A Comparison of Double-End Partial Discharge Localization Algorithms in Power Cables

Abstract

1. Introduction

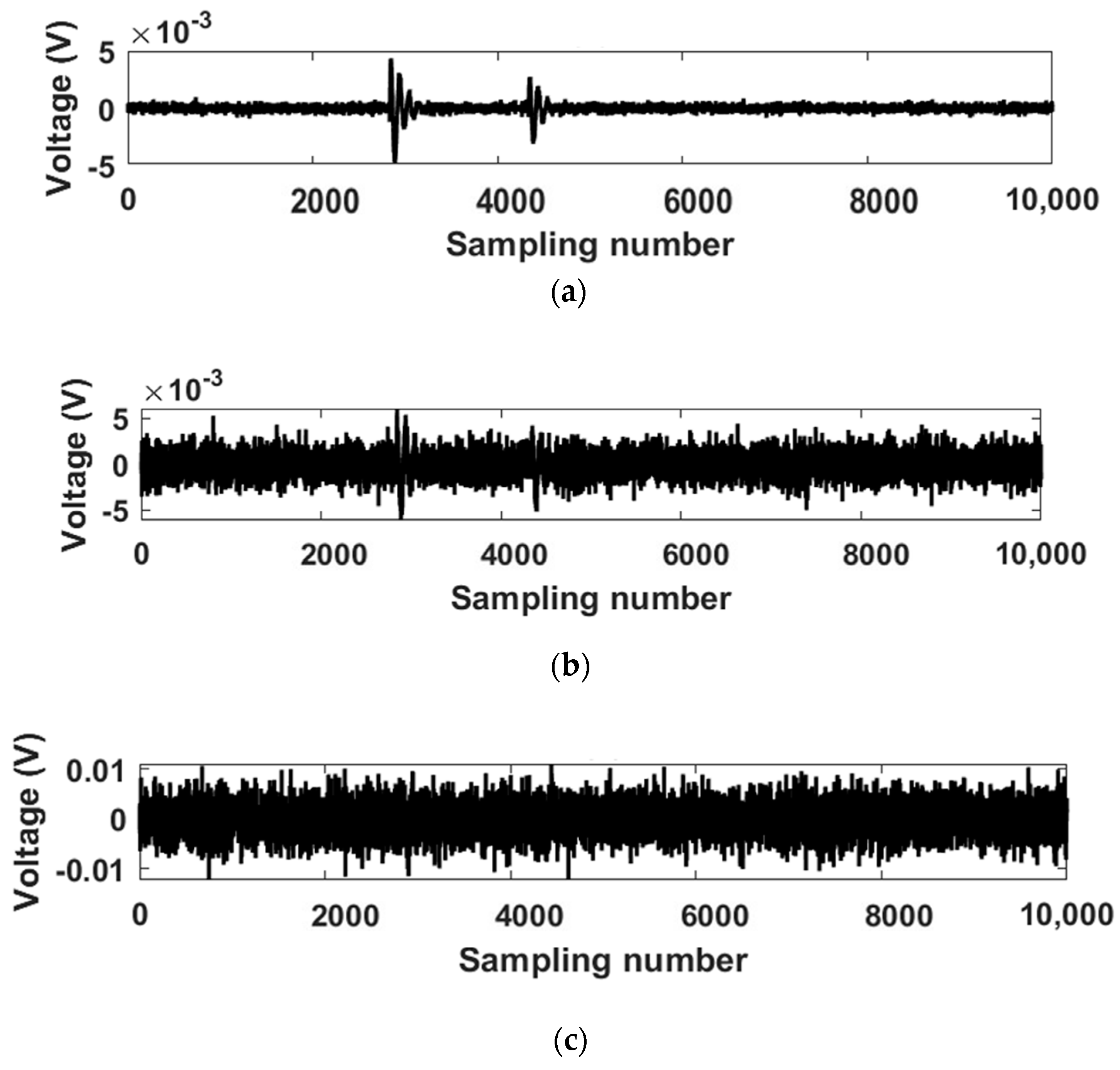

2. PD Measurement Methods

2.1. Single-End PD Measurement

- TD—Time difference between consecutive pulses;

- L—Cable length.

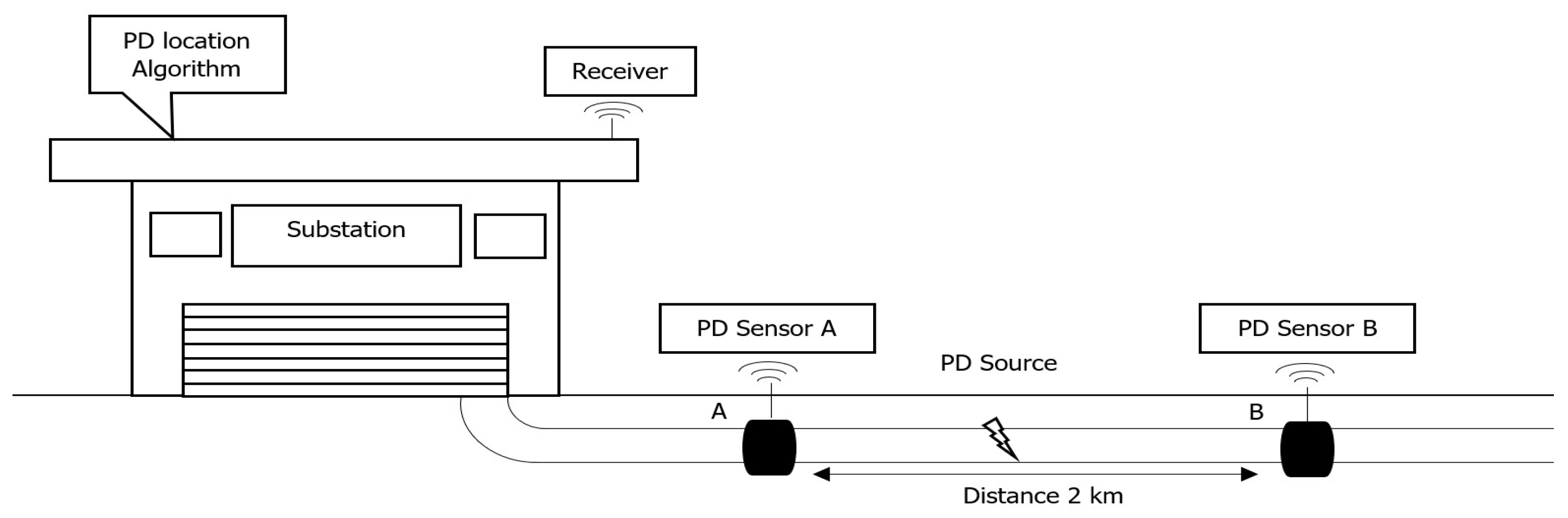

2.2. Double-End PD Measurement

- v—Propagation velocity of the PD signal that travels along the cable;

- TD—Time difference of the PD signal that arrives at two adjacent sensors;

- L—Total length of the cable.

2.3. Multi-End PD Measurement

- Case 1:

- Case 2:

- tab—Time difference between signal A[n] and signal B[n];

- tcb—Time difference between signal C[n] and signal B[n].

- If tab is less than tcb, then Equation (3) is applied. Otherwise, Equation (4) is applied.

3. Methodology

3.1. PD Localization Algorithm

- A—The magnitude coefficient, assumed to be 0.01;

- ;

- ;

- ;

- ;

- .

- ;

- ε—Effective relative permittivity of the cable dielectric and semiconducting screen layers.

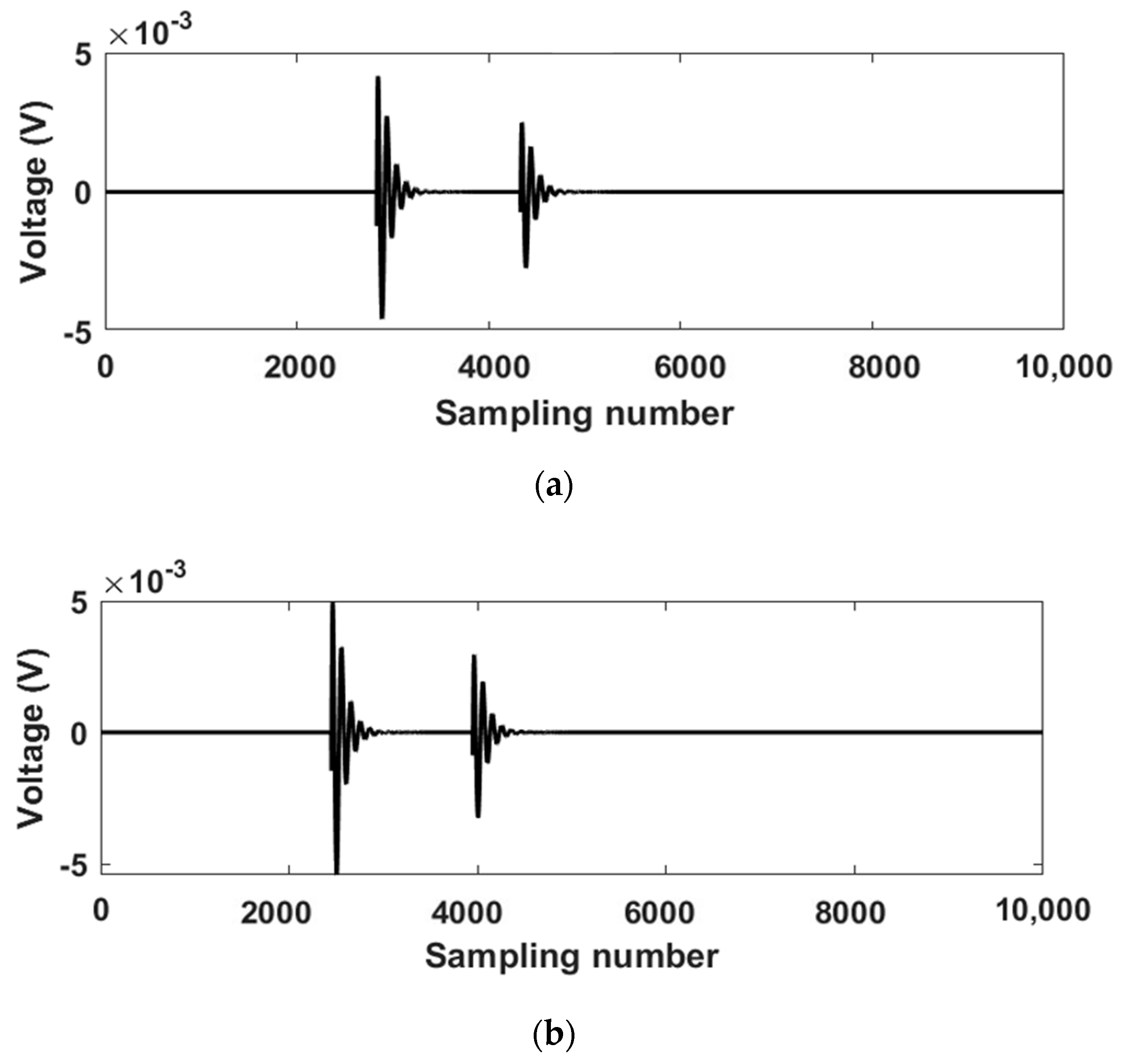

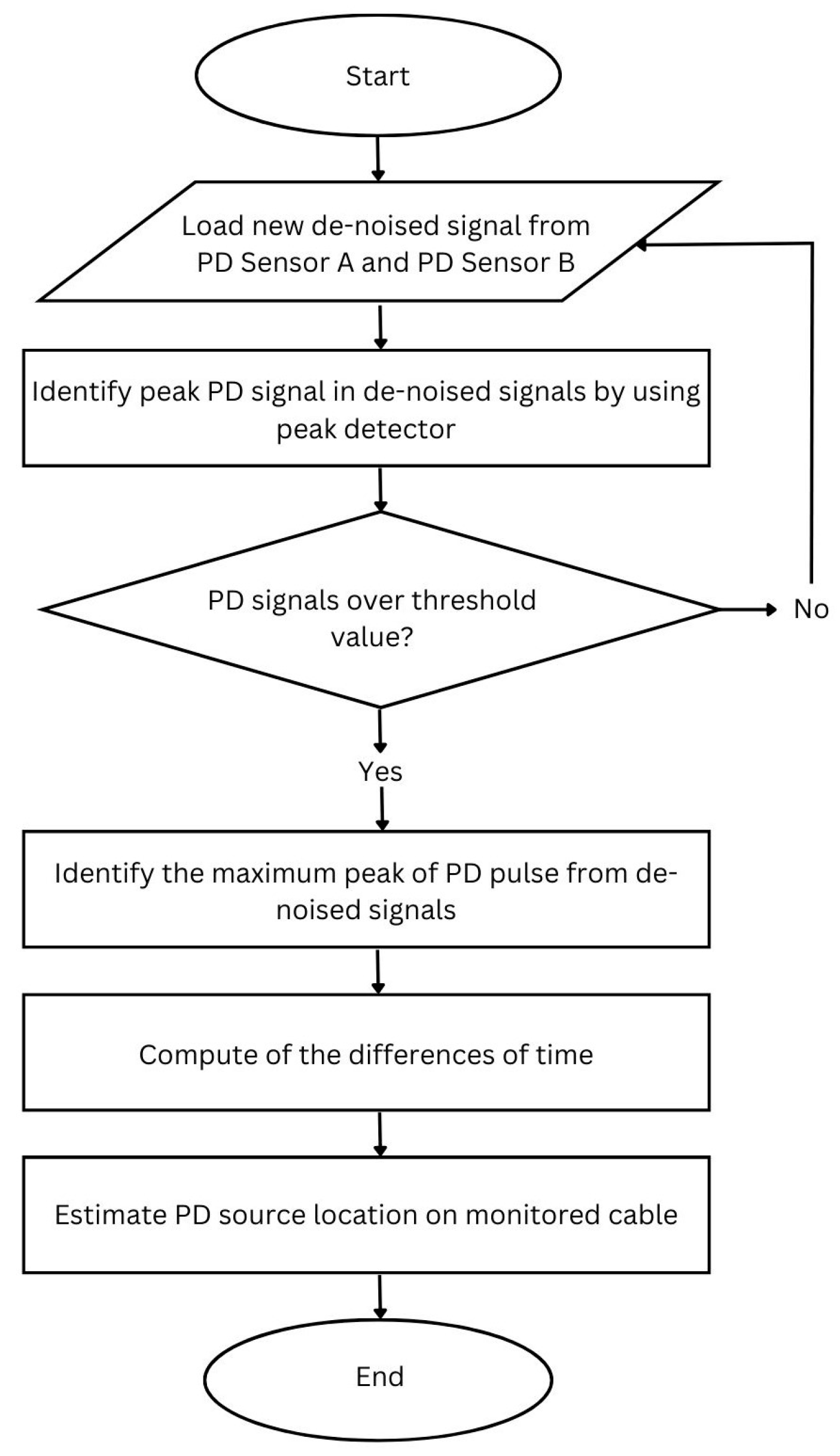

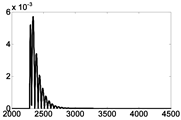

3.2. Maximum Peak Detection Algorithm

- ;

- The time that yields a maximum peak in

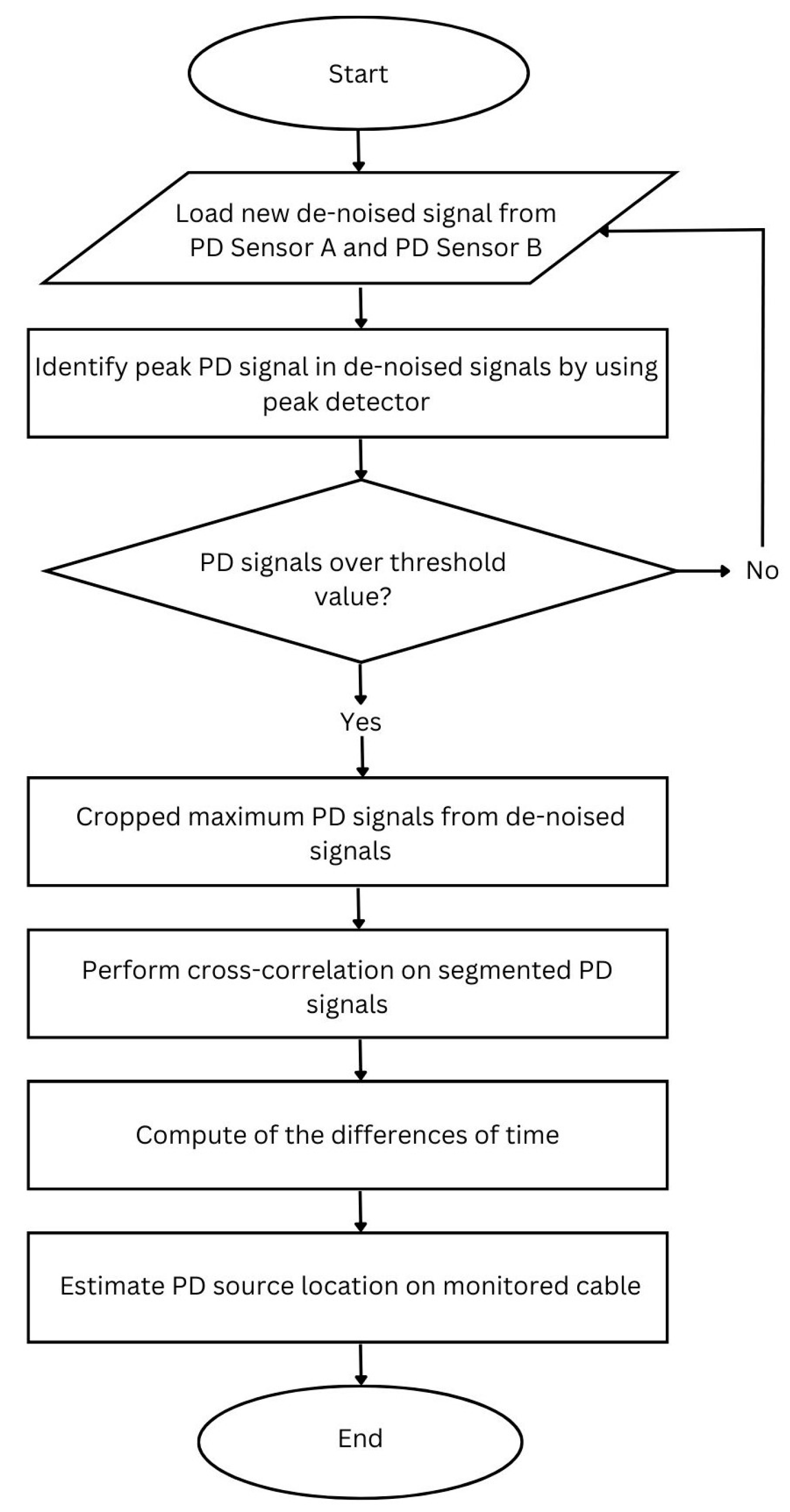

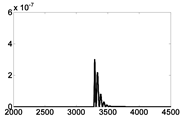

3.3. Segmented Correlation (SC) Algorithm

- TSR—Total samples of the reference signal before the signal was cropped;

- TSRcropped—Total samples of the reference signal after the signal was cropped.

3.4. Segmented Correlation Trimmed Mean Data Filtering (SCTM) Algorithm

- ;

- Sn—Estimated PD localization samples that enter the mod class;

- m—Total number of samples that enter the mod class.

4. Result and Discussion

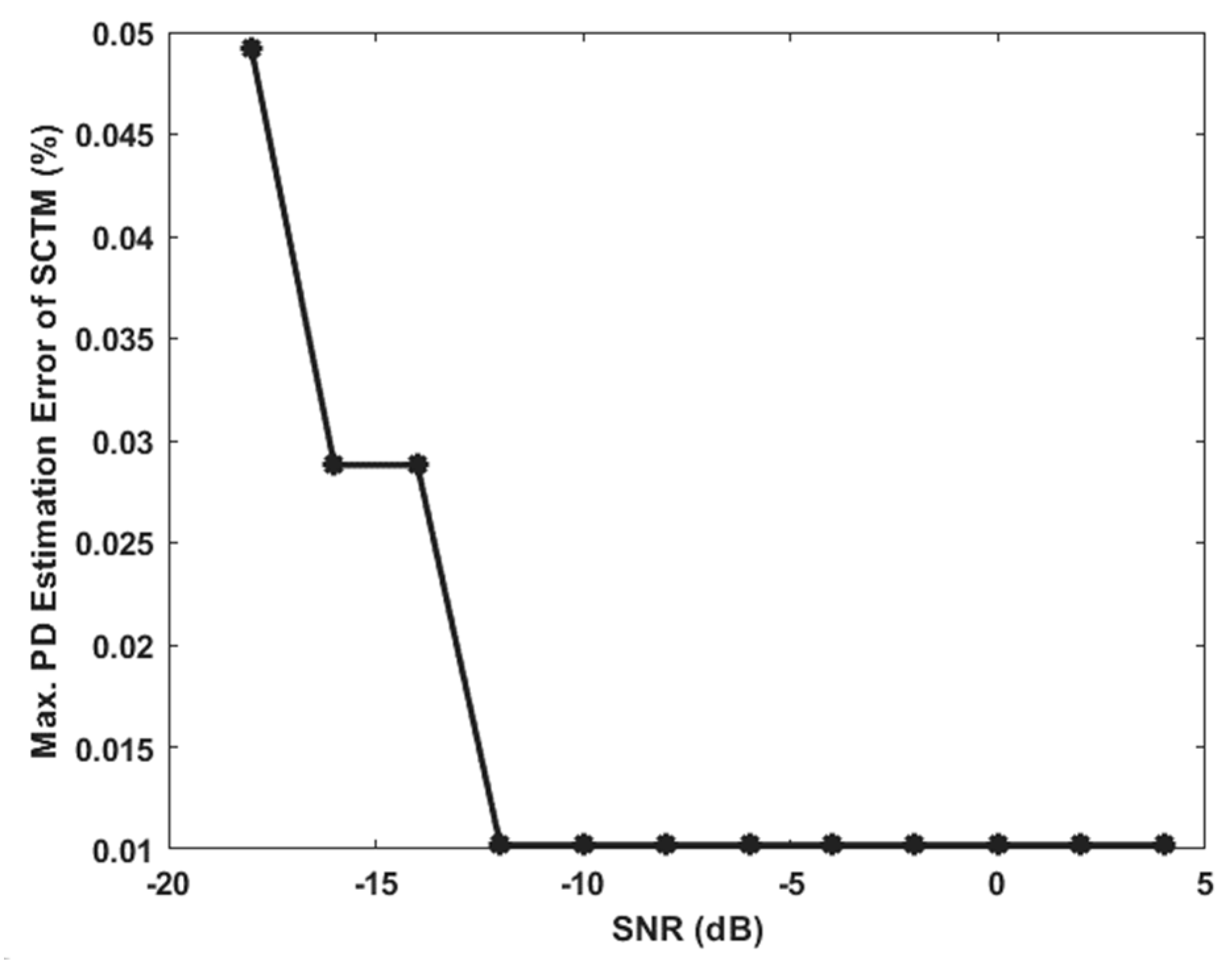

4.1. Maximum PD Estimation Error

4.2. Average PD Estimation Error

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duan, L.; Hu, J.; Zhao, G.; Chen, K.; He, J.; Wang, S. Identification of Partial Discharge Defects Based on Deep Learning Method. IEEE Trans. Power Deliv. 2019, 34, 1557–1568. [Google Scholar] [CrossRef]

- Lu, B.; Li, S.; Cui, Y.; Zhao, X.; Zhang, D.; Kang, Y.; Dong, H. Insulation Degradation Mechanism and Diagnosis Methods of Offshore Wind Power Cables: An Overview. Energies 2022, 16, 322. [Google Scholar] [CrossRef]

- Jin, Y.; Zhang, B.; Mu, H.; Zheng, Y.; Zhan, J.; Xianjun, S.; Li, C.; Zhang, C.; Zhang, G. A Novel Partial Discharge Localization Method in Transformer Based on Signal Propagation in Winding. In Proceedings of the 2021 International Conference on Advanced Electrical Equipment and Reliable Operation (AEERO), Beijing, China, 15–17 October 2021; IEEE: Piscataway, NJ, USA; pp. 1–5. [Google Scholar] [CrossRef]

- Sun, C.; Che, R.; Zhao, Y. Simulation Analysis of Partial Discharge Detection and Localization of Power Cable Based on ATP-EMTP. In Proceedings of the 2020 Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 29–31 May 2020; IEEE: Piscataway, NJ, USA; pp. 275–279. [Google Scholar] [CrossRef]

- Mao, Y.; Ding, Y.; Wu, J.; Chen, J. Research on Partial Discharge Detection Technology for Power Transformers. In Proceedings of the 2020 IEEE 4th Conference on Energy Internet and Energy System Integration (EI2), Wuhan, China, 30 October–01 November 2020; IEEE: Piscataway, NJ, USA; pp. 3956–3959. [Google Scholar] [CrossRef]

- Wen, Z.; Xiong, B.; Gu, G. Detection and Localization of Partial Discharge Based on Flexible Piezoelectric Thin Film Material. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; IEEE: Piscataway, NJ, USA; pp. 1–4. [Google Scholar] [CrossRef]

- Rahimbakhsh, M.; Torres, J.; Werle, P.; Gockenbach, E.; Azirani, M.A. Investigation of Partial Discharge Localization Based on Electrical Measurements. In Proceedings of the 2018 IEEE 2nd International Conference on Dielectrics (ICD), Budapest, Hungary, 1–5 July 2018; IEEE: Piscataway, NJ, USA; pp. 1–4. [Google Scholar] [CrossRef]

- Ali, N.H.N.; Giannakou, M.; Nimmo, R.D.; Lewin, P.L.; Rapisarda, P. Classification and Localisation of Multiple Partial Discharge Sources within a High Voltage Transformer Winding. In Proceedings of the 2016 IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016; IEEE: Piscataway, NJ, USA; pp. 519–522. [Google Scholar] [CrossRef]

- Predl, F.; Guo, W.; Hoek, S.; Krüger, M. Combining Acoustic and Electrical Methods to Locate Partial Discharge in a Power Transformer. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; IEEE: Piscataway, NJ, USA; pp. 424–427. [Google Scholar] [CrossRef]

- Duval, M. A Review of Faults Detectable by Gas-in-Oil Analysis in Transformers. IEEE Electr. Insul. Mag. 2002, 18, 8–17. [Google Scholar] [CrossRef]

- Rathod, V.B.; Kumbhar, G.B.; Bhalja, B.R. Single-Sensor Based Acoustic Time Reversal Technique for Partial Discharge Localization in Power Transformer. In Proceedings of the 2021 IEEE 5th International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Kozhikode, India, 3–5 December 2021; IEEE: Piscataway, NJ, USA; pp. 151–156. [Google Scholar] [CrossRef]

- Karami, H.; Rachidi, F.; Azadifar, M.; Rubinstein, M. An Acoustic Time Reversal Technique to Locate a Partial Discharge Source: Two-Dimensional Numerical Validation. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 2203–2205. [Google Scholar] [CrossRef]

- Ghosh, R.; Chatterjee, B.; Dalai, S. A new method for the estimation of time difference of arrival for localization of partial discharge sources using acoustic detection technique. In Proceedings of the 2016 IEEE 7th Power India International Conference (PIICON), Bikaner, India, 25–27 November 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Markalous, S.M.; Tenbohlen, S.; Feser, K. Detection and Localization of Partial Discharges in Power Transformers Using Acoustic and Electromagnetic Signals. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1576–1583. [Google Scholar] [CrossRef]

- Lundgaard, L.E. Partial Discharge. XIV. Acoustic Partial Discharge Detection-Practical Application. IEEE Electr. Insul. Mag. 1992, 8, 34–43. [Google Scholar] [CrossRef]

- Zhao, L.; Ye, L.; Yu, B.; Lin, H.; Yang, Y.; Zheng, W. Research on Partial Discharge Localization in 252kV GIS Using Ultrasonic Associated with Electromagnetic Wave Method. In Proceedings of the 2020 IEEE 5th International Conference on Integrated Circuits and Microsystems (ICICM), Nanjing, China, 23–25 October 2020; IEEE: Piscataway, NJ, USA; pp. 14–18. [Google Scholar] [CrossRef]

- Shen, P.; Chen, T.; Tang, D.; He, T.; Ju, L.; Wang, H. The Accuracy Improvement Method for Partial Discharge UHF Measurement Data Based on Kalman Filter Algorithm. In Proceedings of the 2022 Power System and Green Energy Conference (PSGEC), Shanghai, China, 25–27 August 2022; IEEE: Piscataway, NJ, USA; pp. 1082–1086. [Google Scholar] [CrossRef]

- Tian, Y.; Qi, B.; Zhuo, R.; Fu, M.; Li, C. Locating Partial Discharge Source Occurring on Transformer Bushing by Using the Improved TDOA Method. In Proceedings of the 2016 International Conference on Condition Monitoring and Diagnosis (CMD), Xi’an, China, 25–28 September 2016; IEEE: Piscataway, NJ, USA; pp. 144–147. [Google Scholar] [CrossRef]

- Tienghong, T.; Promwong, S. A Study of Partial Discharge Localization in Transformer. In Proceedings of the 2019 16th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Pattaya, Thailand, 10–13 July 2019; IEEE: Piscataway, NJ, USA; pp. 333–336. [Google Scholar] [CrossRef]

- Raja, K.; Floribert, T. Comparative Investigations on UHF and Acoustic PD Detection Sensitivity in Transformers. In Proceedings of the 2002 IEEE International Symposium on Electrical Insulation (Cat. No.02CH37316), Boston, MA, USA, 7–10 April 2002; IEEE: Piscataway, NJ, USA; pp. 150–153. [Google Scholar] [CrossRef]

- Judd, M.; Yang, L.; Hunter, I. Partial Discharge Monitoring of Power Transformers Using UHF Sensors. Part I: Sensors and Signal Interpretation. IEEE Electr. Insul. Mag. 2005, 21, 5–14. [Google Scholar] [CrossRef]

- Tenbohlen, S.; Denissov, D.; Hoek, S.M.; Markalous, S. Partial Discharge Measurement in the Ultra High Frequency (UHF) Range. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1544–1552. [Google Scholar] [CrossRef]

- Wang, B.; Dong, M.; Xie, J.; Ma, A. Ultrasonic Localization Research for Corona Discharge Based on Double Helix Array. In Proceedings of the 2018 IEEE International Power Modulator and High Voltage Conference (IPMHVC), Jackson, WY, USA, 3–7 June 2018; pp. 297–300. [Google Scholar] [CrossRef]

- Samaitis, V.; Mažeika, L.; Jankauskas, A.; Rekuvienė, R. Detection and Localization of Partial Discharge in Connectors of Air Power Lines by Means of Ultrasonic Measurements and Artificial Intelligence Models. Sensors 2020, 21, 20. [Google Scholar] [CrossRef]

- Riba, J.-R.; Gomez-Pau, A.; Moreno-Eguilaz, M. Sensor Comparison for Corona Discharge Detection Under Low Pressure Conditions. IEEE Sens. J. 2020, 20, 11698–11706. [Google Scholar] [CrossRef]

- Riba, J.-R.; Gómez-Pau, A.; Moreno-Eguilaz, M. Experimental Study of Visual Corona under Aeronautic Pressure Conditions Using Low-Cost Imaging Sensors. Sensors 2020, 20, 411. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Wang, J.; Wei, G. An Improved Partial Discharge Detection System Based on UV Pulses Detection. Sensors 2020, 20, 4767. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, P.; Deng, X.; Li, N.; Xie, X.; Liu, H.; Tang, J. Evaluation on Partial Discharge Intensity of Electrical Equipment Based on Improved ANFIS and Ultraviolet Pulse Detection Technology. IEEE Access 2019, 7, 126561–126570. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; He, W.; Xu, Z. Assessing Partial Discharge Intensity of Electrical Equipment Based on UV Detection and the ANFIS Algorithm: Assessing Partial Discharge Intensity Based on ANFIS Algorithm. IEEJ Trans. Electr. Electron. Eng. 2019, 14, 245–251. [Google Scholar] [CrossRef]

- Wen, Q.; Pan, X.; Yan, N.; Xu, N. Design of Intelligent Ultraviolet Pulse Detector for GIS Partial Discharge. In Proceedings of the 2018 2nd IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 20–22 October 2018; IEEE: Piscataway, NJ, USA; pp. 1–5. [Google Scholar] [CrossRef]

- Riba, J.-R.; Abomailek, C.; Casals-Torrens, P.; Capelli, F. Simplification and Cost Reduction of Visual Corona Tests. IET Gener. Transm. Distrib. 2018, 12, 834–841. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Zhang, D.; Xiao, Y.; Deng, J.; Xia, G. Comparison of Different Characteristic Parameters Acquired by UV Imager in Detecting Corona Discharge. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1597–1604. [Google Scholar] [CrossRef]

- Wang, S.; He, Y.; Yin, B.; Zeng, W.; Deng, Y.; Hu, Z. A Partial Discharge Localization Method in Transformers Based on Linear Conversion and Density Peak Clustering. IEEE Access 2021, 9, 7447–7459. [Google Scholar] [CrossRef]

- Isa, M.; Elkalashy, N.I.; Lehtonen, M.; Hashmi, G.M.; Elmusrati, M.S. Multi-End Correlation-Based PD Localization Technique for Medium Voltage Covered-Conductor Lines. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 936–946. [Google Scholar] [CrossRef]

- Yii, C.C.; Rohani, M.N.K.H.; Isa, M.; Hassan, S.I.S. Multi-End PD Localization Algorithm Using Segmented Correlation and Trimmed Mean Data Filtering Techniques for MV Underground Cable. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 92–98. [Google Scholar] [CrossRef]

- Wild, M.; Tenbohlen, S.; Gulski, E.; Jongen, R.; De Vries, F. Practical aspects of PD localization for long length power cables. In Proceedings of the 2013 IEEE Electrical Insulation Conference (EIC), Ottawa, ON, Canada, 2–5 June 2013; pp. 499–503. [Google Scholar] [CrossRef]

- Abdullah, A.; Rohani, M.; Isa, M.; Hamid, H.; Arshad, S.; Othman, M. Real On-Site Partial Discharge Measurement Technique in Medium Voltage Power Cable. In Proceedings of the 2018 IEEE 7th International Conference on Power and Energy (PECon), Kuala Lumpur, Malaysia, 3–4 December 2018; IEEE: Piscataway, NJ, USA; pp. 405–408. [Google Scholar] [CrossRef]

- Yii, C.C.; Rohani, M.N.K.H.; Isa, M.; Hassan, S. Three-Point Technique for Partial Discharge Localization on XLPE Armoured Underground Cable. Appl. Mech. Mater. 2015, 793, 119–123. [Google Scholar] [CrossRef]

- Li, J.; Jiang, T.; Grzybowski, S.; Cheng, C. Scale Dependent Wavelet Selection for De-Noising of Partial Discharge Detection. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1705–1714. [Google Scholar] [CrossRef]

- Khan, A.A.; Malik, N.; Al-Arainy, A.; Alghuweinem, S. Investigation of Attenuation Characteristics of PD Pulse during Propagation in XLPE Cable. In Proceedings of the 2013 IEEE Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013; IEEE: Piscataway, NJ, USA; pp. 1–5. [Google Scholar] [CrossRef]

| Localization Techniques | Descriptions |

|---|---|

| Electrical [7,8,9] |

|

| Chemical [10] |

|

| Acoustic [9,11,12,13,14,15] |

|

| Electromagnetic [14,16,17,18,19,20,21,22] |

|

| Ultrasonic [23,24] |

|

| Ultraviolet [25,26,27,28,29,30,31,32] |

|

| Reference signal () |  |  |  |

| Shifting signal () |  |  |  |

| Multiplication of signals () |  |  |  |

| Summation () | |||

| Correlation profile |  | ||

| 128.3491 | 1298.874 | 1299.654 | 1300.435 | 1301.215 |

| 130.6901 | 1298.874 | 1299.654 | 1300.435 | 1301.215 |

| 1259.857 | 1298.874 | 1299.654 | 1300.435 | 1301.215 |

| 1264.539 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1294.972 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1295.753 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1296.533 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1296.533 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1301.995 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1302.776 |

| 1297.313 | 1298.874 | 1299.654 | 1300.435 | 1302.776 |

| 1298.094 | 1298.874 | 1299.654 | 1300.435 | 1302.776 |

| 1298.094 | 1298.874 | 1299.654 | 1300.435 | 1302.776 |

| 1298.094 | 1299.654 | 1299.654 | 1300.435 | 1302.776 |

| 1298.094 | 1299.654 | 1299.654 | 1300.435 | 1303.556 |

| 1298.094 | 1299.654 | 1299.654 | 1300.435 | 1303.556 |

| 1298.094 | 1299.654 | 1299.654 | 1300.435 | 1304.337 |

| 1298.094 | 1299.654 | 1299.654 | 1300.435 | 1304.337 |

| 1298.094 | 1299.654 | 1299.654 | 1300.435 | 1305.117 |

| 1298.094 | 1299.654 | 1299.654 | 1300.435 | 1335.551 |

| 1298.094 | 1299.654 | 1299.654 | 1301.215 | 1336.331 |

| 1298.094 | 1299.654 | 1299.654 | 1301.215 | 1866.969 |

| 1298.094 | 1299.654 | 1299.654 | 1301.215 | 1866.969 |

| 1298.094 | 1299.654 | 1300.435 | 1301.215 | 1868.53 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 1873.212 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 1879.454 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 2467.838 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 2470.179 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 2472.52 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 2472.52 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 2473.301 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 2475.642 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 2476.422 |

| 1298.874 | 1299.654 | 1300.435 | 1301.215 | 2502.174 |

| SNR (dB) | MPD | SC | SCTM |

|---|---|---|---|

| 4 | 0.1068 | 0.0102 | 0.0102 |

| 2 | 1.6490 | 0.0102 | 0.0102 |

| 0 | 1.6675 | 0.0288 | 0.0102 |

| −2 | 1.6880 | 0.0288 | 0.0102 |

| −4 | 1.6880 | 0.0492 | 0.0102 |

| −6 | 1.7066 | 0.0492 | 0.0102 |

| −8 | 1.7456 | 0.0678 | 0.0102 |

| −10 | 1.7660 | 0.0883 | 0.0102 |

| −12 | 1.8050 | 0.1273 | 0.0102 |

| −14 | 1.8440 | 0.1273 | 0.0288 |

| −16 | 58.7111 | 58.5160 | 0.0288 |

| −18 | 59.9021 | 58.6925 | 0.0492 |

| SNR (dB) | MPD | SC | SCTM |

|---|---|---|---|

| 4 | 0.0254 | 0.0102 | 0.0102 |

| 2 | 0.0367 | 0.0102 | 0.0102 |

| 0 | 0.0415 | 0.0113 | 0.0102 |

| −2 | 0.1757 | 0.0127 | 0.0102 |

| −4 | 0.2784 | 0.0134 | 0.0102 |

| −6 | 0.3301 | 0.0167 | 0.0102 |

| −8 | 0.4655 | 0.0204 | 0.0102 |

| −10 | 0.5844 | 0.0215 | 0.0102 |

| −12 | 0.5996 | 0.0257 | 0.0102 |

| −14 | 0.7645 | 0.0391 | 0.0104 |

| −16 | 1.3236 | 0.6343 | 0.0117 |

| −18 | 3.1409 | 4.1756 | 0.0182 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abu Bakar, A.; Yii, C.C.; Fern, C.K.; Hou Pin, Y.; Lago, H.; Rohani, M.N.K.H. A Comparison of Double-End Partial Discharge Localization Algorithms in Power Cables. Energies 2023, 16, 1817. https://doi.org/10.3390/en16041817

Abu Bakar A, Yii CC, Fern CK, Hou Pin Y, Lago H, Rohani MNKH. A Comparison of Double-End Partial Discharge Localization Algorithms in Power Cables. Energies. 2023; 16(4):1817. https://doi.org/10.3390/en16041817

Chicago/Turabian StyleAbu Bakar, Asfarina, Chai Chang Yii, Chin Kui Fern, Yoong Hou Pin, Herwansyah Lago, and Mohamad Nur Khairul Hafizi Rohani. 2023. "A Comparison of Double-End Partial Discharge Localization Algorithms in Power Cables" Energies 16, no. 4: 1817. https://doi.org/10.3390/en16041817

APA StyleAbu Bakar, A., Yii, C. C., Fern, C. K., Hou Pin, Y., Lago, H., & Rohani, M. N. K. H. (2023). A Comparison of Double-End Partial Discharge Localization Algorithms in Power Cables. Energies, 16(4), 1817. https://doi.org/10.3390/en16041817