1. Introduction

With the expansion of new energy grid connections, energy storage technologies, key technologies for new power systems, are considered as an important means to make the new energy output stable [

1,

2,

3]. The household energy storage market boomed around the world in recent years, with the global market size reaching USD 7.5 billion with the Chinese market size arrived at USD 1.337 billion, equivalent to CNY 8.651 billion by 2022. These numbers are expected to reach USD 26.4 billion and USD 4.6 billion, respectively, in 2027 [

4]. However, with the increase in the number of users, a large number of household energy storage products will reach the end of their lives. If they are not properly handled, the precious metal materials used to manufacture the products will be wasted and cause pollution to the environment [

5,

6]. In addition, the research on household energy storage is still at a relatively new stage, and its recycling system has not been established, and there is also a lack of corresponding policies and management methods. At present, household energy storage products have entered the market for only just over ten years and are at the front end of the product development life cycle. In order to promote the sustainable development of the household energy storage market, the key driving force is the efficient recycling of household energy storage products. Therefore, how to assess the recyclability of household energy storage and how to build an efficient recycling system for the enterprises to further promote its sustainable development are emerging as urgent issues which need to be dealt with.

For the study of distributed energy storage like household energy storage, Stuart Speidel and Thomas Bräunl discussed the feasibility and limitations of various renewable energy sources, energy storage, grid connections, and off-grid systems. In addition, they have studied the effect of combining household energy storage with renewable energy generation [

7]. Bila [

8] proposed that the household energy storage system will become the next generation of household appliances in the smart grid environment in addition to the growth of electric vehicles using lithium-ion batteries. Sander et al. [

9] pointed out that household energy storage (HES) and community energy storage (CES) are two promising energy storage schemes for residential power producers, and evaluated and compared the technical and economic feasibility of these two schemes. Sd et al. [

10] studied the technical, environmental, and economic assessment of household energy storage and community energy storage in the UK, and found that both household energy storage and community energy storage can significantly reduce the peak power input and output of the grid, improve the community self-consumption rate (SCR) and self-sufficiency rate (SSR), and contribute to higher energy efficiency. Tungadio et al. [

11] improved off-grid household energy storage by developing a control for the battery storage system based on embedded supercapacitors. In addition, scholars have studied the flexible regulation of distributed energy storage in the distribution side of new power systems, offering new methods to enable the stability of electric systems [

12,

13]. Based on gray correlation analysis, Lv Zheqing and Xiu Jiapeng et al. [

14] have made assessments. The similar trend as the variation of battery capacity with mileage can evaluate the discharge capacity of the battery from the actual working conditions and provide a reference for a more comprehensive assessment of the battery health. The EKPF algorithm proposed by X. H. Du and B. Y. Li [

15] correctly estimated the SOC of the energy storage battery, thus providing a reference for the construction of the operating conditions of the energy storage battery and its performance test. Zhang Xiaoyuan and Jin Hao et al. [

16] put forward a method to evaluate the SOH of power battery based on an improved temporal convolutional network model, which improved the evaluation accuracy and computation time.

In addition, as for recycling, Mou Siyu and Han Xiaogai et al. [

17,

18,

19,

20] analyzed and summarized the development status and existing problems of waste power battery recycling and gave some corresponding countermeasures and suggestions. In terms of recovery and treatment technology, Lei et al. [

21] analyzed the recovery technology of waste batteries, battery composition, and the harm of common electrolytes and organic solvents to the environment and health, and also discussed the potential social security issues and environmental risks in the process of waste battery recovery. Lu Nali et al. [

22] introduced in detail the recovery methods including fire recovery, wet recovery, high temperature solid phase recovery technology, bioleaching technology, mechanical activation treatment recovery technology, electrochemical methods, and other recovery methods. Among them, hydrometallurgy and pyrometallurgy are currently widely used as the main recovery methods for the extraction of battery raw materials [

23]. Wang Bin et al. [

24] described the recovery methods of metal ions in the leaching solution of waste lithium ion batteries globally, and focused on the impact of different methods such as precipitation, deposition, and ion exchange in the wet process on the recovery rate of Co

2+, Mn

2+, Li

2+, and other valuable metal ions in the leaching solution. Gavin Harper et al. [

25] sorted out the development trend of waste batteries and the shortcomings of various recycling technologies in detail, evaluated the current situation of various technologies, and looked forward to future development directions. Tian et al. [

26] performed a comparative study of the main waste lead-acid battery recovery processes in China, and analyzed their economic benefits using the technology cost model based on the local material and energy market prices. Ciez et al. [

27] examined the different recovery processes for lithium-ion batteries and compared the carbon emissions of three recovery technologies (pyrometallurgical recovery, hydrometallurgical recovery, and direct cathode recovery). They found that direct cathode recovery had the potential to reduce emissions and is economically competitive.

In terms of recycling network, Zhang Xuemei [

28], Yao Peifan [

29], and Chen Wei et al. [

30] combed through the recycling standards which have been published or under research and focused on the specific processes of the recycling link and the potential of key resource recovery in retired power batteries. The rise of the recycling rate can effectively alleviate the foreign dependence of key resources required for the production of power batteries, and provide a reference for the industry to recycle used power batteries. Zhong Tong [

31] envisioned a variety of recovery models in reverse logistics, and made a comparative analysis from the perspective of purchase and construction costs, operation risks, etc., and also built a reverse logistics recovery network. T.Li Hsing and Dong Jingfeng et al. [

32,

33,

34] proposed applying a mixed integer programming model to reverse logistics mathematical modeling, and took cost minimization as the objective function to solve the location/allocation problem of the reverse logistics network. Xiong Haiou and Hu Yongjun et al. [

35] used an approach of system dynamics according to the characteristics of blockchain technology to construct a reverse logistics network model of new energy vehicle batteries and analyzed its features. Furthermore, they simulated the model and put forward the policy suggestions. Geng Liyan et al. [

36] designed the reverse logistics network of lead-acid batteries for vehicles, and explained the functions of each logistics node. Finally, suggestions were put forward to improve the reverse logistics network structure for the government, enterprises, and the public. Li Jian [

37] analyzed the characteristics of reverse logistics of household waste batteries in medium-sized enterprises based on green logistics, and provided the construction elements of logistics recycling networks for waste batteries in medium-sized enterprises. Finally, the design scheme and development suggestions of a waste battery logistics recycling network suitable for medium-sized enterprises were put forward. Zhu Lingyun and Chen Ming et al. [

38] have studied the reverse logistics mode and recycling network of waste power batteries, and studied the reverse logistics mode selection of waste power batteries using a fuzzy comprehensive evaluation method. Wu Jie [

39] used Stackelberg game and Bertrand game methods to analyze the existing power battery recovery models of company B, and compared the reverse supply chain decision making under different recovery models, aiming at the reverse supply chain composed of battery supplier, vehicle manufacturer company B, and informal battery recovery enterprises. Shao Zhufeng and Liu Xinyuan et al. [

40] attempted to reach echelon utilization of waste power batteries by leasing, selling, and extracting precious metals by dismantling. After comparing the overall profit of the reverse recycling supply chain, the batteries can be recycled optimally when profit was maximized. Yu Wei et al. [

41] calculated the discharge at different life cycles in line with system structures of new and retired batteries used in energy storage power station. In terms of carbon emissions, it was obtained through the echelon utilization of retired power batteries.

In summary, the majority of the above studies focused on the reverse supply direction, and rarely combined the forward and reverse directions for the purpose of analysis and study. On one hand, there is almost no relevant literature on the design of household energy storage recycling systems, and the academic community lacks research on the recycling aspects of household energy storage at the manufacturing enterprise level. On the other hand, each individual household energy storage product has a distinct level of quality when it comes to recycling. In accordance with the current research on product recycling, the majority of the research focused only on reducing production costs and increasing revenues by recycling raw materials, ignoring the fact that divergent recycled products have distinct quality levels. Furthermore, the design and optimization of recycling networks also have a crucial impact on environmental improvements, and yet most of the literature to date has only singularly considered the economics of the recycling process, with few environmental benefits being integrated throughout the recycling network.

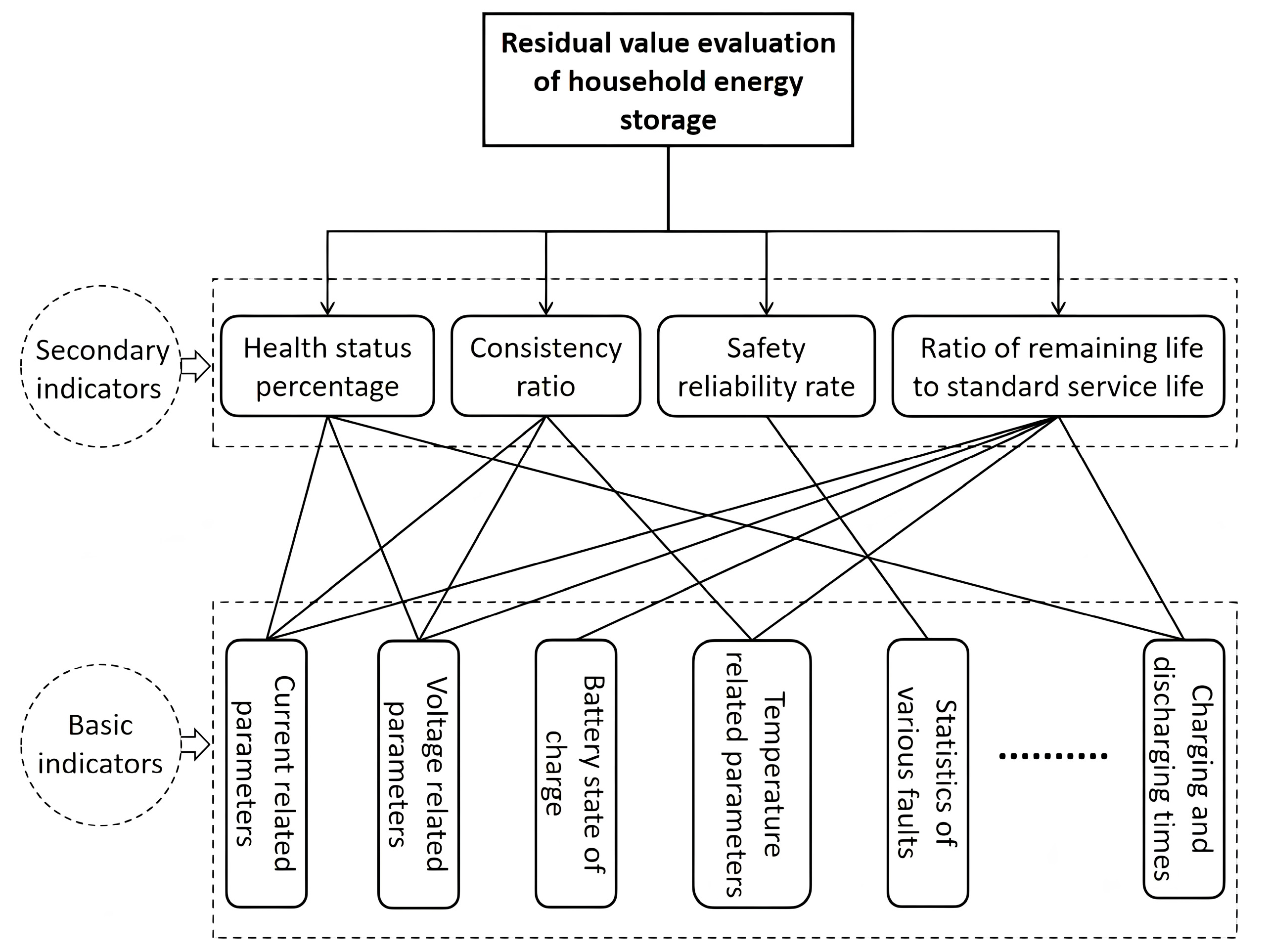

Consequently, to address the above issues, this paper introduces a closed-loop supply chain model and constructs a recycling system that combines forward supply and reverse recovery for household energy storage. On this basis, in order to make this paper more suitable for the development background of the global low-carbon economy, we also study how carbon emissions will affect the design of the household energy storage and recycling system. At the same time, considering the different levels of recovered product quality, this paper further analyzed a series of evaluation indices for the recovery status of household energy storage and constructed a residual value evaluation system for household energy storage. In addition, by classifying household energy storage through the evaluation results, this paper analyzed three distinct recovery strategies, which were assigned to divergent processing centers in the recovery network to achieve the optimization of the whole system. Ultimately, through a case study of the Sichuan and Chongqing regions and the comparative analysis of the scenarios set up by the simulation by changing each factor, this paper verified the feasibility and validity of the model and gives some effective industry suggestions to enterprises on the basis the research results.

2. Construction of Household Energy Storage Recycling System

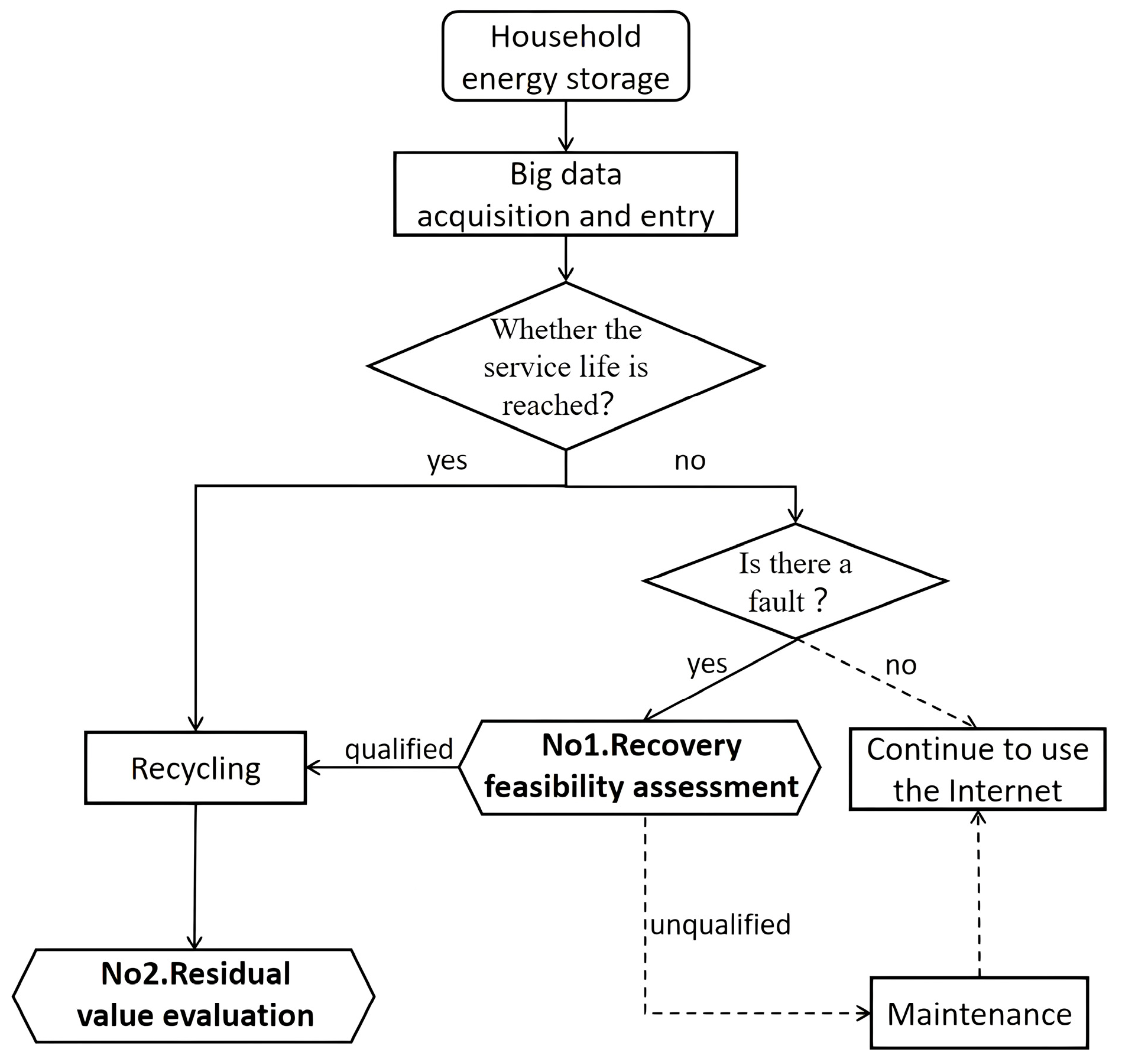

The household energy storage recycling system constructed in this paper is shown in

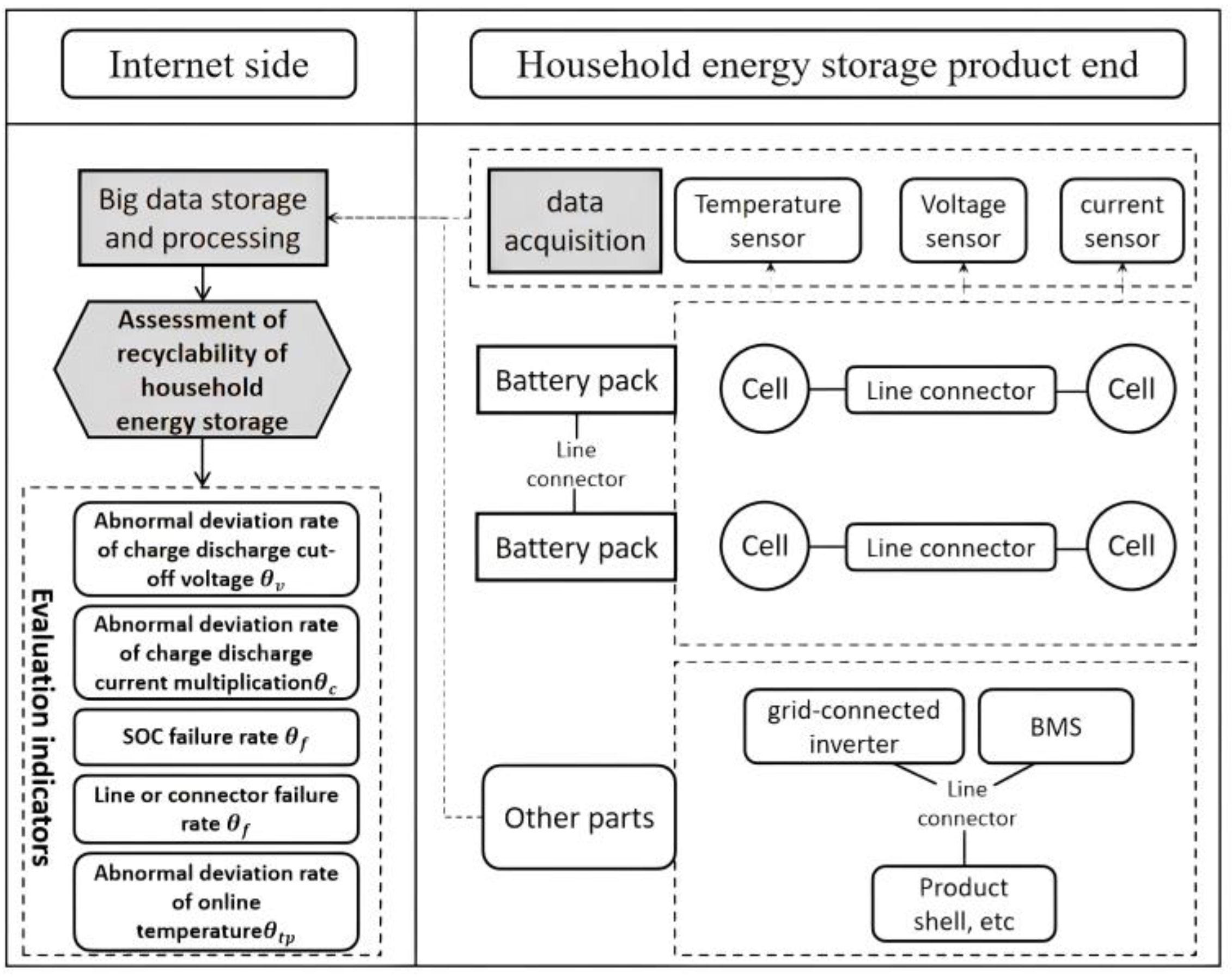

Figure 1. The figure considers a forward supply consisting of manufacturing plants, distribution centers, and sales/collection centers. In addition, the household energy storage manufacturing recycling system, which consists of the reverse supply to the sales/collection center, the recycling center, the waste treatment center, and the manufacturing plant. In the recycling process, the blockchain technology was used to record the source of recycled household energy storage, the detailed data of each center, the flow direction of recycled materials, transaction records, and other information.

In the forward supply stage of products, the raw materials of the manufacturing plant can be supplied by the material supplier or by the raw materials extracted from the recycling center. The manufacturing plant flows into the distribution center for distribution processing after manufacturing the household energy storage products, and then further transports the products to the nearby sales center through the distribution center, and finally sells the products to consumers through the sales center.

In the reverse recovery stage, the sales center plays the role of collecting waste household energy storage products from nearby consumers. First, household energy storage can introduce artificial intelligence, Internet Plus, and other practices and governance mechanism modes into the connection between consumers and the power grid, so as to realize the transmission and sharing of data with the power grid. At the same time, the recyclability and residual value of household energy storage can be evaluated in real time by storing the charging and discharging fault data when the household energy storage is connected to the Internet and conducting big data screening and analysis. Through the final residual value evaluation results, three different recovery strategies were adopted for household energy storage products of different quality levels, namely, directly flowing into the manufacturer’s factory, reassembling, replacing, and refurbishing parts and components to continue to use (M1); transport to the recycling center to extract metal raw materials, and transporting the extracted raw materials to the manufacturer’s factory for new domestic energy storage manufacturing (M2); and directly transporting to the waste treatment center for treatment (M3). Through this more detailed recycling process, the system optimization in the recycling process can be better realized. In addition, the parts can be disassembled at the product site and sold to a third party processing agency for processing

5. Example Analysis

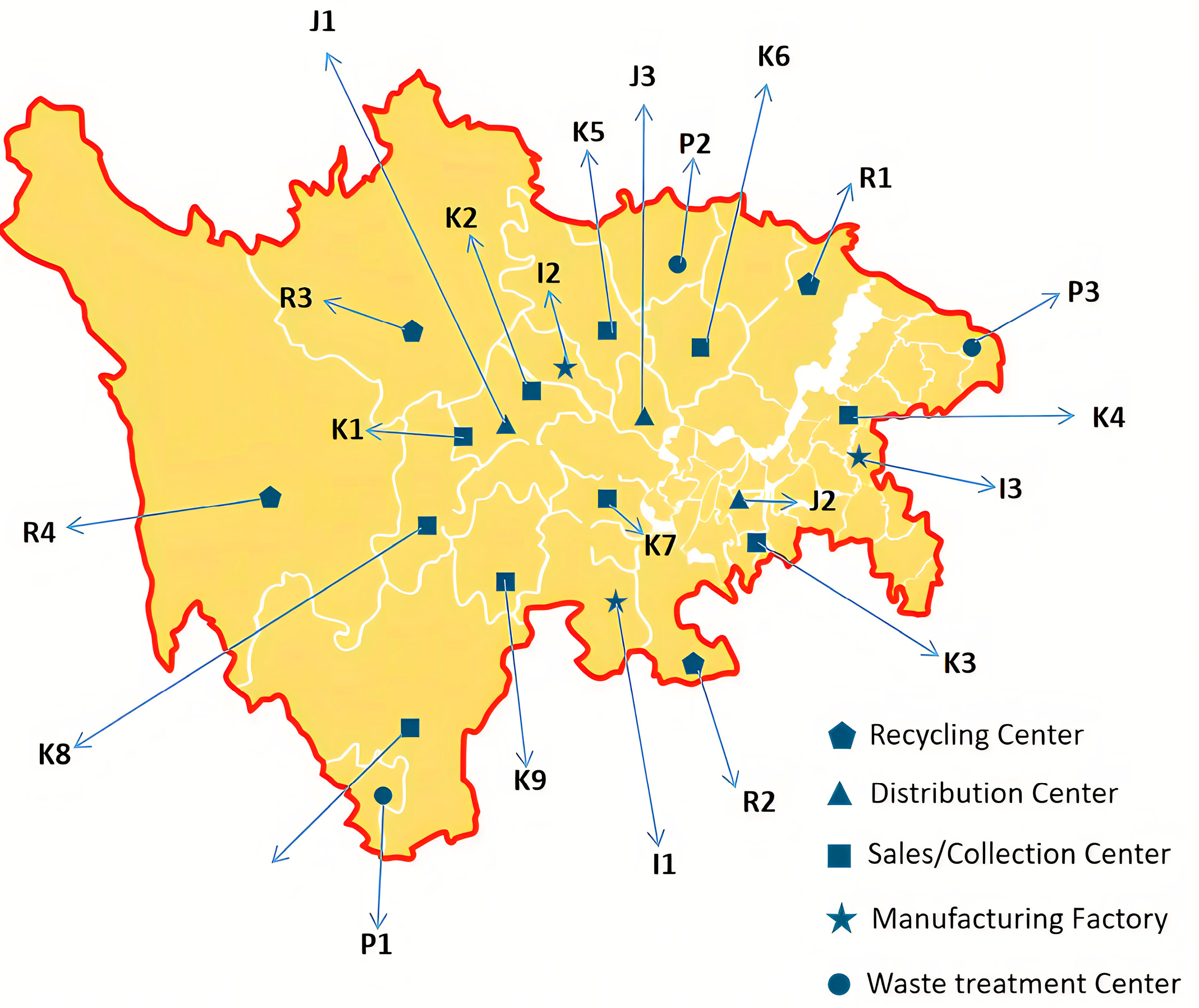

In this paper, the Sichuan and Chongqing region is taken as the main service area of household energy storage Enterprise X. Through the low-carbon recycling system model of household energy storage based on recovery evaluation, the relevant parameters of domestic energy storage are shown in

Table 12; the geographical environment, energy consumption structure, industrial structure, per capita GDP, and other factors of the Sichuan and Chongqing regions are considered. Finally, three alternative manufacturing plants, three alternative distribution centers, four alternative recycling centers, three alternative waste treatment centers, and ten alternative sales/collection centers were selected, as shown in

Figure 5. The location of each processing center is determined and known. According to the longitude and latitude of each node, the distance between each processing center is calculated based on the Gaode open platform. See the

Appendix A Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6 and

Table A7 for specific data. In addition, the enterprise has 27 fixed and known consumption centers, and the market demand and recovery volume of each consumption center are known. See

Appendix A Table A13 for details.

According to the research of Paul et al. [

42], consumption of 1 L diesel fuel can generate about 0.0718 kg of carbon dioxide emissions, while the normal fuel consumption of a truck with a load of about 6 tons per kilometer is about 0.308 L, so the unit carbon emissions of Enterprise X in the product transportation process can be calculated to be about 0.0036 kg CO

2/(ton·km). In addition, each treatment center, treatment cost, unit carbon emission, and treatment capacity are determined and known. See

Appendix A Table A8,

Table A9,

Table A10,

Table A11 and

Table A12 for the relevant data.

5.1. Verification and Analysis of Household Energy Storage Recycling System for Enterprise X Considering Recycling Evaluation

To verify the effectiveness of the system model, two schemes were adopted for comparison, among which scheme 1 is the benchmark scheme, that is, the case of direct recycling without considering the quality of the household energy storage products. Scheme 2 is the recycling model proposed in this paper, that is, we considered the different quality levels of the household energy storage products during recycling, and the situation of adopting three different targeted recycling strategies and distributing them to different processing centers in the recycling network was evaluated. In this paper, we used lingo18 as a platform for us to build the model of programming and simulation; scheme 1 and scheme 2 recycling network as shown in

Figure 6 and the total profit and total carbon emissions results are shown in

Table 13.

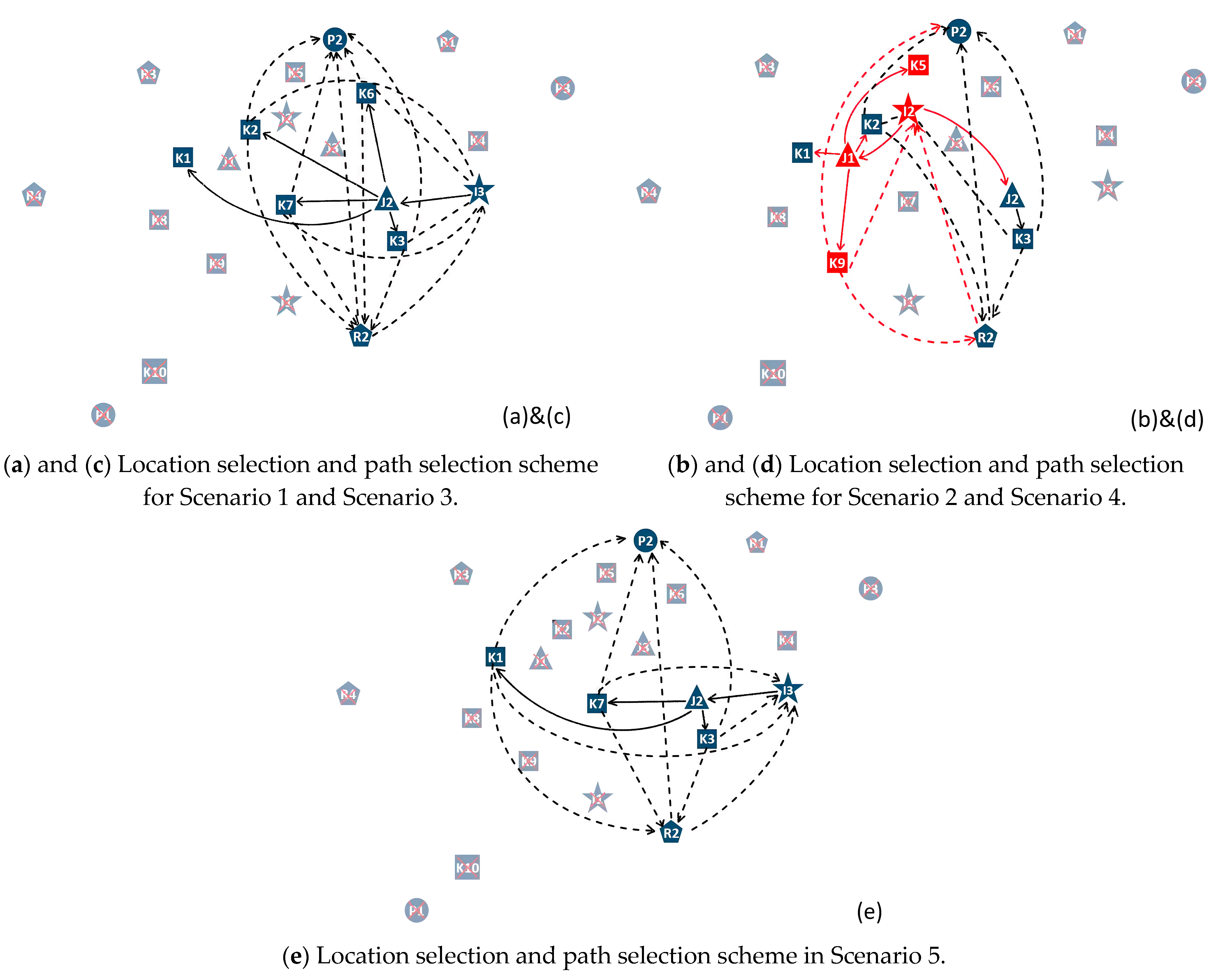

The blue dashed line and the red dashed lines in

Figure 6 show the new recycling strategy, and the red nodes indicate the newly opened center compared to the traditional scheme. It can be seen from the experimental results that the optimized scheme 2 recycling system changed the selection of sales/collection centers, and accordingly, the transportation scheme and route between the centers were also changed, and finally, the overall profit of the household energy storage recycling system was increased by about CNY 1,610,004, and the carbon emissions were reduced by about 1,040,006 kg. These data further verify that it is effective and feasible to adopt different recycling channel optimization schemes for different recycling quality levels after evaluation.

5.2. Evaluation of Scenario Analysis of Household Energy Storage Recycling System for Enterprise X Considering Recycling State

According to the optimization model constructed in this paper and Enterprise X results analysis, it was found that there are many factors affecting the cost, location, and path of the household energy storage low-carbon recycling system. Therefore, we set up five scenarios to simulate the impact on the site location, path, economy, and environmental benefits of the household energy storage recycling system when the various factors were changed.

Scenario 1 (a): Assuming that this case is the reference case, all the parameters are set at the standard level;

Scenario 2 (b): Assuming that the manufacturing plants and recycling centers introduce more advanced processing technology, reducing the processing costs of the manufacturing plants and recycling centers by 60% and 50%, respectively;

Scenario 3 (c): Assuming that each treatment center adopts more advanced emission reduction technology, the unit carbon emissions of each treatment center are reduced by 60%;

Scenario 4 (d): Assuming that the global oil prices rise due to the decline in the DOLLAR index or as an impact of war, the unit transportation costs increase by 60% compared to the original benchmark;

Scenario 5 (e): Suppose that the number of household energy storage products processed at the collection/sales center increases by 55% compared to the original benchmark;

The total profit and cost details in the different scenarios are shown in

Figure 7; the location selection and path selection scheme is shown in

Figure 8.

From the results of (b) and (d), the manufacturing plant changed from I3 to I2, the distribution center added J1, and opened the sales/collection centers K5 and K9 to replace K6 and K7. On the one hand, the improvement of processing technology reduced the unit processing cost; on the other hand, the increase in oil prices increased the transportation cost, which means that the weight of the transportation cost was increased indirectly and directly. After exceeding the economic benefits range of the original location and transportation scheme, the system chose a better location and transportation scheme to maximize the total profits of the whole system.

According to the results of (c), the change of unit carbon emissions of a node had a weak influence on the location selection and path selection of the household energy storage recycling system. From the results shown in (e), the increase of node processing means that some nodes can be considered as meeting the corresponding processing requirements, and the system chose K2 and K6 to reduce the fixed construction cost.