RETRACTED: Investigation and Evaluation of the Hybrid System of Energy Storage for Renewable Energies

Abstract

1. Introduction

2. Materials and Methods

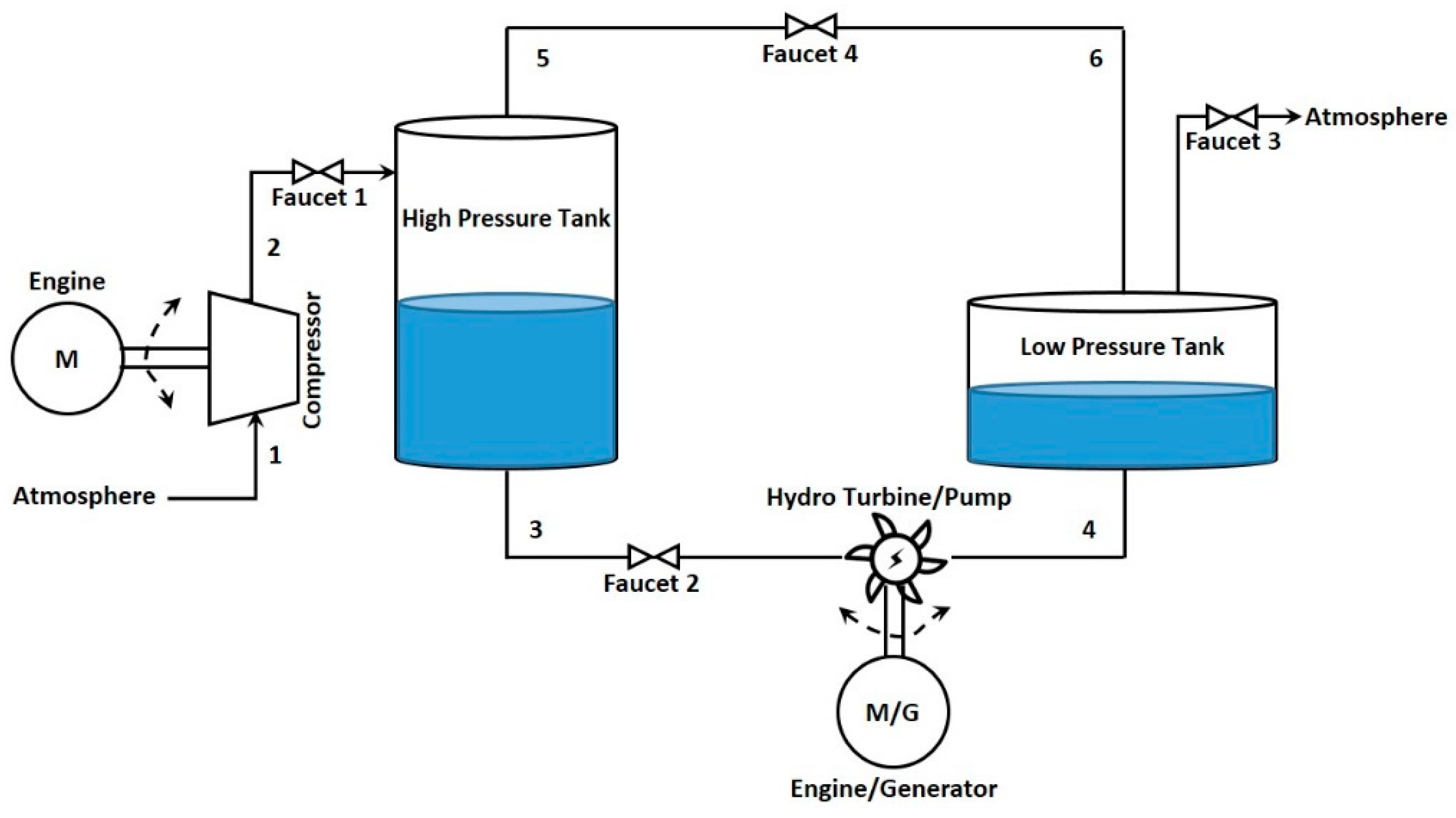

2.1. Description of the System

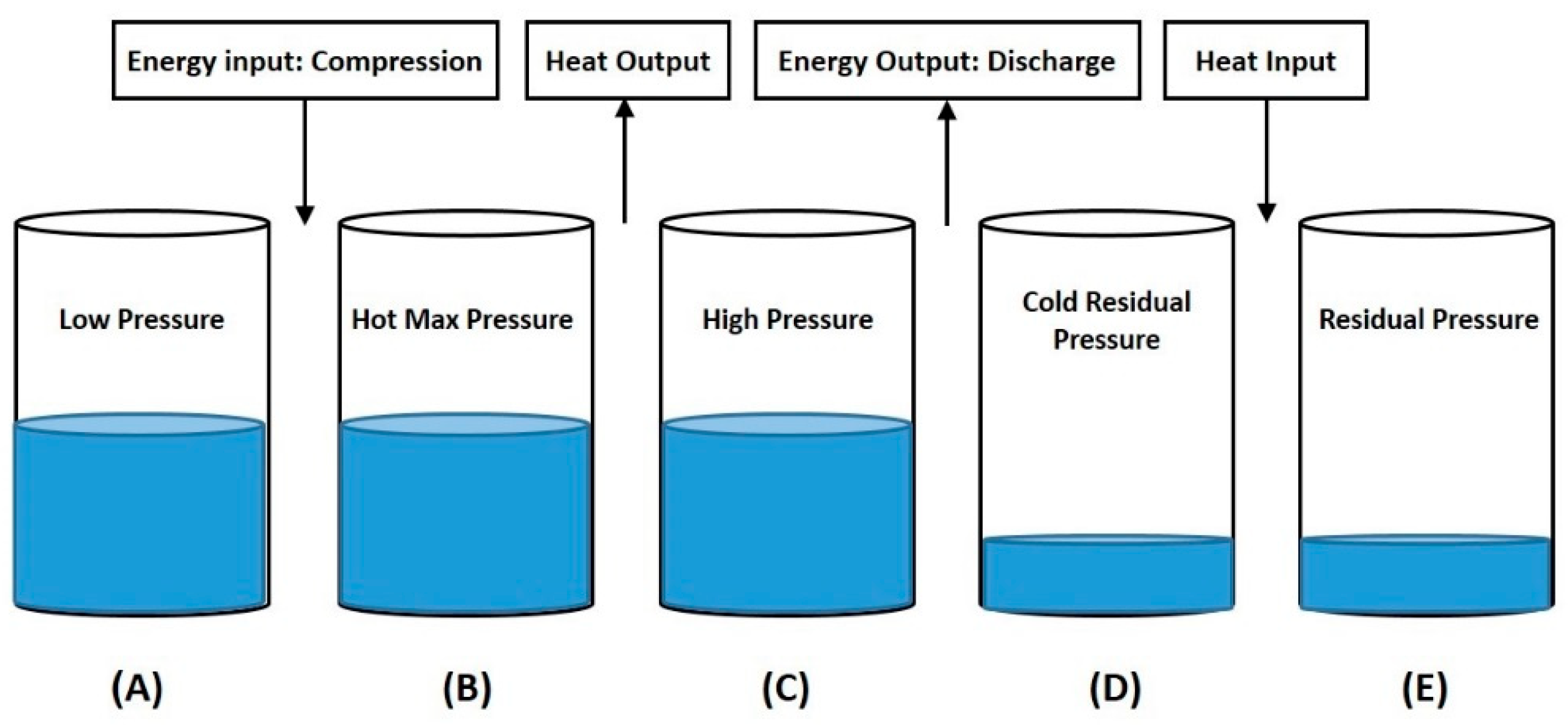

2.1.1. Charging Stage

2.1.2. Discharging Stage

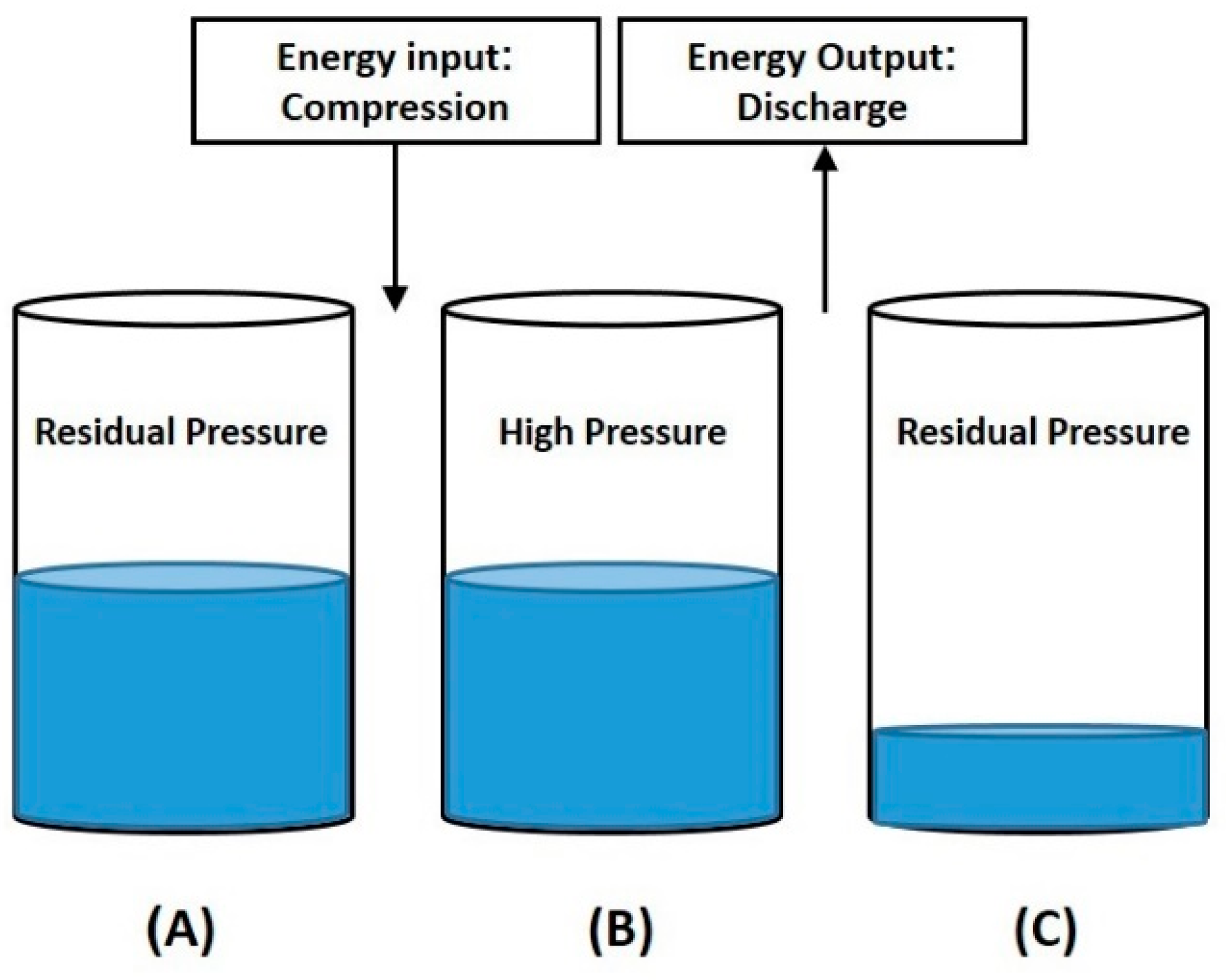

2.1.3. Preparation Stage

2.2. Energy Analysis of the System

- The pressure and temperature of the environment are equal to 100 kPa and 298 °K;

- Due to the adiabatic nature of the processes;

- The heat losses and pressure drop in the pipes are negligible;

- There is an insulated floating surface between water and air;

- Heat transfer between them is negligible.

2.3. System Parameters in the First Circle

2.4. System Parameters in the Closed State

3. Results

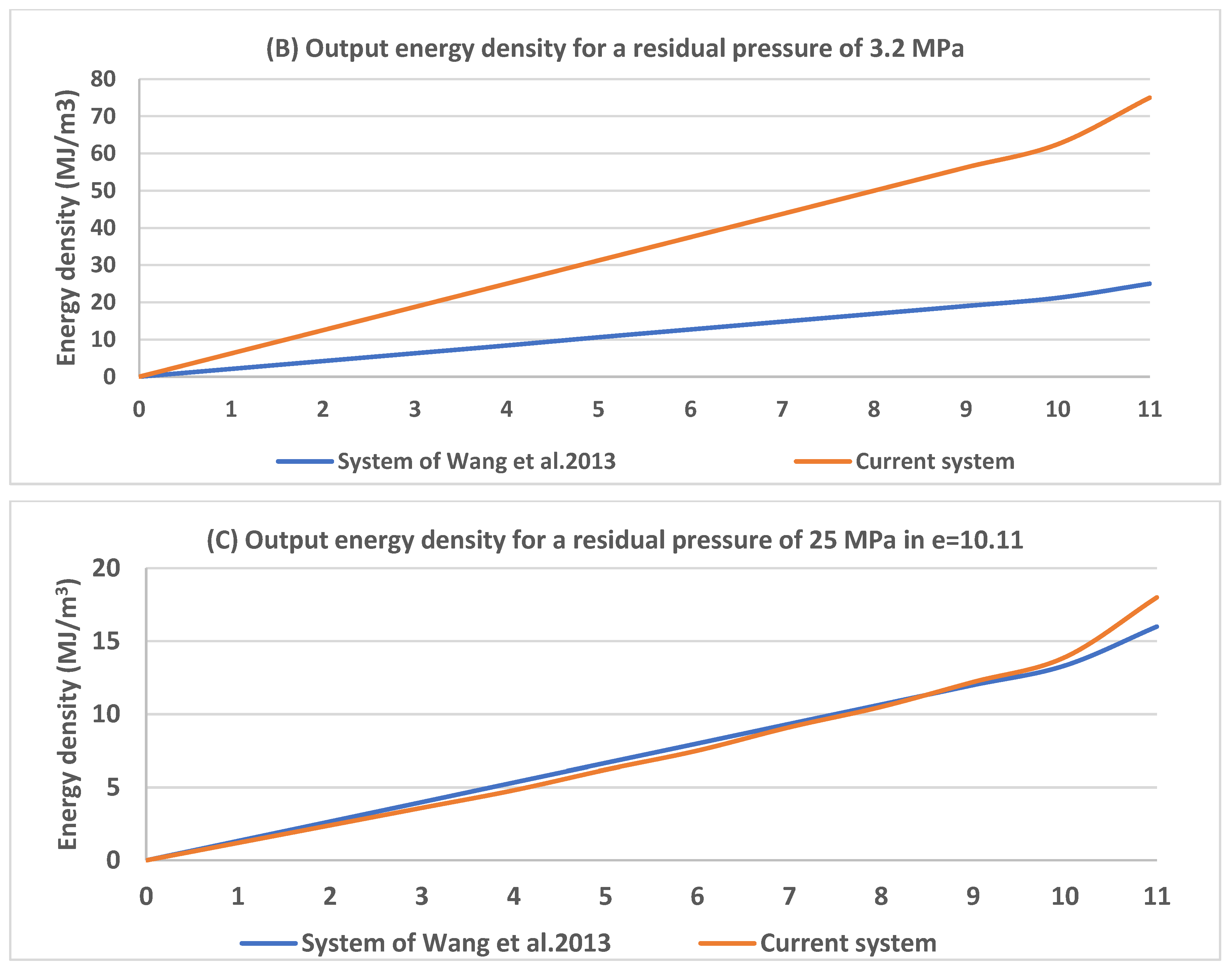

3.1. Validation

3.2. The Effect of the Air Discharge Mechanism

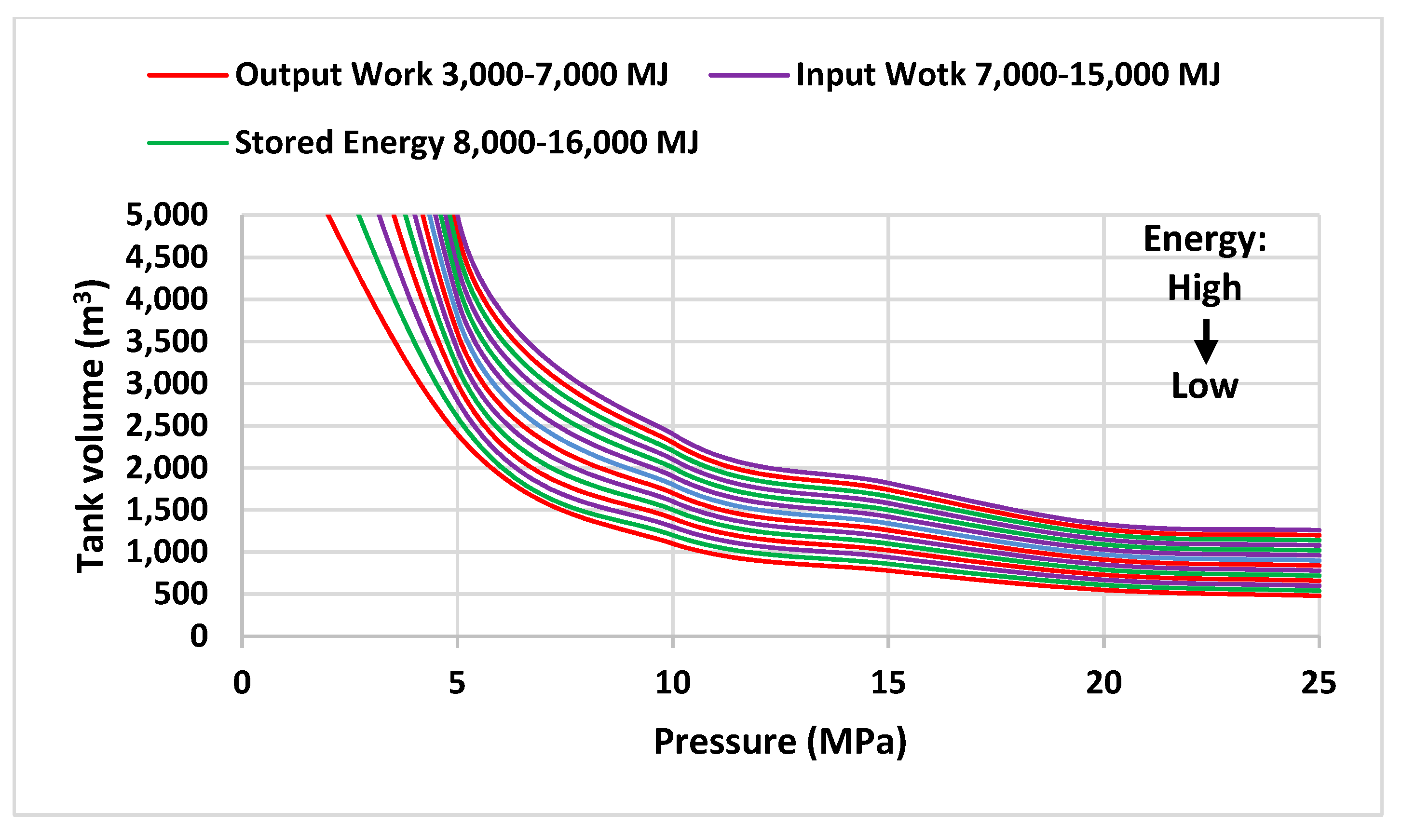

3.3. Determining the Dimensions of the Parameters

4. Conclusions

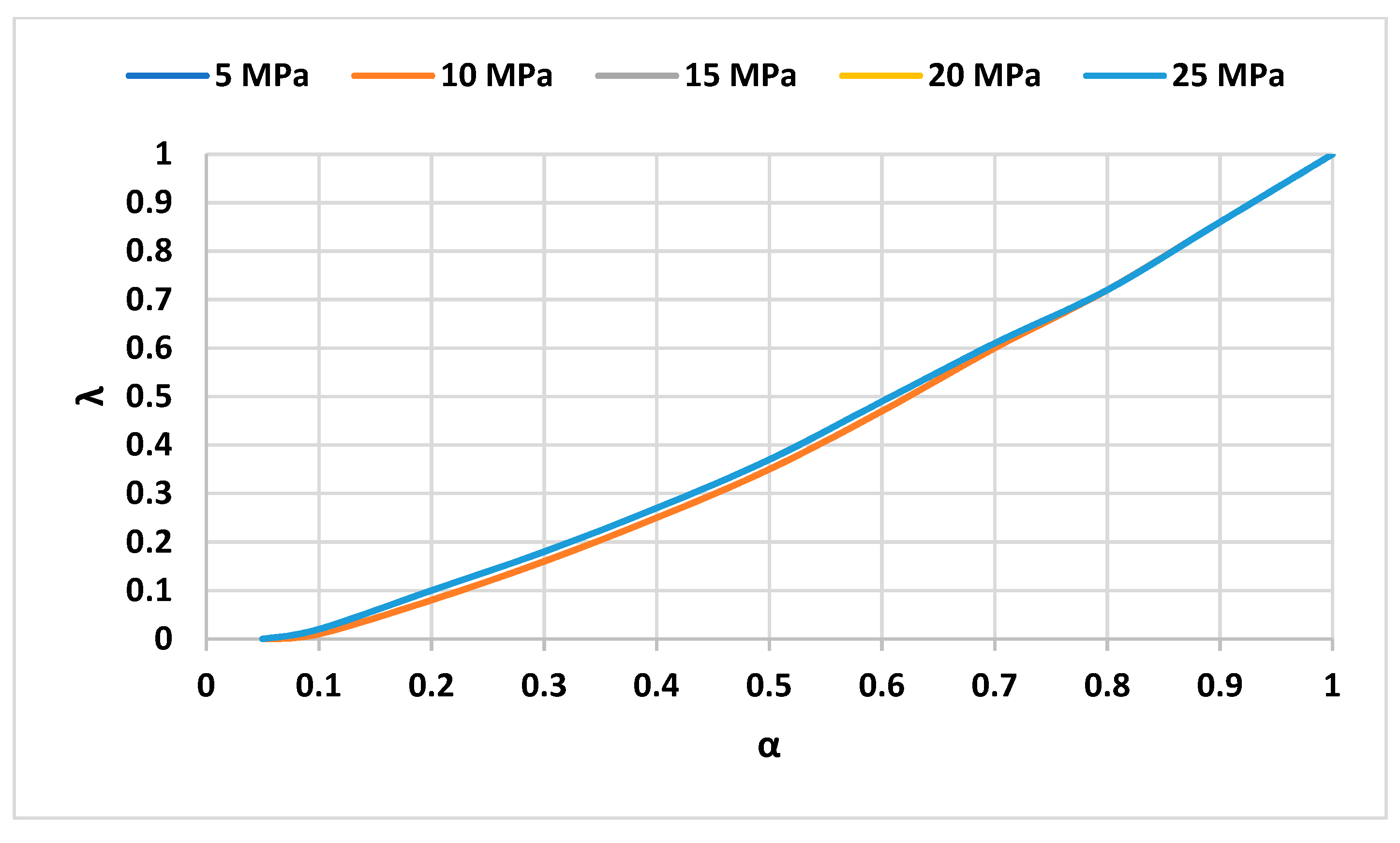

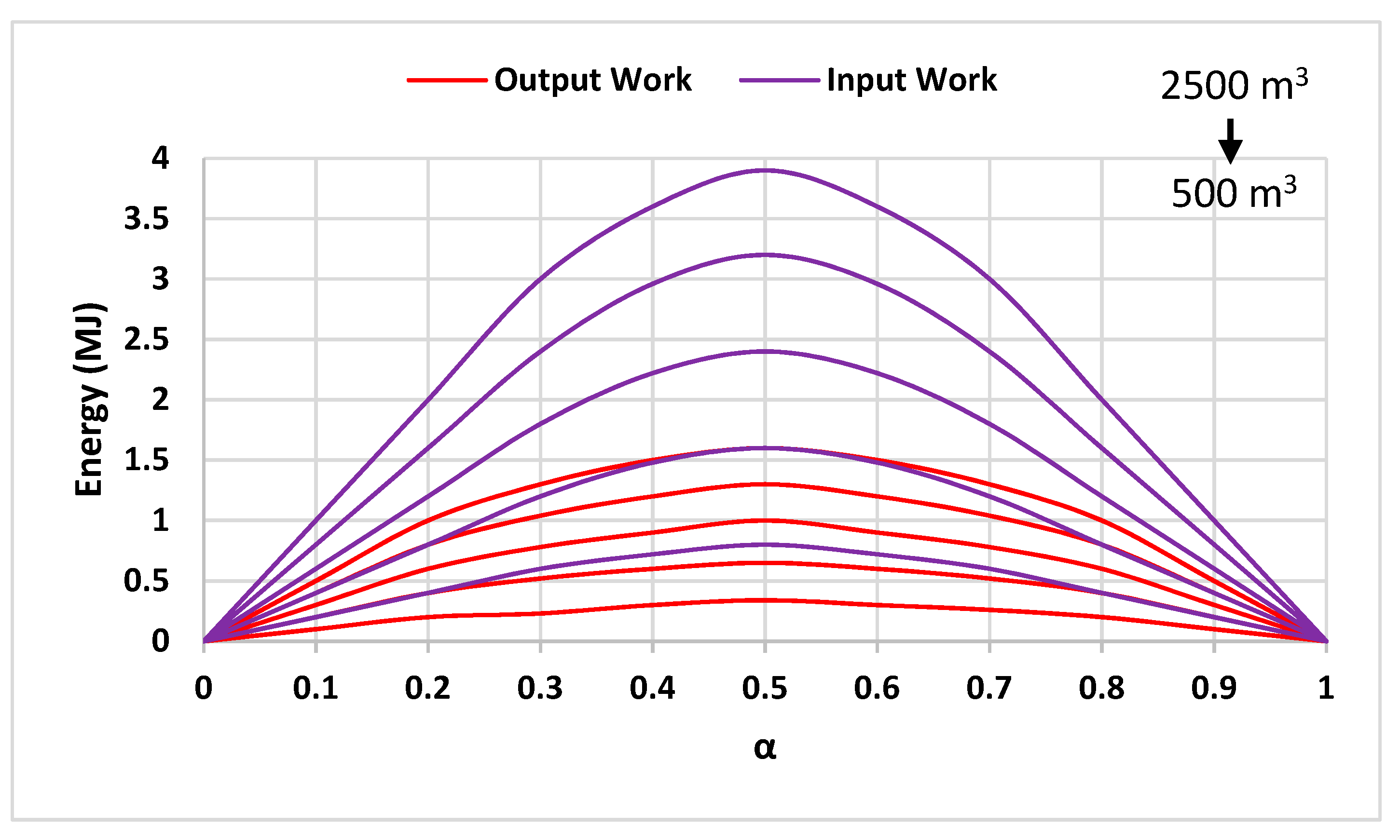

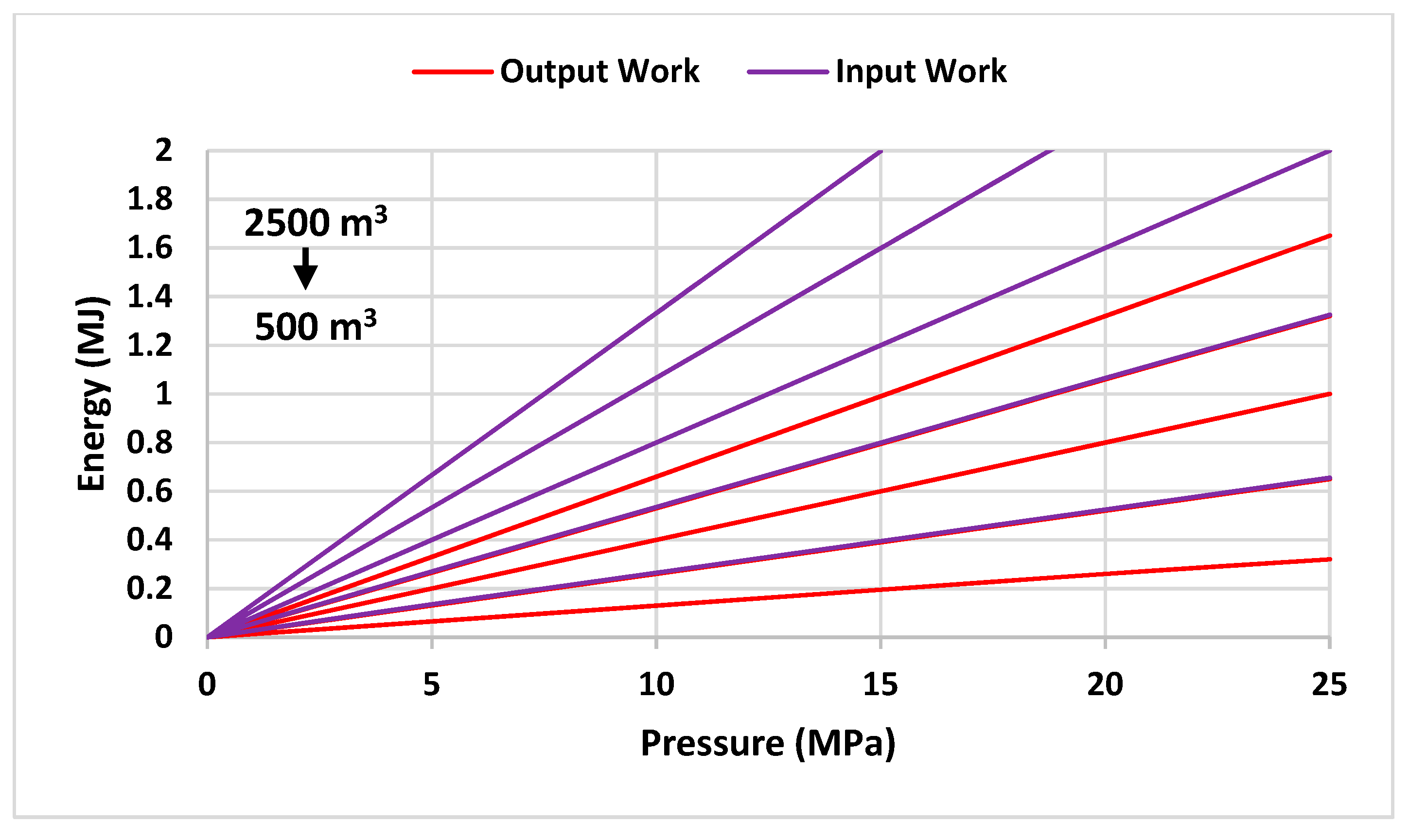

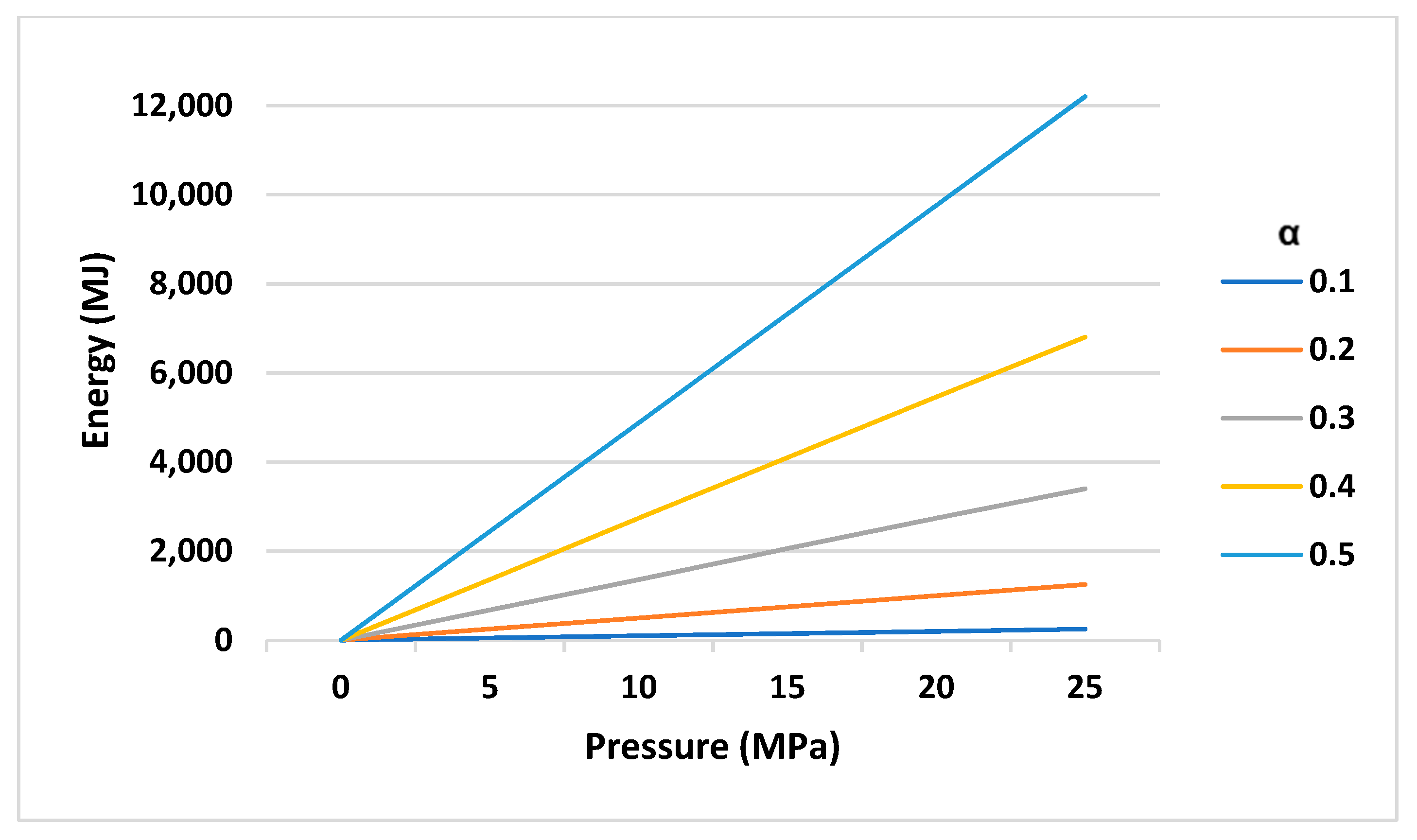

- The effective parameters of this system, including operational pressure or maximum pressure in the high-pressure tank, the volume of the tanks, and the rate of input and output work of the system, depend on each other; however, the most effective parameter in the design of this system is the ratio of air volume to total volume in the high-pressure tank. The input and output work of the system and, consequently, the efficiency of the system depend on the ratio of air volume to the total volume of the high-pressure tank. In this way, by increasing the ratio of air volume to the total volume of the high-pressure tank, the efficiency of the system decreases.

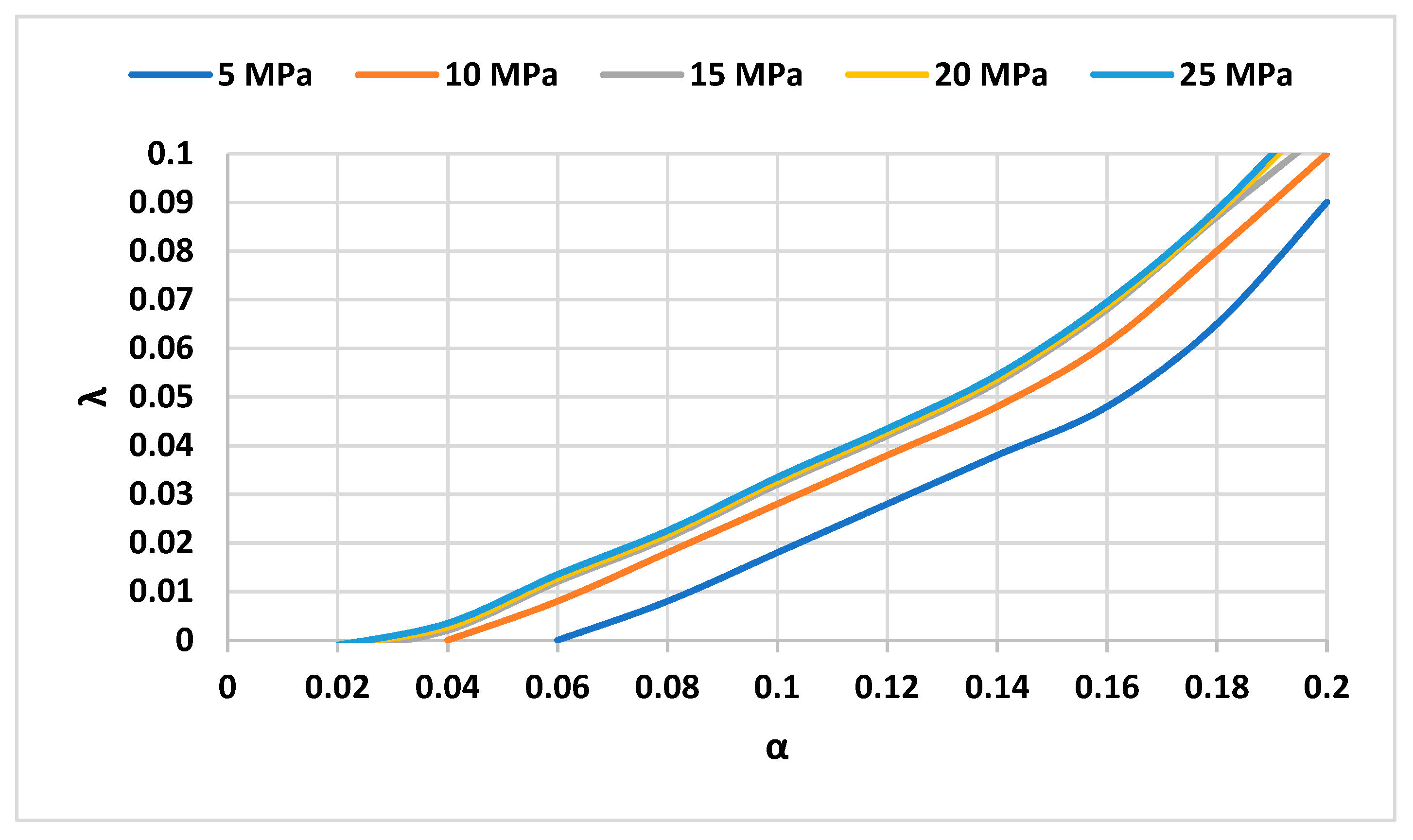

- For the ratio of air volume to the total volume of the high-pressure tank, there are limitations depending on the operating pressure of the system, and these limits are for the minimum amount, which is equal to 0.02 at 25 MPa and 0.062 at 5 MPa. Critical values of air volume to the total volume of the high-pressure tank for input work and output work of the better system are 535.0 and 431.0, before these values, the input capacity and output work of the system is increasing but then decreasing;

- Considering the amount of energy saved as a proportion of the input energy of the system, a clearer analysis is expressed. Thus, the ratio of energy savings to input energy is more a function of the ratio of air volume to the total volume of the high-pressure tank, and the operating pressure has a lower impact on it.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| P | Residual pressure(KPa) | Ratio of air volume to total volume | |

| V | Volume (m3) | Internal energy (J) | |

| m | Mass (Kg) | κ | Polytrophic constant |

| T | Temperature (K) | Ratio of the remaining energy in the tank to the stored energy | |

| R | Gas constant (kJ/kg. K) | Ratio of the remaining energy in the tank to the input energy | |

| C | Specific heat capacity (kJ/kg. K) | W | Power (W) |

| Ratio of internal energy changes | Efficiency | ||

| v | Special volume (m3/kg) | Ratio of saved energy to input energy |

References

- Denholm, P.; Mai, T. Timescales of energy storage needed for reducing renewable energy curtailment. Renew. Energy 2019, 130, 388–399. [Google Scholar] [CrossRef]

- Khazali, M.; Kaabi Nejadian, A. A study on the compressed air energy storage system. Mech. Eng. J. 2020, 29, 47–59. [Google Scholar]

- Akinyele, D.O.; Rayudu, R.K. Review of energy storage technologies for sustainable power networks. Sustain. Energy Technol. Assess. 2014, 8, 74–91. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M. Pumped hydro energy storage system: A technological review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Dursun, B.; Alboyaci, B. The contribution of wind-hydro pumped storage systems in meeting Turkey’s electric energy demand. Renew. Sustain. Energy Rev. 2010, 14, 1979–1988. [Google Scholar] [CrossRef]

- Wang, Z.; Carriveau, R.; Ting, D.S.; Xiong, W.; Wang, Z. A review of marine renewable energy storage. Int. J. Energy Res. 2019, 43, 6108–6150. [Google Scholar] [CrossRef]

- Khazali, M.; Abdalisousan, A. An Overview of Novel Energy Storage Systems with Air Compression Method. Iran. J. Energy 2020, 23, 47–82. [Google Scholar]

- Wolf, D.; Budt, M. LTA-CAES—A low-temperature approach to Adiabatic Compressed Air Energy Storage. Appl. Energy 2014, 125, 158–164. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Krupke, C.; Wang, Y.; Sheng, Y.; Li, J.; Yujie, X.; Dan, W.; Shihong, M.; Haisheng, C. Modelling study, efficiency analysis and optimisation of large-scale Adiabatic Compressed Air Energy Storage systems with low-temperature thermal storage. Appl. Energy 2016, 162, 589–600. [Google Scholar] [CrossRef]

- Li, Y.; Gao, W.; Ruan, Y.; Ushifusa, Y. The performance investigation of increasing share of photovoltaic generation in the public grid with pump hydro storage dispatch system, a case study in Japan. Energy 2018, 164, 811–821. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Guo, H.; Zhang, X.; Guo, C.; Chen, H. A hybrid energy storage system with optimized operating strategy for mitigating wind power fluctuations. Renew. Energy 2018, 125, 121–132. [Google Scholar] [CrossRef]

- Guo, H.; Xu, Y.; Chen, H.; Zhou, X. Thermodynamic characteristics of a novel supercritical compressed air energy storage system. Energy Convers. Manag. 2016, 115, 167–177. [Google Scholar] [CrossRef]

- Khalil, K.M.; Ahmad, A.; Mahmoud, S.; Al-Dadah, R.K. Liquid air/nitrogen energy storage and power generation system for micro-grid applications. J. Clean. Prod. 2017, 164, 606–617. [Google Scholar] [CrossRef]

- Guizzi, G.L.; Manno, M.; Tolomei, L.M.; Vitali, R.M. Thermodynamic analysis of a liquid air energy storage system. Energy 2015, 93, 1639–1647. [Google Scholar] [CrossRef]

- Xie, C.; Hong, Y.; Ding, Y.; Li, Y.; Radcliffe, J. An economic feasibility assessment of decoupled energy storage in the UK: With liquid air energy storage as a case study. Appl. Energy 2018, 225, 244–257. [Google Scholar] [CrossRef]

- Farres-Antunez, P.; Xue, H.; White, A.J. Thermodynamic analysis and optimization of a combined liquid air and pumped thermal energy storage cycle. J. Energy Storage 2018, 18, 90–102. [Google Scholar] [CrossRef]

- Nabat, M.H.; Zeynalian, M.; Razmi, A.R.; Arabkoohsar, A.; Soltani, M. Energy, exergy, and economic analyses of an innovative energy storage system, liquid air energy storage (LAES) combined with high-temperature thermal energy storage (HTES). Energy Convers. Manag. 2020, 226, 113486. [Google Scholar] [CrossRef]

- Kantharaj, B.; Garvey, S.; Pimm, A. Thermodynamic analysis of a hybrid energy storage system based on compressed air and liquid air. Sustain. Energy Technol. Assess. 2015, 11, 159–164. [Google Scholar] [CrossRef]

- An, B.; Chen, J.; Deng, Z.; Zhang, T.; Wang, J.; Yang, L.; Chang, X. Design and testing of a high performance liquid phase cold storage system for liquid air energy storage. Energy Convers. Manag. 2020, 226, 113520. [Google Scholar] [CrossRef]

- Kim, Y.M.; Shin, D.G.; Favrat, D. Operating characteristics of constant-pressure compressed air energy storage (CAES) system combined with pumped hydro storage based on energy and exergy analysis. Energy 2011, 36, 6220–6233. [Google Scholar] [CrossRef]

- Wang, Z.; Ting, D.S.K.; Carriveau, R.; Xiong, W.; Wang, Z. Design and thermodynamic analysis of a multi-level underwater compressed air energy storage system. J. Energy Storage 2016, 5, 203–211. [Google Scholar] [CrossRef]

- Klar, R.; Steidl, B.; Aufleger, M. A floating energy storage system based on fabric. Ocean. Eng. 2018, 165, 328–335. [Google Scholar] [CrossRef]

- Yao, E.; Wang, H.; Xi, G. A Novel Pumped Hydro Combined with Compressed Air Energy [Internet]. In Storing Energy; Letcher, T.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 155–166. [Google Scholar]

- Heidenreich, D.C. Compressed Air Pumped Hydro Energy Storage and Distribution System F03B13/00. U.S. Patent No. 7,281,371, 16 October 2007. [Google Scholar]

- Laugier, A.; Garai, J. Derivation of the ideal gas law. J. Chem. Educ. 2007, 84, 1832–1833. [Google Scholar] [CrossRef]

- Sposito, G.; Chu, S.Y. Internal Energy Balance and the Richards Equation. Soil Sci. Soc. Am. J. 1982, 46, 889–893. [Google Scholar] [CrossRef]

- Erlichson, H. Internal energy in the first law of thermodynamics. Am. J. Phys. 1984, 52, 623–625. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Boles, M.A. Thermodynamics, an Engineering Approach; McGraw-Hill Education: New York, NY, USA, 2015; pp. 359–366. [Google Scholar]

- Villela, D.; Kasinathan, V.V.; De Valle, S.; Alvarez, M.; Frantziskonis, G.; Deymier, P.; Krishna, M. Compressed-air energy storage systems for stand-alone off-grid photovoltaic modules [Internet]. In Proceedings of the IEEE Photovoltaic Specialists Conference, Honolulu, Hawaii, 20–25 June 2010; pp. 962–967. [Google Scholar]

- Wang, H.; Wang, L.; Wang, X.; Yao, E. A Novel Pumped Hydro Combined with Compressed Air Energy Storage System. Energies 2013, 6, 1554–1567. [Google Scholar] [CrossRef]

- Bi, J.; Jiang, T.; Chen, W.; Ma, X. Research on Storage Capacity of Compressed Air Pumped Hydro Energy Storage Equipment. Energy Power Eng. 2013, 5, 26–30. [Google Scholar] [CrossRef]

| Parameters | Effective Factors | Variable Type | ||

|---|---|---|---|---|

| Cost | Energy | Power | ||

| Target pressure | √ | √ | √ | Cost and Performance |

| Tank volume | √ | √ | - | Cost |

| - | √ | - | Performance | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anazi, A.A.A.; Barboza-Arenas, L.A.; Romero-Parra, R.M.; Sivaraman, R.; Qasim, M.T.; Al-Khafaji, S.H.; Gatea, M.A.; Alayi, R.; Farooq, W.; Jasiński, M.; et al. RETRACTED: Investigation and Evaluation of the Hybrid System of Energy Storage for Renewable Energies. Energies 2023, 16, 2337. https://doi.org/10.3390/en16052337

Anazi AAA, Barboza-Arenas LA, Romero-Parra RM, Sivaraman R, Qasim MT, Al-Khafaji SH, Gatea MA, Alayi R, Farooq W, Jasiński M, et al. RETRACTED: Investigation and Evaluation of the Hybrid System of Energy Storage for Renewable Energies. Energies. 2023; 16(5):2337. https://doi.org/10.3390/en16052337

Chicago/Turabian StyleAnazi, Abeer Abdullah Al, Luis Andres Barboza-Arenas, Rosario Mireya Romero-Parra, Ramaswamy Sivaraman, Maytham T. Qasim, Sara Hakem Al-Khafaji, Maher Abdulfadhil Gatea, Reza Alayi, Waqas Farooq, Michał Jasiński, and et al. 2023. "RETRACTED: Investigation and Evaluation of the Hybrid System of Energy Storage for Renewable Energies" Energies 16, no. 5: 2337. https://doi.org/10.3390/en16052337

APA StyleAnazi, A. A. A., Barboza-Arenas, L. A., Romero-Parra, R. M., Sivaraman, R., Qasim, M. T., Al-Khafaji, S. H., Gatea, M. A., Alayi, R., Farooq, W., Jasiński, M., Leonowicz, Z., Novak, F., & Gono, R. (2023). RETRACTED: Investigation and Evaluation of the Hybrid System of Energy Storage for Renewable Energies. Energies, 16(5), 2337. https://doi.org/10.3390/en16052337