Thermohydraulic and Economic Evaluation of a New Design for Printed Circuit Heat Exchangers in Supercritical CO2 Brayton Cycle

Abstract

1. Introduction

2. Computational Model

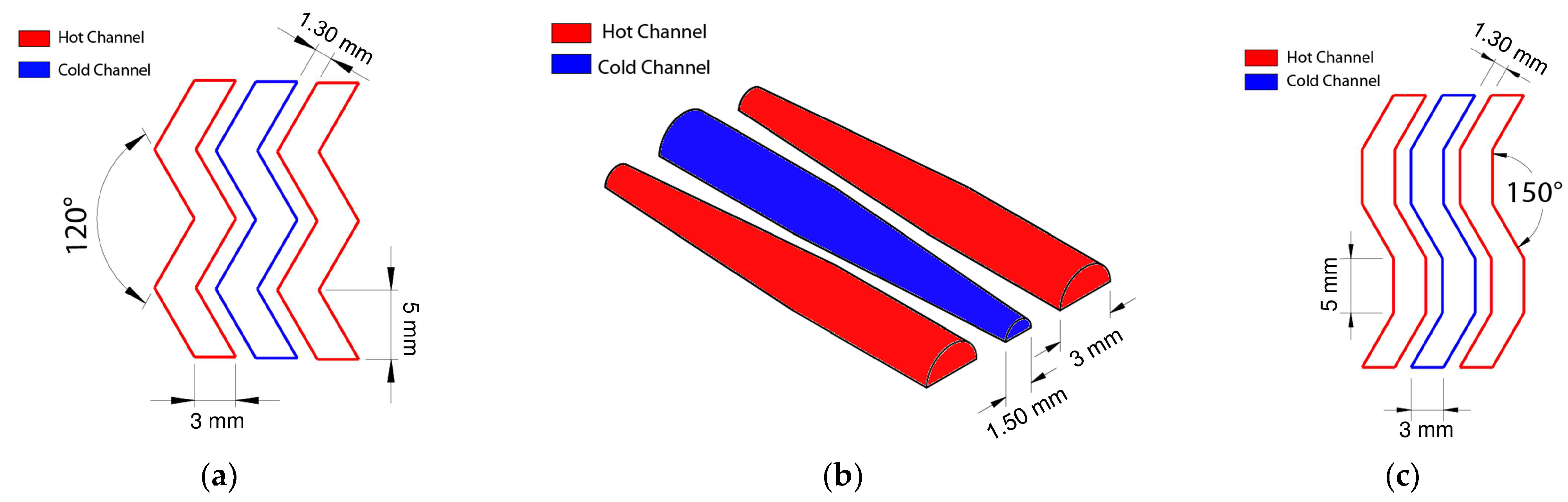

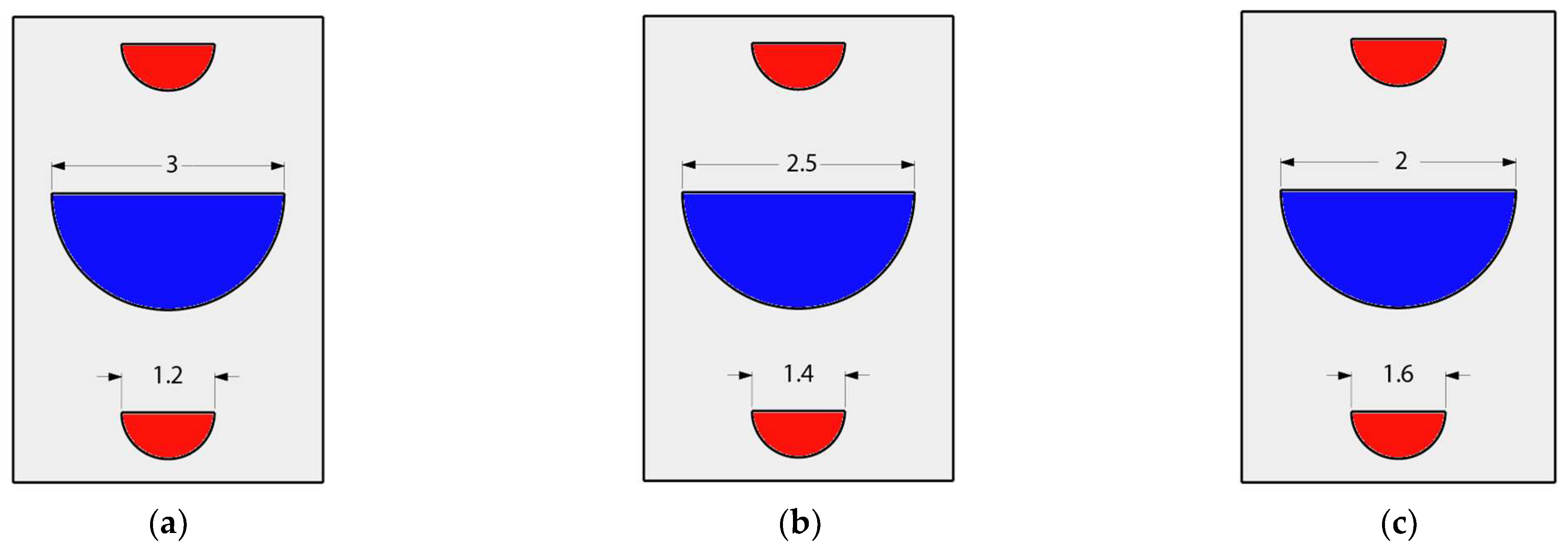

2.1. Geometric Characteristics

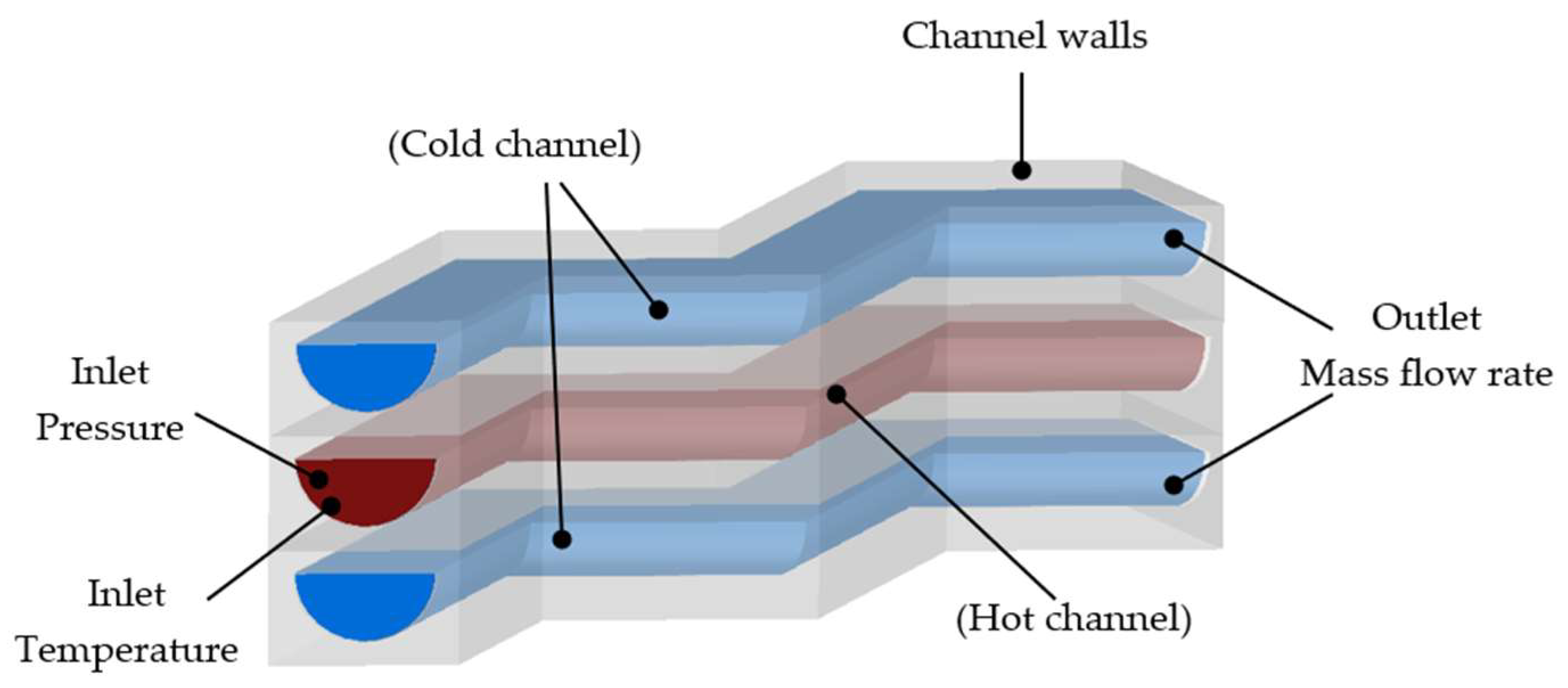

2.2. Boundary Conditions

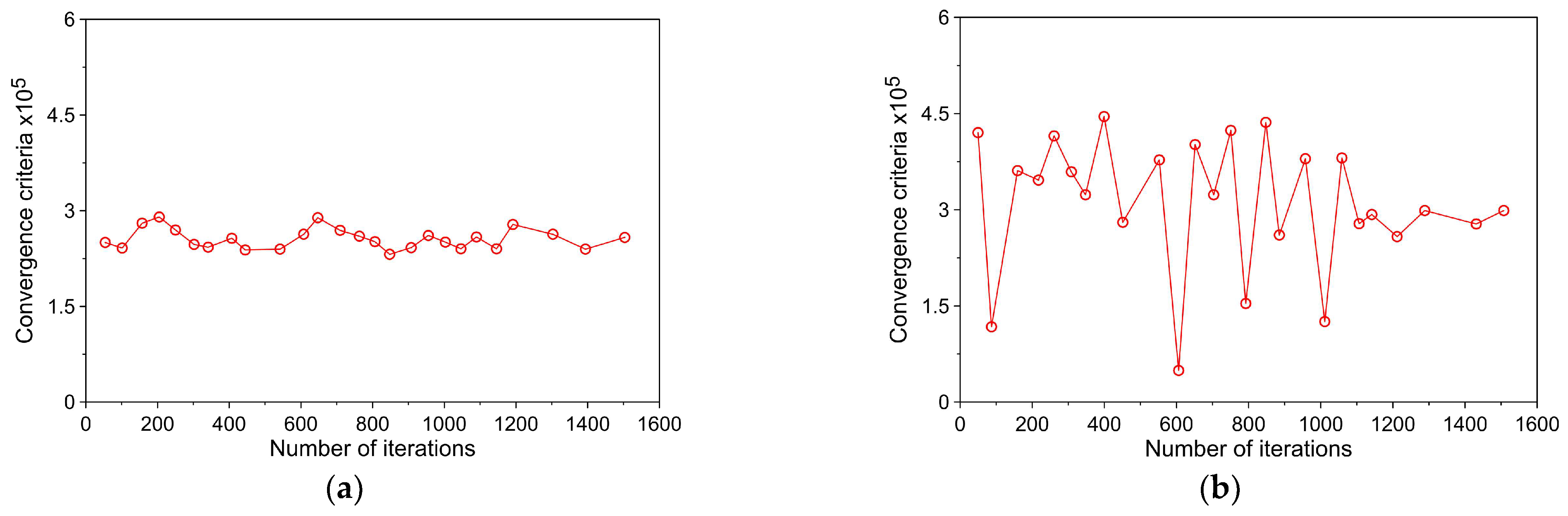

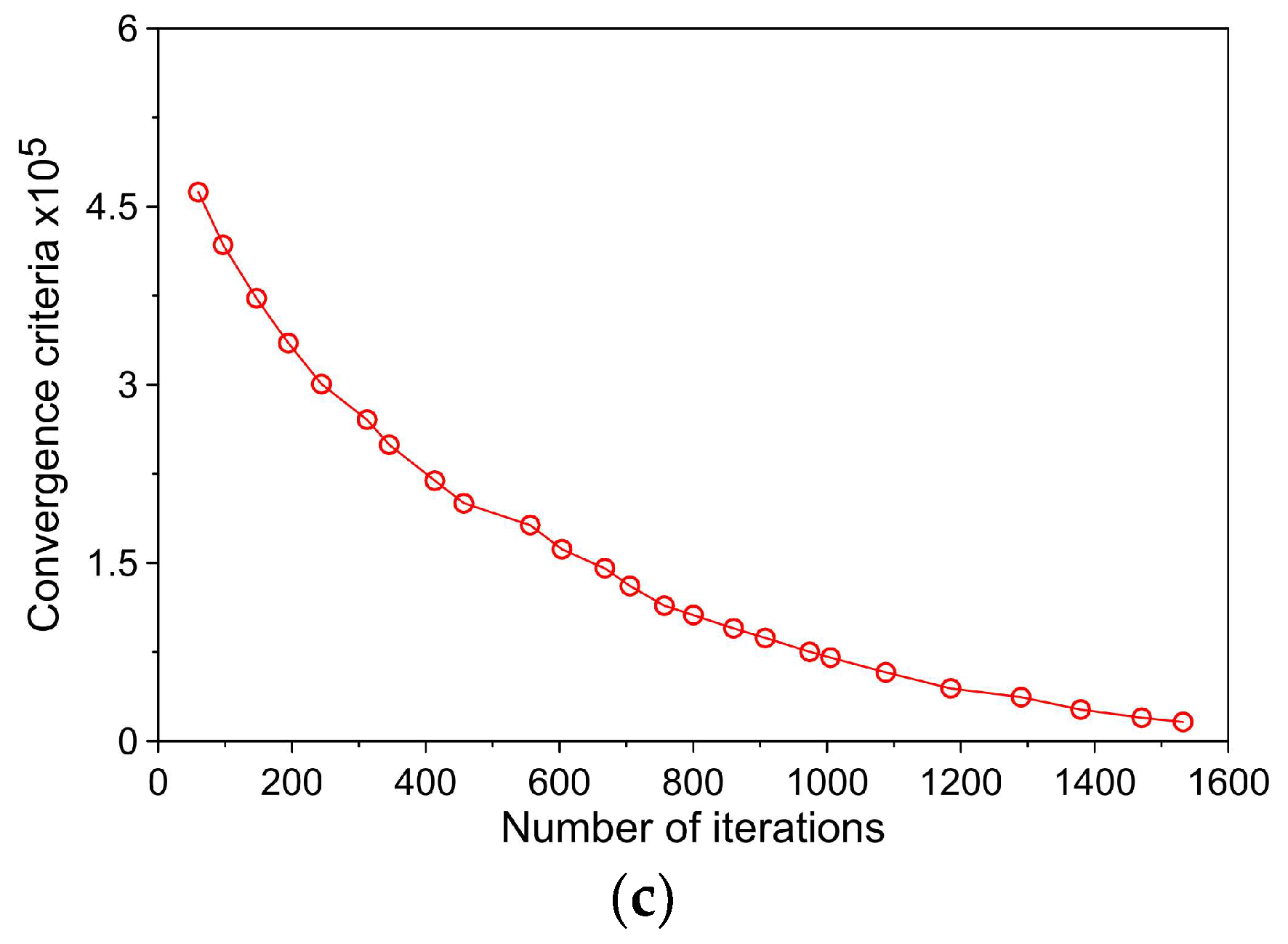

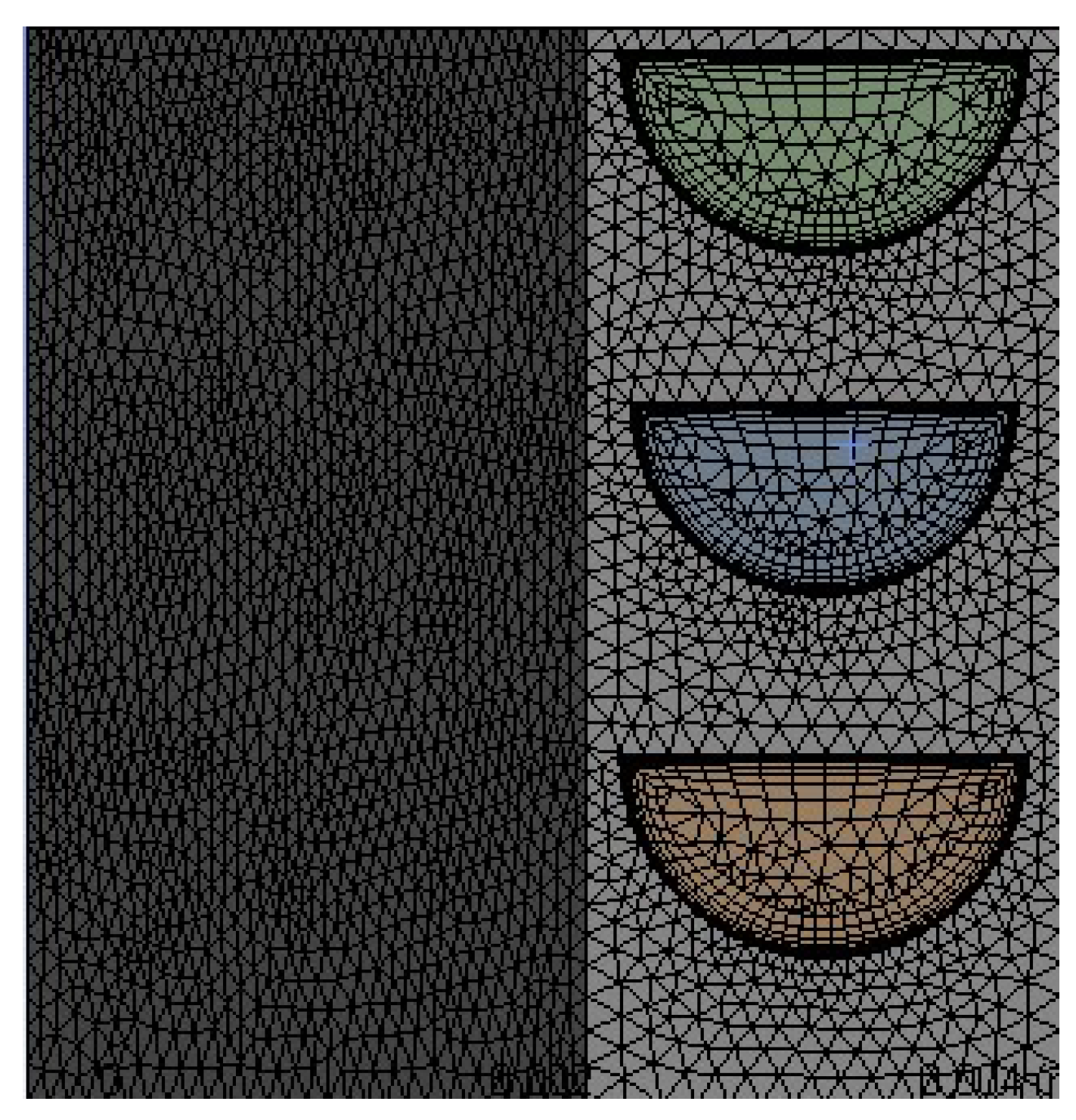

2.3. Mesh Independence

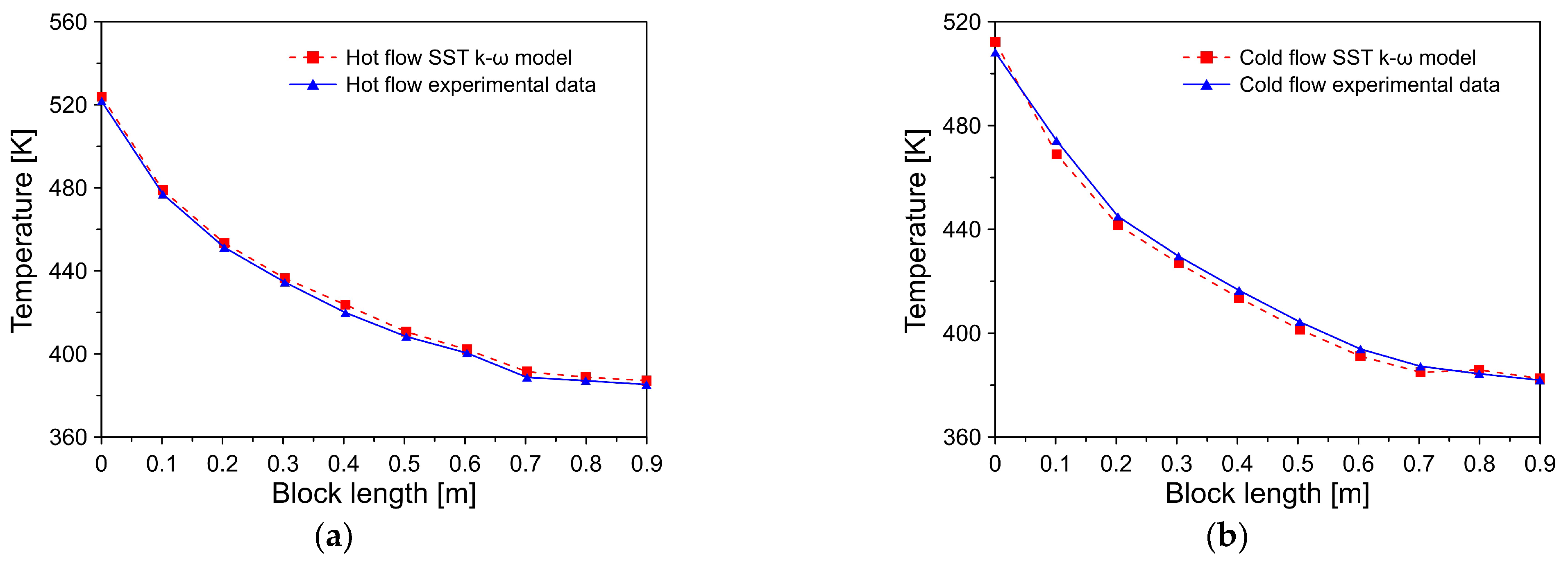

3. CFD Model Validation

4. Results and Discussions

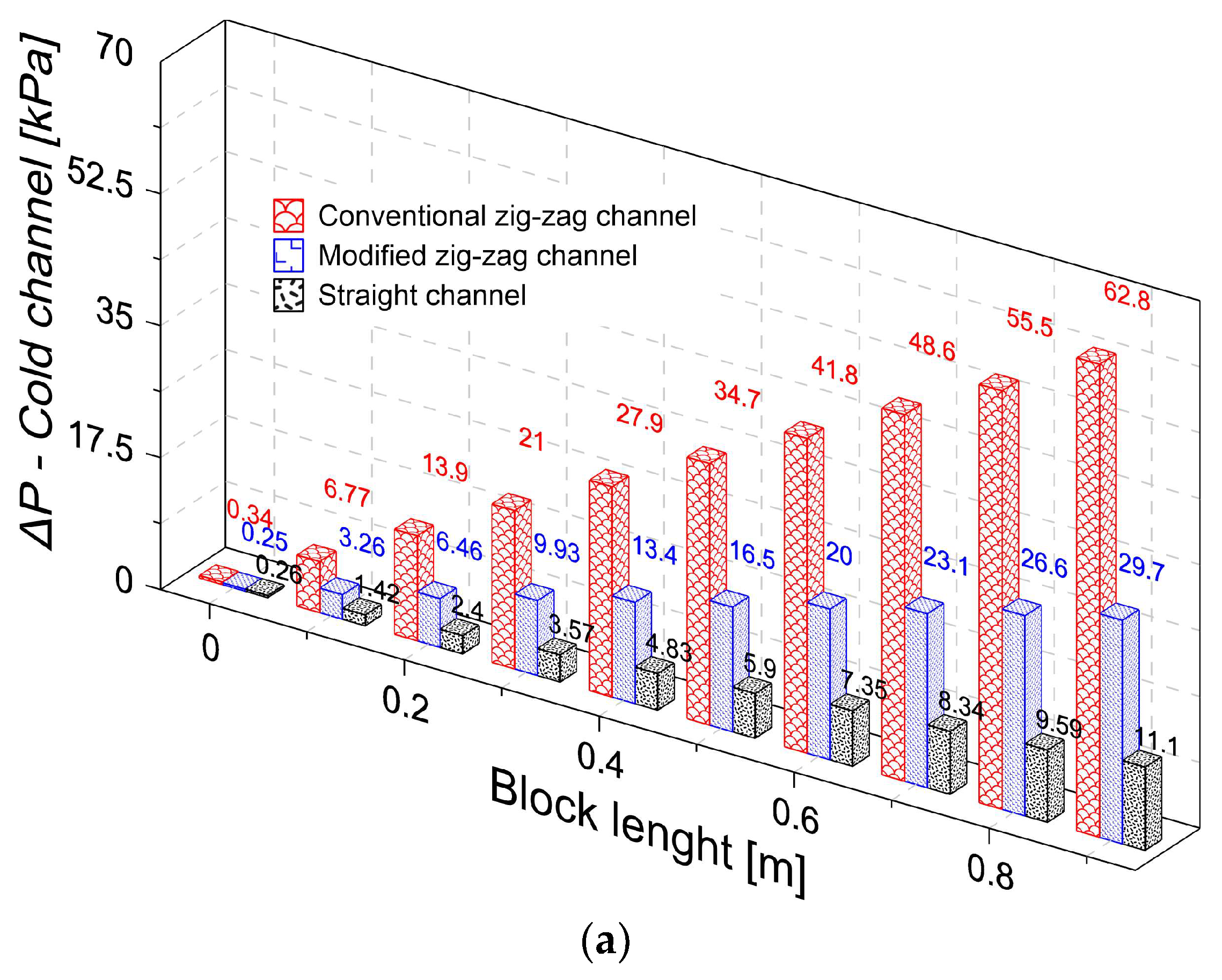

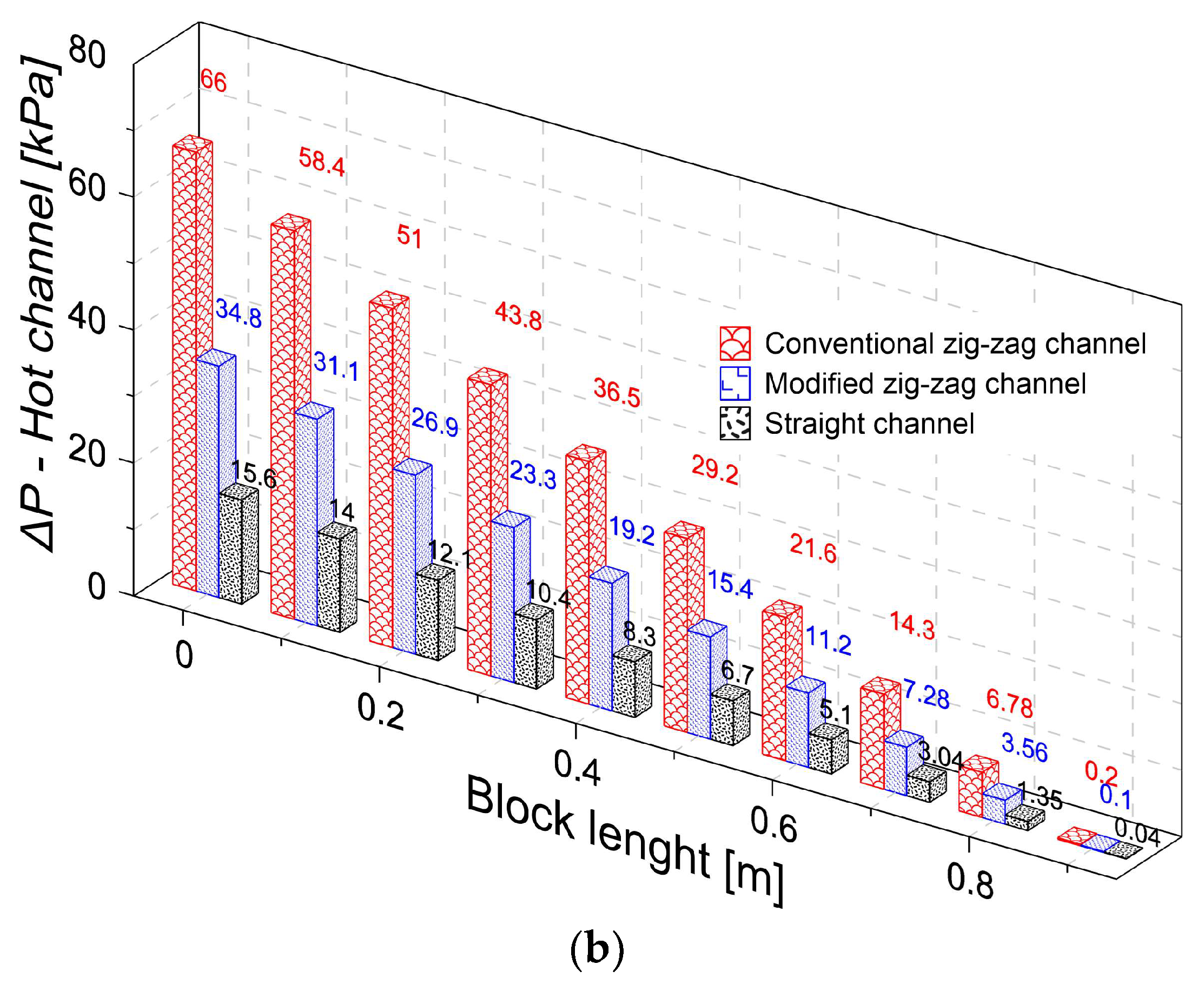

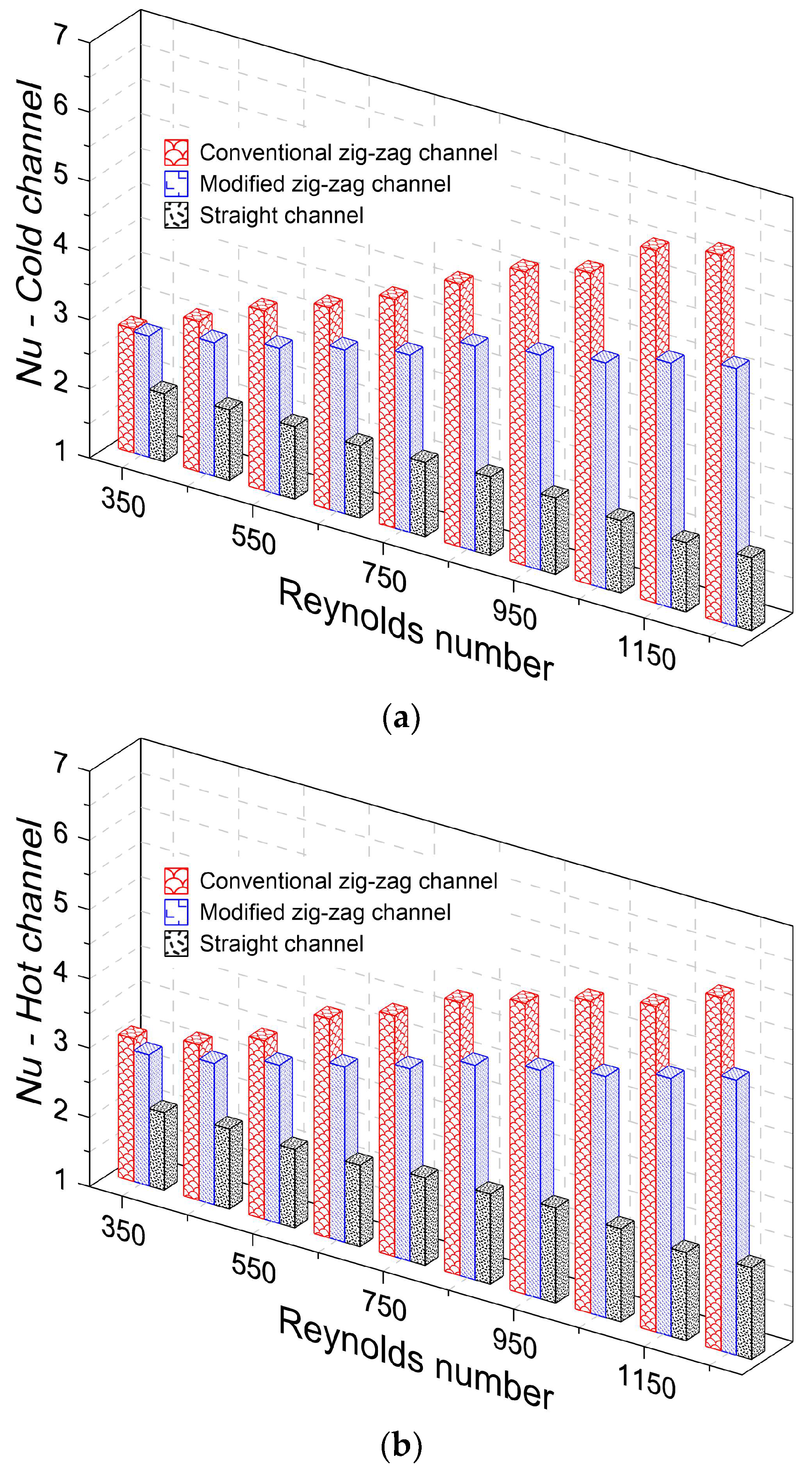

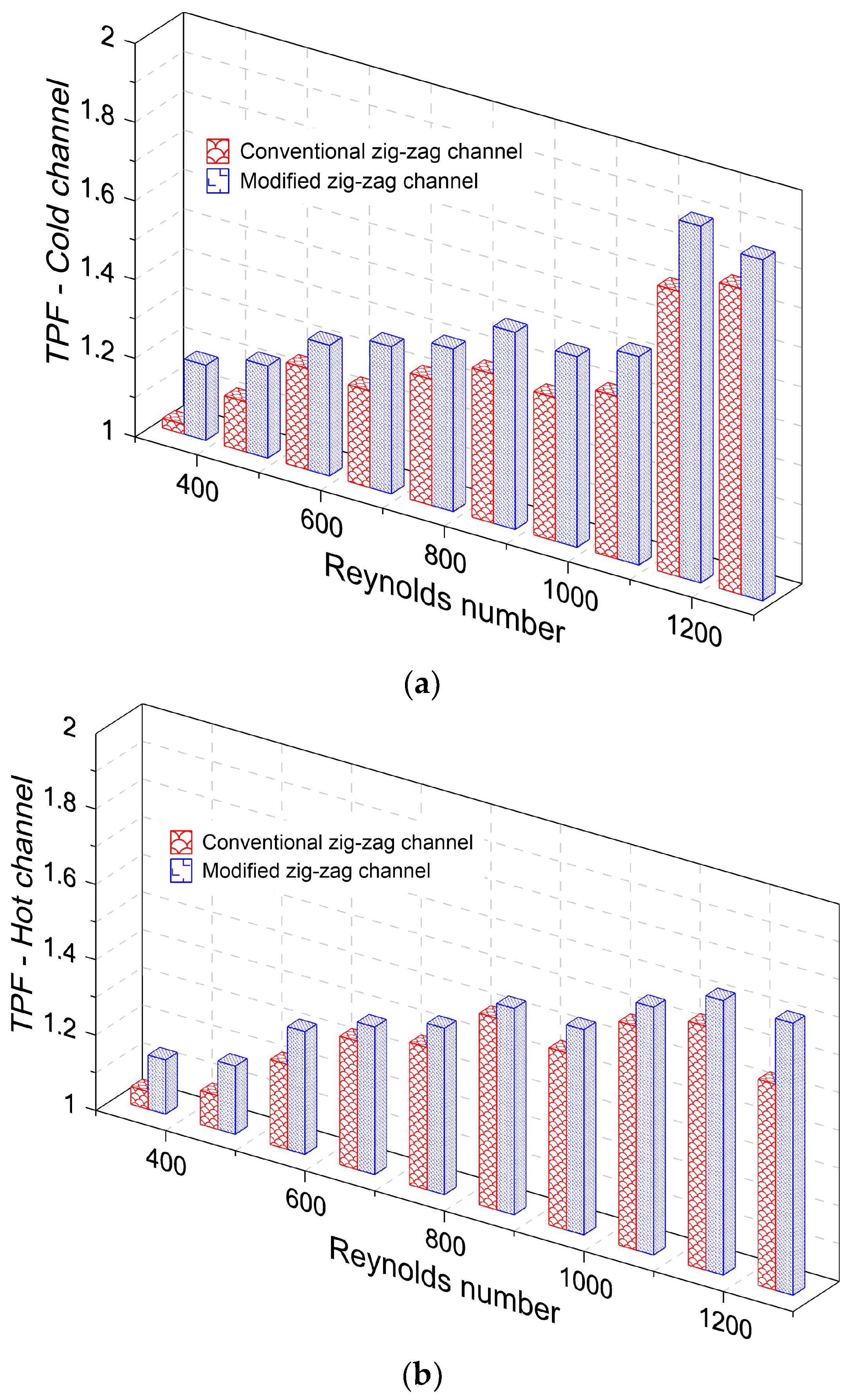

4.1. Thermal and Hydraulic Performance Analysis

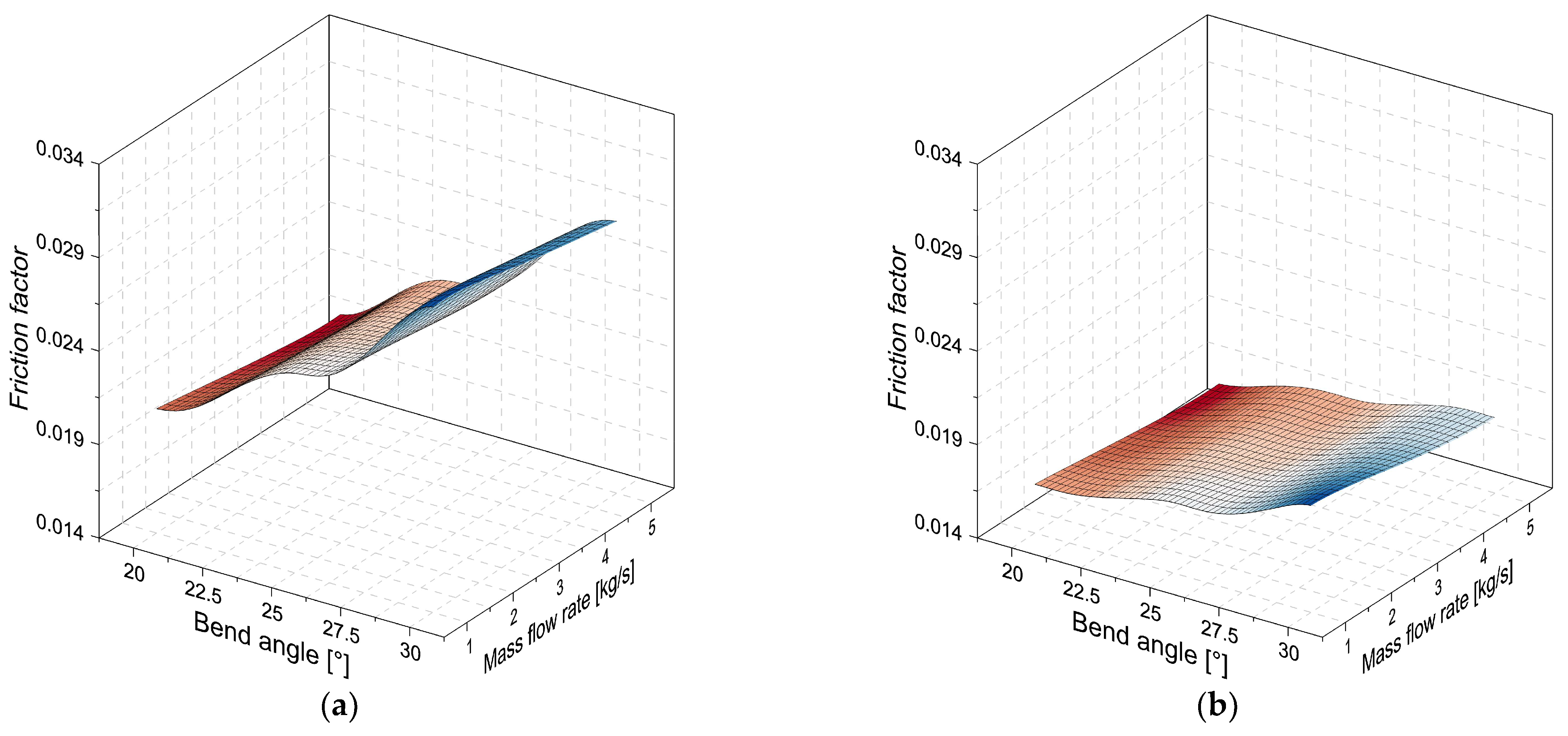

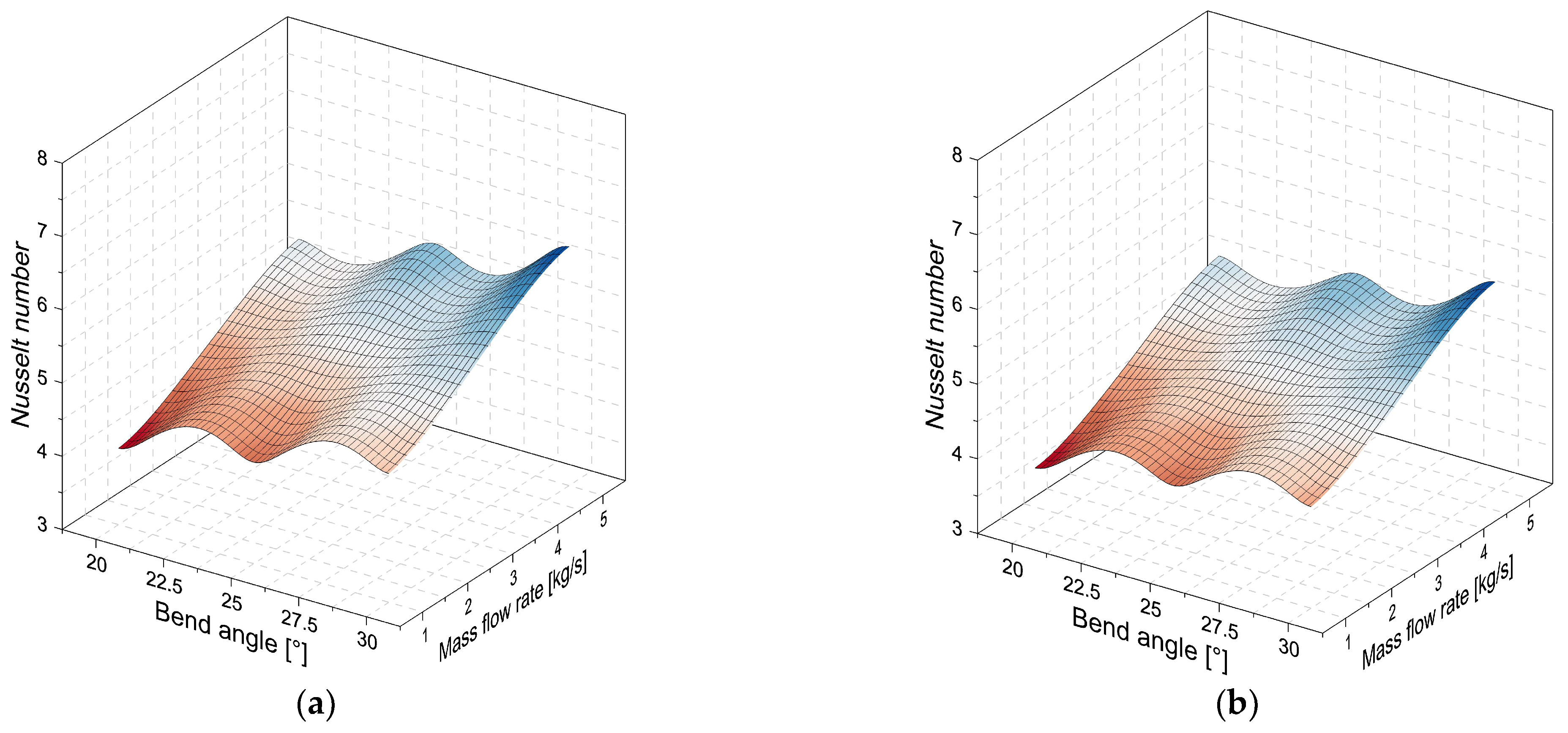

4.2. Effect of Bend Angle on Channels

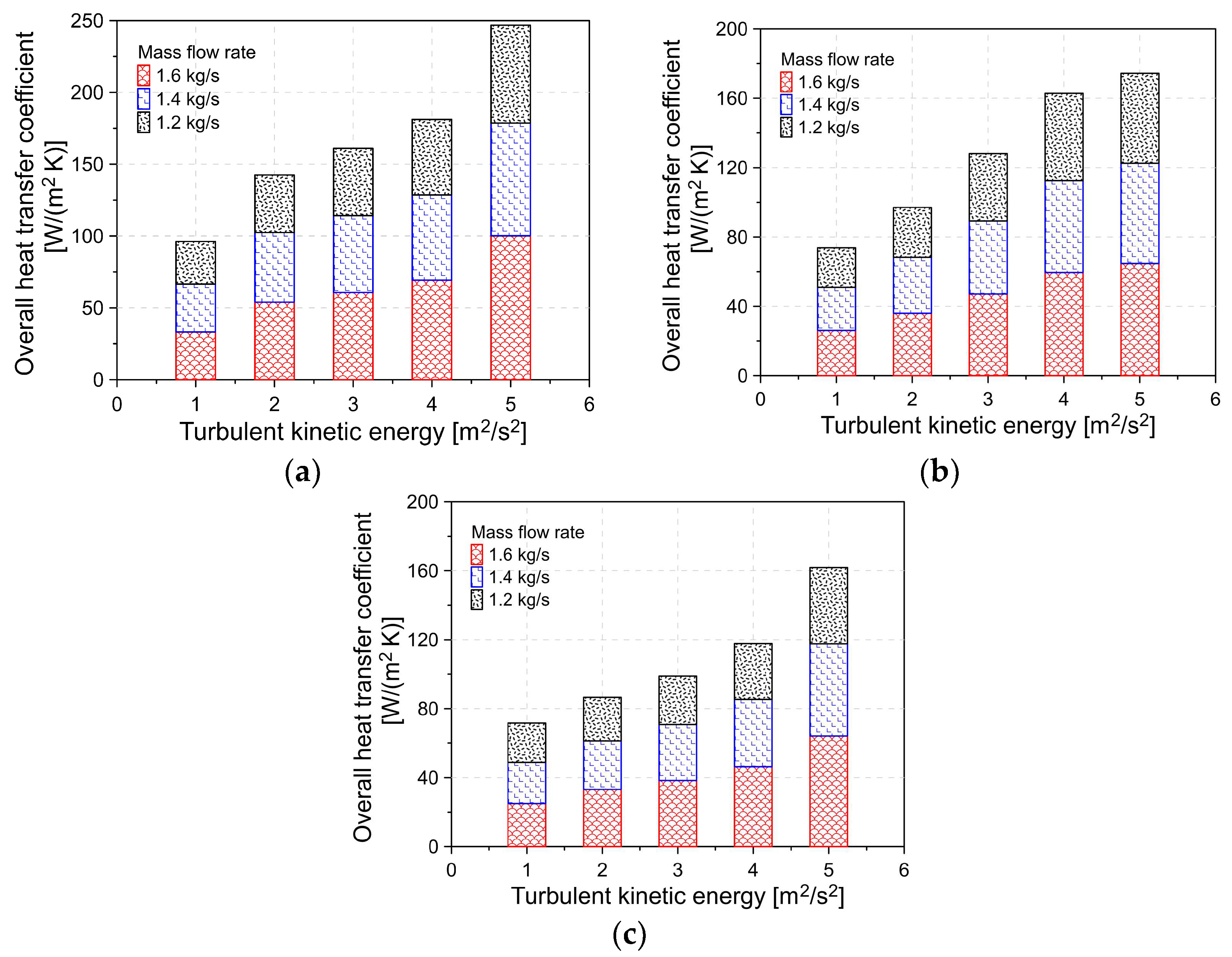

4.3. Heat Transfer Analysis

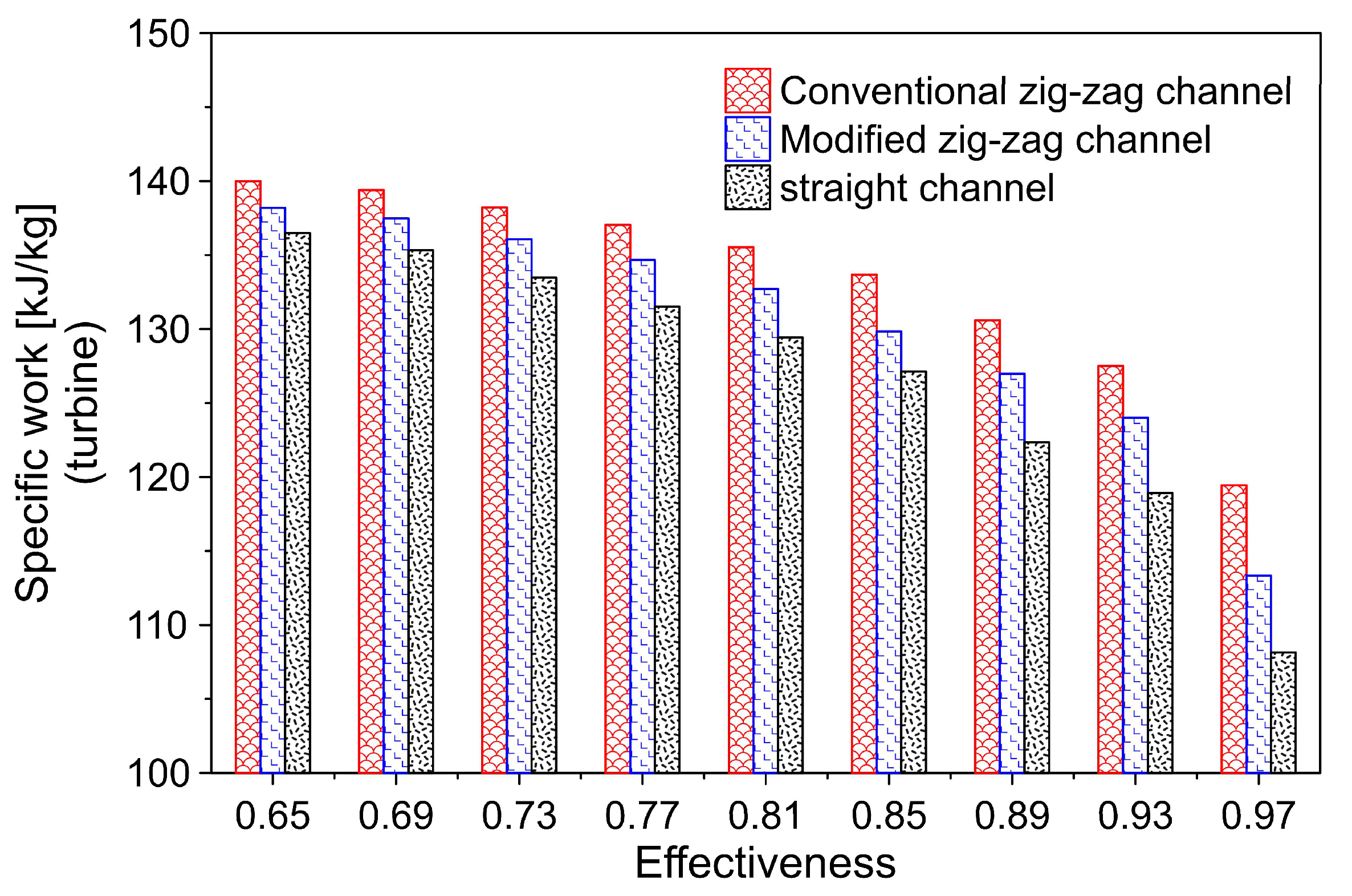

4.4. Effect of PCHE Designs on the Supercritical CO2 Brayton Cycle

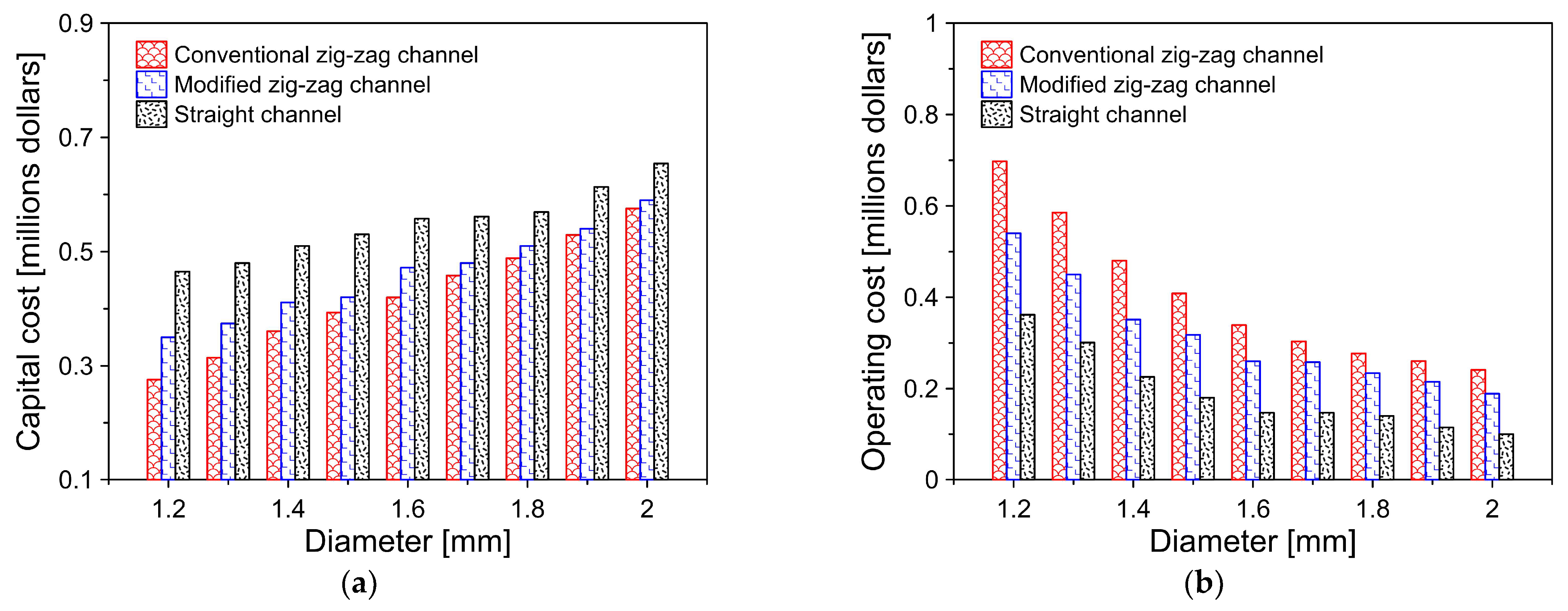

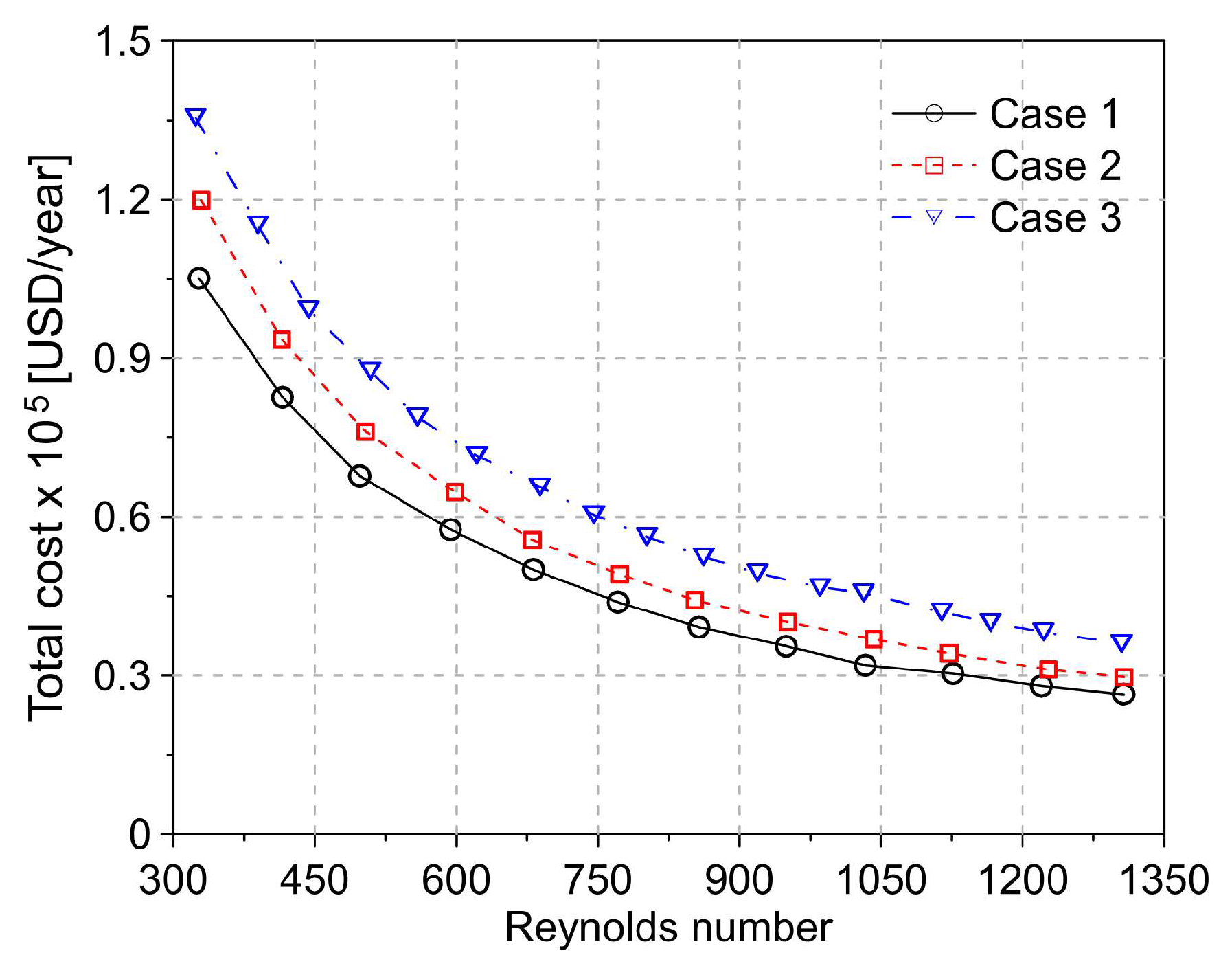

4.5. Economic Analysis

4.6. Analysis of Geometric Parameters

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CFD | Computational fluid dynamics |

| CSP | Concentrated Solar Power |

| TEG | Thermoelectric Generator |

| WHR | Waste Heat Recovery |

| PCHE | Printed Circuit Heat Exchanger |

| sCO2 | Supercritical carbon dioxide |

| TPF | Thermal performance factor |

| Nusselt number | |

| Capital cost | |

| Volume | |

| Cost per unit mass | |

| Interest rate | |

| Lifetime | |

| Operating cost | |

| Operating cost per pumping work | |

| Pressure drop | |

| Flow rate | |

| Total cost | |

| Pressure | |

| Temperature | |

| Velocity | |

| Specific heat | |

| Enthalpy | |

| Greek symbol | |

| Density | |

| Friction factor | |

| Viscous stress tensor | |

| Dynamic viscosity | |

| Thermal conductivity | |

References

- Estrada, L.; Moreno, E.; Gonzalez-Quiroga, A.; Bula, A.; Duarte-Forero, J. Experimental assessment of performance and emissions for hydrogen-diesel dual fuel operation in a low displacement compression ignition engine. Heliyon 2022, 8, e09285. [Google Scholar] [CrossRef]

- Duarte-Forero, J.; Mendoza-Casseres, D.; Valencia-Ochoa, G. Energy, Exergy, and emissions (3E) assessment of a low-displacement engine powered by biodiesel blends of palm oil mill effluent (POME) and hydroxy gas. Therm. Sci. Eng. Prog. 2021, 26, 101126. [Google Scholar] [CrossRef]

- Espinel Blanco, E.; Valencia Ochoa, G.; Duarte Forero, J. Thermodynamic, Exergy and Environmental Impact Assessment of SCO2 Brayton Cycle Coupled with ORC as Bottoming Cycle. Energies 2020, 13, 2259. [Google Scholar] [CrossRef]

- Vasquez, R.; Chean, Y.; Too, S.; Benito, R.; Stein, W. Exergetic analysis of supercritical CO2 Brayton cycles integrated with solar central receivers. Appl. Energy 2015, 148, 348–365. [Google Scholar]

- Valencia Ochoa, G.; Acevedo Peñaloza, C.; Duarte Forero, J. Thermo-Economic Assessment of a Gas Microturbine-Absorption Chiller Trigeneration System under Different Compressor Inlet Air Temperatures. Energies 2019, 12, 4643. [Google Scholar] [CrossRef]

- Peng, M.Y.-P.; Chen, C.; Peng, X.; Marefati, M. Energy and exergy analysis of a new combined concentrating solar collector, solid oxide fuel cell, and steam turbine CCHP system. Sustain. Energy Technol. Assess. 2020, 39, 100713. [Google Scholar] [CrossRef]

- Valencia Ochoa, G.; Piero Rojas, J.; Duarte Forero, J. Advance Exergo-Economic Analysis of a Waste Heat Recovery System Using ORC for a Bottoming Natural Gas Engine. Energies 2020, 13, 267. [Google Scholar] [CrossRef]

- Gholamian, E.; Ahmadi, P.; Hanafizadeh, P.; Ashjaee, M. Dynamic feasibility assessment and 3E analysis of a smart building energy system integrated with hybrid photovoltaic-thermal panels and energy storage. Sustain. Energy Technol. Assess. 2020, 42, 100835. [Google Scholar] [CrossRef]

- Diaz, G.A.; Forero, J.D.; Garcia, J.; Rincon, A.; Fontalvo, A.; Bula, A.; Padilla, R.V. Maximum Power From Fluid Flow by Applying the First and Second Laws of Thermodynamics. J. Energy Resour. Technol. 2017, 139, 032903. [Google Scholar] [CrossRef]

- Guillin-Estrada, W.; Maestre-Cambronel, D.; Bula-Silvera, A.; Gonzalez-Quiroga, A.; Duarte-Forero, J. Combustion and Performance Evaluation of a Spark Ignition Engine Operating with Acetone–Butanol–Ethanol and Hydroxy. Appl. Sci. 2021, 11, 5282. [Google Scholar] [CrossRef]

- Duarte, N.; Arango, D.; Polanco, G.; Valencia, G.; Duarte-Forero, J. Experimental evaluation of low-displacement compression ignited engines operating with hydroxy gas as a supplementary gaseous fuel. Heliyon 2022, 8, e11545. [Google Scholar] [CrossRef]

- Marchionni, M.; Chai, L.; Bianchi, G.; Tassou, S.A. Numerical modelling and transient analysis of a printed circuit heat exchanger used as recuperator for supercritical CO2 heat to power conversion systems. Appl. Therm. Eng. 2019, 161, 114190. [Google Scholar] [CrossRef]

- Park, J.H.; Kwon, J.G.; Kim, T.H.; Kim, M.H.; Cha, J.-E.; Jo, H. Experimental study of a straight channel printed circuit heat exchanger on supercritical CO2 near the critical point with water cooling. Int. J. Heat Mass Transf. 2020, 150, 119364. [Google Scholar] [CrossRef]

- Sanaye, S.; Khakpaay, N.; Chitsaz, A. Thermo-economic and environmental multi-objective optimization of a novel arranged biomass-fueled gas engine and backpressure steam turbine combined system for pulp and paper mills. Sustain. Energy Technol. Assess. 2020, 40, 100778. [Google Scholar] [CrossRef]

- Jing, Q.; Xie, Y.; Zhang, D. Thermal hydraulic performance of printed circuit heat exchanger with various channel configurations and arc ribs for SCO2 Brayton cycle. Int. J. Heat Mass Transf. 2020, 150, 119272. [Google Scholar] [CrossRef]

- Duarte Forero, J.; Obregon, L.; Valencia, G. Comparative analysis of intelligence optimization algorithms in the thermo-economic performance of an energy recovery system based on Organic Rankine Cycle. J. Energy Resour. Technol. 2021, 1–18. [Google Scholar] [CrossRef]

- Stand, L.M.; Ochoa, G.V.; Forero, J.D. Energy and exergy assessment of a combined supercritical Brayton cycle-orc hybrid system using solar radiation and coconut shell biomass as energy source. Renew. Energy 2021, 175, 119–142. [Google Scholar] [CrossRef]

- Valencia Ochoa, G.; Acevedo Peñaloza, C.; Duarte Forero, J. Thermoeconomic Optimization with PSO Algorithm of Waste Heat Recovery Systems Based on Organic Rankine Cycle System for a Natural Gas Engine. Energies 2019, 12, 4165. [Google Scholar] [CrossRef]

- Herrera-Orozco, I.; Valencia-Ochoa, G.; Duarte-Forero, J. Exergo-environmental assessment and multi-objective optimization of waste heat recovery systems based on Organic Rankine cycle configurations. J. Clean. Prod. 2021, 288, 125679–125694. [Google Scholar] [CrossRef]

- Ochoa, G.V.; Prada, G.; Duarte-Forero, J. Carbon footprint analysis and advanced exergo-environmental modeling of a waste heat recovery system based on a recuperative organic Rankine cycle. J. Clean. Prod. 2020, 274, 122838–122857. [Google Scholar] [CrossRef]

- Valencia Ochoa, G.; Isaza-Roldan, C.; Forero, J.D. Economic and Exergo-Advance Analysis of a Waste Heat Recovery System Based on Regenerative Organic Rankine Cycle under Organic Fluids with Low Global Warming Potential. Energies 2020, 13, 1317. [Google Scholar] [CrossRef]

- Habibi, H.; Zoghi, M.; Chitsaz, A.; Javaherdeh, K.; Ayazpour, M.; Bellos, E. Working fluid selection for regenerative supercritical Brayton cycle combined with bottoming ORC driven by molten salt solar power tower using energy—exergy analysis. Sustain. Energy Technol. Assess. 2020, 39, 100699. [Google Scholar] [CrossRef]

- Jiang, Y.; Liese, E.; Zitney, S.E.; Bhattacharyya, D. Optimal design of microtube recuperators for an indirect supercritical carbon dioxide recompression closed Brayton cycle. Appl. Energy 2018, 216, 634–648. [Google Scholar] [CrossRef]

- Yang, D.; Khan, T.S.; Al-Hajri, E.; Ayub, Z.H.; Ayub, A.H. Geometric optimization of shell and tube heat exchanger with interstitial twisted tapes outside the tubes applying CFD techniques. Appl. Therm. Eng. 2019, 152, 559–572. [Google Scholar] [CrossRef]

- de la Torre, R.; François, J.-L.; Lin, C.-X. Assessment of the design effects on the structural performance of the Printed Circuit Heat Exchanger under very high temperature condition. Nucl. Eng. Des. 2020, 365, 110713. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, X.; Christensen, R.; Anderson, M.; Carlson, M. Optimization of S-Shaped Fin Channels in a Printed Circuit Heat Exchanger for Supercritical CO2 Test Loop. In Proceedings of the 5th International Supercritical CO2 Power Cycles Symposium, San Antonio, TX, USA, 29–31 March 2016. [Google Scholar]

- Saeed, M.; Kim, M.H. Thermal and hydraulic performance of SCO2 PCHE with different fin configurations. Appl. Therm. Eng. 2017, 127, 975–985. [Google Scholar] [CrossRef]

- Ngo, T.L.; Kato, Y.; Nikitin, K.; Ishizuka, T. Heat transfer and pressure drop correlations of microchannel heat exchangers with S-shaped and zigzag fins for carbon dioxide cycles. Exp. Therm. Fluid Sci. 2007, 32, 560–570. [Google Scholar] [CrossRef]

- Yoon, S.H.; No, H.C.; Kang, G.B. Assessment of straight, zigzag, S-shape, and airfoil PCHEs for intermediate heat exchangers of HTGRs and SFRs. Nucl. Eng. Des. 2014, 270, 334–343. [Google Scholar] [CrossRef]

- Liu, G.; Huang, Y.; Wang, J.; Liu, R. A review on the thermal-hydraulic performance and optimization of printed circuit heat exchangers for supercritical CO2 in advanced nuclear power systems. Renew. Sustain. Energy Rev. 2020, 133, 110290. [Google Scholar] [CrossRef]

- Bone, V.; McNaughton, R.; Kearney, M.; Jahn, I. Methodology to develop off-design models of heat exchangers with non-ideal fluids. Appl. Therm. Eng. 2018, 145, 716–734. [Google Scholar] [CrossRef]

- Shin, C.W.; No, H.C. Experimental study for pressure drop and flow instability of two-phase flow in the PCHE-type steam generator for SMRs. Nucl. Eng. Des. 2017, 318, 109–118. [Google Scholar] [CrossRef]

- Chai, L.; Tassou, S.A. Numerical study of the thermohydraulic performance of printed circuit heat exchangers for supercritical CO2 Brayton cycle applications. Energy Procedia 2019, 161, 480–488. [Google Scholar] [CrossRef]

- Park, J.H.; Park, H.S.; Kwon, J.G.; Kim, T.H.; Kim, M.H. Optimization and thermodynamic analysis of supercritical CO2 Brayton recompression cycle for various small modular reactors. Energy 2018, 160, 520–535. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, X.; Zhao, K.; Jiang, P.; Chen, Y. Numerical investigation on heat transfer and flow characteristics of supercritical nitrogen in a straight channel of printed circuit heat exchanger. Appl. Therm. Eng. 2017, 126, 717–729. [Google Scholar] [CrossRef]

- Li, X.L.; Tang, G.H.; Fan, Y.H.; Yang, D.L.; Wang, S.Q. Numerical analysis of slotted airfoil fins for printed circuit heat exchanger in SCO2 Brayton cycle. J. Nucl. Eng. Radiat. Sci. 2019, 5, 41303. [Google Scholar] [CrossRef]

- Wang, H.; Leung, L.K.H.; Wang, W.; Bi, Q. A review on recent heat transfer studies to supercritical pressure water in channels. Appl. Therm. Eng. 2018, 142, 573–596. [Google Scholar] [CrossRef]

- John, J.; Pane, E.A.; Suyitno, B.M.; Rahayu, G.H.N.N.; Rhakasywi, D.; Suwandi, A. Computational fluid dynamics simulation of the turbulence models in the tested section on wind tunnel. Ain Shams Eng. J. 2020, 11, 1201–1209. [Google Scholar]

- Djouimaa, S.; Messaoudi, L.; Giel, P.W. Transonic turbine blade loading calculations using different turbulence models—effects of reflecting and non-reflecting boundary conditions. Appl. Therm. Eng. 2007, 27, 779–787. [Google Scholar] [CrossRef]

- Lal, S.; Lucci, F.; Defraeye, T.; Poulikakos, L.D.; Partl, M.N.; Derome, D.; Carmeliet, J. CFD modeling of convective scalar transport in a macroporous material for drying applications. Int. J. Therm. Sci. 2018, 123, 86–98. [Google Scholar] [CrossRef]

- Jiao, Z.; Yuan, S.; Ji, C.; Mannan, M.S.; Wang, Q. Optimization of dilution ventilation layout design in confined environments using Computational Fluid Dynamics (CFD). J. Loss Prev. Process Ind. 2019, 60, 195–202. [Google Scholar] [CrossRef]

- Bennett, K.; Chen, Y. One-way coupled three-dimensional fluid-structure interaction analysis of zigzag-channel supercritical CO2 printed circuit heat exchangers. Nucl. Eng. Des. 2020, 358, 110434. [Google Scholar] [CrossRef]

- GNU; Lesser General Public License (LGPL). Salome. Available online: https://www.salome-platform.org/ (accessed on 25 January 2023).

- Bai, J.; Pan, J.; He, X.; Wang, K.; Tang, L.; Yang, R. Numerical investigation on thermal hydraulic performance of supercritical LNG in sinusoidal wavy channel based printed circuit vaporizer. Appl. Therm. Eng. 2020, 175, 115379. [Google Scholar] [CrossRef]

- Saeed, M.; Kim, M.-H. Thermal-hydraulic analysis of sinusoidal fin-based printed circuit heat exchangers for supercritical CO2 Brayton cycle. Energy Convers. Manag. 2019, 193, 124–139. [Google Scholar] [CrossRef]

- Thulukkanam, K. Heat Exchanger Design Handbook; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Abeykoon, C. Compact heat exchangers—Design and optimization with CFD. Int. J. Heat Mass Transf. 2020, 146, 118766. [Google Scholar] [CrossRef]

- Kim, I.H.; Zhang, X.; Christensen, R.; Sun, X. Design study and cost assessment of straight, zigzag, S-shape, and OSF PCHEs for a FLiNaK—SCO2 Secondary Heat Exchanger in FHRs. Ann. Nucl. Energy 2016, 94, 129–137. [Google Scholar] [CrossRef]

- Yang, Y.; Li, H.; Yao, M.; Gao, W.; Zhang, Y.; Zhang, L. Investigation on the effects of narrowed channel cross-sections on the heat transfer performance of a wavy-channeled PCHE. Int. J. Heat Mass Transf. 2019, 135, 33–43. [Google Scholar] [CrossRef]

| Parameter | Flow Density | Thermal Conductivity | Specific Heat |

|---|---|---|---|

| Units | kg/m3 | W/(m K) | J/(kg K) |

| Value | 8030 | 16.27 | 502.47 |

| Configuration | Nodes | Elements | Orthogonal Quality | Cell Shape | ||

|---|---|---|---|---|---|---|

| Skewness | Aspect Ratio | Squish Index | ||||

| Conventional zig-zag channel | 4,475,253 | 9,648,633 | 0.78044 | 0.26 | 1.30 | 0.35 |

| Straight channel | 2,996,011 | 10,560,881 | 0.77577 | 0.24 | 1.36 | 0.41 |

| Modified zig-zag channel | 4,426,327 | 8,542,693 | 0.790156 | 0.26 | 1.31 | 0.37 |

| Number of Elements | Conventional Zig-Zag Channel | Modified Zig-Zag Channel | Straight Channel | |||

|---|---|---|---|---|---|---|

| Temperature [K] | Deviation [%] | Temperature [K] | Deviation [%] | Temperature [K] | Deviation [%] | |

| 2.25 | 557.30 | [-] | 531.50 | [-] | 501.02 | [-] |

| 3 | 545.26 | 2.16 | 512.72 | 3.53 | 505.07 | 0.81 |

| 3.75 | 533.62 | 2.14 | 494.72 | 3.51 | 508.59 | 0.70 |

| 4.5 | 525.86 | 1.45 | 492.27 | 0.49 | 510.17 | 0.31 |

| 5.25 | 521.08 | 0.91 | 495.80 | 0.72 | 510.71 | 0.11 |

| 6 | 515.53 | 1.07 | 499.19 | 0.68 | 511.38 | 0.13 |

| 6.75 | 516.46 | 0.18 | 505.44 | 1.25 | 512.05 | 0.13 |

| 7.5 | 518.29 | 0.36 | 512.72 | 1.44 | 513.37 | 0.26 |

| 8.25 | 520.26 | 0.38 | 516.24 | 0.69 | 514.16 | 0.16 |

| 9 | 519.89 | 0.07 | 517.04 | 0.16 | 513.54 | 0.12 |

| 9.75 | 520.30 | 0.08 | 517.58 | 0.10 | 513.50 | 0.01 |

| 10.5 | 520.20 | 0.02 | 517.60 | 0.00 | 513.97 | 0.09 |

| 11.25 | 520.09 | 0.02 | 517.10 | 0.10 | 513.73 | 0.05 |

| 12 | 519.85 | 0.05 | 517.26 | 0.03 | 513.89 | 0.03 |

| Parameter | Units | Value |

|---|---|---|

| Maximum pressure | kPa | 8350 |

| Flow temperature | K | 383–523 |

| Corrosion risk | % | 75 |

| PCHE cost | % | 50 |

| Leakage risk | % | 0 |

| Gas compatibility | % | 100 |

| Parameter | Location | Experimental Data [24] | SST k-ω Model | Error (%) |

|---|---|---|---|---|

| Pressure drop between inlet and outlet [kPa] | Cold channel | 67.89 | 62.95 | 7.27 |

| Hot channel | 66.98 | 65.92 | 1.58 | |

| Temperature differential between inlet and outlet [K] | Cold channel | 130.53 | 126.64 | 2.98 |

| Hot channel | 139.58 | 137.11 | 1.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villada-Castillo, D.; Valencia-Ochoa, G.; Duarte-Forero, J. Thermohydraulic and Economic Evaluation of a New Design for Printed Circuit Heat Exchangers in Supercritical CO2 Brayton Cycle. Energies 2023, 16, 2326. https://doi.org/10.3390/en16052326

Villada-Castillo D, Valencia-Ochoa G, Duarte-Forero J. Thermohydraulic and Economic Evaluation of a New Design for Printed Circuit Heat Exchangers in Supercritical CO2 Brayton Cycle. Energies. 2023; 16(5):2326. https://doi.org/10.3390/en16052326

Chicago/Turabian StyleVillada-Castillo, Dora, Guillermo Valencia-Ochoa, and Jorge Duarte-Forero. 2023. "Thermohydraulic and Economic Evaluation of a New Design for Printed Circuit Heat Exchangers in Supercritical CO2 Brayton Cycle" Energies 16, no. 5: 2326. https://doi.org/10.3390/en16052326

APA StyleVillada-Castillo, D., Valencia-Ochoa, G., & Duarte-Forero, J. (2023). Thermohydraulic and Economic Evaluation of a New Design for Printed Circuit Heat Exchangers in Supercritical CO2 Brayton Cycle. Energies, 16(5), 2326. https://doi.org/10.3390/en16052326