The Relationship between the Low-Carbon Industrial Model and Human Well-Being: A Case Study of the Electric Power Industry

Abstract

1. Introduction

2. Methodology

2.1. Research Methods

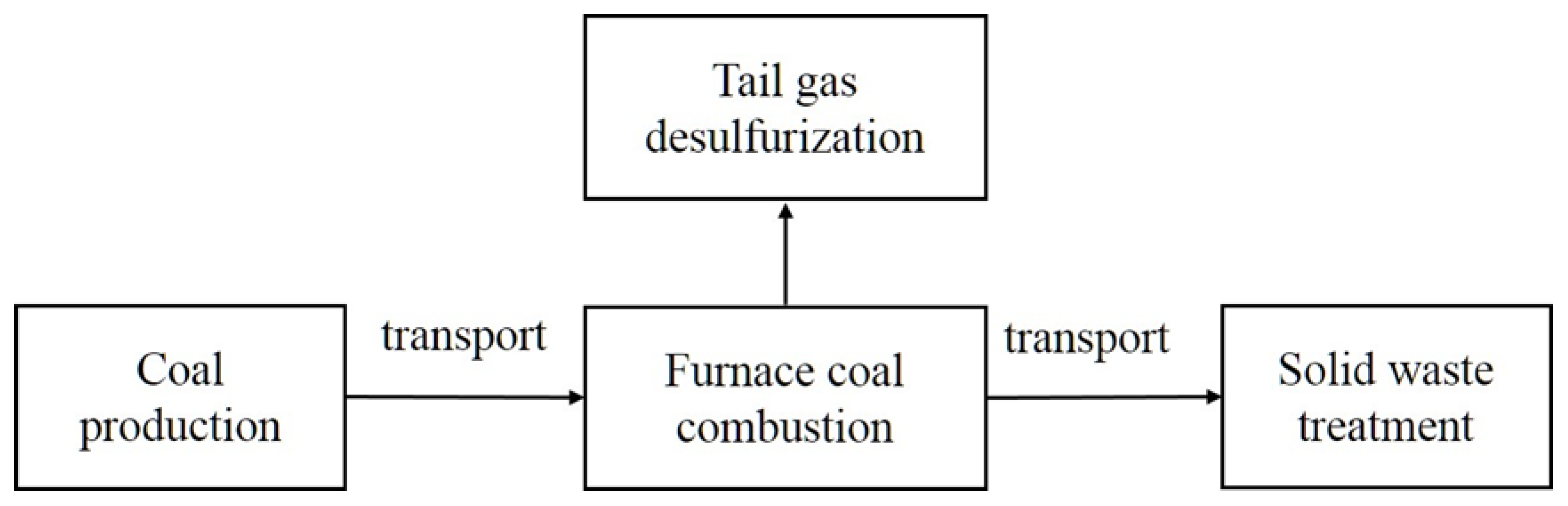

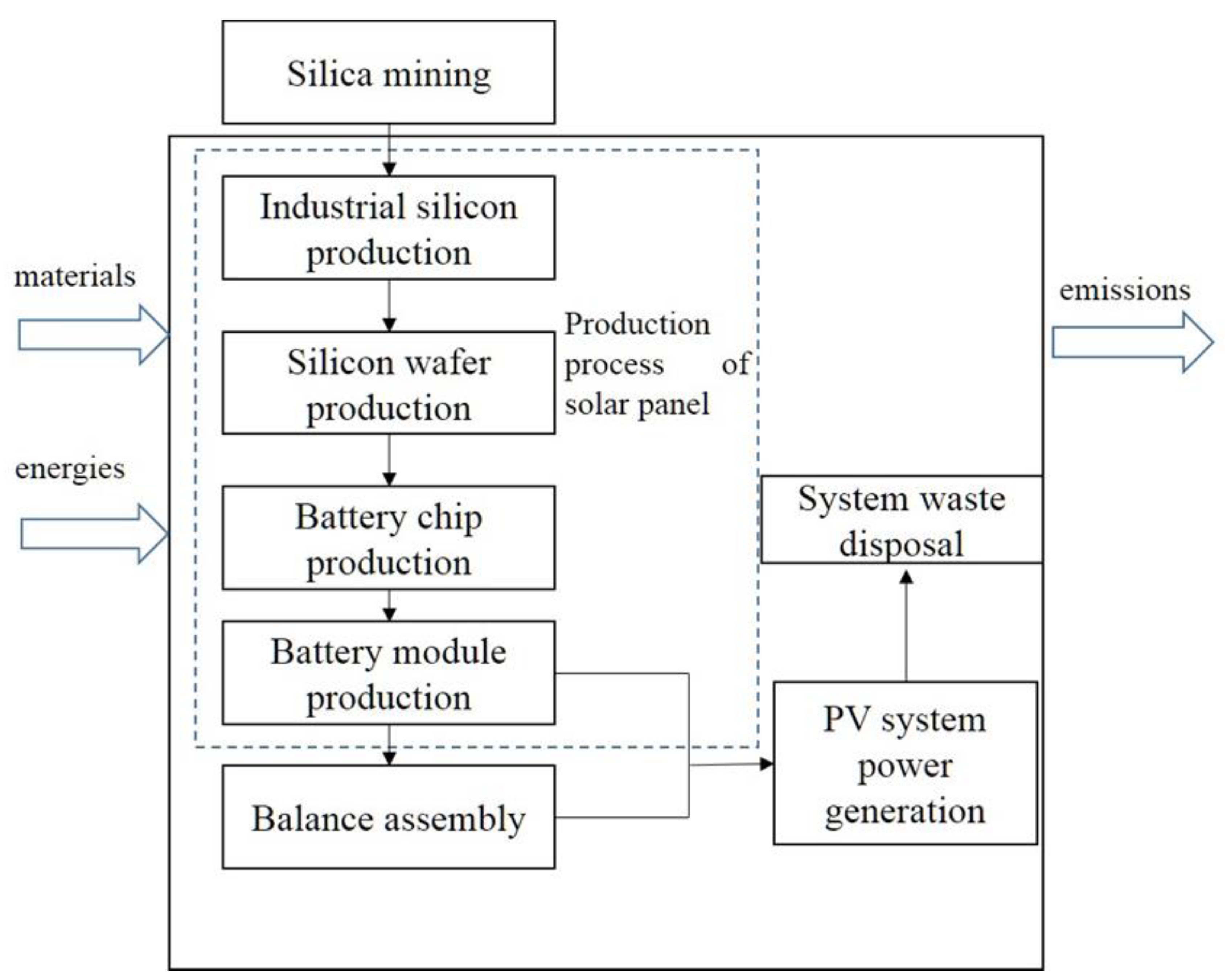

- Establish the flow chart of the life cycle assessment

- 2.

- Establish the system boundary diagram

- 3.

- Data collection and calculation

2.2. Data Sources

3. Results and Analysis

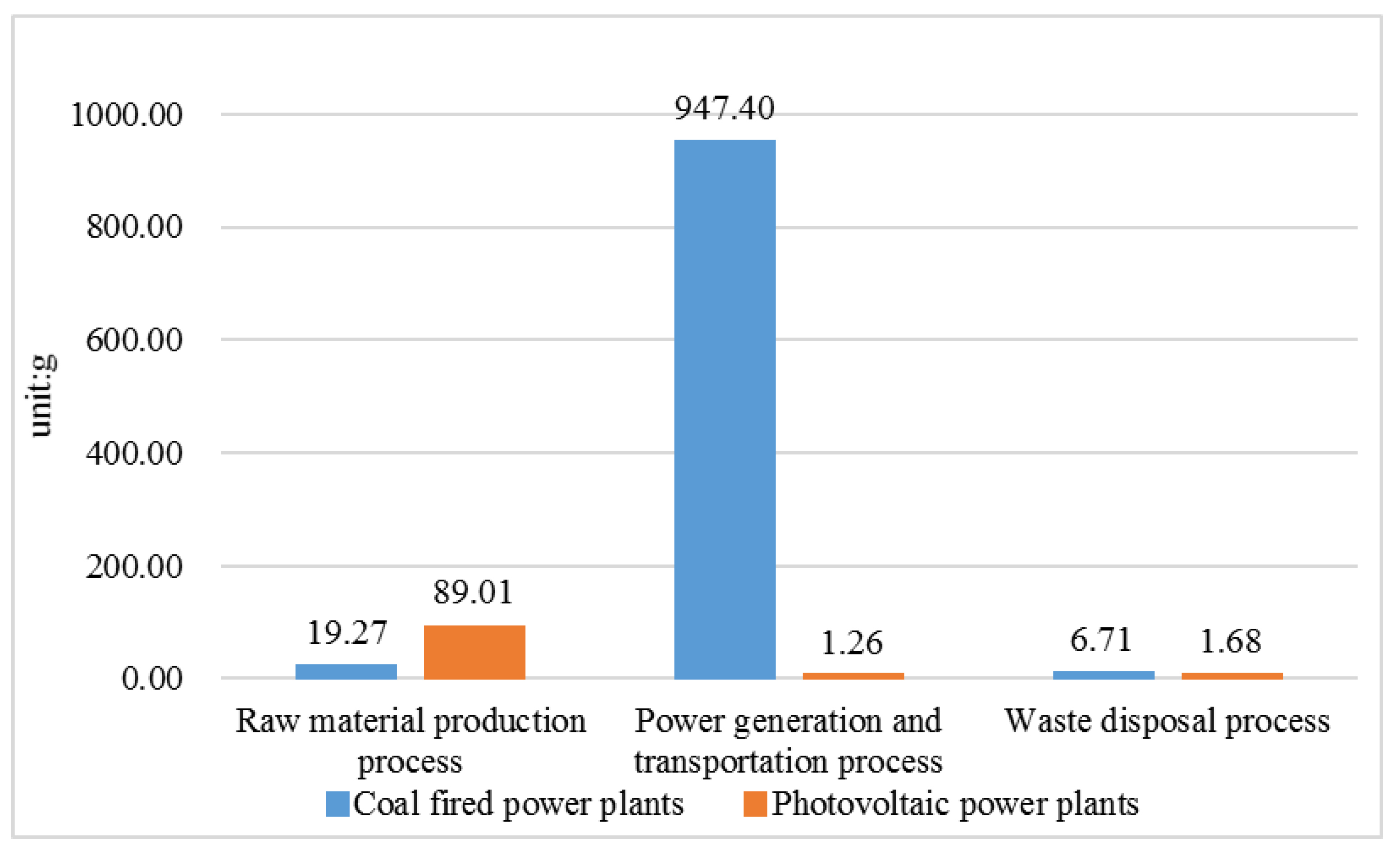

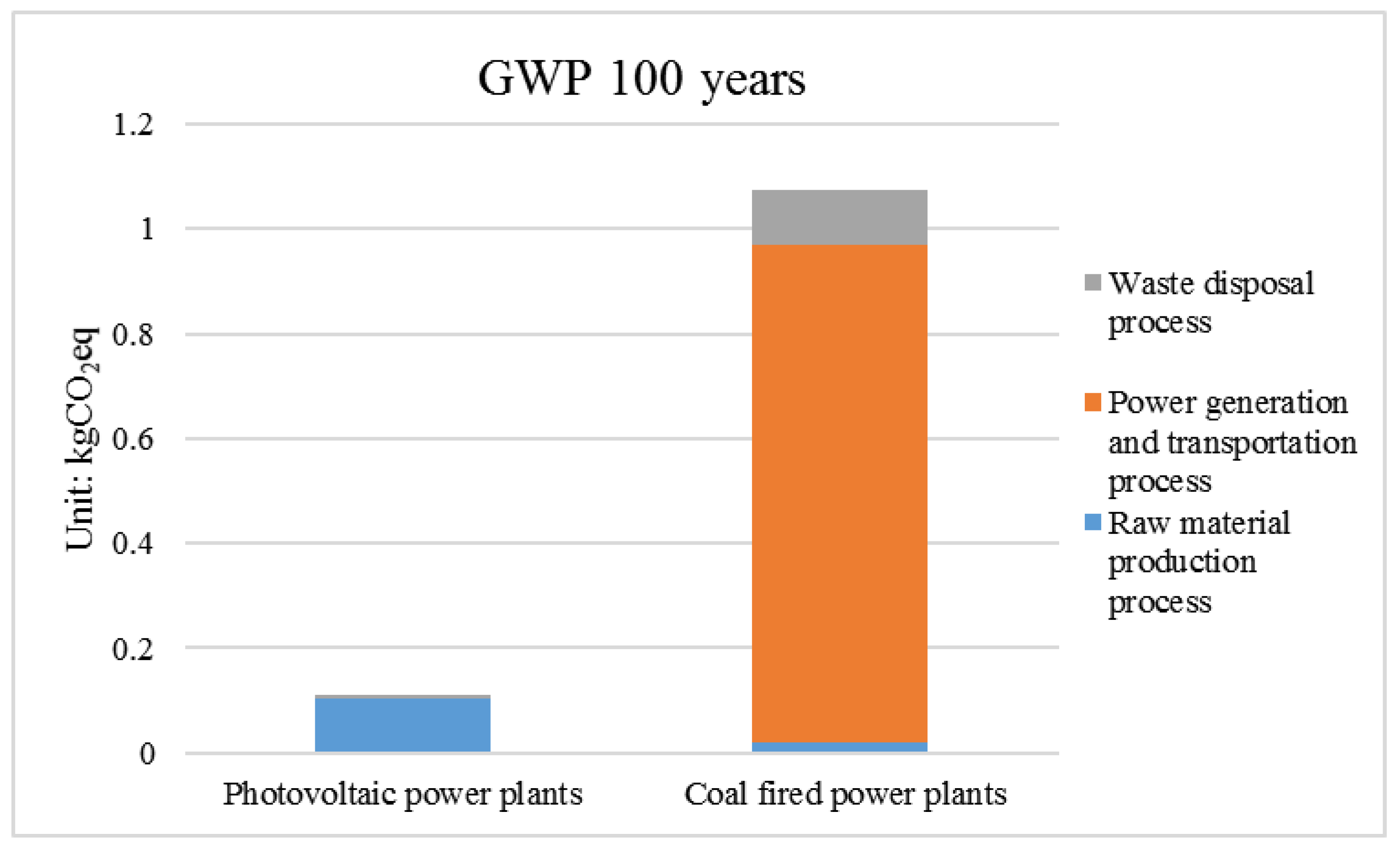

3.1. Comparison of Carbon Emission Results

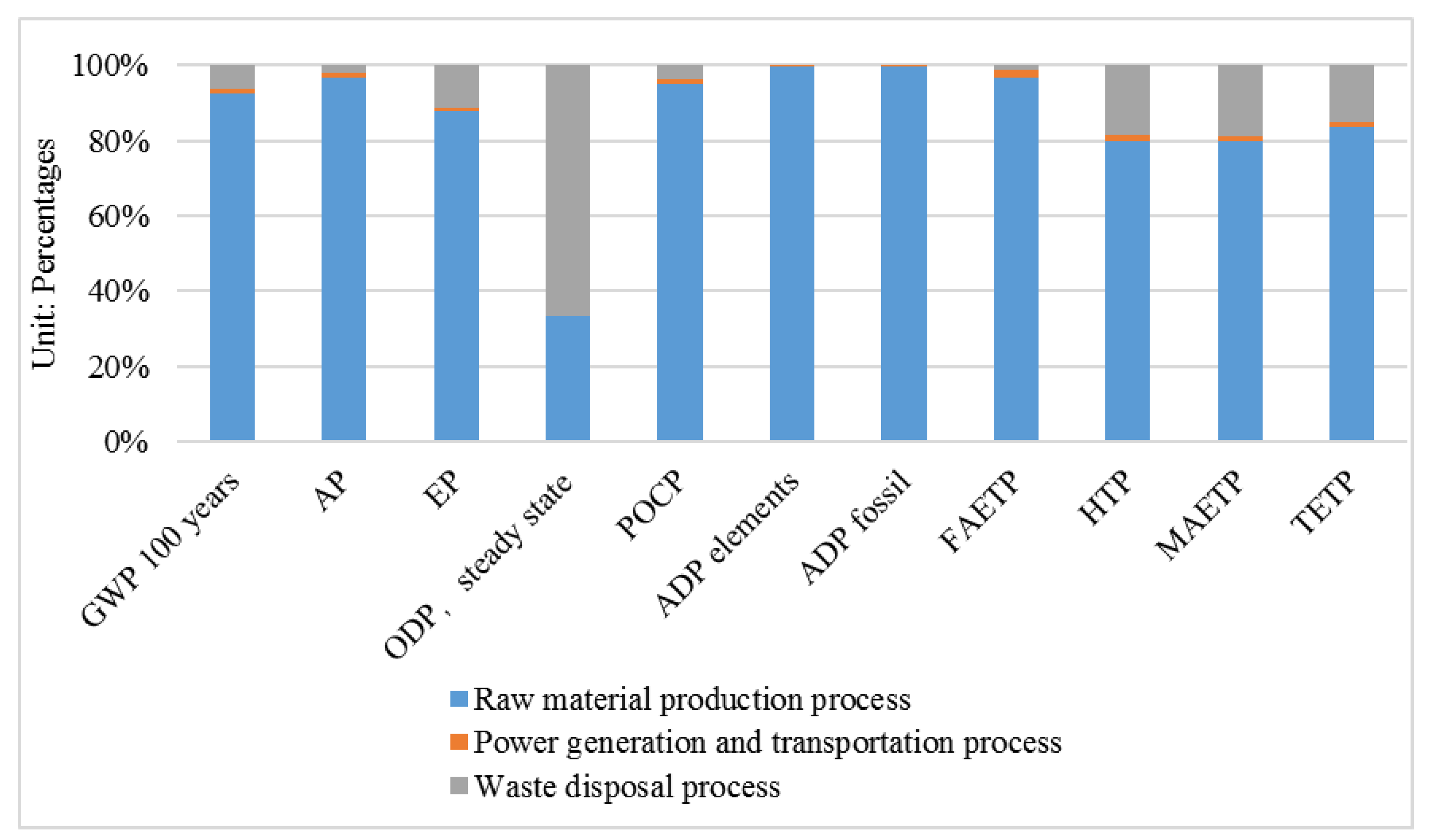

3.2. LCA Results Analysis

3.2.1. Eigenvalue Analysis

3.2.2. Standardized Value Analysis

3.3. Comparison of Employee Well-Being in Coal-Fired Power Plants and Photovoltaic Power Plants

3.3.1. Basic Characteristics of Employee Well-Being in Coal-Fired Power Plants and Photovoltaic Power Plants

3.3.2. Study of the Relationship between Low-Carbon Industrial Models and Human Well-Being

3.3.3. Comparison of Comprehensive Human Well-Being Index

4. Discussion

4.1. Discussion on The Low-Carbon Industrial Model

4.2. Relationship between the Low-Carbon Industrial Model and Human Well-Being

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, J. Study on Carbon Emission of Photovoltaic Power Generation Based on Life Cycle Assessment. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2017. [Google Scholar]

- Brosemer, K.; Schelly, C.; Gagnon, V.; Arola, K.L.; Pearce, J.M.; Bessette, D.; Olabisi, L.S. The energy crises revealed by COVID: Intersections of Indigeneity, inequity, and health. Energy Res. Soc. Sci. 2020, 68, 101661. [Google Scholar] [CrossRef] [PubMed]

- Information Office of the State Council, China. China’s Energy Policy; People’s Publishing House: Beijing, China, 2012; pp. 4–8.

- Destek, M.A.; Sinha, A. Renewable, non-renewable energy consumption, economic growth, trade openness and ecological footprint: Evidence from organisation for economic Co-operation and development countries. J. Clean Prod. 2020, 242, 118537. [Google Scholar] [CrossRef]

- Didenko, I.; Volik, K.; Vasylieva, T.; Lyeonov, S.; Antoniuk, N. Migration, environment, and country safety: Analysis of touchpoints. E3S Web Conf. 2020, 202, 03028. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2021: The Physical Science Basis.Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- Zhao, X.; Luo, D. Driving force of rising renewable energy in China: Environment, regulation and employment. Renew. Sust. Energ. Rev. 2017, 68, 48–56. [Google Scholar] [CrossRef]

- Wang, Z.; Shen YZhang, Y.; Ding, Q. Annual Outlook of China’s Wind and Solar Energy Resources in 2021. 2022. Available online: http://www.cma.gov.cn/zfxxgk/gknr/qxbg/202204/t20220429_4798342.html (accessed on 28 April 2022).

- Cheng, J.; Tong, D.; Zhang, Q.; Liu, Y.; Lei, Y.; Yan, G.; Yan, L.; Yu, S.; Cui, R.Y.; Clarke, L.; et al. Pathways of China’s PM2.5 air quality 2015–2060 in the context of carbon neutrality. Natl. Sci. Rev. 2021, 8, nwab078. [Google Scholar] [CrossRef]

- Guo, X.; Lin, K.; Huang, H.; Li, Y. Carbon footprint of the photovoltaic power supply chain in China. J. Clean Prod. 2019, 233, 626–633. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, H.; Zeng, X. A Life-Cycle Carbon Footprint Assessment of Electric Power Companies. Resour. Sci. 2011, 33, 653–658. [Google Scholar]

- Yi, Y. Comparison of Material Flow and Energy Flow between PV Power Generation and Thermal Power Generation; Shan Dong University: Jinan, China, 2018. [Google Scholar]

- Alizadeh, S.; Avami, A. Development of a framework for the sustainability evaluation of renewable and fossil fuel power plants using integrated LCA-emergy analysis: A case study in Iran. Renew. Energ. 2021, 179, 1548–1564. [Google Scholar] [CrossRef]

- Zak, P.; Hrdina, D.; Kudlacek, I. Comparison of Technical and Environmental Performance of Photovoltaic Panels. In Proceedings of the 13th International Scientific Conference on Electric Power Engineering (EPE), Brno, Czech Republic, 23–25 May 2012. [Google Scholar]

- Liu, S.; Mao, X.; Xing, Y. Estimation and Comparison of Greenhouse Gas Mitigation Potential of New Energy by Life Cycle Assessment in China. Adv. Clim. Chang. Res. 2012, 8, 48–53. [Google Scholar] [CrossRef]

- Xie, Z.; Ma, X.; Huang, Z.; Liao, Y. Life cycle assessment of photovoltaic electricity generation. Environ. Pollut. Control 2013, 35, 106–110. [Google Scholar]

- Jia, Y.; Wang, J.; Han, Z.; Pang, Y.; An, P. Analysis on Environmental Load of Wind, PV and Coal-fired Power Generation Based on Life Cycle Assessment. J. Chin. Soc. Power Eng. 2016, 36, 1000–1009. [Google Scholar]

- Wang, N.; Ren, Y.; Zhu, T.; Meng, F.; Wen, Z.; Liu, G. Life cycle carbon emission modelling of coal-fired power: Chinese case. Energy 2018, 162, 841–852. [Google Scholar] [CrossRef]

- Piasecka, I.; Bałdowska-Witos, P.; Piotrowska, K.; Tomporowski, A. Tomporowski Eco-Energetical Life Cycle Assessment of Materials and Components of Photovoltaic Power Plant. Energies 2020, 13, 1385. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, G. Comparative Study on Life Cycle Assessment of Photovoltaic Power Generation and Coal fired Power Generation. Environ. Sci. Manag. 2014, 39, 86–90. [Google Scholar]

- Song, J.; Lin, P.; Zhang, Z.; Huang, R.; Zhang, J.; Gao, P. Life Cycle Assessment and Environmental Collaborative Development of New Energy Power Generation—A Case Study of New Energy Power Generation in Gansu Province. Resour. Util. China 2020, 38, 170–175. [Google Scholar]

- Yan, H.; Feng, L. Comprehensive Benefit Analysis of Photovoltaic Sand Control Based on EROI. Ecol. Econ. 2020, 36, 170–175. [Google Scholar]

- Liu, M.; Wei, H.; Dong, X.; Wang, X.-C.; Zhao, B.; Zhang, Y. Integrating Land Use, EcosystemService, and Human Well-Being: A Systematic Review. Sustainability 2022, 14, 6926. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, X.; Wang, X.C.; Liu, M.; Zhang, P.; Liu, R.; Huang, J.; Dong, S. Study on the Relationship between Low-Carbon Circular Farming and Animal Husbandry Models and Human Well-Being: A Case Study of Yongchang County, Gansu Province. Sustainability 2022, 14, 8230. [Google Scholar] [CrossRef]

- Can, B.; Ahmed, Z.; Ahmad, M.; Can, M. Do renewable energy consumption and green trade openness matter for human well-being? Empirical evidence from European Union countries. Soc. Indic. Res. 2022, 164, 1043–1059. [Google Scholar]

- Li, Q.; Chen, H. The Relationship between Human Well-Being and Carbon Emissions. Sustainability 2021, 13, 547. [Google Scholar] [CrossRef]

- Wang, T.; Gao, F.; Wang, B.; Wang, P.; Wang, Q.; Song, H.; Yin, C. Status and suggestions on ecological protection and restoration of Qilian Mountains. J. Glaciol. Geocryol. 2017, 39, 229–234. [Google Scholar]

- Zhang, C.N.; Zhang, Y. Evaluation of ecosystem service value of qilian mountain national park in qinghai province. Environ. Prot. 2019, 47, 41–47. [Google Scholar]

- Yu, X.; Fu, D. Summary of Comprehensive Evaluation Methods of Multiple Indexes. Stat. Decis. 2004, 11, 119–121. [Google Scholar]

- Cai, G.Y.; Yin, X.J.; Zhao, J.R. Recognition and comprehensive evaluation of human well-being in Qinghai Lake basin. J. Glaciol. Geocryol. 2014, 36, 469–478. [Google Scholar]

- Hall, J.; Giovannini, E.; Morrone, A.; Ranuzzi, G. A Framework to Measure the Progress of Societies; Statistics Directorate Working Paper No.34; OECD Publishing: Paris, France, 2010. [Google Scholar]

- Li, J.; Li, S.; Wu, F. Research on carbon emission reduction benefit of wind power project based on life cycle assessment theory. Renew. Energ. 2020, 155, 456–468. [Google Scholar] [CrossRef]

- Chang, Z.; Liu, S.; Wang, Q.; Wang, F.; Sun, T.; Liu, S.; Wang, F. The ecological function of desert and Gobi photovoltaic industry in sand control and sand management—Gansu Hexi Corridor as an example. Ecol. Econ. 2018, 34, 199–202+208. [Google Scholar]

- Zhou, N. Connotation and evaluation of low-carbon industry. Poyang Lake Acad. J. 2012, 01, 24–30. [Google Scholar]

- Cha, J.M.; Price, V.; Stevis, D.; Vachon, T.E.; Brescia-Weiler, M. Workers and Communities in Transition: Report of the Just Transition Listening Project; Labor Network for Sustainability: Takoma Park, MD, USA, 2021. [Google Scholar]

- Sicotte, D.M.; Joyce, K.A.; Hesse, A. Necessary, welcome or dreaded? Insights on low-carbon transitions from unionized energy workers in the United States. Energy Res. Soc. Sci. 2022, 88, 102511. [Google Scholar]

- Nitzbon, J.; Heitzig, J.; Parlitz, U. Sustainability, collapse and oscillations in a simple World-Earth model. Environ. Res. Lett. 2017, 12, 074020. [Google Scholar] [CrossRef]

| Material and Energy Input | Quantity | Material and Energy Output | Quantity | |

|---|---|---|---|---|

| Power generation stage of coal-fired power plant | Standard coal /kg | 0.353 | CO2/kg | 0.947 |

| recycled water /kg | 0.325 | Fly ash /kg | 0.133 | |

| electric energy /MJ | 0.150 | slag /kg | 0.028 | |

| limestone /kg | 9.76 × 10−3 | SO2/kg | 4.93 × 10−5 | |

| NOX/kg | 1.17 × 10−4 | |||

| smoke /kg | 3.59 × 10−6 | |||

| Power generation/MJ | 3.60 | |||

| Heating capacity/MJ | 4.35 |

| Materials and Energy Consumption at Each Stage | Material Input | Material Output | ||

|---|---|---|---|---|

| Industrial silicon production | material | value | material | value |

| silica /(kg*kg−1) | 27.85 | CO2/kg | 48.15 | |

| charcoal /(kg*kg−1) | 4.27 | NOx/kg | 2 | |

| petroleum coke /(kg*kg−1) | 7.2 | SiO2/kg | 2.82 | |

| graphite electrode /(kg*kg−1) | 0.69 | solid waste/kg | 7.24 | |

| wood chips /(kg*kg−1) | 4.08 | SO2/kg | 7.34 | |

| bituminous coal /(kg*kg−1) | 1.68 | industrial silicon/kg | 10.2 | |

| circulating water /(kg*kg−1) | 1836.2 | |||

| electricity consumption /(kW*h*kg−1) | 119.28 | |||

| Polysilicon | industrial silicon /(kg*kg−1) | 10.2 | solid waste/kg | 1.75 |

| hydrogen /(kg*kg−1) | 0.68 | Hydrogen chloride/kg | 0.91 | |

| chlorine /(kg*kg−1) | 9.13 | COD/g | 35.08 | |

| NaOH/(kg*kg−1) | 448.99 | SS/g | 39.42 | |

| electricity consumption /(kW*h*kg−1) | 875.15 | sludge/g | 142.08 | |

| cooling water /(kg*kg−1) | 1642.24 | chloride/g | 11.02 | |

| polysilicon/kg | 7.61 | |||

| Silicon wafer | polysilicon /(kg*kg−1) | 7.61 | silicon wafer/kg | 240.72 |

| silicon carbide /(kg*kg−1) | 15.38 | waste cutting fluid/kg | 3.71 | |

| quartz crucible /(kg*kg−1) | 2.28 | solid waste/kg | 0.067 | |

| steel wire /(kg*kg−1) | 8.71 | COD/kg | 2.85 | |

| argon /(kg*kg−1) | 1.75 | chloride/kg | 0.067 | |

| polyethylene glycol /(kg*kg−1) | 15.85 | |||

| HCl/(kg*kg−1) | 0.016 | |||

| NaOH/(kg*kg−1) | 0.058 | |||

| electricity consumption/(kW*h*kg−1) | 175.73 | |||

| Battery chip production | polysilicon chip /(kg*kg−1) | 240.72 | battery chip /kWp | 1.02 |

| fresh water /(kg*kg−1) | 1261.72 | Cl2/kg | 0.083 | |

| silver /(kg*kg−1) | 0.063 | NOx/kg | 0.031 | |

| aluminum/(kg*kg−1) | 0.388 | solid waste/kg | 0.289 | |

| nitrogen /(kg*kg−1) | 10.92 | VOC/kg | 1.19 | |

| oxygen /(kg*kg−1) | 0.115 | COD/kg | 0.129 | |

| NaOH/(kg*kg−1) | 0.201 | chloride/kg | 0.016 | |

| HCl/(kg*kg−1) | 0.204 | fluoride/kg | 0.02 | |

| electricity consumption /(kW*h*kg−1) | 126.48 | HCl/kg | 0.004 | |

| SiH4/(kg*kg−1) | 0.015 | |||

| NH3/(kg*kg−1) | 0.051 | |||

| POCl3/(kg*kg−1) | 0.007 | |||

| HF/(kg*kg−1) | 1 | |||

| HNO3/(kg*kg−1) | 0.112 | |||

| Battery panel production | battery chip/(kWp * pcs −1) | 1.02 | solar cells/kWp | 1 |

| aluminum frame/(kg* pcs−1) | 13.12 | TVOC/g | 3.24 | |

| toughened glass/(kg* pcs −1) | 62.22 | welding fume/g | 1.04 | |

| EVA/(kg* pcs −1) | 7.06 | solid waste/g | 132 | |

| TPA Backplane/(kg* pcs −1) | 3.64 | |||

| organic silica gel/(kg* pcs −1) | 40 | |||

| copper/(kg* pcs −1) | 0.49 | |||

| water/(kg* pcs −1) | 348,610 | |||

| electricity consumption/(kW*h* pcs −1) | 58.5 | |||

| Inverter and bracket system | aluminum/(kg /m2) | 2.8 | ||

| steel/(kg /m2) | 1.5 | |||

| other/(kg /m2) | 0.1 | |||

| inverter W/pcs | 2 × 500 | |||

| Energy consumption during transportation | transportation energy consumption/(kWh/kWp) | 47 | ||

| installation energy consumption/(kWh/kWp) | 0.08 | |||

| Energy consumption in waste treatment stage | transportation energy consumption/(kWh/kWp) | 12 | ||

| energy consumption of silicon wafer recovery/(kWh/kWp) | 364 | |||

| crushing energy consumption/(kWh/kWp) | 0.02 | |||

| Parameter Type | Value |

|---|---|

| Dimension and structure (mm) | 1638*982*40 |

| Maximum power | 245 Wp |

| Component life | 25 years |

| Conversion efficiency | 15.23% |

| Type | Raw Material Production Process | Power Generation and Transportation Process | Waste Disposal Process | Unit |

|---|---|---|---|---|

| GWP100 years | 2.06 × 10−2 | 9.48 × 10−1 | 1.07 × 10−1 | kg CO2eq. |

| AP | 1.01 × 10−4 | 5.99 × 10−5 | −3.99 × 10−6 | kg SO2eq. |

| EP | 1.82 × 10−5 | 1.56 × 10−5 | 1.12 × 10−4 | kg Phosphate eq. |

| ODP, steady state | 3.59 × 10−17 | 1.02 × 10−17 | −8.20 × 10−18 | kg R11 eq. |

| POCP | −1.90 × 10−5 | 3.39 × 10−1 | 2.51 × 10−5 | kg Ethene eq. |

| ADP elements | 6.32 × 10−10 | 3.98 × 10−9 | 1.06 × 10−9 | kg Sb eq. |

| ADP fossil | 1.23 × 10−1 | 5.38 × 10−3 | 2.03 × 10−2 | MJ |

| FAETP | 1.12 × 10−4 | 2.22 × 10−6 | 1.35 × 10−5 | kg DCB eq. |

| HTP | 3.70 × 10−3 | 1.69 × 10−4 | −2.86 × 10−3 | kg DCB eq. |

| MAETP | 1.94 × 10 | 6.40 × 10−2 | −9.58 × 10−1 | kg DCB eq. |

| TETP | 8.35 × 10−5 | 1.10 × 10−6 | 1.56 × 10−4 | kg DCB eq. |

| Type | Raw Material Production Process | Power Generation and Transportation Process | Waste Disposal Process | Unit |

|---|---|---|---|---|

| GWP100 years | 1.04 × 10−1 | 1.36 × 10−3 | 7.04 × 10−3 | kg CO2eq. |

| AP | 4.41 × 10−4 | 5.71 × 10−6 | 8.95 × 10−6 | kg SO2eq. |

| EP | 4.86 × 10−5 | 4.15 × 10−7 | 6.26 × 10−6 | kg Phosphate eq. |

| ODP, steady state | 4.76 × 10−14 | 4.85 × 10−18 | 9.46 × 10−14 | kg R11 eq. |

| POCP | 4.63 × 10−5 | 5.42 × 10−7 | 1.79 × 10−6 | kg Ethene eq. |

| ADP elements | 7.03 × 10−7 | 7.81 × 10−11 | 9.60 × 10−10 | kg Sb eq. |

| ADP fossil | 1.23 × 101 | 1.37 × 10−2 | 1.67 × 10−2 | MJ |

| FAETP | 5.25 × 10−4 | 1.32 × 10−5 | 5.94 × 10−6 | kg DCB eq. |

| HTP | 1.87 × 10−2 | 4.80 × 10−4 | 4.31 × 10−3 | kg DCB eq. |

| MAETP | 1.53 × 101 | 2.59 × 10−1 | 3.61 × 10 | kg DCB eq. |

| TETP | 6.05 × 10−4 | 1.13 × 10−5 | 1.09 × 10−4 | kg DCB eq. |

| Different Power Models | Type | Raw Material Production Process | Power Generation and Transportation Process | Waste Disposal Process | Total | Unit |

|---|---|---|---|---|---|---|

| Coal fired power plant | GWP100 years | 4.43 × 10−15 | 2.09 × 10−13 | 2.04 × 10−14 | 2.34 × 10−13 | kg CO2eq. |

| AP | 2.57 × 10−15 | 1.53 × 10−15 | −1.02 × 10−16 | 4.00 × 10−15 | kg SO2eq. | |

| EP | 7.62 × 10−16 | 6.51 × 10−16 | 4.70 × 10−15 | 6.11 × 10−15 | kg Phosphate eq. | |

| ODP, steady state | 9.81 × 10−25 | 2.79 × 10−25 | −2.24 × 10−25 | 1.04 × 10−24 | kg R11 eq. | |

| POCP | −3.36 × 10−15 | 5.99 × 10−16 | 4.44 × 10−15 | 1.68 × 10−15 | kg Ethene eq. | |

| ADP elements | 1.14 × 10−17 | 7.06 × 10−17 | 1.88 × 10−17 | 1.01 × 10−16 | kg Sb eq. | |

| ADP fossil | 2.27 × 10−15 | 9.91 × 10−17 | 3.74 × 10−16 | 2.74 × 10−15 | MJ | |

| FAETP | 3.22 × 10−16 | 6.40 × 10−18 | 3.89 × 10−17 | 3.67 × 10−16 | kg DCB eq. | |

| HTP | 1.02 × 10−14 | 4.64 × 10−16 | −7.86 × 10−15 | 2.79 × 10−15 | kg DCB eq. | |

| MAETP | 6.77 × 10−14 | 2.23 × 10−15 | −3.34 × 10−14 | 3.65 × 10−14 | kg DCB eq. | |

| TETP | 5.21 × 10−16 | 6.84 × 10−18 | 9.72 × 10−16 | 1.50 × 10−15 | kg DCB eq. | |

| photovoltaic power plant | GWP100 years | 2.22 × 10−14 | 3.01 × 10−16 | 1.38 × 10−15 | 2.39 × 10−14 | kg CO2eq |

| AP | 1.09 × 10−14 | 1.46 × 10−16 | 2.28 × 10−16 | 1.13 × 10−14 | kg SO2eq. | |

| EP | 2.03 × 10−15 | 1.73 × 10−17 | 2.61 × 10−16 | 2.31 × 10−15 | kg Phosphate eq. | |

| ODP, steady state | 1.30 × 10−21 | 1.32 × 10−25 | 2.58 × 10−21 | 3.88 × 10−21 | kg R11 eq. | |

| POCP | 8.80 × 10−15 | 9.57 × 10−17 | 3.16 × 10−16 | 9.21 × 10−15 | kg Ethene eq. | |

| ADP elements | 1.25 × 10−14 | 1.41 × 10−18 | 1.70 × 10−17 | 1.25 × 10−14 | kg Sb eq. | |

| ADP fossil | 2.12 × 10−14 | 2.52 × 10−16 | 3.08 × 10−16 | 2.18 × 10−14 | MJ | |

| FAETP | 1.51 × 10−15 | 3.80 × 10−17 | 1.71 × 10−17 | 1.57 × 10−15 | kg DCB eq. | |

| HTP | 5.16 × 10−14 | 1.32 × 10−15 | 1.19 × 10−14 | 6.48 × 10−14 | kg DCB eq. | |

| MAETP | 5.33 × 10−13 | 9.02 × 10−15 | 1.26 × 10−13 | 6.68 × 10−13 | kg DCB eq. | |

| TETP | 3.78 × 10−15 | 7.02 × 10−17 | 6.80 × 10−16 | 4.53 × 10−15 | kg DCB eq. |

| Target Layer | Standard Layer | Index Layer | Coal-Fired Power Plant Employees | Photovoltaic Power Plant Employees | |

|---|---|---|---|---|---|

| The basic conditions needed to maintain a high-quality life | Economic living standard | Per capita monthly net income (yuan) | 2819 | 4019 | |

| Income satisfaction | Quite satisfied | Quite satisfied | |||

| Energy consumption | Energy consumption per capita (Structure) | Coal (kg) | 0 | 395 | |

| Natural gas (m3) | 457.4 | 5.15 | |||

| Electricity (kwh) | 460.5 | 592.6 | |||

| Heating cost (yuan) | 494.8 | 414.6 | |||

| Housing conditions | Per capita housing area (m2) | 33.3 | 36.7 | ||

| Network communication coverage | Satisfaction of network communication | Not really satisfied | General | ||

| Health | Vegetable and meat satisfaction | Vegetable and meat satisfaction | General | General | |

| Physical health satisfaction | Physical health satisfaction | Quite satisfied | Quite satisfied | ||

| Satisfaction of water quality | Satisfaction of water quality | General | General | ||

| Satisfaction with medical conditions and facilities | Satisfaction with medical conditions and facilities | General | General | ||

| Proportion of purchase of “five insurances and one fund” or insurance | Proportion of people participating in five insurances and one fund to the total | 80% | 94.1% | ||

| Security | Satisfaction with ecological security | Satisfaction with ecological security | General | General | |

| Satisfaction with living safety | Housing satisfaction | Quite satisfied | General | ||

| Work safety | Number of work-related injuries | 0 | 0 | ||

| Good social relations | Educational level | Percentage of people with high school degree or above in total | 93.3% | 82.2% | |

| Social relations | Satisfaction with social relations | Quite satisfied | Quite satisfied | ||

| Family burden | Total number of family dependents | 2 | 3 | ||

| Family Status | Family relationship satisfaction | Quite satisfied | Quite satisfied | ||

| Feature | Category | Frequency | Percentage/% | Feature | Category | Frequency | Percentage/% | ||

|---|---|---|---|---|---|---|---|---|---|

| Socio economic characteristics of employees in coal-fired power plants | Gender | Male | 24 | 80 | Socio economic characteristics of photovoltaic power plant employees | Gender | Man | 12 | 70.6 |

| Female | 6 | 20 | female | 5 | 29.4 | ||||

| Age | 18–30 years old | 15 | 50 | Age | 18–30 years old | 7 | 41.2 | ||

| 30–40 years old | 3 | 10 | 30–40 years old | 6 | 35.3 | ||||

| 40–50 years old | 6 | 20 | 40–50 years old | 2 | 11.8 | ||||

| 50–70 years old | 6 | 20 | 50–70 years old | 2 | 11.8 | ||||

| Over 70 years old | 0 | 0 | Over 70 years old | 0 | 0 | ||||

| Nationality | Han nationality | 24 | 80 | Nationality | Han nationality | 17 | 100 | ||

| Hui nationality | 6 | 20 | Hui nationality | 0 | 0 | ||||

| other | 0 | 0 | other | 0 | 0 | ||||

| Annual income (yuan) | <10,000 | 0 | 0 | Annual income (yuan) | <10,000 | 0 | 0 | ||

| 10,000 to 30,000 | 11 | 36.7 | 10,000 to 30,000 | 7 | 41.2 | ||||

| 30,000 to 50,000 (inclusive) | 18 | 60 | 30,000 to 50,000 (inclusive) | 2 | 11.8 | ||||

| 50,000–100,000 yuan (inclusive) | 1 | 3.3 | 50,000–100,000 yuan (inclusive) | 8 | 47 | ||||

| 100,000 to 200,000 | 0 | 0 | 100,000 to 200,000 | 0 | 0 | ||||

| Is there a “five social insurance and one housing fund” | yes | 24 | 80 | Is there a “five social insurance and one housing fund” | yes | 17 | 100 | ||

| no | 6 | 20 | no | 0 | 0 | ||||

| How many people in the family | ≤2 | 1 | 3.3 | How many people in the family | ≤2 | 0 | 0 | ||

| 3 | 14 | 46.7 | 3 | 1 | 5.8 | ||||

| 4 | 14 | 46.7 | 4 | 2 | 11.8 | ||||

| 5 | 1 | 3.3 | 5 | 4 | 23.5 | ||||

| >5 | 0 | 0 | >5 | 10 | 58.8 | ||||

| Education level | Junior high school and below | 2 | 6.7 | Education level | Junior high school and below | 2 | 11.8 | ||

| High school or technical secondary school | 6 | 20 | High school or technical secondary school | 2 | 11.8 | ||||

| Junior college | 8 | 26.7 | Junior college | 12 | 70.6 | ||||

| Bachelor or college | 14 | 46.7 | Bachelor or college | 1 | 5.9 | ||||

| Postgraduate | 0 | 0 | Postgraduate | 0 | 0 |

| Per Capita Income–Environmental Benefits | Coal-Fired Plants | PV Plants | Units |

|---|---|---|---|

| IAP | 7.04 × 1017 | 3.57 × 1017 | CNY/kg SO2-Equiv. |

| IGWP | 1.21 × 1016 | 1.68 × 1017 | CNY/kg CO2-Equiv. |

| IPOCP | 1.68 × 1018 | 4.37 × 1017 | CNY/kg R11-Equiv. |

| IODP | 2.72 × 1027 | 1.04 × 1024 | CNY/kg Ethene-Equiv. |

| IEP | 4.61 × 1017 | 1.74 × 1018 | CNY/kg R11-Equiv. |

| IFAETP | 7.67 × 1018 | 2.56 × 1018 | CNY/kg P-Equiv. |

| IHTP | 1.01 × 1018 | 6.20 × 1016 | CNY/kg DCB-Equiv. |

| IMAETP | 7.71 × 1016 | 6.02 × 1015 | CNY/kg DCB-Equiv. |

| ITETP | 1.88 × 1018 | 8.88 × 1017 | CNY/kg DCB-Equiv. |

| Employee Well-Being in Coal-Fired Power Plant | Employee Well-Being in Photovoltaic Power Plant | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Target layer | Standard Layer | Standardized value | Weight | Single score | Total score | Standardized value | Weight | Single score | Total score |

| Socio economic characteristics of employees in coal-fired power plants | Economic living standard | 0.333 | 0.209 | 0.070 | 0.175 | 0.529 | 0.155 | 0.082 | 0.175 |

| Energy consumption | 0.484 | 0.074 | 0.036 | 0.328 | 0.065 | 0.021 | |||

| Network communication | 0.433 | 0.066 | 0.028 | 0.667 | 0.061 | 0.041 | |||

| Housing conditions | 0.665 | 0.062 | 0.041 | 0.388 | 0.079 | 0.031 | |||

| Health | Vegetable and meat satisfaction | 0.533 | 0.052 | 0.028 | 0.187 | 0.588 | 0.052 | 0.031 | 0.281 |

| Satisfaction with medical facilities | 0.633 | 0.049 | 0.031 | 0.627 | 0.076 | 0.048 | |||

| Satisfaction of water quality | 0.500 | 0.041 | 0.020 | 0.647 | 0.068 | 0.044 | |||

| Satisfaction with physical health | 0.689 | 0.099 | 0.068 | 0.676 | 0.124 | 0.084 | |||

| Proportion of purchasing “five insurances and one fund” | 0.800 | 0.049 | 0.039 | 0.941 | 0.080 | 0.075 | |||

| Security | Satisfaction with ecological security | 0.567 | 0.053 | 0.030 | 0.118 | 0.431 | 0.056 | 0.024 | 0.095 |

| Satisfaction with living safety | 0.578 | 0.068 | 0.039 | 0.529 | 0.050 | 0.026 | |||

| Work safety | 1.000 | 0.049 | 0.049 | 1.000 | 0.045 | 0.045 | |||

| Good social relationships | Education Level | 0.933 | 0.025 | 0.023 | 0.081 | 0.882 | 0.026 | 0.023 | 0.061 |

| Social Relations | 0.589 | 0.043 | 0.025 | 0.441 | 0.024 | 0.011 | |||

| Level of family burden | 0.678 | 0.030 | 0.020 | 0.392 | 0.035 | 0.014 | |||

| Family status satisfaction | 0.383 | 0.033 | 0.012 | 0.559 | 0.024 | 0.014 | |||

| Comprehensive human well-being index | 0.561 | 0.613 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Dong, X.; Wang, X.; Zhang, P.; Liu, M.; Zhang, Y.; Xiao, R. The Relationship between the Low-Carbon Industrial Model and Human Well-Being: A Case Study of the Electric Power Industry. Energies 2023, 16, 1357. https://doi.org/10.3390/en16031357

Zhang Y, Dong X, Wang X, Zhang P, Liu M, Zhang Y, Xiao R. The Relationship between the Low-Carbon Industrial Model and Human Well-Being: A Case Study of the Electric Power Industry. Energies. 2023; 16(3):1357. https://doi.org/10.3390/en16031357

Chicago/Turabian StyleZhang, Ying, Xiaobin Dong, Xuechao Wang, Peng Zhang, Mengxue Liu, Yufang Zhang, and Ruiming Xiao. 2023. "The Relationship between the Low-Carbon Industrial Model and Human Well-Being: A Case Study of the Electric Power Industry" Energies 16, no. 3: 1357. https://doi.org/10.3390/en16031357

APA StyleZhang, Y., Dong, X., Wang, X., Zhang, P., Liu, M., Zhang, Y., & Xiao, R. (2023). The Relationship between the Low-Carbon Industrial Model and Human Well-Being: A Case Study of the Electric Power Industry. Energies, 16(3), 1357. https://doi.org/10.3390/en16031357