Abstract

Daytime passive radiative cooling (DPRC) has remained a challenge over the past decades due to the necessity of precisely defined materials with a significantly high emissivity of thermal radiation within the atmospheric transparent window wavelength range (8–13 μm) as well as high reflectivity in the solar spectrum (0.2–3 μm). Fortunately, recent advances and technological improvements in nanoscience and metamaterials are making it possible to create diverse metamaterials. This enables the production of DPRC in direct solar irradiation. The development of a material that is appropriate for effective DPRC is also a noteworthy development in this field of technology. This review gives a thorough introduction and discussion of the fundamental ideas, as well as the state-of-the-art and current trends in passive radiative cooling, and describes the cutting-edge materials and various photonic radiator structures that are useful in enhancing net cooling performance. This work also addresses a novel skylight window that offers passive cooling developed at the Åbo Akademi (ÅA) University, Finland. In conclusion, nanomaterials and nanoparticle-based coatings are preferred over all other approaches for commercialization in the future because of their low cost, the ability for large-scale production, simplicity in fabrication, and great potential for further increasing cooling performance.

1. Introduction

The two greatest threats to human life posed by climate change in many parts of the world in recent years have been energy scarcity and global warming. A major contributor to climate change is anthropogenic greenhouse gas (GHG) emissions. In a study conducted by the International Energy Agency (IEA), buildings currently utilize 20–40% of the world’s energy with conventional HVAC systems engrossing most of its primary energy [1]. There are numerous applications, including domestic, commercial, and industrial, where cooling requires a substantial quantity of energy. Major reasons for the high-energy usage of cooling are the growing population, improved living standards in developing countries—particularly in hot climate regions—and industrial development [2]. Conventional cooling systems utilize 15% of the world’s electricity and result in 10% of GHG emissions. The global CO2 concentration is now 147% higher than it was before industrialization, and rising. Emissions of gaseous refrigerants are predicted to make up 45% of all GHG emissions by the end of 2050 [3]. Therefore, there is a pressing need for innovation in cooling technologies to reduce both energy usage and GHG emissions.

The current ubiquitous vapor compression-based cooling technologies are facing issues with energy usage and the global warming effect due to the refrigerants used, e.g., hydrofluorocarbons (HFCs), which consequently cause environmental problems. The increased spotlight on the energy crisis and environmental concerns has upsurged an interest in enhancing the efficiency of existing cooling systems and monitoring various cooling technologies. Analysis of various cooling processes suggests that passive radiative cooling (PRC) is the most effective way to cool buildings. Further, PRC is a technology that provides cooling alternatives to heat pumps. Recently, PRC techniques and their potential applications have gained noticeable attention for energy-saving applications. The PRC technique that cools with no power required could therefore make an exceptional difference in energy usage and the reduction in emissions that cause global warming. The general principle of passive cooling is the dissipation of heat from buildings to an environmental heat sink. Many research studies address PRC strategies under different climatic conditions. This technology can be used to reduce energy usage in both buildings and automobiles, solve urban heat islands, and tackle water issues [2,4]. In spite of the possibility that PRC approaches might be useful in building design, they are not widely used. Two cited challenges in this area are technical and cost problems. Technical problems are low cooling capacity, expensive specialized manufacturing techniques or suitable materials, challenging system implementation, issues with durability, and maintenance concerns [5].

Thermal radiation depends on spectrum characteristics due to Kirchhoff’s law of heat absorption, which links emittance to absorptance. A significant application of this technology is that it is possible to alter the rate of radiative heat transfer between objects by changing the spectral absorption or emissivity of these, which is dependent on how electromagnetic waves interact with them. Increased reflectance on a surface, for example, reduces heat absorption and hence prevents a temperature gain, which is critical in a radiative cooling scenario. Reduced reflectance and greater absorption of incident power, on the other hand, result in temperature increase, which is critical in radiative heating applications. Accordingly, good thermal radiation control results in greater system efficiency and lower maintenance costs of temperature control systems due to increased component lifespan because of reduced thermal loads [6].

The field of radiative cooling has been the focus of many authors since the mid-20th century. Nonetheless, it appears as if radiative cooling research has fallen very short of its potential due to a lack of researchers engaged in this area, as well as a lack of complete analysis of its diverse technological scope [7]. This idea provided the impetus for the compilation of a review paper that includes thorough and methodical mathematical descriptions of radiative cooling, information updates on various leading-edge radiator materials, and introduces novel applications of PRC [8]. The research work conducted by Lu et al. [9] concentrated on advancements in the PRC of buildings, including the formulation of theoretical models and calculations, the structural design and configuration of cooling systems, and the forecasting of potential and prospects. Muntasir et al. [10], Sun et al. [11], and others later introduced the concept of radiative cooling from basic fundamental principles, materials, and radiators. In their work, the main topic was the progress of sophisticated materials and radiators that provide radiative cooling during both day and night, together with metamaterials and photonic radiators. Sergi et al. [12] conducted a thorough analysis of the PRC theory and nocturnal radiators, with particular emphasis on atmospheric radiation and selective radiative emitters. Furthermore, their work also covered several numerical simulation methods and radiative cooling prototypes, but they did not address how to realize commercial applications. Researchers are still having trouble sufficiently improving cooling performance during the daytime towards implementation in a consumer product because it is impossible to ignore direct solar irradiance. A substantial amount of research is yet to be undertaken on diurnal radiative cooling, which is more challenging than nocturnal radiative cooling [13,14,15].

In fact, this article also provides a comprehensive analysis of the fundamental physics underlying PRC, considering radiation to the atmosphere and space beyond that. Several other variables, in addition to the incoming atmospheric radiation, have an impact on a radiator’s cooling capacity. For instance, the effect of non-radiative heat transfer gain from the environment (conduction and convection heat gain) on radiative cooling must be taken into account [16]. Correspondingly, it has been possible to compile modern radiative structures and exotic materials [2,9,17,18,19] which are discussed in further sections. The main distinction between this work and others is demonstrated by an example provided in it, namely a passive skylight window design that provides a passive cooling skylight prototype developed at Åbo Akademi University (ÅA) in Finland [20]. This skylight provides passive cooling at a rate of 100 W/m2 without external power. The core concept of that PRC skylight, realized using widely accessible materials, could enhance the performance of current cooling systems, which will enable next-generation thermal management of buildings. Further sections concentrate on providing a brief overview of the nocturnal (nighttime) and diurnal (daytime) materials as well as information on various investigations based on the experimental findings for each structure and material to enhance net cooling performance. The following sections go over advanced radiator types, metamaterial developments, recent research on nanophotonic structures and nanoparticle-based techniques, challenges and potential application developments and improvements in this technology, as well as opportunities for radiative cooling. Finally, the discussion includes informative ideas and suggestions for commercializing this technology. There are a few points to keep in mind when promoting PRC technology on a large scale, such as the low energy density, low cooling capacity, and constrained sky-facing area hampers the large-scale application of PRC technology [2,21,22,23]. It is undeniable that further research into this technology is required in order to develop a new generation of PRC coolers with high efficiency, less energy usage, and the capability of maximizing net cooling performance at all times.

1.1. Passive Radiative Cooling

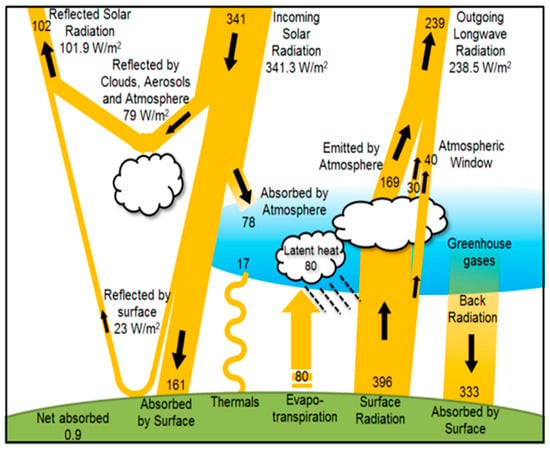

PRC is the phenomenon that reduces the temperature of a system by promoting heat transfer with the sky. Our planet earth must eventually reemit all solar radiation absorbed by it into space through heat radiation. If not, the earth would continue to heat. Figure 1 shows average heat flows in the earth–atmosphere energy balance. The average incident radiation is 341.3 W/m2, of which the atmosphere reflects 79 W/m2 and the surface absorbs 161 W/m2. As shown in the figure below, radiative cooling transfers all heat from the earth to space [20].

Figure 1.

Representation of earth–atmosphere energy balance [24].

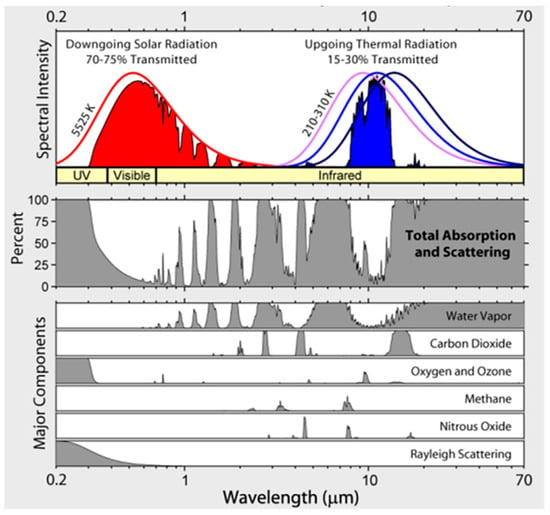

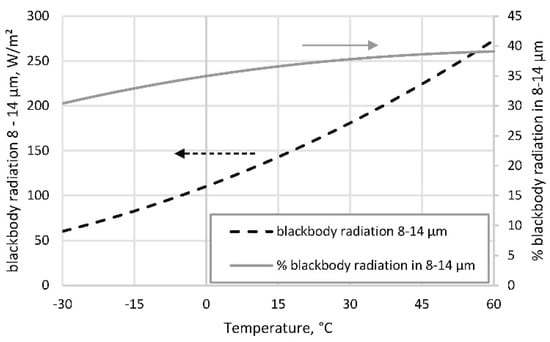

Considering that the earth’s surface temperature is around 300 K, and the universe is blackbody radiation at 3 K, it is possible to use this large temperature difference acting as a main driving force to cool the surface by radiating thermal infrared radiation to the universe via the atmosphere. The atmosphere, which consists of several gases located between the planet’s surface and the universe, participates in PRC via the superposition of radiation to and from its constituent elements. A benefit is that our earth’s atmosphere has an “atmospheric window”—a region from 8–13 μm where it is highly transparent. Different gases can absorb and emit heat radiation in various parts of the spectrum. The primary atmospheric gases’ absorption spectra are shown in Figure 2 sub-pictures. The atmospheric window’s wavelength range can still fit into these various spectra. Due to its limited transmittance in most wavelength bands, the atmosphere blocks heat radiation from the earth’s surface to the universe. Regardless, the atmosphere serves as a semi-transparent medium for radiative cooling applications [20].

Figure 2.

Thermal radiation transmission by the atmosphere [25].

The principle of PRC relies on the fact that the atmosphere transmits about 87% of the outgoing radiation from the Earth in the “atmospheric window” region. Surfaces can exchange heat with cold space (3 K) through this atmospheric window region. If surfaces (or participating gases, for that matter) experience a mismatch between outgoing and incoming thermal radiation, they can reach a lower steady-state temperature than the ambient due to strong emission in this wavelength region and strong reflection outside of it [26].

Fortunately, the wavelength of the atmospheric window falls within the black body’s peak thermal radiation region at room temperature (300 K), as defined by Plank’s law. This property allows a passive cooling mechanism for a terrestrial body to operate at room temperature by removing heat through the atmospheric window. The Earth’s atmosphere acts as a huge thermal reservoir that allows radiation to escape into space directly. Consequently, any terrestrial object with a high emissivity in the atmospheric window can radiate heat into space effectively. Even so, a number of factors, such as geographical location, cloudiness, and humidity levels, affect atmospheric window transmittance. When the sky is clear and dry, the atmospheric window transmittance is high [8].

When the sky is clear at night, PRC can produce around 100 W/m2 of net cooling power, which suggests that a relatively large surface area is required to deliver significant cooling power of a few kilowatts (kW) or more. Demanding a larger surface area in building applications certainly leads to the development of sophisticated material technology to produce suitable radiators, which entails high installation and production costs, and maintenance issues [5]. The main problem, however, is material science, i.e., finding practical window materials for effective cooling during day and night that can afford outstanding performance at a lower cost; this technique will be a challenging solution to PRC acceptability.

1.2. Classification of PRC

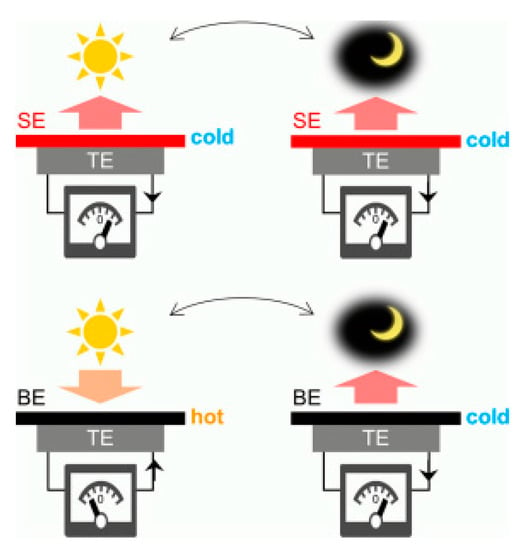

PRC research falls into two main categories: radiative cooling at night (nocturnal) and radiative cooling during the day (diurnal). The design of PRC systems typically involves adjusting the spectral reflection, emission, absorption, and transmission at various wavelength intervals. While radiative cooling is difficult in the daytime, nocturnal cooling has been an established practice for centuries. A considerable amount of research has been conducted on nocturnal PRC materials, as well as on the potential uses of nocturnal radiative cooling. According to Eriksson and Granqvist [27], the initial scientific study to investigate the effects of nocturnal cooling in 1828, Arago revealed the existence of this phenomenon. Arago recorded a temperature drop of 6–8 °C below the surrounding air for the small amount of grass, cotton, and quilt placed outside in a tranquil environment during the night. Later, Alan K [28] made the first suggestion for selective infrared (IR) emitters to enhance PRC’s performance at night. Since then, several strategies have been developed to improve radiative cooling.

There are actually two types of conventional radiators in use for overnight radiation cooling. A thermal blackbody emitter is the first kind of radiator to have a high emissivity in all thermal radiation bands. A selective radiator is another form of radiator that emits significant heat solely through the atmospheric window wavelength. There is experimental evidence that it is possible to achieve nocturnal cooling up to around 100 W/m2. Under cloudless skies, radiative heat flux from a thermal blackbody emitter at near ambient temperatures can reach up to 120 W/m2 [29]. The ability to reach a minimum temperature below the surroundings is limited by the inverse effect of radiative thermal absorption outside the 8–13 μm wavelength, which makes it difficult to attain temperatures lower than 6 and 8 °C below the ambient. Thus, alternative methods for mitigating adverse thermal absorption at sub-ambient temperatures include using metallic mirrors (typically aluminum or silver) surrounded by thin layers of material that only absorb/emit within the atmospheric window and are transparent to other wavelength regions. Metallic mirrors reflect undesirable solar irradiation, while emitters transfer thermal energy to space by emitting radiation within the range of the atmospheric window. For the top portion of the emitting materials, a wide variety of materials have been suggested, including polymers, pigmented paints, metal oxides, gas slabs, multilayer semiconductors, and metal–dielectric photonic and plasmonic structures [30].

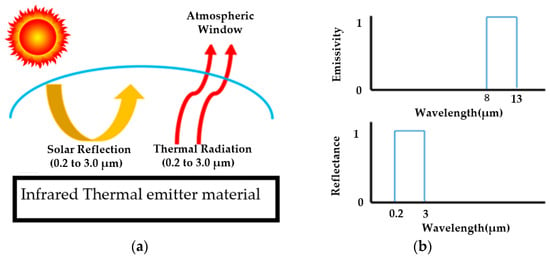

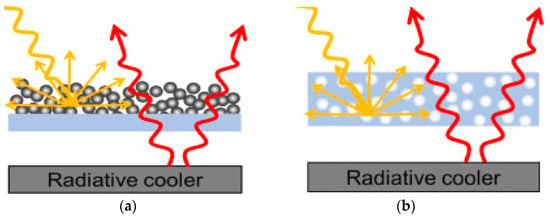

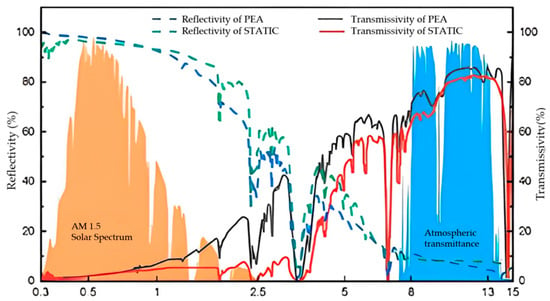

However, the challenge with daytime cooling is solar irradiation, and exposure to direct sunlight during the daytime (around noon) reduces the effectiveness of the devices and systems due to the need for much larger cooling power (up to 1000 W/m2). Around noon, a small amount of solar absorption of 1000 W/m2 might be sufficient to counteract the surface temperature dependent on the outgoing radiative cooling power of between 100 and 150 W/m2. The solar spectral region, which has shorter wavelengths between 0.2–3 μm, and the atmospheric transparency window, which has wavelengths between 8 and 13 μm, need to be addressed simultaneously in the development of effective high-performance DPRC materials [2] (see Figure 3).

Figure 3.

(a) Radiative cooling: Schematic presentation. (b) Radiative cooling properties of materials for ideal reflection and emission (adapted from [31]).

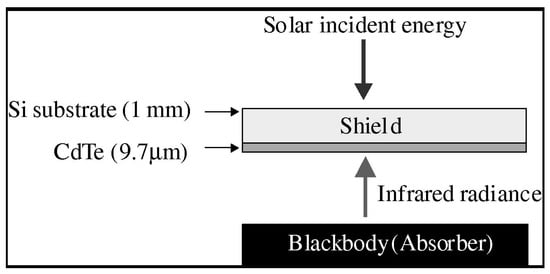

To limit solar heating during the day, these materials must have low absorption (100% reflectance) in the solar spectrum. In addition, they should also have high emissivity (≈1) in the atmospheric transparency window in order to transfer excess heat effectively to the sky and, eventually, to outer space as the final heat sink of radiative cooling. In the early attempts to obtain these specific characteristics, a radiative cover shield was fixed at the top of the radiative cooler. During the day, the radiative cooler beneath the cover shield can emit radiation into space because it reflects solar radiation while remaining transparent to long wavelengths inside the atmospheric window. Various researchers have contemplated polyethylene foils covered or doped with TiO2, ZnS, and ZnO for this application [32,33,34]. Nevertheless, it is difficult to achieve high solar reflectance and high IR transmittance simultaneously. Furthermore, PRC systems are based on various materials and structures such as bulk media (painted metal and gypsum), thin films (ZnS, CdTe, SiO, PbSe, MgO), and gases (ammonia, ethylene, ethylene oxide), including functional films coated with SiO and Si3N4, have been explored and tested. Although these radiators also emit large amounts of radiation into the atmosphere, these materials perform poorly and have limitations when exposed directly to sunlight during the daytime. So none of the experiments using these materials and techniques has succeeded in obtaining sub-ambient temperatures when exposed to direct sunlight [35].

Fortunately, the recent demonstration of effective DPRC under direct sunlight through the development of innovative classes of selective infrared radiators, combined with metamaterials, nanophotonic structures, nanoparticle methods, also cutting-edge design methodologies enabled the fabrication of precise structures with tailored radiative properties for various energy applications. This also results in daytime cooling that results in temperatures below ambient. During the daytime, these novel radiators provide significant diurnal radiative cooling due to their high reflection capability within the range of solar radiation and strong emissivity within the atmospheric wavelength.

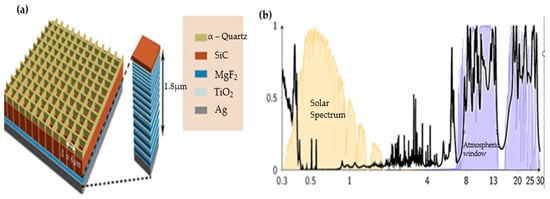

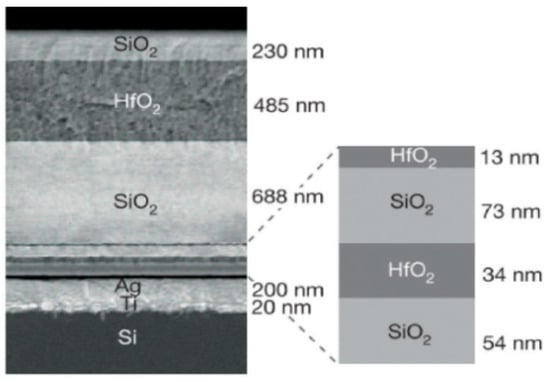

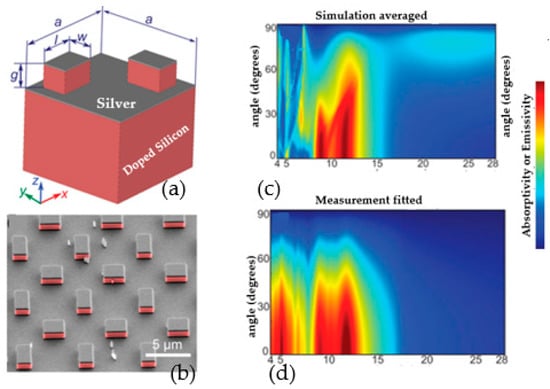

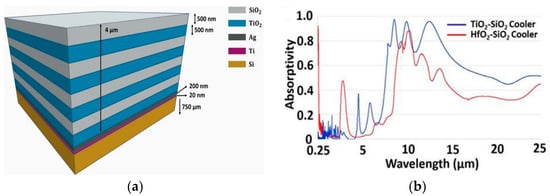

The importance of this research has grown steadily over the past decade. In 2013, Raman et al. [36] published the first theoretical design of a metal–dielectric planar photonic structure for DPRC based on adjusting the spectral behaviour/responses of the material. Later, in 2014, ref. [37] they achieved DPRC for the first time experimentally using a precisely designed nanophotonic structure radiative cooler. In this photonic radiative cooler, seven alternate dielectric layers are deposited onto a silver mirror, allowing it to cool to 4.9 °C below the surrounding temperature by reflecting 97% of incident solar irradiance while selectively emitting in the wavelength of the atmospheric transparency window.

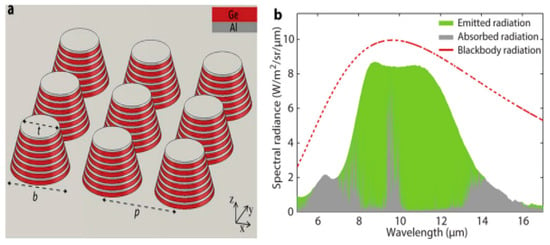

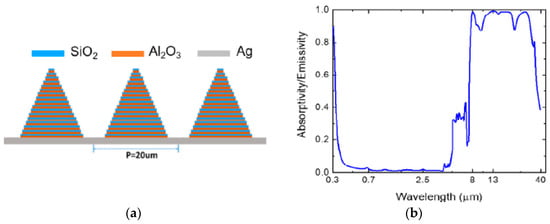

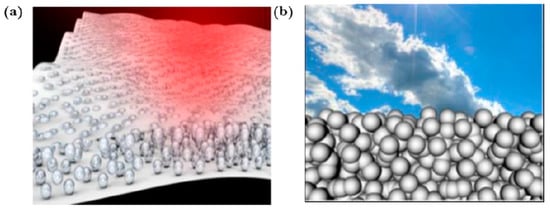

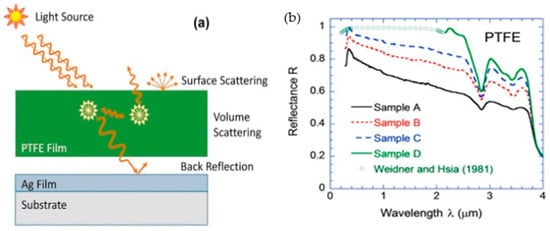

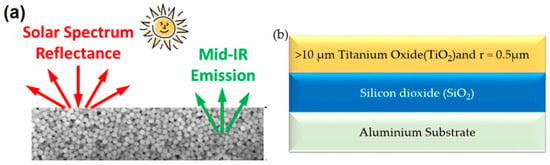

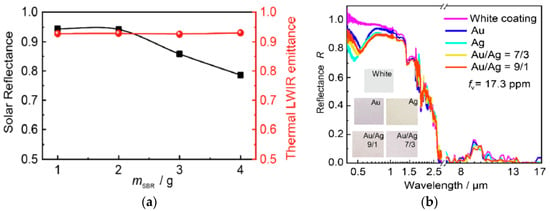

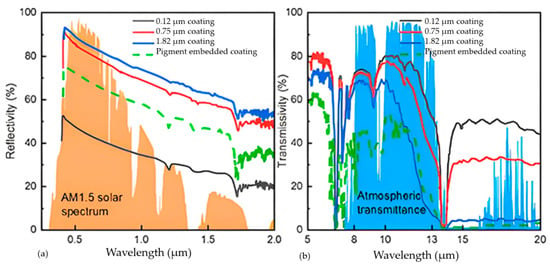

Another effective example is the DPRC structure suggested and created by Zhai et al. [38] using a polymer embedded with micron-sized dielectric spheres on top of a silver (Ag) substrate as the back reflector In spite of this, many photonic structures are not widely used due to their high production cost, production complexities, and other complicated manufacturing techniques [21,30,39]. Besides emissive properties, a DPRC must have adequate heat-insulating properties to keep the temperature differential with the surroundings. Currently, the most prominent strategies combining the DPRC techniques are to be solar irradiance backscattering, thin film forming, cooling coating, pumping of mid-infrared thermal radiation from the radiator, and phonon control, all of which result in continuous sub-ambient cooling during the day and at night. Backscattering is the most popular method for obtaining material for DPRC, based on reflection [40]. It is possible to achieve this by incorporating Titania (TiO2) and silica (SiO2) particles in high concentrations (40–50% Wt) into a paint or coating. Several potential pigments, including TiO2, ZrO2, ZnS, ZnSe, and ZnO, were tested with a pigment fraction of 0.10–0.15 in 400-μm-thick polyethylene. In terms of radiative cooling properties, ZnS performed better, which had 84.9% solar reflectivity, but due to peak solar radiation, they were unable to achieve daytime cooling at noon. TiO2 has higher solar reflectivity but absorbs UV radiation due to bandgap overlap, whereas ZrO2 is lossless in UV but has a lower refractive index and thus reflects less than titania. Many of the proposals suggested in the application of PRC in buildings are still lacking research and development, mostly regarding the transmissivity/emissivity of the material or the use of PRC to maximize net cooling performance. Inclusive of the above, daytime radiative cooling still has three significant issues. To begin with, it is unclear which structures are essential for radiative cooling to perform at it is their best. Secondly, it is difficult to avoid the heat losses produced by the different available coolers, which restricts both cooling power and temperature drop to less than 105 W/m2 and 10 °C, respectively. Therefore, these materials should have substantial emissivity in other wavelengths, preferably within the atmospheric window, while having extremely low absorptivity in the intense solar spectrum [5,22].

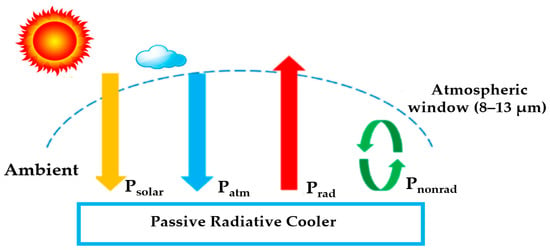

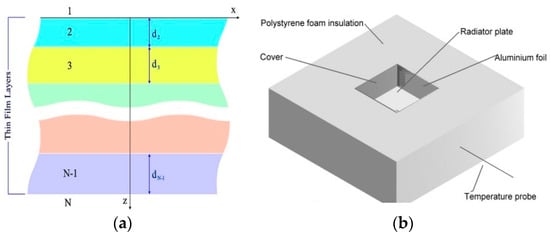

1.3. Fundamental Physics of Radiative Cooling

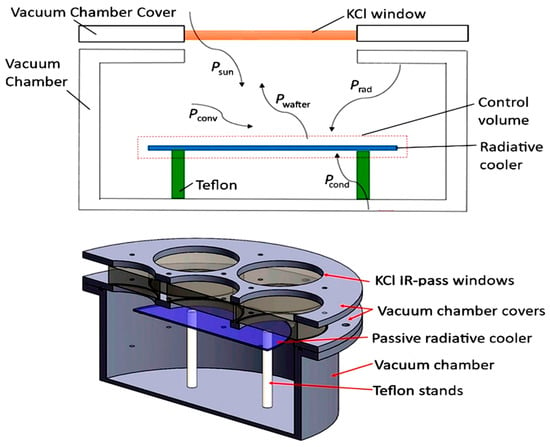

Developing dynamic and efficient radiative coolers for specific applications requires accurate engineering and design. This subsection discusses the design issues for radiative coolers and the physics involved in PRC as described by the heat-transfer balance equation (see Figure 4). In fact, estimating the incoming spectrum irradiation on a terrestrial body is crucial for determining the cooling capability of radiative coolers. Generally, a terrestrial body may partially absorb, reflect, or transmit the radiation. A body’s absorption (α), reflection (ρ), and transmission (τ) are related as follows: α() + ρ() + τ() = 1. Kirchhoff’s law states that absorptivity and emissivity (ε) are equal α() = ε() for every object in thermal equilibrium in all directions and for all wavelengths [30].

Let us consider a material that has similar absorption qualities to a black body with α = ε = 1. It can predominantly absorb incident light from the surroundings and achieve complete absorption across all spectral regions. Kirchhoff’s law would thus predict that the material would also possess excellent thermal radiation emission properties. Consequently, the following Equation (1) [41] represents spectral radiation from a black body at temperature T:

where IBB represents the radiation intensity of the blackbody at a given temperature T (K), and wavelength λ, h is a Planck’s constant and its value is 6.626 × 0−34 J·s, k = 1.381 × 10−23 J/K is Boltzmann’s constant, and c = 3 × 108 m/s is the speed of light.

For a given temperature, certainly, a black body emits energy into its surroundings, according to Equation (1). Furthermore, it may be possible for heat from the material to be transferred by conduction and convection besides thermal radiation. To compute the net cooling impact of a radiative cooler, it is necessary to consider all heat transfer mechanisms, which can be determined by using the formula below from Equation (2): [41]

where Psolar represents the power density of the sun (say, 1000 W/m2) and Prad is the Radiative power emitted by the radiative cooler, given by the following:

Pnet = Prad − Patm − Pnonrad − Psolar (W/m2)

represents the zenith angle in the above equation.

Figure 4.

Schematic representation of radiative cooling surface (adapted from [42]).

Based on the above equation, the thermal radiative intensity of an object directly correlates with its structure and shape as well as the temperature. It is therefore possible to use the shape and structure of the object to improve the thermal radiative power throughout the effective area and control the emissivity of the radiative cooler in the appropriate wave band to achieve an optimal cooling capacity [21]. A radiative cooler’s performance, however, will be significantly impacted by weather factors like humidity and clouds [41].

1.4. Impact of Solar Irradiation on DPRC

Solar radiation has a significant impact on how effectively radiative cooling operates throughout the day. A cooler’s cooling power also referred to as its total cooling heat flux, is the first determinant (Pnet). The emissivity of the structure should be close to that of a blackbody emitter in the 8–13 μm range and near zero at wavelengths where the atmosphere is strongly emitting. During the day, however, the structure’s solar absorptivity is the dominating factor that determines its cooling efficiency. Therefore, it is crucial that the structure’s solar heat absorption remains well below 10% during the daytime in order to achieve meaningful cooling. Another important criterion is the temperature difference that can be achieved by a radiative cooler (ΔT = Ts − Ta), where Ts represents the surface temperature and Ta is an ambient temperature. The temperature at which Pnet reaches zero is the lowest temperature difference that can exist (the cooler’s heat fluxes are then balanced between absorbing heat and emitting heat) [30].

Let us consider that if solar radiation is 800 W/m2, a radiator with a 5–10% solar absorption will absorb 40–80 W/m2, which is close to or may exceed a radiator’s cooling capacity. Accordingly, the performance of the radiative cooler will decrease as more sunlight is absorbed by the cooler. The power of the radiative cooler for absorbing solar radiation (Psolar) can be determined using the following expression: [8]

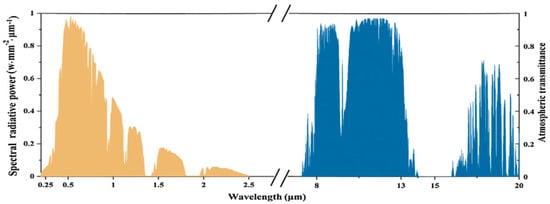

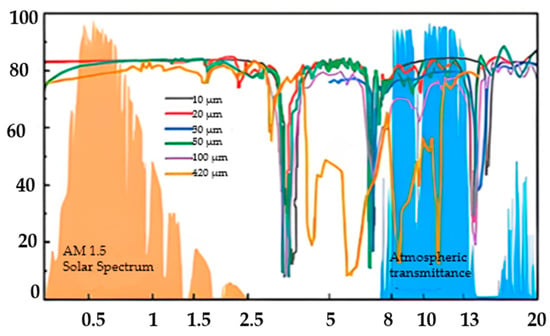

where IAM1.5() stands for the typical sun spectral irradiance (1000 W/m2) distribution for reference and AM1.5 represents 1.5 air masses as the path through the atmosphere. A global spectrum profile of AM1.5 is shown in Figure 5; the yellow color illustrates the sun’s spectrum across various wavelengths together with the atmospheric window (blue) region. In principle, the cooler must have high reflectivity in order to provide PRC during the day by reducing the absorption of solar energy [21].

Figure 5.

AM1.5 standard solar spectrum (Yellow in color), Atmospheric window (Blue in Color 8 to 13 μm) [21].

The spectral energy of the solar spectrum can be measured experimentally using spectro-radiometers. Later, by using the global AM1.5 spectrum, it is possible to validate the applicability of this experimental method to local weather conditions [8]. On the other hand, one of the accepted methods is the ASHRAE clear sky radiation model, which can be used to determine the solar heat flux that eventually needs to be cooled from a surface or from a volume of participating gas [43].

1.5. Influence of Atmospheric Radiation

The atmosphere between the surface of the earth and space is intricate; atmospheric radiation is the result of the superposition of radiation from elements that exist in the atmosphere. Nitrogen (N2) and oxygen (O2), the atmosphere’s gas composition, also consists of water vapor, carbon dioxide (CO2), ozone (O3), hydrocarbons, nitrogen oxides (NOx), etc. Therefore, it is in the atmosphere’s capacity to absorb/emit different infrared wavelengths between 3 and 50 μm radiation that limits the cooling effect, inhibiting the process of thermal radiation from terrestrial objects to space. Water vapor emits/absorbs substantially at 6.3 μm and 20-μm. For CO2 the main IR emission characteristic is a broadband-intensive emission band primarily focused at 15 μm. While water vapor and carbon dioxide obscure most of the ozone emission bands in the infrared region, a narrow emission bandwidth at 9.6 μm is eminent [30].

The atmospheric radiation in the zenith direction (AM1.0) is minimum. When the air is dry in the wavelength range of 8–13 μm, the so-called atmospheric window allows for practically complete transmission across the atmosphere without absorption. Mainly, the CO2 and water vapor emission bands, however, are responsible for an overall emission/absorption effect in this range [30]. Sky emission in the atmospheric window wavelength is also highly dependent on air moisture content, ambient temperature, and dew point temperature. Usually, the sky emissivity is greater at larger zenith angles because of the longer path length. Further, the second and the less considerable transparent window for low concentrations of water vapor in the atmosphere is present in the 16–22 μm range. Atmospheric window transparency is only high in good weather. Moreover, if the atmospheric window is blocked by clouds, rain, or humid conditions, radiative cooling will have a lower cooling effect [30].

Then, in accordance with the thermal radiation theory, Patm is power absorbed by the radiative cooler from the incident atmospheric radiation and is given by,

Furthermore, both the angle and the wavelength have an impact on atmospheric emissivity. The following Equation (6) emerges, by applying Kirchhoff’s rules.

(θ,λ) represents the spectral directional emissivity of the radiator, and τa(λ) denotes the transmittance of the atmosphere in a specific direction [21].

Moreover, the atmosphere is almost a blackbody radiator with a temperature of 1–2 °C below ground level ambient temperature for a cloudy sky, according to the measurements on spectral atmospheric radiance made by Bell et al. [32]. This renders the PRC effect for cloudy skies inappropriate. The atmosphere emissivity of a sky under various conditions is a crucial consideration when evaluating PRC systems in order to assess the accuracy of the radiative model. The two most significant variables in calculating sky radiation, besides sky emissivity, are spectral emittance profile and atmospheric temperature. Imagine the atmosphere to be a gray-emitting body at temperature (Ta), with an effective emittance value of for a total hemispheric emittance (i.e., the ratio of the material’s total emissive power to the total emissive power of an ideal black body). Atmospheric radiative heat flux is then as follows [30]:

Pa = εσTa4 (W/m2)

Following Zevenhoven et al. [44], one shortwave (SW) band < 4 μm plus three longwave (LW) bands, including 4–8 μm, 8–13 μm (the atmospheric window), and >13 μm, can be used to describe how thermal radiation travels through the atmosphere. The atmosphere’s transmittance is τai = 1 − εai, (i = 1 to 4) for zero reflectance. Consequently, for all four bands, the approximate atmospheric emittance values are with the values εa1 = 0.26 for SW radiation and εa2 =1, εa3 = 0.55, 0.65, and εa4 = 1, respectively [16], can used for LW radiation. With the exception of wavelengths between 8 and 13 μm, Kondratyev treated the atmosphere as opaque. Using the correlation shown below, a value for εa3 was determined here using Equation (8), [44]

In recent years, several researchers have used empirical correlations to estimate the atmospheric hemispherical emittance more precisely. Such relationships depend on direct measurements of sky radiance and empirical equations to fit experimental observations. For instance, Catalanotti et al. as well as other researchers also report approximate measurements for the atmospheric emittance values. They endorsed total emittance values for clear skies of 0.5–0.6 for arid areas at high elevation, 0.8–0.9 at sea level, and close to 1.0 for cloudy skies. Brunt et al. developed the following mathematical equation for the sky’s total emittance based on the partial water vapor pressure in the atmosphere [30]:

where p stands for partial water pressure (mbar), and A and B are empirical constants with values ranging from 0.34 to 0.71 and 0.023 to 0.110, respectively.

εa = A + B√(p)

Later, Murray [30], derived an empirical equation for total atmospheric emittance by considering dew point temperature (Tdp in °C) and ambient temperature (Ta in °C). It is given by the following:

a and b are considered empirical constants in the above Equation (11), and their values are as follows: a = 1.727, 0 ≤ RH ≤ 1, and b = Ta/(Ta + 273.3), where Ta = ambient temperature.

εa = 0.741 + 0.0062Tdp (−)

Similar to this, Martin and Berdahl [30] presented an empirical equation for the relationship between wavelength (λ), zenith angle(θ), and total sky emittance in the case of spectral sky emittance.

The values are t(λ)/tav, b implicitly dependents shown in tabular form in [30], valid for −13 < Tdp < 24 °C, = total sky emittance, and Tdp = dew point temperature (°C). The above Equations (7)–(13) above are most commonly used to properly assess atmospheric emittance and its parameters.

The use of the effective total emittance value () and modeling the atmosphere as a gray body at an ambient temperature mainly have two implications according to studies conducted by a number of researchers (Ta). The first one is that, initially, many studies made the wrong assumption that the sky emits as a black body outside the range of atmospheric wavelengths. This led to inaccurate estimates of the high cooling capacities for blackbody emitters used as nocturnal PRC. The second point of concern is that experimental measurements presented in [30] showed that the amount of moisture and the zenith angle have a significant effect on directional sky radiation within the atmospheric window wavelength. The variation in atmospheric emissions caused by differences in water vapor amounts, as well as their directional dependence, are greatly reduced when the sky is seen as a gray body.

1.6. Non-Radiative Heat Transfer (Conduction and Convection)

Heat conduction and convective heat transfer affect radiative cooler performance, in addition to its own heat radiation, solar radiation, and atmospheric heat radiation. Convectional and conductional heat transfer from the surroundings is represented by the Pnonrad, which is given by,

Pnonrad = h·(Trad − Tatm) (W/m2)

The cooler temperature and atmospheric irradiance temperature are Trad and Tatm, respectively, and h stands for the non-radiative heat transfer coefficient (W/m2K) that results from the heat transfer mechanisms (natural plus forced convection and typically much smaller conduction of heat) from the radiative cooler to its surroundings. A well-controlled h value ranges from 2.0 to 6.9 W/m2 K. A higher value for non-radiative heat coefficient (h) indicates greater conductive and convective heat exchange with the ground level environment, and a radiative cooler (Pnonrad), which results in less cooling power for the fixed temperatures Trad and Tatm. To obtain the highest cooling power (Pnet), it is mandatory to increase the radiative power emitted by the radiative cooler (Prad), while reducing the power absorption from the incident atmospheric gains for effective radiative cooling, Prad >> Pnonrad. Thus, from the perception of the optimum radiative cooler design, zero absorption (i.e., nearly 100% reflection) across the entire solar spectrum, selective and nearly total absorption/emissivity across the wavelength region from 8 to 13 μm matching the atmospheric transparence window, and reduced excessive energy dissipation by conduction and convection are the important factors [41]. In addition, several researchers have put forth some of the equations for the radiative cooler’s non-radiative heat transfer coefficient. The equations h = 5.7 + 3.8 V and h = 2.8 + 3.0 V, respectively, where V is wind speed in m/s, have been suggested to describe a radiative cooler without the windshield and with the windshield in [41]. Based on the outcomes of the simulation for a particular case with the windshield, Rephaeli et al. [45] and Zhu et al. [36] determined that h = 6, 12, and 40 [W/m2K] for the velocities at V = 1, 3, and 12 m/s, respectively. The values of h are presented for the case of a radiative cooler without the windshield in [46] and [47], where h = 1 + (6 V3/4) and h = 1.8 + (3.8 V), respectively—valid if V lies between 1.35 and 4.5 m/s.

Zeyghami et al. [30] calculated and compared the cooling characteristics of a broadband IR radiator and ideal IR emitter by considering three cooling surfaces in two scenarios for surface temperatures T s ≤ Tamb and T ≥ Tamb. Cooling heat fluxes up to 80 W/m2 have been determined for a broadband IR radiator and an ideal IR emitter at room temperature. The cooling heat flux decreases until zero as the surface temperature gradually decreases. The ideal IR emitter has a ΔTmin of −9 °C and the broadband IR radiator has a ΔTmin of −6 °C, i.e., when a radiative cooler is intended to produce cooling effects at a temperature below ambient, non-radiative heat transfer has a significant impact on the surface ability to cool. Reaching ΔTmin −14 °C for a broadband IR emitter and ΔTmin −43 °C for an ideal IR emitter is possible by eliminating non-radiative heat transfer completely in the case of T ≥ Tamb. A value Pnet = 490 W/m2 was calculated for the broadband IR radiator at ΔT = 20 °C higher than the surrounding temperature. A cooling heat flux of up to 405 W/m2 was found for an ideal IR emitter under similar circumstances. It makes sense that the non-radiative cooling effect would take over as the dominant cooling phenomenon at higher surface temperatures. Similar research findings by Granqvist and co-workers demonstrated that for an ideal IR emitter, increasing ambient temperature and or a lower air humidity would improve the radiative cooler’s performance and raise Pnet and ΔTmin values [43].

However, the majority of current studies on radiative cooling assume that the cooler surface temperature is the same as the ambient temperature and disregard non-radiative heat transfer (Pnonrad). In real-world situations, this temperature difference is significant, which lowers the cooling effect. Maintaining the temperature drop achieved by cooling with radiant coolers that require effective heat convection insulation is crucial. In conclusion, DPRC performance can be improved or optimized by utilizing four different ways. (1) Improving the radiator’s ability to radiate heat effectively. (2) The radiative cooler’s ability to reflect more sunlight. (3) Adjusting thermal radiation’s wavelength to focus in the range of 8–13 μm. (4) Lastly, controlling the radiation of heat from the radiative cooler to the environment, i.e., the sky through the atmosphere. When developing an ideal radiative cooler, it is crucial to take the material, the structure, and the shape into consideration. By choosing the right materials (today’s challenge is also from the material resources availability point of view), the radiative cooler should have high solar reflectivity. However, the power of the sun’s radiation, the amount of water in the air, the speed of the wind, and the pressure of the cloud cover all have a significant impact on how efficient radiative coolers are. Certainly, it is essential to take into account the local climatic conditions when developing future radiative coolers [21].

2. A Comparison of Active and Passive Daytime Cooling Technologies for Buildings

Solar energy can be used to provide electricity, heat, light, and cooling for both residential and commercial buildings without harming the environment, apart from the effects of constructing the equipment. In order to brighten the indoor environment, it is possible to gather solar energy as daylight. A passive daytime system often also collects and distributes sunlight for efficient interior building lighting. Daytime passive cooling systems give both daylighting as well as cooling in order to achieve the goal of low-energy buildings [48].

Solar light is gathered and dispersed in a variety of ways; passive and active day-lighting systems are extricated based on how light is gathered and dispersed. Skylight windows, sliding glass doors, static waveguides, etc., are just a few examples of the non-tracking, static designs used as part of passive daytime cooling systems to capture, reflect, and disperse the sunlight into a building’s interior. In daylighting systems that actively collect sunlight, mechanical and optical devices are equipped with sun-tracking mechanisms that move with the sun and then distribute it through waveguides into buildings’ structures [49,50]. The tracking device in an active daylighting system makes it functional when daylight begins early in the morning and lasts until the evening, giving it an edge over stationary passive daytime systems. An active daytime system does have a drawback, though, in that it has a high initial installation cost, related maintenance, and operating costs [48]. The use of passive daytime systems in sustainable building design has a number of benefits, including affordability, simple installation, and aesthetic design (good visual appearance). The following advantages can be mentioned:

- (1)

- All types of buildings can have DPRC installed, and existing construction projects can even use it at a reduced cost.

- (2)

- Daytime cooling systems improve the quality of the indoor air because they do not use forced air systems.

- (3)

- The lack of mechanical components makes passive daytime systems easier to maintain than active daylighting systems.

- (4)

- Savings on electricity-driven cooling and heating expenses are among the long-term advantages of passive cooling during the daytime [48,51].

Passive daytime cooling systems are little more expensive than buildings made only of concrete and bricks, though they will end up costing less over time, according to specialists in passive solar design. The incorporation of passive daytime systems into sustainable building designs presents a number of difficulties:

- (1)

- Due to the fact that glass types and qualities can vary widely, picking the right glass to meet DPRC specifications can be challenging. When choosing materials for passive daytime cooling homes, choosing the wrong glass or other high SW transmittance material is an expensive mistake. The location (north, south, east, or west) and climate of a building will determine the best type of glass to use.

- (2)

- A strong connection exists between daylight and heat. The use of daytime lighting during the summer or in areas where the climate is warm all year can increase the amount of energy used by the air-conditioning systems.

- (3)

- A poorly designed passive daytime system can produce a glare on household items and appliances (furniture, televisions, refrigerators, and laptops). As a result, the placement of items in the home necessitates careful consideration [48].

2.1. Technical Description of Passive Daytime Systems

Passive cooling skylights are used in buildings that do not have enough wall openings so that sunlight can enter through the roof or other horizontal surfaces. Examples of passive daytime cooling techniques include louvers, tubular daylight, skylights, slope glazing, roof windows, solar lights made from soda bottles, windows, light shelves, reflectors, and sawtooth roofs. This section describes a variety of skylight types and their advantages since it is hard to list all kinds of passive daytime systems [52].

2.2. Types of Skylights

A skylight is a usually covered opening in a roof that allows sunlight to penetrate a building from above and brighten it. The material selected for making skylights can have a significant impact on both the quality of daylight and the energy efficiency of the building structure. Polymers and glass in a range of colors and thicknesses are popular skylight glazing materials. Installing pitched or dome-shaped skylights at the same height as a building’s roof is standard practice. Light wells are an essential component while designing the skylight. Light wells direct daylight into the building before it enters the interiors by channeling it via the roof and ceiling. A light well accomplishes two tasks: it diffuses light and protects the observer from direct sunshine [53].

Fixed unit skylight: Generally, this type of skylight typically lacks ventilation and has a structural perimeter frame that supports the light-transmitting portion, which is generally constructed using plastic or glass [48].

Operable skylight: Residents can reach this type of skylight if it is accessible through the roof. It rotates at the top and resembles a single-window frame that opens a few inches higher to allow for greater air circulation and sunlight. Skylights that are operated manually may feature manual locks that allow them to open and close at a specific level [48].

Tubular daylighting device: This fixed unit roof skylight captures sunlight and transfers it to a light-diffusing element via some type of light conveyance optical conduit. This system absorbs and transmits solar light via a roof-mounted dome measuring 0.254 m to 0.559 m in diameter. The building’s dome gathers light beams, which are then scattered by a system of aluminum tubes and spread throughout it by a number of specular reflections. The size of the dome is determined by the building’s size and is made of acrylic or polycarbonate to block UV light [48].

Retractable skylight: This type of skylight is made up of a single retractable window frame or a group of retractable window frames positioned on top of a roof. When the window is controlled, it slides out of the frame and onto a set of rails, enabling a full opening to the exterior for direct sunshine or ventilation of the building’s interior. They use a mechanical cable system to retract left and right as well as up and down [48].

Straight and splayed skylight: There are two types of skylights, straight and splayed. Both of them allow light to enter the building from the rooftop. The spread skylight design spreads light more widely across the building than the straight skylight design, which is how these two designs differ from one another. On the other hand, spread skylights must be closer together than straight skylights to produce the same amount of light [48].

Sloped glazing: When designing and developing sloping glazing assemblies for a specific project, sections are often used. They combine several infill panels in a frame structure. Single clear glass, single glazing with gray tint, double clear glass, double glazing with gray tint, double glazing with selective tint, double glazing with reduced emissivity (Low-E), and triple glazing with Low-E are some of the glazing types that are frequently used in residential windows. It becomes more difficult to select the ideal glazing material when both energy savings and natural light are taken into account simultaneously [54,55,56].

3. Transmissive Radiative Cooling Skylights

The structural and material engineering for PRC studies is essential, as discussed above, and has been proposed and investigated since the second half of the 20th century. As the first design of a radiative cooler in the 1980′s, silicon compounds like silicon dioxide (SiO2) and silicon nitride (Si3N4) were produced on aluminum (Al) film-coated glass substrates using the vacuum deposition technique. These designs successfully achieved PRC, which in practice obtained a net cooling power of about 100 W/m2. Following the pioneering work and looking for window materials for skylights allowing passive cooling [57], ÅA has developed and tested a skylight that offers nocturnal PRC up to ≈100 W/m2.

The possibility of running water through a double-glass window for simultaneous water heating and air conditioning was presented by a few researchers in the past [58]. However, little research has been conducted concerning the use of so-called participating gases inside skylights that interact with thermal radiation in specific, preselected wavelength bands. Since then, ÅA has been researching PRC strategies to improve cooling performance using skylights during the daytime, an approach that has received little attention. So far, ÅA has investigated and published the fundamentals and possibilities of this technology and its viability through simulations and experimental results [20]. See Section 3.1 of a skylight filled with a participating gas that absorbs and emits thermal radiation, with necessary high absorption, emission, and transmittance of gases and window materials in the atmospheric window range of 8–13 μm.

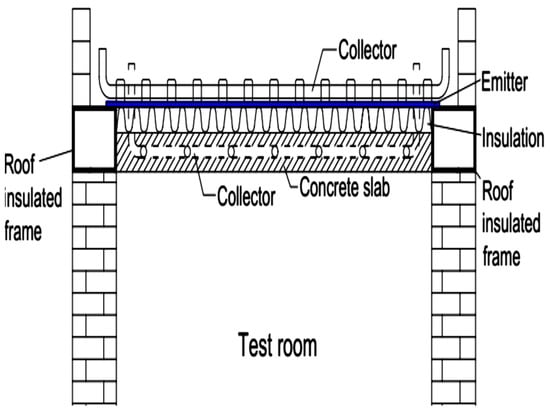

3.1. ÅA Skylight Prototype

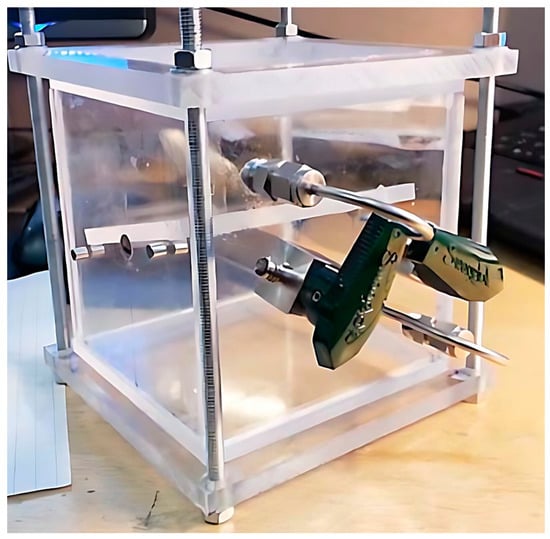

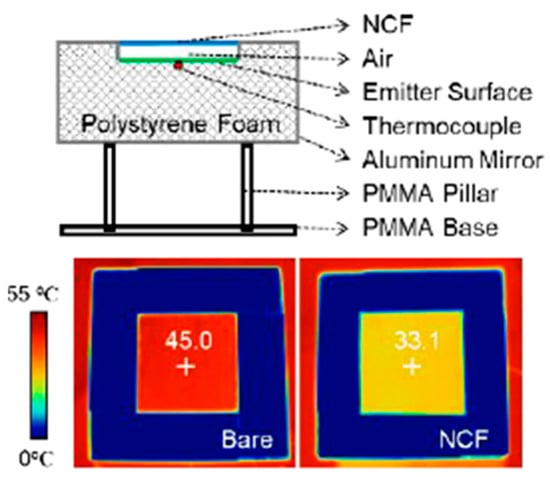

This skylight model, the design and function of which was developed at ÅA, was assessed for effectiveness as both a passive cooler during summer and a thermal insulator during winter. The 10 × 10 × 10 cm3 small skylight setup for proof-of-concept experiments is shown in Figure 6. Acrylic plastic (non-transparent for long-wavelength thermal radiation, i.e., >4 μm) is used for the construction, except for two zinc sulfide (ZnS) windows as top and bottom cover. The central window (which guides the convective heat flow inside skylight) is constructed of acrylic plastic, which has a reflection coefficient of ρ = 0.9 at all wavelengths. The central window divides the skylight into two sections that absorb from below, emitting heat to the atmosphere and space above via thermal radiation-driven (natural) convection while minimizing turbulence.

Figure 6.

Skylight prototype at the ÅA University, PST laboratory [20].

The circulation provides cooling to a room beneath the skylight. When this circulation is interrupted, the skylight functions as a thermal insulator. The spaces between these three windows are filled with GHGs, such as pure CO2, HFC-125, or NH3, other than air. Therefore, the following are sections that provide detailed information about selecting the proper gas and window materials.

3.2. Selecting Participating Gas for Passive Skylight

When selecting a suitable participating gas, it is critical to take the following measures:

- The radiative pathway in the gas must be long enough for it to be capable of radiating enough heat.

- The gas must have high absorptance in the spectral range of the atmospheric window and highly transparent at visible wavelengths.

- In order to achieve adequate convective cooling, the gas thickness must be both large enough to permit and small enough to inhibit convective heat transfer.

- The viscosity of the gas should be as low as practical in order to reduce fluid convective flow limitations

- It is important that the gas has a heat conductivity that is low enough and to give conductive heat transfer << convective heat transfer. Moreover, the gas needs to have a high thermal capacity to minimize mass needed.

- It is critical that a gas’s boiling point (BP) is significantly lower than the lowest temperature inside the skylight [20].

Health and safety standards: Consider any leaks near the skylight window in terms of health and safety laws. It is necessary to carefully select gases for skylight windows. The gas cannot be toxic or combustible. Therefore, according to the standards set forth by the International Institute of refrigeration (IIR), gases classified as A2L are appropriate for this application [59].

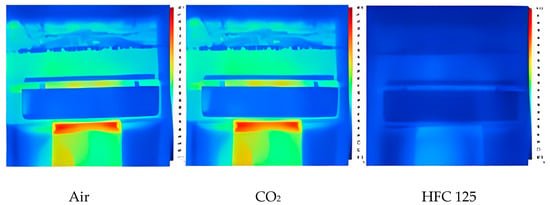

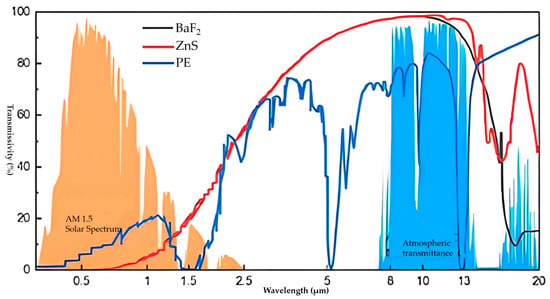

Effect of the gas on the environment: The potential threats of ozone depletion and global warming from the gas need to be taken into account. Gases that damage the ozone layer are outlawed with strict enforcement, especially in Europe. Consequently, the gases required for a skylight should have a higher global warming potential (GWP) while preferably being sensitive to conversion into harmless species if eventually released into the environment and have no effect on the ozone layer. At ÅA, CO2 and HFC-125 were considered; it was possible to compare the two gases (see Figure 7) by filling the skylights with CO2 and HFC-125. The results from the experiments revealed that HFC-125 may achieve temperatures lower than the surrounding air and has a noticeably larger cooling effect compared to CO2 [60].

Figure 7.

Thermal infrared images of skylights after testing with air, CO2 and HFC-125 [20].

For CO2 gas to reach temperatures below the ambient, an elevated pressure may be recommended which, however, would require thick glass with consequently lowered transmissivity. In response to this, this led to the choice of HFC-125 refrigerant for skylight construction. Other mixed refrigerants such as NH3 (strong pungent smell), HFC-32, HFC-134A, HFC-143A, and SF6 were also studied or considered, but their flammability and other safety reasons preclude their usage. Due to the recent phase-out of HFC-125 [61], R-32, R-410a, R454b, and R449A are likely to be considered for the further scale-up of the skylight window prototype at the ÅA-PST laboratory.

3.3. Selection of Suitable Window Material

The basic and primary function of window materials is to keep the outside weather from affecting the interior climate. A skylight should last for decades, and window material should be mechanically sturdy enough to withstand exterior weather conditions (e.g., it should be resistant to severe winds and snow, and it should not be soluble in rainwater). In addition, direct sunlight must not damage the material. Zinc selenium (ZnSe), despite its viability, was not chosen as a window material for ÅA skylight due to its high cost. Actually, before we found the Cleartran, thin, low-density polyethylene sheets (LDPE) were used as window materials [20]. Later, ZnS was a preferred material since it is transparent to both long-wave and visible light heat radiation. It also possesses a transparency of about 80% [62] in the atmospheric window region. Thus, this material can be used as a several-mm-thick glass sheet that is similar to normal window glass.

3.4. Working Principle and Design Changes for Improving Passive Skylight

With a prototype skylight that contains a GHG-filled inter glazing space, it was shown to be possible to control the radiative heat flux from a building to the sky and ambient surroundings. The third center window and the gas regulate the balance between insulation and cooling while its angle can be used to regulate the (natural) convection for minimal turbulence.

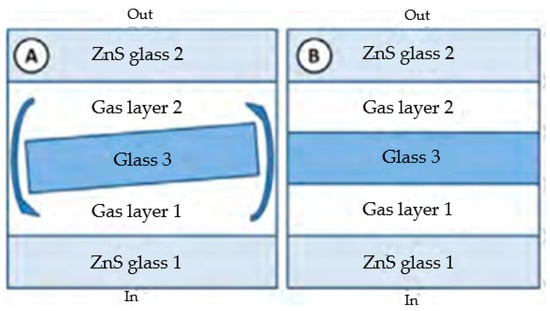

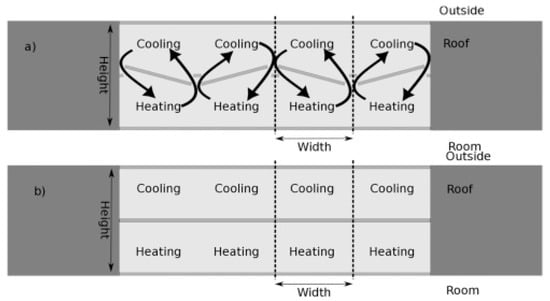

The central window, as previously mentioned, divides the skylight into an upper and a lower portion. The gas functions as the working fluid in a heat exchanger that “connects” the room with the sky. An appropriate participating gas must have a higher thermal emittance value in the atmospheric window’s wavelength (8–13 μm) range. The developed skylight can be adjusted to work in either a cooling mode or an insulating mode (see Figure 8) [20].

Figure 8.

Different skylight configurations Ⓐ cooling mode Ⓑ insulating mode [20].

When the skylight is in its cooling mode, heat from the below room is transferred to the gas via the lower window (ZnS glass 1) via radiation, conduction and natural convection. Due to the decrease in gas density, the heated gas travels to the upper compartment. The radiative heat transfer through this makes it travel to the lower compartment from the upper window (ZnS glass 2) and the atmospheric window to the cooler air masses in the upper atmosphere, which cools the gas in the upper compartment. Additionally, above the skylight, forced convective heat transfer typically occurs between the upper portion of the skylight and its direct surroundings because of wind. The impact of this heat transfer depends on the ambient temperature. When cooling is not required, the connection between the two gas areas (gas layer 1 and gas layer 2) is closed, causing the roof’s components to act as thermal insulators rather than passive radiative coolers.

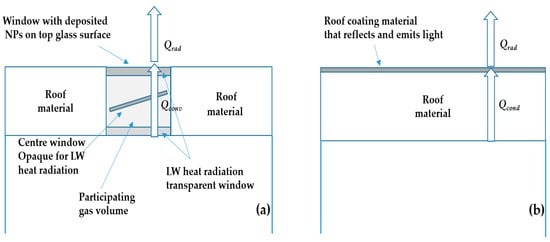

Figure 9a illustrates a side view of the ÅA proof-of-concept passive cooling skylight presented recently. Its performance is comparable to that of a roof paint or other covering material that, in addition to reflecting thermal radiation, has a high emissivity in the wavelength range for the atmospheric window, as illustrated in Figure 9b [63].

Figure 9.

(a) A skylight design with reflective NPs on a ZnS substrate and (b) compared with a rooftop reflecting and emitting coating material [63].

The skylight provides more heat transfer (per square meter) from the building envelope to the outside top surface, which is governed by convective circulation heat transfer inside the skylight. This is stronger than conductive heat transfer via the material of the building roof (Qconv >> Qcond), and eventually the limiting heat flow will determine the heat radiation to the sky (Qrad). Therefore, the building’s top surface must have direct visual contact with the sky (and beyond that, this enables the skylight to illuminate the room). The center window will no longer be necessary for future ÅA skylight designs (ongoing work).

As said earlier, ZnS is widely used in long-wave infrared systems as an infrared transmitting window material. Skylight passive cooling applications benefit from Cleartran’s material’s excellent thermal, mechanical, and optical properties over a wide range of wavelengths. Because of its non-hygroscopic nature, high refractive index, thermal conductivity, and thermal expansion, this substance was exceptional and frequently used in engineering design applications [64]. However, difficulties with ZnS identified are as follows: (1) it requires an external sunshade to minimize the solar radiation absorbed by the radiative cooler because of its noticeably high solar absorptivity of ≈0.13. (2) When exposed to direct solar irradiation, ZnS heats the radiative coolers. Thus, ZnS is not ideally effective for establishing DPRC as intended, particularly during the day (around noon), and therefore tough challenge persists. Further investigation into finding suitable materials is necessary in order to create surface coatings such as single-layer/multi-layer radiative cooling coatings or additives on ZnS glass.

The development of sustainable PRC technology demands a significant amount of research work, and efficient methodologies must be refined, possibly through experiments, mathematical modeling, and validation of the obtained experimental data by building the models using numerical simulation software (Ansys Fluent/Comsol Multiphysics). Another motivating factor is the fact that PRC applications have developed significantly and ingeniously in recent years. As a result, ÅA PST is currently developing a PRC skylight that should be capable of dissipating a few 100 W/m2 of cooling during daytime, which can be used to lower the energy required to meet a building’s heating and cooling needs. It is possible to classify PRC methodologies into two Groups:

Group 1: fundamental principles such as the emissivity properties of radiative cooling surfaces and the wavelength dependence of radiative cooling surfaces. The main goal here is to find a suitable PRC method—even though many studies focus on cooling technologies, there is a scarcity of research offering PRC approaches that lower energy usage. As a result, the focus of this study is on enhancing the impacts of PRC strategies to increase building energy performance [2].

Group 2: this is a practical research phase. The second area of research focuses on finding suitable materials with preferred radiative properties, investigating diurnal cooling for energy-saving applications (such as cooling of residential and commercial buildings, and solar cells), and maximizing net cooling power. The idea is to use the most recent developments in material technology to design and fabricate a skylight using various metamaterials, photonic structures, and thin films with precisely designed nanoparticles (TiO2, SiO2, Al2O3, and AgNO3) dispersed on the surfaces [2].

According to previous research by a few researchers, PRC systems made of various materials are capable of influencing system performance, and it is a notable technique to achieve perfect sub-ambient radiative cooling. Although the research is progressing toward a more comprehensive and coherent theory for developing PRC technologies, the findings remain diverse and even fragmented.

Motivated by such considerations, ÅA PST’s current research activity will involve finding the suitable material used as top and bottom window glass surface for reasonable PRC during both daytime and nighttime, and then combining the materials in a design that can turn into a commercial product.

One benefit is that this skylight PRC system could reduce the need for conventional cooling systems, resulting in savings, but is also applicable for the refrigeration of food products and vehicle applications. In addition, it is very likely to expand this PRC skylight to provide engineering designs for passive cooling systems for cars or trucks parked in the sun. ÅA [65] has already reported work on this. That research showed that the passive cooling effect of almost 27 W/m2 from the vehicular skylight is achievable for the summer season in Finland. Therefore, when a car is equipped with a skylight for passive cooling, its annual energy usage may decrease while it is inside temperature is controlled, also while being parked in the open air under solar irradiation.

4. Radiative Cooling Materials

The concept of radiative cooling has been largely limited to nocturnal radiators thus far. Natural materials typically exhibit poor radiative cooling efficiency and do not have both a significant high emissivity in the atmospheric window and very high reflectivity in the solar spectrum wavelength. That means a lucrative DPRC structure should have a solar reflectivity much higher than 90% (preferably > 97%) together with a large emissivity value (>0.9) in the atmospheric window. The ability to modify a material structure at the nanoscale and enhance electromagnetic radiation emissivity and spectral absorption, however, is now possible due to the most neoteric developments in material science and the rapid upgrading of nanofabrication technologies. There is speculation that a variety of photonic structures, including multilayer planar photonic thin films, metamaterials, 2D and 3D photonic devices, and plasmonic structures, can be adapted to increase either emissivity of the material in the atmospheric window or increase reflectivity in the solar spectrum [66,67,68].

While solar radiation at high intensity is present during the day, many of the proposed photonic structures have been able to operate at temperatures lower than ambient temperatures. These radiators, designed to reduce costs and complexity in polymer photonics, use electromagnetic resonators that are generally excited inside a polymer surface, resulting in a very high emissivity in the wavelength of 8–13 μm. Conversely, more recently developed PRC systems—like advanced paints—attempt a high potential for radiative cooling at a significantly lower cost. However, problems that need to be resolved include optical aging brought on by dust accumulation, other atmospheric constituents adhering to paints, and unwanted cooling during the heating period [69]. Due to the extensive research focused primarily on advanced photonic and plasmonic surface technologies, metamaterials led to the development of sub-ambient DPRC. It appears that these developed technologies can indeed increase buildings’ daytime cooling capacity.

There are, as said, two kinds of PRC materials to provide cooling for nocturnal and diurnal periods. During the night, achieving sub-ambient temperatures is very straightforward, but under direct sunlight, it is quite challenging due to the material requirements. Thus, this section aims to summarize materials for PRC during the day and at night. Nevertheless, it mainly focuses on highlighting the most significant advantages and disadvantages of DPRC materials and their potential applications in building cooling. Besides that, their scalability as well as various materials’ effectiveness are investigated for producing diurnal and nocturnal PRC capabilities. The following section covers more detail on the materials and structural categories [19].

4.1. PRC Materials for Nighttime (Nocturnal) Cooling

In the past few decades, most nocturnal PRC research has focused mainly on a particular surface in the atmospheric window to reach higher sub-ambient temperatures. The following are some types of materials:

4.1.1. Polymer-Based Materials, Including Paints Made from a Polymeric Binder and Various Pigments, Composite Polymer Materials, and Polyvinyl Chloride (PVC), Polymethyl Methacrylate (PMMA), and Modified Polyphenylene Oxide (PPO) Resin

A thin layer of polymer and a reflective metal are typically the components of polymer-based radiative cooling materials (e.g., aluminium). Prior to now, Catalanotti et al. [70] developed a 12.5-μm-thick polyvinyl-fluoride (PVF) film with an aluminum back coating.

The results revealed strong emissivity within the atmospheric window (8–13 μm) and high IR reflectivity for other wavelengths. This PRC was able to cool to almost 15 °C below ambient temperature using a thermally insulated box covered in IR transparent PE film. Certain polymer films, such as PPO and polymethyl pentene (PMP or TPX), also demonstrated their effectiveness at nighttime cooling [2].

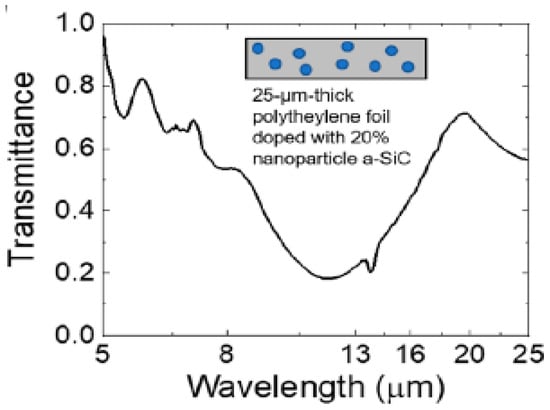

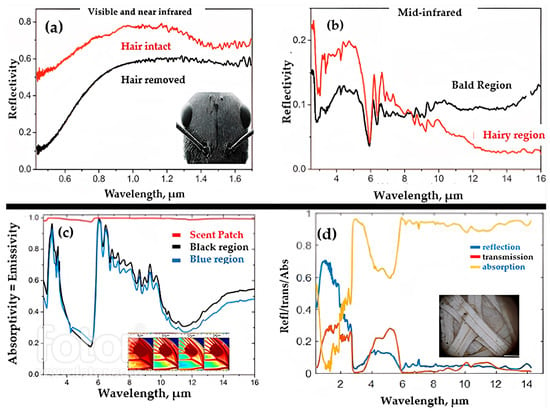

Likewise, composites that combine nanoparticles and IR-transmitting polymers have the potential to produce polymer-based materials. Due to the narrow absorption bands that these nanoparticles typically have within the atmospheric window, the composite material can have its absorption spectrum completely within the atmospheric window by adjusting the nanoparticle concentration. Amorphous silicon carbide (SiC) nanoparticles were doped into a 25-μm PE film at a 20% concentration (see Figure 10) in a composite material created by Gentle et al. [71]. Nanoparticles produce a considerably higher absorption in the 8–13 μm range in comparison to a pure PE film (highly transparent) in the atmospheric window. Besides Si2N2O3, SiO2, and carbon-based nanomaterials such as nanodiamonds and multilayer carbon nanotubes, carbon black also served as effective materials [72,73,74].

Figure 10.

Polyethylene (PE) thin film with amorphous SiC nanoparticles [71].

4.1.2. Thin-Film Inorganic Coatings of Materials Such as Silicon Monoxide (SiO), Silicon Dioxide (SiO2), Silicon Oxynitride (SiOxNy), Silicon Nitride (SiN) and White Pigmented Paints

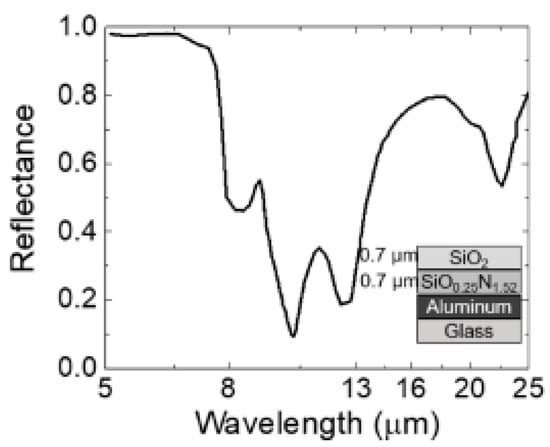

Since the Si-N and Si-O bonds are both absorptive at 11.5 μm and 9.5 μm, respectively, silicon-based oxide and nitride thin coatings (SiO, Si3N4, and SiOxNy) have a relatively high mid-IR emissivity [75,76]. SiO film that is 1 μm thick is optimized to reduce IR reflection through destructive interference while increasing emissivity [77]. A bilayer of SiO2 and SiO0.25N1.52 on aluminum is depicted in Figure 11 as an example of computed spectral reflectance in the 5 to 25 μm wavelength range [78,79].

Figure 11.

Silicon oxide and Nitride film on Aluminium [2].

Ceramic materials with PRC capabilities include lithium fluoride (LiF) and magnesium oxide (MgO), when supported by an IR-reflective layer, silicon-based thin film. A nearly 20 °C sub-ambient cooling temperature was observed on the 1.1-mm-thick MgO film during a dry, clear sky night [80].

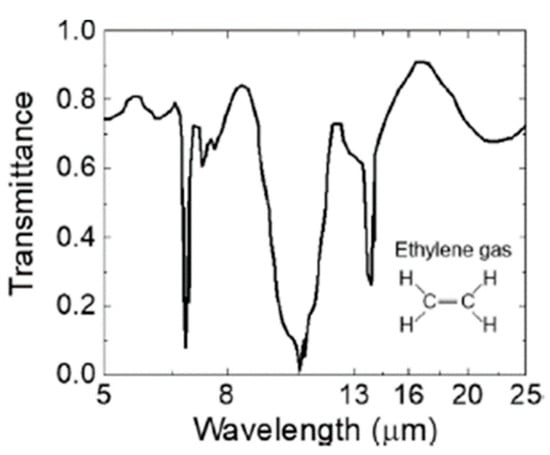

4.1.3. Ammonia (NH3), Ethylene (C2H4), and Ethylene Oxide (C2H4O) Emit IR When Enclosed in an IR Transparent Container, Which Makes IR Emissivity Possible

To produce spectrally selective infrared emissivity, a slab of selectively infrared-emitting gas can be contained within an infrared transparent container. Strong infrared absorption is obtained for certain molecular stretching and rotation modes within the 8–13 μm wavelength. For instance, the C = C bond absorbs the light strongly between 10 μm and 12.5 μm. As C-O and C-N stretching bonds absorb from 8 to 10 μm, and as OH deformation vibration absorbs between 8 and 10 μm, these bonds emit IR absorption [81,82]. Granqvist et al. looked into the viability of using various confined gases, such as NH3, C2H4, and C2H4O, or mixtures of them, as PRC materials [82,83]. Figure 12, which shows the optical transmission spectrum for C2H4 with a good level of a thickness (up to a few cm), suggests that these molecules could be suitable PRC candidates.

Figure 12.

The slab of selectively infrared emitting ethylene gases [83].

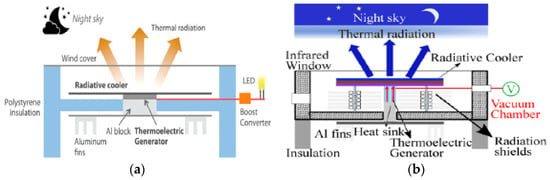

When the solar light is shaded during the day, experimental results showed that 12–18 °C sub-ambient cooling is possible. The key benefit of using such a gas slab on a solid PRC surface is that no additional heat transfer fluid is required to build an efficient cooling device [84]. The aforementioned materials demonstrate that selective emitters have been developed and successfully tested for nighttime radiative cooling at both ambient and below-ambient temperatures. However, the inherently low cooling power density of radiative coolers makes them inefficient for nocturnal applications.

4.2. Nocturnal Cooling Structures for Energy-Efficient Buildings

Due to its outstanding PRC capabilities, this DPRC technology hopes to have a significant influence in a variety of fields, including those pertaining to energy-efficient buildings, also known as smart buildings. It has been extensively studied and used in practice to use nocturnal PRC systems. The building incorporated PRC systems fall into two categories based on how the cooling process operates, as shown below [8].

4.2.1. Air-Based Cooling (ABC) Systems

The ABC system, which uses air as the heat exchange medium, is a straightforward way to integrate PRC with a building cooling system. It is mainly composed of a connection loop, a driving fan, and a radiative cooling surface. Prior to entering a building, either the air is cooled naturally or using a fan-driven sky radiant cooler attached to the roof [9,85]. In these systems, it is actually necessary to have a small air passage beneath the radiator and a large surface area in order to cool the exchange the air effectively.

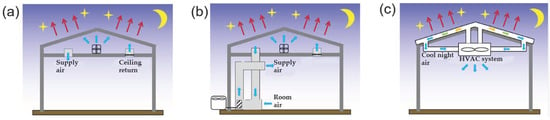

Illustrated by Figure 13, Lu et al. [9] compared three different ABC systems with various system configurations. While Figure 13b,c incorporate an air conditioning system for auxiliary cooling, Figure 13a is a relatively straightforward system that directly cools the roof by using it as a radiator.

Figure 13.

Different air-based system configurations [2].

Kimball et al. [86] developed a PRC-based air box convector. The component comprises two heat exchangers connected in series with a fan for cooling and dehumidification in tropical climates. Their experimental findings showed that this innovative system, when used in conjunction with PRC, could reduce the energy used to maintain an ideal indoor environment by 14–18%. Likewise, The National Solar Test Facility (NSTF) of Canada tested various transpired solar collectors to evaluate the volume of air that could be cooled at night and the temperature difference from ambient as measured. The experiments demonstrated that nocturnal PRC reduces ambient air temperatures by up to 4.7 °C [87]. The patented ABC system invented by the company Conserval Engineering comprises perforated metal panels that operate at night through radiant cooling and in the daytime through above-the-sheathing ventilation [9]. In a theoretical study, Zevenhoven et al. presented the idea of regulating passive skylights for cooling purposes via radiative cooling, and the performance was tested using weather data from Helsinki [88].

Overall, ABC is a concise design that offers instant cooling. Additionally, if it combines well with PRC material and has the advantage of reduced installation and maintenance costs. However, due to the air’s poor heat transfer efficiency and low specific heat capacity, it is challenging to meet the building’s cooling needs when using natural air circulation. There might be a slight cooling enhancement by including a driven fan, but only by 20–30 W/m2 [89]. When it comes to cooling large buildings, a simple combination with an air-based ventilation system can be difficult. Due to the substantial occupied space, as well as the introduction of ducts and other hardware, the integration of the ABC systems in buildings is also inferior. Its usage is currently restricted to the upper floors of multi-story or residential buildings.

4.2.2. Water-Based Cooling (WBC) Systems

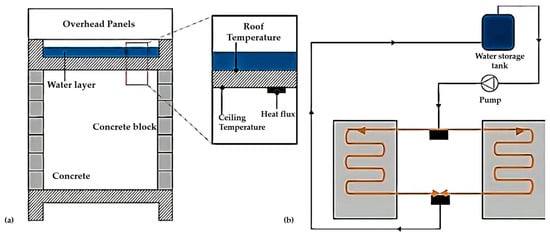

Some studies recommended using PRC in conjunction with WBC systems because ABC systems, as discussed in 4.1.1, are insufficient to meet most buildings’ needs. A WBC system can provide around 40 W/m2 of cooling. Again, depending on how they operate, these cooling systems can be defined as either closed-loop or open-loop systems. An open-loop system such as a rooftop pool transfers heat between the interior and exterior via thermal radiation and phase change evaporation. However, in arid areas, open-loop water-based systems can only be used to a certain extent [8,90].

According to Figure 14, a closed-loop cooling system integrates closed pipes in a flat plate radiant system to cool water using water as a heat carrier [91]. Pumps typically move the cooling water back and forth between the storage tanks and pipes. Sodha et al. [92] and Nahar et al. [93] studied the water cooling of an open-air roof pond system with movable thermal insulation through evaporation and nocturnal radiation, experimentally and analytically.

Figure 14.

(a) Open-loop cooling system [90] and (b) Closed-loop cooling system [91].

With the aid of experiments, Chen et al. validated the model set up of a roof pond that was connected directly to a room where water was sprayed over floating-coated insulation [9]. In a roof pond consisting of gunny bags floating on the water’s surface, Tang et al. [94,95] presented the theoretical analysis and experimental study of WBC systems by use of night sky thermal radiation and evaporation. To increase the efficiency of the WBC systems, Spanaki et al. [96] introduced 12 different types of rooftop pools, inspected their benefits and drawbacks, and went over the detailed design requirements. Roof ponds may be one of the more effective PRC methods, but there are still a number of significant problems limiting their widespread use.

Meiret et al. [15] used an open-loop radiative system in Oslo that consisted of a 5.3 m2 radiant and a 280 L tank to confirm that it can provide the cooling requirements of the majority of standard homes, with the exception of the midsummer time when relative humidity is high. Despite the fact that these are affected by outside humidity, open-loop cooling systems are still capable of achieving efficient PRC. However, according to Givoni [88], the wet-bulb temperature (WBT) of the environment must be less than 20 °C for the system to work effectively. This led to a further study of closed-loop WBC systems. In the intervening years, Goldstein et al. [97] proposed a non-evaporative water-cooled panel system with a cooling power of 40–70 W/m2 and a temperature of the water reduction up to 3–5 °C for particular water flow conditions. The installation of this system in a two-story building can cut summertime electricity usage by 21%. The system suggested by Zhao et al. [98] produces water that is 10.6 °C cold under direct sunlight with the use of glass polymer. This system’s nocturnal cooling capacity was found to be 1296 W at a rate of 64% to 82% energy savings. WBC systems use nocturnal radiation to store energy and produce cold water for DPRC. Although achieving a lower outlet temperature and pursuing a greater cooling intensity conflict, a lower outlet temperature results in inadequate cooling of cold water, which limits the application. Two processes of heat transfer are involved in the space’s heat dissipation in WBC systems: first, heat is transferred to the water in circulation, and then, via the radiator, heat is released into the atmosphere. Therefore, WBC systems are frequently integrated with other advanced technologies because of these factors.

A summary of the materials, structures, and radiative properties of the radiators designed for nocturnal cooling can be found in Table 1.

Table 1.

An overview of the material composition, structures, and characteristics of a radiator designed for nocturnal cooling.

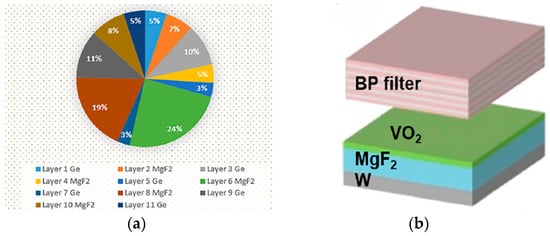

4.3. PRC Materials for Daytime (Diurnal) Cooling

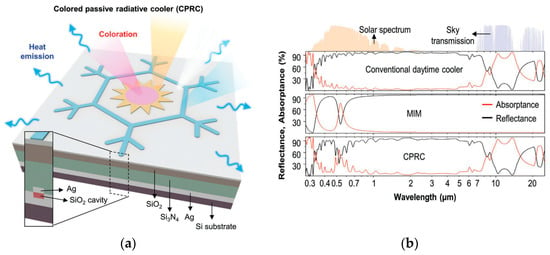

DPRC is more fascinating than nocturnal cooling, however, it also poses quite a challenge due to the need to design, fabricate, and optimize structures that can reflect sunlight as well as maximum emission within the entire atmospheric window wavelength. Several advanced materials, including metal oxides, nano-photonic structures, bio-mimetic (manmade) materials, polymer-based porous films, metamaterial, paints, and coatings are described that are efficient at meeting sub-ambient daytime cooling under direct sunlight. It is, therefore, the purpose of this section to discuss recent developments in radiative cooling materials, particularly DPRC materials.

Owing to its high reflectivity within the visible wavelength range, a number of metal carbonates and oxides, such as those of aluminum, zinc, titanium, and silver, are found to be suitable for this application [117]. Besides that, a few other researchers tried to study PRC during the day and used various shields to avoid solar irradiation. In many applications, especially those involving large surfaces, it is impractical to shade the radiative cooling surface from the sun. A nanostructured metamaterial, for instance, has the ability to both reflect solar irradiance and emit strong thermal radiation throughout the entire atmospheric window wavelength. Ideal absorbers, reflectors, and spectral filters can now be developed using metamaterials. These artificial structures are capable of realizing a wide range of optical properties that do not exist in nature. In addition, with the competence to collectively activate the electromagnetic resonators within random metamaterial structures to procure ideal emissivity, random optical metamaterials can significantly reduce the temperature during the day by radiative cooling [2,117].