Carbon Footprint and Energy Recovery Potential of Primary Wastewater Treatment in Decentralized Areas: A Critical Review on Septic and Imhoff Tanks

Abstract

:1. Introduction

2. Materials and Methods

3. Technology Description

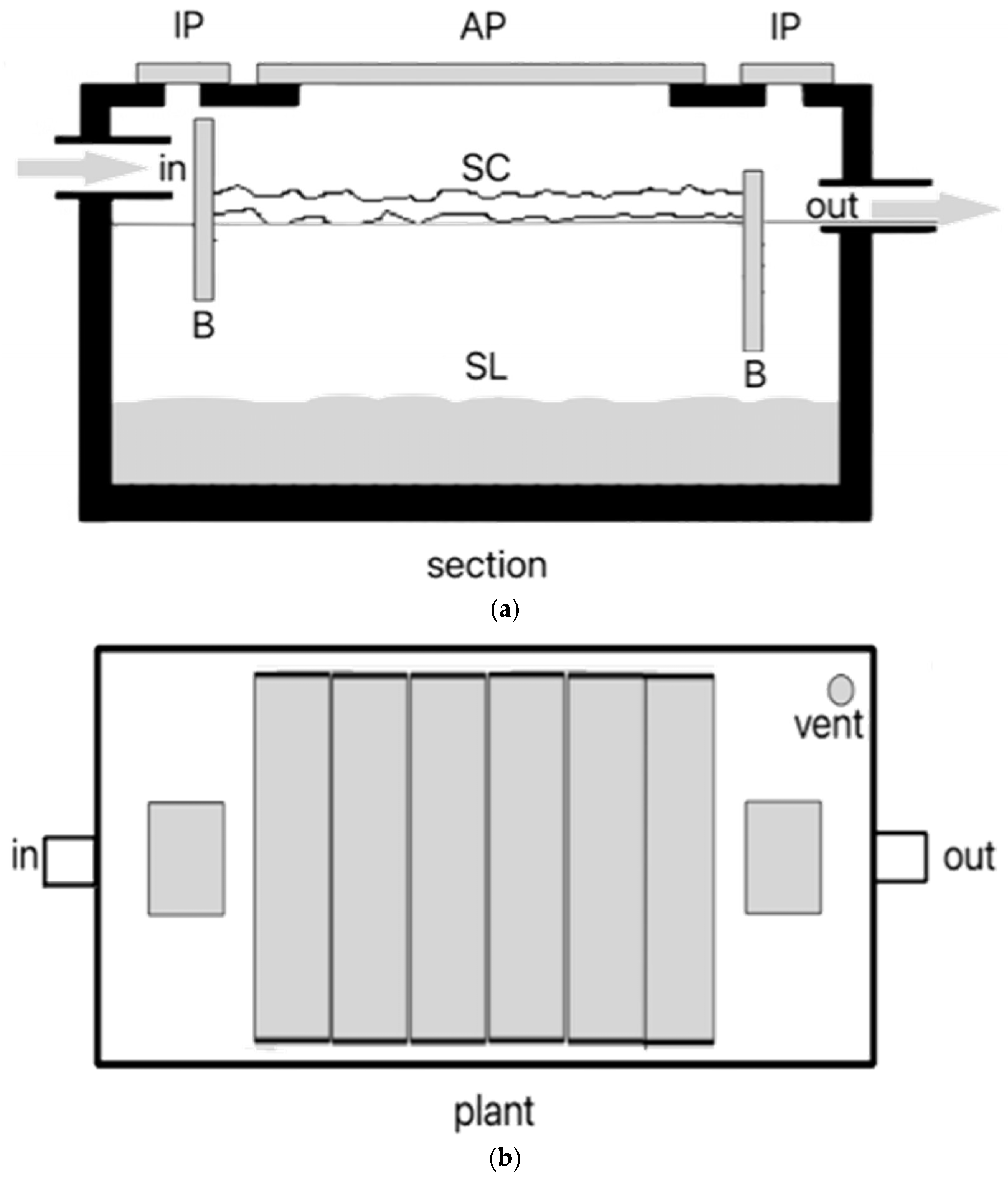

3.1. Septic Tanks

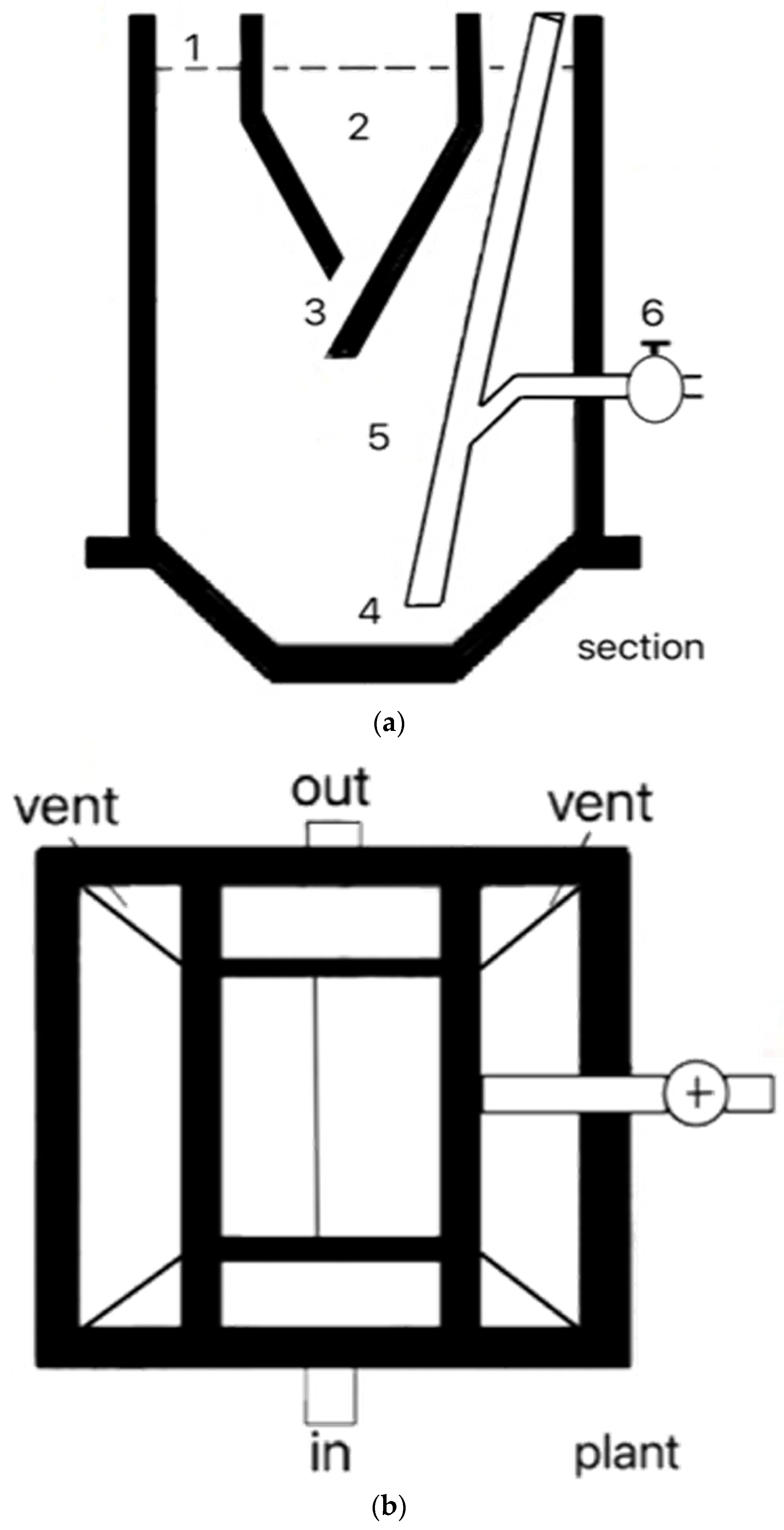

3.2. Imhoff Tanks

4. Quantification and Monitoring of Biogas Production and Composition

5. Environmental and Operational Factors Affecting Biogas Production and Composition

| Factor | Effect | Source | |

|---|---|---|---|

| Temperature | Environmental (air) | Positive | [18,30] |

| Digestion compartment | Positive | [28,30,83] | |

| Positive till 25–26.7 °C. If temperature increases further, negative | [86] | ||

| Sewage | Positive | [6,30,84] | |

| pH | Positive till optimal value | [18,30,84,95,97,98] | |

| Sludge accumulation/withdrawal | Positive/Negative | [6,11,30,83,84] | |

| Pressure | Negative | [30] | |

6. Energy Recovery from Septic and Imhoff Tanks

7. Conclusions

- a lack of up-to-date research about gas emissions from Imhoff tanks has emerged;

- research about septic tanks should be carried out involving longer periods of time to incorporate the effect of seasonal variations;

- temperature is found to be a dominant parameter strongly promoting methane and biogas production in both septic and Imhoff tanks;

- besides temperature, other important parameters affecting gas production in both types of tank are pH and sludge accumulation;

- operationally speaking, liming has been a common practice in Imhoff tanks to keep pH within its optimal range during their start-up and recovery from a low-temperature period;

- carefully optimizing sludge withdrawal is found to strongly affect biogas production in both septic and Imhoff tanks;

- biogas from both septic and Imhoff tanks can be used for energy production, although research has focused essentially on energy production exclusively from Imhoff tank methane. This energy could be used for human beings’ daily needs or to heat up digestion compartments and improve system capacity by reducing sludge accumulation;

- electrochemically assisted anaerobic digestion via microbial electrolysis cells (MECs) can be beneficial to increase the energy yields from septic tanks;

- improving the biodegradability of sewage COD by promoting organic matter solubilization in the sludge through the application of dedicated pretreatment technologies is another way to improve energy recovery from septic tanks;

- another option for stabilizing and improving septic tank performance, leading to a transition to high-rate septic tanks and consequently increasing CH4 output, is to add biochar generated from biosolids: by increasing the organic loading rate (OLR), biochar-amended reactors were found to produce 4.3 times more methane per day than the control;

- reduction of carbon footprint and improved energy recovery from septic tanks have been achieved through integrated solar energy generation (e.g., through photovoltaic installation).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Truhlar, A.M.; Ortega, K.L.; Walter, M.T. Seasonal and Diel Variation in Greenhouse Gas Emissions from Septic System Leach Fields. Int. J. Environ. Sci. Technol. 2019, 16, 6043–6052. [Google Scholar] [CrossRef]

- Pang, J.; Pan, J.; Tong, D.; Fu, X.; Sun, B.; Yang, M.; Li, H. How Do Hydraulic Load and Intermittent Aeration Affect Pollutants Removal and Greenhouse Gases Emission in Wastewater Ecological Soil Infiltration Systems? Ecol. Eng. 2020, 146, 105747. [Google Scholar] [CrossRef]

- Caselles-Osorio, A.; Puigagut, J.; Segú, E.; Vaello, N.; Granés, F.; García, D.; García, J. Solids Accumulation in Six Full-Scale Subsurface Flow Constructed Wetlands. Water Res. 2007, 41, 1388–1398. [Google Scholar] [CrossRef]

- Puigagut, J.; Villaseñor, J.; Salas, J.J.; Bécares, E.; García, J. Subsurface-Flow Constructed Wetlands in Spain for the Sanitation of Small Communities: A Comparative Study. Ecol. Eng. 2007, 30, 312–319. [Google Scholar] [CrossRef]

- Barrett, J.O. Report on the Operation and Maintenance of the Westerly Sewage Treatment Plant, Cleveland, Ohio, for the Years 1952 and 1953. Sewage Ind. Waste. 1955, 27, 980–982. [Google Scholar]

- Hatfield, W.D.; Morkert, K. The Removal of Suspended Solids and Production of Gas by the Imhoff Tanks of Decatur, Illinois. Sewage Work. J. 1932, 4, 790–794. [Google Scholar]

- Mahlie, W.S. A Comparison of the Performance of Imhoff Tanks against Primary Settling Tanks. Sewage Work. J. 1939, 11, 68–71. [Google Scholar]

- Galvão, A.; Matos, J.; Rodrigues, J.; Heath, P. Sustainable Sewage Solutions for Small Agglomerations. Water Sci. Technol. 2005, 52, 25–32. [Google Scholar] [CrossRef]

- Álvarez, J.A.; Ruíz, I.; Soto, M. Anaerobic Digesters as a Pretreatment for Constructed Wetlands. Ecol. Eng. 2008, 33, 54–67. [Google Scholar] [CrossRef]

- Beaumont, H.M. The Operation of Imhoff Tanks. Sewage Work. J. 1929, 1, 211–217. [Google Scholar] [CrossRef]

- Daniels, P.N. The Care and Operation of Imhoff Tanks. Sewage Work. J. 1945, 17, 995–1000. [Google Scholar]

- Neralla, S.; Weaver, R.W.; Lesikar, B.J.; Persyn, R.A. Improvement of Domestic Wastewater Quality by Subsurface Flow Constructed Wetlands. Bioresour. Technol. 2000, 75, 19–25. [Google Scholar] [CrossRef]

- Hansen, S.P.; Culp, G.L.; Stukenberg, J.R. Practical Application of Idealized Sedimentation Theory in Wastewater Treatment. Water Pollut. Control Fed. J. 1969, 41, 1421–1444. [Google Scholar]

- Behera, C.R.; Santoro, D.; Gernaey, K.V.; Sin, G. Organic Carbon Recovery Modeling for a Rotating Belt Filter and Its Impact Assessment on a Plant-Wide Scale. Chem. Eng. J. 2018, 334, 1965–1976. [Google Scholar] [CrossRef]

- Boiocchi, R.; Behera, C.R.; Sherratt, A.; Degroot, C.T.; Gernaey, K.V.; Sin, G.; Santoro, D. Dynamic Model Validation and Advanced Polymer Control for Rotating Belt Filtration as Primary Treatment of Domestic Wastewaters. Chem. Eng. Sci. 2020, 217, 115510. [Google Scholar] [CrossRef]

- Sherratt, A.; DeGroot, C.T.; Straatman, A.G.; Santoro, D. A Numerical Approach for Determining the Resistance of Fine Mesh Filters. Can. Soc. Mech. Eng. Trans. 2018, 43, 221–229. [Google Scholar] [CrossRef]

- Sherratt, A.; DeGroot, C.T.; Straatman, A.G.; Santoro, D. Numerical Modeling and Control of Solids Separation Using Continuously Moving Fine Mesh Filters. Chem. Eng. Sci. 2018, 195, 881–893. [Google Scholar] [CrossRef]

- Donaldson, W. Gas Collection from Imhoff Tanks. Sewage Work. J. 1929, 1, 608–614. [Google Scholar]

- Leverenz, H.L.; Tchobanoglous, G.; Darby, J.L. Evaluation of Greenhouse Gas Emissions from Septic Systems; Water Environment Research Foundation: Denver, CO, USA, 2010. [Google Scholar]

- Gilman, C.; Charles, B.; Hyde, G. Gas Collection and Utilization. Sewage Work. J. 1944, 16, 1221–1226. [Google Scholar]

- Sayers, R.R. Gas Hazards in Sewers and Sewage-Treatment Plants. Public Health Rep. 1934, 49, 145. [Google Scholar] [CrossRef]

- UPM Umwelt-Projekt-Management GmbH. Comprehensive Overview of Biogas for Sanitation Options-Training of Trainers. In Methodologies & Application from Documented Experience; UPM Umwelt-Projekt-Management GmbH: Munich, Germany, 2021; Available online: https://www.pseau.org/outils/ouvrages/upm_comprehensive_overview_of_biogas_for_sanitation_options_training_of_trainers_2021.pdf (accessed on 7 November 2023).

- Boiocchi, R.; Zhang, Q.; Gao, M.; Liu, Y. Modeling and Optimization of an Upflow Anaerobic Sludge Blanket (UASB) System Treating Blackwaters. J. Environ. Chem. Eng. 2022, 10, 107614. [Google Scholar] [CrossRef]

- Mainardis, M.; Buttazzoni, M.; Goi, D. Up-Flow Anaerobic Sludge Blanket (Uasb) Technology for Energy Recovery: A Review on State-of-the-Art and Recent Technological Advances. Bioengineering 2020, 7, 43. [Google Scholar] [CrossRef]

- Luostarinen, S.; Sanders, W.; Kujawa-Roeleveld, K.; Zeeman, G. Effect of Temperature on Anaerobic Treatment of Black Water in UASB-Septic Tank Systems. Bioresour. Technol. 2007, 98, 980–986. [Google Scholar] [CrossRef]

- Currie, A.C.H. Sludge Digestion. Sewage Work. J. 1934, 6, 529–530. [Google Scholar]

- McLean, R.C. Honduras Wastewater Treatment: Chemically Enhanced Primary Treatment and Sustainable Secondary Treatment Technologies for Use with Imhoff Tanks; Massachusetts Institute of Technology: Cambridge, MA, USA, 2009. [Google Scholar]

- Goodman, A.H.; Wheeler, C.E. Sludge Disposal at the Calumet Sewage Treatment Works. Sewage Work. J. 1929, 1, 444–450. [Google Scholar]

- Krum, H.J.; Meckley, E.W. Operation of the Allentown Sewage Treatment Works. Sewage Work. J. 1936, 8, 943–961. [Google Scholar]

- Zack, S.I.; Edwards, G.P. Gas Production from Sewage Sludge. Sewage Work. J. 1929, 1, 160–186. [Google Scholar]

- Haseltine, T.R. The Use of Sludge Digestion Gas for Power Production. Cause and Effect of Variations in Composition of Gas. Sewage Work. J. 1933, 5, 482–501. [Google Scholar]

- Toczyłowska-Mamińska, R.; Mamiński, M. Wastewater as a Renewable Energy Source—Utilisation of Microbial Fuel Cell Technology. Energies 2022, 15, 6928. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving Energy Neutrality in Wastewater Treatment Plants through Energy Savings and Enhancing Renewable Energy Production; Springer: Dordrecht, The Netherlands, 2018; Volume 17, ISBN 1115701894. [Google Scholar]

- Ariffin, M.; Sulaiman, S.N.M. Regulating Sewage Pollution of Malaysian Rivers and Its Challenges. Procedia Environ. Sci. 2015, 30, 168–173. [Google Scholar] [CrossRef]

- Cheng, S.; Long, J.; Evans, B.; Zhan, Z.; Li, T.; Chen, C.; Mang, H.P.; Li, Z. Non-Negligible Greenhouse Gas Emissions from Non-Sewered Sanitation Systems: A Meta-Analysis. Environ. Res. 2022, 212, 113468. [Google Scholar] [CrossRef] [PubMed]

- Istenič, D.; Bodík, I.; Merisaar, M.; Gajewska, M.; Šereš, M.; Griessler Bulc, T. Challenges and Perspectives of Nature-Based Wastewater Treatment and Reuse in Rural Areas of Central and Eastern Europe. Sustainability 2023, 15, 8145. [Google Scholar] [CrossRef]

- Dubber, D.; Gill, L. Application of On-Site Wastewater Treatment in Ireland and Perspectives on Its Sustainability. Sustainability 2014, 6, 1623–1642. [Google Scholar] [CrossRef]

- Massoud, M.A.; Tarhini, A.; Nasr, J.A. Decentralized Approaches to Wastewater Treatment and Management: Applicability in Developing Countries. J. Environ. Manag. 2009, 90, 652–659. [Google Scholar] [CrossRef] [PubMed]

- Mahon, J.M.; Knappe, J.; Gill, L.W. Sludge Accumulation Rates in Septic Tanks Used as Part of the On-Site Treatment of Domestic Wastewater in a Northern Maritime Temperate Climate. J. Environ. Manag. 2022, 304, 114199. [Google Scholar] [CrossRef]

- Truhlar, A.M.; Rahm, B.G.; Brooks, R.A.; Nadeau, S.A.; Makarsky, E.T.; Walter, M.T. Greenhouse Gas Emissions from Septic Systems in New York State. J. Environ. Qual. 2016, 45, 1153–1160. [Google Scholar] [CrossRef]

- United Nations Sustainable Development Goals. Available online: https://sdgs.un.org/goals (accessed on 7 November 2023).

- Gabr, M.E. Impact of Climatic Changes on Future Irrigation Water Requirement in the Middle East and North Africa’s Region: A Case Study of Upper Egypt. Appl. Water Sci. 2023, 13, 158. [Google Scholar] [CrossRef]

- El-Rawy, M.; Batelaan, O.; Al-Arifi, N.; Alotaibi, A.; Abdalla, F.; Gabr, M.E. Climate Change Impacts on Water Resources in Arid and Semi-Arid Regions: A Case Study in Saudi Arabia. Water 2023, 15, 606. [Google Scholar] [CrossRef]

- Singh, H.; Tomar, S.; Qureshi, K.A.; Jaremko, M.; Rai, P.K. Recent Advances in Biomass Pretreatment Technologies for Biohydrogen Production. Energies 2022, 15, 999. [Google Scholar] [CrossRef]

- Diaz-Valbuena, L.R.; Leverenz, H.L.; Cappa, C.D.; Tchobanoglous, G.; Horwath, W.R.; Darby, J.L. Methane, Carbon Dioxide, and Nitrous Oxide Emissions from Septic Tank Systems. Environ. Sci. Technol. 2011, 45, 2741–2747. [Google Scholar] [CrossRef]

- Google Scholar. Available online: https://scholar.google.com/ (accessed on 7 November 2023).

- Internet Archive. Available online: https://archive.org (accessed on 7 November 2023).

- Kinnicutt, L.P.; Winslow, C.E.A.; Pratt, R.W. Sewage Disposal; John Wiley and Sons: New York, NY, USA, 1910. [Google Scholar]

- Brown, G.C.; MacAdam, J.; Dotro, G.; Jefferson, B. A Wholelife Cost and Carbon Perspective of Alternatives to Septic Tanks Utilising Nature-Based Solutions. H2Open J. 2023, 6, 361–372. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, Q.; Hu, L.; Geng, Y.; Liu, C. Understanding the Greenhouse Gas Emissions from China’s Wastewater Treatment Plants: Based on Life Cycle Assessment Coupled with Statistical Data. Ecotoxicol. Environ. Saf. 2023, 259, 115007. [Google Scholar] [CrossRef]

- Johnson, J.; Zakaria, F.; Nkurunziza, A.G.; Way, C.; Camargo-Valero, M.A.; Evans, B. Whole-System Analysis Reveals High Greenhouse-Gas Emissions from Citywide Sanitation in Kampala, Uganda. Commun. Earth Environ. 2022, 3, 80. [Google Scholar] [CrossRef]

- Risch, E.; Boutin, C.; Roux, P. Applying Life Cycle Assessment to Assess the Environmental Performance of Decentralised versus Centralised Wastewater Systems. Water Res. 2021, 196, 116991. [Google Scholar] [CrossRef]

- Shaw, K.; Kennedy, C.; Dorea, C.C. Non-Sewered Sanitation Systems’ Global Greenhouse Gas Emissions: Balancing Sustainable Development Goal Tradeoffs to End Open Defecation. Sustainability 2021, 13, 11884. [Google Scholar] [CrossRef]

- Sairan, F.M.; Md Din, M.F.; Nor-Anuar, A. A New Inventory System to Estimate Greenhouse Gas Emissions from Domestic Wastewater Treatment Plant. Water Pract. Technol. 2013, 8, 425–432. [Google Scholar] [CrossRef]

- Huynh, L.T.; Harada, H.; Fujii, S.; Nguyen, L.P.H.; Hoang, T.H.T.; Huynh, H.T. Greenhouse Gas Emissions from Blackwater Septic Systems. Environ. Sci. Technol. 2021, 55, 1209–1217. [Google Scholar] [CrossRef]

- Knappe, J.; Somlai, C.; Gill, L.W. Assessing the Spatial and Temporal Variability of Greenhouse Gas Emissions from Different Configurations of On-Site Wastewater Treatment System Using Discrete and Continuous Gas Flux Measurement. Biogeosciences 2022, 19, 1067–1085. [Google Scholar] [CrossRef]

- Fuller, G.W.; McClintock, J.R. Solving Sewage Problems; McGraw-Hill, Inc.: New York, NY, USA, 1926. [Google Scholar]

- Abbassi, B.E.; Abuharb, R.; Ammary, B.; Almanaseer, N.; Kinsley, C. Modified Septic Tank: Innovative Onsite Wastewater Treatment System. Water 2018, 10, 578. [Google Scholar] [CrossRef]

- Chen, C.X.; Aris, A.; Yong, E.L.; Noor, Z.Z. Evaluation of the Occurrence of Antibiotics at Different Treatment Stages of Decentralised and Conventional Sewage Treatment Plants. Int. J. Environ. Sci. Technol. 2022, 19, 5547–5562. [Google Scholar] [CrossRef]

- Zamalloa, C.; Arends, J.B.A.; Boon, N.; Verstraete, W. Performance of a Lab-Scale Bio-Electrochemical Assisted Septic Tank for the Anaerobic Treatment of Black Water. N. Biotechnol. 2013, 30, 573–580. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Liu, W.; Zhang, X.; Williams, N.; Hu, B. Microbial Electrochemical Septic Tanks (MESTs): An Alternative Configuration with Improved Performance and Minimal Modifications on Conventional Septic Systems. Biochem. Eng. J. 2017, 120, 146–156. [Google Scholar] [CrossRef]

- Beal, C.D.; Gardner, E.A.; Menzies, N.W. Process, Performance, and Pollution Potential: A Review of Septic Tank-Soil Absorption Systems. Aust. J. Soil Res. 2005, 43, 781–802. [Google Scholar] [CrossRef]

- Mallin, M.A. Septic Systems in the Coastal Environment. Multiple Water Quality Problems in Many Areas; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 9780444593955. [Google Scholar]

- Devitt, C.; O’Neill, E.; Waldron, R. Drivers and Barriers among Householders to Managing Domestic Wastewater Treatment Systems in the Republic of Ireland Implications for Risk Prevention Behaviour. J. Hydrol. 2016, 535, 534–546. [Google Scholar] [CrossRef]

- Mikelonis, A.M. Chemically Enhanced Primary Treatment of Wastewater in Honduran Imhoff Tanks; Massachusetts Institute of Technology: Cambridge, MA, USA, 2008. [Google Scholar]

- Mancl, K. Septic Tank. In Environmental Geology. Encyclopedia of Earth Science; Oxford University Press: Oxford, UK, 1999; ISBN 978-1-4020-4494-6. [Google Scholar]

- Butler, D.; Payne, J. Septic Tanks: Problems and Practice. Build. Environ. 1995, 30, 419–425. [Google Scholar] [CrossRef]

- Koottatep, T.; Pussayanavin, T.; Khamyai, S.; Polprasert, C. Performance of Novel Constructed Wetlands for Treating Solar Septic Tank Effluent. Sci. Total Environ. 2021, 754, 142447. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Shafy, H.I.; El-Khateeb, M.A. Integration of Septic Tank and Constructed Wetland for the Treatment of Wastewater in Egypt. Desalin. Water Treat. 2013, 51, 3539–3546. [Google Scholar] [CrossRef]

- Li, Y.H.; Li, H.B.; Xu, X.Y.; Wang, S.Q.; Pan, J. Does Carbon-Nitrogen Ratio Affect Nitrous Oxide Emission and Spatial Distribution in Subsurface Wastewater Infiltration System? Bioresour. Technol. 2018, 250, 846–852. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, Z.; Chen, Y.; Qiu, Y.; Tao, T.; Du, X.; Pan, J. Pollutants Removal, Greenhouse Gases Emission and Functional Genes in Wastewater Ecological Soil Infiltration Systems: Influences of Influent Surface Organic Loading and Aeration Mode. Water Sci. Technol. 2021, 83, 1619–1632. [Google Scholar] [CrossRef]

- Kihila, J.M.; Balengayabo, J.G. Adaptable Improved Onsite Wastewater Treatment Systems for Urban Settlements in Developing Countries. Cogent Environ. Sci. 2020, 6, 1823633. [Google Scholar] [CrossRef]

- Aly Nasr, F.; Mikhaeil, B. Treatment of Domestic Wastewater Using Modified Septic Tank. Desalin. Water Treat. 2015, 56, 2073–2081. [Google Scholar] [CrossRef]

- Sharma, M.K.; Kazmi, A.A. Anaerobic Onsite Treatment of Black Water Using Filter-Based Packaged System as an Alternative of Conventional Septic Tank. Ecol. Eng. 2015, 75, 457–461. [Google Scholar] [CrossRef]

- Anil, R.; Neera, A.L. Modified Septic Tank Treatment System. Procedia Technol. 2016, 24, 240–247. [Google Scholar] [CrossRef]

- Oduah, U.I.; Ogunye, E.B. A Smart Solution for Preventing Environmental Pollution Caused by Overflowing Onsite Sewage Septic Tank. Heliyon 2023, 9, e14925. [Google Scholar] [CrossRef]

- Mikelonis, A.; Herrera, A.; Adams, E.E.; Hodge, M. Honduran Imhoff Tanks: Potentials and Pitfalls. J. Water Manag. Model. 2010, 18, 363–377. [Google Scholar] [CrossRef]

- Machado, A.P.; Urbano, L.; Brito, A.G.; Janknecht, P.; Salas, J.J.; Nogueira, R. Life Cycle Assessment of Wastewater Treatment Options for Small and Decentralized Communities. Water Sci. Technol. 2007, 56, 15–22. [Google Scholar] [CrossRef]

- Darvishmotevalli, M.; Moradnia, M.; Asgari, A.; Noorisepehr, M.; Mohammadi, H. Reduction of Pathogenic Microorganisms in an Imhoff Tank-Constructed Wetland System. Desalin. Water Treat. 2019, 154, 283–288. [Google Scholar] [CrossRef]

- Ghrabi, A.; Bousselmi, L.; Masi, F.; Regelsberger, M. Constructed Wetland as a Low Cost and Sustainable Solution for Wastewater Treatment Adapted to Rural Settlements: The Chorfech Wastewater Treatment Pilot Plant. Water Sci. Technol. 2011, 63, 3006–3012. [Google Scholar] [CrossRef]

- Toribio-Román, F.M.; Cahuana-Huamani, L.M.; Contreras-López, E.; Portuguez-Maurtua, M. Vermifilter with Hot-Wall Technique in Combination with an Imhoff Tank for Wastewater Treatment in a Rural Andean Community. Water Energy Int. 2023, 66r, 9–15. [Google Scholar]

- Winneberger, J.H.T. Septic-Tank Systems: A Consultant’s Toolkit. In The Septic Tank; Ann Arbor Science: New York, NY, USA, 1984; Volume 2, ISBN 9780250406340. [Google Scholar]

- Babbitt, H.E. Sewage Investigations at the University of Illinois. Sewage Work J. 1931, 3, 580–587. [Google Scholar]

- Nugent, B.J. Operation of New Castle Sewage Plant. Sewage Work J. 1931, 3, 404–410. [Google Scholar]

- IPCC. IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- Fulweiler, W.H. Use of Sewage Gas as City Gas. Sewage Work J. 1930, 2, 424–434. [Google Scholar]

- O’Shaughnessy, F.R. Destructive Anaerobic Fermentation. Sewage Work J. 1931, 3, 86–95. [Google Scholar]

- Hickey, J.L.; Duncan, D.L. Performance of Single Family Septic Tank Systems in Alaska. J. Water Pollut. Control Fed. 1966, 38, 1298–1309. [Google Scholar]

- Schouten, P.W.; Burn, S.; Goodman, N. Greenhouse Gas Emissions from Decentralized Systems. In Urban Water Reuse Handbook; Routledge: Milton, OX, USA, 2016. [Google Scholar]

- Kashyap, D.R.; Dadhich, K.S.; Sharma, S.K. Biomethanation under Psychrophilic Conditions: A Review. Bioresour. Technol. 2003, 87, 147–153. [Google Scholar] [CrossRef]

- Tiwari, B.R.; Rouissi, T.; Brar, S.K.; Surampalli, R.Y. Critical Insights into Psychrophilic Anaerobic Digestion: Novel Strategies for Improving Biogas Production. Waste Manag. 2021, 131, 513–526. [Google Scholar] [CrossRef]

- Schmidt, T.; Harris, P.; Lee, S.; McCabe, B.K. Investigating the Impact of Seasonal Temperature Variation on Biogas Production from Covered Anaerobic Lagoons Treating Slaughterhouse Wastewater Using Lab Scale Studies. J. Environ. Chem. Eng. 2019, 7, 103077. [Google Scholar] [CrossRef]

- Younus Bhuiyan Sabbir, A.S.M.; Saha, C.K.; Nandi, R.; Zaman, M.F.U.; Alam, M.M.; Sarker, S. Effects of Seasonal Temperature Variation on Slurry Temperature and Biogas Composition of a Commercial Fixed-Dome Anaerobic Digester Used in Bangladesh. Sustainability 2021, 13, 11096. [Google Scholar] [CrossRef]

- Coburn, S.E. Practical Application of Hydrogen-Ion Control in the Digestion of Sewage Solids. Ind. Eng. Chem. 1927, 19, 235–236. [Google Scholar] [CrossRef]

- Heukelekian, H. Sewage Plant Operation by PH Control. Sewage Work J. 1931, 3, 428–438. [Google Scholar]

- Anukam, A.; Mohammadi, A.; Naqvi, M.; Granström, K. A Review of the Chemistry of Anaerobic Digestion: Methods of Accelerating and Optimizing Process Efficiency. Processes 2019, 7, 504. [Google Scholar] [CrossRef]

- Giles, J.H.L. Liming of Sludge Digesters or Digestion Compartments. Sewage Work J. 1949, 21, 1072–1076. [Google Scholar]

- Bachmann, F. Hydrogen-Ion Control in the Digestion of Sewage Sludge on a Practical Plant Scale. Sewage Work J. 1929, 1, 218–222. [Google Scholar]

- Lu, H.; Wang, H.; Wu, Q.; Luo, H.; Zhao, Q.; Liu, B.; Si, Q.; Zheng, S.; Guo, W.; Ren, N. Automatic Control and Optimal Operation for Greenhouse Gas Mitigation in Sustainable Wastewater Treatment Plants: A Review. Sci. Total Environ. 2023, 855, 158849. [Google Scholar] [CrossRef]

- Sorenson, C.; Ding, L.; Zamalloa, C.; Arsenault, A.; Debeni, N.; Hu, B. Illuminated Septic Tank—A Microalgae Assisted Onsite Wastewater Treatment System. J. Environ. Chem. Eng. 2023, 11, 110768. [Google Scholar] [CrossRef]

- Pheakdey, D.V.; Noudeng, V.; Xuan, T.D. Landfill Biogas Recovery and Its Contribution to Greenhouse Gas Mitigation. Energies 2023, 16, 4699. [Google Scholar] [CrossRef]

- Pasqualino, J.C.; Meneses, M.; Abella, M.; Castells, F. LCA as a Decision Support Tool for the Environmental Improvement of the Operation of a Municipal Wastewater Treatment Plant. Environ. Sci. Technol. 2009, 43, 3300–3307. [Google Scholar] [CrossRef]

- Boiocchi, R.; Viotti, P.; Lancione, D.; Stracqualursi, N.; Torretta, V.; Ragazzi, M.; Ionescu, G.; Rada, E.C. A Study on the Carbon Footprint Contributions from a Large Wastewater Treatment Plant. Energy Rep. 2023, 9, 274–286. [Google Scholar] [CrossRef]

- Pizzuti, L.; Martins, C.A.; Lacava, P.T. Laminar Burning Velocity and Flammability Limits in Biogas: A Literature Review. Renew. Sustain. Energy Rev. 2016, 62, 856–865. [Google Scholar] [CrossRef]

- Pertiwiningrum, A.; Harto, A.W.; Wuri, M.A.; Budiarto, R. Assessment of Calorific Value of Biogas after Carbon Dioxide Adsorption Process Using Natural Zeolite and Biochar. Int. J. Environ. Sci. Dev. 2018, 9, 327–330. [Google Scholar] [CrossRef]

- Mohammed, M.; Egyir, I.S.; Donkor, A.K.; Amoah, P.; Nyarko, S.; Boateng, K.K.; Ziwu, C. Feasibility Study for Biogas Integration into Waste Treatment Plants in Ghana. Egypt. J. Pet. 2017, 26, 695–703. [Google Scholar] [CrossRef]

- Ngozi Claribelle, N.; Nkemakolam Chinedu, I.; Princewill Nnaemeka, O.; Stanley Toochukwu, E. Production of Electricity from Human Waste as a Strategy for Curbing Electricity Generation Problem in Nigeria. Int. J. Sustain. Green Energy 2020, 9, 85–96. [Google Scholar] [CrossRef]

- Tartakovsky, B.; Mehta, P.; Bourque, J.S.; Guiot, S.R. Electrolysis-Enhanced Anaerobic Digestion of Wastewater. Bioresour. Technol. 2011, 102, 5685–5691. [Google Scholar] [CrossRef]

- Thulasinathan, B.; Nainamohamed, S.; Ebenezer Samuel, J.O.; Soorangkattan, S.; Muthuramalingam, J.B.; Kulanthaisamy, M.; Balasubramani, R.; Nguyen, D.D.; Chang, S.W.; Bolan, N.; et al. Comparative Study on Cronobacter Sakazakii and Pseudomonas Otitidis Isolated from Septic Tank Wastewater in Microbial Fuel Cell for Bioelectricity Generation. Fuel 2019, 248, 47–55. [Google Scholar] [CrossRef]

- Verma, M.; Verma, M.K.; Singh, V.; Singh, J.; Singh, V.; Mishra, V. Advancements in Applicability of Microbial Fuel Cell for Energy Recovery from Human Waste. Bioresour. Technol. Rep. 2022, 17, 100978. [Google Scholar] [CrossRef]

- Thulasinathan, B.; Jayabalan, T.; Sethupathi, M.; Kim, W.; Muniyasamy, S.; Sengottuvelan, N.; Nainamohamed, S.; Ponnuchamy, K.; Alagarsamy, A. Bioelectricity Generation by Natural Microflora of Septic Tank Wastewater (STWW) and Biodegradation of Persistent Petrogenic Pollutants by Basidiomycetes Fungi: An Integrated Microbial Fuel Cell System. J. Hazard. Mater. 2021, 412, 125228. [Google Scholar] [CrossRef]

- Yazdi, H.; Alzate-Gaviria, L.; Ren, Z.J. Pluggable Microbial Fuel Cell Stacks for Septic Wastewater Treatment and Electricity Production. Bioresour. Technol. 2015, 180, 258–263. [Google Scholar] [CrossRef]

- Akatah, B.M.; Kalagbor, I.A.; Gwarah, L.S. Electricity Generation from Septic Waste Water Using Septic Tank as Microbial Fuel Cell. Sustain. Energy 2019, 7, 1–5. [Google Scholar]

- Shekhar Bose, R.; Zakaria, B.S.; Kumar Tiwari, M.; Ranjan Dhar, B. High-Rate Blackwater Anaerobic Digestion under Septic Tank Conditions with the Amendment of Biosolids-Derived Biochar Synthesized at Different Temperatures. Bioresour. Technol. 2021, 331, 125052. [Google Scholar] [CrossRef]

- Leton, T.G.; Yusuf, M.; Akatah, B.M. Utilization of Multistage Microbial Fuel Cell for Septic Wastewater Treatment. IOSR J. Mech. Civ. Eng. 2016, 13, 80–86. [Google Scholar]

- Alzate-Gaviria, L.; García-Rodríguez, O.; Flota-Bañuelos, M.; Del Rio Jorge-Rivera, F.; Cámara-Chalé, G.; Domínguez-Maldonado, J. Stacked-MFC into a Typical Septic Tank Used in Public Housing. Biofuels 2016, 7, 79–86. [Google Scholar] [CrossRef]

- Mainardis, M.; Buttazzoni, M.; Gievers, F.; Vance, C.; Magnolo, F.; Murphy, F.; Goi, D. Life Cycle Assessment of Sewage Sludge Pretreatment for Biogas Production: From Laboratory Tests to Full-Scale Applicability. J. Clean. Prod. 2021, 322, 129056. [Google Scholar] [CrossRef]

- Chatterjee, P.; Ghangrekar, M.M.; Rao, S. Biogas Production from Partially Digested Septic Tank Sludge and Its Kinetics. Waste Biomass Valoriz. 2019, 10, 387–398. [Google Scholar] [CrossRef]

- Di Palma, L.; Merli, C.; Petrucci, E. Environmental Protection Through Self-Powered Plants for Isolated Communities; Elsevier, Ltd.: Amsterdam, The Netherlands, 1998; pp. 119–123. [Google Scholar] [CrossRef]

| (a) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Per Capita Carbon Footprint (b) | CH4 Contribution to Carbon Footprint (b) | CO2 Contribution to Carbon Footprint (b) | CH4 Emission Factor | CO2 Emission Factor | Per Capita Biogas Production | Biogas Composition | Source | |

| [g CO2eq·d−1. Capita 1] | [%-CO2eq-Mass] | [g CH4·d−1. Capita 1] | [g CO2·d−1. Capita 1] | [L·d−1. Capita 1] | [%-CH4 vol] | [%-CO2 vol] | ||

| SEPTIC TANKS | ||||||||

| 310.44 (c) | 92.3 | 7.7 | 13.64 ± 5.05 (c) | 24.00 ± 10.34 (c) | 33.5 (g) | n.a. | [55] | |

| 265.9 | 86.9 | 12.5 | 11 ± 2.2 | 33.3 ± 2.7 | 34.6 (g) | 35–65 (f,g) | 65–35 (f,g) | [19,45] |

| 621.7 | 36.14 | 53.9 | 10.7 ± 1.7 | 335 ± 2.1 | 198.2 (g) | n.a. | ||

| 391 | 54 | 37.4 | 11 ± 12 | 160 ± 3.2 | 103.5 (g) | n.a. | [40] | |

| 214.3 (a) | 99 (a) | 1 (a) | 10.1 | 2.18 (d) | 16.3 (g) | 75.2 | 5.9 | [48] |

| 236.6 (a,e) | 97.8 (a) | 2.2 (a) | 11.02 | 5.16 | 22.65 (d) | 72.9 | 12.4 | [82] |

| 15.6 | 47.8 | 52.2 | 0.35 | 8.14 | 4.95 (g) | n.a. | n.a. | [56] |

| IMHOFF TANKS | ||||||||

| 121.4 (a) | 97.6 | 2.4 | 5.7 | 3 | 11.5 | 74.4 | 14.2 | [28] |

| 135.4 (a) | 97.5 | 2.5 | 6.4 | 3.4 | 12.46 | 76.6 | 14.7 | [30,86] |

| Not computable | n.a. | Not computable | n.a. | 3.24–4.05 | 11.9–14.7 | n.a. | 15 | [84] |

| (b) | ||||||||

| Period of Measurement | Number of Measurement Days Per Septic or Imhoff System | Overall Number of Measurements Per Septic or Imhoff System | Number of Septic or Imhoff Systems Analyzed | Measurement Location in the Septic or Imhoff System | Location of Measurements | Temporal Range of Measurements | Source | |

| SEPTIC TANKS | ||||||||

| 1 week for each septic tank | 1→2 | 1→2 | 10 | Liquid surface | Hanoi, Vietnam, | June and July, 2019 | [55] | |

| 2 months and 2 weeks | 2→5 | 6→36 | 8 | Liquid surface | Davis and Cool, CA, USA | September to December, 2009 | [19,45] | |

| 1→5 | 1→9 | 2 | Gas vent | |||||

| 3 months | n.a. | Minimum 3 samples per septic system | 7 | Gas vent | New York, NY, USA | June to August, 2014 | [40] | |

| 1 year | n.a. | 15 | n.a. | Liquid surface | Worcester, MA, USA | Unknown, in 1902 or a year prior to 1902 | [48] | |

| 10 months | Per capita biogas production from first compartment was calculated based on assumptions, while gas composition was measured for several days within a month for each septic tank | 7 | Liquid surface | n.a. | Unknown, in 1984 or in a year prior to 1984 | [82] | ||

| 446 days | 13–14 for CO2 8–9 for CH4 | 13–14 for CO2 8–9 for CH4 | 2 | Liquid surface | County Limerick, Ireland | June/July 2017 to July/August 2018 | [56] | |

| IMHOFF TANKS | ||||||||

| 1 year | 365 | 365 * | 1 | Digestion compartment vents | Calumet, Chicago, USA | 1927 | [28] | |

| 1 year | 365 | 365 * | 1 | Digestion compartment vents | Calumet, Chicago, USA | September 1926 to August 1927 | [30,86] | |

| 1 year | 365 | 365 * | 6 | Digestion compartment vents | New Castle, Pennsylvania, USA | June 1929 to May 1930 | [84] | |

| (a) | ||

|---|---|---|

| Factor | Effect | Source |

| Temperature | Neutral | [45,55] |

| Positive | [48] | |

| Septage storage time | Positive | [55] |

| COD content in septage | Positive | [55] |

| BOD content in septage | Positive | [55] |

| ORP | Negative | [55] |

| Dissolved oxygen | Neutral | [55] |

| Scum layer thickness | Neutral | [45] |

| Household greywater disturbance | Positive | [19] |

| (b) | ||

| Factor | Effect | Source |

| Water hardness (measured as calcium carbonate) | Negative | [45] |

| Scum layer thickness | Neutral | [45] |

| Household greywater disturbance | Neutral | [19] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boiocchi, R.; Mainardis, M.; Rada, E.C.; Ragazzi, M.; Salvati, S.C. Carbon Footprint and Energy Recovery Potential of Primary Wastewater Treatment in Decentralized Areas: A Critical Review on Septic and Imhoff Tanks. Energies 2023, 16, 7938. https://doi.org/10.3390/en16247938

Boiocchi R, Mainardis M, Rada EC, Ragazzi M, Salvati SC. Carbon Footprint and Energy Recovery Potential of Primary Wastewater Treatment in Decentralized Areas: A Critical Review on Septic and Imhoff Tanks. Energies. 2023; 16(24):7938. https://doi.org/10.3390/en16247938

Chicago/Turabian StyleBoiocchi, Riccardo, Matia Mainardis, Elena Cristina Rada, Marco Ragazzi, and Silvana Carla Salvati. 2023. "Carbon Footprint and Energy Recovery Potential of Primary Wastewater Treatment in Decentralized Areas: A Critical Review on Septic and Imhoff Tanks" Energies 16, no. 24: 7938. https://doi.org/10.3390/en16247938

APA StyleBoiocchi, R., Mainardis, M., Rada, E. C., Ragazzi, M., & Salvati, S. C. (2023). Carbon Footprint and Energy Recovery Potential of Primary Wastewater Treatment in Decentralized Areas: A Critical Review on Septic and Imhoff Tanks. Energies, 16(24), 7938. https://doi.org/10.3390/en16247938