Online Multiphase Flow Measurement of Crude Oil Properties Using Nuclear (Proton) Magnetic Resonance Automated Measurement Complex for Energy Safety at Smart Oil Deposits

Abstract

1. Introduction

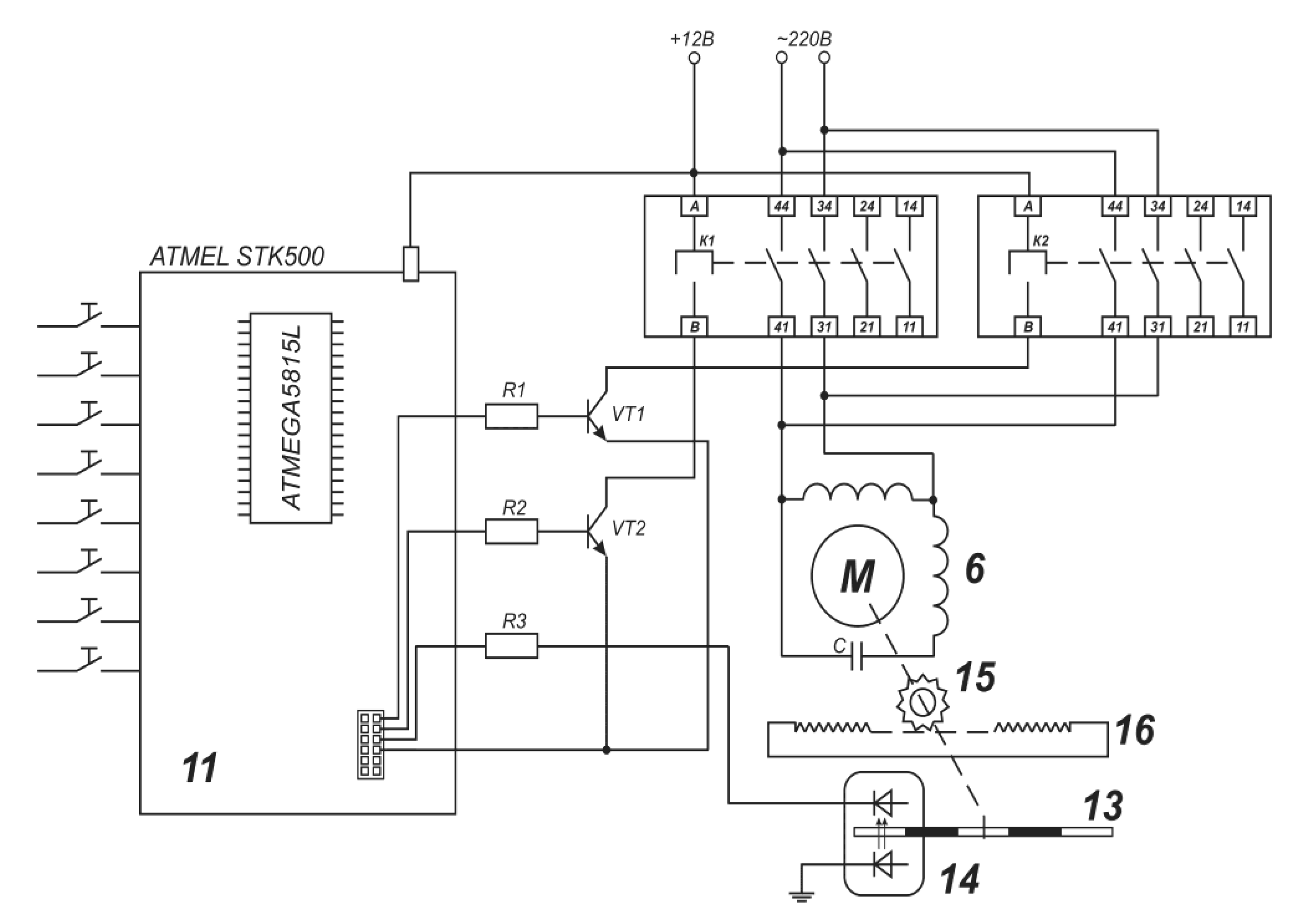

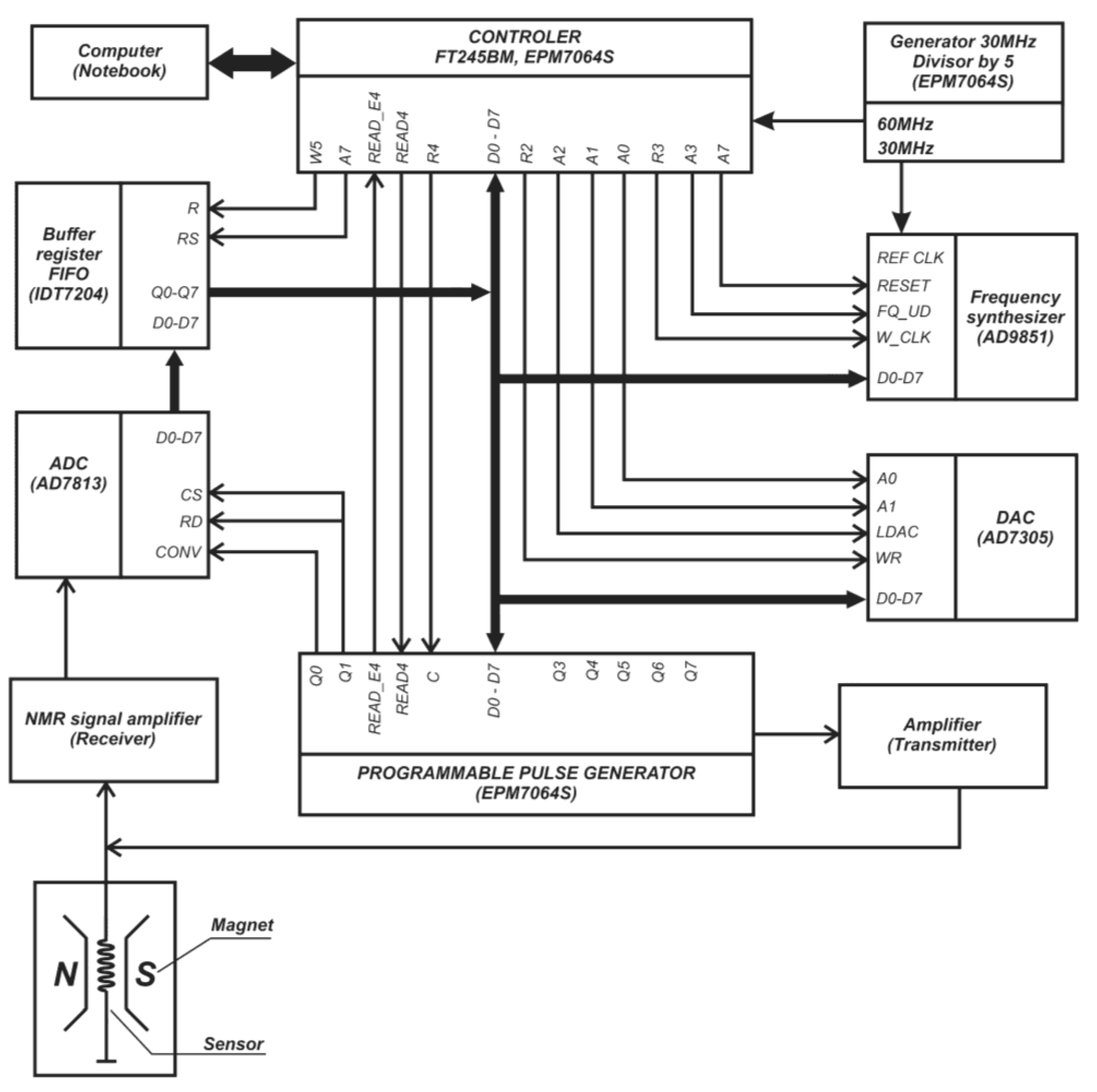

2. Methodology and Apparatus for Monitoring of the Oil Disperse Systems

- Versatility and ease of installation in production lines, and control of opaque, aggressive liquids in real time.

- A wide range of measured ODS characteristics in the entire range of their changes: velocities υi of the fluid component flows; concentrations of water W and oil O, gas factor G, density ρ, viscosity η, and concentrations of ARP; and molecular weight and pour points. Multi-component analysis by a single complex, and selection of homogenized samples from pipes of any diameter in the bypass mode.

- Lack of contact with the measured liquid and, therefore, the absence of its destruction and destructive effect on the equipment. No moving parts for measurements.

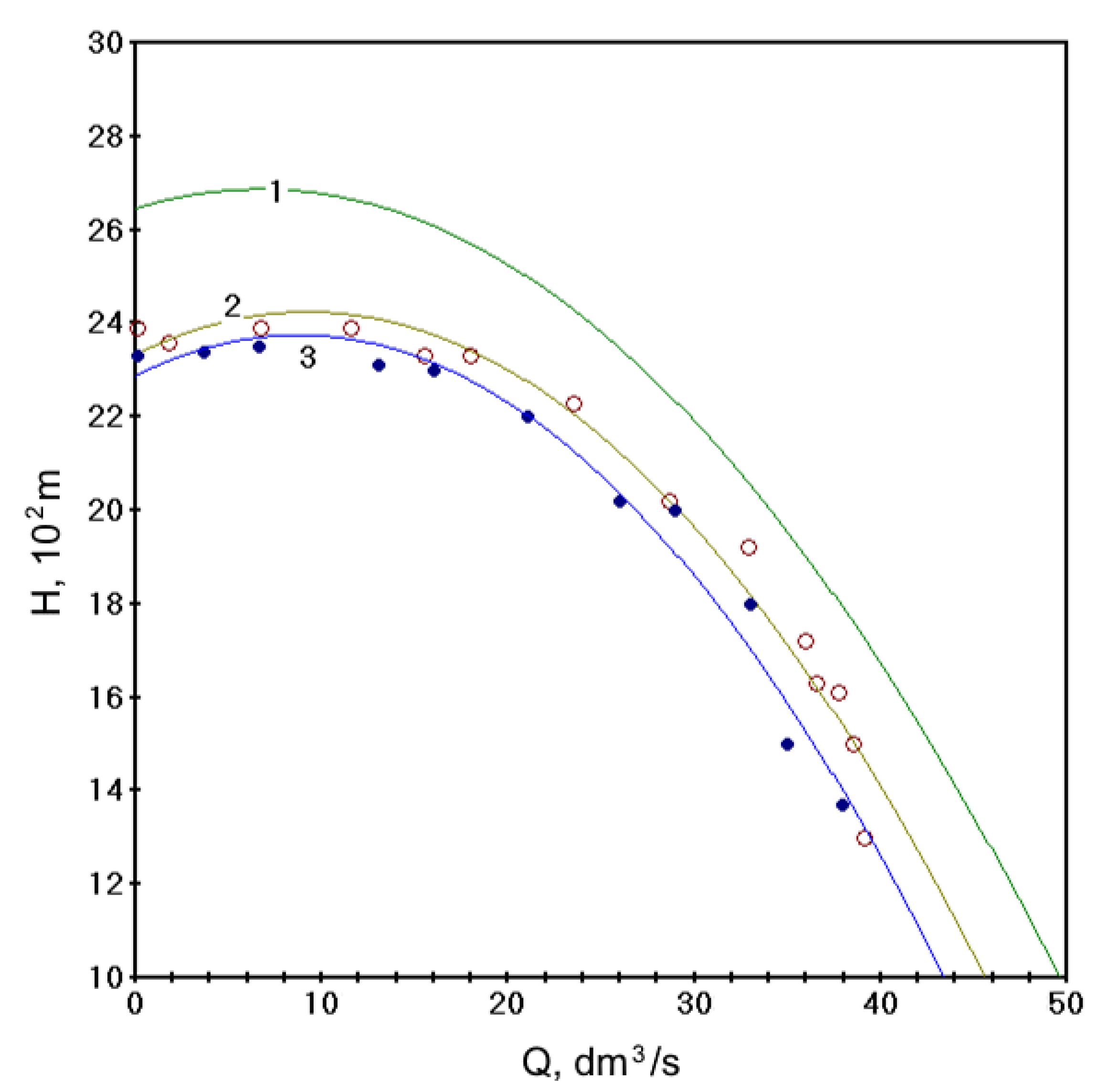

3. Results and Discussion

- -

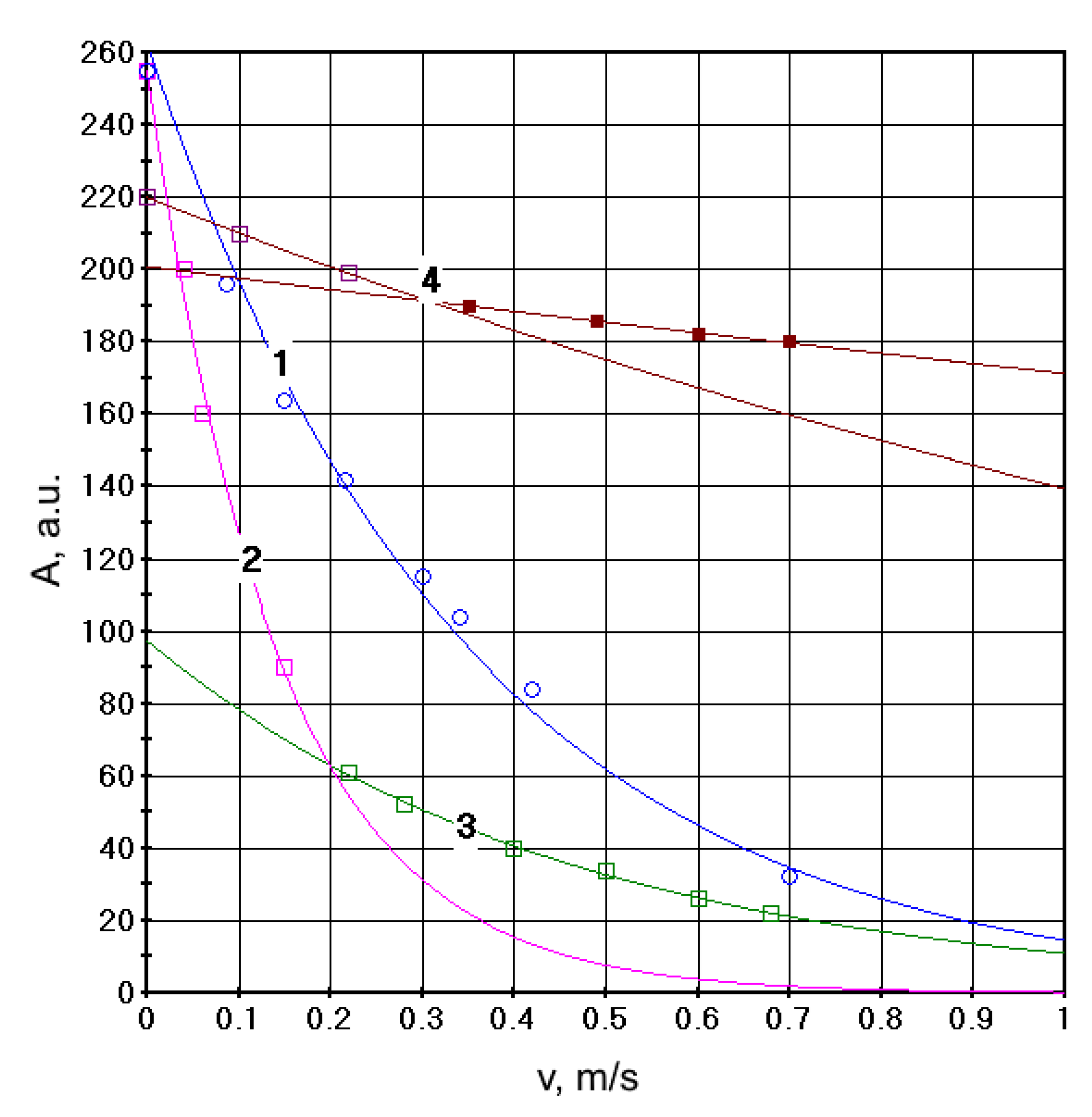

- Measurement of the spin-spin relaxation times and SE amplitudes Ai in immobile water T2W and oil/oil product T2O in the time range t = 2Nτ, where N—number of RF-pulses in the CPMG-sequence 90° − Tτo − T[180° − 2τo]N − T;

- -

- Online measurement of the effective spin-spin relaxation times T2* in flow emulsion and using them for:

- 2.

- Determination of gas saturation of the oil-well liquid GPMR in the range GPMR = 0–250 with error δ ≈ ±3.8% using the equation [56,57,58,59,63,70,79]:where A0 and AG—initial SE amplitudes in the filled by liquid probe head and filled oil-well liquid, containing gas, KG—correction coefficient. It should be mentioned that PMR parameter GPMR allows for the control of specific energy consumption (SEC) at pipeline transportation because for SEC and GPMR, the following equation is valid:GPMR = KG(A0 − AG)/A0,SEC = 155.3 − 0.796GPMR,

- 3.

- Measurement of oil density ρo in the expanded range 700–1200 kg/m3 with main reduced error ∆ρ/ρmax~±1%:

- 4.

- 5.

- 6.

- Measurement of oil mean molecular mass with the error δ ≈ 2.1% in the expanded range MM = 50–1000 a.u.m. using the equation:

- 7.

- 8.

- Measurement of salts concentrations C in water using the equation:

- 9.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ODS | oil dispersed system |

| AMC | automatic measuring complex |

| PMR | nuclear (proton) magnetic resonance |

| DSF | digital smart field |

| AR | asphaltene–resins |

| ARP | asphaltene–resins–paraffins |

| PMRR | PMR relaxometry |

| RF | radio frequency |

| SE | spin-echo |

| ADC | analog-to-digital converter |

| SEC | specific energy consumption |

References

- Liu, Q.; Zhao, Z.; Liu, Y.; He, Y. Natural resources commodity prices volatility, economic performance and environment: Evaluating the role of oil rents. Resour. Policy 2022, 76, 102548. [Google Scholar] [CrossRef]

- Cengiz, E.; Babagiray, M.; Emre Aysal, F.; Aksoy, F. Kinematic viscosity estimation of fuel oil with comparison of machine learning methods. Fuel 2022, 316, 123422. [Google Scholar] [CrossRef]

- Xu, Y.; Lun, Z.; Pan, Z.; Wang, H.; Zhou, X.; Zhao, C.; Zhang, D. Occurrence space and state of shale oil: A review. J. Pet. Sci. Eng. 2022, 211, 110183. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, L.; Wei, Z.; Wang, Y.; Deng, J. Effect of components on the emulsification characteristic of glucose solution emulsified heavy fuel oil. Energy 2022, 244, 123147. [Google Scholar] [CrossRef]

- Gizatullin, B.; Gafurov, M.; Murzakhanov, F.; Vakhin, A.; Mattea, C.; Stapf, S. Molecular Dynamics and Proton Hyperpolarization via Synthetic and Crude Oil Porphyrin Complexes in Solid and Solution States. Langmuir 2021, 37, 6783–6791. [Google Scholar] [CrossRef]

- De Robbio, R.; Cameretti, M.C.; Mancaruso, E. Investigation by modelling of a plug-in hybrid electric commercial vehicle with diesel engine on WLTC. Fuel 2022, 317, 123519. [Google Scholar] [CrossRef]

- Luján, J.M.; García, A.; Monsalve-Serrano, J.; Martínez-Boggio, S. Effectiveness of hybrid powertrains to reduce the fuel consumption and NOx emissions of a Euro 6d-temp diesel engine under real-life driving conditions. Energy Convers. Manag. 2019, 199, 111987. [Google Scholar] [CrossRef]

- Davydov, R.; Dudkin, V. The Nuclear Magnetic Flowmeter for Monitoring the Consumption and Composition of Oil and Its Complex Mixtures in Real-Time. Energies 2022, 15, 3259. [Google Scholar] [CrossRef]

- Nascimento da Silva, G.; Rochedo, P.R.R.; Szklo, A. Renewable hydrogen production to deal with wind power surpluses and mitigate carbon dioxide emissions from oil refineries. Appl. Energy 2022, 311, 118631. [Google Scholar] [CrossRef]

- Davydov, V.V.; Myazin, N.S.; Davydov, R.V. Multiphase NMR Flowmeter-Relaxometer for Controlling the State and Rapidly Changing Flow Rates of Oil Mixtures. Meas. Tech. 2022, 65, 444–452. [Google Scholar] [CrossRef]

- Davydov, V.V.; Myazin, N.S.; Grebenikova, N.M. Determination of the Composition and Concentrations of the Components of Mixtures of Hydrocarbon Media in the Course of its Express Analysis. Meas. Tech. 2020, 62, 1090–1098. [Google Scholar] [CrossRef]

- Nourelfath, M.; Lababidi, H.M.S.; Aldowaisan, T. Socio-economic impacts of strategic oil and gas megaprojects: A case study in Kuwait. Int. J. Prod. Econ. 2022, 246, 108416. [Google Scholar] [CrossRef]

- Faksness, L.-G.; Leirvik, F.; Taban, I.C.; Engen, F.; Vensen, H.V.; Holbu, J.W.; Dolva, H.; Bråtveit, M. Offshore field experiments with in-situ burning of oil: Emissions and burn efficiency. Environ. Res. 2022, 205, 112419. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, Y.; Wang, J.; Lu, Z. Optimal Operation for Integrated Electricity–Heat System with Improved Heat Pump and Storage Model to Enhance Local Energy Utilization. Energies 2020, 13, 6729. [Google Scholar] [CrossRef]

- Rosendahl, T.; Hepso, V. Integrated Operations in the Oil and Gas Industry: Sustanability and Capabability Development; IGI Global: Hershey, PA, USA, 2013. [Google Scholar]

- Tihomirnov, L.I. Digitalization: Key factors of success. Oil Gas 2019, 1–2, 142–143. [Google Scholar]

- Marchenko, I. Features of geotechnical surveys and leg penetration analysis for drilling platforms in the Arctic seas. IOP Conf. Ser. Mater. Sci. Eng. 2019, 700, 012047. [Google Scholar] [CrossRef]

- Tarasenko, M.Y.; Lenets, V.A.; Akulich, N.V.; Yalunina, T.R. Features of use direct and external modulation in fiber optical simulators of a false target for testing radar station. In Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2017; Volume 10531, pp. 227–232. [Google Scholar]

- Petrov, A.A. Digital Frequency Synthesizer for 133Cs-Vapor Atomic Clock. J. Commun. Technol. Electron. 2017, 62, 289–293. [Google Scholar] [CrossRef]

- Zhang, S.; Lei, Q.; Wu, L.; Wang, Y.; Zheng, L.; Chen, X. Supply chain design and integration for the Co-Processing of bio-oil and vacuum gas oil in a refinery. Energy 2022, 241, 122912. [Google Scholar] [CrossRef]

- Ocampo Batlle, E.A.; Escobar Palacio, J.C.; Silva Lora, E.E.; Bortoni, E.D.C.; Horta Nogueira, L.A.; Carrillo Caballero, G.E.; Vitoriano Julio, A.A.; Escorcia, Y.C. Energy, economic, and environmental assessment of the integrated production of palm oil biodiesel and sugarcane ethanol. J. Clean. Prod. 2021, 311, 127638. [Google Scholar] [CrossRef]

- Alekseeva, M.N.; Svarovskaya, L.I.; Yashchenko, I.G. Risks of pollution of Arctic territories by oil and oil products. AIP Conf. Proc. 2019, 2167, 02000. [Google Scholar] [CrossRef]

- Oliveira-Pinto, S.; Rosa-Santos, P.; Taveira-Pinto, F. Electricity supply to offshore oil and gas platforms from renewable ocean wave energy: Overview and case study analysis. Energy Convers. Manag. 2019, 186, 556–569. [Google Scholar] [CrossRef]

- Pye, M. The discovery and development of the Brae Area Fields, U.K. South Viking Graben. AAPG Mem. 2018, 115, 155–161. [Google Scholar] [CrossRef]

- Jones, D.W.; Van Bergen, P. Reservoir geology of the upper jurassic brae sandstone member, kingfisher field, South Viking Graben, U.K. North Sea. AAPG Mem. 2018, 115, 283–305. [Google Scholar] [CrossRef]

- Krueger, S.; Sharpe, R.; Attridge, W.; Ruszka, J. Introduction of new drilling technology provides continuous high build rate capability in complex corkscrew well trajectory, accessing unswept reserves in the north sea. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Hague, The Netherlands, 14–16 March 2017. [Google Scholar] [CrossRef]

- Feng, Q.; Xu, L.; Liu, C.; Hao, Y.; Yang, Z.; Zhang, T.; Liu, Y.; Su, H. Enhancing the anode performance of microbial fuel cells in the treatment of oil-based drill sludge by adjusting the stirring rate and supplementing oil-based drill cuttings. Sustain. Energy Fuels 2021, 5, 5773–5788. [Google Scholar] [CrossRef]

- Coto, B.; Suárez, I.; Tenorio, M.J.; Huerga, I. Extraction of aromatic and polyaromatic compounds with NMP: Experimental and model description. Fluid Phase Equilibria 2022, 554, 113293. [Google Scholar] [CrossRef]

- Li, Y.; Wang, D.; Xu, G.; Li, Q.; Yong, L.; Hongyu, G.; Lei, S.; Dongwei, L.; Meng, G.; Guoran, L.; et al. ZIF-8/PI Nanofibrous Membranes with High-Temperature Resistance for Highly Efficient PM0.3 Air Filtration and Oil-Water Separation. Front. Chem. 2021, 9, 810861. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Zeng, X.; Zhao, W.; Zhu, F.; Hou, M.; Fan, G. Structural optimization for an axial oil-water separator with multi-stage separation. Heat Mass Transf. 2021, 57, 1949–1963. [Google Scholar] [CrossRef]

- Jafarinejad, S.; Esfahani, M.R. A review on the nanofiltration process for treating wastewaters from the petroleum industry. Separations 2021, 8, 206. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, Y.; Xi, J.; Ye, D.; Hu, W.; Song, L.; Hu, Y.; Cai, W.; Gui, Z. Scalable production of hydrophobic and photo-thermal conversion bio-based 3D scaffold: Towards oil-water separation and continuous oil collection. J. Clean. Prod. 2021, 319, 128567. [Google Scholar] [CrossRef]

- Erith, M.; Alfonso, Z.; Erik, L. A Multi-Sensor Approach to Separate Palm Oil Plantations from Forest Cover Using NDFI and a Modified Pauli Decomposition Technique. In Proceedings of the International Geoscience and Remote Sensing Symposium (IGARSS 2020), Waikoloa, HI, USA, 26 September-–2 October 2020. [Google Scholar] [CrossRef]

- Shafi, H.; Velswamy, K.; Ibrahim, F.; Huang, B. A hierarchical constrained reinforcement learning for optimization of bitumen recovery rate in a primary separation vessel. Comput. Chem. Eng. 2020, 140, 106939. [Google Scholar] [CrossRef]

- Acharya, T.; Casimiro, L. Evaluation of flow characteristics in an onshore horizontal separator using computational fluid dynamics. J. Ocean Eng. Sci. 2020, 5, 261–268. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, Z.; Zhang, Z.; Chu, Y.; Yuan, B.; Wei, Z. Development of highly porous mullite whisker ceramic membranes for oil-in-water separation and resource utilization of coal gangue. Sep. Purif. Technol. 2020, 237, 116483. [Google Scholar] [CrossRef]

- Mahmoud, M.; Tariq, Z.; Kamal, M.S.; Al-Naser, M. Intelligent prediction of optimum separation parameters in the multistage crude oil production facilities. J. Pet. Explor. Prod. Technol. 2019, 9, 2979–2995. [Google Scholar] [CrossRef]

- Patrone, P.N.; Cooksey, G.; Kearsley, A. Dynamic Measurement of Nanoflows: Analysis and Theory of an Optofluidic Flowmeter. Phys. Rev. Appl. 2019, 11, 034025. [Google Scholar] [CrossRef]

- Gu, Y.; Zhao, Y.; Lv, R.; Yang, Y. Theory and structure of a modified optical fiber turbine flowmeter. Flow Meas. Instrum. 2016, 50, 178–184. [Google Scholar] [CrossRef]

- Shaaban, S. Design and optimization of a novel flowmeter for liquid hydrogen. Int. J. Hydrogen Energy 2017, 42, 14621–14632. [Google Scholar] [CrossRef]

- Klingensmith, W.C.; Mays, D.C. Information Content of Wastewater Flowmeter Data before and during a Surcharge. J. Environ. Eng. 2018, 144, 05018004. [Google Scholar] [CrossRef]

- Yang, Y.; Ha, W.; Zhang, C.; Liu, M.; Zhang, X.; Wang, D. Measurement of high-water-content oil-water two-phase flow by electromagnetic flowmeter and differential pressure based on phase-isolation. Flow Meas. Instrum. 2022, 84, 102142. [Google Scholar] [CrossRef]

- Jin, N.; Yu, C.; Han, Y.; Yang, Q.; Ren, Y.; Zhai, L. The Performance Characteristics of Electromagnetic Flowmeter in Vertical Low-Velocity Oil-Water Two-Phase Flow. IEEE Sens. J. 2021, 21, 464–475. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Liu, X.; Chen, L.; Xie, R.; Han, L. A Novel Method for Measuring the Flow Rate of High Viscous Fluid in Polymer Injection Well by Nonuniform Magnetic Field Electromagnetic Flowmeter. In Proceedings of the 8th Annual IEEE International Conference on Cyber Technology in Automation, Control and Intelligent Systems, Tianjin, China, 19–23 July 2018. [Google Scholar] [CrossRef]

- Davydov, V.V. Control of the longitudinal relaxation time T1 of a flowing liquid in NMR flowmeters. Russ. Phys. J. 1999, 42, 822–825. [Google Scholar] [CrossRef]

- Han, Y.; Jin, N.; He, Y.; Ren, Y. Flow Measurement of Oil-in-Water Emulsions Using Arc-Type Conductivity Probes and Electromagnetic Flowmeter. IEEE Trans. Instrum. Meas. 2018, 67, 667–677. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Liu, X.; Zhang, Y.; Xie, R.; Huang, C.; Hu, J.; Deng, G. Novel downhole electromagnetic flowmeter for oil-water two-phase flow in high-water-cut oil-producingwells. Sensors 2016, 16, 1703. [Google Scholar] [CrossRef] [PubMed]

- Davydov, V.V.; Myazin, N.S.; Makeev, S.S. Method for Monitoring the Longitudinal Relaxation Time of 1Flowing Liquids Over the Entire Range of Flow Rate. Meas. Tech. 2020, 63, 368–374. [Google Scholar] [CrossRef]

- Myazin, N.S.; Yushkova, V.V.; Davydova, T.I. New nondestructive method for determining the composition of components in biological objects in express mode. J. Phys. Conf. Ser. 2017, 917, 042017. [Google Scholar] [CrossRef]

- Davydov, V.V.; Grebenikova, N.M. On the Possibility of Express Recording of Nuclear Magnetic Resonance Spectra of Liquid Media in Weak Fields. Tech. Phys. 2018, 63, 1845–1850. [Google Scholar] [CrossRef]

- Myazin, N.S. Peculiarities of magnetic resonance signals processing during the express control of the liquid media state. J. Phys. Conf. Ser. 2019, 1236, 012026. [Google Scholar] [CrossRef]

- Davydov, V.V.; Dudkin, V.I.; Karseev, A.Y. Feasibility of Using Nuclear Magnetic Spectroscopy for Rapid Monitoring of Liquid Media. J. Appl. Spectrosc. 2015, 82, 794–800. [Google Scholar] [CrossRef]

- Shikhof, I.; Arns, C.H. Temperature-Dependent Oxygen Effect on NMR D-T2 Relaxation-Diffusion Correlation of n-Alkanes. Appl. Magn. Res. 2016, 47, 1391. [Google Scholar] [CrossRef]

- Zalesskiy, S.S.; Danieli, E.; Blumich, B.; Ananikov, V.P. Miniaturization of nmr systems: Desktop spectrometers, microcoil spectroscopy, and “nmr on a chip” for chemistry, biochemistry, and industry. Chem. Rev. 2014, 114, 5641–5677. [Google Scholar] [CrossRef]

- Haratt, W.N.; Lee, V.E.; Priestley, R.D.; Cabral, J.T. Precision polymer particles by flash nanomicrofluidic droplet extraction. ACS Appl. Polym. Mater. 2021, 3, 4746–4768. [Google Scholar]

- Kashaev, R.S.; Kozelkov, O.V. On-line express-analyzer and method of water monitoring on the base of proton magnetic resonance. IOP Conf.Ser. Earth Environ. Sci. 2019, 288, 012035. [Google Scholar] [CrossRef]

- Kashaev, R.S.H. Oil Disperse Systems Study Using Nuclear Magnetic Resonance Relaxometry (NMRR). In Advances in Energy Research; Nova Science Publishers: Hauppauge, NY, USA, 2013; Volume 16. [Google Scholar]

- Kashaev, R.; Faskchiev, N. Nuclear (proton) magnetic resonance relaxometry study of the effect of rotating magnetic field on the emulsion structure. Appl. Magn. Reson. 2011, 41, 31–43. [Google Scholar] [CrossRef]

- Kashaev, R.S.; Kien, N.C.; Tung, T.V.; Kozelkov, O.V. Fast Proton Magnetic Resonance Relaxometry Methods for Determining Viscosity and Concentration of Asphaltenes in Crude Oils. J. Appl.Spectrosc. 2019, 86, 890–895. [Google Scholar] [CrossRef]

- Callaghan, P.T. Principles Reo-NMR: Nuclear Magnetic Resonance and the Rheology of Complex Fluids. Rep. Prog. Phys. 1999, 62, 599–668. [Google Scholar] [CrossRef]

- Davydov, V.V.; Dudkin, V.I.; Karseev, A.Y. Formation of the nutation line in NMR measuring system with flowing samples. Tech. Phys. Lett. 2015, 41, 355–358. [Google Scholar] [CrossRef]

- Khasanova, N.; Sakharov, B.; Volkov, V.; Nurgaliev, D. Low field method for analysis of heavy oils without extraction. In Proceedings of the 17th International Multidisciplinary Scientific Geoconference SGEM2017, Viena, Austria, 27–29 November 2017; pp. 297–304. [Google Scholar]

- Kashaev, R.S.; Masiab, A.N. Study of phase transitions in some phase changing organic matters by use of NMR relaxometry. Chem. Mater. Eng. 2013, 1, 78–84. [Google Scholar] [CrossRef]

- Davydov, V.V.; Dudkin, V.I.; Karseev, A.Y. A Compact Nuclear Magnetic Relaxometer for the Express Monitoring of the State of Liquid and Viscous Media. Meas. Tech. 2014, 57, 912–918. [Google Scholar] [CrossRef]

- Aleksandrov, A.S.; Ivanov, A.A.; Archipov, R.V.; Gafurov, M.R. TagirovMS Pulsed NMR spectrometer with dynamic nuclear polarization for weak magnetic fields. Magn. Reson. Solids 2019, 21, 19203. [Google Scholar]

- Davydov, V.V.; Dudkin, V.I.; Velichko, E.N. Method for Measuring the Sensitivity of Nuclear-Resonance Magnetometers with Flowing Liquid. Meas. Tech. 2016, 59, 176–182. [Google Scholar] [CrossRef]

- Hogendoorn, J.; Boer, A.; Appel, M.; de Jong, H.; de Leeuw, R. Magnetic Resonance Technology. A New Concept for Multiphase Flow Measurement. In Proceedings of the 31th International North Sea Flow Measurement Workshop, Tonsberg, Norway, 22–25 October 2013. [Google Scholar]

- Deng, F.; Xiao, L.; Wanget, M.; Tao, Y.; Kong, L.; Zhang, X.; Liu, X.; Geng, D. Online NMR Flowing Fluid Measurements. Appl. Magn. Reson. 2016, 47, 1239–1253. [Google Scholar] [CrossRef]

- Davydov, V.V. Some specific features of the NMR study of fluid flows. Opt. Spectrosc. 2016, 121, 18–24. [Google Scholar] [CrossRef]

- Safieva, R.Z.; Mishin, V.D. Systems Analysis of the Evolutiom of Views on Oil Systems: From Petroleum Chemistry to Petroinformatics. Pet. Chem. 2021, 61, 539–554. [Google Scholar] [CrossRef]

- Davydov, V.V.; Dudkin, V.I.; Karseev, A.Y. A Compact Marked Nuclear-Magnetic Flowmeter for Measurement of Rapidly Varying Flow Rates of Liquid. Meas. Tech. 2015, 58, 317–322. [Google Scholar] [CrossRef]

- Davydov, V.V.; Dudkin, V.I.; Myazin, N.S. Nutation line shape for the nonstationary regime of magnetic resonance flowmeter–relaxometerю. J. Commun. Technol. Electron. 2016, 61, 1159–1165. [Google Scholar] [CrossRef]

- Uskova, E.I.; Doroginitski, M.M.; Skirda, V.D.; Fatkhutdinov, I.H. New Approach to Analyze 2D Map T1-T2. Appl. Magn. Res. 2020, 51, 183–193. [Google Scholar] [CrossRef]

- Mills, C. Process effects on coriolis flowmeter calibration. Hydrocarb. Process. 2020, 99, 8. [Google Scholar]

- Prakhova, M.Y.; Krasnov, A.N. Coriolis flowmeter for commercial accounting of crude oil. J. Phys. Conf. Ser. 2020, 1582, 012071. [Google Scholar] [CrossRef]

- Rondon, J.; Barrufet, M.A.; Falcone, G. A novel downhole sensor to determine fluid viscosity. Flow Meas. Instrum. 2012, 23, 9–18. [Google Scholar] [CrossRef]

- Falcone, G.; Hewitt, G.F.; Alimonti, C.; Harrison, B. Multiphase Flow Metering: Current Trends and Future Developments. J. Pet Technol. 2002, 54, 77–84. [Google Scholar] [CrossRef]

- Davydov, V.V.; Myazin, N.S.; Kiryukhin, A.V. Nuclear-Magnetic Flowmeter-Relaxometers for Monitoring Coolant and Feed water Flow and Status in Npp. Atom. Energy 2020, 127, 274–279. [Google Scholar] [CrossRef]

- Kashaev, R.S.; Kozelkov, O.V.; Temnikov, A.N.; Van Tung, T.; Kein, N.T. Relaxometer of proton magnetic resonance. Instrum. Exp. Tech. 2019, 2, 145–148. [Google Scholar]

- Davydov, V.V.; Dudkin, V.I.; Karseev, A.Y.; Vologdin, V.A. Special Features in Application of Nuclear Magnetic Spectroscopy to Study Flows of Liquid Media. J. Appl. Spectrosc. 2016, 82, 1013–1019. [Google Scholar] [CrossRef]

- Davydov, V.V.; Myazin, N.S.; Dudkin, V.I.; Davydov, R.V. Determination of the Longitudinal Relaxation Time of a Flowing Liquid Using a Differential Nuclear Magnetic Spectrometer. Tech. Phys. Lett. 2020, 46, 1147–1151. [Google Scholar] [CrossRef]

- Khan, N.S.; Kumam, P.; Thounthong, P. Computational Approach to Dynamic Systems through Similarity Measure and Homotopy Analysis Method for Renewable Energy. Crystals 2020, 10, 1086. [Google Scholar] [CrossRef]

- Khan, N.S.; Gul, T.; Kumam, P.; Shah, Z.; Islam, S.; Khan, W.; Zuhra, S.; Sohail, A. Influence of Inclined Magnetic Field on Carreau Nanoliquid Thin Film Flow and Heat Transfer with Graphene Nanoparticles. Energies 2019, 12, 1459. [Google Scholar] [CrossRef]

- Kashaev, R.S.; Idiyatullin, Z.S.; Temnikov, A.N.; Dautov, I.R. Design for Measurement of Composition and Flow Rate by NMR-Method. RF Patent № 74710, 24 April 2008. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kashaev, R.; Ahn, N.D.; Kozelkova, V.; Kozelkov, O.; Dudkin, V. Online Multiphase Flow Measurement of Crude Oil Properties Using Nuclear (Proton) Magnetic Resonance Automated Measurement Complex for Energy Safety at Smart Oil Deposits. Energies 2023, 16, 1080. https://doi.org/10.3390/en16031080

Kashaev R, Ahn ND, Kozelkova V, Kozelkov O, Dudkin V. Online Multiphase Flow Measurement of Crude Oil Properties Using Nuclear (Proton) Magnetic Resonance Automated Measurement Complex for Energy Safety at Smart Oil Deposits. Energies. 2023; 16(3):1080. https://doi.org/10.3390/en16031080

Chicago/Turabian StyleKashaev, Rustem, Nguyen Duc Ahn, Valeriya Kozelkova, Oleg Kozelkov, and Valentin Dudkin. 2023. "Online Multiphase Flow Measurement of Crude Oil Properties Using Nuclear (Proton) Magnetic Resonance Automated Measurement Complex for Energy Safety at Smart Oil Deposits" Energies 16, no. 3: 1080. https://doi.org/10.3390/en16031080

APA StyleKashaev, R., Ahn, N. D., Kozelkova, V., Kozelkov, O., & Dudkin, V. (2023). Online Multiphase Flow Measurement of Crude Oil Properties Using Nuclear (Proton) Magnetic Resonance Automated Measurement Complex for Energy Safety at Smart Oil Deposits. Energies, 16(3), 1080. https://doi.org/10.3390/en16031080