Hydrogen Cooling of Turbo Aggregates and the Problem of Rotor Shafts Materials Degradation Evaluation

Abstract

1. Introduction

2. Literature Survey: State-of-the-Art

3. Formulation of the Problem: Materials and Methodology

4. Results and Discussions

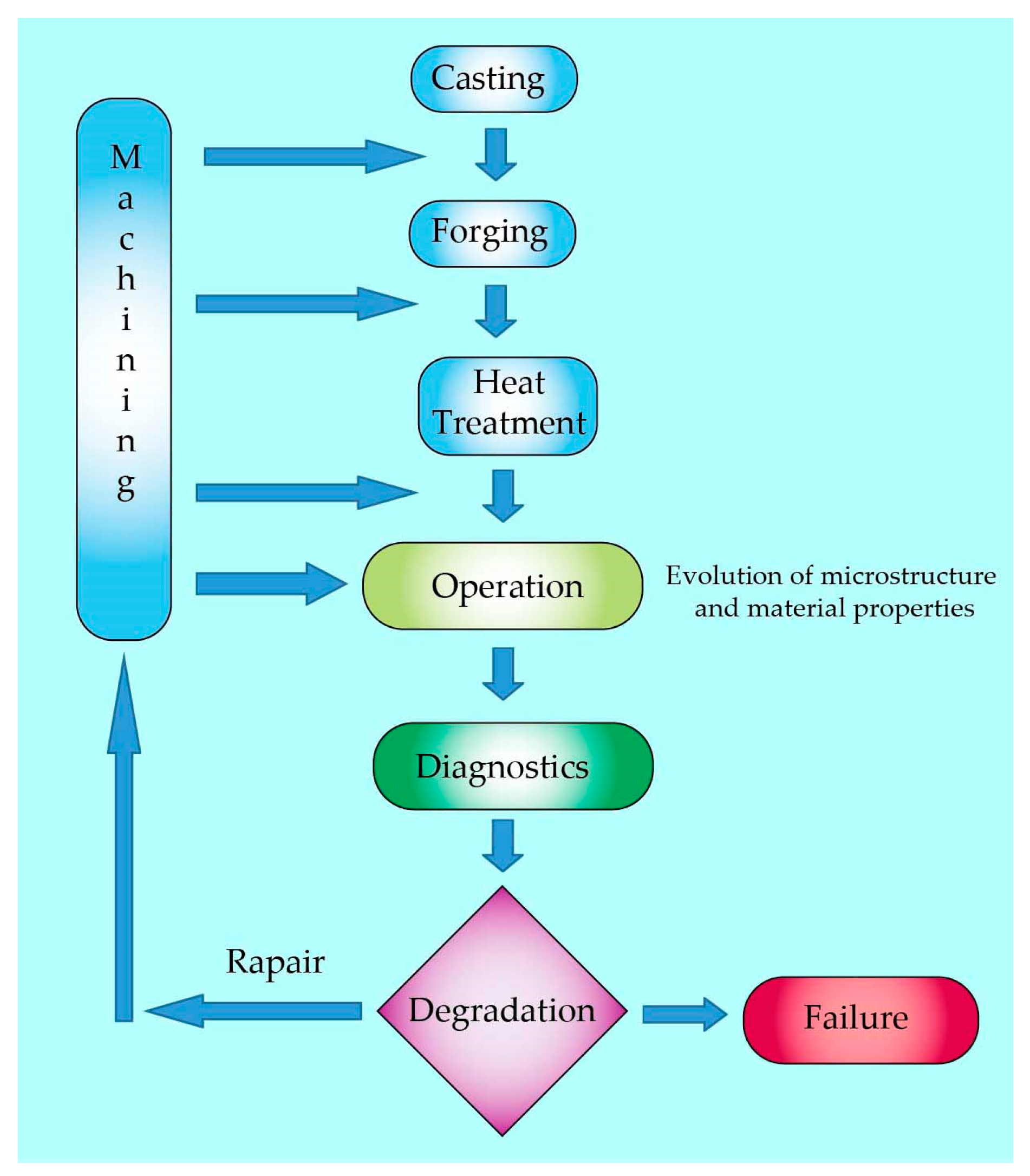

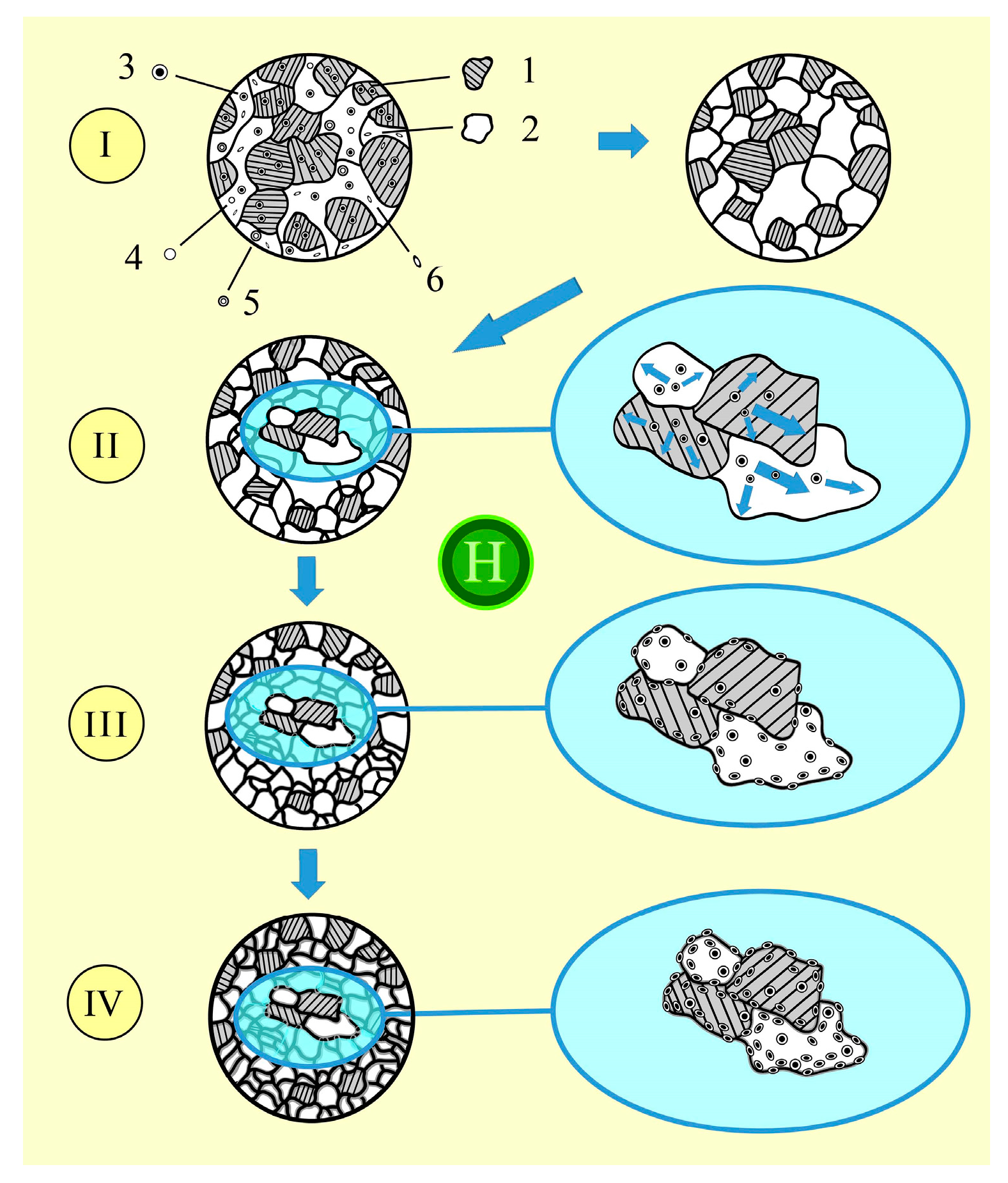

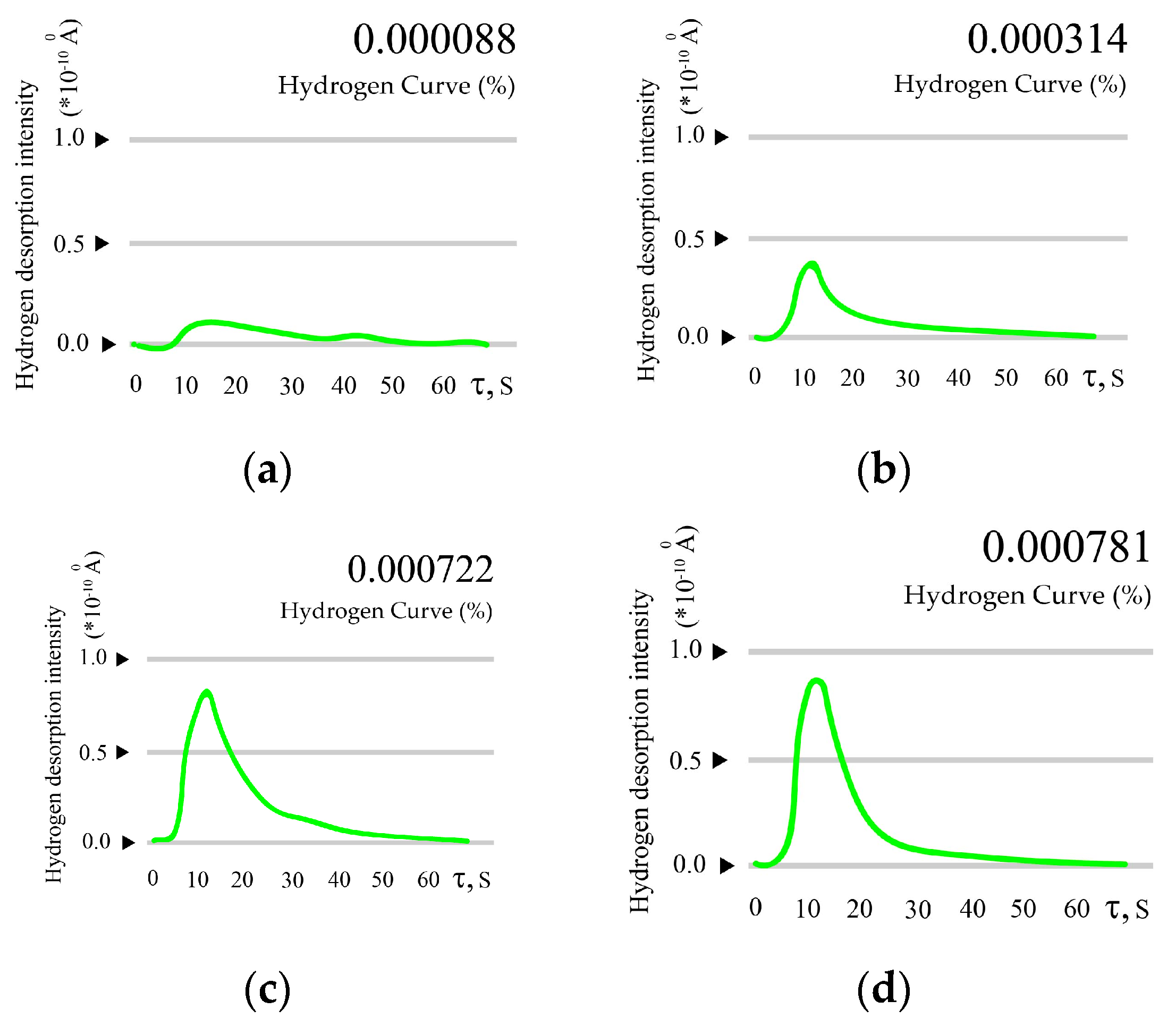

4.1. “Life Cycle” of the Rotor Shaft during Operation

4.2. Evolution of Microstructure and Microhardness of Rotor Steel during Operation

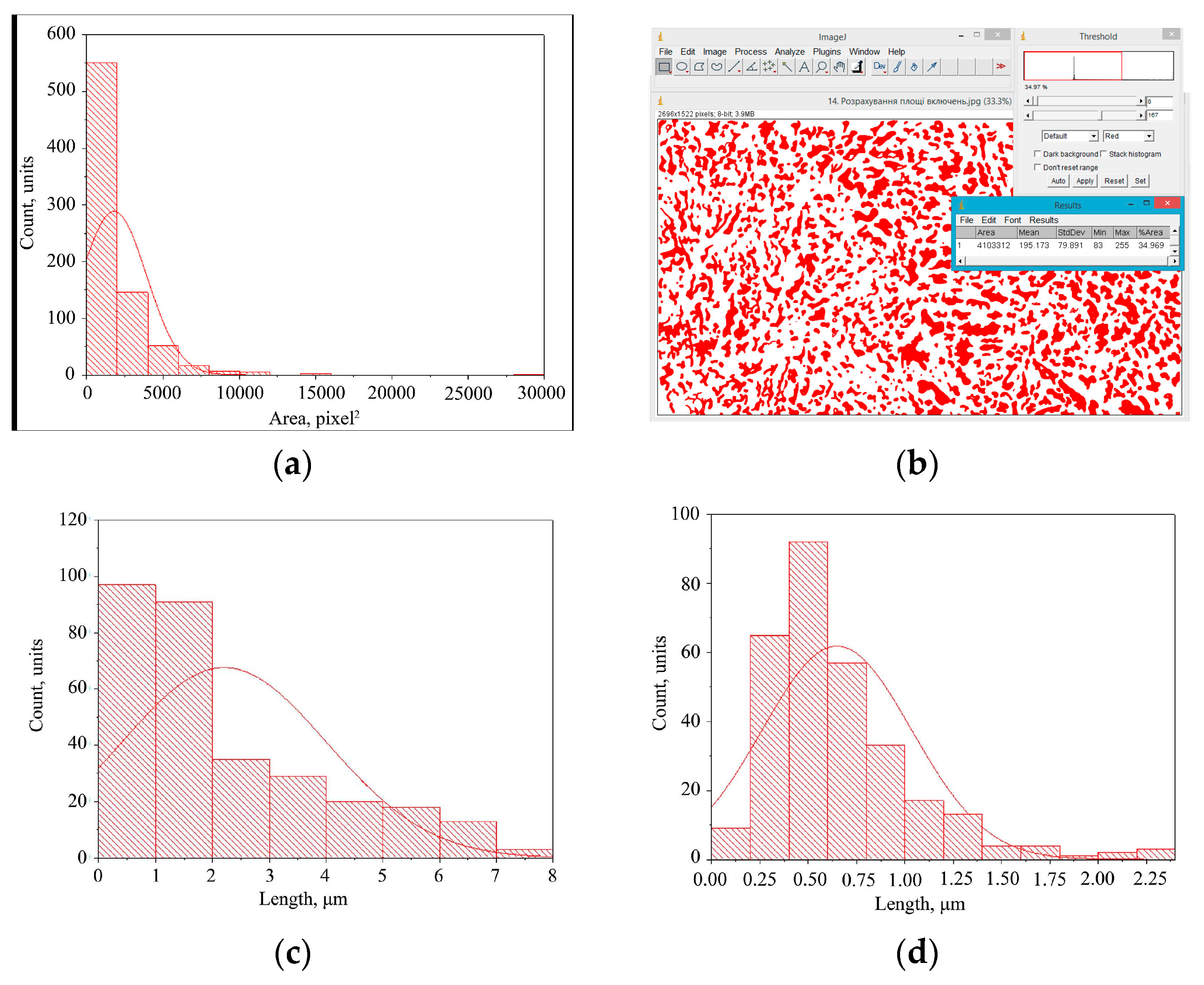

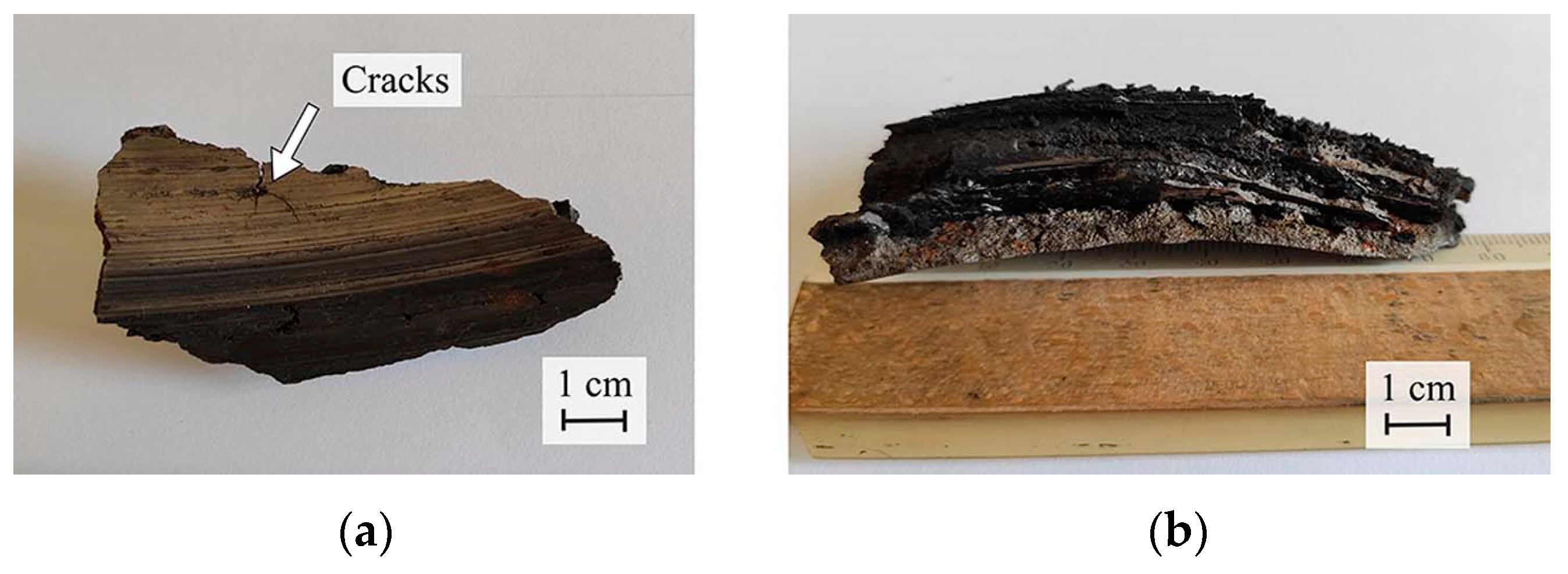

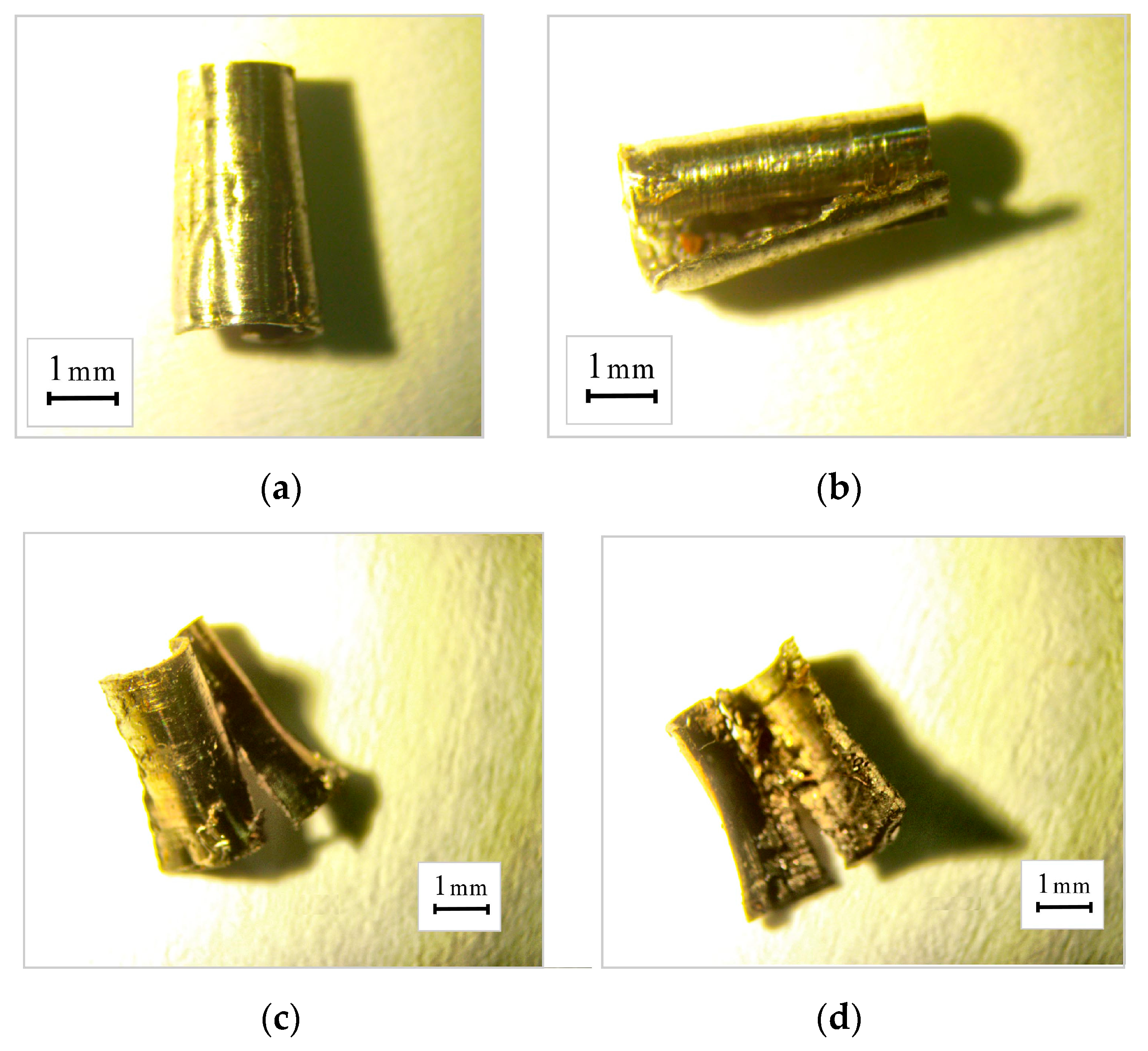

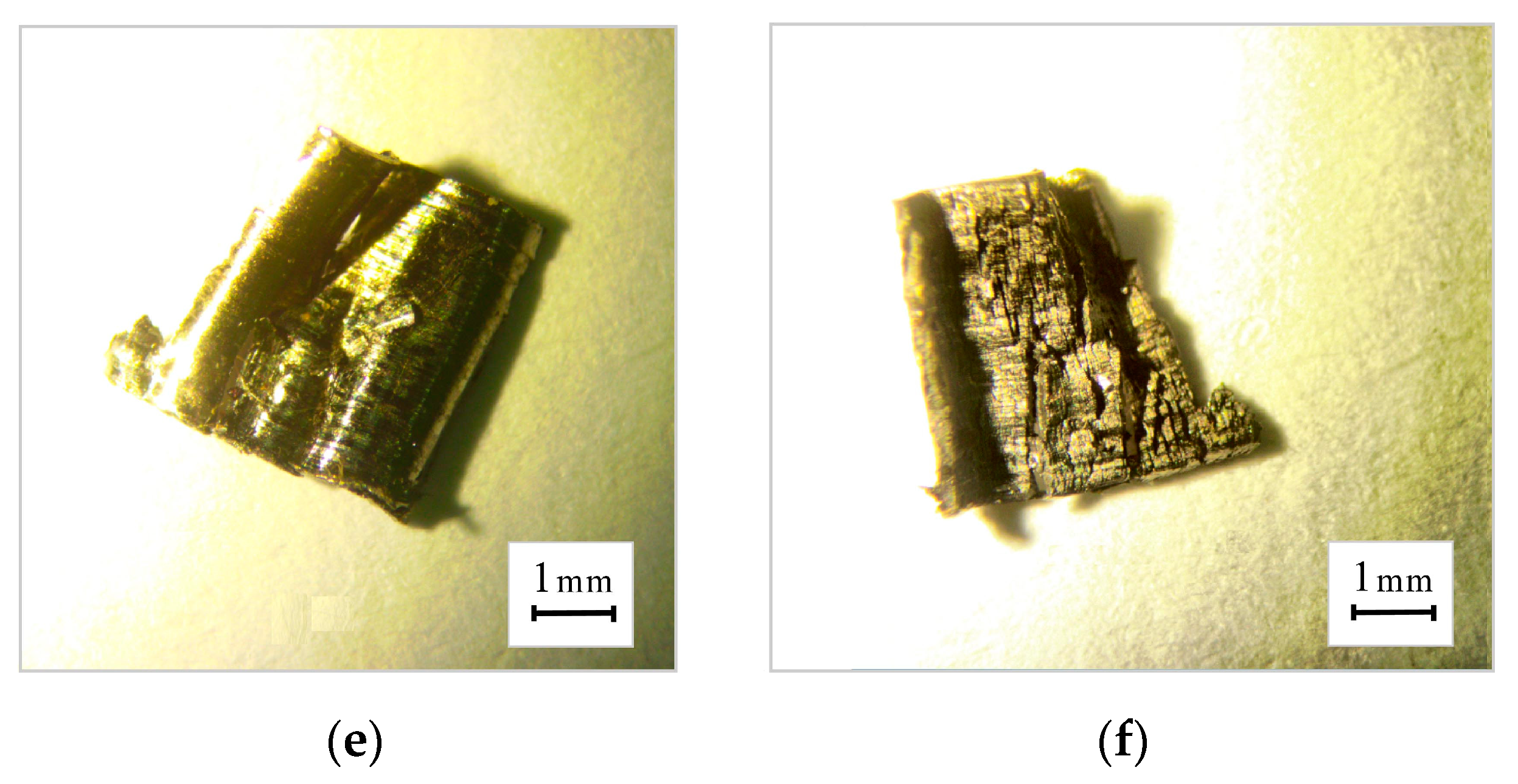

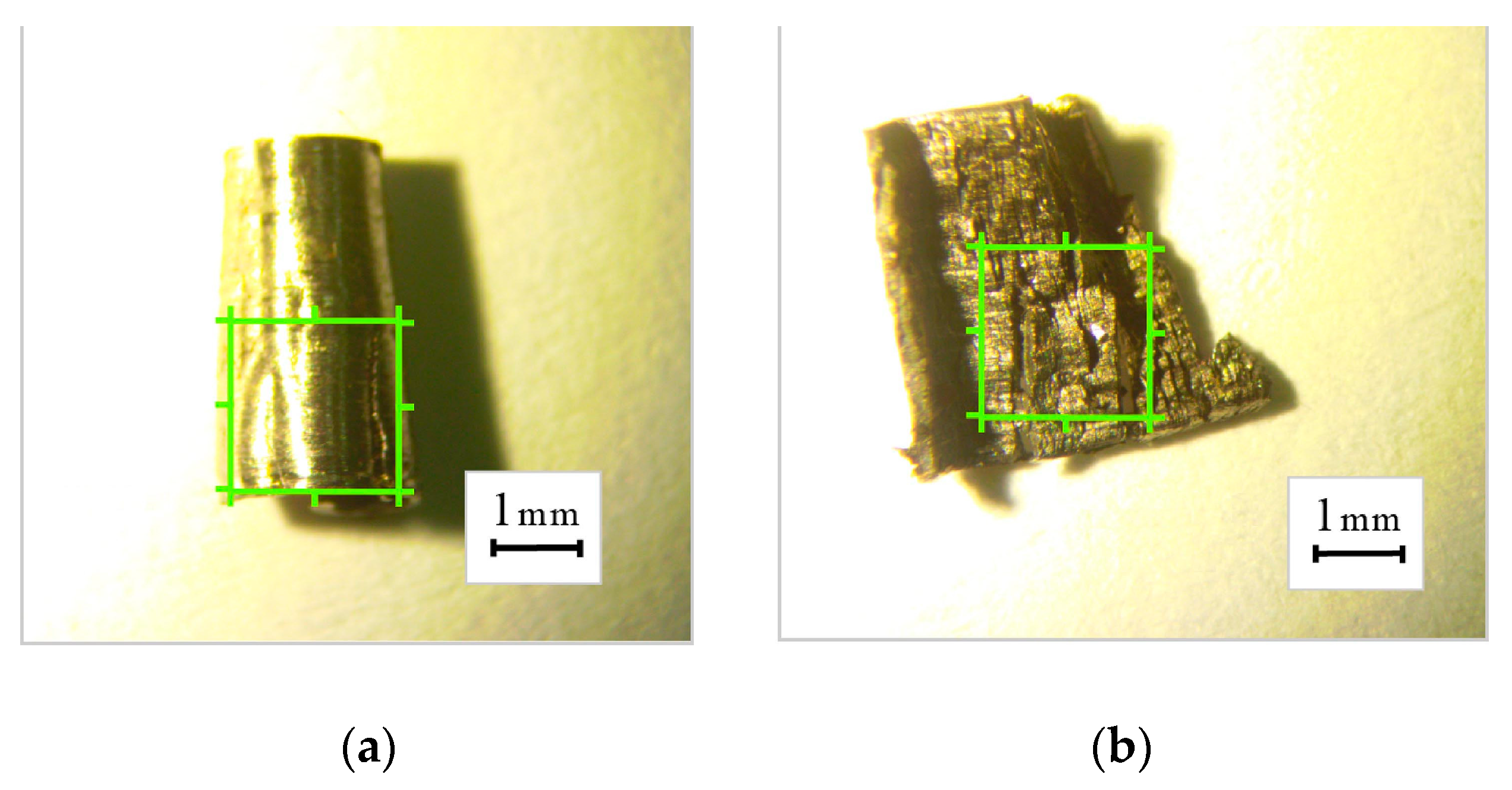

4.3. Analysis of Particles of Degraded Material That Separated from the Rotor Shaft

5. Conclusions

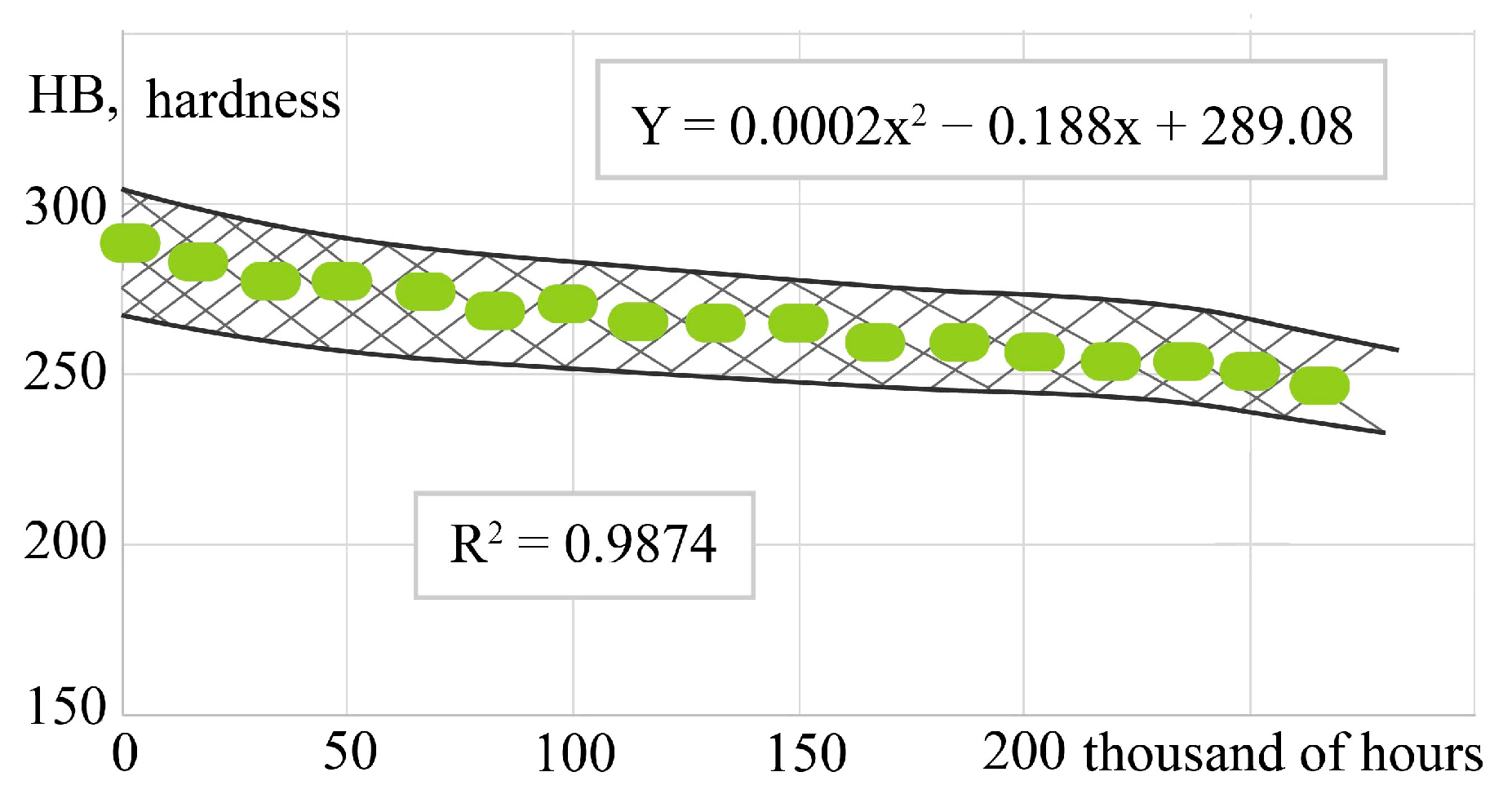

- A decrease in the hardness of the 38KhN3MFA rotor steel surface after long-term operation was shown. It was found that, after its operation up to 250 thousand hours, bainite decomposition occurs, and the hardness decreases by 15%. Thus, the hardness of the steel in the initial state is 290 HB (cementite—80…87%), and after 250 thousand hours of operation, it decreases to 250 HB (cementite component—up to 62%; ferrite grains are detected).

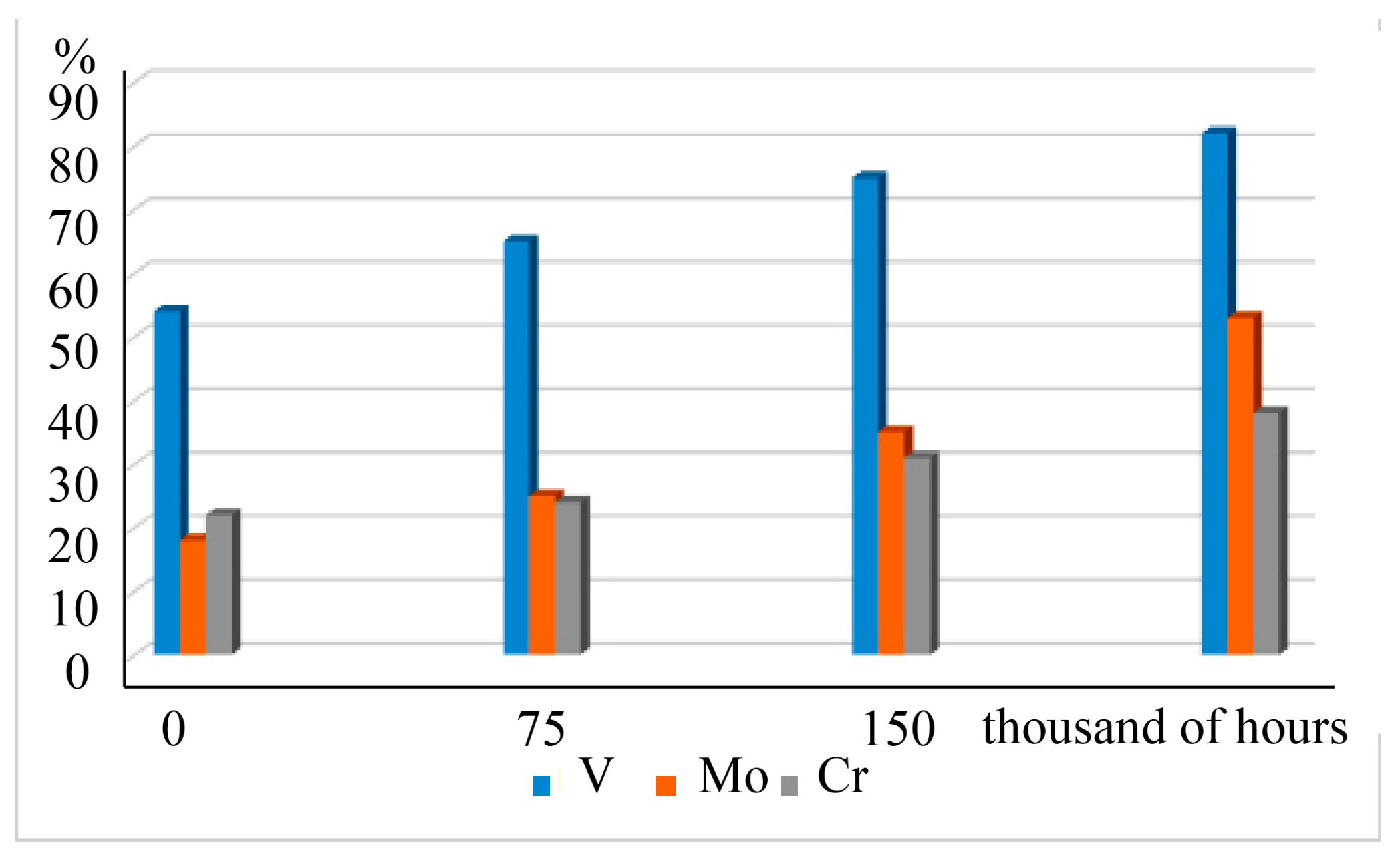

- The intensification of the diffusion processes increases the concentration of carbide-forming elements: both in carbides and near grain boundaries. An increase in the content of alloying elements in carbides was recorded: Cr and V—by 1.15–1.6 times; Mo—by 2.2–2.8 times after 250 thousand hours of operation.

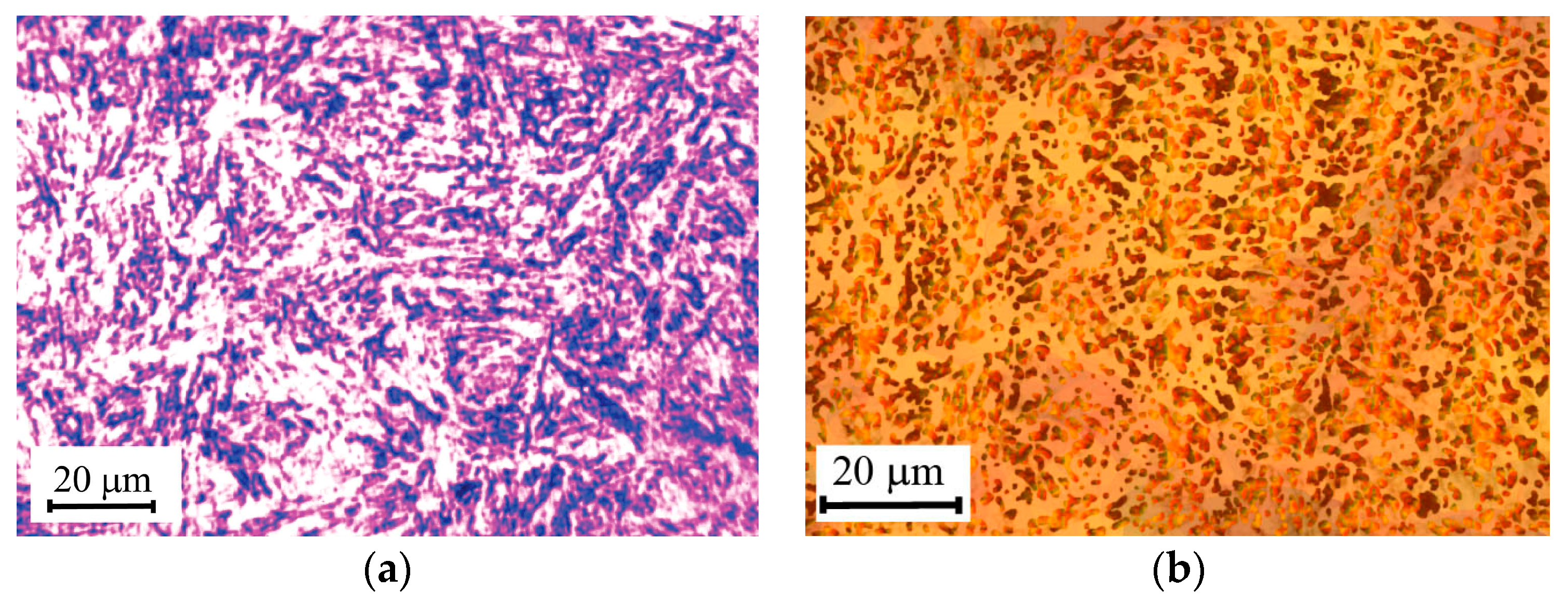

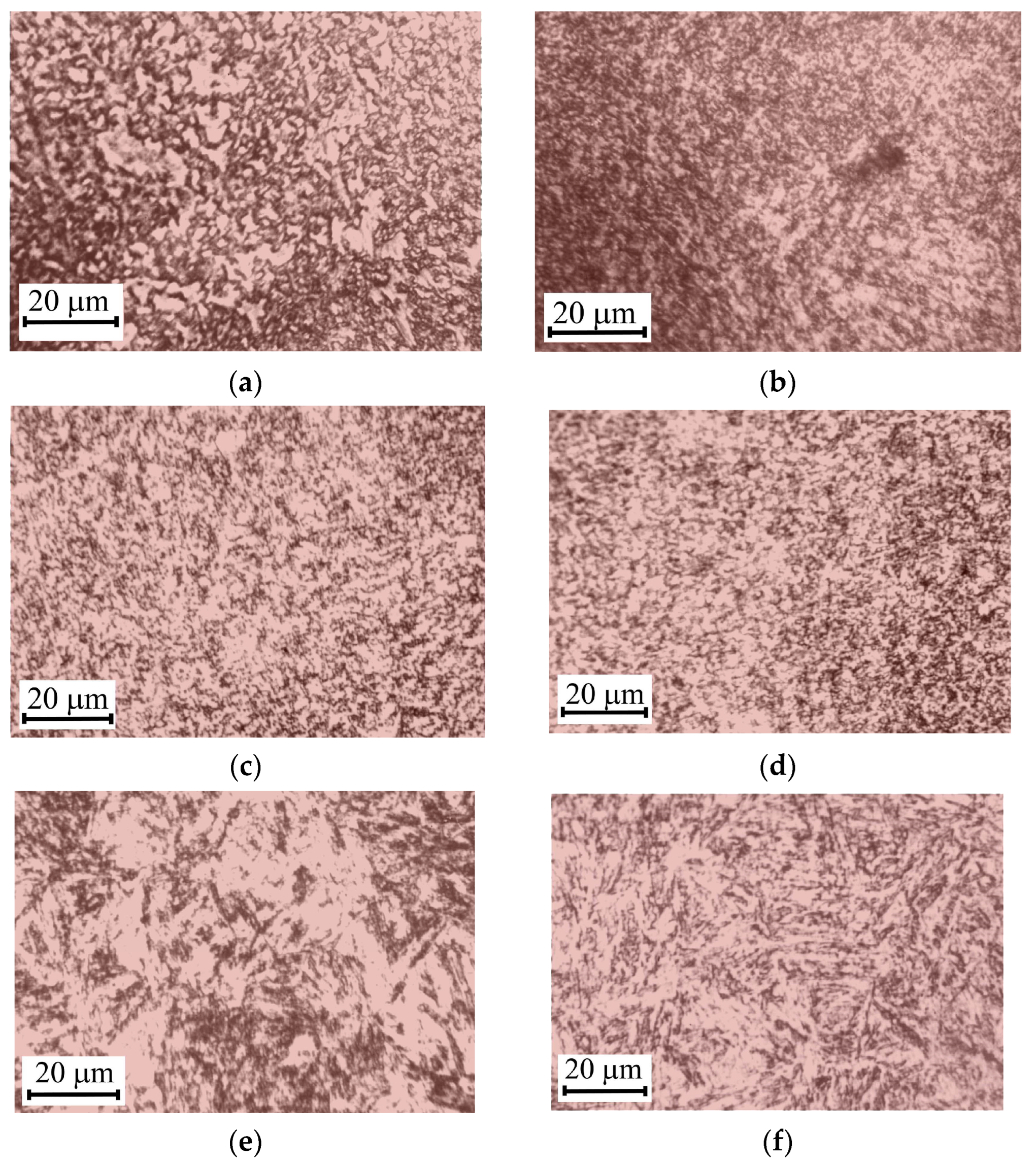

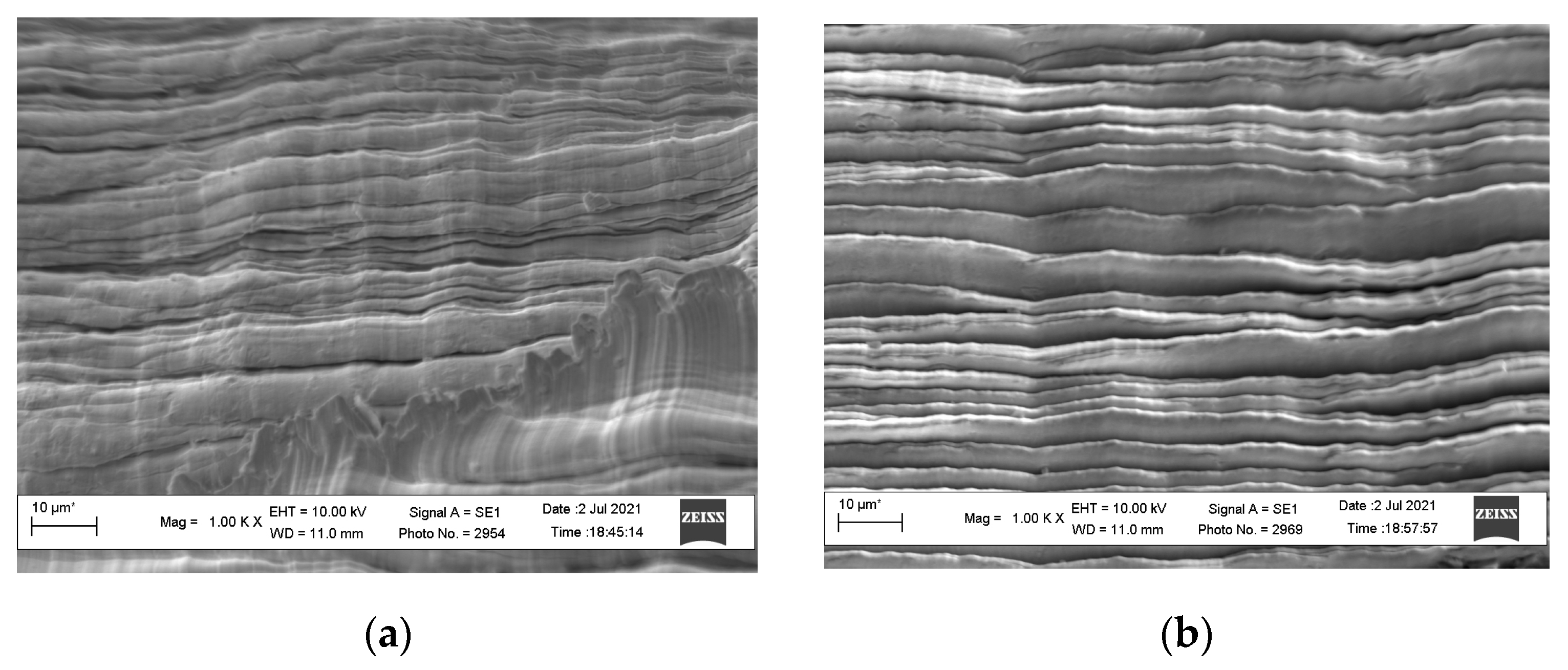

- The analysis of the rotor shaft surface microstructures showed that such shaft microstructures in the initial state are fine-grained and bainitic. For the operated state, in the presence of the greatest mechanical and thermal impacts, the release of finely dispersed carbides along the grain boundaries is observed, as well as a certain orientation of pearlite due to deformation.

- A life cycle diagram of the rotor shaft of a turbine unit was developed. According to this scheme, in the course of long-term operation, due to the complex action of factors, there is a need for repair work, including machining, and in the most extreme case, the rotor shaft may fail.

- A scheme of the microstructure “evolution” for 38KhN3MFA steel, from which the rotor shaft is made, was proposed. It shows that there is a migration of complex carbides and VC carbides from the central part of the grain to the periphery and grain boundaries; the amount of pearlite phase decreases, and the ferrite phase increases. Along the boundaries of ferrite grains and on the periphery of pearlite colonies, coagulated carbides are recorded, which have a slightly deformed, elongated appearance. In some areas of the rotor shaft, the boundaries of pearlite colonies were blurred.

- The concentration of hydrogen in the chips formed during the use of LCL based on sunflower oil LCLs is 7.22 ppm, and on the basis of petroleum oil LCLo—7.81 ppm. Thus, the use of LCLs reduces the amount of hydrogen that is concentrated in the surface layer of the rotor shaft and participates in destructive processes during machining.

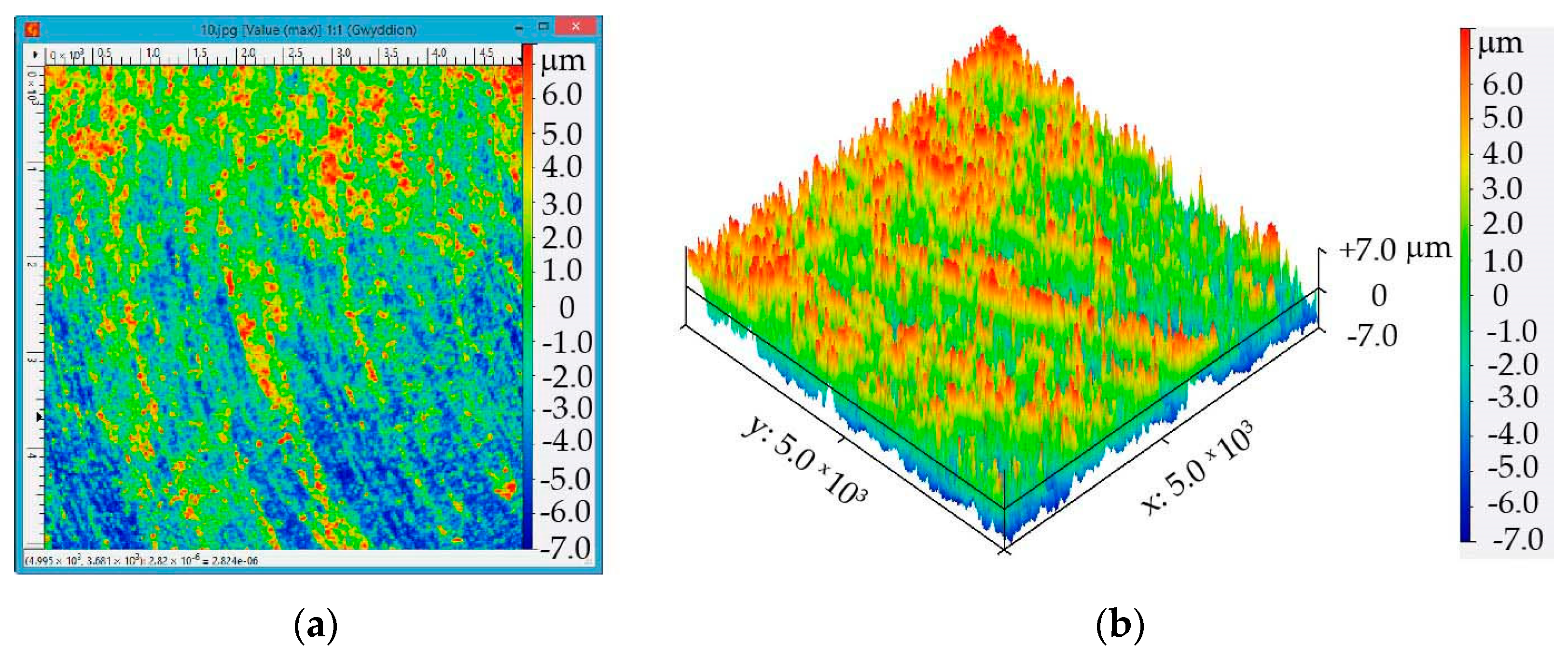

- The surface profiles (2D and 3D reconstruction) after machining of the studied samples made from 38KhN3MFA steel (cut from the rotor shaft surface) were compared: those that did not undergo intensive degradation processes and those that underwent intensive degradation. For the undegraded surface, the roughness (Rz) is in the range of 4-to-8 microns. And for a surface that has undergone intensive degradation, it is 20…40 microns. The analysis of the cutting surface confirms the fact of the brittle nature of fracture during degradation processes.

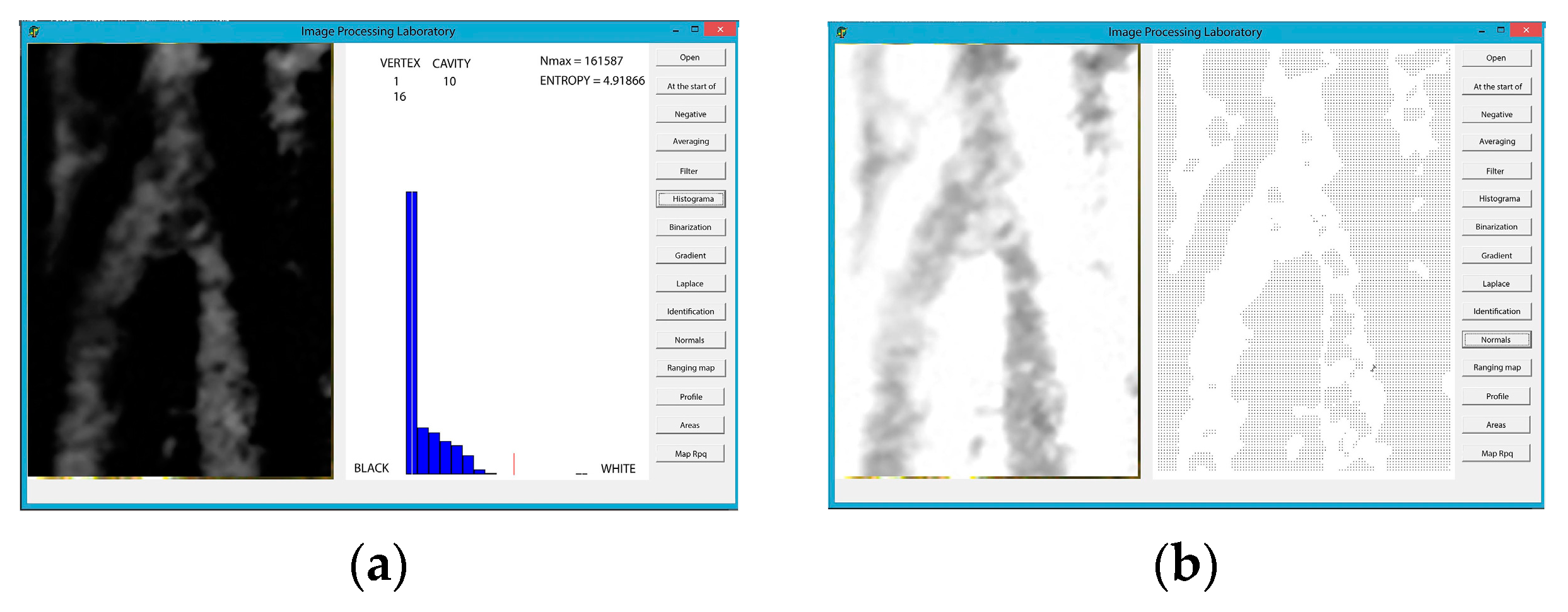

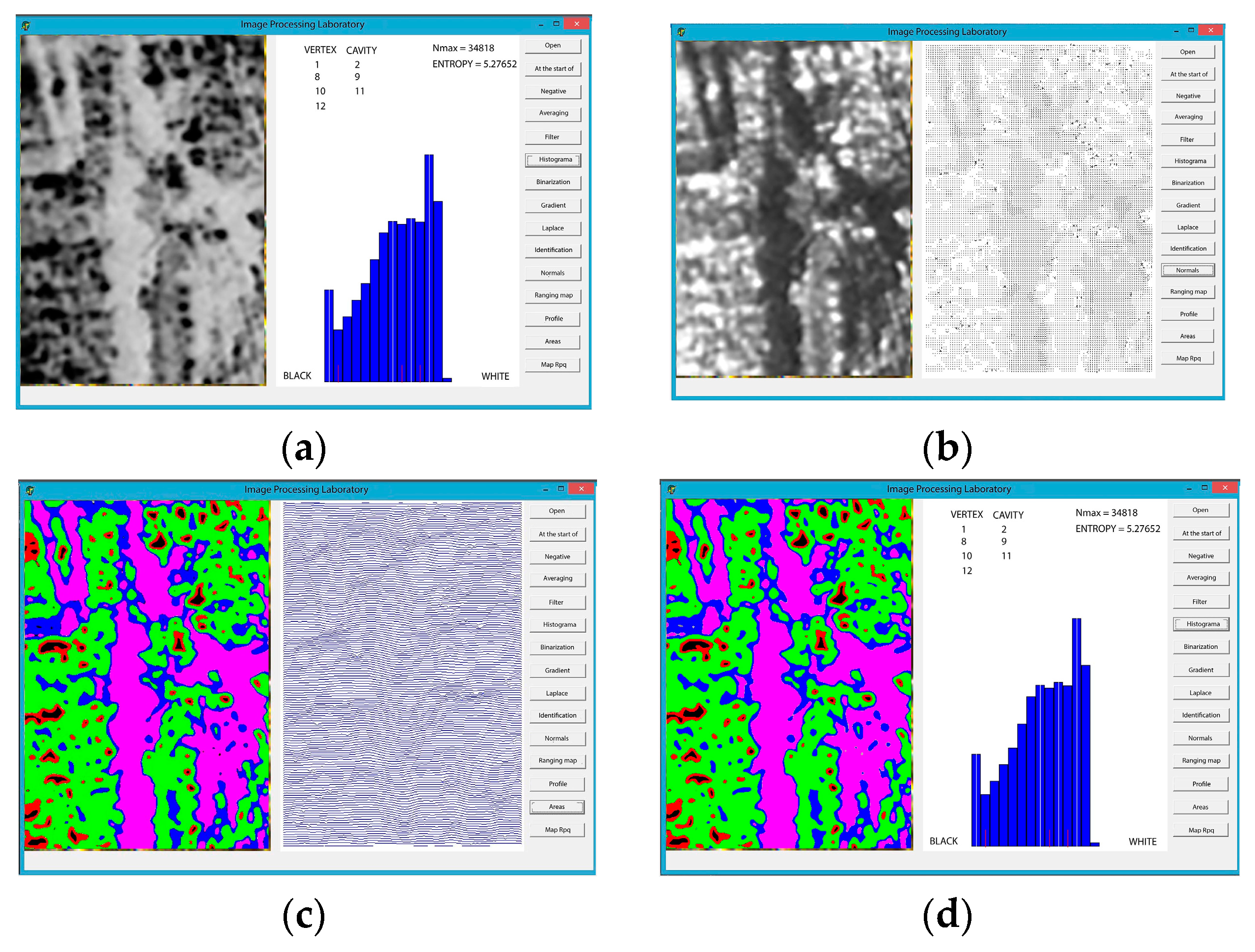

- The developed program was used to compare the chips corresponding to the undegraded state and the chips obtained from the degraded section of the rotor shaft. This makes it possible to identify damaged areas of the rotor shaft online. The fixation on an increased number of cracks and other microrelief indicates the occurrence of intensive degradation processes and is a signal for rotor repair work. The use of machine and computer vision methods is an integral trend that will be used in the Industry 4.0 and Industry 5.0 paradigms.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Abbreviations

| LCL | lubricating cooling liquids |

| LCLo | lubricating cooling liquids based on petroleum oil |

| LCLs | lubricating cooling liquids based on sunflower oil |

| LCLr | lubricating cooling liquids based on rapeseed oil |

| CH | hydrogen concentration |

| ppm | parts per millions |

| TA | turbo aggregate (turbine + turbogenerator) |

| HCTG | hydrogen-cooled turbogenerator |

References

- Balitski, A.; Krohmalny, O.; Ripey, I. Hydrogen cooling of turbogenerators and the problem of rotor retaining ring materials degradation. Int. J. Hydrogen Energy 2000, 25, 167–171. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Havrilyuk, M.R.; Balitska, V.O.; Kolesnikov, V.O.; Ivaskevych, L.M. Increasing turbine hall safety by using fire-resistant, hydrogen-containing lubricant cooling liquid for rotor steel mechanical treatment. Energies 2023, 16, 535. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y. Influence of 12Cr1MoV Material on tissue properties at high temperature and long operating time. Processes 2022, 10, 192. [Google Scholar] [CrossRef]

- Dmytrakh, I.M.; Syrotyuk, A.M.; Leshchak, R.L. Specific features of the deformation and fracture of low-alloy steels in hydrogen-containing media: Influence of hydrogen concentration in the metal. Mater. Sci. 2018, 54, 295–308. [Google Scholar] [CrossRef]

- Nykyforchyn, H.M.; Student, O.Z.; Krechkovs’ka, H.V.; Markov, A.D. Evaluation of the influence of shutdowns of a technological process on changes in the in-service state of the metal of main steam pipelines of thermal power plants. Mater. Sci. 2010, 46, 177–189. [Google Scholar] [CrossRef]

- Krasowsky, A.Y.; Dolgiy, A.A.; Torop, V.M. Charpy testing to estimate pipeline steel degradation after 30 years of operation. In Proceedings of the Charpy Centary Conference, Poitiers, France, 2–5 October 2001; Volume 1, pp. 489–495. [Google Scholar]

- Nagano, S.; Kitajima, T.; Yoshida, K.; Kazao, Y.; Kabata, Y.; Murata, D.; Nagakura, K. Development of world’s largest hydrogen cooled turbine generator. In Proceedings of the IEEE Power Engineering Society Summer Meeting, Chicago, IL, USA, 21–25 July 2002; Volume 2, pp. 657–663. Available online: https://ieeexplore.ieee.org/document/1043376 (accessed on 16 October 2023).

- Xu, H.; Huang, X.-K.; Yang, Z.; Pan, J.-T. Property changes of 12Cr1MoV with 10CrMo910 main steam piping after long-term high-temperature service. Eng. Fail. Anal. 2003, 10, 245–250. [Google Scholar] [CrossRef]

- Zhuang, K.; Fu, C.; Weng, J.; Cheng, H. Cutting edge microgeometries in metal cutting: A review. Int. J. Adv. Manuf. Technol. 2021, 116, 2045–2092. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Kolesnikov, V.O.; Havrylyuk, M.R. Influence of lubricating liquid on the formation of the products of cutting of 38KhN3MFA steel. Mater. Sci. 2019, 54, 722–727. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Kolesnikov, V.O.; Havrylyuk, M.R. Influence of modification of 38KhN3MFA steel on the structural-phase state and cutting products under variable technological conditions. Mater. Sci. 2020, 55, 915–920. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Ivaskevich, L.M.; Balitskii, O.A. Rotor steels crack resistance and fracture behavior for hydrogen targeted materials ever-widening database. Eng. Fract. Mech. 2022, 260, 108168. [Google Scholar] [CrossRef]

- Chernousenko, O.; Rindyuk, D.; Peshko, V.; Goryazhenko, V. Development of a technological approach to the control of turbine casings resource for supercritical steam parameters. East. Eur. J. Enterp. Technol. 2018, 2, 51–56. [Google Scholar] [CrossRef]

- Chernousenko, O.; Rindyuk, D.; Peshko, V.; Bednarska, I. Effect of start-up operating modes on the cyclic damage of thermal power plant units. In Proceedings of the 2022 IEEE 8th International Conference on Energy Smart Systems (ESS), Kyiv, Ukraine, 7–9 September 2022; pp. 233–238. [Google Scholar] [CrossRef]

- Chernousenko, O.; Peshko, V.; Marisyuk, B.; Bovsunovsky, A. Estimation of steam turbine shafts fatigue damage caused by torsional vibrations. In Proceedings of the 8th International Conference on Fracture, Fatigue and Wear (FFW 2020), Virtual, 26–27 August 2020; Springer: Singapore, 2021; pp. 533–541. [Google Scholar] [CrossRef]

- Chernousenko, O.; Peshko, V.; Nikulenkova, T.; Rindyuk, D. Extension of the operating time of high-speed turbines of nuclear power plants. In Proceedings of the 2020 IEEE 7th International Conference on Energy Smart Systems (ESS), Kyiv, Ukraine, 2–4 November 2020; pp. 101–104. [Google Scholar] [CrossRef]

- Chernousenko, O.; Nikulenkova, T.; Peshko, V.; Nikulenkov, A. Maintaining electricity production through a comprehensive approach to service life extension of steam turbines. In Proceedings of the 2020 IEEE 7th International Conference on Energy Smart Systems (ESS), Kyiv, Ukraine, 2–4 November 2020; pp. 54–57. [Google Scholar] [CrossRef]

- Peshko, V.; Chernousenko, O.; Nikulenkova, T.; Nikulenkov, A. Comprehensive rotor service life study for high & intermediate pressure cylinders of high power steam turbines. Propuls. Power Res. 2016, 5, 302–309. [Google Scholar] [CrossRef]

- Chernousenko, O.Y.; Ryndiuk, D.V.; Peshko, V.A. The Stress-strain state of the K-1000-60/3000 turbine rotor at typical operating modes. Bull. Natl. Tech. Univ. "KhPI" Ser. Energy Heat Eng. Process. Equip. 2019, 3, 4–10. [Google Scholar] [CrossRef]

- Chernousenko, O.; Krylova, I.; Shramko, A.; Borodavka, O.; Kozlov, A. Research on residual service life of automatic locking valve of turbine K-200-130. East. Eur. J. Enterp. Technol. 2017, 5, 39–44. [Google Scholar] [CrossRef]

- Tretiak, O.; Kritskiy, D.; Kobzar, I.; Sokolova, V.; Arefieva, M.; Tretiak, I.; Denys, H.; Nazarenko, V. Modeling of the stress–strain of the suspensions of the stators of high-power turbogenerators. Computation 2022, 10, 191. [Google Scholar] [CrossRef]

- Tretiak, O.; Kritskiy, D.; Kobzar, I.; Arefieva, M.; Nazarenko, V. The methods of three-dimensional modeling of the hydrogenerator thrust bearing. Computation 2022, 10, 152. [Google Scholar] [CrossRef]

- Gakal, P.; Ovsiannykova, O.; Przybysz, J.; Tretiak, O. Analysis of the temperature field of the rotor of 550-MW turbogenerator with direct hydrogen cooling. Prz. Elektrotech. 2017, 93, 43–47. Available online: http://pe.org.pl/articles/2017/2/11.pdf (accessed on 16 October 2023).

- Abdul Rahman, A.G.; Noroozi, S.; Dupac, M.; Syed Mohd Al-Attas, S.M.; Vinney, J.E. A Hybrid approach for nondestructive assessment and design optimisation and testing of in-service machinery. Nondestruct. Test. Eval. 2013, 28, 44–57. [Google Scholar] [CrossRef]

- Training Guidelines in Non-Destructive Testing Testing Techniques: Manual for Ultrasonic Testing at Level 2; IAEA-TCS-67; IAEA: Vienna, Austria, 2018; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/TCS-67web.pdf/ (accessed on 16 October 2023).

- Siegel, M.; Rauschenbach, H.; Metzner, B. Nondestructive examination of turbine and generator components: Experience with mechanized examination techniques. In Proceedings of the VGB-ESKOM International Materials Conference, Pretoria, South Africa, 18–20 September 2000; Available online: https://www.imia.com/wp-content/uploads/2023/07/EP05_2003-NonDestructiveExamination-4.pdf (accessed on 16 October 2023).

- Golis, M.J.; Brown, S.D. Nondestructive Evaluation of Steam Turbine Rotors: An Analysis of the Systems and Techniques Utilized for In-Service Inspection. Interim Report; United States. 1978. Available online: https://www.osti.gov/servlets/purl/6874849 (accessed on 16 October 2023).

- Poursaeidi, E.; Mohammadi Arhani, M.R. Failure investigation of an auxiliary steam turbine. Eng. Fail. Anal. 2010, 17, 1328–1336. [Google Scholar] [CrossRef]

- Mazur, Z.; Illescas, R.G.; Romano, J.A.; Rodrigue, N.P. Steam turbine blade failure analysis. Eng. Fail. Anal. 2008, 15, 129–141. [Google Scholar] [CrossRef]

- Sărăcin, I.; Paraschiv, G.; Pandia, O.; Bozgă, I.; Toma, D. Researches on corrosion cracking phenomenon that occurs on welded of agricultural equipment. Metalurgija 2015, 54, 395–398. [Google Scholar]

- Barella, S.; Bellogini, M.; Boniardi, M.; Cincera, S. Failure analysis of a steam turbine rotor. Eng. Fail. Anal. 2011, 18, 511–519. [Google Scholar] [CrossRef]

- Balitskii, O.I.; Kvasnytska, Y.H.; Ivaskevych, L.M.; Mialnitsa, H.P.; Kvasnytska, K.H. Fatigue fracture of the blades of gas turbine engine made of a new refractory nickel alloy. Mater. Sci. 2022, 57, 475–483. [Google Scholar] [CrossRef]

- Trebuňa, P.; Pástor, M.; Trebuňa, F.; Šimčák, F. The analysis of failure causes of the rotor shaft of steam turbines. Metalurgija 2017, 56, 233–236. Available online: http://hrcak.srce.hr/file/249341 (accessed on 16 October 2023).

- Zhu, M.-L.; Mei, L.-B.; Xuan, F.-Z. Effect of microstructure on mechanical behavior of a combined steam turbine rotor steel. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition. Volume 7A: Structures and Dynamics, Montreal, QC, Canada, 15–19 June 2015; GT2015-44132; V07AT28A018. ASME: New York, NY, USA, 2015; p. 7. [Google Scholar] [CrossRef]

- Zhu, M.-L.; Xuan, F.-Z.; Wang, G.-Z. Effect of microstructure on fatigue crack propagation behavior in a steam turbine rotor steel. Mater. Sci. Eng. A 2009, 515, 85–92. [Google Scholar] [CrossRef]

- Racic, Z.; Hidalgo, J. Practical balancing of flexible rotors for power. In Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Las Vegas, NV, USA, 4–7 September 2007; DETC2007-34333. ASME: New York, NY, USA, 2009; pp. 1143–1152. [Google Scholar] [CrossRef]

- Ranjan, G.; Tiwari, R. On-site high-speed balancing of flexible rotor-bearing system using virtual trial unbalances at slow run. Int. J. Mech. Sci. 2020, 183, 105786. [Google Scholar] [CrossRef]

- Racic, Z.; Racic, M. Development of a new balancing approach for significantly eccentric or bowed rotors. In Proceedings of the 9th IFToMM International Conference on Rotor Dynamics, Milan, Italy, 22–25 September 2014; Pennacchi, P., Ed.; Springer: Cham, Switzerland, 2015; p. 21. [Google Scholar] [CrossRef]

- Hidalgo, J.; Racic, Z. Diagnosis and treatment of bowed, misalign, and eccentric rotor trains. In Proceedings of the 22nd Biennial Conference on Mechanical Vibration and Noise, San Diego, CA, USA, 30 August–2 September 2009; IDETC-CIE, DETC 2009-86307. ASME: New York, NY, USA, 2010; pp. 987–998. [Google Scholar] [CrossRef]

- Fatsis, A. Design point analysis of two-shaft gas turbine engines topped by four-port wave rotors for power generation systems. Propuls. Power Res. 2019, 8, 183–193. [Google Scholar] [CrossRef]

- Rauschenbach, H.; Opheys, M. Experience with advanced NDT methods in turbine field service. In Proceedings of the 19th World Conference on Non-Destructive Testing, Munich, Germany, 13–17 June 2016; Available online: https://www.ndt.net/article/wcndt2016/papers/th4a3.pdf (accessed on 16 October 2023).

- Nurbanasari, M. Integrity inspection of a steam turbine rotor in a geothermal power plant. In Proceedings of the 2015 International Conference on Electrical, Automation and Mechanical Engineering (EAME 2015), Phuket, Thailand, 26–27 July 2015. Advances in Engineering Research. [Google Scholar] [CrossRef]

- Kim, T.; Kim, T. Optimization of hammer peening process for gas turbine rotor straightening. Machines 2022, 10, 950. [Google Scholar] [CrossRef]

- Burhani, A.; Rozaq, F.; Supriyanto, E. Case study application of cold peening in combination with thermal stress relieving as effective method for straightening large turbine rotor. In Proceedings of the International Conference on Power, Energy, Control and Transmission Systems (ICPECTS), Chennai, India, 10–11 December 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Pei, Y.C.; Wang, J.W.; Tan, Q.C.; Yuan, D.Z.; Zhang, F. An investigation on the bending straightening process of D-type cross section shaft. Int. J. Mech. Sci. 2017, 131–132, 1082–1091. [Google Scholar] [CrossRef]

- Lopez, R.H.; Ritto, T.G.; Sampaio, R.; De Cursi, J.S. A new algorithm for the robust optimization of rotor-bearing systems. Eng. Optim. 2014, 46, 1123–1138. [Google Scholar] [CrossRef]

- Heinz, P.; Murari, B.; Singh, P. Steam Turbines: Design, Applications, and Rerating, 2nd ed.; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2009; ISBN 9780071508216. [Google Scholar]

- Kvasnytska, Y.H.; Ivaskevych, L.M.; Balytskyi, O.I.; Maksyuta, I.I.; Myalnitsa, H.P. High-temperature salt corrosion of a heat-resistant nickel alloy. Mater. Sci. 2020, 56, 432. [Google Scholar] [CrossRef]

- Glotka, A.A.; Ol’shanetskii, V.E. Prediction thermo-physical characteristics of heat-resistant nickel alloys directional crystallization. Acta Metall. Slovaca 2021, 27, 68–71. [Google Scholar] [CrossRef]

- Glotka, O.A.; Haiduk, S.V. Distribution of elements in carbides of multicomponent superalloys. Metallofiz. Noveishie Tekhnol. 2020, 42, 869–884. [Google Scholar] [CrossRef]

- Glotka, A.A.; Moroz, A.N. Comparison of the effects of carbides and nonmetallic inclusions on formation of fatigue microcracks in steels. Metal Sci. Heat Treat. 2019, 61, 521–524. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Kolesnikov, V.O.; Kubicki, E. Enhancement of the crack resistance of manganese cast irons. Mater. Sci. 2005, 41, 67–73. [Google Scholar] [CrossRef]

- Balitskii, A.; Kolesnikov, V.; Abramek, K.F.; Balitskii, O.; Eliasz, J.; Havrilyuk, M.; Ivaskevych, L.; Kolesnikova, I. Influence of hydrogen-containing fuels and environmentally friendly lubricating coolant on nitrogen steels wear resistance for spark ingnition engine pistons and rings kit gasket set. Energies 2021, 14, 7583. [Google Scholar] [CrossRef]

- Korniy, S.A.; Zin, I.M.; Danyliak, M.O. Eco-friendly metal corrosion inhibitors based on natural polymers (A Review). Mater. Sci. 2023, 58, 567–578. [Google Scholar] [CrossRef]

- Zhu, M.-L.; Xuan, F.-Z. Effect of microstructure on appearance of near-threshold fatigue fracture in Cr–Mo–V steel. Int. J. Fract. 2009, 159, 111–120. [Google Scholar] [CrossRef]

- Niu, L.-B.; Kobayashi, M.; Takaku, H.; Azuma, T. Aging effect on creep rupture properties of super-clean 9%CrMoV steel for steam turbine rotors of combined cycle power plants. Key Eng. Mater. 2004, 274–276, 931–936. [Google Scholar] [CrossRef]

- Poon, C.; Vitale, D.; Singh, M.; Hoeppner, D. Fatigue crack propagation behaviour of rotor and wheel materials used in steam turbines. Int. J. Fatigue 1983, 5, 87–93. [Google Scholar] [CrossRef]

- Liu, P.; Lu, F.; Liu, X.; Ji, H.; Gao, Y. Study on fatigue property and microstructure characteristics of welded nuclear power rotor with heavy section. J. Alloys Compd. 2014, 584, 430–437. [Google Scholar] [CrossRef]

- Papadopoulos, C.A. The strain energy release approach for modeling cracks in rotors: A state of the art review. Mech. Syst. Signal Process. 2008, 22, 763–789. [Google Scholar] [CrossRef]

- Wang, D.; Cao, H.; Yang, Y.; Du, M. Dynamic modeling and vibration analysis of cracked rotor-bearing system based on rigid body element method. Mech. Syst. Signal Process. 2023, 191, 110152. [Google Scholar] [CrossRef]

- Abbasi, A.; Nazari, F.; Nataraj, C. Adaptive modeling of vibrations and structural fatigue for analyzing crack propagation in a rotating system. J. Sound Vib. 2022, 541, 117276. [Google Scholar] [CrossRef]

- Imdad, A.; Zafra, A.; Arniella, V.; Belzunce, J. Hydrogen diffusivity in different microstructures of 42CrMo4 steel. Hydrogen 2021, 2, 414–427. [Google Scholar] [CrossRef]

- Sun, Z.; Moriconi, C.; Benoit, G.; Halm, D.; Henaff, G. Fatigue crack grow thunder high pressure of gaseous hydrogen in a 15-5PH martensitic stain less steel: Influence of pressure and loading frequency. Metall. Mater. Trans. A 2013, 44, 1320–1330. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Prevention of hydrogen embrittlement in steels. ISIJ Int. 2016, 56, 24–36. [Google Scholar] [CrossRef]

- Kimura, Y.; Sakai, Y.; Hara, T.; Belyakov, A.; Tsuzaki, K. Hydrogen-induced delayed fracture of ultrafine grained 0.6% O steel with dispersed oxide particles. Scripta Mater. 2003, 49, 1111–1116. [Google Scholar] [CrossRef]

- Robertson, I.M.; Sofronis, P.; Nagao, A.; Martin, M.L.; Wang, S.; Gross, D.W.; Nygren, K.E. Hydrogen embrittlement understood. Metall. Mater. Trans. B 2015, 46, 1085–1103. [Google Scholar] [CrossRef]

- Brahimi, S.V.; Yue, S.; Sriraman, K.R. Alloy and composition dependence of hydrogen embrittlement susceptibility in high-strength steel fasteners. Phil. Trans. R. Soc. A 2017, 375, 20160407. [Google Scholar] [CrossRef]

- Martin, M.L.; Connolly, M.J.; DelRio, F.W.; Slifka, A.J. Hydrogen embrittlement in ferritic steels. Appl. Phys. Rev. 2020, 7, 041301. [Google Scholar] [CrossRef] [PubMed]

- Ohaeri, E.; Eduok, U.; Szpunar, J. Hydrogen related degradation in pipeline steel: A review. Int. J. Hydrogen Energy 2018, 43, 14584–14617. [Google Scholar] [CrossRef]

- Mine, Y.; Tachibana, K.; Horita, Z. Effect of hydrogen on tensile properties of ultrafine-grained type 310S austenitic stainless steel processed by high-pressure torsion. Metall. Mater. Trans. A 2011, 42, 1619–1629. [Google Scholar] [CrossRef]

- Mine, Y.; Tsumagari, T.; Horita, Z. Hydrogen trapping on lattice defects produced by high-pressure torsion in Fe–0.01 mass % C Alloy. Scripta Mater. 2010, 63, 552–555. [Google Scholar] [CrossRef]

- Balitskii, A.; Ivaskevich, L.; Mochulskyi, V.; Eliasz, J.; Skolozdra, O. Influence of high pressure and high temperature hydrogen on fracture toughness of Ni-containing steels and alloys. Arch. Mech. Eng. 2014, 61, 129–138. [Google Scholar] [CrossRef]

- Choo, W.Y.; Lee, J. Hydrogen trapping phenomena in carbon steel. J. Mater. Sci. 1982, 17, 1930–1938. [Google Scholar] [CrossRef]

- Krom, A.H.M.; Bakker, A. Hydrogen Trapping Models in Steel. Metall. Mater. Trans. B 2000, 31, 1475–1482. [Google Scholar] [CrossRef]

- Gong, P.; Turk, A.; Nutter, J.; Yu, F.; Wynne, B.; Rivera-Diaz-del-Castillo, P.; Rainforth, W.M. Hydrogen embrittlement mechanisms in advanced high strength steel. Acta Mater. 2023, 223, 117488. [Google Scholar] [CrossRef]

- Jang, W.J.; Seo, H.J.; Jung, B.-I.; Choi, S.; Lee, C.S. Effect of Bainite Fraction on Hydrogen Embrittlement of Bainite/Martensite Steel. Mater. Sci. Eng. A 2021, 814, 141226. [Google Scholar] [CrossRef]

- Gong, P.; Nutter, J.; Rivera-Diaz-Del-Castillo, P.E.J.; Rainforth, W.M. Hydrogen embrittlement through the formation of low-energy dislocation nanostructures in nanoprecipitation-strengthened steels. Sci. Adv. 2020, 6, 6152. [Google Scholar] [CrossRef]

- Sun, B.; Lu, W.; Gault, B.; Bei, H.; Tasan, C.C. Chemical Heterogeneity Enhances Hydrogen Resistance in High-Strength Steels. Nat. Mater. 2021, 20, 1629–1634. [Google Scholar] [CrossRef] [PubMed]

- Mweta, F.J.; Adachi, N.; Todaka, Y.; Ueno, A.; Ikenaga, A.; Nakamura, H.; Takahashi, S.; Tsuzaki, K. Effect of hetero- and homo-nanostructure on the hydrogen embrittlement resistance in heavily deformed 316LN austenitic stainless steel. MRS Adv. 2021, 6, 682–688. [Google Scholar] [CrossRef]

- Rahman, K.M.M.; Qin, W.; Szpunar, J.A.; Kozinski, J.; Song, M.; Zhu, N. New insight into the role of inclusions in hydrogen-induced degradation of fracture toughness: Three-dimensional imaging and modeling of materials. Philos. Mag. Part A 2021, 101, 976–996. [Google Scholar] [CrossRef]

- Jin, T.Y.; Liu, Z.Y.; Cheng, Y.F. Effect of non-metallic inclusions on hydrogen-induced cracking of API5L X100 steel. Int. J. Hydrogen Energy 2010, 35, 8014–8021. [Google Scholar] [CrossRef]

- Singh, V.; Khan, R.; Bandi, B.; Roy, G.G.; Srirangam, P. Effect of non-metallic inclusions (NMI) on crack formation in forged steel. Mater. Today Proc. 2021, 41, 1096–1102. [Google Scholar] [CrossRef]

- Abraham, S.; Bodnar, R.; Raines, J.; Schwerdt, B.; Chumbley, L.; Yin, F. Inclusion engineering and metallurgy of calcium treatment. J. Iron Steel Res. Int. 2018, 25, 133–145. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, L.; Ren, Y.; Luo, Y.; Sun, X. Effect of calcium treatment on non-metallic inclusions in steel during refining process. In Proceedings of the 12th International Symposium on High-Temperature Metallurgical Processing; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2022; Volume 30, pp. 265–274. [Google Scholar] [CrossRef]

- Nagumo, M.; Takai, K. The predominant role of strain-induced vacancies in hydrogen embrittlement of steels: Overview. Acta Mater. 2019, 165, 722–733. [Google Scholar] [CrossRef]

- Schoop, J. In-situ calibrated modeling of residual stresses induced in machining under various cooling and lubricating environments. Lubricants 2021, 9, 28. [Google Scholar] [CrossRef]

- Cai, L.; Feng, Y.; Liang, S.Y. Analytical modeling of residual stress in end-milling with minimum quantity lubrication. Mech. Ind. 2022, 23, 5. [Google Scholar] [CrossRef]

- Schoop, J.; Adeniji, D.; Brown, I. Computationally efficient, multi-domain hybrid modeling of surface integrity in machining and related thermomechanical finishing processes. Procedia CIRP 2019, 82, 356–361. [Google Scholar] [CrossRef]

- Liu, X.; Devor, R.E.; Kapoor, S.G. An analytical model for the prediction of minimum chip thickness in micromachining. J. Manuf. Sci. Eng. 2006, 128, 474–481. [Google Scholar] [CrossRef]

- Arrazola, P.; Özel, T.; Umbrello, D.; Davies, M.; Jawahir, I. Recent advances in modelling of metal machining processes. CIRP Ann. 2013, 62, 695–718. [Google Scholar] [CrossRef]

- Li, B.; Deng, H.; Hui, D.; Hu, Z.; Zhang, W. A semi-analytical model for predicting the machining deformation of thin-walled parts considering machining-induced and blank initial residual stress. Int. J. Adv. Manuf. Technol. 2020, 110, 139–161. [Google Scholar] [CrossRef]

- Pan, Z.; Feng, Y.; Ji, X.; Liang, S.Y. Turning induced residual stress prediction of AISI 4130 considering dynamic recrystallization. Mach. Sci. Technol. 2017, 22, 507–521. [Google Scholar] [CrossRef]

- Brown, A.A.; Kostka, T.D.; Antoun, B.R.; Beghini, L.L. Predicting Residual Stresses Due to Forging and Machining Processes. Available online: https://www.osti.gov/servlets/purl/1106210 (accessed on 16 October 2023).

- Makhesana, M.A.; Baravaliya, J.A.; Parmar, R.J.; Patel, V.R.; Vyas, D.B. Machinability improvement and sustainability assessment during machining of AISI 4140 using vegetable oil-based MQL. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 535. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. A Critical assessment of lubrication techniques in machining processes: A case for minimum quantity lubrication using vegetable oil-based lubricant. J. Clean. Prod. 2013, 41, 210–221. [Google Scholar] [CrossRef]

- Wang, W.; Saifullah, M.K.; Aßmuth, R.; Biermann, D.; Arif, A.F.M.; Veldhuis, S.C. Effect of edge preparation technologies on cutting edge properties and tool performance. Int. J. Adv. Manuf. Technol. 2020, 106, 1823–1838. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Park, D. The occupational exposure limit for fluid aerosol generated in metalworking operations: Limitations and recommendations. Saf. Health Work. 2012, 3, 1–10. [Google Scholar] [CrossRef]

- Padmini, R.; Vamsi Krishna, P.; Krishna Mohana Rao, G. Effectiveness of vegetable oil based nanofluids as potential cutting fluids in turning AISI 1040 steel. Tribol. Int. 2016, 94, 490–501. [Google Scholar] [CrossRef]

- Balitskii, O.; Borowiak-Palen, E.; Konicki, W. Synthesis and characterization of colloidal gallium selenide nanowires. Cryst. Res. Technol. 2011, 46, 417–420. [Google Scholar] [CrossRef]

- Williams, J.A. Wear and wear particles—Some fundamentals. Tribol. Int. 2005, 38, 863–870. [Google Scholar] [CrossRef]

- Howe, A.A. Wear resistant steels. Mater. Sci. Technol. 2016, 32, 255–256. [Google Scholar] [CrossRef]

- Safyari, M.; Mori, G.; Ucsnik, S.; Moshtaghi, M. Mechanisms of hydrogen absorption, trapping and release during galvanostatic anodization of high-strength aluminum alloys. J. Mater. Res. Technol. 2023, 22, 80–88. [Google Scholar] [CrossRef]

- Moshtaghi, M.; Safyari, M.; Mori, G. Combined thermal desorption spectroscopy, hydrogen visualization, HRTEM and EBSD investigation of a Ni–Fe–Cr Alloy: The role of hydrogen trapping behavior in hydrogen-assisted fracture. Mater. Sci. Eng. A 2022, 848, 143428. [Google Scholar] [CrossRef]

- Takakuwa, O.; Ogawa, Y.; Okazaki, S.; Nakamura, M.; Matsunaga, H. A mechanism behind hydrogen-assisted fatigue crack growth in ferrite-pearlite steel focusing on its behavior in gaseous environment at elevated temperature. Corros. Sci. 2020, 168, 108558. [Google Scholar] [CrossRef]

- Ogawa, Y.; Iwata, K. Resistance of pearlite against hydrogen-assisted fatigue crack growth. Int. J. Hydrogen Energy 2022, 47, 31703–31708. [Google Scholar] [CrossRef]

- Thebault, F.; Designolle, V. Hydrogen Stress Cracking Resistance of Seamless Pipes for Hydrogen Storage and Transport Applications; ADIPEC: Abu Dhabi, United Arab Emirates, 2022. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Kolesnikov, V.O.; Eliasz, Y.; Havrylyuk, M.R. Specific features of the fracture of hydrogenated high-nitrogen manganese steels under conditions of rolling friction. Mater. Sci. 2015, 50, 604–611. [Google Scholar] [CrossRef]

- Balitskii, O.A.; Kolesnikov, V.O.; Balitskii, A.I. Wear resistance of hydrogenated high nitrogen steel at dry and solid state lubricants assist ant friction. Arch. Mater. Sci. Eng. 2019, 98, 57–67. [Google Scholar] [CrossRef]

- Balitskii, A.; Kindrachuk, M.; Volchenko, D.; Abramek, K.F.; Balitskii, O.; Skrypnyk, V.; Zhuravlev, D.; Bekish, I.; Ostashuk, M.; Kolesnikov, V. Hydrogen containing nano fluids in the spark engine’s cylinder head cooling system. Energies 2022, 15, 59. [Google Scholar] [CrossRef]

- Balitskii, A.A.; Kolesnikov, V.A.; Vus, O.B. Tribotechnical properties of nitrogen manganese steels under rolling friction at addition of (GaSe)xIn1-x powders into contact zone. Metallofiz. Noveishie Tekhnologii 2010, 32, 685–695. [Google Scholar] [CrossRef]

- Korniy, S.A.; Zin, I.M.; Tymus, M.B. Steel corrosion inhibition by microbial polysaccharide and tartrate mixture. J. Bio Tribo-Corros. 2022, 8, 6. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Kolesnikov, V.O.; Kawiak, P. Tribo engineering properties of austenitic manganese steels and castirons under the conditions of sliding friction. Mater. Sci. 2005, 41, 624–630. [Google Scholar] [CrossRef]

- Protsenko, V.S.; Butyrina, T.E.; Bobrova, L.S.; Korniy, S.A.; Danilov, F.I. Enhancing corrosion resistance of nickel surface by electropolishing in a deep eutectic solvent. Mater. Lett. 2020, 270, 127719. [Google Scholar] [CrossRef]

- Slobodyan, Z.V.; Zin, I.M.; Korniy, S.A. New environment friendly corrosion inhibitor based on plant extracts and technology of chemical cleaning of thermal power equipment with its use. Sci. Innov. 2021, 17, 15–24. [Google Scholar] [CrossRef]

- Balyts’kyi, A.I.; Kvasnyts’ka, Y.H.; Ivas’kevich, L.M.; Myal’nitsa, H.P. Corrosion and hydrogen-resistance of heat-resistant blade nickel-cobalt alloys. Mater. Sci. 2018, 54, 230–239. [Google Scholar] [CrossRef]

- Zin’, I.M.; Karpenko, O.V.; Pokyn’broda, T.Y.; Korets’ka, N.; Tymus’, M.B.; Kwiatkowski, L.; Kornii, S. Inhibition of the corrosion of carbon steels by trehalose lipid surfactants. Mater. Sci. 2019, 54, 477–484. [Google Scholar] [CrossRef]

- Pokhmurs’kyi, V.I.; Kornii, S.A.; Kosarevych, B.P. Investigation of the adsorption and diffusion of hydrogen in iron clusters by the method of density functional. Mater. Sci. 2014, 49, 485–492. [Google Scholar] [CrossRef]

- Billi, F.; Benya, P.; Ebramzadeh, E.; Campbell, P.; Chan, F.; Mc Kellop, H.A. Metal wear particles: What we know, what we do not know, and why. SAS J. 2009, 3, 133–142. [Google Scholar] [CrossRef]

- Laghari, M.S.; Hassan, A. Wear Particle Texture Analysis. Proceedings 2019, 43, 67–72. [Google Scholar]

- Balitskii, O.; Kolesnikov, V. Identification of wear products in the automotive tribotechnical system using computer vision methods, artificial intelligence and Big Data. In Proceedings of the 2019 XIth International Scientific and Practical Conference on Electronics and Information Technologies (ELIT), Lviv, Ukraine, 16–18 September 2019; pp. 24–27. [Google Scholar] [CrossRef]

- Suraj, R.; Jithish, K.S. Wear analysis on EN8, EN9, and EN24. World J. Eng. 2017, 14, 188–192. [Google Scholar] [CrossRef]

- Hsu, S.M.; Shen, M.C.; Ruff, A.W. Wear prediction for metals. Tribol. Int. 1997, 30, 377–383. [Google Scholar] [CrossRef]

- Li, H.; Li, L.; Wang, H. Defect detection for wear debris based on few-shot contrastive learning. Appl. Sci. 2022, 12, 11893. [Google Scholar] [CrossRef]

- Wang, H.; Huang, R.; Gao, L.; Wang, W.; Xu, A.; Yuan, F. Wear debris classification of steel production equipment using feature fusion and case-based reasoning. ISIJ Int. 2018, 58, 1293–1299. [Google Scholar] [CrossRef]

- Pfirrmann, D.; Baumann, J.; Krebs, E.; Biermann, D.; Wiederkehr, P. Material defects detection based on in-process measurements in milling of Ti6246 alloy. Procedia CIRP 2021, 99, 165–170. [Google Scholar] [CrossRef]

- Govekar, E.; Gradišek, J.; Grabec, I. Analysis of acoustic emission signals and monitoring of machining processes. Ultrasonics 2000, 38, 598–603. [Google Scholar] [CrossRef]

- Axinte, D.A.; Natarajan, D.R.; Gindy, N.N.Z. An approach to use an array of three acoustic emission sensors to locate uneven events in machining.Part 1: Method and validation. Int. J. Mach. Tools Manuf. 2005, 45, 1605–1613. [Google Scholar] [CrossRef]

- Tönshoff, H.K.; Jung, M.; Männel, S.; Rietz, W. Using acoustic emission signals for monitoring of production processes. Ultrasonics 2000, 37, 681–686. [Google Scholar] [CrossRef]

- Marinescu, I.; Dragos, A.; Axinte, A. Critical analysis of effectiveness of acoustic emission signals to detect tool and workpiece malfunctions in milling operations. Int. J. Mach. Tools Manuf. 2008, 48, 1148–1160. [Google Scholar] [CrossRef]

- Courbon, C.; Arrieta, I.M.; Cabanettes, F.; Rech, J.; Arrazola, P.-J. The contribution of microstructure and friction in broaching ferrite–pearlite steels. CIRP Ann. 2020, 69, 57–60. [Google Scholar] [CrossRef]

- Chaudhari, A.; Soh, Z.Y.; Wang, H.; Kumar, A.S. Rehbinder effect in ultraprecision machining of ductile materials. Int. J. Mach. Tools Manuf. 2018, 133, 47–60. [Google Scholar] [CrossRef]

- He, Y.; Zhang, J.; Qi, Y.; Liu, H.; Memon, A.R.; Zhao, W. Numerical study of microstructural effects on chip formation in high-speed cutting of ductile iron with discrete element method. J. Mater. Process. Technol. 2017, 249, 291–301. [Google Scholar] [CrossRef]

- Fabre, D.; Bonnet, C.; Rech, J.; Mabrouki, T. Optimization of surface roughness in broaching. CIRP J. Manuf. Sci. Technol. 2017, 18, 115–127. [Google Scholar] [CrossRef]

- Lin, J.; Yang, J.; Huang, Y.; Wang, F.; Hu, X.; Zhang, Y. Defect identification of metal additive manufacturing parts based on laser-induced breakdown spectroscopy and machine learning. Appl. Phys. B 2021, 127, 173. [Google Scholar] [CrossRef]

- Mabrouki, T.; Courbon, C.; Fabre, D.; Arrieta, I.; Arrazola, P.-J.; Rech, J. Influence of microstructure on chip formation when broaching ferritic-pearlitic steels. Procedia CIRP 2017, 58, 43–48. [Google Scholar] [CrossRef]

- Choi, Y. Influence of feed rate on surface integrity and fatigue performance of machined surfaces. Int. J. Fatigue 2015, 78, 46–52. [Google Scholar] [CrossRef]

- Ma, J.; Duong, N.H.; Lei, S. Numerical investigation of the performance of microbump textured cutting tool in dry machining of AISI 1045 steel. J. Manuf. Process. 2015, 19, 194–204. [Google Scholar] [CrossRef]

- Rahman, M.A.; Rahman, M.; Kumar, A.S. Modelling of flow stress by correlating the material grain size and chip thickness in ultra-precision machining. Int. J. Mach. Tools Manuf. 2017, 123, 57–75. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Singla, A.K.; Khan, A.M.; Khanna, N.; Pimenov, D.Y. Environment and economic burden of sustainable cooling/lubrication methods in machining of Inconel-800. J. Clean. Prod. 2021, 287, 125074. [Google Scholar] [CrossRef]

- Bag, R.; Panda, A.; Sahoo, A.K.; Kumar, R. A perspective review on surface integrity and its machining behavior of AISI 4340 hardened alloy steel. Mater. Today Proc. 2019, 18, 3532–3538. [Google Scholar] [CrossRef]

- Aggogeri, F.; Pellegrini, N.; Tagliani, F.L. Recent advances on machine learning applications in machining processes. Appl. Sci. 2021, 11, 8764. [Google Scholar] [CrossRef]

- Yang, J.; Li, S.; Wang, Z.; Dong, H.; Wang, J.; Tang, S. Using deep learning to detect defects in manufacturing: A comprehensive survey and current challenges. Materials 2020, 13, 5755. [Google Scholar] [CrossRef] [PubMed]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; De Felice, F. Artificial intelligence and machine learning applications in smart production: Progress, trends, and directions. Sustainability 2020, 12, 492. [Google Scholar] [CrossRef]

- Van de Schoot, R.; de Bruin, J.; Schram, R.; Zahedi, P.; de Boer, M.R.; Weijdema, F.; Ten Have, W.; Borsboom, D. An open source machine learning framework for efficient and transparent systematic reviews. Nat. Mach. Intell. 2021, 3, 125–133. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Y.; Zhou, X.; Mou, A. Automatic identification of tool wear based on convolutional neural network in face milling. Process Sens. 2019, 19, 3817. [Google Scholar] [CrossRef]

- He, Y.; Wu, P.; Li, Y.; Wang, Y.; Tao, F.; Wang, Y. A generic energy prediction model of machine tools using deep learning algorithms. Appl. Energy 2020, 275, 115402. [Google Scholar] [CrossRef]

- Kim, D.-H.; Kim, T.J.Y.; Wang, X.; Kim, M.; Quan, Y.-J.; Oh, J.W.; Min, S.-H.; Kim, H.; Bhandari, B.; Yang, I.; et al. Smart machining process using machine learning: A review and perspective on machining industry. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 555–568. [Google Scholar] [CrossRef]

- Pan, Y.; Kang, R.; Dong, Z.; Du, W.; Yin, S.; Bao, Y. On-line prediction of ultrasonic elliptical vibration cutting surface roughness of tungsten heavy alloy based on deep learning. J. Intell. Manuf. 2020, 33, 675–685. [Google Scholar] [CrossRef]

- Thankachan, T.; Prakash, K.S.; Malini, R.; Ramu, S.; Sundararaj, P.; Rajandran, S.; Ramasamy, D.; Jothi, S. Prediction of surface roughness and material removal rate in wire electrical discharge machining on aluminum based alloys/composites using Taguchi coupled grey relational analysis and artificial neural networks. Appl. Surf. Sci. 2019, 472, 22–35. [Google Scholar] [CrossRef]

- Rai, R.; Tiwari, M.K.; Ivanov, D.; Dolgui, A. Machine learning in manufacturing and industry 4.0 Applications. Int. J. Prod. Res. 2021, 59, 4773–4778. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R. Exploring impact and features of machine vision for progressive Industry 4.0 culture. Sensors 2022, 3, 100132. [Google Scholar] [CrossRef]

- Penumuru, D.P.; Muthuswamy, S.; Karumbu, P. Identification and classification of materials using machine vision and machine learning in the context of industry 4.0. J. Intell. Manuf. 2020, 31, 1229–1241. [Google Scholar] [CrossRef]

- Varshney, A.; Garg, N.; Nagla, K.S.; Nair, T.S.; Jaiswal, S.K.; Yadav, S.; Aswal, D.K. Challenges in sensors technology for industry 4.0 for futuristic metrological applications. MAPAN 2021, 36, 215–226. [Google Scholar] [CrossRef]

- Shpotyuk, O.I.; Balitska, V.O.; Vakiv, M.M.; Shpotyuk, L.I. Sensors of high-energy radiation based on amorphous chalcogenides. Sens. Actuators A Phys. 1998, 68, 356–358. [Google Scholar] [CrossRef]

- Strelkova, T.A.; Lytyuga, A.P.; Kalmykov, A.S. Statistical characteristics of optical signals and images in machine vision systems. In Examining Optoelectronics in Machine Vision and Applications in Industry 4.0; IGI Global: Hershey, PA, USA, 2021; pp. 134–162. [Google Scholar] [CrossRef]

- Moreno, A.; Velez, G.; Ardanza, A.; Barandiaran, I.; de Infante, Á.R.; Chopitea, R. Virtualisation process of a sheet metal punching machine within the Industry 4.0 Vision. Int. J. Interact. Des. Manuf. 2017, 11, 365–373. [Google Scholar] [CrossRef]

- Silva, R.L.; Rudek, M.; Szejka, A.L.; Junior, O.C. Machine vision systems for industrial quality control inspections. In Proceedings of the IFIP International Conference on Product Lifecycle Management; Springer: Cham, Switzerland, 2018; pp. 631–641. [Google Scholar] [CrossRef]

- Miranda-Vega, J.E.; Rivera-Castillo, J.; Rivas-López, M.; Flores-Fuentes, W.; Sergiyenko, O.; Rodríguez-Quiñonez, J.C.; Hernández-Balbuena, D. Reducing the optical noise of machine vision optical scanners for landslide monitoring. In Examining Optoelectronics in Machine Vision and Applications in Industry 4.0; IGI Global: Hershey, PA, USA, 2021; pp. 103–133. [Google Scholar] [CrossRef]

- Balitska, V.; Filipecki, J.; Shpotyuk, O.; Swiatek, J.; Vakiv, M. Dynamic radiation-induced effects in chalcogenide vitreous compounds. J. Non-Cryst. Solids 2001, 287, 216–221. [Google Scholar] [CrossRef]

- Balitska, V.; Shpotyuk, Y.; Filipecki, J.; Shpotyuk, O.; Iovu, M. Post-irradiation relaxation in vitreous arsenic/antimony trisulphides. J. Non-Cryst. Solids 2011, 357, 487–489. [Google Scholar] [CrossRef]

- Kindrachuk, M.; Volchenko, D.; Balitskii, A.; Abramek, K.F.; Volchenko, M.; Balitskii, O.; Skrypnyk, V.; Zhuravlev, D.; Yurchuk, A.; Kolesnikov, V. Wear resistance of spark ignition engine piston rings in hydrogen-containing environments. Energies 2021, 14, 4801. [Google Scholar] [CrossRef]

- Massaro, A.; Contuzzi, N.; Galiano, A. Intelligent processes in automated production involving Industry 4.0 technologies and artificial intelligence. In Advanced Robotics and Intelligent Automation in Manufacturing; IGI Global: Hershey, PA, USA, 2020; pp. 97–122. [Google Scholar] [CrossRef]

- Adeyeri, M.K.; Mpofu, K.; Olukorede, T.A. Integration of agent technology into manufacturing enterprise: A review and platform for Industry 4.0. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management (IEOM), Dubai, United Arab Emirates, 3–5 March 2015; pp. 1–10. [Google Scholar] [CrossRef]

- Cejnek, M.; Oswald, C. Machine vision object measurement in difficult industry environment. Proceedings 2019, 37, 26. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Banafaa, M.; Shayea, I.; Din, J.; Azmi, M.H.; Alashbi, A.; Daradkeh, Y.I.; Alhammadi, A. 6G mobile communication technology: Requirements, targets, applications, challenges, advantages, and opportunities. Alex. Eng. J. 2023, 64, 245–274. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Tkachov, V.I.; Ivas’kevych, L.M.; Vutvyts’kyi, V.I. Methodological aspects of determination of hydrogen resistance of steels. Mater. Sci. 2002, 38, 484–493. [Google Scholar] [CrossRef]

- Ostash, O.P.; Vol’demarov, O.V.; Hladysh, P.V. Cyclic crack Resistance of the Steels of Bends of Steam Pipelines After Long-Term Operation. Mater. Sci. 2013, 48, 427–437. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Ivas’kevich, L.M.; Mochulskyi, V.M. Mechanical properties of martensitic steels in gaseous hydrogen. Strength Mater. 2012, 44, 64–71. [Google Scholar] [CrossRef]

- Ostash, O.P.; Vol’demarov, O.V.; Hladysh, P.V.; Ivasyshyn, A.D. Evaluation of the degradation of steels of steam pipelines according to their structural, mechanical, and electrochemical characteristics. Mater. Sci. 2011, 46, 431–439. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Panasyuk, V.V. Workability assessment of structural steels of power plant units in hydrogen environments. Strength Mater. 2009, 41, 52–57. [Google Scholar] [CrossRef]

- Krechkovs’ka, H.V.; Student, O.Z.; Nykyforchyn, H.M. Diagnostics of the engineering state of steam pipeline of thermal power plants by the hardness and crack resistance of steel. Mater. Sci. 2019, 54, 627–637. [Google Scholar] [CrossRef]

- Pokhmurs’kyi, V.I.; Kopylets’, V.I.; Kornii, S.A. Modeling of the corrosion-electrochemical processes on the metal–electrolyte interface. Mater. Sci. 2013, 49, 59–62. [Google Scholar] [CrossRef]

- Krechkovska, H.; Student, O.; Hredil, M.; Tsybailo, I.; Holovchuk, M.; Shtoyko, I. Visualization of fractographic signs of operational degradation of heat-resistant steel for estimating its actual structure-mechanical state. Procedia Struct. Integr. 2022, 42, 1398–1405. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Kostyuk, I.F. Strength of welded joints of Cr-Mn steels with elevated content of nitrogen in hydrogen-containing media. Mater. Sci. 2009, 45, 97–107. [Google Scholar] [CrossRef]

- Djukic, M.B.; Bakic, G.M.; Zeravcic, V.S.; Rajicic, B.; Sedmak, A.; Mitrovic, R.; Miskovic, Z. Towards a Unified and Practical Industrial Model for Prediction of Hydrogen Embrittlement and Damagein Steels. Procedia Struct. Integr. 2016, 2, 604–611. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Vytvytskyi, V.I.; Ivaskevich, L.M. The low-cycle fatigue of corrosion-resistant steels in high pressure hydrogen. Procedia Eng. 2010, 2, 2367–2371. [Google Scholar] [CrossRef][Green Version]

- Zvirko, O.; Dzioba, I.; Hredil, M.; Pała, R.; Oliynyk, O.; Furmańczyk, P. Specimen Size Effectonthe Tensile Properties of Rolled Steel of Long-Term-Operated Portal Crane. Materials 2023, 16, 3017. [Google Scholar] [CrossRef]

- Balitskii, O.I.; Ivaskevich, L.M.; Mochulskyi, V.M. Temperature dependences of age-hardening austenitic steels mechanical properties in gaseous hydrogen. In Proceedings of the 12th International Conference on Fracture, ICF-12, Ottawa, ON, Canada, 12–17 July 2009; Elboujdaini, M., Ed.; NRC: Ottawa, ON, Canada, 2009. Paper No. T19.001; Code 93954. Volume 8, pp. 5786–5792. Available online: https://www.researchgate.net/publication/281269596_Temperature_Dependences_of_Age-hardening_Austenitic_Steels_Mechanical_Properties_in_Gaseous_Hydrogen (accessed on 16 October 2023).

| No. | Experiments | Rz | CH (ppm) |

|---|---|---|---|

| 1 | Air | 37.08 | 0.88 |

| 2 | Water | 5.01 | 3.14 |

| 3 | LCLs | 4.43 | 7.22 |

| 4 | LCLo | 6.36 | 7.81 |

| No. | Sample | Vertex | Cavity | Nmax | Entropy |

|---|---|---|---|---|---|

| 1 | Not hydrogenated | 16 | 8 | 53,428 | 4.22754 |

| 2 | Degraded | 34 | 19 | 74,539 | 7.833468 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balitskii, A.I.; Syrotyuk, A.M.; Havrilyuk, M.R.; Balitska, V.O.; Kolesnikov, V.O.; Ivaskevych, L.M. Hydrogen Cooling of Turbo Aggregates and the Problem of Rotor Shafts Materials Degradation Evaluation. Energies 2023, 16, 7851. https://doi.org/10.3390/en16237851

Balitskii AI, Syrotyuk AM, Havrilyuk MR, Balitska VO, Kolesnikov VO, Ivaskevych LM. Hydrogen Cooling of Turbo Aggregates and the Problem of Rotor Shafts Materials Degradation Evaluation. Energies. 2023; 16(23):7851. https://doi.org/10.3390/en16237851

Chicago/Turabian StyleBalitskii, Alexander I., Andriy M. Syrotyuk, Maria R. Havrilyuk, Valentina O. Balitska, Valerii O. Kolesnikov, and Ljubomyr M. Ivaskevych. 2023. "Hydrogen Cooling of Turbo Aggregates and the Problem of Rotor Shafts Materials Degradation Evaluation" Energies 16, no. 23: 7851. https://doi.org/10.3390/en16237851

APA StyleBalitskii, A. I., Syrotyuk, A. M., Havrilyuk, M. R., Balitska, V. O., Kolesnikov, V. O., & Ivaskevych, L. M. (2023). Hydrogen Cooling of Turbo Aggregates and the Problem of Rotor Shafts Materials Degradation Evaluation. Energies, 16(23), 7851. https://doi.org/10.3390/en16237851