Research on High-Torque-Density Design for Axial Modular Flux-Reversal Permanent Magnet Machine

Abstract

:1. Introduction

2. AM-FRPM Machine Topology

3. Operation Principle for AM-FRPM Machines

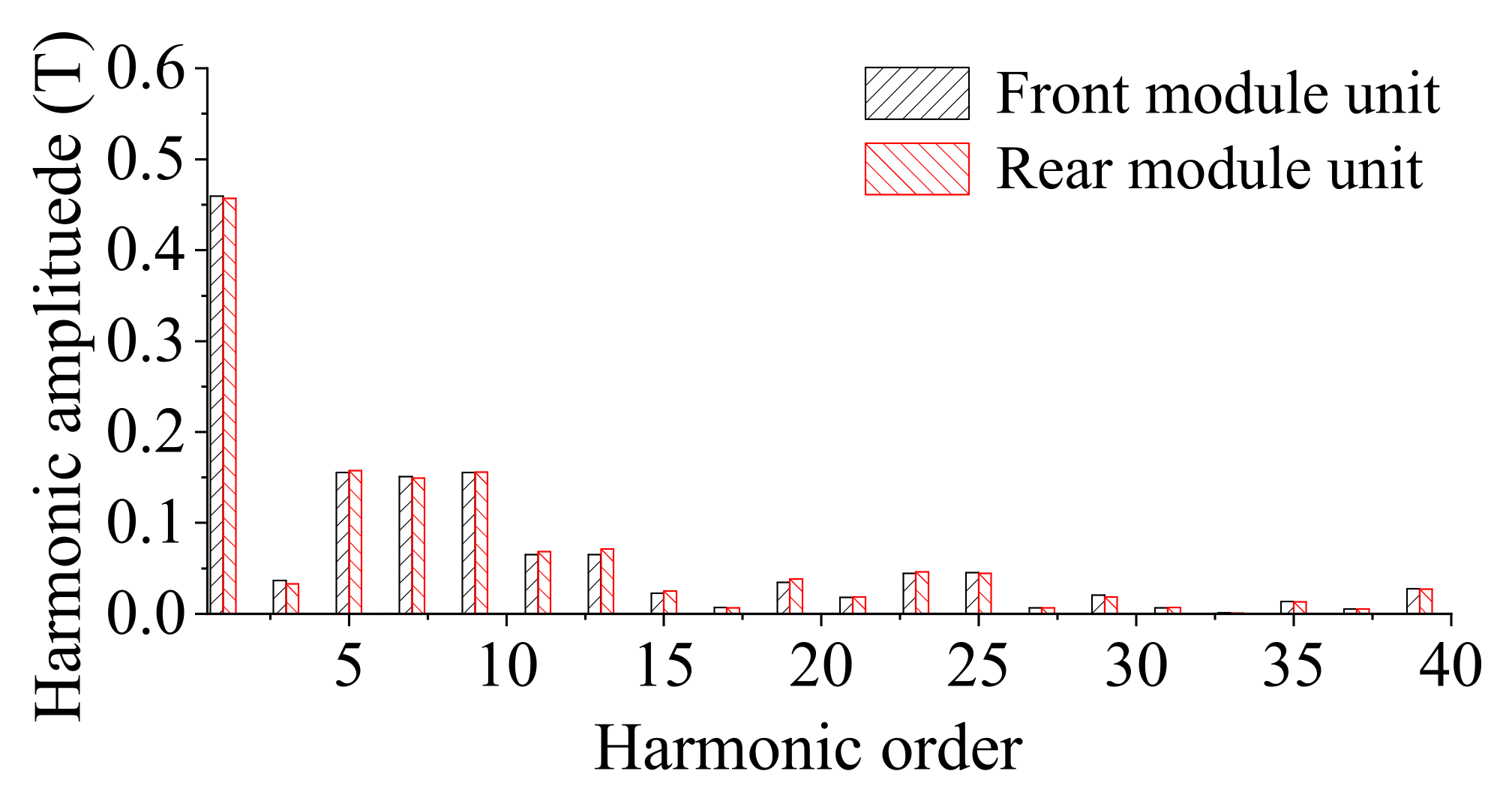

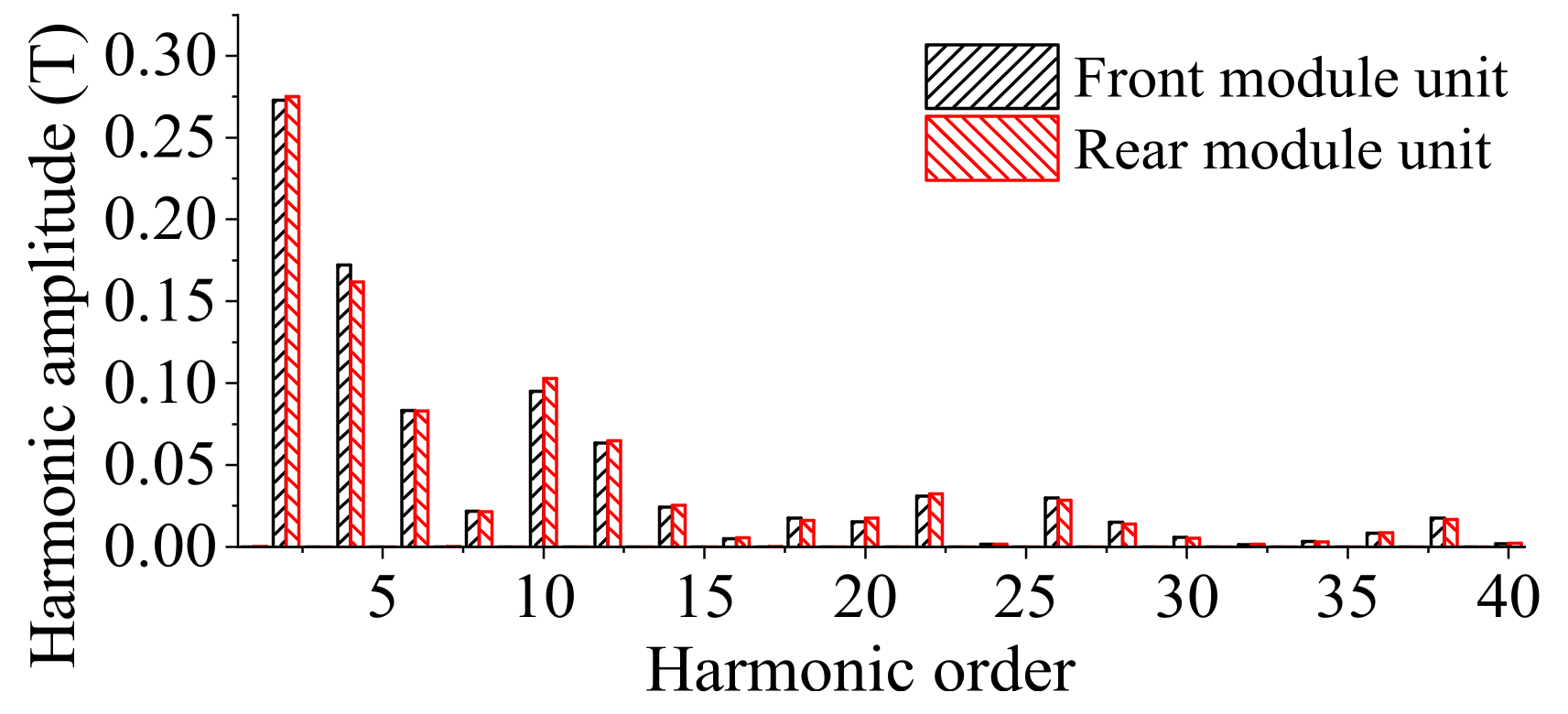

3.1. PM Field Modulation

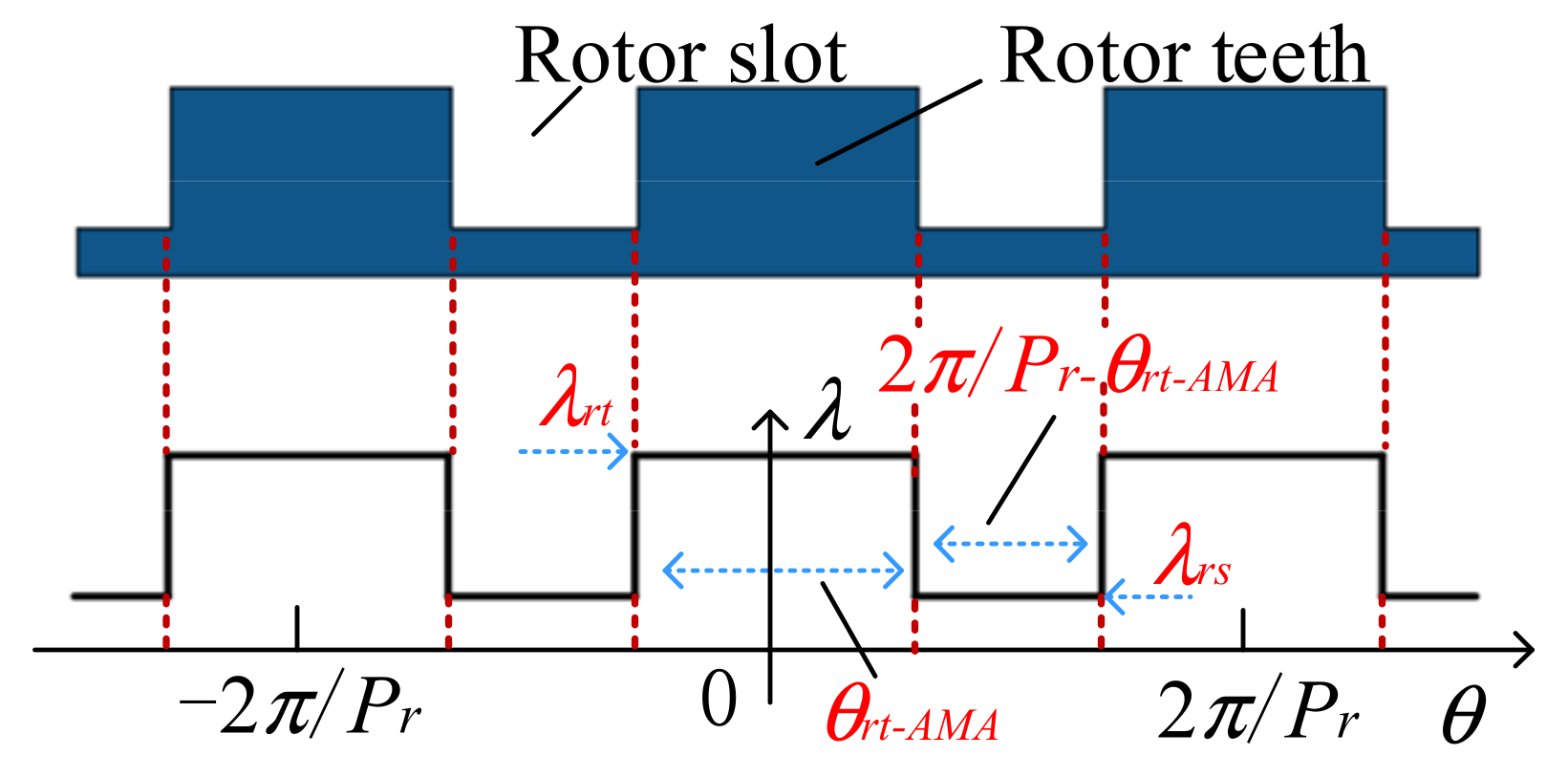

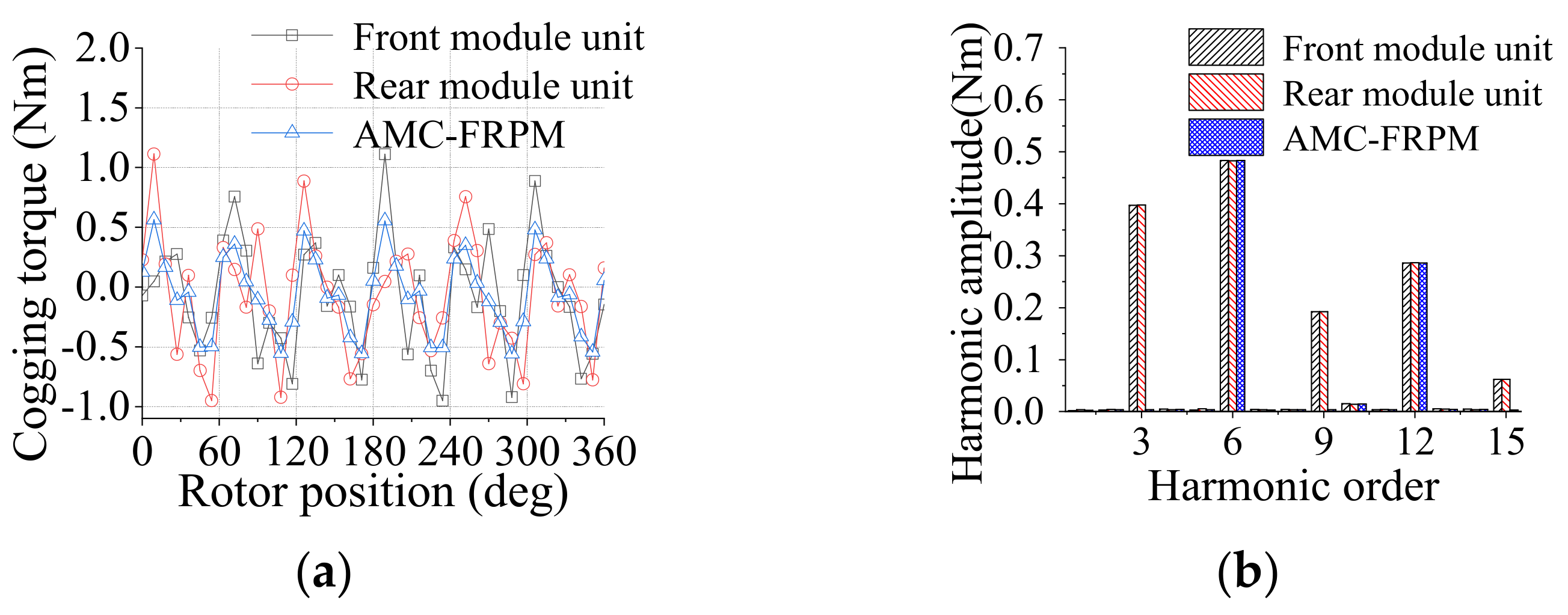

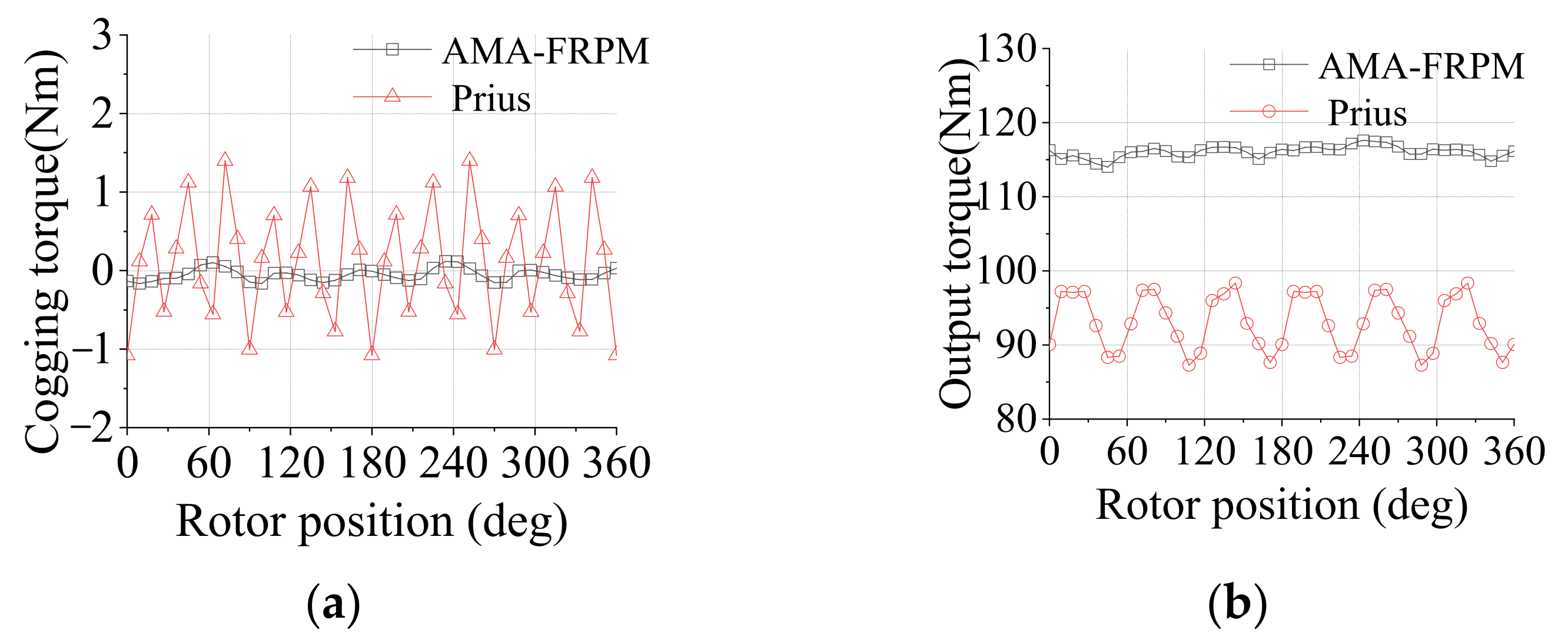

3.2. Cogging Torque

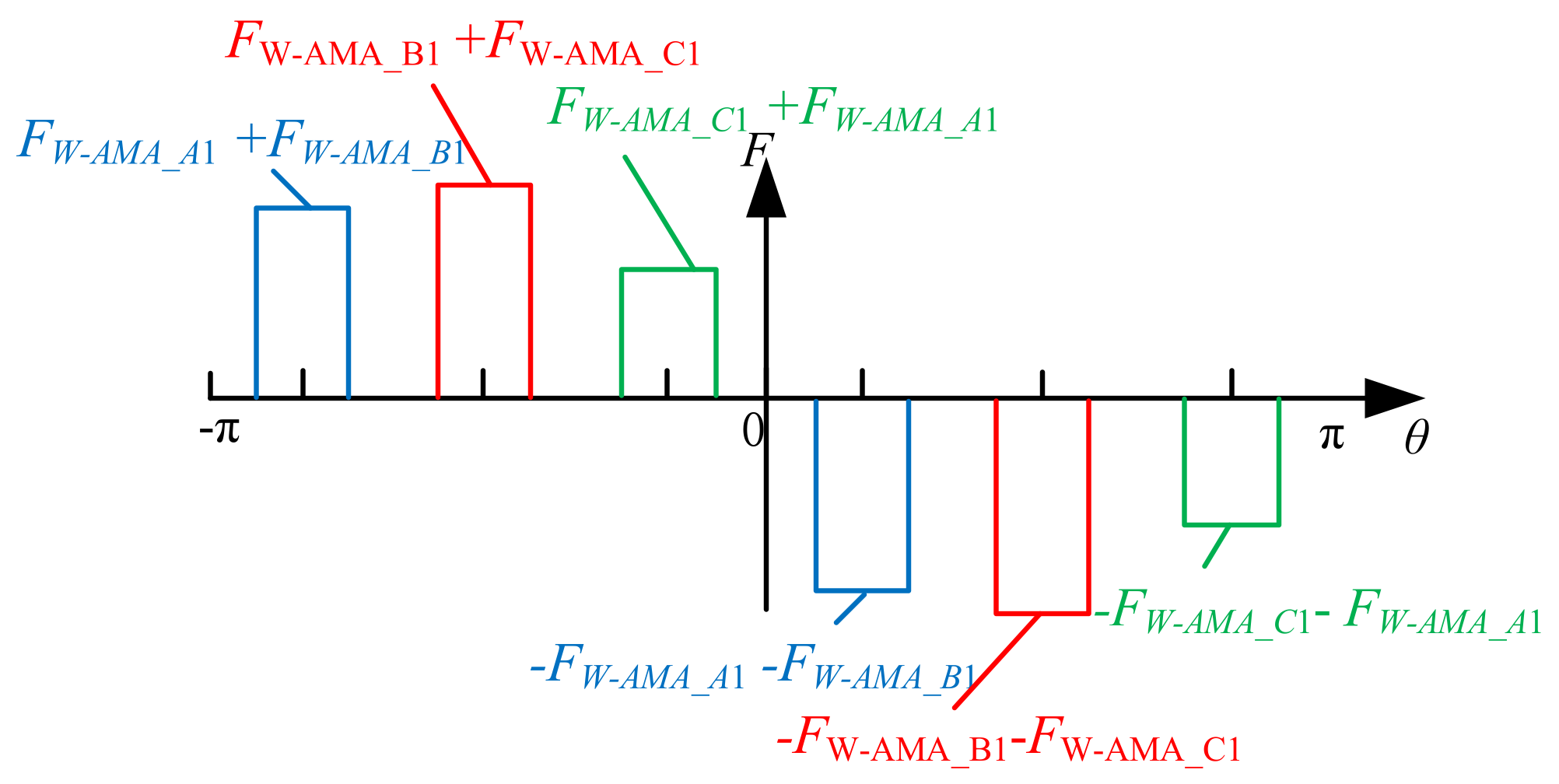

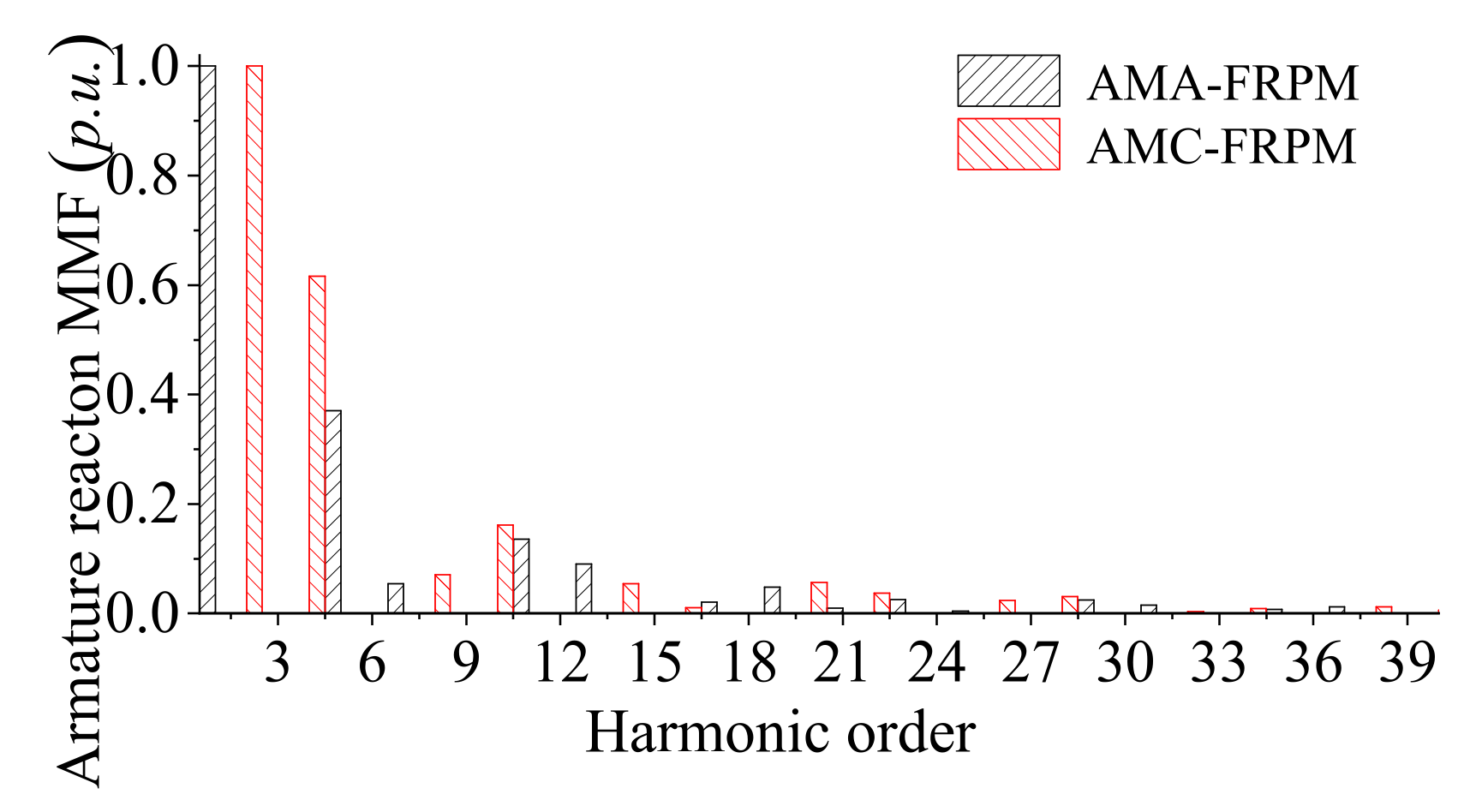

3.3. Modulation Principle for Armature Reaction Magnetic Field in AM-FRPM Machines

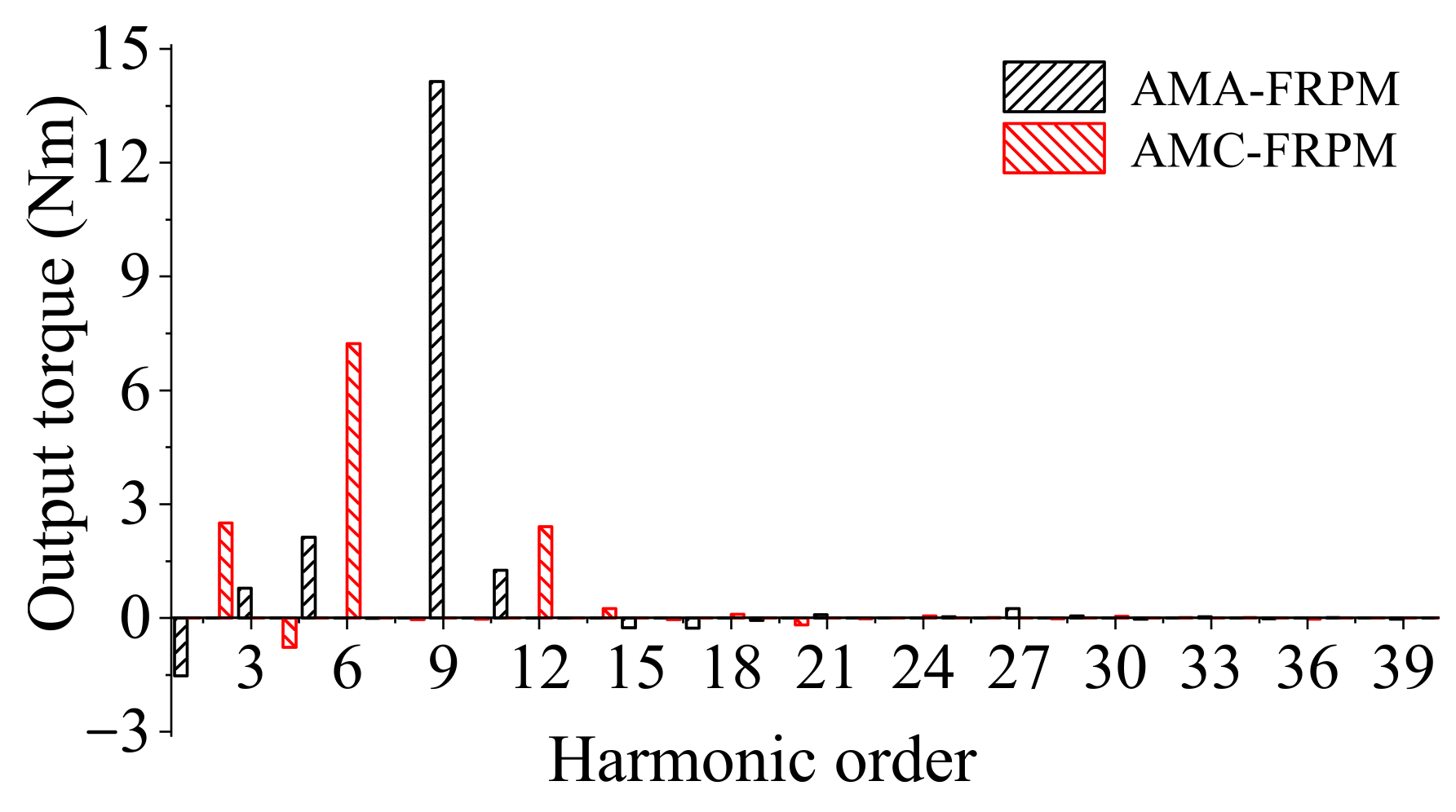

3.4. Electromagnetic Torque

4. Electromagnetic Characteristics Analysis

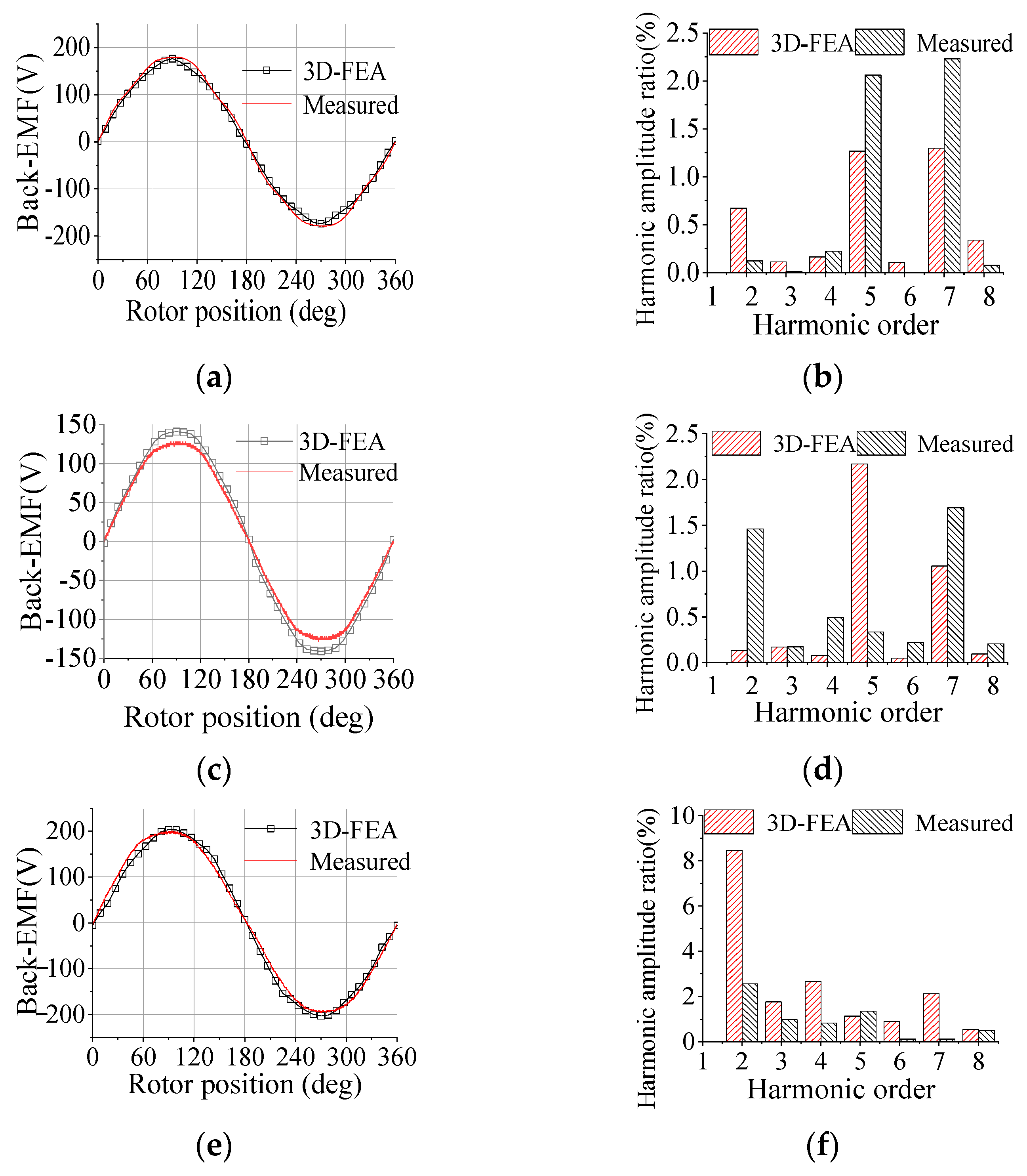

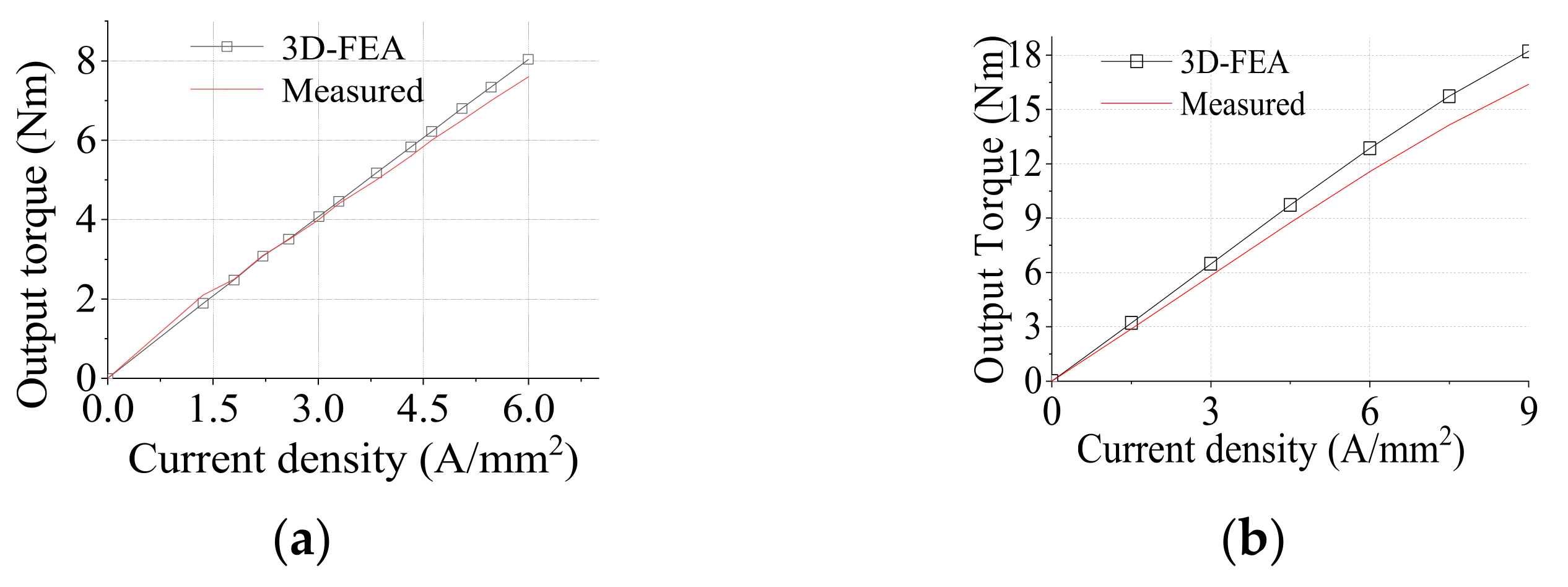

5. Experiment Validation

6. Conclusions

- (1)

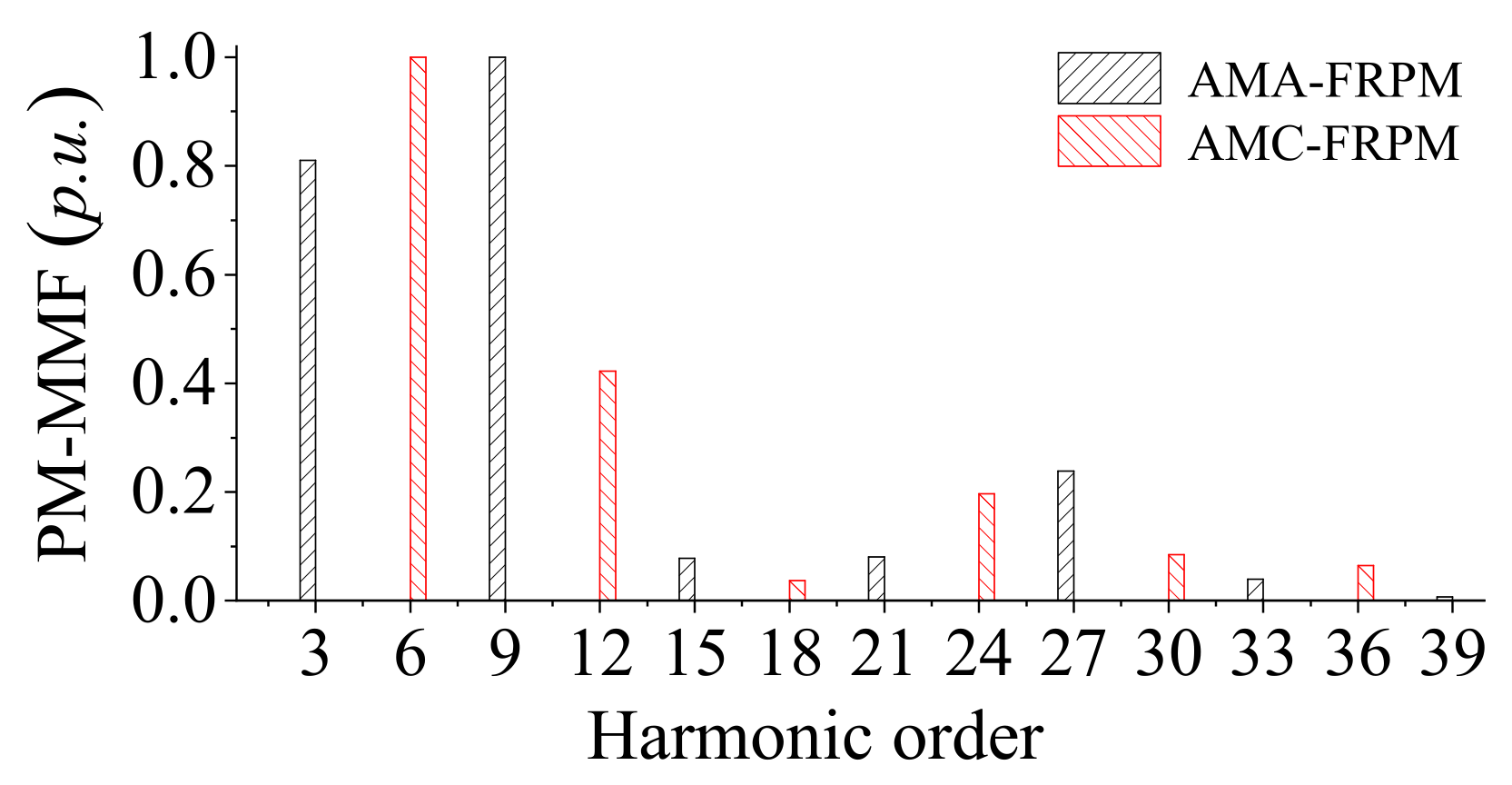

- The electromagnetic torque of the AMC-FRPM machine is mainly generated by the fundamental harmonic of the PM-MMF (nPs, (n = 1)), while the torque of the AMA-FRPM machine is mainly generated by the third harmonic of the PM-MMF (nPs/2 (n = 3));

- (2)

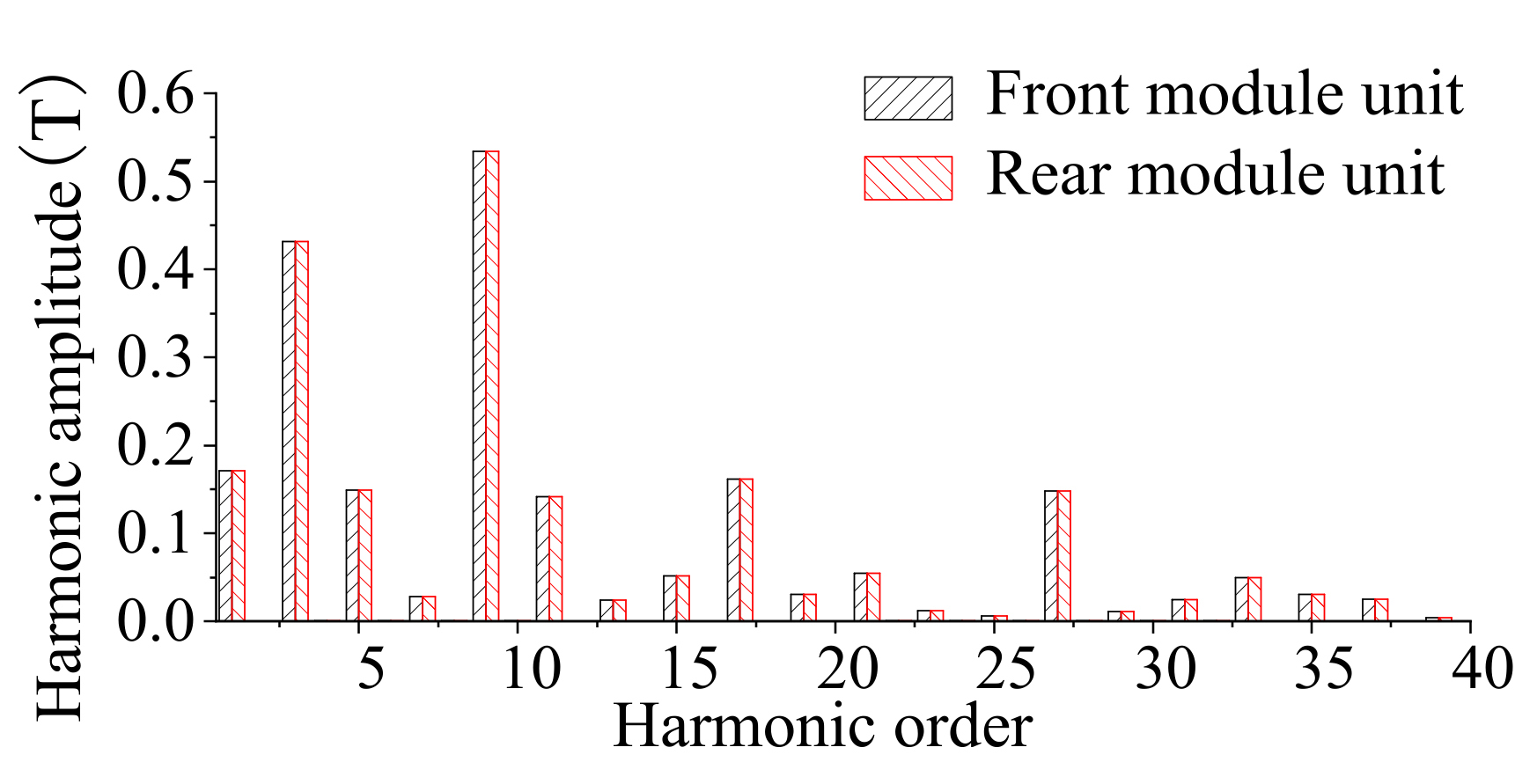

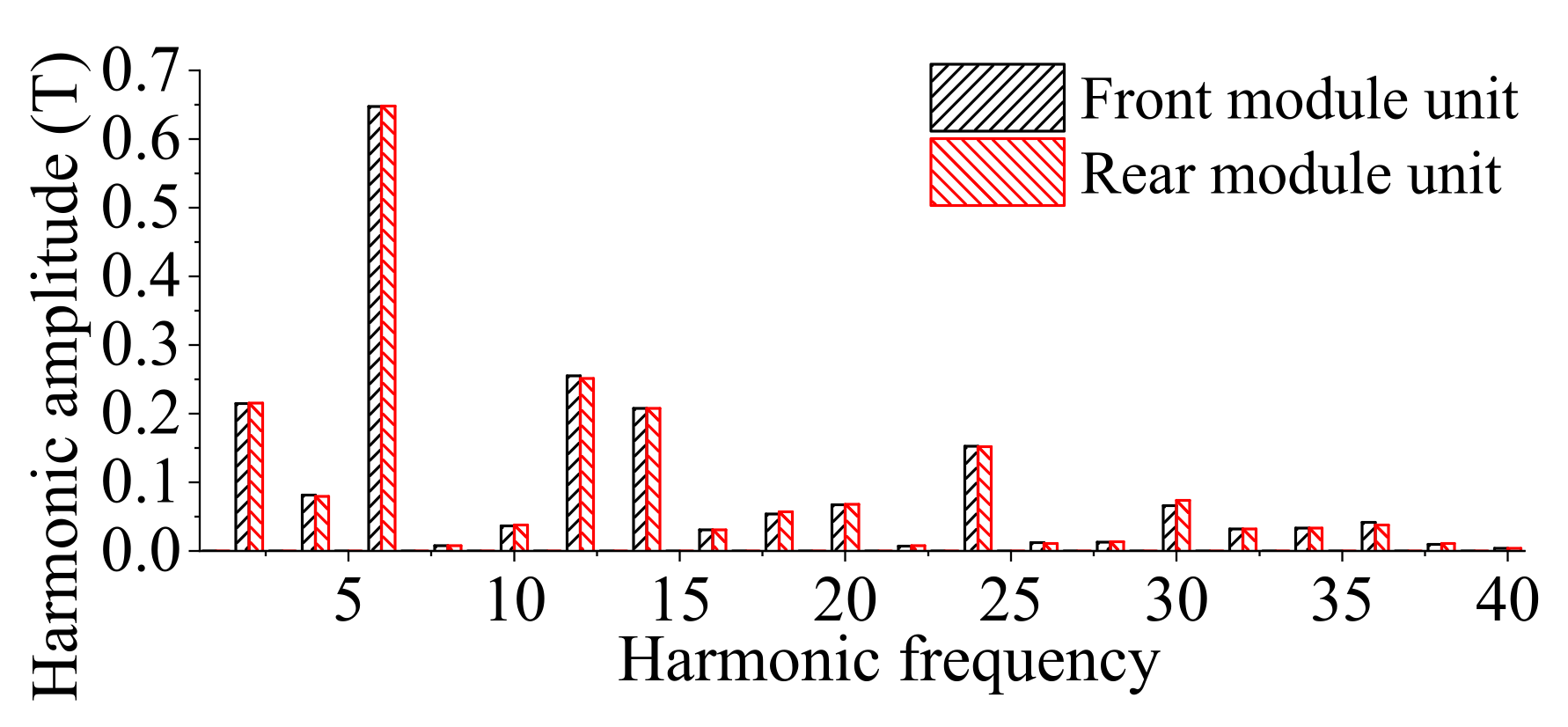

- With regard to the armature reaction air-gap flux density, the amplitude of the ninth (nPs/2 (n = 3)) harmonic in the AMA-FRPM machine is 1.85 times that of the sixth (nPs, (n = 1)) harmonic in the AMC-FRPM machine. Moreover, the corresponding difference in the harmonic amplitudes between the PM magnetic fields of the two machines is only 15%. The ninth harmonic of the AMA-FRPM machine generates higher output torque, 1.92 times that of the sixth harmonic of the AMC-FRPM machine, with a better harmonic utilization rate;

- (3)

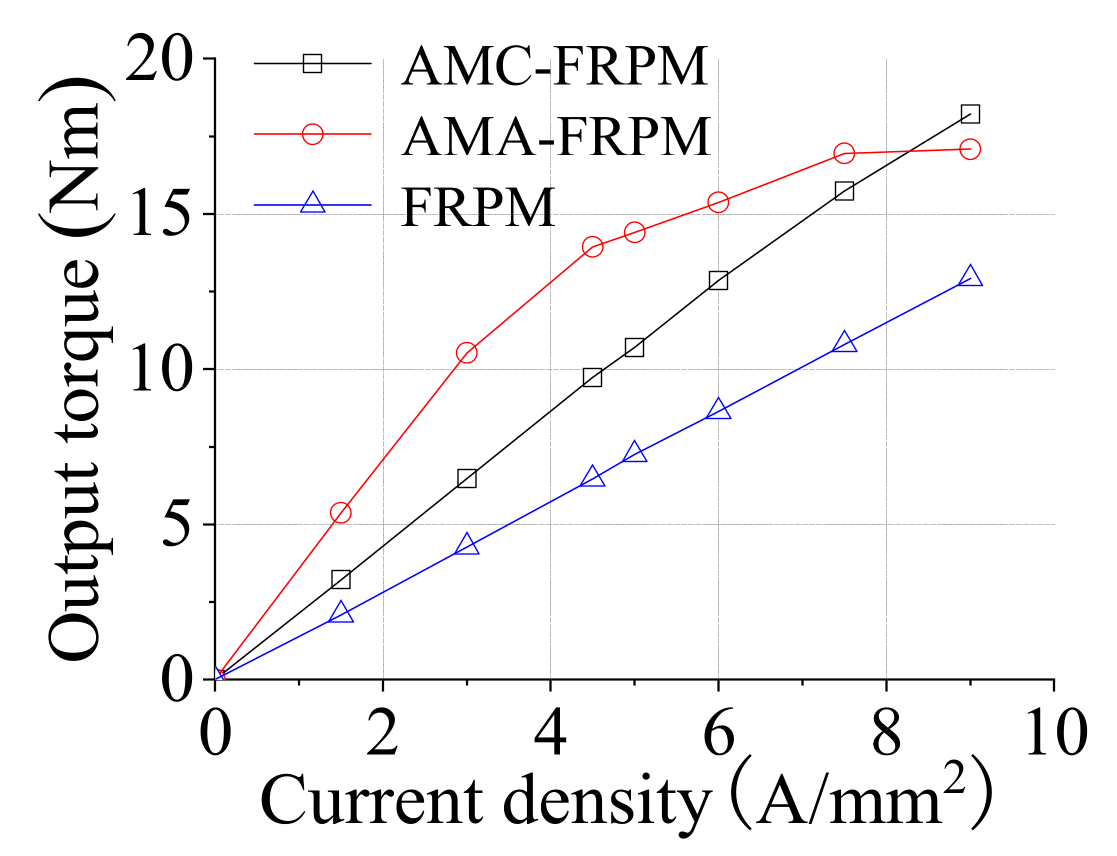

- Due to the toroidal winding and axial module structure, the AM-FRPM machines have the advantages of higher output torque and lower torque ripple compared to FRPM machines. The AMA-FRPM machine has the highest torque output capacity, and the AMC-FRPM machine has a stronger overload capacity;

- (4)

- By analyzing the cogging torque suppression mechanism, it was found that the AM-FRPM machines can cancel the odd-harmonic component of the cogging torque through the combination of module units, providing guidance for the selection of stator-slot and rotor-pole combinations;

- (5)

- Compared to the Prius IPM machine, the AMA-FRPM machine has a better torque output capacity at Jsa < 13 A/mm2. Therefore, the AM-FRPM machine holds promise for application in EVs and HEVs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, W.; Zhu, X.; Quan, L.; Wu, W.; Xu, L.; Liu, Y. Flux-Weakening Capability Enhancement Design and Optimization of a Controllable Leakage Flux Multilayer Barrier PM Motor. IEEE Trans. Ind. Electron. 2020, 68, 7814–7825. [Google Scholar] [CrossRef]

- Jiang, M.; Zhu, X.; Xiang, Z.; Quan, L.; Que, H.; Yu, B. Suppression of Torque Ripple of a Flux-Switching Permanent Magnet Motor in Perspective of Flux-Modulation Principle. IEEE Trans. Transp. Electrif. 2021, 8, 1116–1127. [Google Scholar] [CrossRef]

- Yang, K.; Zhao, F.; Wang, Y.; Bao, Z. Consequent-Pole Flux Reversal Permanent Magnet Machine With Halbach Array Magnets in Rotor Slot. IEEE Trans. Magn. 2020, 57, 1–5. [Google Scholar] [CrossRef]

- Li, H.; Zhu, Z.Q.; Hua, H. Comparative Analysis of Flux Reversal Permanent Magnet Machines With Toroidal and Concentrated Windings. IEEE Trans. Ind. Electron. 2019, 67, 5278–5290. [Google Scholar] [CrossRef]

- Li, H.; Zhu, Z.Q. Influence of Adjacent Teeth Magnet Polarities on the Performance of Flux Reversal Permanent Magnet Machine. IEEE Trans. Ind. Appl. 2018, 55, 354–365. [Google Scholar] [CrossRef]

- Meng, Y.; Fang, S.; Pan, Z.; Liu, W.; Qin, L. Design and Analysis of a New Partitioned Stator Hybrid-Excited Flux Reversal Machine With Dual-PM. IEEE Trans. Magn. 2021, 58, 1–6. [Google Scholar] [CrossRef]

- Xie, K.; Li, D.; Qu, R.; Yu, Z.; Gao, Y.; Pan, Y. Analysis of a Flux Reversal Machine With Quasi-Halbach Magnets in Stator Slot Opening. IEEE Trans. Ind. Appl. 2018, 55, 1250–1260. [Google Scholar] [CrossRef]

- Yang, H.; Lin, H.; Zhu, Z.Q.; Lyu, S.; Liu, Y. Design and Analysis of Novel Asymmetric-Stator-Pole Flux Reversal PM Machine. IEEE Trans. Ind. Electron. 2019, 67, 101–114. [Google Scholar] [CrossRef]

- Vidhya, B.; Srinivas, K.N. Effect of stator permanent magnet thickness and rotor geometry modifications on the minimization of cogging torque of a flux reversal machine. Turk. J. Electr. Eng. Comput. Sci. 2017, 25, 4907–4922. [Google Scholar] [CrossRef]

- Yuansheng, Z.; Baoquan, K.; Xiaokun, Z. A Study of Torque Characteristics of a Novel Flux Reversal Machine. In 2019 22nd International Conference on Electrical Machines and Systems (ICEMS); IEEE: New York, NY, USA, 2019; pp. 1–5. [Google Scholar]

- Kim, T.H.; Won, S.H.; Bong, K.; Lee, J. Reduction of cogging torque in flux-reversal machine by rotor teeth pairing. IEEE Trans. Magn. 2005, 41, 3964–3966. [Google Scholar]

- Kim, J.H.; Li, Y.; Cetin, E.; Sarlioglu, B. Influence of Rotor Tooth Shaping on Cogging Torque of Axial Flux-Switching Permanent Magnet Machine. IEEE Trans. Ind. Appl. 2019, 55, 1290–1298. [Google Scholar] [CrossRef]

- Ren, W.; Xu, Q.; Li, Q.; Zhou, L. Reduction of Cogging Torque and Torque Ripple in Interior PM Machines With Asymmetrical V-Type Rotor Design. IEEE Trans. Magn. 2016, 52, 1–5. [Google Scholar] [CrossRef]

- Pan, Z.; Fang, S.; Lin, H.; Yang, H.; Qin, L.; Lyu, S. A New Hybrid-Excited Flux Reversal Arc Permanent Magnet Machine Having Partitioned Stators for Large Telescope Application. IEEE Trans. Magn. 2019, 55, 1–10. [Google Scholar] [CrossRef]

- Zheng, Y.; Wu, L.; Zhu, J.; Fang, Y.; Qiu, L. Analysis of Dual-Armature Flux Reversal Permanent Magnet Machines With Halbach Array Magnets. IEEE Trans. Energy Convers. 2021, 36, 3044–3052. [Google Scholar] [CrossRef]

- Qu, H.; Zhu, Z.Q. Analysis of Spoke Array Permanent Magnet Flux Reversal Machines. IEEE Trans. Energy Convers. 2020, 35, 1688–1696. [Google Scholar] [CrossRef]

- Zhu, X.; Hua, W.; Wang, W.; Huang, W. Analysis of Back-EMF in Flux-Reversal Permanent Magnet Machines by Air Gap Field Modulation Theory. IEEE Trans. Ind. Electron. 2018, 66, 3344–3355. [Google Scholar] [CrossRef]

- Cheng, M.; Han, P.; Hua, W. General Airgap Field Modulation Theory for Electrical Machines. IEEE Trans. Ind. Electron. 2017, 64, 6063–6074. [Google Scholar] [CrossRef]

- Wang, P.; Hua, W.; Zhang, G.; Wang, B.; Cheng, M. Principle of Flux-Switching Permanent Magnet Machine by Magnetic Field Modulation Theory Part I: Back-Electromotive-Force Generation. IEEE Trans. Ind. Electron. 2021, 69, 2370–2379. [Google Scholar] [CrossRef]

- Wang, P.; Hua, W.; Zhang, G.; Wang, B.; Cheng, M. Principle of Flux-Switching PM Machine by Magnetic Field Modulation Theory Part II: Electromagnetic Torque Generation. IEEE Trans. Ind. Electron. 2021, 69, 2437–2446. [Google Scholar] [CrossRef]

- Gao, J.; Xiang, Z.; Dai, L.; Huang, S.; Ni, D.; Yao, C. Cogging Torque Dynamic Reduction Based on Harmonic Torque Counteract. IEEE Trans. Magn. 2022, 58, 1–5. [Google Scholar] [CrossRef]

- Zhu, X.; Hua, W.; Wu, Z. Cogging torque suppression in flux-reversal permanent magnet machines. IET Electr. Power Appl. 2017, 12, 135–143. [Google Scholar] [CrossRef]

- Su, P.; Hua, W.; Hu, M.; Wu, Z.; Si, J.; Chen, Z.; Cheng, M. Analysis of Stator Slots and Rotor Pole Pairs Combinations of Rotor-Permanent Magnet Flux-Switching Machines. IEEE Trans. Ind. Electron. 2019, 67, 906–918. [Google Scholar] [CrossRef]

| Ps | Pr | K |

|---|---|---|

| 6 | 8, 10, 14, 16 | 3j |

| 12 | 8, 16 | 3j |

| 10, 14 | 6j | |

| 18 | 6 | 3j |

| 8, 10, 12, 14, 16 | 9j |

| Parameters | AMA-FRPM | AMC-FRPM | FRPM |

|---|---|---|---|

| Ps/Pr | 6s/8p | ||

| Speed n (r/min) | 1500 | ||

| Stator outer diameter Dso (mm) | 128 | ||

| Stator inner diameter Dsi (mm) | 70.4 | ||

| Effective shaft length la (mm) | 75 | ||

| Rotor inner diameter Dri (mm) | 22 | ||

| Air-gap length g (mm) | 0.35 | ||

| Rotor pole arc θrt (deg) | 20 | ||

| Stator tooth width θst (deg) | 41.5 | 40.0 | |

| PM thickness hpm (mm) | 1.60 | 1.84 | |

| PM width θpm (deg) | 18.5 | 20.0 | |

| PM notch width θpmgaap (deg) | 4.5 | 0 | |

| PM magnetization mode | NSSN | NSNS | NSNS |

| Silicon steel sheet material | 50WW470 | ||

| PM material | N35SH | ||

| Number of turns of winding | 64 | 117 | 107 |

| Wire diameter (mm) | 2.01 | 1.53 | 1.01 |

| Parameters | AMA-FRPM | AMC-FRPM | FRPM |

|---|---|---|---|

| Cogging torque Tcog (Nm) | 1.20 | 1.12 | 2.6 |

| Torque Te (Nm) | 13.83 | 10.60 | 7.00 |

| Torque ripple Trip (%) | 8.00 | 11.00 | 34.60 |

| PM utilization ratio KT/VPM (Nm/L) | 874.2 | 670.0 | 340.0 |

| Torque density KT/V (Nm/L) | 14.33 | 10.98 | 7.22 |

| Power Pout (W) | 2420.4 | 1671.2 | 1095.0 |

| PM eddy current loss PPM (W) | 29.72 | 28.00 | 43.00 |

| Core loss PFe (W) | 76.77 | 38.50 | 20.00 |

| Copper loss PCu (W) | 147.02 | 133.0 | 94.00 |

| Efficient η (%) | 89.83 | 89.30 | 87.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.; Chang, L.; Su, P.; Li, Y.; Hua, W.; Shen, Y. Research on High-Torque-Density Design for Axial Modular Flux-Reversal Permanent Magnet Machine. Energies 2023, 16, 1691. https://doi.org/10.3390/en16041691

Lin S, Chang L, Su P, Li Y, Hua W, Shen Y. Research on High-Torque-Density Design for Axial Modular Flux-Reversal Permanent Magnet Machine. Energies. 2023; 16(4):1691. https://doi.org/10.3390/en16041691

Chicago/Turabian StyleLin, Shan, Lanchao Chang, Peng Su, Yongjian Li, Wei Hua, and Yi Shen. 2023. "Research on High-Torque-Density Design for Axial Modular Flux-Reversal Permanent Magnet Machine" Energies 16, no. 4: 1691. https://doi.org/10.3390/en16041691

APA StyleLin, S., Chang, L., Su, P., Li, Y., Hua, W., & Shen, Y. (2023). Research on High-Torque-Density Design for Axial Modular Flux-Reversal Permanent Magnet Machine. Energies, 16(4), 1691. https://doi.org/10.3390/en16041691