [Google Scholar] [CrossRef]

- Parker, C.M.; Leftwich, M.C. The effect of tip speed ratio on a vertical axis wind turbine at high Reynolds numbers. Exp. Fluids 2016, 57, 1–11. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, X.; Yu, T.; Shu, H.; Fang, Z. Grouped grey wolf optimizer for maximum power point tracking of doubly-fed induction generator based wind turbine. Energy Convers. Manag. 2017, 133, 427–443. [Google Scholar] [CrossRef]

- Abdullah, M.A.; Al-Hadhrami, T.; Tan, C.W.; Yatim, A.H. Towards green energy for smart cities: Particle swarm optimization based MPPT approach. IEEE Access 2018, 6, 58427–58438. [Google Scholar] [CrossRef]

- Altwallbah, N.M.M.; Radzi, M.A.M.; Azis, N.; Shafie, S.; Zainuri, M.A.A.M. New perturb and observe algorithm based on trapezoidal rule: Uniform and partial shading conditions. Energy Convers. Manag. 2022, 264, 115738. [Google Scholar] [CrossRef]

- Mahmod Mohammad, A.N.; Amran Mohd Radzi, M.; Azis, N.; Shafie, S.; Atiqi Mohd, M.A. Composite trapezoidal rule-based maximum power point tracking algorithm for photovoltaic systems under complex shading conditions. In Proceedings of the PECon 2020—2020 IEEE International Conference on Power and Energy, Penang, Malaysia, 7–8 December 2020; Institute of Electrical and Electronics Engineers Inc.: Piscatawaj, NJ, USA, 2020; pp. 270–275. [Google Scholar] [CrossRef]

- Mousa, H.H.H.; Youssef, A.R.; Mohamed, E.E.M. International Journal of Electrical Power and Energy Systems State of the art perturb and observe MPPT algorithms based wind energy conversion systems: A technology review. Int. J. Electr. Power Energy Syst. 2021, 126, 106598. [Google Scholar] [CrossRef]

| Issues in Existing MPPT Techniques for WECS | Contribution of the Proposed MPPT Algorithm |

|---|---|

| Complex tracking | Simple tracking approach, employing trapezoidal-rule-based perturb and observe algorithm |

| Higher computational complexity | Reduced computational complexity |

| Accuracy and convergence dependent on best solution provided by metaheuristic methods | Accurate convergence is achieved without the involvement of random steps, thereby helping to reduce oscillation in the generated power. |

| Parameters for Wind Turbine | Value and Unit |

|---|---|

| R | 1.8 m |

| 1.22 kg/m3 | |

| Power rating | 3 kW |

| 0 | |

| Parameters for PMSG | Value and Unit |

| Power rating | 3 kW |

| Number of pole pairs | 4 |

| Rs | 0.4578 ohms |

| Ld = Lq | 3.34 mH |

| J | 0.00496 kgm2 |

| Parameters for the Boost Converter | Value and Unit |

| L | 75 mH |

| C | 0.468 F |

| fs | 5000 Hz |

| RL | 54 ohms |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pande, J.; Nasikkar, P. A Maximum Power Point Tracking Technique for a Wind Power System Based on the Trapezoidal Rule. Energies 2023, 16, 2799. https://doi.org/10.3390/en16062799

Pande J, Nasikkar P. A Maximum Power Point Tracking Technique for a Wind Power System Based on the Trapezoidal Rule. Energies. 2023; 16(6):2799. https://doi.org/10.3390/en16062799

Chicago/Turabian StylePande, Jayshree, and Paresh Nasikkar. 2023. "A Maximum Power Point Tracking Technique for a Wind Power System Based on the Trapezoidal Rule" Energies 16, no. 6: 2799. https://doi.org/10.3390/en16062799

APA StylePande, J., & Nasikkar, P. (2023). A Maximum Power Point Tracking Technique for a Wind Power System Based on the Trapezoidal Rule. Energies, 16(6), 2799. https://doi.org/10.3390/en16062799