The Impact of Windows Replacement on Airtightness and Energy Consumption of a Single Apartment in a Multi-Family Residential Building in Montenegro: A Case Study

Abstract

1. Introduction

1.1. Literature Review on Airtightness Measurement

1.2. Literature Review on Energy Impact of Airtightness

2. Materials and Methods

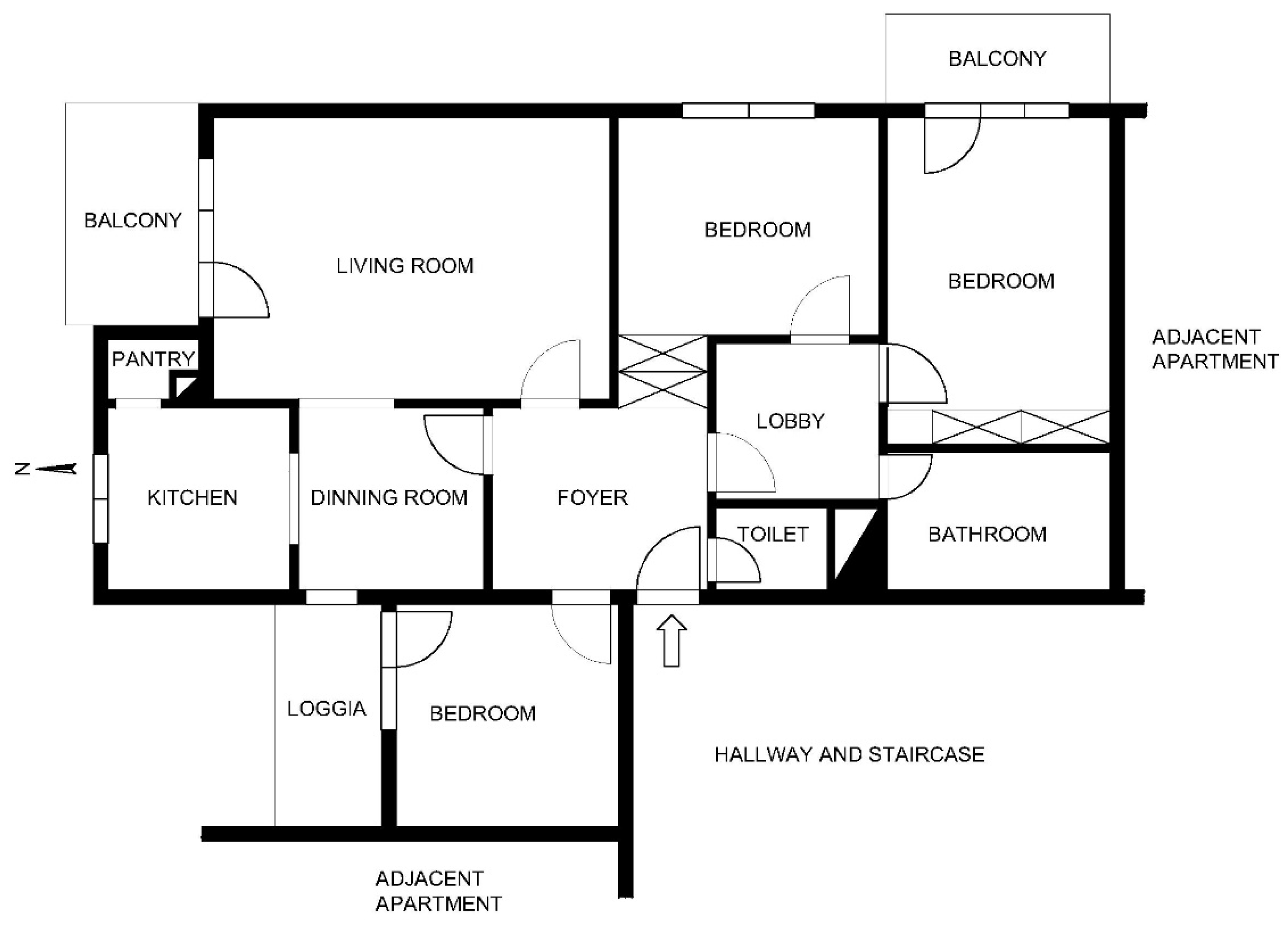

2.1. About the Apartment Being Tested for Airtightness

2.2. Airtightness Measurement

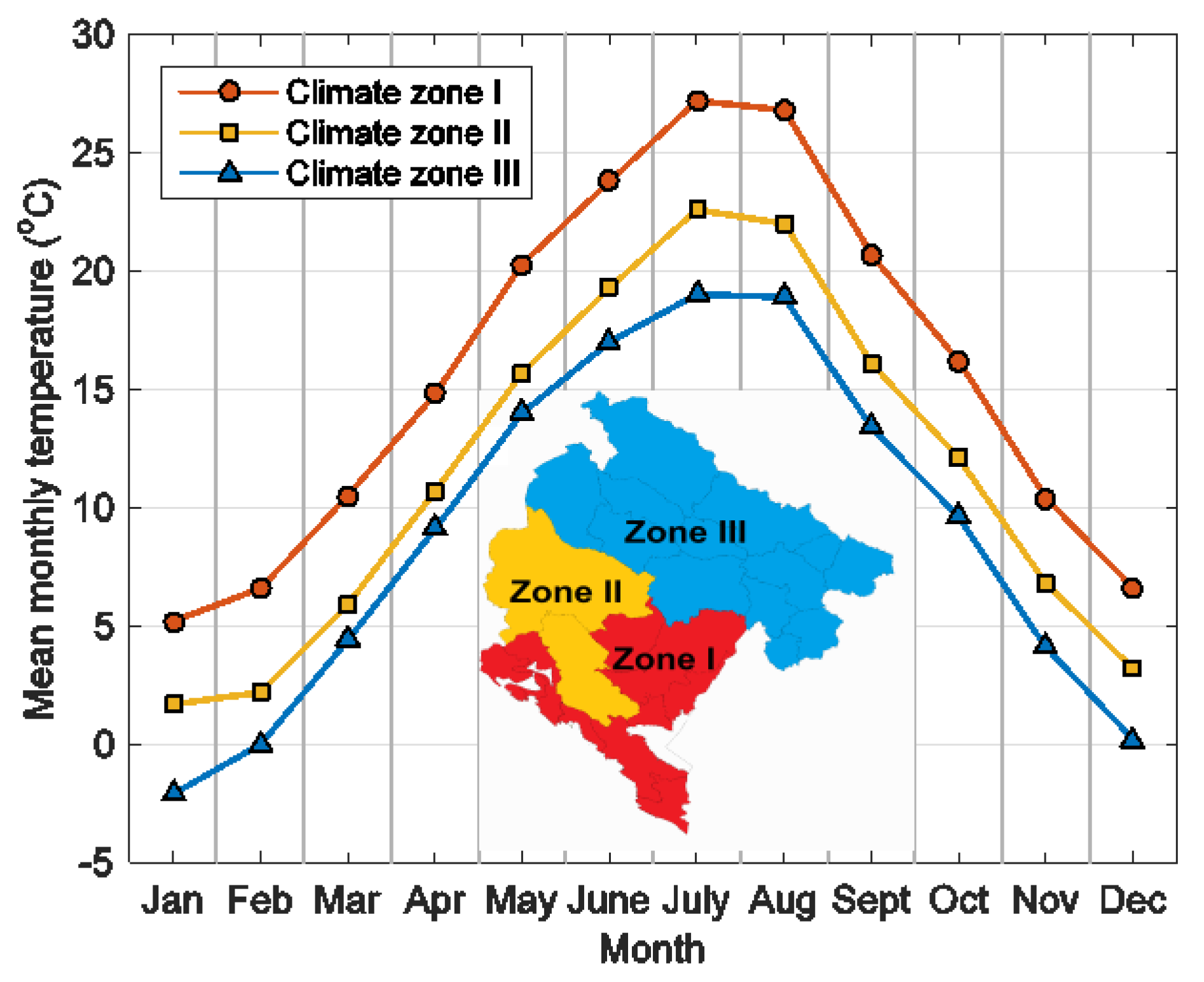

2.3. Calculation of Energy Consumption for Heating and Cooling

3. Results and Discussion

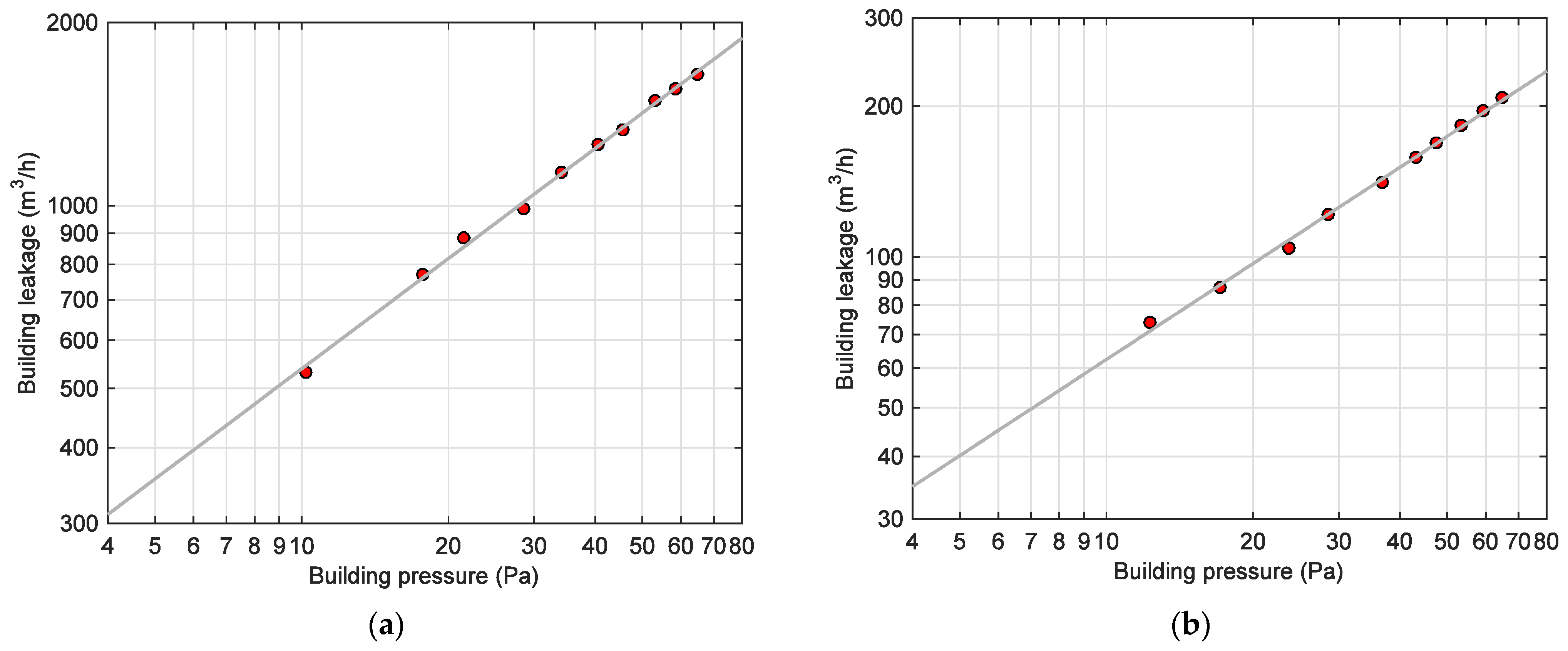

3.1. Results of Blower Door Tests

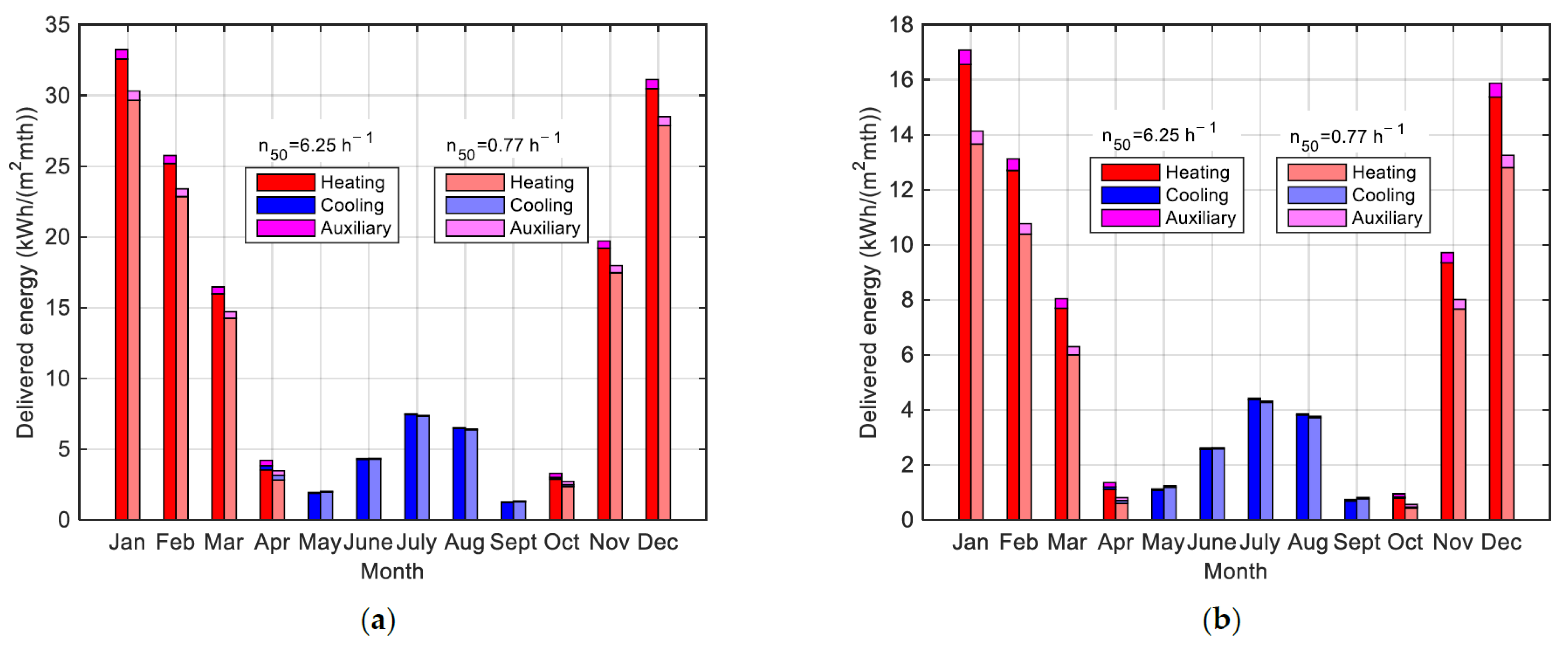

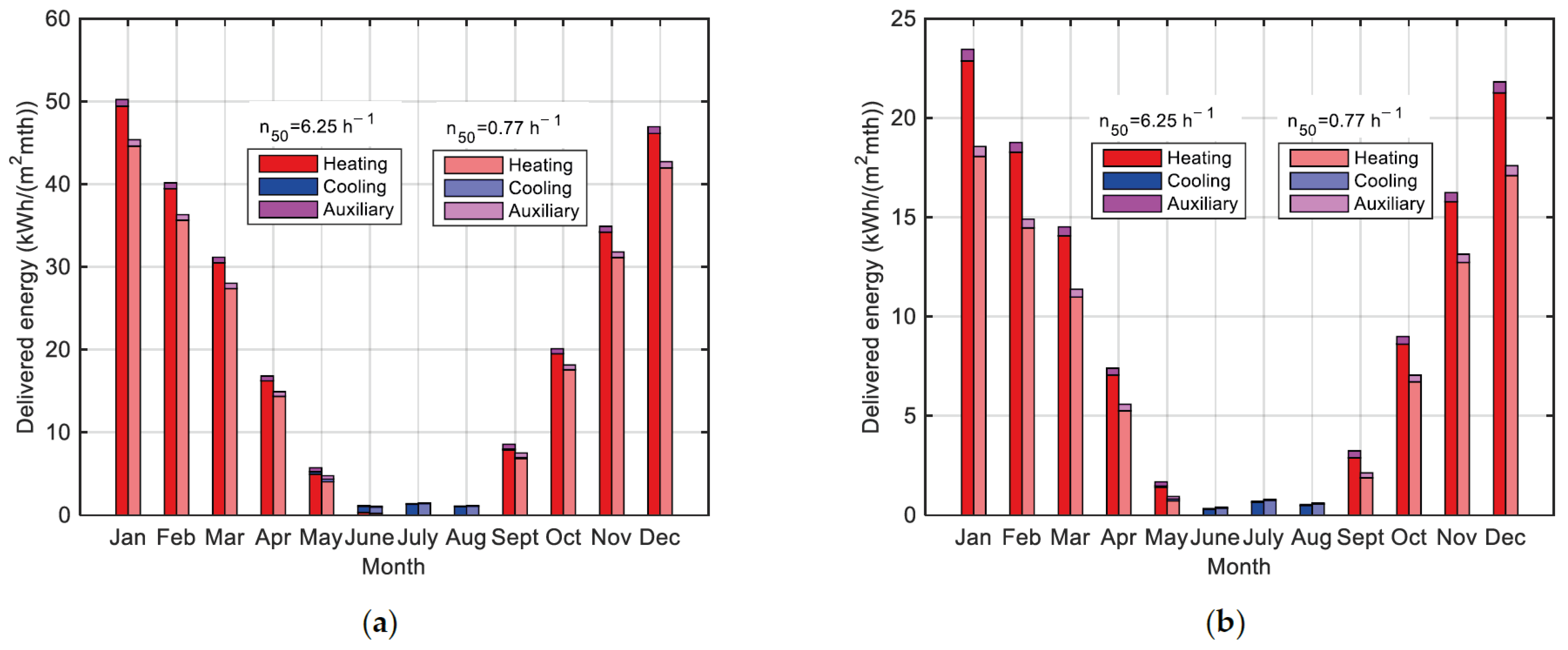

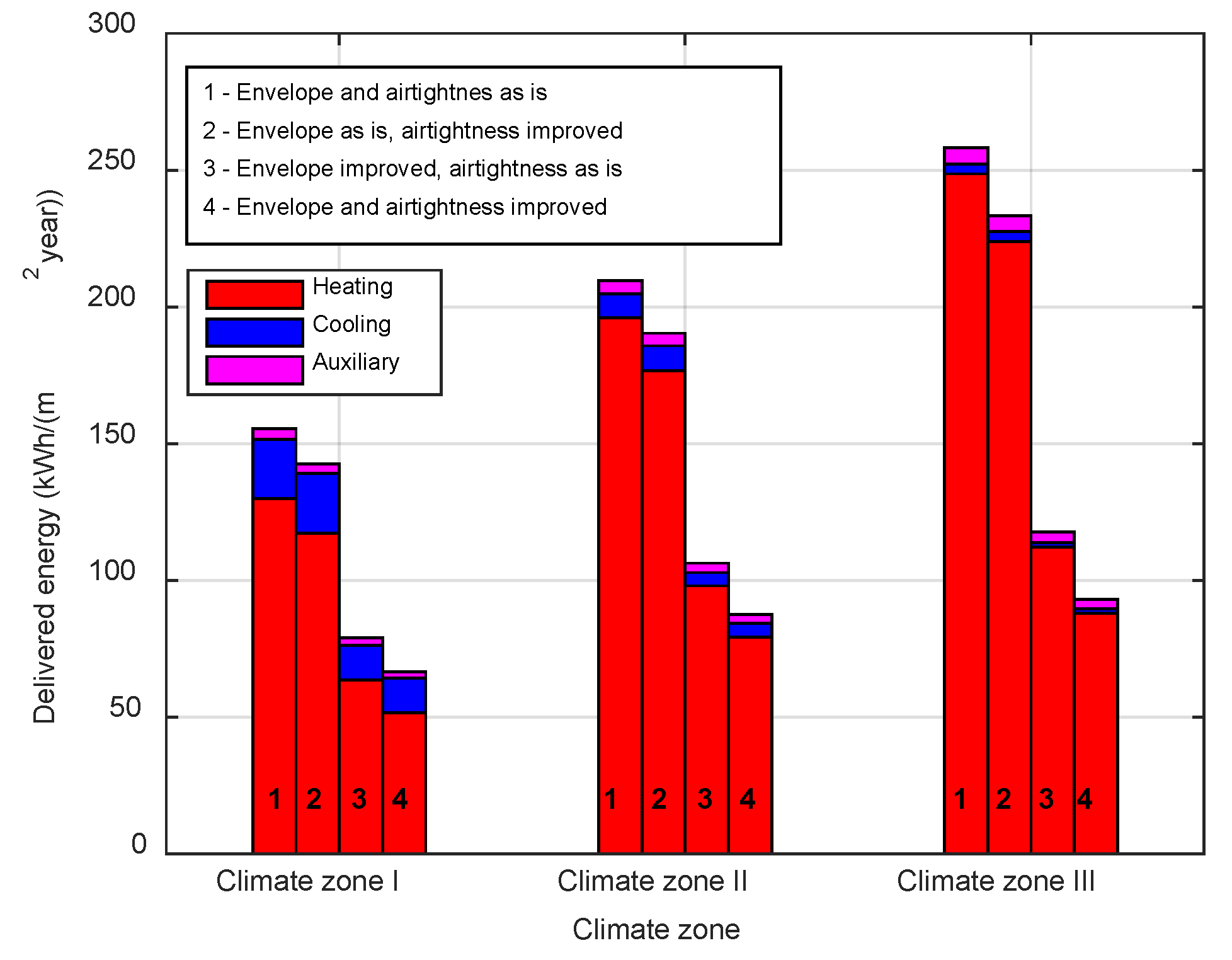

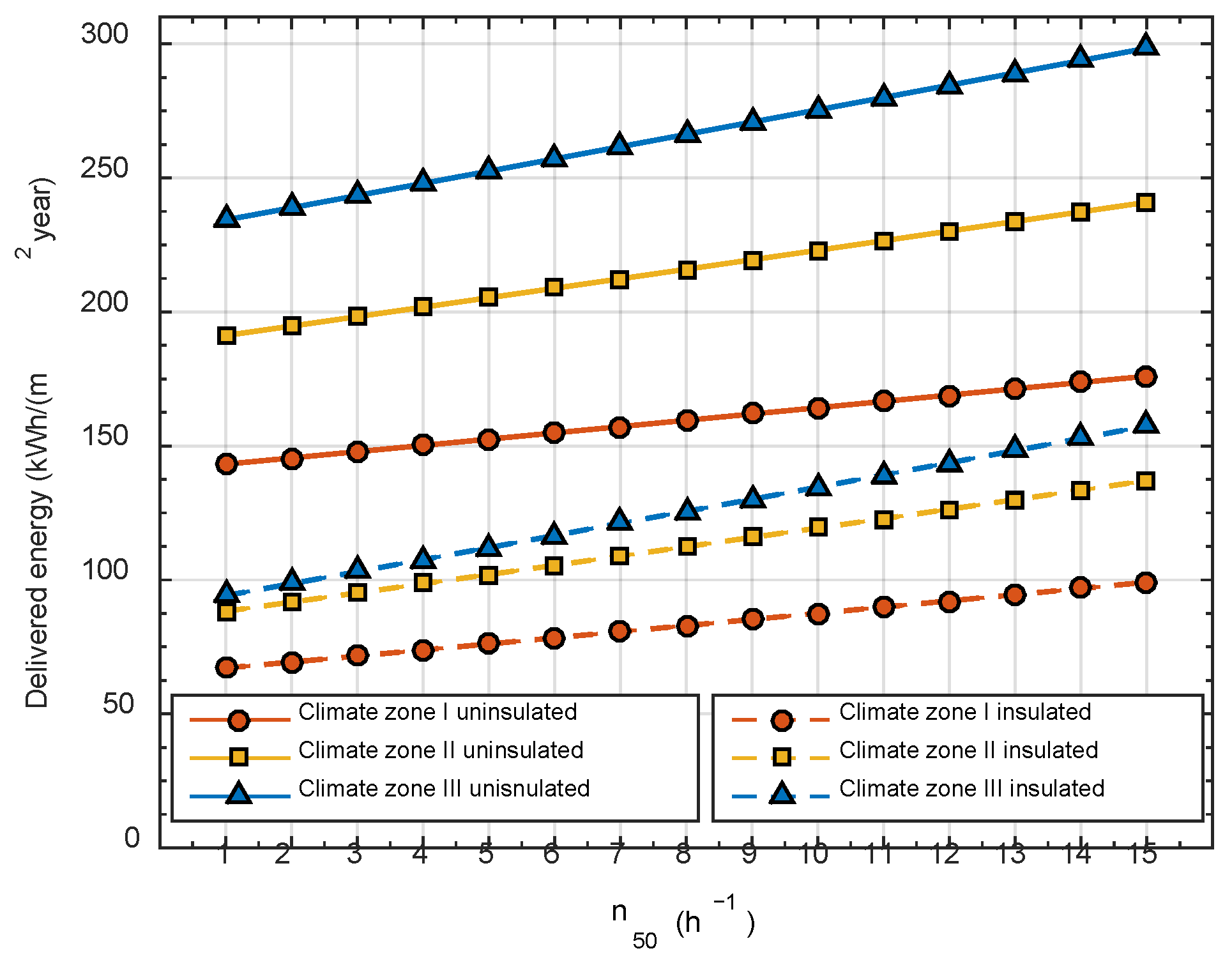

3.2. Energy Impact of Airtightness

4. Conclusions

- The air change rate at the reference pressure difference of 50 Pa is reduced by replacing the windows by almost 90%. This points to the fact that with this type of construction, windows are the weakest link in the envelope as far as airtightness is concerned. The rest of the envelope is very airtight, which is to be expected considering that it is mostly made of cast-in-place reinforced concrete and that there are no visible leaks around penetrations for water and sewer pipes and electrical installations. Therefore, with this type of construction, windows replacement proves to be an effective measure with which airtightness can be improved almost to the standard of a passive house;

- By replacing the windows, the air flow exponent increases indicating a change in the character of the leakage from leakage through short and relatively large openings to leakage through long and relatively narrow passages.

- By increasing airtightness through windows replacement, energy consumption for heating is significantly reduced, while the reduction in energy consumption for cooling is practically negligible;

- In relative terms, the reduction in energy consumption due to the increase in airtightness is more pronounced in colder climates and when the thermal envelope is improved so that heat transfer losses through the envelope are reduced;

- Energy consumption increases linearly with increasing air leakage rate. When n50 increases by a unit value, energy consumption increases from 2.3 kWh/m2·year in Climate zone I to 4.6 kWh/m2·year in Climate zone III.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission. In Focus: Energy Efficiency in Buildings. Available online: http://commission.europa.eu/news/focus-energy-efficiency-buildings-2020-02-17_en (accessed on 21 December 2022).

- European Parliament. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (Recast). 2010/31/EU. Off. J. Eur. Union 2010, 153, 13. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:153:0013:0035:EN:PDF (accessed on 21 December 2022).

- Government of Montenegro. Rulebook on Minimum Energy Efficiency Requirements of Buildings. Official Gazette of Montenegro, No. 75/15. Available online: https://www.gov.me/en/documents/bebd6764-d23f-4a05-8e3a-349716321483 (accessed on 21 December 2022).

- Cardoso, V.E.M.; Pereira, P.F.; Ramos, N.M.M.; Almeida, R.M.S.F. The Impacts of Air Leakage Paths and Airtightness Levels on Air Change Rates. Buildings 2020, 10, 55. [Google Scholar] [CrossRef]

- Fraunhofer Institute of Building Physics. MEEC—Montenegrin Energy Efficiency Certification. Available online: https://www.meec.me/index.php/en/ (accessed on 21 December 2021).

- DIN Standard V 18599-1:2018-09; Energy Efficiency of Buildings—Calculation of the Net, Final and Primary Energy Demand for Heating, Cooling, Ventilation, Domestic hot Water and Lighting—Part 1: General Balancing Procedures, Terms and Definitions, Zoning and Evaluation of Energy Sources. German Institute for Standardization: Berlin, Germany, 2018.

- Sherman, M.H.; Chan, W.R. Building Air Tightness: Research and Practice. In Building Ventilation: The State of the Art, 1st ed.; Santamouris, M., Wouters, P., Eds.; Earthscan: London, UK, 2006; pp. 137–156. [Google Scholar]

- Sherman, M.H.; Dickerhoff, D. Airtightness of U.S. dwellings. ASHRAE Trans. 1998, 104, 1359–1367. [Google Scholar]

- McWilliams, J.; Jung, M. Development of a Mathematical Air-Leakage Model from Measured Data. Ernest Orlando Lawrence Berkeley National Laboratory. 2006. Available online: https://osti.gov/servlets/purl/883786 (accessed on 21 December 2022).

- Sinnott, D.; Dyer, M. Air-tightness field data for dwellings in Ireland. Build. Environ. 2012, 51, 269–275. [Google Scholar] [CrossRef]

- Jokisalo, J.; Kurnitski, J.; Korpi, M.; Kalamees, T.; Vinha, J. Building leakage, infiltration, and energy performance analyses for Finnish detached houses. Build. Environ. 2009, 44, 377–387. [Google Scholar] [CrossRef]

- Pan, W. Relationships between airtightness and its influencing factors of post-2006 new-build dwellings in the UK. Build. Environ. 2010, 45, 2387–2399. [Google Scholar] [CrossRef]

- Carrié, R.; Jobert, R.; Fournier, M.; Berthault, S. Perméabilité à l’air del’enveloppe des Batiments. Generalites et Sensibilization; CETE de Lyon: Lyon, France, 2006. [Google Scholar]

- Sfakianaki, A.; Pavlou, K.; Santamouris, M.; Livada, I.; Assimakopoulos, M.N.; Mantas, P.; Christakopoulos, A. Air tightness measurements of residential houses in Athens, Greece. Build. Environ. 2008, 43, 398–405. [Google Scholar] [CrossRef]

- D’Ambrosio Alfano, F.R.; Dell’Isola, M.; Ficco, G.; Tassini, F. Experimental analysis of air tightness in Mediterranean buildings using the fan pressurization method. Build. Environ. 2012, 53, 16–25. [Google Scholar] [CrossRef]

- Villi, G.; Peretti, C.; Graci, S.; De Carli, M. Building leakage analysis and infiltration modelling for an Italian multi-family building. J. Build. Perform. Simul. 2013, 6, 98–118. [Google Scholar] [CrossRef]

- Pinto, M.; Viegas, J.; de Freitas, V.P. Air permeability measurements of dwellings and building components in Portugal. Build. Environ. 2011, 46, 2480–2489. [Google Scholar] [CrossRef]

- Salehi, A.; Torres, I.; Ramos, A. Experimental analysis of building airtightness in traditional residential Portuguese buildings. Energy Build. 2017, 151, 198–205. [Google Scholar] [CrossRef]

- Feijó-Muñoz, J.; Poza-Casado, I.; González-Lezcano, R.A.; Pardal, C.; Echarri, V.; Assiego De Larriva, R.; Fernández-Agüera, J.; Dios-Viéitez, M.J.; Del Campo-Díaz, V.J.; Montesdeoca Calderín, M.; et al. Methodology for the Study of the Envelope Airtightness of Residential Buildings in Spain: A Case Study. Energies 2018, 11, 704. [Google Scholar] [CrossRef]

- D’Ambrosio Alfano, F.R.; Dell’Isola, M.; Ficco, G.; Palella, B.I.; Riccio, G. Experimental Air-Tightness Analysis in Mediterranean Buildings after Windows Retrofit. Sustainability 2016, 8, 991. [Google Scholar] [CrossRef]

- Gillott, M.C.; Loveday, D.L.; White, J.; Wood, C.J.; Chmutina, K.; Vadodaria, K. Improving the airtightness in an existing UK dwelling: The challenges, the measures and their effectiveness. Build. Environ. 2016, 95, 227–239. [Google Scholar] [CrossRef]

- Paukštys, V.; Cinelis, G.; Mockienė, J.; Daukšys, M. Airtightness and Heat Energy Loss of Mid-Size Terraced Houses Built of Different Construction Materials. Energies 2021, 14, 6367. [Google Scholar] [CrossRef]

- Balaras, C.A.; Gaglia, A.G.; Georgopoulou, E.; Mirasgedis, S.; Sarafidis, Y.; Lalas, D.P. European residential buildings and empirical assessment of the Hellenic building stock, energy consumption, emissions and potential energy savings. Build. Environ. 2007, 42, 1298–1314. [Google Scholar] [CrossRef]

- Poza-Casado, I.; Meiss, A.; Padilla-Marcos, M.Á.; Feijó-Muñoz, J. Airtightness and energy impact of air infiltration in residential buildings in Spain. Int. J. Vent. 2021, 20, 258–264. [Google Scholar] [CrossRef]

- Feijó-Muñoz, J.; Pardal, C.; Echarri, V.; Fernández-Agüera, J.; Assiego de Larriva, R.; Montesdeoca Calderín, M.; Poza-Casado, I.; Padilla-Marcos, M.A.; Meiss, A. Energy impact of the air infiltration in residential buildings in the Mediterranean area of Spain and the Canary Islands. Energy Build. 2019, 188–189, 226–238. [Google Scholar] [CrossRef]

- RAL-Gütegemeinschaft Fenster, Fassaden und Haustüren e.V. Frankfurt; ift Institut für Fenstertechnik Rosenheim. Leitfaden zur Planung und Ausführung der Montage von Fenstern und Haustüren für Neubau und Renovierung; RAL-Gütegemeinschaft Fenster, Fassaden und Haustüren e.V. Frankfurt: Frankfurt am Main, Germany, 2020. [Google Scholar]

- CAN/CGSB Standard 149.10-2019; Determination of the Air Tightness of Building Envelopes by the Fan Depressurization Method. Canadian General Standard Board: Ottawa, ON, Canada, 2019.

- ASTM Standard E779-19; Standard Test Method for Determining Air Leakage Rate by Fan Pressurization. American Society of Testing and Materials: West Conshohocken, PA, USA, 2019.

- ISO Standard 9972:2015; Thermal Performance of Buildings—Determination of Air Permeability of Buildings—Fan Pressurization Method. International Organization for Standardization: Geneva, Switzerland, 2015.

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger climate classification updated. Meteorol. Z 2006, 15, 259–263. [Google Scholar] [CrossRef] [PubMed]

| Metric and Definition | Equation | Unit |

|---|---|---|

| Air leakage rate at the reference pressure difference of 50 Pa, | m3/h | |

| Air change rate at the reference pressure difference of 50 Pa, | 1/h | |

| The air change rate at the reference pressure difference of 50 Pa, , is calculated by dividing the air leakage rate at 50 Pa, by the internal volume, . | ||

| Air permeability at the reference pressure difference, | m3/h/m2 | |

| The air permeability at the reference pressure difference of 50 Pa is calculated by dividing the air leakage rate at 50 Pa, by the envelope area AE. | ||

| Specific leakage rate at the reference pressure difference, w50 | m3/h/m2 | |

| The specific leakage rate at the reference pressure difference of 50 Pa is calculated by dividing the air leakage rate at 50 Pa by the net floor area AF. | ||

| Effective leakage area, ELA | m2 | |

| Effective leakage area is the area of a fictitious orifice that allows the same air flow as the building envelope at the pressure difference of 4 Pa. |

| Value | Before | After |

|---|---|---|

| Air leakage rate, (m3/h) | 1418 | 174 |

| Air change rate, (1/h) | 6.25 | 0.77 |

| Air permeability, (m3/h/m2) | 11.53 | 1.41 |

| Specific leakage rate, (m3/h/m2) | 16.69 | 2.05 |

| Effective leakage area, ELA (cm2) | 334.5 | 37.5 |

| Building Leakage Curve | ||

| Air leakage coefficient, (m3/h/Pan) | 134.8 | 14.4 |

| Air flow exponent, | 0.602 | 0.637 |

| Climate Zone | Building Envelope | n50 (h−1) | Delivered Energy (kWh/m2·year) | |||

|---|---|---|---|---|---|---|

| Heating | Cooling | Auxiliary | Total | |||

| I | Existing thermal envelope | 6.25 | 129.84 | 21.78 | 3.82 | 155.44 |

| 0.77 | 117.32 | 21.73 | 3.58 | 142.63 | ||

| Improved thermal envelope | 6.25 | 63.60 | 12.67 | 2.68 | 78.95 | |

| 0.77 | 51.57 | 12.67 | 2.37 | 66.61 | ||

| II | Existing thermal envelope | 6.25 | 196.01 | 8.84 | 4.85 | 209.70 |

| 0.77 | 176.70 | 9.06 | 4.61 | 190.37 | ||

| Improved thermal envelope | 6.25 | 98.02 | 4.85 | 3.43 | 106.30 | |

| 0.77 | 79.28 | 5.13 | 3.11 | 87.52 | ||

| III | Existing thermal envelope | 6.25 | 248.67 | 3.50 | 6.04 | 258.21 |

| 0.77 | 223.85 | 3.68 | 5.73 | 233.26 | ||

| Improved thermal envelope | 6.25 | 112.25 | 1.49 | 3.92 | 117.66 | |

| 0.77 | 87.95 | 1.75 | 3.41 | 93.11 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tombarević, E.; Vušanović, I.; Šekularac, M. The Impact of Windows Replacement on Airtightness and Energy Consumption of a Single Apartment in a Multi-Family Residential Building in Montenegro: A Case Study. Energies 2023, 16, 2208. https://doi.org/10.3390/en16052208

Tombarević E, Vušanović I, Šekularac M. The Impact of Windows Replacement on Airtightness and Energy Consumption of a Single Apartment in a Multi-Family Residential Building in Montenegro: A Case Study. Energies. 2023; 16(5):2208. https://doi.org/10.3390/en16052208

Chicago/Turabian StyleTombarević, Esad, Igor Vušanović, and Milan Šekularac. 2023. "The Impact of Windows Replacement on Airtightness and Energy Consumption of a Single Apartment in a Multi-Family Residential Building in Montenegro: A Case Study" Energies 16, no. 5: 2208. https://doi.org/10.3390/en16052208

APA StyleTombarević, E., Vušanović, I., & Šekularac, M. (2023). The Impact of Windows Replacement on Airtightness and Energy Consumption of a Single Apartment in a Multi-Family Residential Building in Montenegro: A Case Study. Energies, 16(5), 2208. https://doi.org/10.3390/en16052208