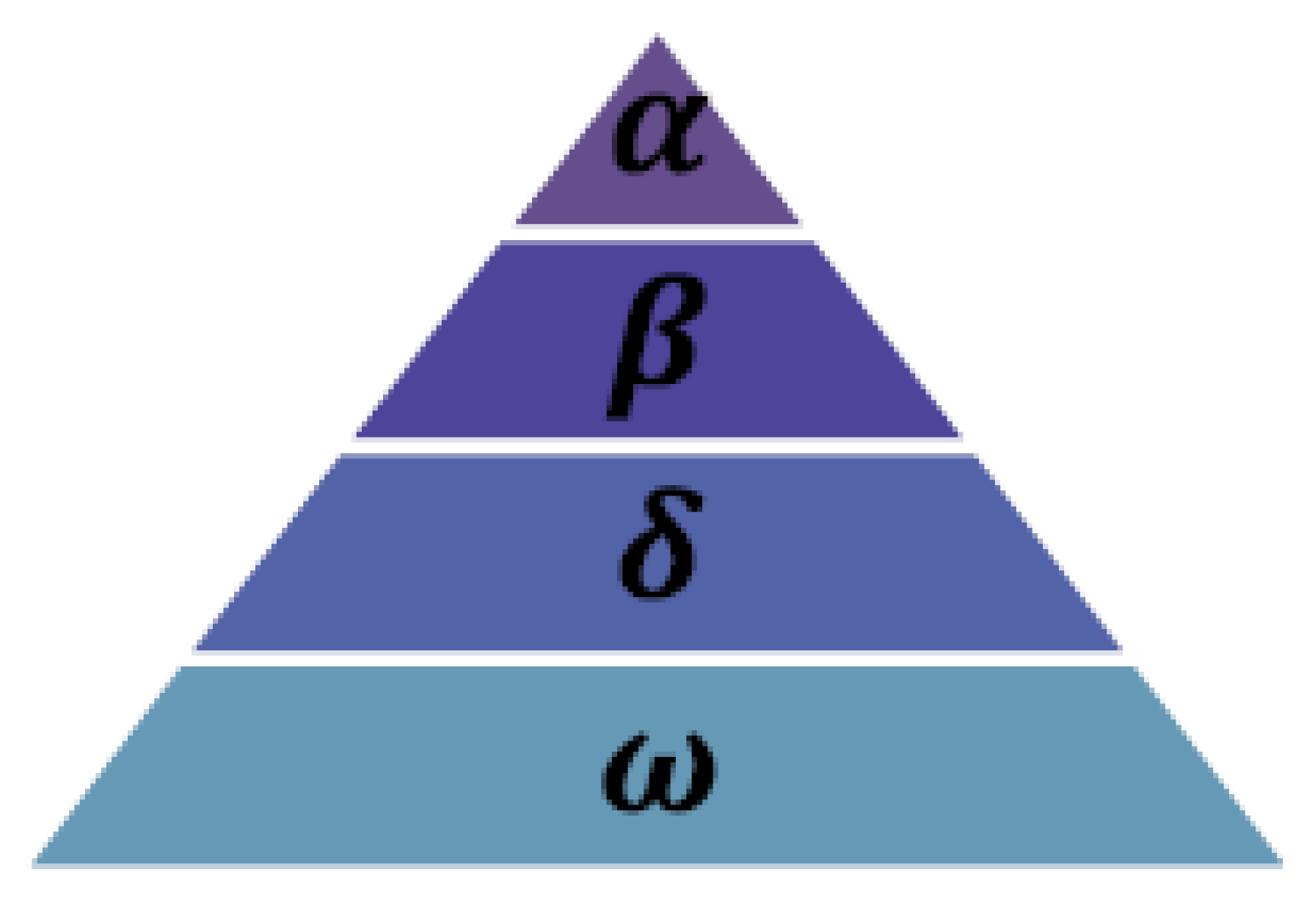

GWO imitates the directorial hierarchies and also the hunting mechanisms that gray wolves exhibit in their own environment, essentially. Each pack is made up of alpha, beta, delta, and omega grey wolves. In addition, there are three steps in their hunting procedure: scouting, encircling, and attacking prey. All of these procedures are carried out concurrently with the optimization operation. GWO, a new and effective meta-heuristic technique, is offered by Mirjalili [

27]. Since it is based on animals and nature, it is comprehended and practical to execute. The primary advantage of GWO is its adaptability, simplicity, and clarity. When compared to other well-known and effective meta-heuristic conceptions, a few recent research indicate that GWO may offer gratifying outcomes. For instance, this occurred when Mirjalili used 29 test functions in order to compare of GWO with the Gravitational Search Algorithm (GSA), Differential Evolution (DE), PSO, Evolution Strategy, and Evolutionary Programming.

Any optimization problem that postulates the best solution, or alpha (α), can be solved mathematically by illustrating the wolf’s social hierarchy. The expressions “beta” (β) and “delta” (δ) refer to the second- and third-best solutions, respectively, while “omega” (ω) refers to other options.

2.3.1. Method for Hunting Gray Wolves

In explaining and teaching the gray wolf algorithm, we can say that this algorithm consists of 3 main steps:

Track, search, chase, and approach the potential prey.

Harass and encircle a prey until the prey no longer moves.

Attack the prey.

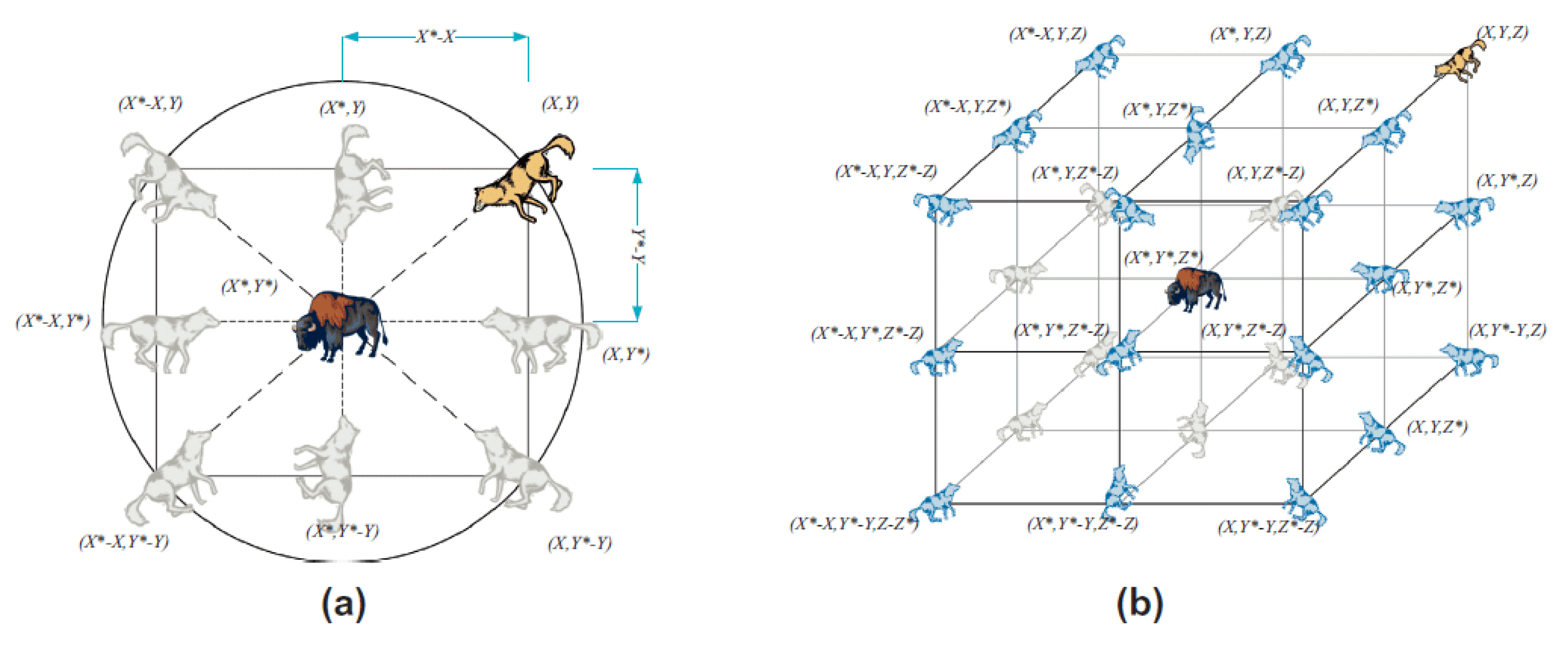

Figure 5a shows the effects of Equations (1) and (2), some possible neighbors, and a 2D positional vector. The mentioned figure also illustrates the wolf’s position (X, Y) that changes/updates with respect to the prey’s location (X*, Y*). The contents of

and

vectors can be adjusted to attain places close to the best agent. Here, (X* − X, Y*) serves as an example that we can reach by adjusting

(1,0) and

(1,1). In

Figure 5b, a grey wolf’s possible updated positions are depicted in a 3D space. It is important to understand that wolves can access any location among the points because of the accidental vectors

and,

as

Figure 5 illustrates. Consequently, a gray wolf may update its location in any random location in the space surrounding the prey using Equations (1) and (2).

The attack is commanded by the alpha wolf as the prey is surrounded by wolves and do not move anymore. The reduction of the vector an is used to model this process. The coefficient vector A reduces as (a) lowers since it is an accidental vector in the range [−2a, 2a]. The wolf alpha will approach the prey (and the other wolves) if |A| < 1, and the wolf will avoid the prey (and the rest of the wolves) if |A| > 1. All wolves must update their positions in accordance with the positions of the alpha, beta, and delta wolves according to the gray wolf algorithm.

During the hunt, gray wolves surround the predation. The equations that follow provide a mathematical representation of the siege behavior. In the relations below the current iteration

t,

A, and

C are coefficient vectors,

Xp is the prey position vector and

X is the position vector of the gray wolf.

Vectors

A and

C are calculated as follows:

Here, and are the accidental vectors [0, 1] and after iterations, components have been linearly reduced from 2 to 0.

Searching and excavation operations will be typically directed by alpha. Beta and delta

To conclude, the search for an optimized solution, or in other words, prey, initiates with creating random grey wolves’ population (or candidate solutions) using the GWO algorithm. After a considerable number of iterations, three top wolves (alpha, beta, and delta) estimate the prey’s position. Based on that, every candidate solution (wolf) changes (updates) its distance from the selected prey. To explore and exploit further, we reduced the parameter a from 2 to 0. As || > 1, the candidate solutions diverge from the prey, however when || < 1 is true, the candidate solutions converge toward the prey. At the end, when the end criterion is met, we terminate the GWO.

According to the contents of the flowchart, the gray wolf algorithm can be considered as follows. This flowchart will only work by specifying the values of vectors

A and

C. Explaining this flowchart is very simple by studying the above-mentioned steps.

Figure 7 indicated the Flowchart of the Gray Wolf Algorithm.

This looks and introduces the grey wolf optimizer into a unique set of rules to generate the global seek vector for decreasing the characteristic numbers from the fault indicators that created by guide enforcing in Simulink to attain the capabilities for global exploration. Numerous steps are contained in the gray wolf optimizer:

- (1)

Social hierarchy mechanism

According to their fitness values, the wolves are separated into 4 groups (W1, W2, W3, and W4). The first three groups have the ability to control the wolves and are made up of excellent adaptable gray wolves.

- (2)

Surround the prey

The grey wolves must surround their prey while predation. A mathematical model can be found here:

In which

x represents the cutting-edge new release number.

is the distance and route of the wolf from its prey.

is the location of the prey.

gives the placement of the wolves.

and

are coefficient vectors and can be described as follows:

In this equation a is factor of attenuation.

When the range of iterations rises, the coefficient experiences a linear decrease from 2 to zero.

- (3)

Hunting

The wolf

W1 instructs wolves

W2 and

W3 to reduce the prey’s surrounding circle (domain) in order to gain the motive for hunting. The mathematical model is given as:

where,

,

indicate the positions of wolf

W1, wolf

W2 and wolf

W3, respectively.

gives the location and position information belonging to the remaining wolves.

,

,

indicate the rout and step size (step length) of wolf

W4 which moves toward wolf

W1, wolf

W2 and wolf

W3, respectively.

- (4)

Generation a global search vector

The global search vector is defined as the following:

The improved position update formula is as follows:

In Equation (15) the features from the created data matrix can be obtained. These features will be used in the training of the neural network.

2.3.2. Hybrid GWO-PI Controller

In this section, the development of H-GWO-PI controller is presented.

Figure 8 shows the Simulink model for H-GWO-PI controller. In this figure, GWO tuner provides the gain contents for the PI controller regarding to the reference value and the actual value of error.

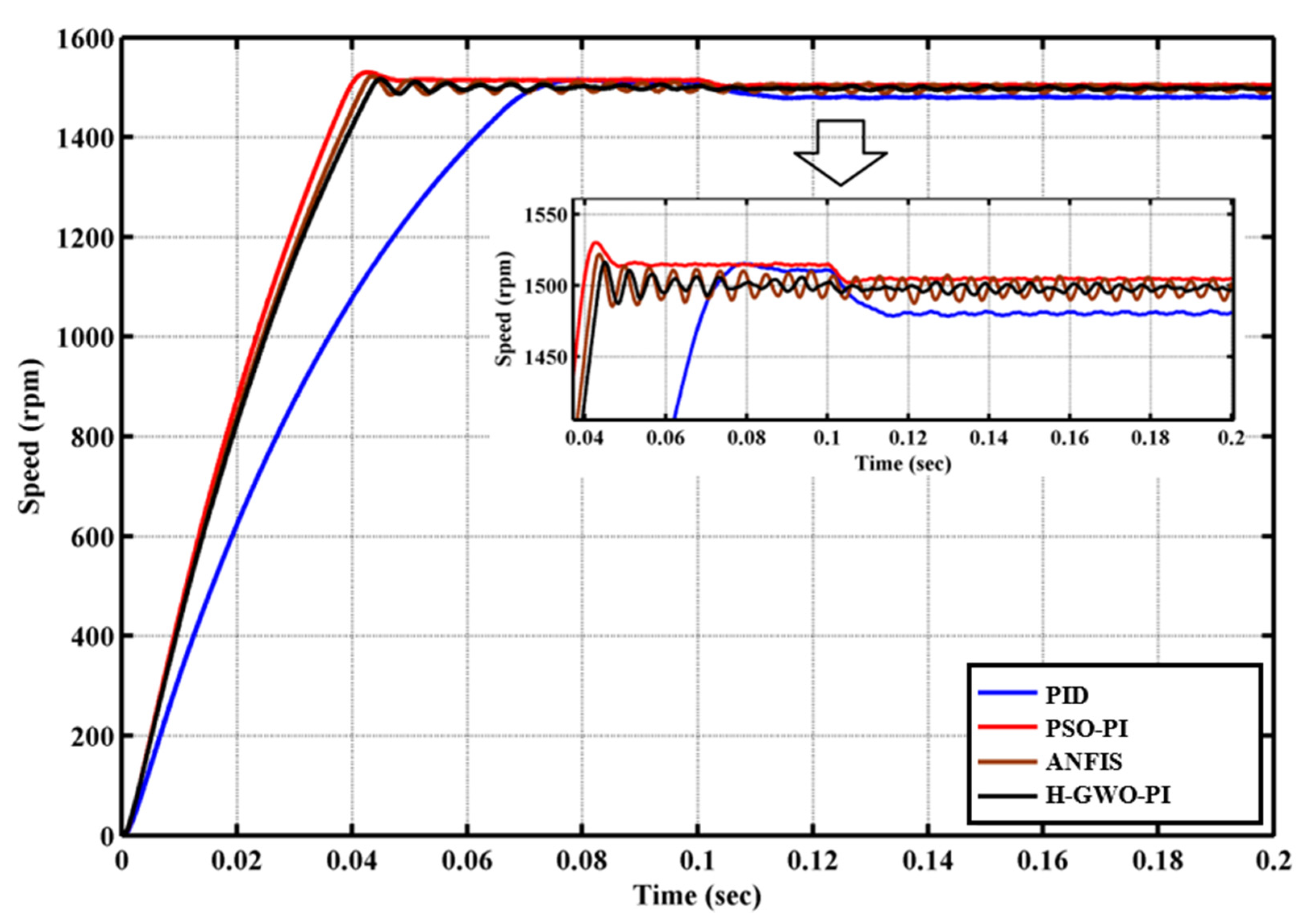

The speed response of the contemplated Brush-less DC motor is examined for fixed load situations, varying set speed situations and varying load situations. Time domain parameters and performance indices for the hybrid GWO-PI are obtained and compared, including recovery time, settling time, rising time, steady state error, undershoot, overshoot, RMSE, ITAE, IAE, and ISE PID controller, PSO-PI controller, ANFIS controller, hybrid GWO-PI. The BLDC motor’s characteristics have been extracted from [

26].

As seen in

Figure 8, the Error1 is the input of the first controller (speed PI controller), and the difference between output of first Speed PI controller and the filtered current value is the input of the second current PI controller. The red colored circle and direction shows the PI controller tuned by GWO algorithm. The objective function is the error between reference and the actual value. The aim of this objective function is reducing the error value.

The absolute value of the error speed and error current is measured from the simulation for different set of values of the PI controller’s parameter from the GWO algorithm. After completion of maximum iteration, GWO provide optimal parameter results for the PI controllers such as Kp1, Ki1, Kp2 and Ki2. The limits or constraints for the control variables such as Kp1, Ki1, Kp2, and Ki2 are between 0.01 (Lower bound) to 3 (Upper bound). The GWO provide the values for two PI controllers such as Kp1, Ki1, Kp2, and Ki2. For each set of population, measuring objective function value stated in the Equation (22). For each iteration, best results are stored separately, and end of the final iteration, GWO provide the optimal parameters for the two PI controllers.