Autonomous Electric-Vehicle Control Using Speed Planning Algorithm and Back-Stepping Approach

Abstract

1. Introduction

2. Related Works

2.1. Speed Profile Generation

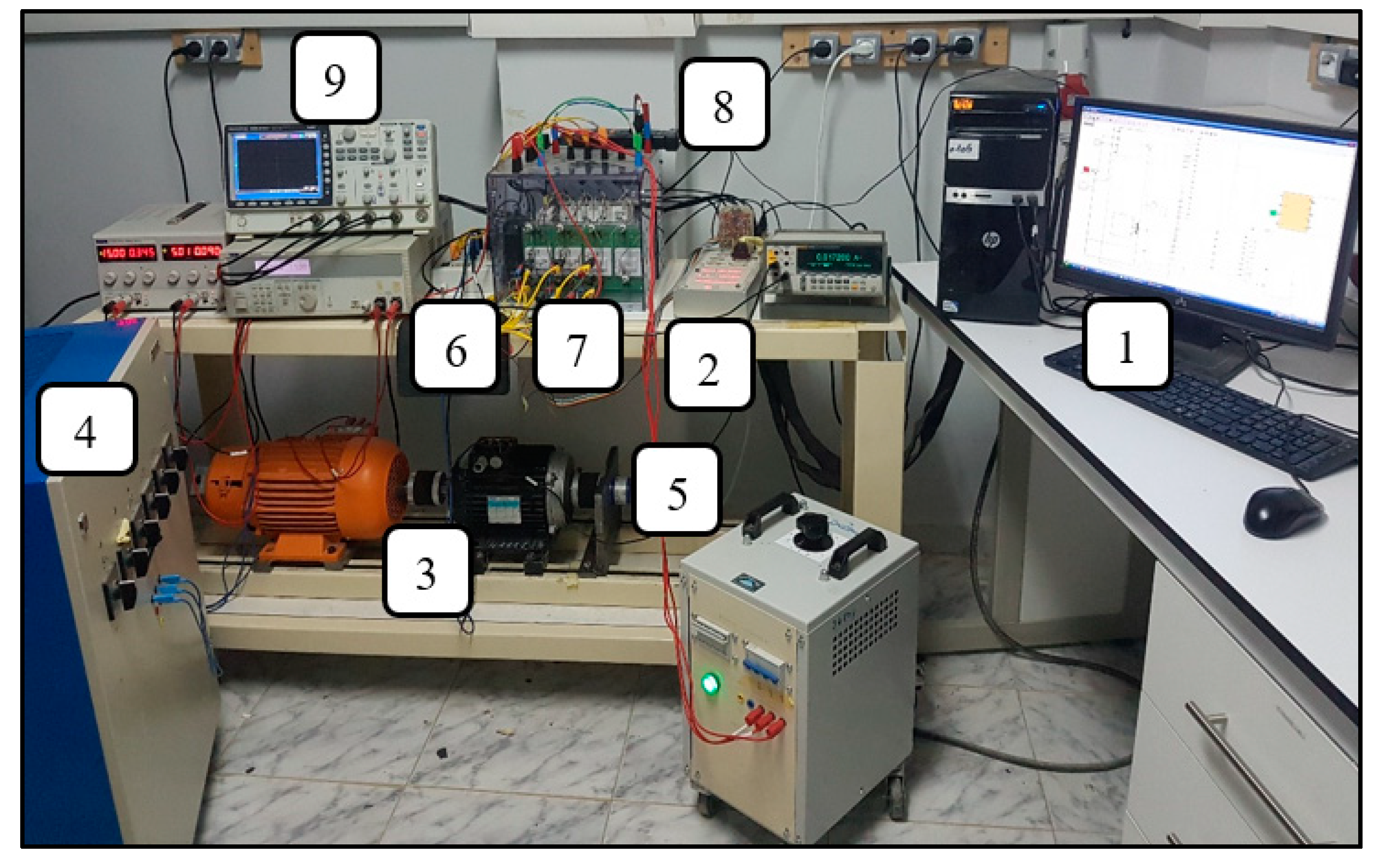

2.2. IM Speed Control

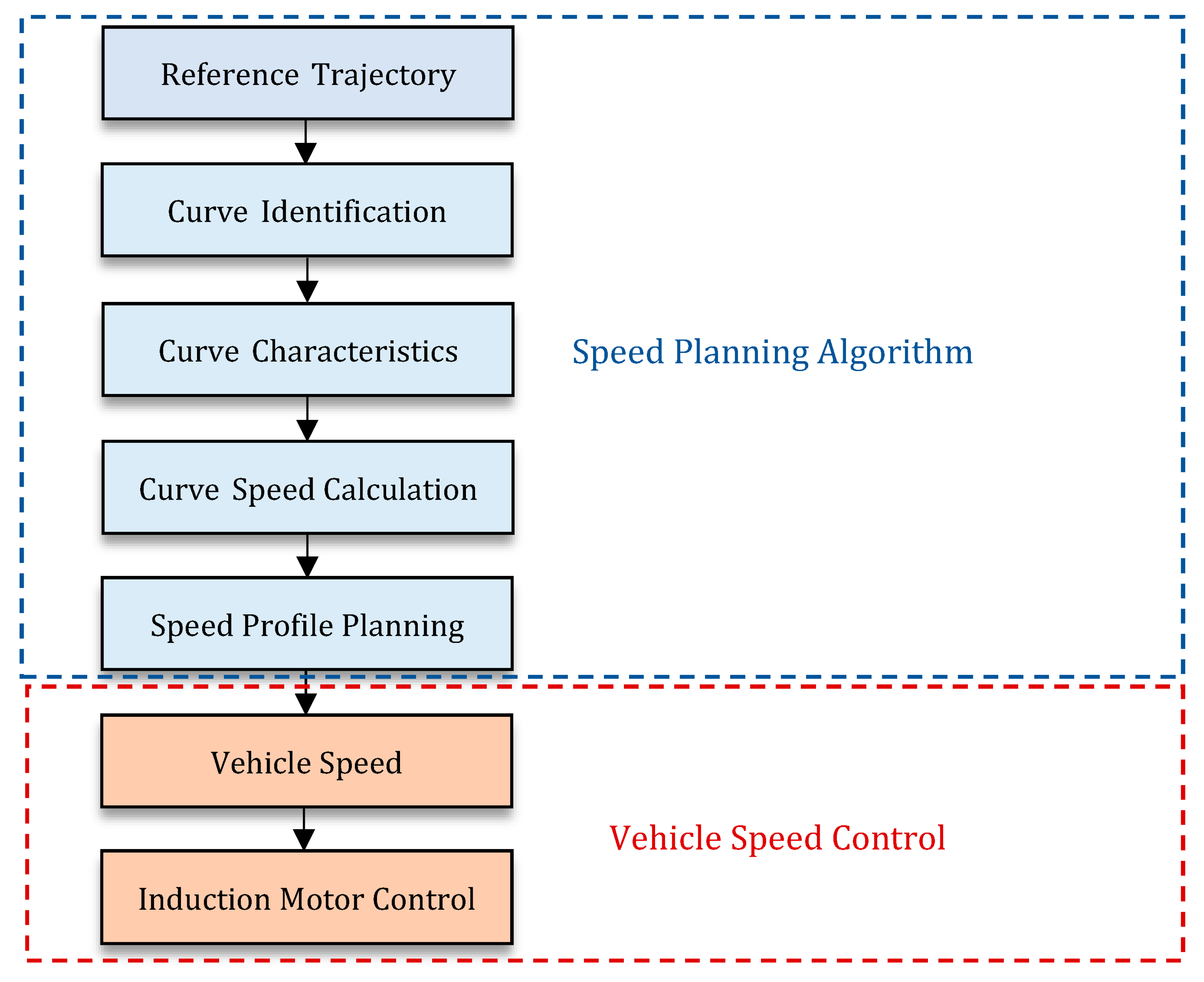

3. Vehicle Velocity Planning

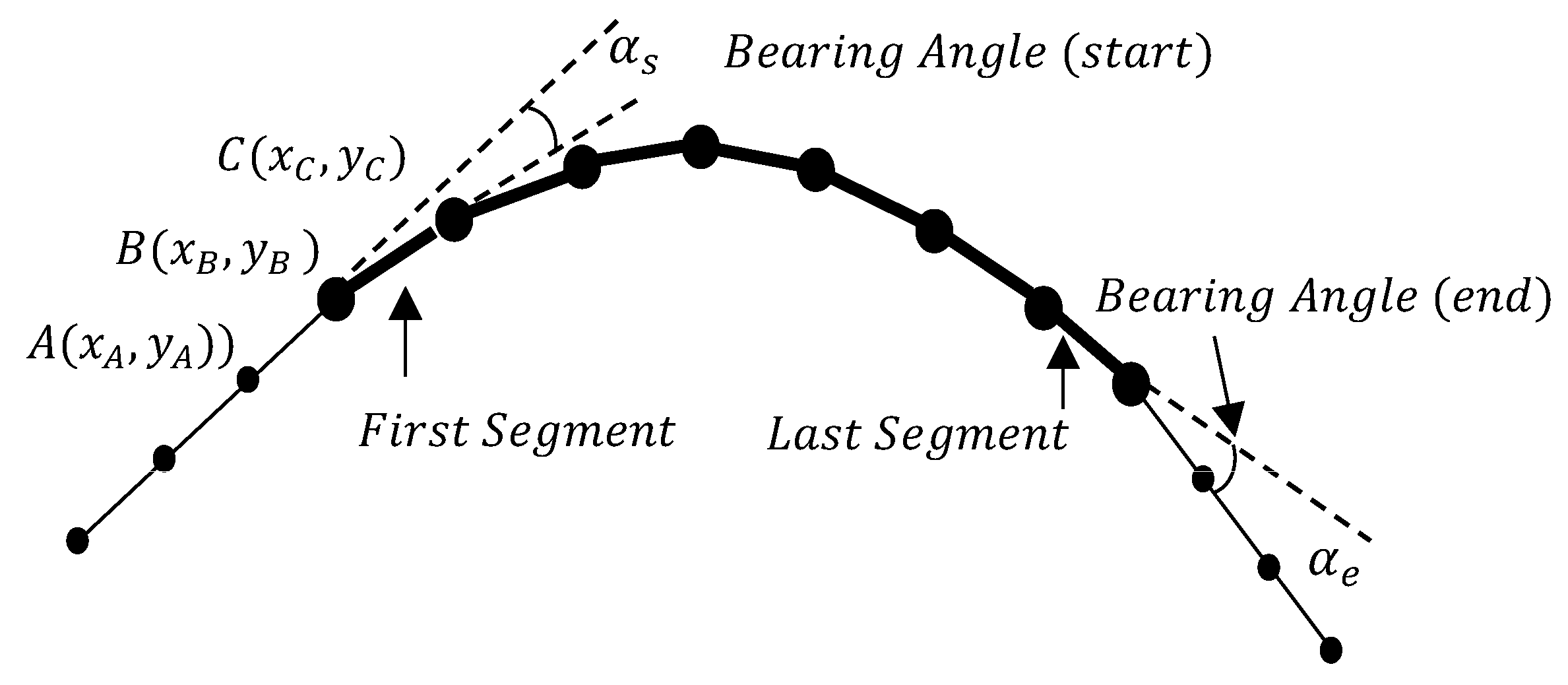

3.1. Curve Identification

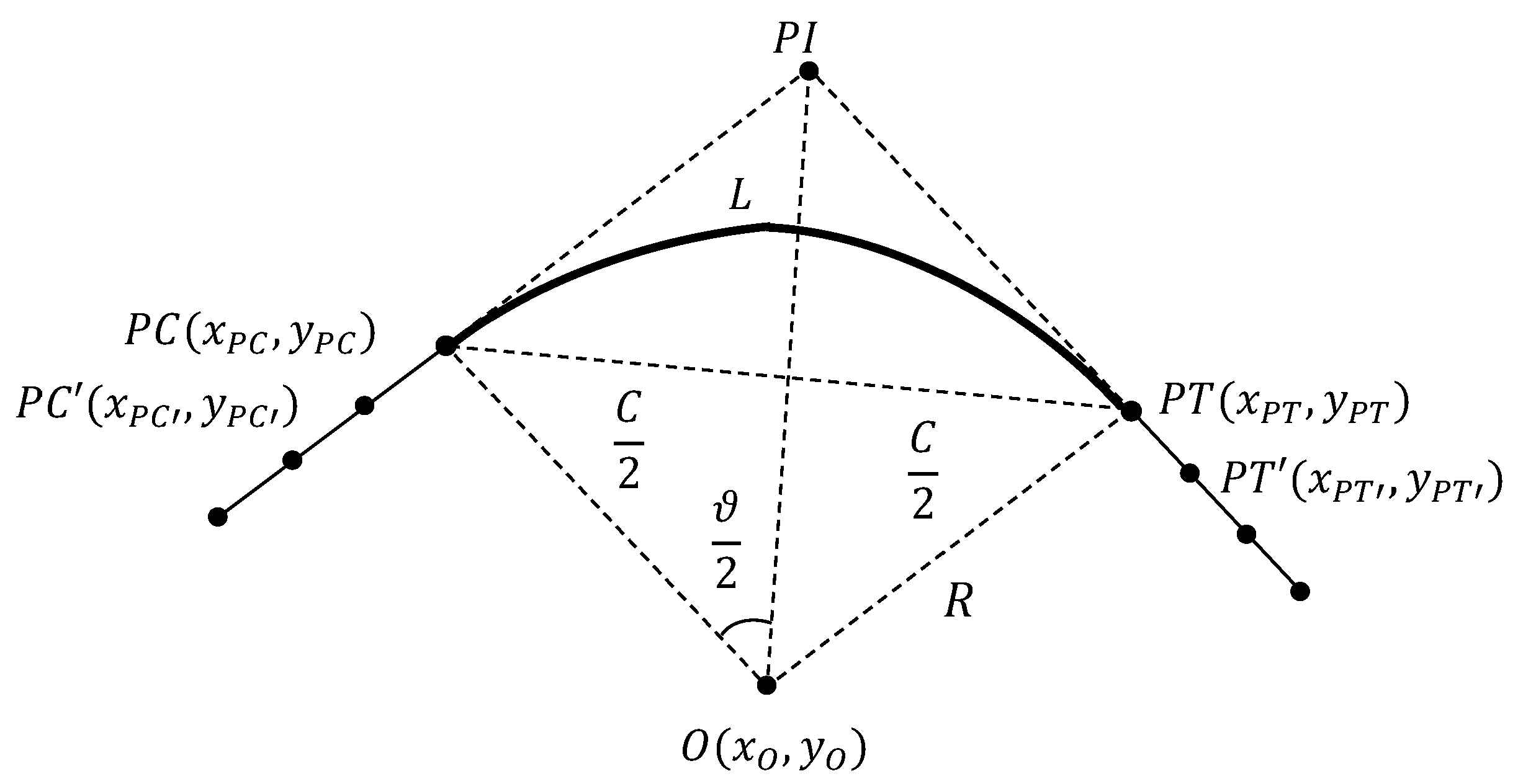

3.2. Curve Characteristics

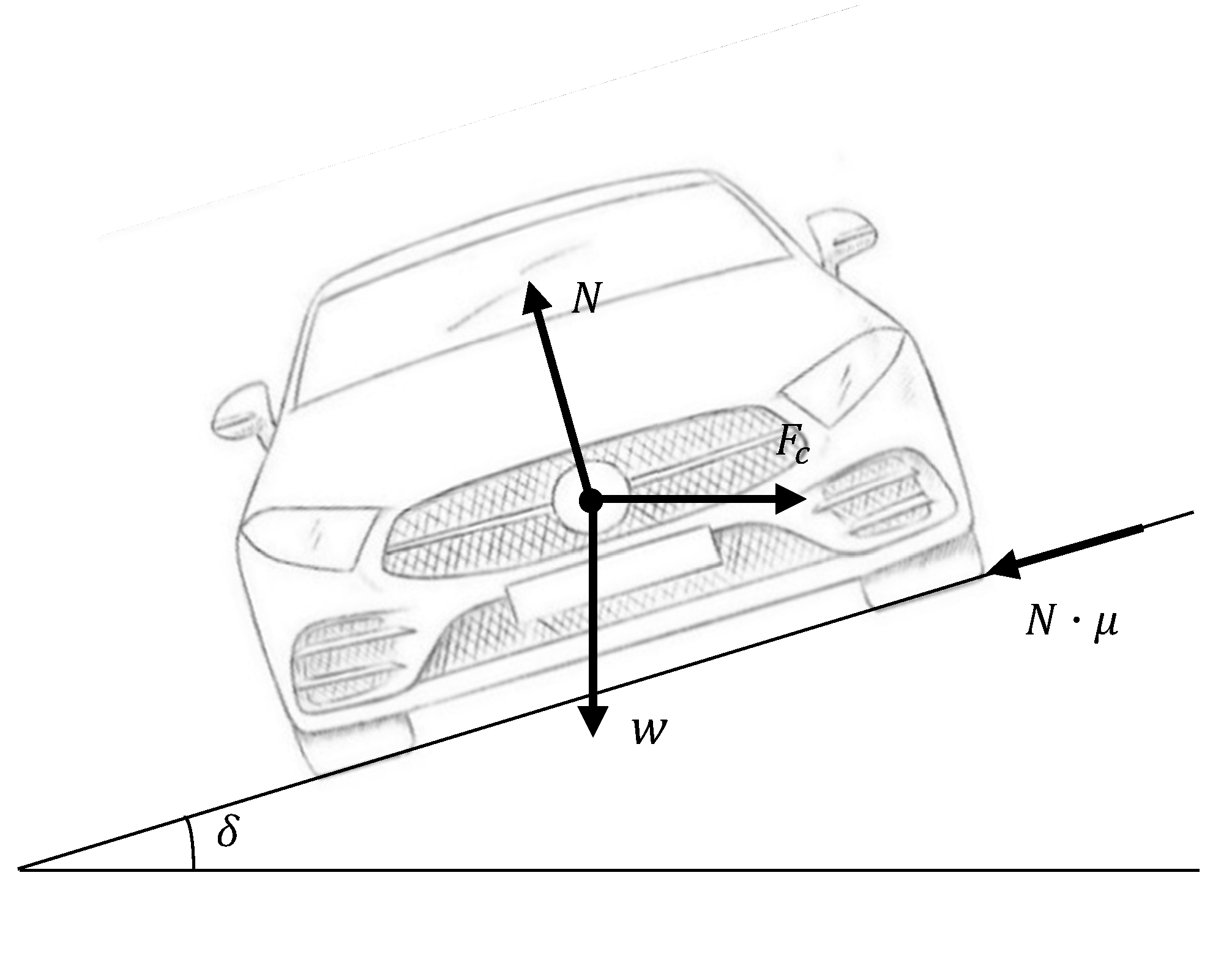

3.3. Curve Speed Calculation

3.4. Speed Profile Planning

- The actual traveled distance is greater than the difference between the curve distance and the required distance to reach the curve.

- The actual traveled distance is less than the summation of the curve distance and the curve length .

- The actual speed is greater than the next curve speed.

4. Vehicle Speed Control

4.1. IM Model Presentation

4.2. Back-Stepping SVM Control Design

- Step 1: Outer loops control

- Step 2: Inner loops control

4.3. Load Torque Estimation

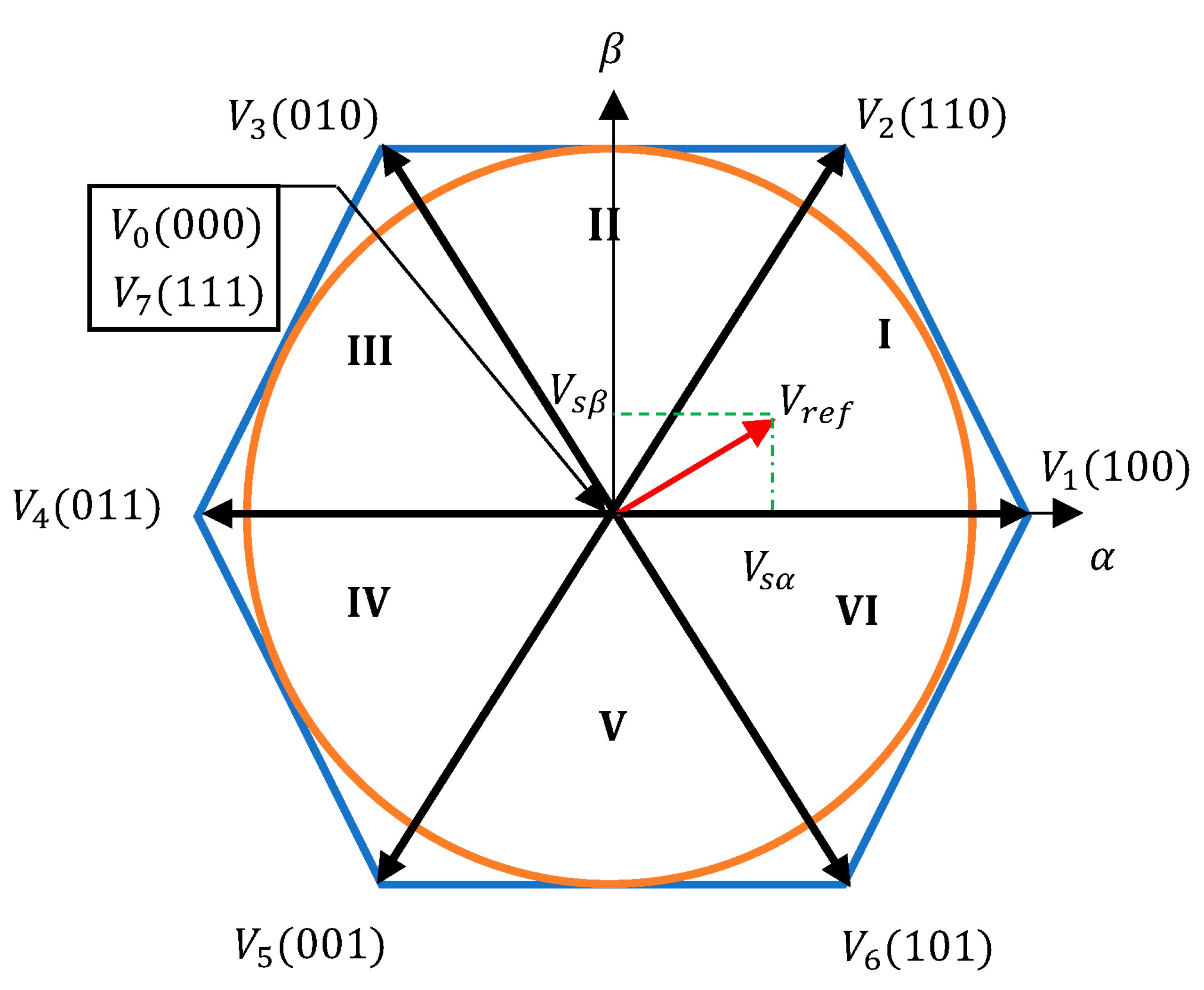

4.4. SVM Strategy Control

5. Results and Discussion

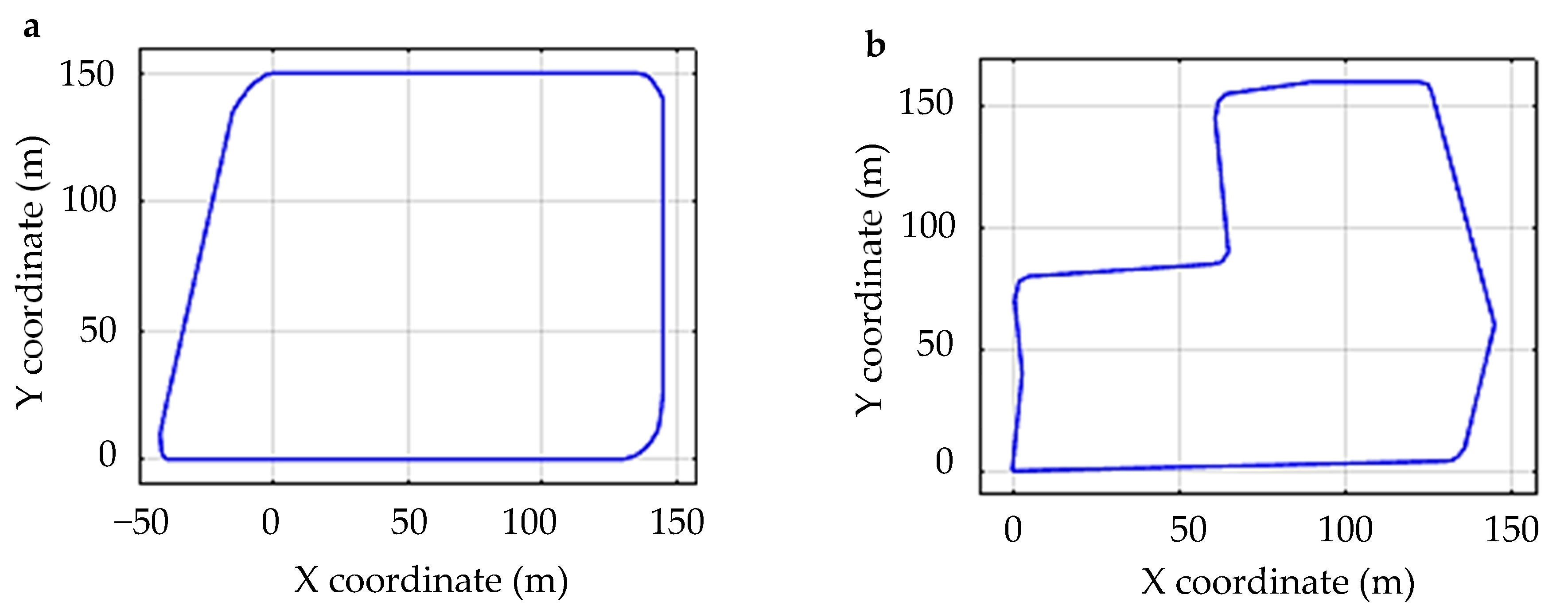

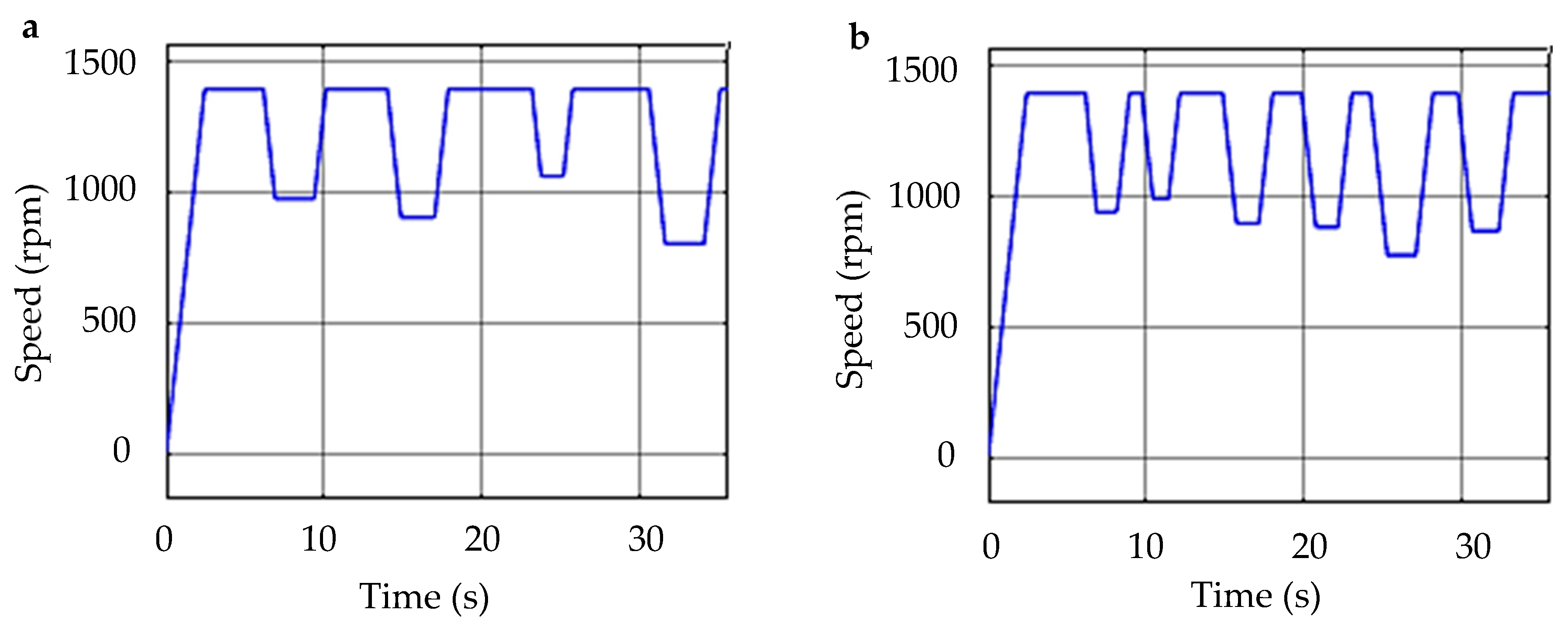

5.1. Speed Planning Results

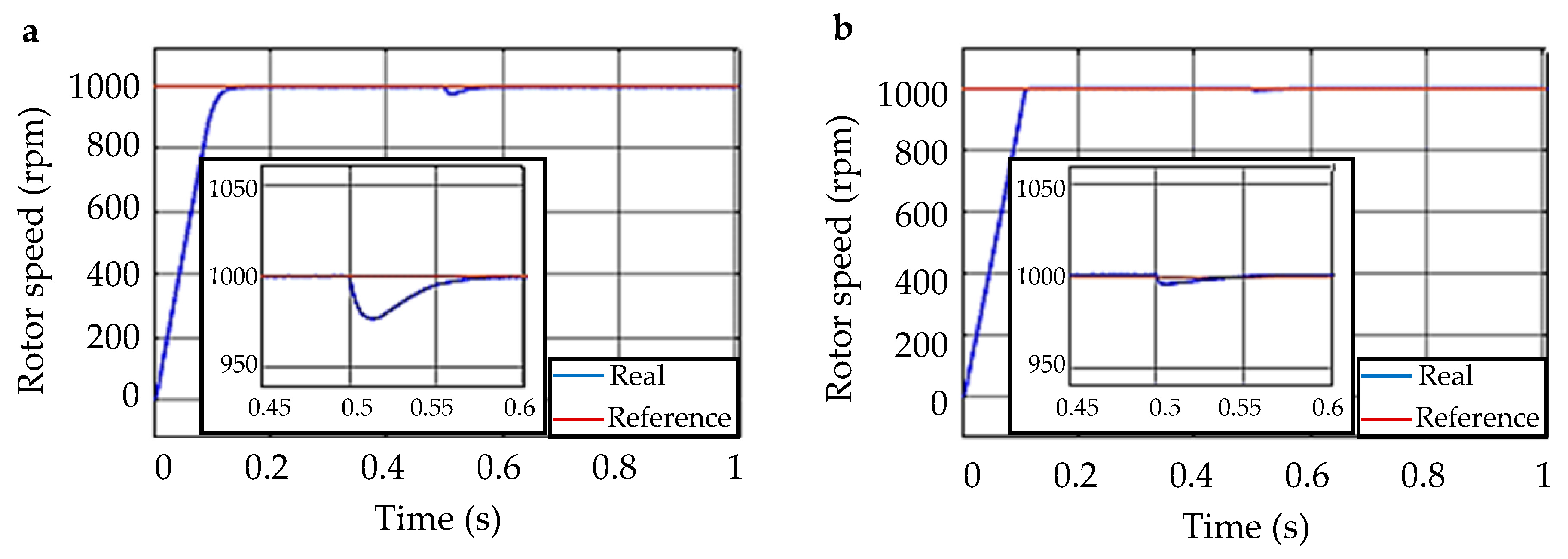

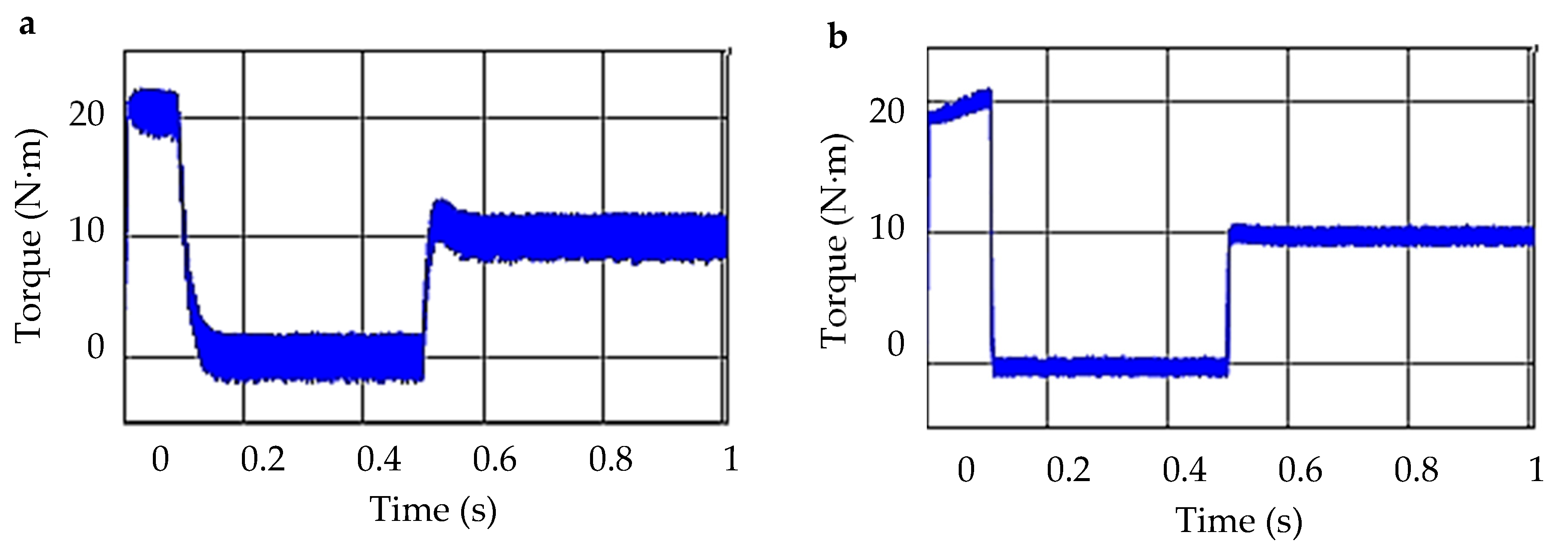

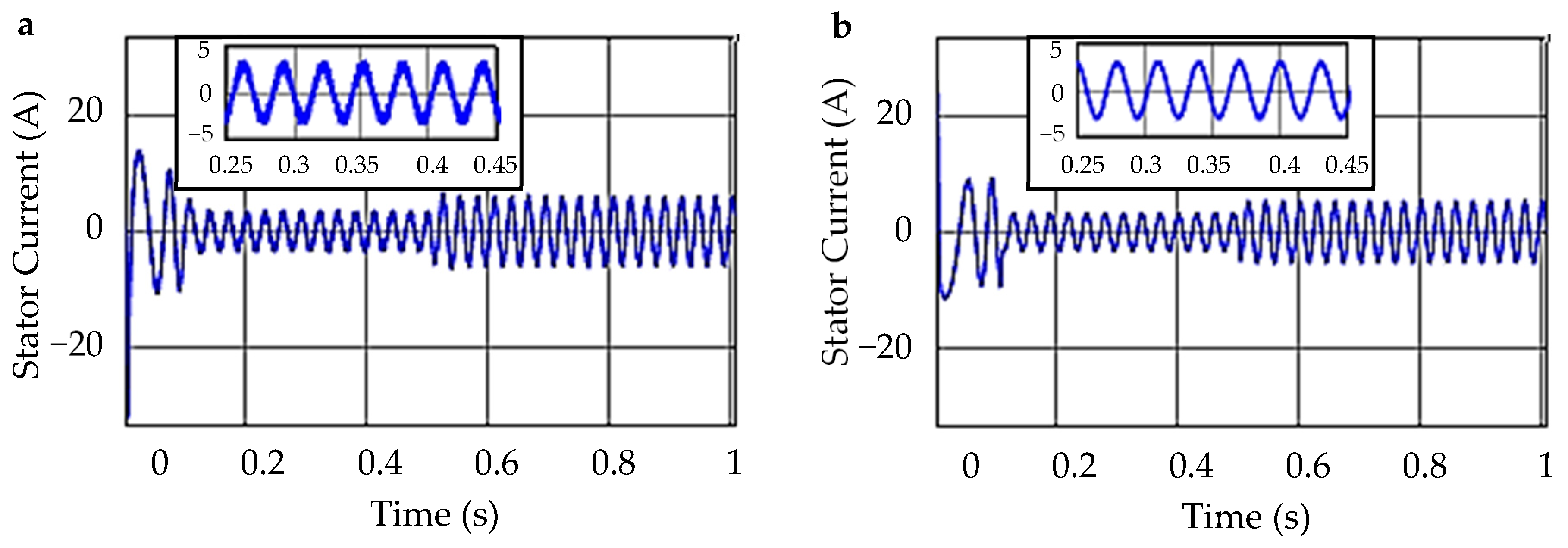

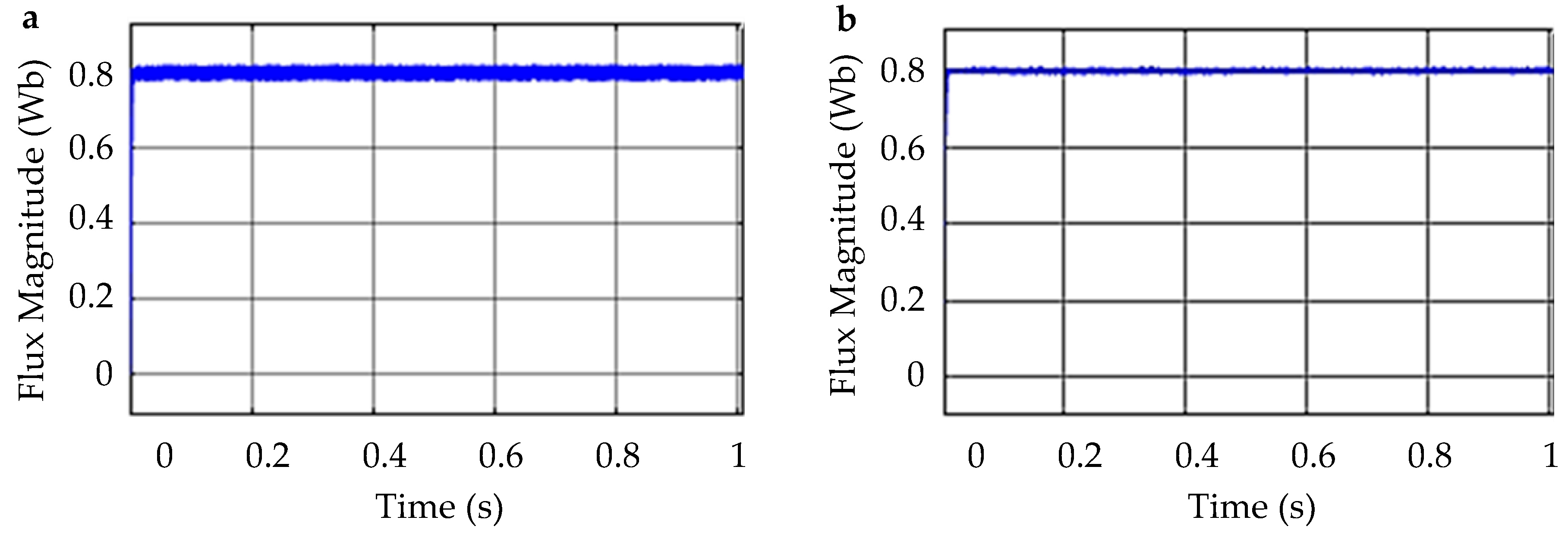

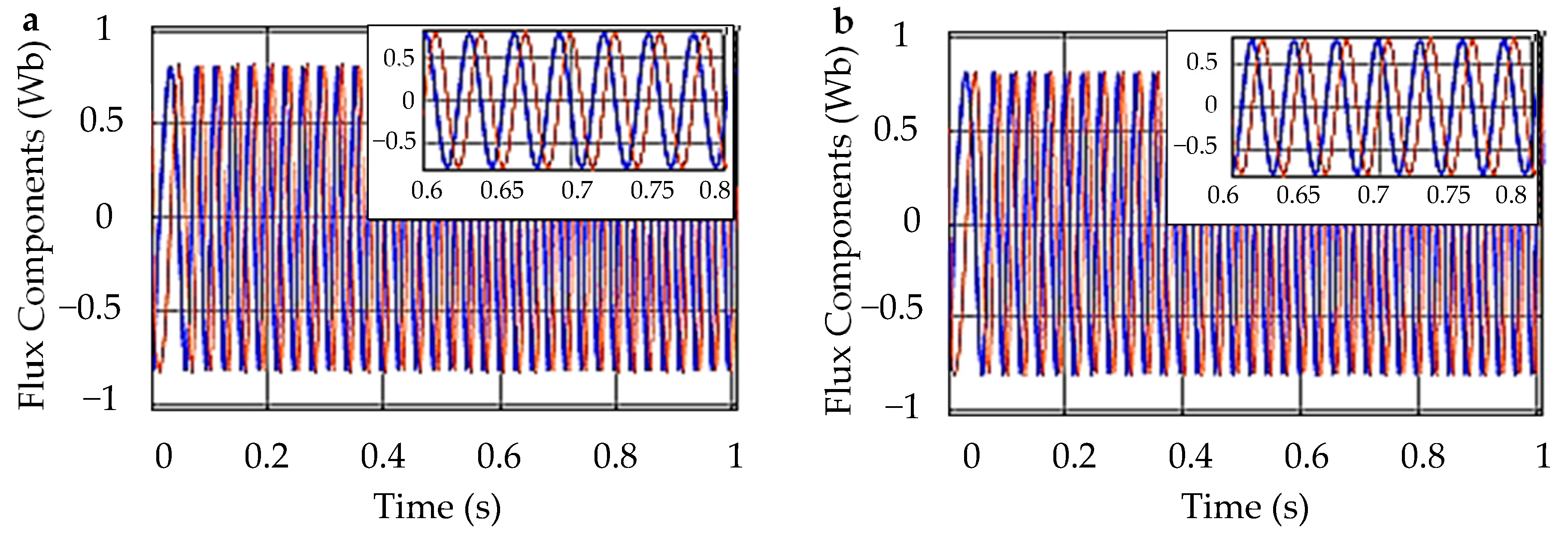

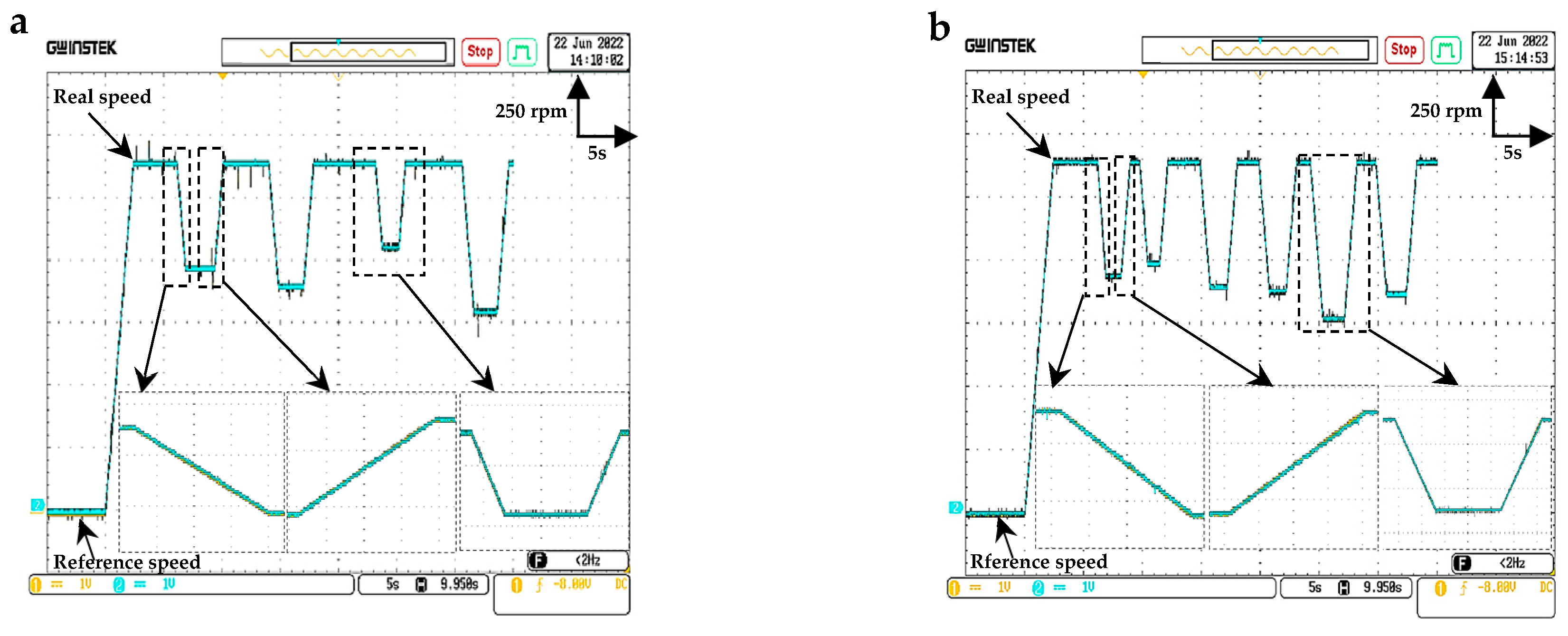

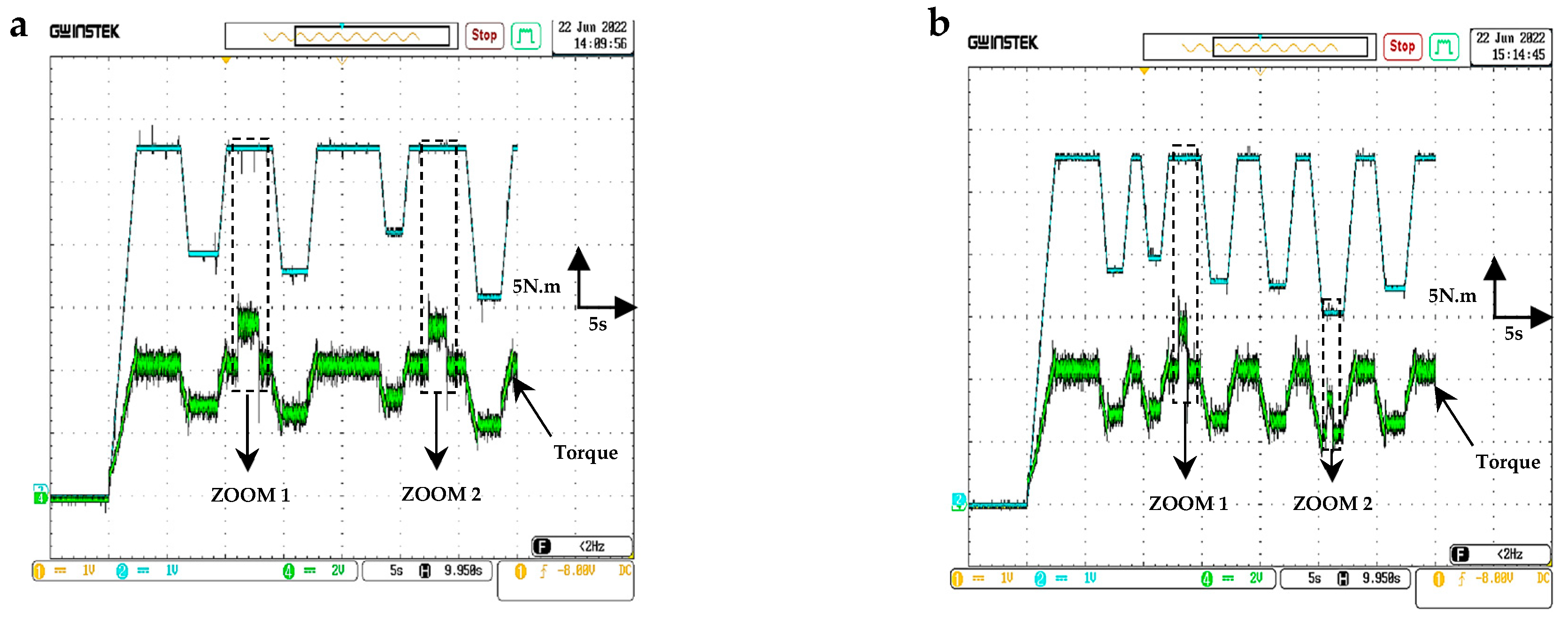

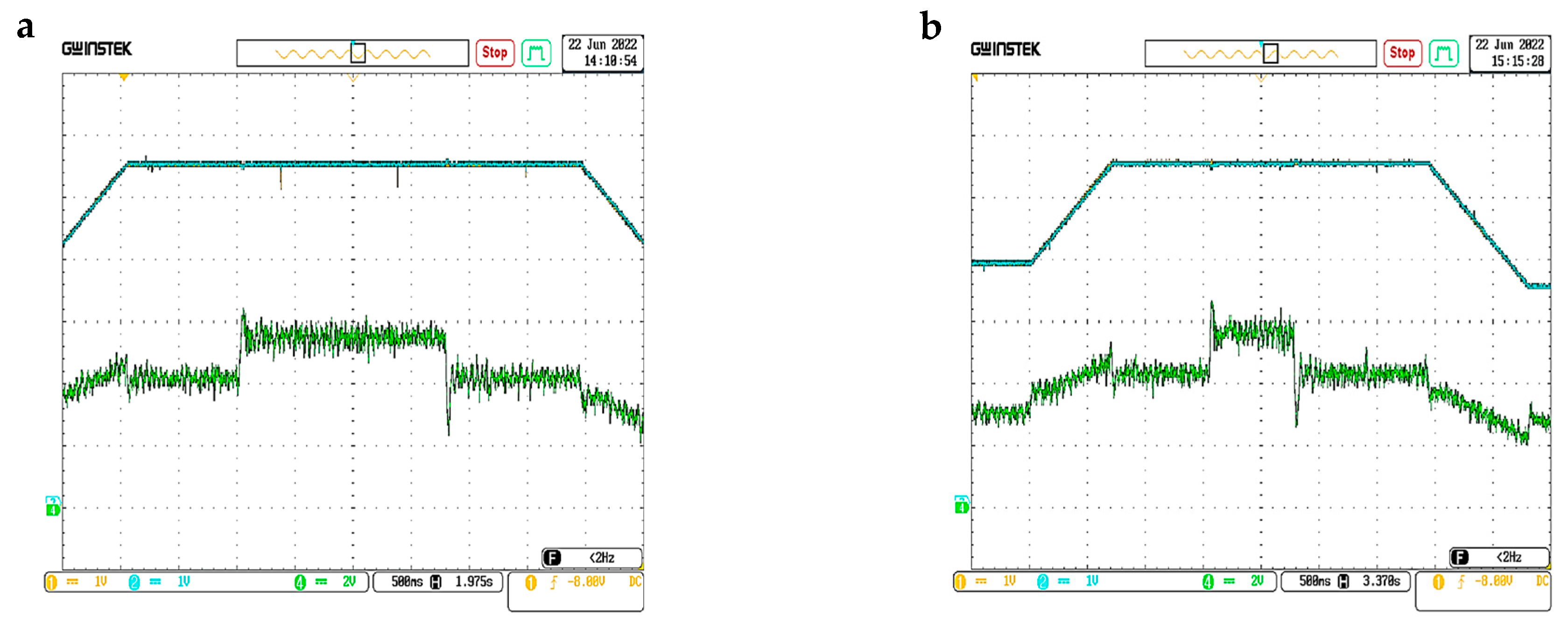

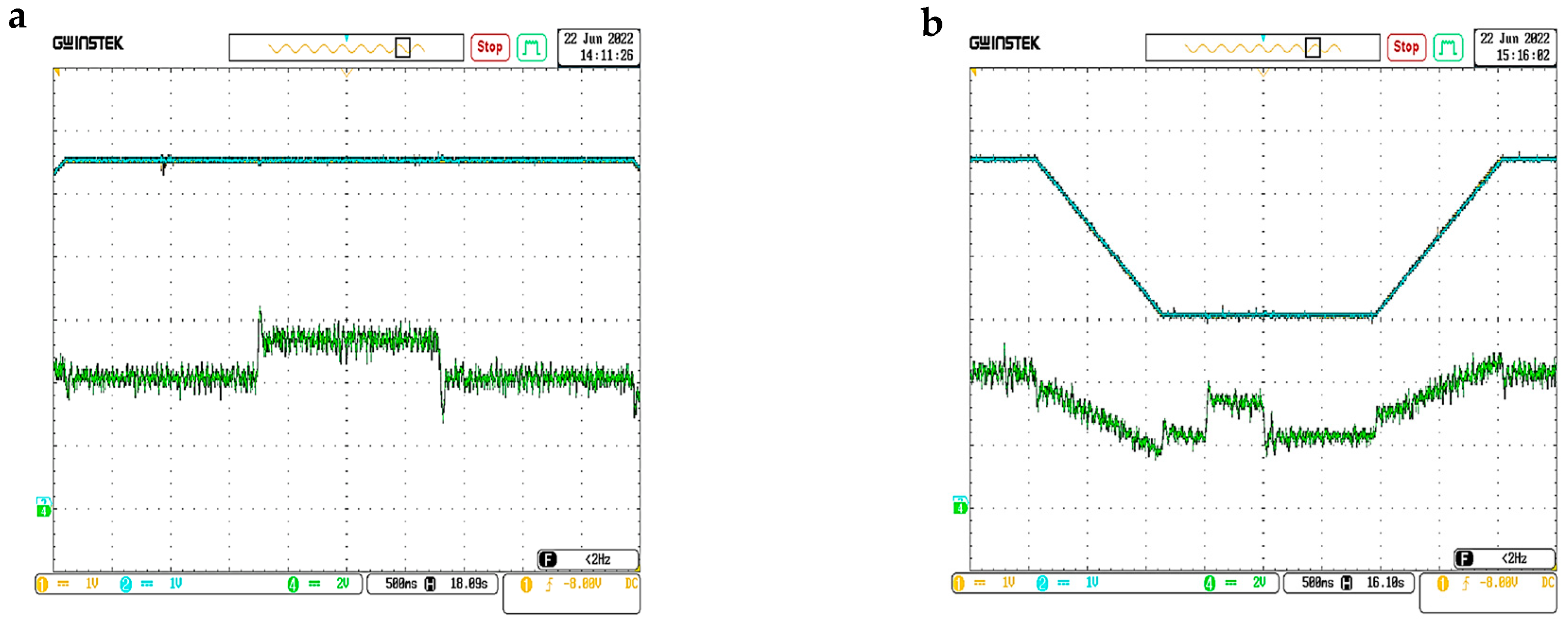

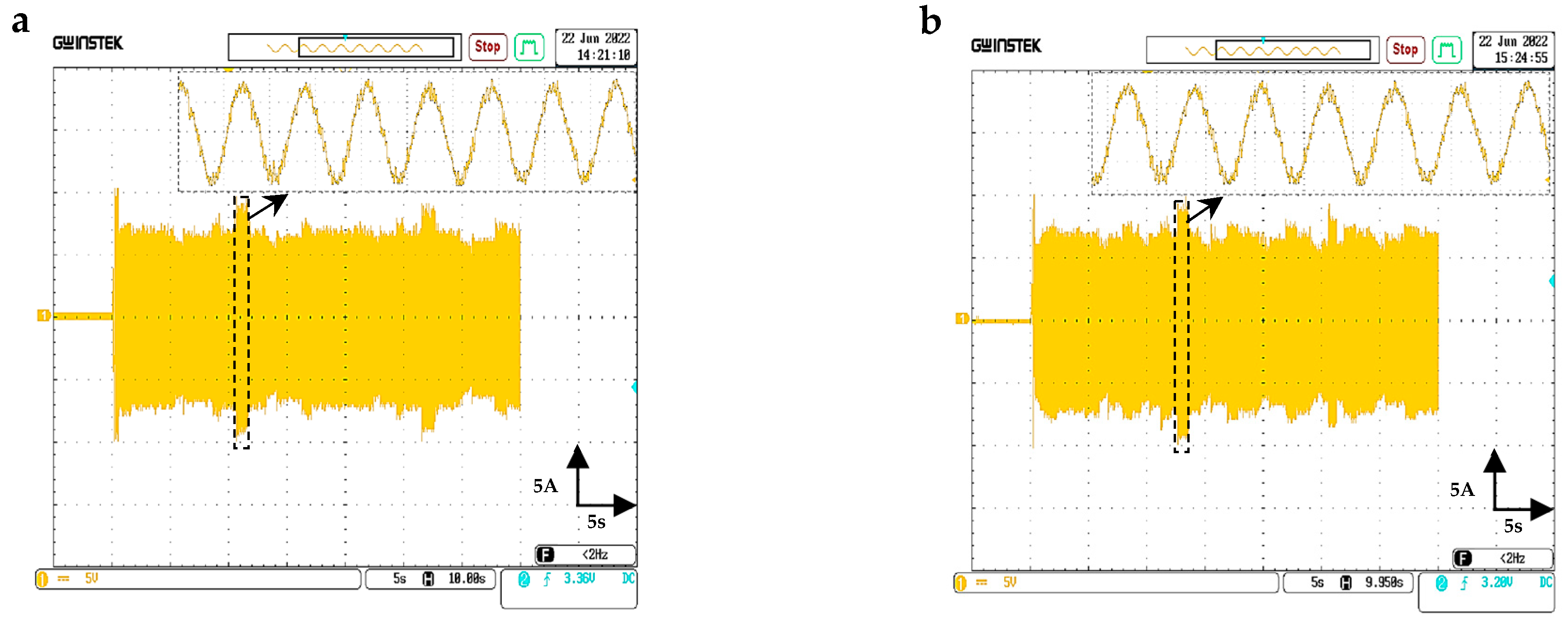

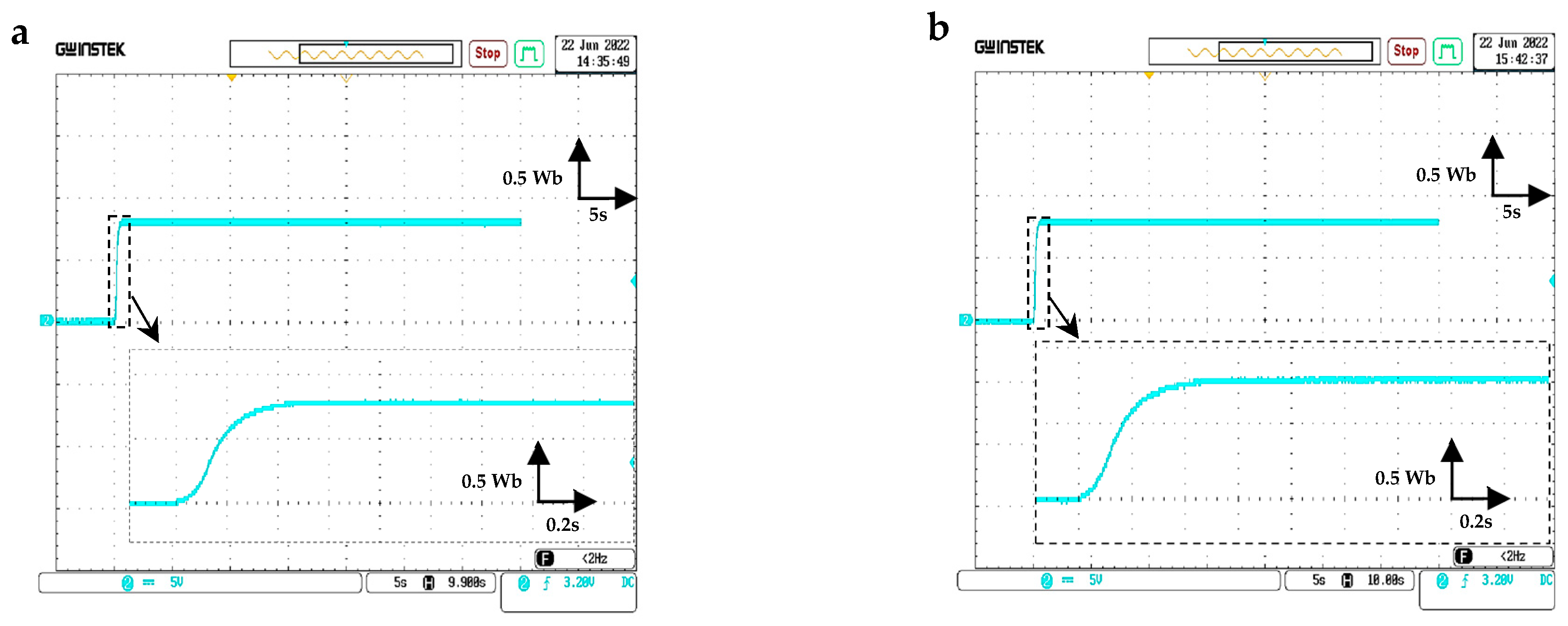

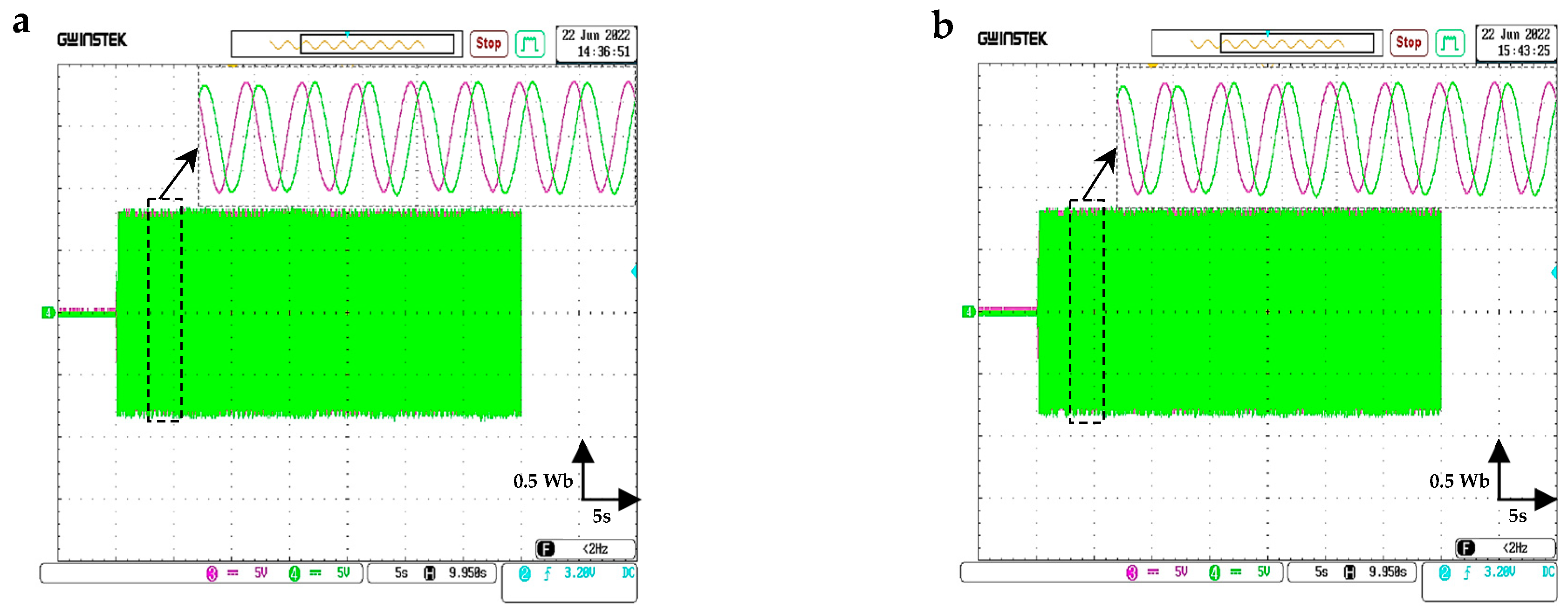

5.2. Back-Stepping SVM and Classical DTC Comparative Analysis

5.3. Vehicle Speed Control Results

6. Conclusions

7. Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, R.R.; Alok, K. Adoption of electric vehicle: A literature review and prospects for sustainability. J. Clean Prod. 2020, 253, 119911. [Google Scholar] [CrossRef]

- Li, Z.; Khajepour, A.; Song, J. A comprehensive review of the key technologies for pure electric vehicles. Energy 2019, 182, 824–839. [Google Scholar] [CrossRef]

- İnci, M.; Büyük, M.; Demir, M.H.; İlbey, G. A review and research on fuel cell electric vehicles: Topologies, power electronic converters, energy management methods, technical challenges, marketing and future aspects. Renew. Sustain. Energy Rev. 2021, 137, 110648. [Google Scholar] [CrossRef]

- Karki, A.; Phuyal, S.; Tuladhar, D.; Basnet, S.; Shrestha, B.P. Status of pure electric vehicle power train technology and future prospects. Appl. Syst. Innov. 2020, 3, 35. [Google Scholar] [CrossRef]

- Lai, F.; Carsten, O.; Tate, F. How much benefit does Intelligent Speed Adaptation deliver: An analysis of its potential contribution to safety and environment. Accid. Anal. Prev. 2012, 48, 63–72. [Google Scholar] [CrossRef] [PubMed]

- Lai, F.; Carsten, O. What benefit does Intelligent Speed Adaptation deliver: A close examination of its effect on vehicle speeds. Accid. Anal. Prev. 2012, 48, 4–9. [Google Scholar] [CrossRef] [PubMed]

- Aguil-Éra, V.; Glaser, S. Data Requirements for Enhanced Digital Maps in an Advanced Curve-Speed Warning System. Transp. Res. Rec. J. Transp. Res. Board 2004, 1886, 109–118. [Google Scholar] [CrossRef]

- Glaser, S.; Nouvelire, L.; Lusetti, B. Speed limitation based on an advanced curve warning system. In Proceedings of the 2007 IEEE Intelligent Vehicles Symposium, Istanbul, Turkey, 13–15 June 2007; pp. 686–691. [Google Scholar]

- Funk, J.; Wirth, J.; Bonugli, E.; Watson, R. An Integrated Model of Rolling and Sliding in Rollover Crashes; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Pratt, M.P.; Geedipally, S.R. Developing a framework for evaluating and selecting curve safety treatments. In Proceedings of the Transportation Research Board 95th Annual Meeting, Washington, DC, USA, 10–14 January 2016. [Google Scholar]

- Roy, S.; Pandey, R. A Review on Motor and Drive System for Electric Vehicle. In Planning of Hybrid Renewable Energy Systems, Electric Vehicles and Microgrid: Modeling, Control and Optimization; Springer: Singapore, 2022; pp. 601–628. [Google Scholar]

- De Klerk, M.L.; Saha, A.K. A comprehensive review of advanced traction motor control techniques suitable for electric vehicle applications. IEEE Access 2021, 9, 125080–125108. [Google Scholar] [CrossRef]

- Men, X.; Guo, Y.; Wu, G.; Chen, S.; Shi, C. Implementation of an Improved Motor Control for Electric Vehicles. Energies 2022, 15, 4833. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z.; Mei, X.; Rodríguez, J.; Kennel, R. Advanced Control Strategies of Induction Machine: Field Oriented Control, Direct Torque Control and Model Predictive Control. Energies 2018, 11, 120. [Google Scholar] [CrossRef]

- El Ouanjli, N.; Derouich, A.; el Ghzizal, A.; Chebabhi, A.; Taoussi, M. A comparative study between FOC and DTC control of the Doubly Fed Induction Motor (DFIM). In Proceedings of the 2017 International Conference on Electrical and Information Technologies ICEIT, Rabat, Morocco, 15–18 November 2017; pp. 1–6. [Google Scholar]

- Chinthakunta, U.R.; Prabhakar, K.K.; Singh, A.K.; Kumar, P. Direct torque control induction motor drive performance evaluation based on torque error status selection methods. IET Electr. Syst. Transp. 2019, 9, 113–127. [Google Scholar] [CrossRef]

- Taïb, N.; Metidji, B.; Rekioua, T. A fixed switching frequency direct torque control strategy for induction motor drives using indirect matrix converter. Arab. J. Sci. Eng. 2014, 39, 2001–2011. [Google Scholar] [CrossRef]

- Farajpour, Y.; Alzayed, M.; Chaoui, H.; Kelouwani, S. A Novel Switching Table for a Modified Three-Level Inverter-Fed DTC Drive with Torque and Flux Ripple Minimization. Energies 2020, 13, 4646. [Google Scholar] [CrossRef]

- Costa, B.L.G.; Graciola, C.L.; Angélico, B.A.; Goedtel, A.; Castoldi, M.F.; de Andrade Pereira, W.C. A practical framework for tuning DTC-SVM drive of three-phase induction motors. Control Eng. Pract. 2019, 88, 119–127. [Google Scholar] [CrossRef]

- Zahraoui, Y.; Akherraz, M.; Fahassa, C.; Elbadaoui, S. Induction Motor DTC Performance Improvement by Reducing Flux and Torque Ripples in Low Speed. J. Robot. Control. (JRC) 2022, 3, 93–100. [Google Scholar] [CrossRef]

- Aktas, M.; Awaili, K.; Ehsani, M.; Arisoy, A. Direct torque control versus indirect field-oriented control of induction motors for electric vehicle applications. Eng. Sci. Technol. Int. J. 2020, 23, 1134–1143. [Google Scholar] [CrossRef]

- Solea, R.; Nunes, U. Trajectory planning and sliding-mode control based trajectory-tracking for cybercars. Integr. Comput. Aided Eng. 2007, 14, 33–47. [Google Scholar] [CrossRef]

- Bacha, S.; Saadi, R.; Ayad, M.-Y.; Aboubou, A. Speed-planning algorithm and super twisting control for autonomous vehicle steering system. Bull. Electr. Eng. Inform. 2023, 12, 109–120. [Google Scholar] [CrossRef]

- Lee, J.; Prabhuswamy, S. A Unified Framework of Adaptive Cruise Control for Speed Limit Follower and Curve Speed Control Function; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- García, A.; Camacho-Torregrosa, F.J.; Baez, P.V.P. Examining the effect of road horizontal alignment on the speed of semi-automated vehicles. Accid. Anal. Prev. 2020, 146, 105732. [Google Scholar] [CrossRef]

- Deng, Z.; Chu, D.; Wu, C.; He, Y.; Cui, J. Curve safe speed model considering driving style based on driver behaviour questionnaire. Transp. Res. Part F Traffic Psychol. Behav. 2019, 65, 536–547. [Google Scholar] [CrossRef]

- Rosique, F.; Navarro, P.J.; Miller, L.; Salas, E. Autonomous Vehicle Dataset with Real Multi-Driver Scenes and Biometric Data. Sensors 2023, 23, 2009. [Google Scholar] [CrossRef] [PubMed]

- Colombaroni, C.; Fusco, G.; Isaenko, N. Coherence analysis of road safe speed and driving behaviour from floating car data. IET Intell. Transp. Syst. 2020, 14, 985–992. [Google Scholar] [CrossRef]

- Malek, Y.N.; Najib, M.; Bakhouya, M.; Essaaidi, M. Multivariate deep learning approach for electric vehicle speed forecasting. Big Data Min. Anal. 2021, 4, 56–64. [Google Scholar] [CrossRef]

- Park, J.; Murphey, Y.L.; McGee, R.; Kristinsson, J.G.; Kuang, M.L.; Phillips, A.M. Intelligent trip modeling for the prediction of an origin–destination traveling speed profile. IEEE Trans. Intell. Transp. Syst. 2014, 15, 1039–1053. [Google Scholar] [CrossRef]

- Jiang, B.; Fei, Y. Vehicle speed prediction by two-level data driven models in vehicular networks. IEEE Trans. Intell. Transp. Syst. 2016, 18, 1793–1801. [Google Scholar] [CrossRef]

- El-Sousy, F.F.M.; Amin, M.M.; Mohammed, O.A. Robust adaptive neural network tracking control with optimized super-twisting sliding-mode technique for induction motor drive system. IEEE Trans. Ind. Appl. 2022, 58, 4134–4157. [Google Scholar] [CrossRef]

- Ammar, A. Performance improvement of direct torque control for induction motor drive via fuzzy logic-feedback linearization: Simulation and experimental assessment. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 672–692. [Google Scholar] [CrossRef]

- Ammar, A.; Talbi, B.; Ameid, T.; Azzoug, Y.; Kerrache, A. Predictive direct torque control with reduced ripples for induction motor drive based on T-S fuzzy speed controller. Asian J. Control 2019, 21, 2155–2166. [Google Scholar] [CrossRef]

- Dan, H.; Zeng, P.; Xiong, W.; Wen, M.; Su, M.; Rivera, M. Model predictive control-based direct torque control for matrix converter-fed induction motor with reduced torque ripple. CES Trans. Electr. Mach. Syst. 2021, 5, 90–99. [Google Scholar] [CrossRef]

- Maidana, P.; Medina, C.; Rodas, J.; Maqueda, E.; Gregor, R.; Wheeler, P. Sliding-Mode Current Control with Exponential Reaching Law for a Three-Phase Induction Machine Fed by a Direct Matrix Converter. Energies 2022, 15, 8379. [Google Scholar] [CrossRef]

- Lascu, C.; Argeseanu, A.; Blaabjerg, F. Supertwisting sliding-mode direct torque and flux control of induction machine drives. IEEE Trans. Power Electron. 2019, 35, 5057–5065. [Google Scholar] [CrossRef]

- Ammar, A.; Kheldoun, A.; Metidji, B.; Ameid, T.; Azzoug, Y. Feedback linearization based sensorless direct torque control using stator flux MRAS-sliding mode observer for induction motor drive. ISA Trans. 2020, 98, 382–392. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Yu, H. Backstepping sliding mode control of induction motor based on disturbance observer. IET Electr. Power Appl. 2020, 14, 2537–2546. [Google Scholar] [CrossRef]

- Li, Z.; Chitturi, M.; Bill, A.R.; Noyce, D.A. Automated identification and extraction of horizontal curve information from geographic information system roadway maps. Transp. Res. Rec. 2012, 2291, 80–92. [Google Scholar] [CrossRef]

- Luo, W.; Li, L. Automatic geometry measurement for curved ramps using inertial measurement unit and 3D LiDAR system. Autom Constr. 2018, 94, 214–232. [Google Scholar] [CrossRef]

- Gargoum, S.; El-Basyouny, K.; Sabbagh, J. Automated extraction of horizontal curve attributes using LiDAR data. Transp. Res. Rec. 2018, 2672, 98–106. [Google Scholar] [CrossRef]

- Park, M.; Lee, S.; Han, W. Development of steering control system for autonomous vehicle using geometry-based path tracking algorithm. Etri J. 2015, 37, 617–625. [Google Scholar] [CrossRef]

- Hancock, M.W.; Wright, B. A Policy on Geometric Design of Highways and Streets; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- Ehsani, M.; Gao, Y.; Miller, J.M. Hybrid electric vehicles: Architecture and motor drives. Proc. IEEE 2007, 95, 719–728. [Google Scholar] [CrossRef]

- Zhu, Z.-Q.; Howe, D. Electrical machines and drives for electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 746–765. [Google Scholar] [CrossRef]

- Habetler, T.G.; Profumo, F.; Pastorelli, M.; Tolbert, L.M. Direct torque control of induction machines using space vector modulation. IEEE Trans. Ind. Appl. 1992, 28, 1045–1053. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Initial position | |

| Final position | & |

| Initial speed | |

| Max. speed | |

| Longitudinal acc. |

| Parameters | Value |

|---|---|

| Power | |

| Frequency | |

| Stator resistance | |

| Rotor resistance | |

| Stator inductance | |

| Rotor inductance | |

| Mutual inductance | |

| Friction coefficient | |

| Total inertia | |

| Pole pairs |

| Benefits | Description |

|---|---|

| Adaptability | Ability to adapt speed to changing roads and curvature |

| Safety | Driving over straight and curving stretches at safe speeds |

| Comfortability | Ensuring smooth speed changes to respect passenger comfort |

| Versatility | Applicable to different types of vehicles |

| Efficiency | Fast tracking of the reference speed with high accuracy and low error |

| Robustness | The system’s ability to quickly respond to external load disturbances. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bacha, S.; Saadi, R.; Ayad, M.Y.; Sahraoui, M.; Laadjal, K.; Cardoso, A.J.M. Autonomous Electric-Vehicle Control Using Speed Planning Algorithm and Back-Stepping Approach. Energies 2023, 16, 2459. https://doi.org/10.3390/en16052459

Bacha S, Saadi R, Ayad MY, Sahraoui M, Laadjal K, Cardoso AJM. Autonomous Electric-Vehicle Control Using Speed Planning Algorithm and Back-Stepping Approach. Energies. 2023; 16(5):2459. https://doi.org/10.3390/en16052459

Chicago/Turabian StyleBacha, Sofiane, Ramzi Saadi, Mohamed Yacine Ayad, Mohamed Sahraoui, Khaled Laadjal, and Antonio J. Marques Cardoso. 2023. "Autonomous Electric-Vehicle Control Using Speed Planning Algorithm and Back-Stepping Approach" Energies 16, no. 5: 2459. https://doi.org/10.3390/en16052459

APA StyleBacha, S., Saadi, R., Ayad, M. Y., Sahraoui, M., Laadjal, K., & Cardoso, A. J. M. (2023). Autonomous Electric-Vehicle Control Using Speed Planning Algorithm and Back-Stepping Approach. Energies, 16(5), 2459. https://doi.org/10.3390/en16052459