Abstract

With the rapid development of the new energy vehicle industry, the number of power battery decommissioning is increasing year by year. The recycling of power batteries is of great significance for protecting the ecological environment, improving the efficiency of resource utilization, and ensuring the sustainable and healthy development of the new energy automobile industry. In this study, the chemical compositions of power batteries were introduced, the technical path and development status of the echelon utilization of decommissioned power batteries were discussed, and the specific steps and challenges of regenerative utilization of decommissioned power batteries were described in detail from two aspects of pyrometallurgy and hydrometallurgy. Combined with the relevant research results, the main methods of the direct regeneration of positive electrode materials were analyzed. Finally, the main development direction and related suggestions for the resource utilization of decommissioned power batteries were put forward.

1. Introduction

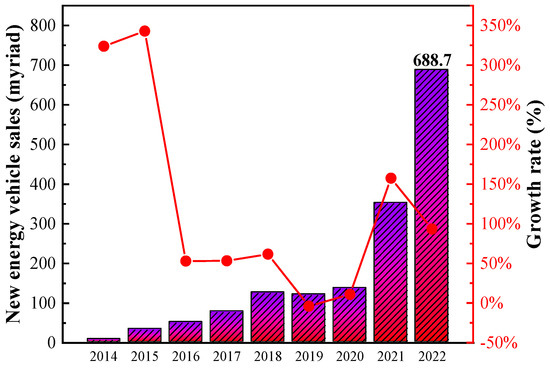

With the aggravation of global warming and the shortage of oil resources, the promotion of the use of new energy vehicles has become an important measure for the Chinese government to cope with the pressure of energy security and ecological protection [1]. With the power supply of clean energy such as wind energy and solar energy, new energy vehicles have gradually become an important channel for decarbonization in the transportation and energy sectors and have produced good environmental benefits. In addition, they can also be used as portable distributed energy storage systems to store energy, thus playing a vital role in microgrid energy management [2,3]. Since the launch of the “Ten Cities, One Thousand Vehicles” program in 2009, China’s new energy vehicle industry has maintained a rapid growth trend, and in 2022, the sales of new energy vehicles exceeded 6.8 million, accounting for 25.6% of the total sales of vehicles, as shown in Figure 1 depicting China’s new energy vehicle sales and growth rates in 2014–2022. New energy vehicles instead of fuel vehicles have become an inevitable development trend [4,5].

Figure 1.

China’s new energy vehicle sales and growth rate from 2014 to 2022 (data from China Association of Automobile Manufacturers).

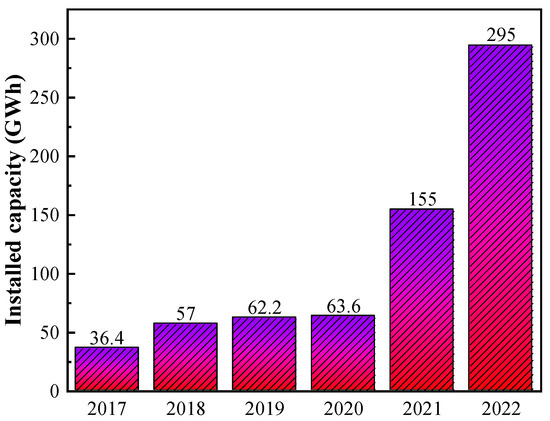

As the “heart” of new energy vehicles, the service life of a power battery is usually 5–8 years, and the effective life is only 4–6 years. The installed capacity of power batteries in China has been maintaining a rapid growth trend, and by 2022, the installed capacity will reach 295 GWh, as shown in Figure 2. Starting from 2018, China’s new energy vehicle power batteries have entered the decommissioning period one after another, and the industry generally believes that there will be a peak in power battery decommissioning in 2025. As of 2021, China’s power battery decommissioning amounted to about 26 GWh, and it is expected that the decommissioning amount will reach 90 GWh by 2025 [6]. For this reason, the Chinese government has continuously issued relevant policies to encourage enterprises to actively carry out the recycling of power batteries [7,8].

Figure 2.

China’s power battery installed capacity (data from China Association of Automobile Manufacturers).

With the advancement of battery manufacturing technology, the current power batteries that dominate the market no longer contain heavy metal elements such as lead and cadmium, but they still have a variety of pollutants such as carbon black, graphene, and sulfuric acid [9,10]. In recent years, the power battery’s upstream raw material, such as nickel, cobalt, lithium, and other metals, prices continued to rise [11,12]. Taking battery-grade lithium carbonate, for example, at the beginning of 2021, its average price was only 50,000 RMB/ton, and at the beginning of 2022, the price had jumped to 290,000 RMB/ton, a rise of 480%, the highest quoted price even exceeded 300,000 RMB/ton, which makes the power battery recycling have more economic value. Therefore, based on the multi-dimensional considerations of improving power battery utilization efficiency, environmental protection, resource recycling, reducing the risk of the power battery industry supply chain, and realizing the green, low-carbon, and sustainable development of the new energy vehicle industry, it is imperative to effectively recycle and efficiently utilize the decommissioned power battery [13,14].

By analyzing the chemical composition of waste power batteries and combining the literature in recent years, this study provided a comprehensive review of the current status of their resource utilization, pointing out the current challenges and future developmental prospects, which are of great significance to the field of energy and environmental protection.

2. Composition of Power Battery

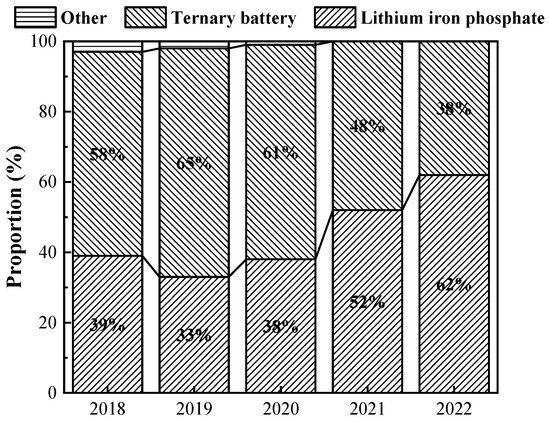

At present, power batteries applied to automobiles can be divided into secondary batteries (including lead–acid batteries, nickel–metal hydride batteries, nickel–chromium batteries, and lithium-ion batteries) and fuel cells [15]. Among them, lithium-ion batteries have better safety, recycling, and repeatable charging performance, as well as higher energy conversion efficiency and more mature manufacturing technology, coupled with China’s lithium resources being more abundant, so lithium-ion batteries have gradually become the mainstream development of power batteries and the first choice for new energy vehicles [16,17,18]. Lithium-ion batteries can be mainly categorized into lithium iron phosphate batteries and ternary batteries. In the early stage of the development of new energy vehicles, lithium iron phosphate batteries occupied a major market share. With the battery energy density included in the subsidy reference, ternary batteries were gradually promoted and used in new energy vehicles. But since 2020, the new energy vehicle subsidy policy has gradually sloped back, and the era of high energy density in exchange for high subsidies has quietly come to an end; lithium iron phosphate batteries, which are better in safety and more cost-effective, have re-entered the field of vision of most automobile enterprises; and the proportion of various types of power battery installations from 2018 to 2022 is shown in Figure 3.

Figure 3.

Proportion of installed capacity of various types of power batteries from 2018 to 2022 (data from China Association of Automobile Manufacturers).

Lithium-ion power battery mainly consists of a positive electrode, a diaphragm, a negative electrode, an external protective case, and the electrolyte added in it [19]. The positive electrodes are made of a lithium-containing metal compound coated on a collector and pressed into a sheet, and the lithium-containing compounds used in commercial lithium-ion batteries are usually lithium metal oxides, such as lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), lithium nickel oxide (LiNiO2), lithium–nickel–cobalt–manganese oxide (LiNixCoyMnzO2, 0 < x, y, z < 1, x + y + z = 1), and lithium iron phosphate (LiFePO4). Negative electrodes are made by coating negative electrode materials (graphite, LTO) onto a copper foil (collector). The electrolyte affects the rate of energy release by controlling the mass flow rate within the cell. The diaphragm is a permeable membrane between the positive and negative electrodes of the battery, mostly made of polymers such as polyethylene or polypropylene, which, on the one hand, prevents physical contact between the electrodes and allows ion transport through the electrolyte and, on the other hand, serves as a safety device; if the battery is overheated, the porous membrane melts and irreversibly seals the electrodes. The external protective case is used to maintain the physical integrity of the battery. The positive and negative electrode materials are the most recyclable parts of a lithium-ion battery.

3. Recycling Methods of Power Battery

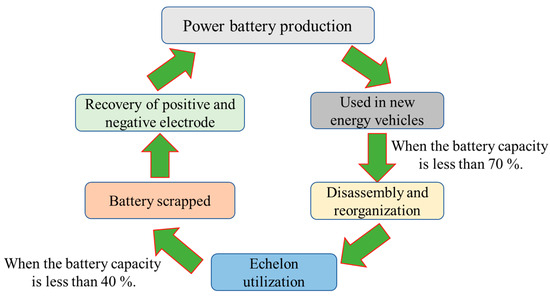

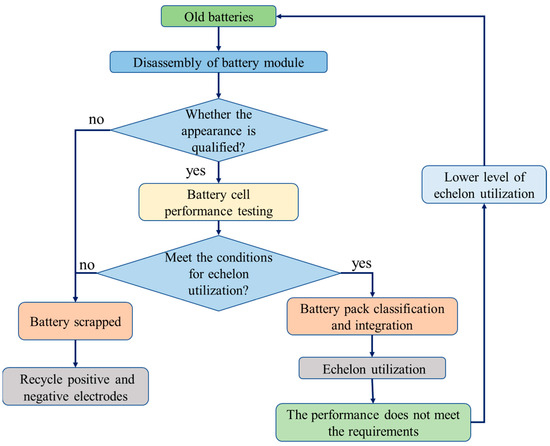

The lithium-ion battery recycling route is shown in Figure 4. Power batteries are installed in new energy vehicles after leaving the factory. With the increase in the number of times they are used, the capacity and attenuation performance of the battery gradually decreases. When its performance drops to 70%, it no longer meets the use of electric vehicles, but it can still be used for occasions with low requirements for the performance of the battery, such as energy storage systems, low-speed electric transportation, and at this time, it enters the stage of echelon utilization [20,21]. When the performance of the battery further declines to less than 40%, the value of the echelon utilization is also lost. At this time, the battery can be recycled through the dismantling and recycling methods. According to the above analysis, the method of recycling power batteries can be divided into echelon utilization and recycling.

Figure 4.

The recycling route of lithium-ion batteries.

3.1. Echelon Utilization

Generally, power batteries can be used as a power source for new energy vehicles for about 5 years, but their full life cycle from the beginning of use to the complete depletion of energy is about 20 years, which means that vehicle power batteries still have a residual life of about 15 years after scrapping. The echelon utilization is to use the end-of-life vehicle power batteries for other fields with lower requirements on battery performance, the process of which is shown in Figure 5 [22] and usually includes steps such as battery pack disassembly, battery sieving, battery restructuring, and battery module system integration. The decommissioned power battery module needs to be tested twice after disassembly. For the first time, the appearance inspection is used to judge whether the appearance of the battery is qualified, and the battery with bulge, leakage, and deformation is eliminated. The second is the performance test to determine whether the basic performance of the battery meets the requirements and to eliminate the battery with a capacity lower than 40% of the original capacity, abnormal terminal voltage, or excessive internal resistance. The batteries that are qualified in the two tests are classified and integrated to achieve echelon utilization. The unqualified batteries can only be recycled via regenerative utilization.

Figure 5.

Processes of the echelon utilization for power batteries [22].

Disassembling is the first step of power battery recycling, and the disassembling method and disassembling efficiency directly affect the echelon utilization. Wegener et al. [23] manually disassembled the hybrid powertrain of an Audi Q5 automobile, derived a disassembly sequence based on a prioritized relationship matrix, and illustrated the disassembly. Some scholars have attempted to introduce automated techniques to battery disassembly. Ren et al. [24] designed a power battery disassembling task and automatic disassembling action planning system based on neural symbol theory and provided a program for intelligent disassembling. Li et al. [25] designed an automatic disassembling device for cell batteries, which realized the separation of positive and negative cells, diaphragm, and aluminum casing of the battery. Due to the variety of battery pack types, internal and external structural designs, module connection methods, different process technologies, and varying lifespans, it is still challenging to minimize the cost of battery pack disassembly while ensuring safety and efficiency. The application of deep learning and automation technology in the field of battery disassembly will be a major trend in the future.

The state of charge (SOC) and state of health (SOH) of the battery are key factors in determining the occasions for echelon utilization [26]. Therefore, after completing the battery pack disassembly, the disassembled battery cells need to be evaluated for SOC and SOH. SOC is a hidden state quantity, which is difficult to obtain directly from the sensor and can only be estimated based on the parameters of the external characteristics of the battery (terminal voltage, current, temperature). The traditional methods for estimating the SOC of a battery include the open-circuit voltage method [27,28], the internal resistance method [29,30], and the ampere-time integration method [31,32]. With the continuous development of related technologies, the estimation methods and accuracy of the SOC are constantly being revolutionized. Estimating the SOC by modeling is a hot topic in current research. Hendricks et al. [33] proposed a calculation model based on the theoretical cycle life of the battery, which can predict the battery life without the complete charge and discharge data of the use process. Based on the second-order equivalent circuit model, Dai et al. [34] used the double-extended Kalman filter algorithm to simultaneously estimate the internal resistance and SOC of the battery. Based on the equivalent circuit model, Stuart et al. [35] estimated the SOC of the battery using the Kalman filter method. Yang et al. [36] invented a system that evaluated the performance of the recycled battery module by selecting the battery evaluation algorithm that performs optimal evaluation according to the battery characteristics, performs accurate evaluation, and increases the recycling rate.

The estimation methods of SOH state can be divided into two kinds: offline estimation method and online estimation method. Among them, offline estimation has the advantages of simplicity and low computation, but it demands strict requirements on the test environment, and the experiments are too time-consuming. In recent years, researchers have proposed some online estimation methods based on offline estimation, such as the slip film observer method [37], voltage curve fitting method [38,39], neural network method [40], and fuzzy logic inference method [41,42], which can realize real-time online estimation of SOH. Nevertheless, SOH evaluation is still difficult due to the many factors affecting the SOH state, including ambient temperature, charge/discharge multiplier, depth of discharge, and charge/discharge cycle, and SOH is a highly nonlinear time-varying system [43]. After disassembly and residual life assessment, batteries need to be regrouped according to parameters, such as battery capacity, material system, residual cycle life, and internal resistance, in order to realize battery module system integration. Due to the uneven types and sizes of power batteries, the nominal capacity, open-circuit voltage, and resistance of battery modules from different manufacturers and batches are different, and battery module system integration is one of the current challenges in the echelon utilization of power batteries.

The echelon utilization of power batteries has a certain cost advantage over new batteries, but its safety and reliability are far from new batteries, and the operation and maintenance costs of subsequent products are high. Adopting the modular design of battery packs and coding batteries to improve the manufacturing technology of power batteries and reduce the cost of pre-processing are important directions for echelon utilization in the future.

3.2. Regenerative Utilization

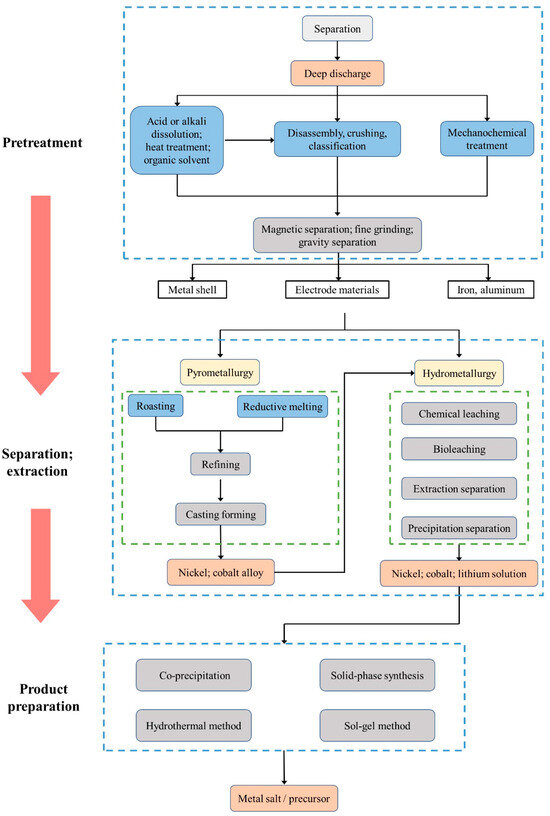

Another resource utilization path for decommissioned power batteries is regeneration, where the batteries that cannot be utilized in the echelon are scrapped, and the valuable metals are refined for the production of new power batteries. Among them, the positive electrode of power batteries contains abundant lithium, cobalt, nickel, manganese, and other metal elements, which have high recycling value and are the core of recycling and reutilization of decommissioned power batteries [44]. Scholars have conducted a lot of research on the regeneration of decommissioned power batteries and summarized the main processes, which mainly include pretreatment, separation and extraction, and product preparation, as shown in Figure 6.

Figure 6.

Recycling process of decommissioned power battery [6].

3.2.1. Pretreatment Process

The purpose of pretreatment is to effectively separate the components in the battery and enrich the valuable metal elements, which mainly includes deep discharge, disassembly, classification, crushing and screening, separation, and mechanochemical treatment.

Lithium-ion batteries have a high energy density. At the start of recycling, the batteries still have residual power, so the first step in pre-treatment is to deeply discharge the batteries to avoid spontaneous combustion or explosion during the pre-treatment process [45]. Common discharge methods include immersion, resistance, and perforated discharge. Kruger [46] utilized semiconductors and graphite to short-circuit decommissioned lithium-ion power batteries for discharge. Zhang et al. [47] achieved complete discharge of decommissioned lithium-ion batteries by immersing them in a 5% NaCl solution for 24 h. Sony invented a battery-perforated discharge process that promotes rapid battery discharge [48]. In general, the problem of discharge depth can be effectively solved with low temperature and immersion, but there is still no good coping strategy for the safety problem during battery discharge, which needs to be explored continuously in the future.

Disassembly and classification are the key link to realize the regeneration of decommissioned power batteries. Initially, the disassembly and classification were manually realized, and the disassembly efficiency was low. With the development of mechanical and automation technology, researchers have invented numerous devices and systems for the automatic disassembly of power batteries [49]. The most representative is the automated disassembly and recycling demonstration line for power batteries built by AVIC Lithium in 2017, with a metal recovery rate of 98% and a positive electrode material recovery rate of more than 90% after commissioning and operation.

The disassembled and classified power batteries are crushed; then, physical sorting methods (re-election, electrical, and magnetic separation) can be used to realize the further separation and recovery of different component materials. The crushing process produces exhaust gases, liquids, and residues that are hazardous to human health [50]. Scholars have attempted to improve treatment to avoid the release of toxic and harmful gases. The Recupyl process proposed to crush the cells in an atmosphere filled with argon and carbon dioxide, which effectively avoided the contact of lithium metal, electrolyte, and water, making the crushing process HF-free [51]. Screening the crushed material is the key to improving the purity of the output product. Shin [52] enriched positive electrode active materials from decommissioned power batteries by sieving, magnetic separation, fine grinding, and gravity sorting. Bertuol [53] utilized an airflow sorting bed to separate the components of the crushed product one by one. Dorella et al. [54] directly crushed decommissioned lithium cobalt acid batteries and then sieved them through a sieve with a pore size of 12 mm, and the Co content in the sieve rejects amounted to 28%. Yuan et al. [55] invented a crushing and sorting device for lithium battery recycling. Crushing the positive electrode, negative electrode, and battery shell separately avoids the large mixing of metal powder and battery graphite, which is convenient for the recovery of lithium batteries. Exploring more efficient and reasonable screening methods is still an important part of scholars’ research.

Crushing and sieving are difficult to dislodge the positive and negative electrode materials from the aluminum and copper foils, so further separation and extraction is required, and the main methods are alkaline dissolution [56], heat treatment [57], organic solvent [58] and ultrasonic treatment [59]. The alkaline dissolution method takes advantage of that the positive electrode material can be stabilized in alkaline conditions, and the aluminum foil will be completely dissolved to make the positive electrode material off. The method is more reported and widely used, so the study will not be introduced in detail. The small safety factor is the main drawback of this method, as the operation requires a high concentration of alkaline solution. The heat treatment method uses high temperatures to volatilize or pyrolyze the binder to separate the positive material from the aluminum foil. Song et al. [60] heated the sorted positive electrode material at 350 °C for 2 h and then placed it in a hydrostatic stirring tank, and the final shedding rate of positive electrode material reached 88.6%. Sun et al. [61] treated decommissioned lithium-ion batteries via vacuum pyrolysis and determined the optimal experimental conditions for the stripping of positive electrode material from aluminum foil: temperature of 600 °C, vacuum evaporation time of 30 min, and residual air pressure of 1 KPa. The main problem faced by the thermal treatment method is the high cost, on the one hand, and the high energy consumption, on the other hand, including the need to install supporting environmental protection facilities to deal with the waste gas generated during the operation. The organic solvent method utilizes the principle of similar solubility and uses an organic solvent to dissolve the binder, prompting the positive electrode material to detach from the aluminum foil. Due to the toxicity of organic solvents and the difficulty of post-treatment of dissolved waste liquids, the method has not yet been realized for industrial application. In addition, ultrasonic treatment proved to be effective in separating the positive electrode material from the aluminum foil.

The composition of the battery is complex, and each pretreatment method has limitations, so the use of a combination of methods to achieve safe and efficient pretreatment of decommissioned lithium-ion batteries is the current development trend. Ji et al. [62] used heat treatment combined with ultrasound to separate aluminum foil and positive electrode active material and concluded that the optimal heat treatment temperature for positive electrode material shedding was 450 °C for 60 min. Han et al. [63] combined the alkaline dissolution method with the organic solvent dissolution method to treat decommissioned lithium cobaltate batteries. Firstly, the battery fragments were placed in a NaOH solution with a concentration of 0.4 mol∙L−1 and a solid–liquid ratio of 100 g∙L−1, and then filtered and washed after stirring for 30 min, the obtained solid residue was then placed in a methyl pyrrolidone solution at a temperature of 60 °C to achieve complete separation of the positive material and the binder. Guo [64] invented a physical recycling method for decommissioned power batteries. On the basis of heat treatment, the broken products were subjected to multi-stage dust removal and vibrating screening, which improved the recovery rate of valuable metals.

3.2.2. Separation and Extraction

The pretreatment process realizes the enrichment of valuable metal components, but further recovery of valuable metals such as cobalt, lithium, and nickel requires further separation and extraction of the pretreated products. Pyrometallurgy and hydrometallurgy are the most common separation and purification methods at present.

- (1)

- Pyrometallurgy

Pyrometallurgy refers to the removal of the organic binder in the electrode material with the help of high temperature, and at the same time, the metal and its compounds therein undergo a series of chemical reactions, and finally, the extraction of the target metal material is realized through subsequent separation [65]. The pyrometallurgical process is widely studied because of its simple operation, good adaptability of raw materials, and easy realization of large-scale production. Wang et al. [66] recovered Co, Li, and Al from decommissioned LiCo-based lithium-ion batteries using aluminum foil as a reducing agent at 600 °C under the Ar atmosphere. In recent years, scholars have found that the carbothermal reduction method can efficiently reduce positive materials to metal oxides, singlet metals, and lithium carbonate, which may become a hot spot for future research. Li et al. [67] developed an environmentally friendly process for the in situ recovery of Co and LiCO3 by calcining a mixture of LiCO3 and graphite powder for 30 min under a nitrogen atmosphere and a temperature of 1000 °C to realize the recycling of decommissioned lithium manganese-acid batteries. Some scholars have introduced microwave-assisted heating to pyrometallurgy. Zhao et al. [68] tested the dielectric properties of positive electrode powders from ternary batteries at different temperatures, carbon dosages, and apparent densities to study their wave-absorbing properties, thus providing a reference for fundamental research on microwave-assisted pyrometallurgy. The experimental results showed that the positive material has good wave-absorbing properties when mixed with carbon, and the dielectric properties of the material increased rapidly from 600 °C as the reduction reaction proceeds, which meant that microwave heating can promote the reduction reaction. Currently, pyrometallurgy faces challenges such as high energy consumption and serious pollution.

- (2)

- Hydrometallurgy

Hydrometallurgy refers to the use of the redox properties of acid or alkali solution to transfer the solid metal in the electrode material into the solution, and then the metal ions in the solution are separated via solvent extraction, chemical precipitation, and other techniques. The hydrometallurgical process is usually divided into two steps: leaching, and separation and purification. Among them, leaching plays a decisive role in the efficiency of metal dissolution, while separation and purification are essential for the production of high-purity materials. According to the type of solvent used for leaching, leaching can be categorized into alkali leaching, acid leaching, and bioleaching.

Alkaline leaching systems usually consist of ammonia and reducing agents (Na2SO3, (NH4)2SO3, H2O2) [69]. NH3 easily reacts with Ni and Co metal ions to form stable, water-soluble ammonia complexes for metal leaching [70]. Qi et al. [71] found that the leaching rate of Co and Li by ammonia leaching could reach 91.16% and 97.57%, respectively, under optimal conditions. Zhang et al. [72] studied the selective leaching of Li in lithium iron phosphate battery using Na2S2O8 as an oxidant and leaching agent to form highly soluble Li2SO4, as shown in the following formula.

2LiFePO4 + Na2S2O8→2FePO4 + Li2SO4 + Na2SO4

When the dosage of Na2S2O8 is 0.05 times the theoretical dosage, the leaching rate of Li can reach 99%. However, due to the weak complexation ability of Mn with ammonia, the effect of ammonia leaching in recovering Mn is poor.

The acid leaching method has attracted much attention because of its high leaching efficiency and low cost, which can be categorized into inorganic acid leaching and organic acid leaching, both of which can dissolve almost all the metals in decommissioned lithium batteries into the leaching solution. Inorganic acid leaching agents include HCl, HNO3, H2SO4, and H3PO4. It has been shown that the addition of reducing agents (H2O2 and Na2S2O3) to inorganic acid-leaching agents can lower the valence state of metal ions, thereby accelerating dissolution [73,74]. The process of inorganic acid leaching produces acidic waste liquid and toxic gases (SO3, Cl2), so organic acid leaching has gradually attracted attention, and commonly used organic acid leaching agents include citric acid, malic acid, and oxalic acid. Zou et al. [75] used citric acid to leach valent metals from the positive electrode materials of decommissioned nickel-cobalt-manganese ternary lithium-ion batteries using lactose as a reducing agent, and the maximum leaching efficiencies of Li, Mn, Co, and Ni were 96.84%, 95.75%, 95.37%, and 95.68%, respectively. To reduce the amount of acid used and increase the leaching efficiency, the acid leaching process is usually combined with electrochemical, ultrasonic treatment, and mechanochemical methods.

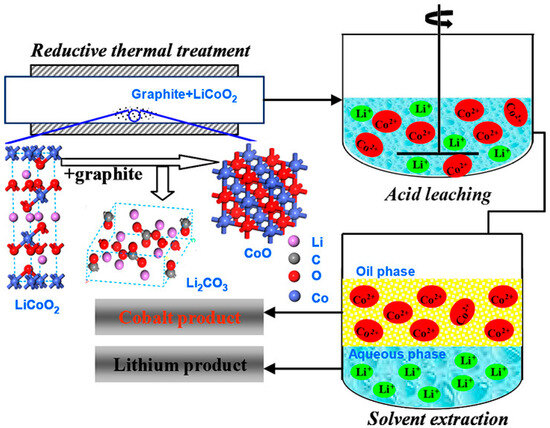

Bioleaching refers to the leaching of metals from decommissioned lithium-ion batteries using inorganic or organic acids produced during bacterial or fungal metabolism. Bioleaching has outstanding environmental and energy-saving advantages and has been widely studied in recent years. Joseph et al. [76] used acidithiobacillus ferrooxidans to leach valuable metals in lithium-ion batteries; the process of operation is shown in Figure 7. The recovery rates of Ni, Mn, Co, and Li were 90%, 92%, 82%, and 89%, respectively. Xin et al. [77] used sulfur-acidophilic oxidizing thiobacillus, pyrite-leptospirillum ferrophilum, and their mixtures for the leaching of decommissioned power batteries, and the leaching rates of positive electrode materials were more than 95%. Bahaloo [78] and Biswal et al. [79] used Aspergillus niger as a leaching strain and achieved 100% leaching of lithium at pH 3.3 and 3.5, respectively. Due to the low leaching efficiency and the long microbial cultivation period, easy to contaminate, the bioleaching method is difficult to achieve industrial application and is still in the laboratory research stage.

Further separation and purification of the metals in the leach solution are required to obtain high-purity valuable metals, mainly including solvent extraction and chemical precipitation. Solvent extraction achieves selective removal of impurity ions based on the difference in selectivity of organic agents to metal ions and the different partition coefficients of metal ions in specific organic solvents. Commonly used solvent extractants are bis-D2EHPA, PC-88A, USTB-1, and Cyanex272. Li et al. [80] effectively recovered Mn and Fe from decommissioned Li-ion batteries by extracting the sulfuric acid leach solution. The solvent extraction method has a good separation effect and low energy consumption, but the process is complicated, and the cost of the extractant is high. Studies in recent years have shown that the extraction system composed of a variety of solvent extractants has higher extraction efficiency and metal selectivity, so the mixed extractant may become the main direction for the development of the solvent extraction method. Chemical precipitation is the process of adjusting the pH value of a solution with the aid of a precipitating agent, thereby generating an insoluble precipitate and thus realizing the separation of valuable metals. Wang et al. [81] recovered the valuable metals in the leaching solution of decommissioned lithium-ion batteries via chemical precipitation, obtaining the recovered purities of 96.97%, 98.23%, 96.94%, and 97.43% for lithium, manganese, cobalt, and nickel, respectively. Liu et al. [82] produced lithium carbonate with a purity greater than 99% via the chemical precipitation method using cobalt extraction after recycling industrial lithium-ion battery positive electrode waste as raw material. Yang et al. [83] proposed to recover valuable metals from spent lithium-ion batteries via a combination of reduction thermal treatment and facile acid leaching; the mechanism is shown in Figure 7. LiCoO3 reacts with graphite at 600 °C to form Li2Co3 and CoO, which makes the leaching efficiency of Li+ and Co2+ close to 100%. Finally, Co and Li are recovered via solvent extraction. The chemical precipitation method is easy to operate and has a high recovery rate, but it is difficult to realize sequential separation due to the large number of ionic species in the leaching solution and the similar nature of the transition metals. The development of selectable precipitants is an important path to solve this problem.

Figure 7.

The mechanism of recovering valuable metals from spent lithium-ion batteries via a combination of reduction thermal treatment and facile acid leaching [83].

Compared with pyrometallurgy, the hydrometallurgy process is complex and costly, but with low energy consumption and high purity of recovered products, it has a better development prospect.

3.2.3. Product Preparation

The products of pyrometallurgy can be used to produce cobalt-nickel alloys through refining and casting. The products of hydrometallurgy can be used to prepare single-metal salts and to resynthesize battery materials. When preparing single metal salts, nickel, cobalt, and lithium salts need to be separated from the leach solution and further prepared into cobalt sulfate, cobalt chloride, nickel sulfate, nickel carbonate, lithium carbonate, and other products. Resynthesizing battery materials refers to the preparation of positive material precursors by adjusting the pH value and the ratio of metal components after removing the impurity metals from the leach solution, including co-precipitation [84,85], sol-gel [86], high-temperature solid-phase synthesis [87], and hydrothermal methods [88].

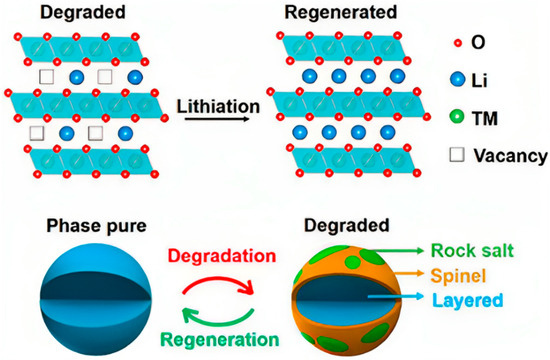

3.3. Direct Regeneration of Positive Electrode Materials

The direct regeneration of positive electrode materials improves the electrochemical performance by adding lithium to the decommissioned positive electrode materials without destroying their crystal structure [89,90]. Compared with other recycling technologies, direct regeneration has the outstanding advantages of a simple process, low cost, and environmental friendliness, and the regenerated positive electrode material can be reused, so it has been developed rapidly. Lithium depletion is the main reason for the failure of lithium-ion battery’s positive electrode materials. The purpose of direct regeneration technology is to combine different lithium replenishment technologies with heat treatment, thus realizing the direct repair of used batteries, including direct solid-state calcination, hydrothermal regeneration, molten salt lithiation, and electrochemical lithium replenishment. Figure 8 shows the direct regeneration of waste ternary materials via lithium supplementation.

Figure 8.

Direct regeneration of waste ternary materials via lithium supplementation [91].

Direct solid-state calcination is the most widely used direct regeneration method, especially for batteries with single-component positive electrode materials such as LiCoO2, LiFePO4, and NCM. Chi et al. [92] directly utilized Li2CO3 present on the surface of the waste positive electrode material as a lithium source, placed it together with the positive electrode material to be regenerated in an oxygen atmosphere, and calcined them for 12 h at a temperature of 850 °C to achieve the regeneration purpose. Li et al. [90] regenerated decommissioned LiFePO4 batteries by doping Li2CO3 and obtained excellent physical, chemical, and electrochemical properties at 650 °C. Chen et al. [93] doped Li2CO3 additive at 850 °C and directly regenerated LiCoO2 positive electrode materials via solid-state calcination, and the regenerated LiCoO2 was tested to meet the needs of commercial reuse. Zhou et al. [94] used lithium acetate as the lithium source, and lithium acetate and its mixture with NCM were sequentially calcined at 500 °C and 900 °C for 5 h and 12 h, respectively, to complete the lithium replenishment process.

The hydrothermal regeneration method is to uniformly distribute the lithium source in the aqueous solution so that it is in direct contact with the positive electrode material, thereby supplementing lithium for the failed positive electrode material. Shi et al. [91] filled a high-pressure reactor with waste positive electrode material powder and LiOH solution for hydrothermal lithiation, followed by calcination in oxygen to obtain regenerated positive electrode material. Meng et al. [95] achieved high-performance regeneration of NCM111-V2O5 positive electrode material by simultaneously treating waste lithium-ion batteries and vanadium-containing slag with the hydrothermal method.

Compared with solid-state calcination and hydrothermal regeneration, molten salt lithiation has the advantages of excellent medium and fast ion diffusion and is considered a highly promising method for the direct regeneration of positive materials. Shi et al. [96] utilized the eutectic molten salt method for regenerative repair of failed positive electrode materials and obtained electrochemically stable NCM523 positive electrode materials. Yang et al. [97] repaired failed LCO positive electrodes using LiOH and KOH as oxidizing fluxes and Li2CO3 as a lithium source. Wang et al. [98] directly regenerated positive electrode materials for ternary batteries via ionothermal synthesis using low-cost lithium halide as a Li source.

Ganter et al. [99] demonstrated the feasibility of electrochemical lithium replenishment. They regenerated LiFePO4 material using lithium metal as the negative electrode and LiFePO4 positive electrode sheet from waste batteries as the positive electrode and replenished lithium from the negative electrode into the positive electrode through charging and discharging. Fan et al. [100] proposed a method to regenerate LiFePO4 positive electrode materials using functionalized, pre-lithiated diaphragms with in situ electrochemistry.

Although the technology of direct regeneration of battery positive electrode materials has been rapidly developed in recent years, the direct regeneration technology is still in the laboratory research stage due to the diversity of the composition of positive electrode materials and the inconsistency of the degree of its failure. Developing suitable pretreatment processes to ensure the purity and original crystal structure of positive electrode materials and seeking methods to accurately and quickly determine the amount of lithium deficiency in decommissioned positive electrode materials will be important for the development of direct regeneration technology.

4. Conclusions and Prospect

Recycling waste power batteries is crucial for environmental protection and sustainable utilization of resources and has a broad development prospect.

The echelon utilization is an important method for the resource utilization of decommissioned power batteries. Restricted by technology and cost, it is difficult to accurately assess the SOH and SOC of the battery. It is the main development direction of the echelon utilization to improve the manufacturing technology of the power battery and reduce the cost of pre-processing. In addition, the development of new methods for rapid and safe assessment of SOH and SOC is also the focus of future researchers.

Regenerative utilization is the main method of resource utilization of decommissioned power batteries. Pre-treatment is the key to the regenerative utilization of power batteries, in which safety, fast, deep discharge, and efficient separation of battery components are the main challenges, and the combination of multiple separation methods is an inevitable choice for the battery pre-treatment link. Pyrometallurgy and hydrometallurgy are the main methods of separation and extraction. Compared with pyrometallurgy, hydrometallurgy has lower energy consumption and less pollution, but its high cost limits its large-scale industrial application. Seeking cheap and efficient leaching agents is the focus of future research.

The direct regeneration of positive electrode materials is the most promising recycling method for decommissioned power batteries. Compositional diversity and uncertainty in the degree of failure are the main factors hindering the direct regeneration of positive electrode materials. Developing suitable pretreatment processes to ensure the extraction of higher purity positive electrode materials without destroying the original crystal structure, as well as exploring how to accurately and rapidly determine the lack of lithium in the waste positive electrode materials, are the future directions for the direct regeneration of positive electrode materials.

Author Contributions

Z.L.: Writing—original draft, Formal analysis, Investigation, Validation. T.Z.: Methodology, Writing—review and editing. H.Y.: Supervision. Z.H.: Resources, Funding acquisition. Y.Z.: Resources, Funding acquisition. M.Z.: Supervision, Funding acquisition, Methodology, Resources. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Beijing Natural Science Foundation’s “Research on circulating fluidized bed combustion reconstruction method and resource utilization of high-aluminum coal ash” (JQ23010).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

References

- Fu, L. Research on the Cooperation Mode between New Energy Vehicle Enterprises and Echelon Utilization Enterprises under the Perspective of Power Battery Recycling and Utilization; Harbin University of Science and Technology: Harbin, China, 2023. [Google Scholar]

- Chen, Y.; Dou, A.; Zhang, Y. A review of recycling status of decommissioned lithium batteries. Front. Mater. 2021, 8, 634667. [Google Scholar] [CrossRef]

- Toro, L.; Moscardini, E.; Baldassari, L.; Forte, F.; Falcone, I.; Coletta, J.; Toro, L. A systematic review of battery recycling technologies: Advances, challenges, and future prospects. Energies 2023, 16, 6571. [Google Scholar] [CrossRef]

- Zhang, C.; Jasni, J.; Radzi, M.; Azis, N.; He, X. A comprehensive review of stage-of-the-art subsystems configurations, technical methodologies, advancements, and prospects for new energy electric vehicles. Ionics 2023, 29, 2529–2547. [Google Scholar] [CrossRef]

- Liu, Z.; Hao, H.; Cheng, X.; Zhao, F. Critical issues of energy efficient and new energy vehicles development in China. Energy Policy 2018, 115, 92–97. [Google Scholar] [CrossRef]

- Liu, H. Research on the Recycling System of Waste Power Batteries of New Energy Vehicles; Shanghai Polytechnic University: Shanghai, China, 2022. [Google Scholar]

- Qiu, L.; Yang, D.; Hong, K.; Wu, W.; Zeng, W. The Prospect of China’s renewable automotive industry upon shrinking subsidies. Front. Energy Res. 2021, 9, 661585. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, G. Subsidy strategy on new-energy vehicle based on incomplete information: A case in China. Phys. A Stat. Mech. Its Appl. 2020, 541, 123370. [Google Scholar] [CrossRef]

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Camargos, P.H.; dos Santos, P.H.J.; dos Santos, I.R.; Ribeiro, G.S.; Caetano, R.E. Perspectives on Li-ion battery categories for electric vehicle applications: A review of state of the art. Int. J. Energy Res. 2022, 46, 19258–19268. [Google Scholar] [CrossRef]

- Barman, P.; Dutta, L.; Azzopardi, B. Electric vehicle battery supply chain and critical materials: A brief survey of state of the art. Energies 2023, 16, 3369. [Google Scholar] [CrossRef]

- Sharmili, N.; Nagi, R.; Wang, P. A review of research in the Li-ion battery production and reverse supply chains. J. Energy Storage 2023, 68, 107622. [Google Scholar] [CrossRef]

- Zante, G.; Braun, A.; Masmoudi, A.; Barillon, R.; Trebouet, D.; Boltoeva, M. Solvent extraction fractionation of manganese, cobalt, nickel and lithium using ionic liquids and deep eutectic solvents. Miner. Eng. 2020, 156, 106512. [Google Scholar] [CrossRef]

- Maddukuri, S.; Malka, D.; Chae, M.S.; Elias, Y.; Luski, S.; Aurbach, D. On the challenge of large energy storage by electrochemical devices. Electrochim. Acta 2020, 354, 136771. [Google Scholar] [CrossRef]

- Xu, Z.; Tian, Y.; Li, J.; Wu, Y.; Huang, J. Development of electric vehicle power battery and its temperature management. Auto Electr. Parts 2018, 54, 1–3. [Google Scholar]

- Lai, X.; Gu, H.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Han, X.; Guo, Y.; Bhagat, R.; Zheng, Y. Investigating greenhouse gas emissions and environmental impacts from the production of lithium-ion batteries in China. J. Clean. Prod. 2022, 372, 133756. [Google Scholar] [CrossRef]

- Wang, S.; Yu, J. A comparative life cycle assessment on lithium-ion battery: Case study on electric vehicle battery in China considering battery evolution. Waste Manag. Res. 2021, 39, 156–164. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yu, Y.; Huang, K.; Tang, B. From the perspective of battery production: Energy-Environment-Economy (3E) analysis of lithium-ion batteries in China. Sustainability 2019, 11, 6941. [Google Scholar] [CrossRef]

- Liu, Y. Structure & Properties Regeneration of Layered Oxides Cathode in Spent Lithium-Ion Batteries; Zhejiang University: Hangzhou, China, 2023. [Google Scholar]

- Chen, H.; Zhang, T.; Gao, Q.; Han, Z.; Jin, Y.; Li, L.; Yang, K.; Xu, Y.; Liu, X.; Xu, X.; et al. Assessment and management of health status in full life cycle of echelon utilization for retired power lithium batteries. J. Clean. Prod. 2022, 379, 134583. [Google Scholar] [CrossRef]

- Wang, N.; Garg, A.; Su, S.; Mou, J.; Gao, L.; Li, W. Echelon utilization of retired power lithium-ion batteries: Challenges and prospects. Batteries 2022, 8, 96. [Google Scholar] [CrossRef]

- Gao, S.; Zhu, H.; Liu, Z.; Zhao, J.; Bi, H. Reutilization grouping of retired electric vehicle battery based on K-means clustering. Chin. J. Power Sources 2020, 44, 1479–1482+1513. Chin. J. Power Source 2020, 44, 1479–1482+1513. [Google Scholar]

- Wegener, K.; Andrew, S.; Raatz, A.; Droder, K.; Herrmann, C. Disassembly of electric vehicle batteries using the example of the audi Q5 hybrid system. Procedia CIRP 2014, 23, 155–160. [Google Scholar] [CrossRef]

- Ren, W.; Wang, Z.; Yang, H.; Zhang, Y.; Chen, M. NeuroSymbolic task and motion planner for disassembly electric vehicle batteries. J. Comput. Res. Dev. 2021, 58, 2604–2617. [Google Scholar]

- Li, L.; Zheng, P.; Yang, T.; Sturges, R.; Ellis, M.W.; Li, Z. Disassembly automation for recycling end-of-life lithium-ion pouch cells. J. Met. 2019, 71, 4457–4464. [Google Scholar] [CrossRef]

- Liang, S. Decline Mode Classification and Performance Evaluation of Electric Vehicle Power Battery; Harbin Institute of Technology: Harbin, China, 2016. [Google Scholar]

- Ma, J.; Zhu, D.; Fang, Y.; Han, Y.; Li, Y. A research on the performance prediction of valve-regulated lead acid battery for BSG hybrid electrical vehicle. Automot. Eng. 2008, 3, 219–221+226. [Google Scholar]

- Campestrini, C.; Kosch, S.; Jossen, A. Influence of change in open circuit voltage on the state of charge estimation with an extended Kalman filter. J. Energy Storage 2017, 12, 149–156. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, Y. EV battery management system and accurate estimation of SOC. Chin. J. Power Source 2016, 40, 1090–1093. [Google Scholar]

- Pan, D.; Guo, H.; Tang, S.; Li, X.; Wang, Z.; Peng, W.; Wang, J.; Yan, G. Evaluating the accuracy of electro-thermal coupling model in lithium-ion battery via altering internal resistance acquisition methods. J. Power Source 2020, 463, 228174. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Z.; Li, Y.; Wang, D.; Wang, G. State of charge and parameters estimation for Lithium-ion battery using dual adaptive unscented Kalman filter. In Proceedings of the 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; pp. 4962–4966. [Google Scholar]

- Xiao, Z.; Wu, S. Discharge curve-based formation of retired power batteries for secondary use. Int. J. Low-Carbon Technol. 2021, 16, 790–797. [Google Scholar] [CrossRef]

- Hendricks, C.; Williard, N.; Mathew, S.; Pecht, M. A failure modes, mechanisms, and effects analysis (FMMEA) of lithium-ion batteries. J. Power Source 2015, 297, 113–120. [Google Scholar] [CrossRef]

- Dai, H.; Sun, Z.; Wei, X. Estimation of internal states of power lithium-ion batteries used on electric vehicles by dual extended Kalman filter. J. Mech. Eng. 2009, 45, 95–101. [Google Scholar] [CrossRef]

- Stuart, T.A.; Zhu, W. Modularized battery management for large lithium ion cells. J. Power Source 2010, 196, 458–464. [Google Scholar] [CrossRef]

- Yang, S. System for Evaluating Performance of Recycled Battery Used in Electric Vehicle. KR 2022112650A, 11 August 2022. (In Korea). [Google Scholar]

- Kim, I.-S. A technique for estimating the state of health of lithium batteries through a dual-sliding-mode observer. IEEE Trans. Power Electron. 2009, 25, 1013–1022. [Google Scholar]

- Liu, X. The Estimating of Lithium-Ion Battery Model and SOH of Electric Vehicle; Jilin University: Changchun, China, 2014. [Google Scholar]

- Lee, S.; Lee, D. Voltage relaxation curve-based state of charge estimation method with reduced measurement time. Electron. Lett. 2023, 59, 12990. [Google Scholar] [CrossRef]

- Andre, D.; Nuhic, A.; Soczka-Guth, T.; Sauer, D.U. Comparative study of a structured neural network and an extended Kalman filter for state of health determination of lithium-ion batteries in hybrid electricvehicles. Eng. Appl. Artif. Intell. 2013, 26, 951–961. [Google Scholar] [CrossRef]

- Zenati, A.; Desprez, P.; Razik, H. Estimation of the SOC and the SOH of Li-ion batteries by combining impedance measurements with the fuzzy logic inference. In Proceedings of the IECON 2010-36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 1773–1778. [Google Scholar]

- Ben Lazreg, M.; Jemmali, S.; Manai, B.; Hamouda, M. Enhanced EKF and SVSF for state of charge estimation of Li-ion battery in electric vehicle using a fuzzy parameters model. IET Electr. Syst. Transp. 2022, 12, 315–329. [Google Scholar] [CrossRef]

- Zhang, Q.C.; Li, X.Z.; Du, Z.C.; Liao, Q.Q. Aging performance characterization and state-of-health assessment of retired lithium-ion battery modules. J. Energy Storage 2021, 40, 102743. [Google Scholar] [CrossRef]

- Bai, Y.; Li, M.; Jafta, C.; Dai, Q.; Essehli, R.; Polzin, B.J.; Belharouak, I. Direct recycling and remanufacturing of anode scraps. Sustain. Mater. Technol. 2023, 35, e00542. [Google Scholar] [CrossRef]

- Li, J. Study on the Physical Separation and Recovery Process of Spent Lithium Ion Power Batteries; General Research Institute for Nonferrous Metals: Beijing, China, 2018. [Google Scholar]

- Krüger, S.; Hanisch, C.; Kwade, A.; Winter, M.; Nowak, S. Effect of impurities caused by a recycling process on the electrochemical performance of Li[Ni0.33Co0.33Mn0.33]O2. J. Electroanal. Chem. 2014, 726, 91–96. [Google Scholar] [CrossRef]

- Zhang, T.; He, Y.; Wang, F.; Li, H.; Duan, C.; Wu, C. Surface analysis of cobalt-enriched crushed products of spent lithium-ion batteries by X-ray photoelectron spectroscopy. Sep. Purif. Technol. 2014, 138, 21–27. [Google Scholar] [CrossRef]

- Netz, A.; Huggins, R.A.; Weppner, W. The formation and properties of amorphous silicon as negative electrode reactant in lithium systems. J. Power Source 2003, 119, 95–100. [Google Scholar] [CrossRef]

- Zhou, L.; Garg, A.; Zheng, J.; Gao, L.; Oh, K.Y. Battery pack recycling challenges for the year 2030: Recommended solutions based on intelligent robotics for safe and efficient disassembly, residual energy detection, and secondary utilization. Energy Storage 2021, 3, e190. [Google Scholar] [CrossRef]

- Horai, K.; Shibata, J.; Murayama, N.; Koyanaka, S.; Niinae, M. Recycling Technology for Lithium Ion Battery by Crushing and Classification, and Hydrometallurgical Process. J. Jpn. Inst. Met. Mater. 2014, 78, 250–257. [Google Scholar] [CrossRef]

- Tedjar, F.; Foudraz, J.-C.; Foudraz, J. Recycling of a Mixture of Fuel Cells and Batteries with Lithium Based Anodes by Hydrometallurgical Treatment to Produce Added Value Compounds from Their Constituents. FR2868603, 1 January 2005. [Google Scholar]

- Shin, S.M.; Kim, N.H.; Sohn, J.S.; Yang, D.H.; Kim, Y.H. Development of a metal recovery process from Li-ion battery wastes. Hydrometallurgy 2005, 79, 172–181. [Google Scholar] [CrossRef]

- Bertuol, D.A.; Toniasso, C.; Jiménez, B.M.; Meili, L.; Dotto, G.L.; Tanabe, E.H.; Aguiar, M.L. Application of spouted bed elutriation in the recycling of lithium ion batteries. J. Power Source 2015, 275, 627–632. [Google Scholar] [CrossRef]

- Dorella, G.; Mansur, M. A study of the separation of cobalt from spent Li-ion battery residues. J. Power Source 2007, 170, 210–215. [Google Scholar] [CrossRef]

- Yuan, C.Y.; Qian, J.; Yuan, C.M.; Yan, X.Q. A Crushing and Sorting Device for Lithium Battery Recycling and Its Use Method. CN 116213429A, 15 September 2023. (In Chinese). [Google Scholar]

- He, X. Efficient Leaching of Valuable Metals from LiCoO2 Cathode Material of Spent Lithium-Ion Batteries with Citric Acid Reducing System; Shanghai Polytechnic University: Shanghai, China, 2018. [Google Scholar]

- Li, L.; Lu, J.; Ren, Y.; Zhang, X.; Chen, R.; Wu, F.; Amine, K. Ascorbic-acid-assisted recovery of cobalt and lithium from spent Li-ion batteries. J. Power Source 2012, 218, 21–27. [Google Scholar] [CrossRef]

- Tran, M.K.; Rodrigues, M.-T.F.; Kato, K.; Babu, G.; Ajayan, P.M. Deep eutectic solvents for cathode recycling of Li-ion batteries. Nat. Energy 2019, 4, 339–345. [Google Scholar] [CrossRef]

- Li, J.; Zhao, R.; He, X.; Liu, H. Preparation of LiCoO2 cathode materials from spent lithium–ion batteries. Ionics 2009, 15, 111–113. [Google Scholar] [CrossRef]

- Song, D.; Wang, X.; Zhou, E.; Hou, P.; Guo, F.; Zhang, L. Recovery and heat treatment of the Li(Ni1/3Co1/3Mn1/3)O2 cathode scrap material for lithium ion battery. J. Power Source 2013, 232, 348–352. [Google Scholar] [CrossRef]

- Sun, L.; Qiu, K. Vacuum pyrolysis and hydrometallurgical process for the recovery of valuable metals from spent lithium-ion batteries. J. Hazard. Mater. 2011, 194, 378–384. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y. Study on Recovery of Spent Ternary Cathode Material and Re-Synthesis and Modification of Li-Rich Mn-Based Materials; Harbin Institute of Technology: Harbin, China, 2018. [Google Scholar]

- Han, X.; Xu, J. Recovery of iron and lithium from phosphate batteries by precipitation process. Guangdong Chem. Spent Lithium Iron Ind. 2017, 44, 12. [Google Scholar]

- Guo, R. Physical Recycling and Reuse Method of Retired Power Battery. CN 111934042A, 31 January 2023. (In Chinese). [Google Scholar]

- Qu, G.; Yang, J.; Wang, H.; Ran, Y.; Li, B.; Wei, Y. Applicability of the reduction smelting recycling process to different types of spent lithium-ion batteries cathode materials. Waste Manag. 2023, 166, 222–232. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhang, Y.; Liu, X.; Xu, S. A simplified process for recovery of Li and Co from spent LiCoO2 cathode using Al foil as the in situ reductant. ACS Sustain. Chem. Eng. 2019, 7, 12222–12230. [Google Scholar] [CrossRef]

- Li, J.; Wang, G.; Xu, Z. Environmentally-friendly oxygen-free roasting/wet magnetic separation technology for in situ recycling cobalt, lithium carbonate and graphite from spent LiCoO2/graphite lithium batteries. J. Hazard. Mater. 2016, 302, 97–104. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, B.; Zhang, L.; Guo, S. Microwave-absorbing properties of cathode material during reduction roasting for spent lithium-ion battery recycling. J. Hazard. Mater. 2020, 384, 121487. [Google Scholar] [CrossRef]

- Wang, H.; Huang, K.; Zhang, Y.; Chen, X.; Jin, W.; Zheng, S.; Zhang, Y.; Li, P. Recovery of lithium, nickel, and cobalt from spent Lithium-ion battery powders by selective ammonia leaching and an adsorption separation system. ACS Sustain. Chem. Eng. 2017, 5, 11489–11495. [Google Scholar] [CrossRef]

- Shen, B.; Gu, W.; Yuan, H.; Zhu, N. A review on leaching and purification technologies of spent ternary Li-ion batteries. Environ. Sci. Technol. 2018, 41, 114–121. [Google Scholar]

- Qi, Y.; Meng, F.; Yi, X.; Shu, J.; Chen, M.; Sun, Z.; Sun, S.; Xiu, F.R. A novel and efficient ammonia leaching method for recycling waste lithium-ion batteries. J. Clean. Prod. 2020, 251, 119665. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, J.; Liu, Y.; Jing, Q.; Yang, C.; Chen, Y.; Wang, C. Sustainable and facile method for the selective recovery of lithium from cathode scrap of spent LiFePO4 batteries. ACS Sustain. Chem. Eng. 2019, 7, 5626–5631. [Google Scholar] [CrossRef]

- Cheng, X.; Guo, G.; Cheng, Y.; Liu, M.; Ji, J. Effect of hydrogen peroxide on the recovery of valuable metals from spent LiNi0.6Co0.2Mn0.2O2 batteries. Energy Technol. 2022, 10, 2200039. [Google Scholar] [CrossRef]

- Higuchi, A.; Ankei, N.; Nishihama, S.; Yoshizuka, K. Selective recovery of lithium from cathode materials of spent lithium-ion battery. JOM 2016, 68, 2624–2631. [Google Scholar] [CrossRef]

- Zou, C. Study on the Recovery and Regeneration of Cathode Materials for Spent Ternary Lithium Ion Batteries; Jiangsu University of Technology: Changzhou, China, 2018. [Google Scholar]

- Jegan Roy, J.; Srinivasan, M.; Cao, B. Bioleaching as an eco-friendly approach for metal recovery from spent NMC-based lithium-ion batteries at a high pulp density. ACS Sustain. Chem. Eng. 2021, 9, 3060–3069. [Google Scholar] [CrossRef]

- Xin, Y.; Guo, X.; Chen, S.; Wang, J.; Wu, F.; Xin, B. Bioleaching of valuable metals Li, Co, Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery. J. Clean. Prod. 2016, 116, 249–258. [Google Scholar] [CrossRef]

- Bahaloo, H.N.; Mousavi, S.M.; Baniasadi, M. Use of adapted metal tolerant Aspergillus niger to enhance bioleaching efficiency of valuable metals from spent lithium-ion mobile phone batteries. J. Clean. Prod. 2018, 197, 1546–1557. [Google Scholar] [CrossRef]

- Biswal, B.K.; Jadhav, U.U.; Madhavyan, M.; Ji, L.; Yang, E.H.; Cao, B. Biological leaching and chemical precipitation methods for recovery of Co and Li from spent lithium-ion batteries. ACS Sustain. Chem. Eng. 2018, 6, 12343–12352. [Google Scholar] [CrossRef]

- Li, J.; Yang, X.; Fu, Y.; Huang, H.; Zhong, Z.; Wang, Y. Recovery of Fe, Mn, Ni and Co in sulfuric acid leaching liquor of spent lithium ion batteries for synthesis of lithium ion-sieve and NixCoyMn1−xy(OH)2. Hydrometallurgy 2019, 190, 105190. [Google Scholar] [CrossRef]

- Wang, R.-C.; Lin, Y.-C.; Wu, S.-H. A novel recovery process of metal values from the cathode active materials of the lithium-ion secondary batteries. Hydrometallurgy 2009, 99, 194–201. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, Y.; Wang, L.; Zhou, J.; Wen, X. Recovery of lithium from lithium liquor produced by cobalt extraction from spent lithium-ion batteries. Inorg. Chem. Ind. 2017, 49, 50–53. [Google Scholar]

- Yang, Y.; Sun, W.; Bu, Y.; Zhang, C.; Song, S.; Hu, Y. Recovering valuable metals from spent lithium ion battery via a combination of reduction thermal treatment and facile acid leaching. ACS Sustain. Chem. Eng. 2018, 6, 10445–10453. [Google Scholar]

- Li, L.; Bian, Y.; Zhang, X.; Guan, Y.; Fan, E.; Wu, F.; Chen, R. Process for recycling mixed-cathode materials from spent lithium-ion batteries and kinetics of leaching. Waste Manag. 2018, 71, 362–371. [Google Scholar] [CrossRef]

- Li, G.; Liu, X.; Zhao, Y.; Shao, Z. The preparation and properties research of lithium-rich Li[Li0.2Mn0.54Ni0.13Co0.13]O2 battery cathode materials. Int. J. Electrochem. Sci. 2018, 13, 7321–7334. [Google Scholar] [CrossRef]

- Zhang, A. Study on Recycle and Reuse of Ternary Cathode Materials from Waste Lithium-Ion Batteries; Harbin Institute of Technology: Harbin, China, 2018. [Google Scholar]

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A critical review and analysis on the recycling of spent lithium-ion batteries. ACS Sustain. Chem. Eng. 2018, 6, 1504–1521. [Google Scholar] [CrossRef]

- Xie, J. Hydrothermal Synthesis of LiNi0.9Co0.1O2 and LiNi1/3Co1/3Mn1/3O2 for Lithium Ion Batteries; Ocean University of China: Jinan, China, 2011. [Google Scholar]

- Mukai, K.; Uyama, T.; Nonaka, T. Thermal behavior of Li1+x[Li1/3Ti5/3]O4 and a proof of concept for sustainable batteries. ACS Appl. Mater. Interfaces 2021, 13, 42791–42802. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Song, D.; Song, J.; Zhang, L. Direct regeneration of recycled cathode material mixture from scrapped LiFePO4 batteries. J. Power Source 2017, 345, 78–84. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, G.; Liu, F.; Yue, X.; Chen, Z. Resolving the compositional and structural defects of degraded LiNixCoyMnzO2 particles to directly regenerate high-performance lithium-ion battery cathodes. ACS Energy Lett. 2018, 3, 1683–1692. [Google Scholar] [CrossRef]

- Chi, Z.; Li, J.; Wang, L.; Li, T.; Wang, Y.; Zhang, Y.; Tao, S.; Zhang, M.; Xiao, Y.; Chen, Y. Direct regeneration method of spent LiNi1/3Co1/3Mn1/3O2 cathode materials via surface lithium residues. Green Chem. 2021, 23, 9099–9108. [Google Scholar] [CrossRef]

- Chen, S.; He, T.; Lu, Y.; Su, Y.; Tian, J.; Li, N.; Chen, G.; Bao, L.; Wu, F. Renovation of LiCoO2 with outstanding cycling stability by thermal treatment with Li2CO3 from spent Li-Ion batteries. J. Energy Storage 2016, 8, 262–273. [Google Scholar] [CrossRef]

- Zhou, H.; Zhao, X.; Yin, C.; Li, J. Regeneration of LiNi0.5Co0.2Mn0.3O2 cathode material from spent lithium-ion batteries. Electrochim. Acta 2018, 291, 142–150. [Google Scholar] [CrossRef]

- Meng, X.; Cao, H.; Hao, J.; Ning, P.; Xu, G.; Sun, Z. Sustainable Preparation of LiNi1/3Co1/3Mn1/3O2–V2O5 cathode materials by recycling waste materials of spent Lithium-Ion battery and vanadium-bearing slag. ACS Sustain. Chem. Eng. 2018, 6, 5797–5805. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, M.; Meng, Y.; Chen, Z. Ambient-pressure relithiation of degraded LixNi0.5Co0.2Mn0.3O2 (0 < x < 1) via eutectic solutions for direct regeneration of Lithium-Ion battery cathodes. Adv. Energy Mater. 2019, 9, 1900454. [Google Scholar]

- Yang, J.; Wang, W.; Yang, H.; Wang, D. One-pot compositional and structural regeneration of degraded LiCoO2 for directly reusing it as a high-performance lithium-ion battery cathode. Green Chem. 2020, 22, 6489–6496. [Google Scholar] [CrossRef]

- Wang, T.; Luo, H.; Bai, Y.; Li, J.; Belharouak, I.; Dai, S. Direct recycling of spent NCM cathodes through ionothermal lithiation. Adv. Energy Mater. 2020, 10, 2001204. [Google Scholar] [CrossRef]

- Ganter, M.J.; Landi, B.J.; Babbitt, C.W.; Anctil, A.; Gaustad, G. Cathode refunctionalization as a lithium-ion battery recycling alternative. J. Power Source 2014, 256, 274–280. [Google Scholar] [CrossRef]

- Fan, M.; Meng, Q.; Chang, X.; Gu, C.; Meng, X.; Yin, Y.; Li, H.; Wan, L.; Guo, Y. In situ electrochemical regeneration of degraded LiFePO4 electrode with functionalized prelithiation separator. Adv. Energy Mater. 2022, 12, 2103630. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).