Ignition Delay and Burning Rate Analysis of Diesel–Carbon Nanotube Blends Stabilized by a Surfactant: A Droplet-Scale Study

Abstract

:1. Introduction

2. Methodology

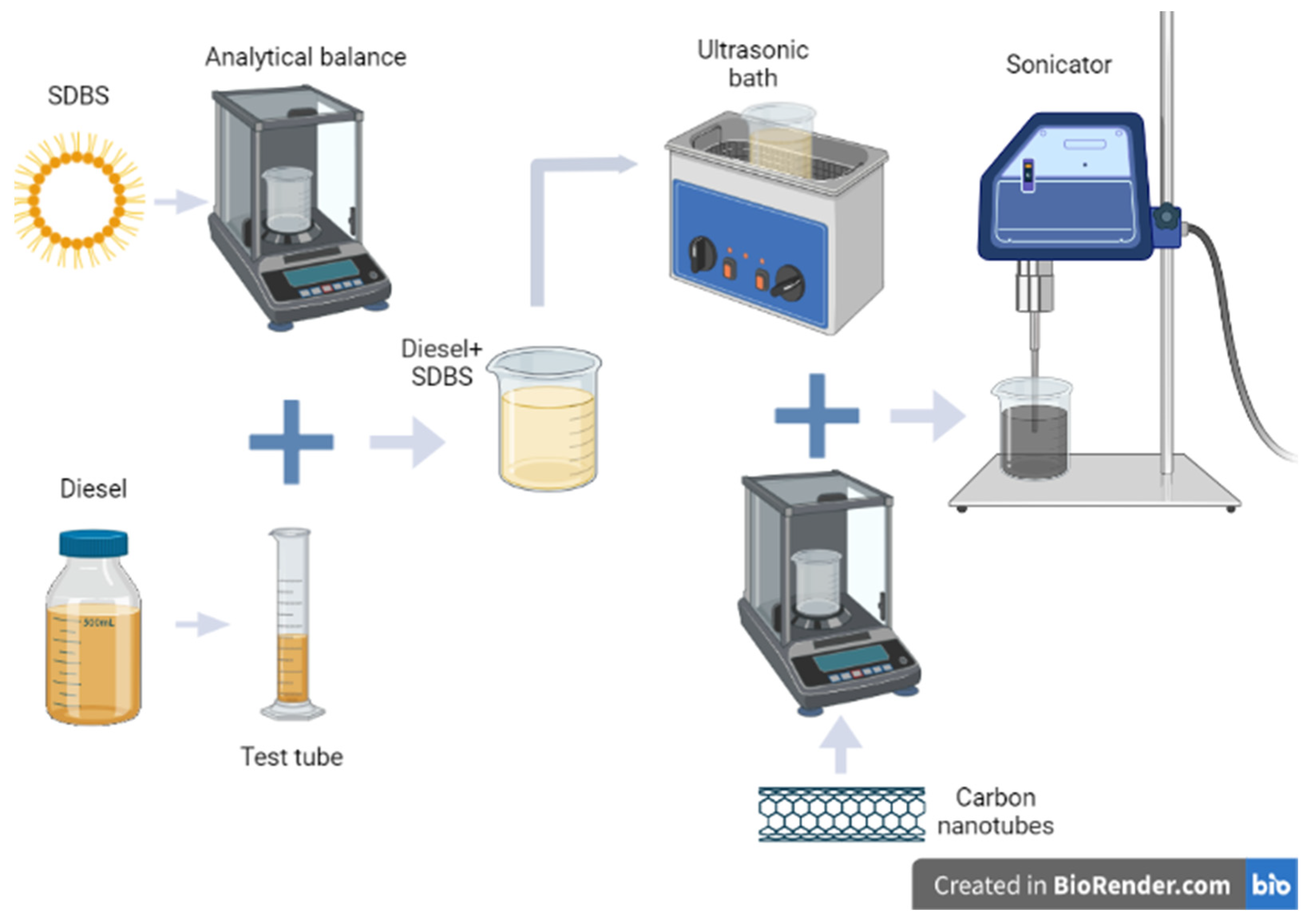

2.1. Nanofuels Preparation and Characterization

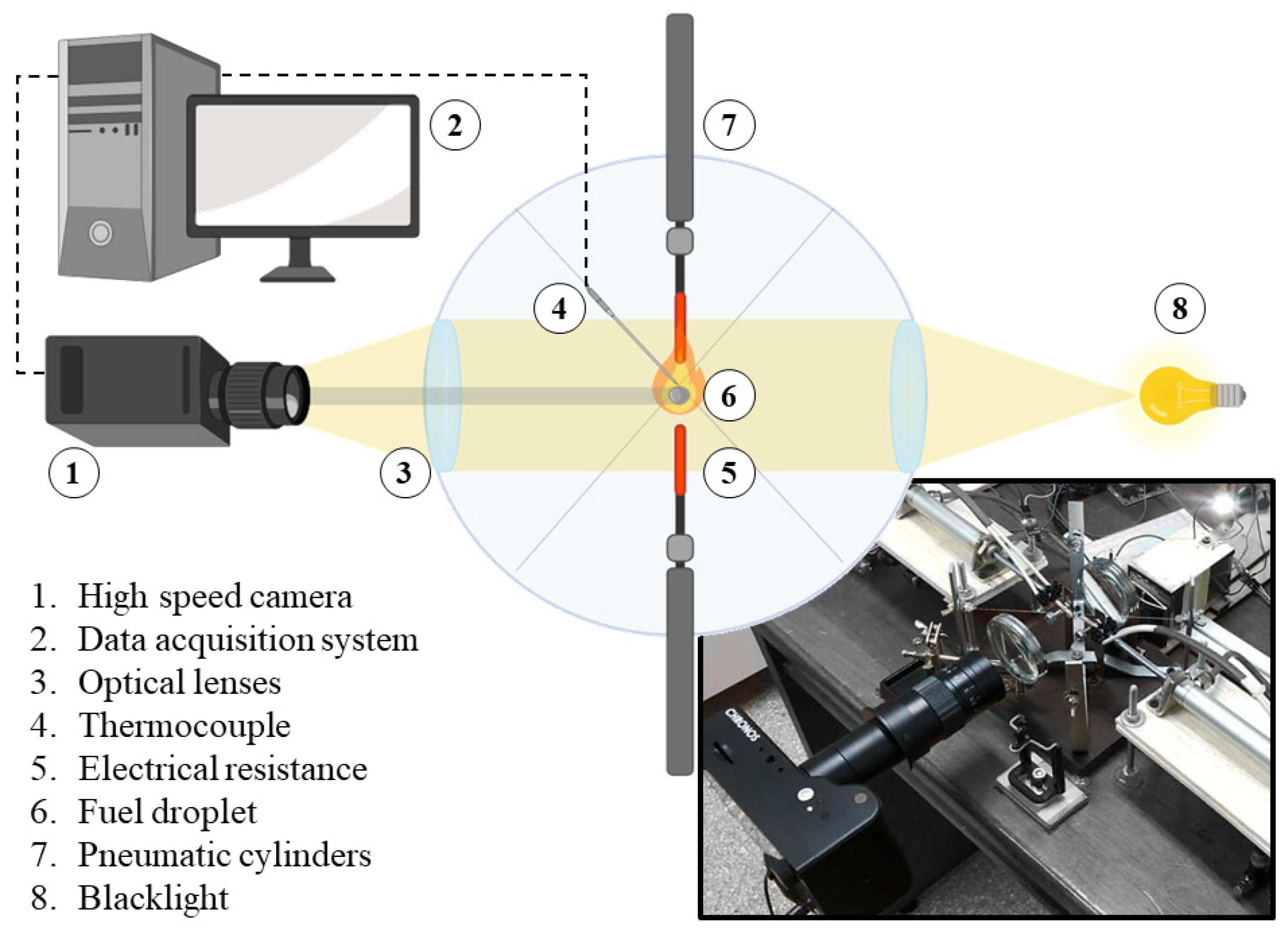

2.2. Experimental Procedure

2.3. Data Reduction

3. Results and Discussion

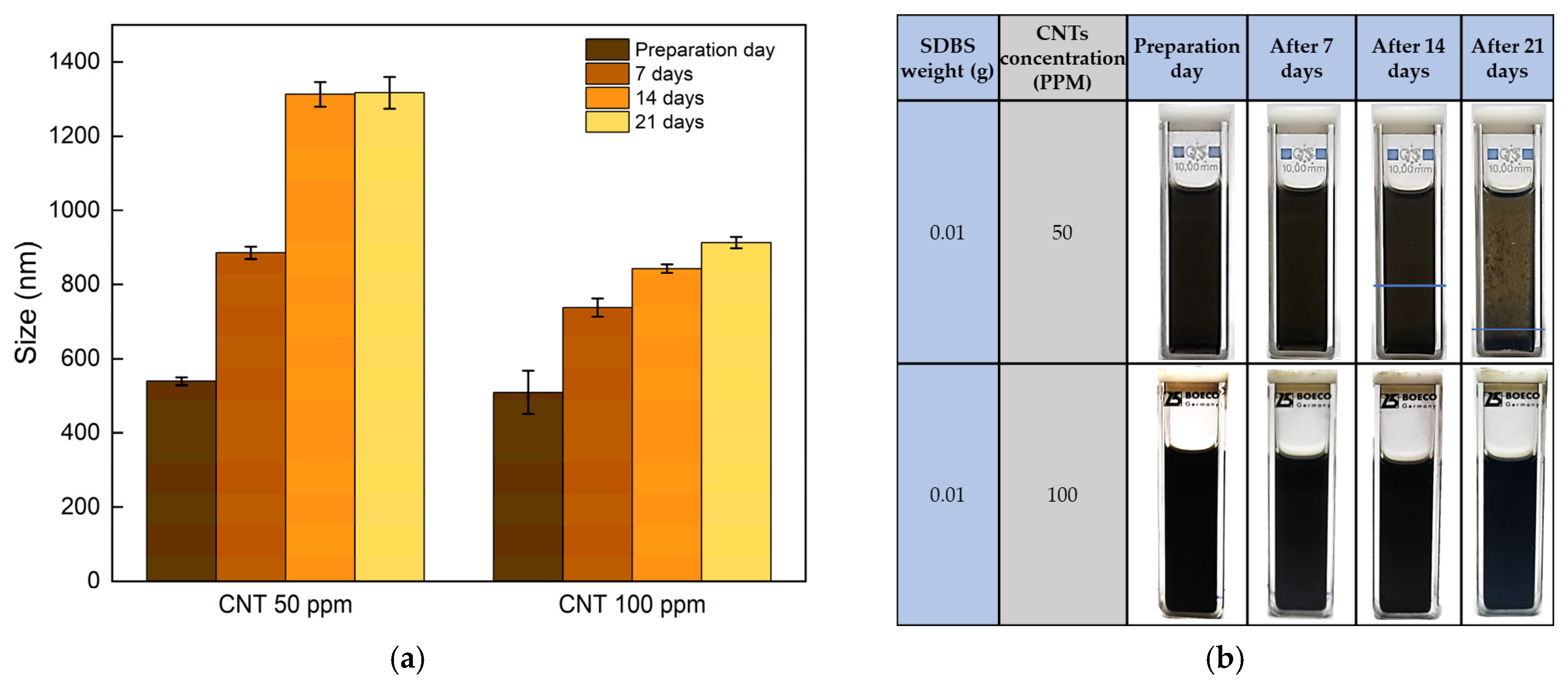

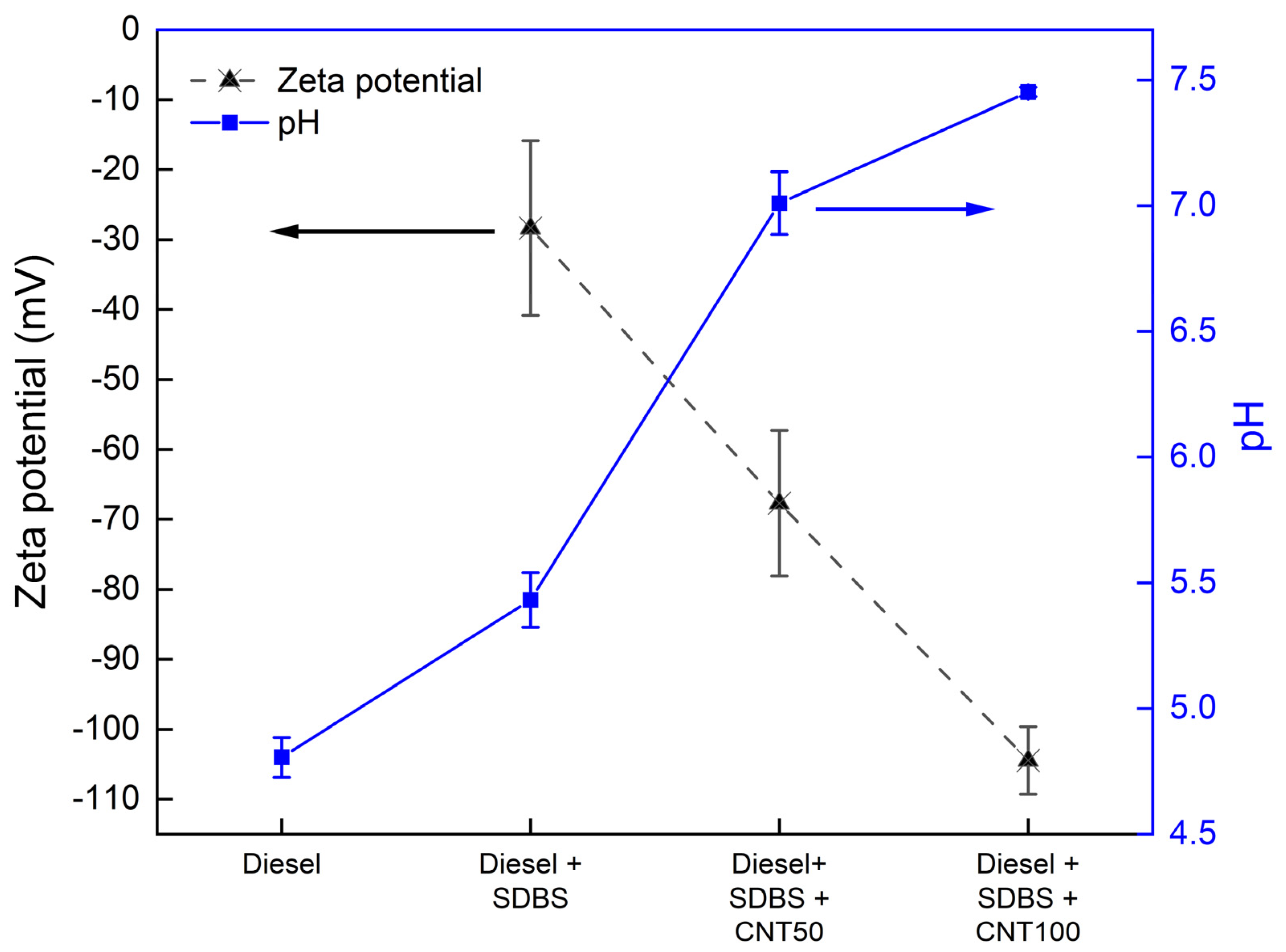

3.1. Stability Analysis

3.2. Thermal Conductivity and Surface Tension of Nanofuels

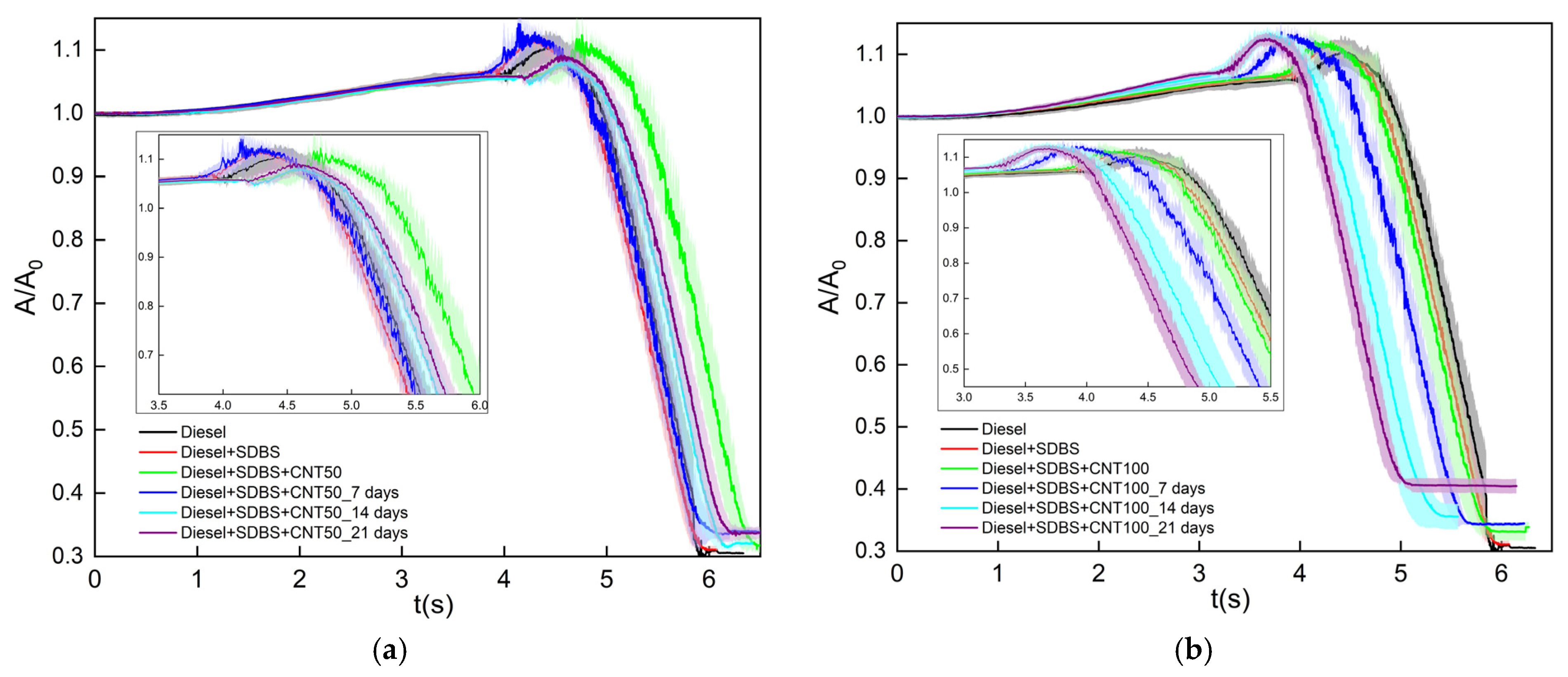

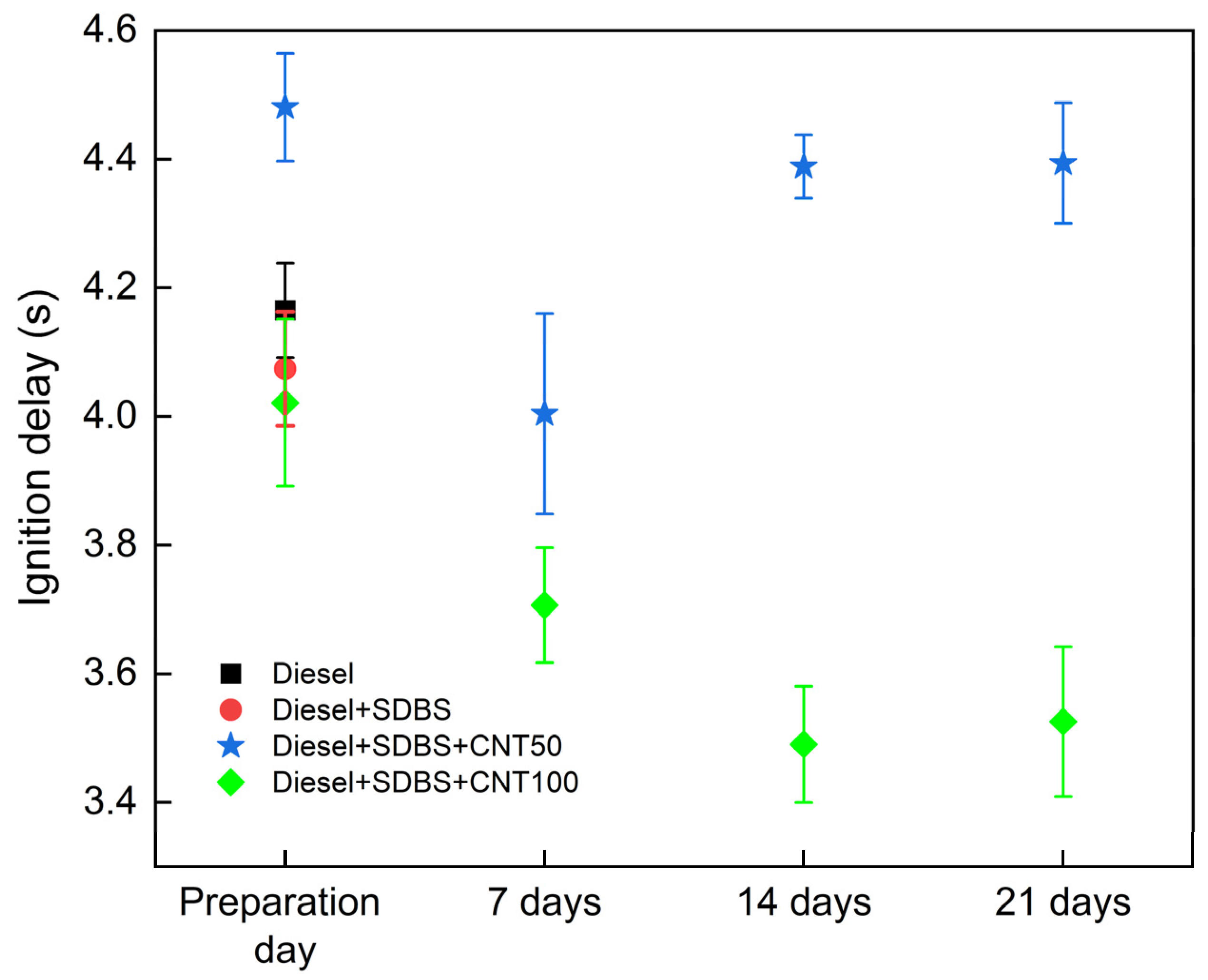

3.3. Evolution of the Normalized Area and Ignition Delay

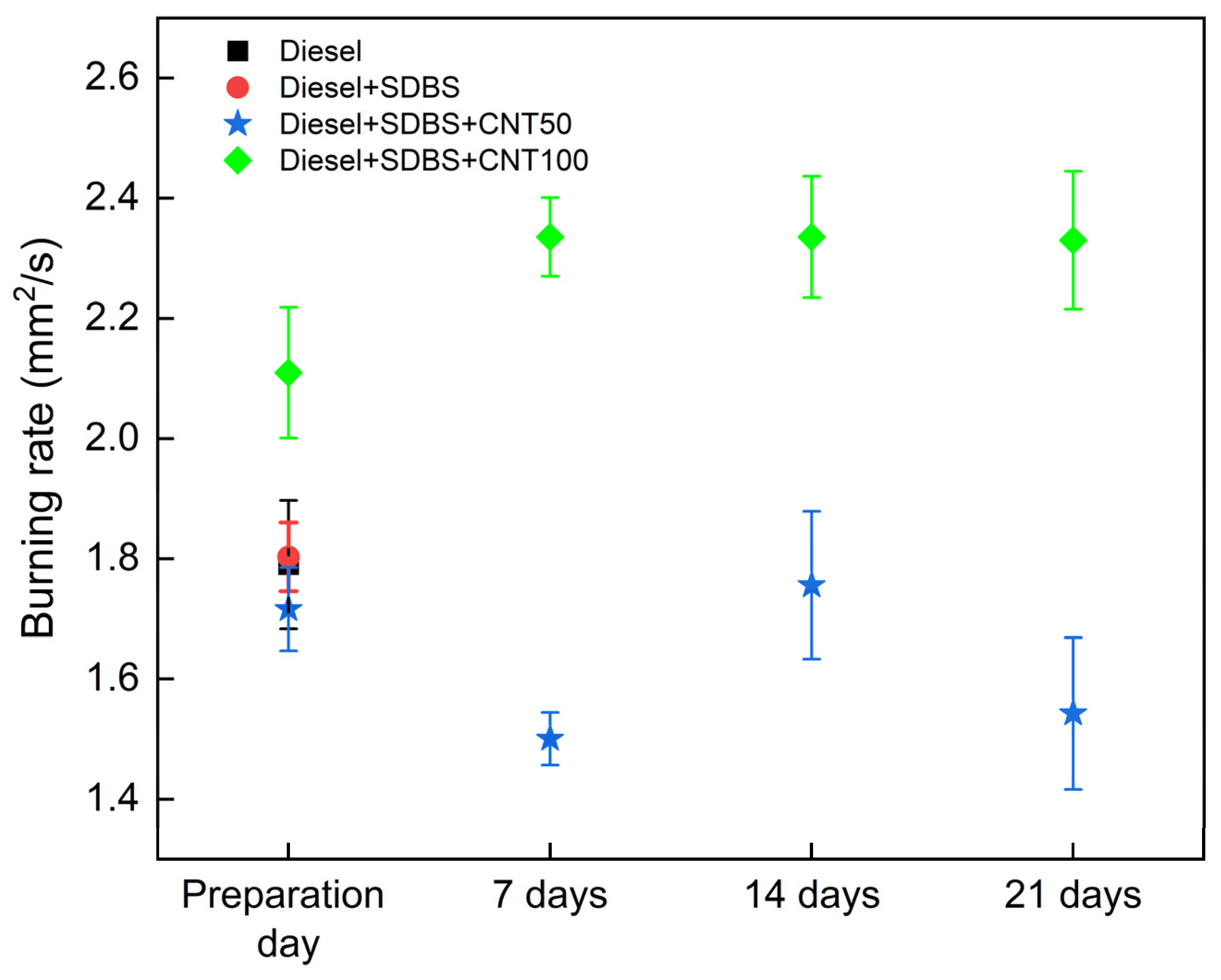

3.4. Burning Rate Analysis

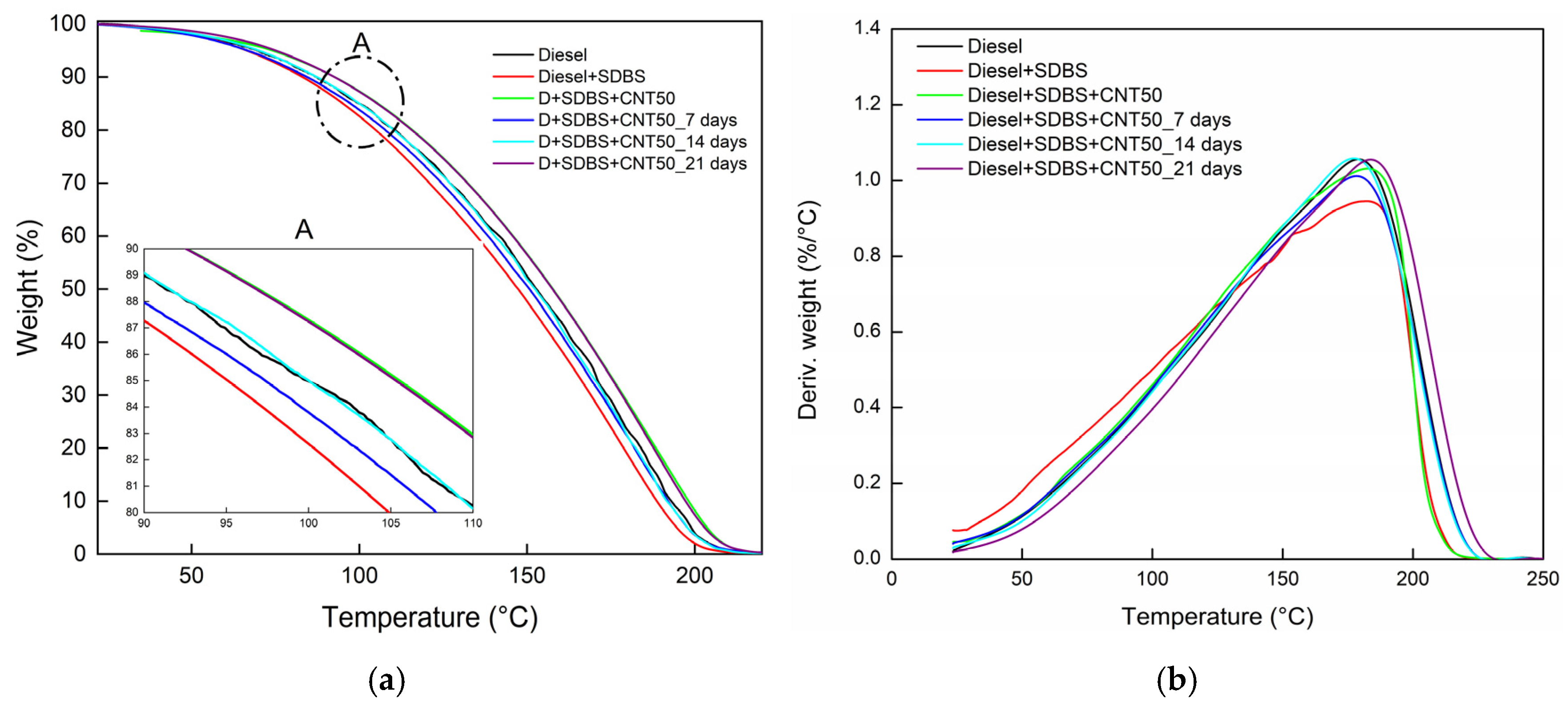

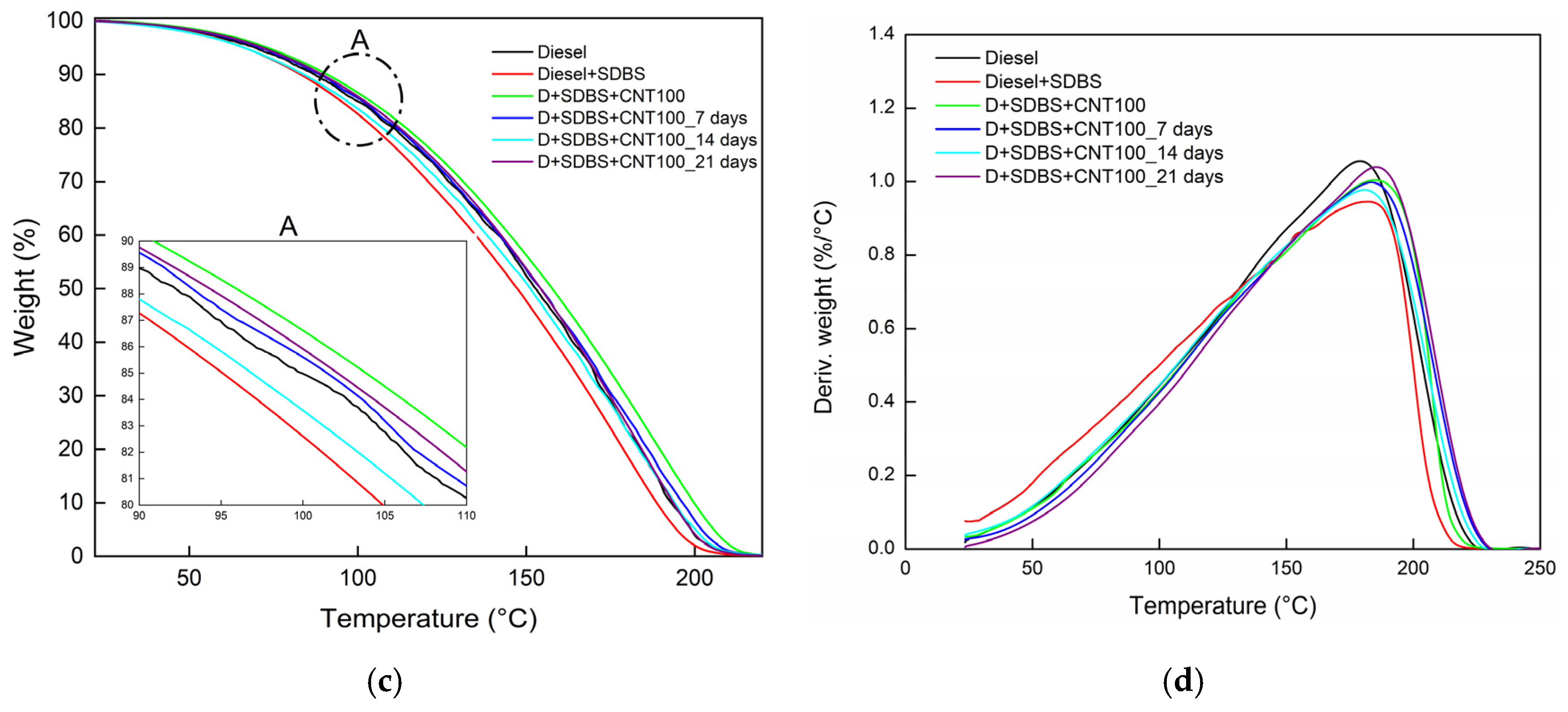

3.5. Thermogravimetric Analysis

4. Conclusions

- Through the use of DLS, visual inspection, pH, and Zeta potential measurement, the nanofuels at a concentration of CNTs at 100 ppm were demonstrated to be more stable than those at 50 ppm. These findings might be explained by the presence of SDBS, which at a CNTs concentration of 50 ppm probably creates macromolecules which promote a decrease in stability. On the other hand, there is possibly the existence of interactions between CNTs and SDBS at a concentration of 100 ppm because SDBS attaches to the surface of CNTs and forms an absorption layer that surrounds the nanomaterials and inhibits the formation of macromolecules, which significantly enhances temporal stability at this concentration.

- The SDBS at a concentration of 0.02 w/v% in commercial diesel had a minimal impact on the thermal conductivity at 20 °C, while by utilizing CNTs at a concentration of 50 ppm and 100 ppm, the thermal conductivity increased by 2% and 4%, respectively. However, at 60 °C, a concentration of 50 ppm showed negative effects on thermal conductivity, whereas with a concentration of 100 ppm, the thermal conductivity increased by around 20%. On the other hand, the results indicate that when diesel–SDBS–CNTs blends are used at temperatures between 20 °C and 60 °C, the surface tension has negligible changes in comparison to commercial diesel.

- The duration of the combustion process is influenced by the stability of nanofuels at a concentration of 50 ppm, with greater durations for the first day and minimal changes after seven days for diesel and diesel–SDBS. However, a concentration of 100 ppm provided better results, since the combustion of diesel and diesel–SDBS took less time after each interval of seven days. This is because, compared to a concentration of 50 ppm, nanoparticles aggregate more slowly and have higher porosity, giving them more time to improve combustion by acting as thermal bridges and having numerous heterogeneous nucleation sites within the droplet. Therefore, adding 50 ppm of CNTs to diesel causes the ignition delay time to increase by roughly 7.6%, and adding 100 ppm causes a decrease by roughly 16.2%.

- According to the data, the combustion rate is lowered by up to 16% at concentrations of 50 ppm. This is a result of the nanofuels’ decreased stability at this concentration, their limited increase in thermal conductivity, and their decreased porosity. On the contrary, at a concentration of 100 ppm of CNT, the burning rate of diesel and diesel–SDBS was improved by between 18% and 30.5%.

- A fundamental study, such as the one described in this work, may demonstrate the impact of carbon nanotubes in fuel dispersions and their subsequent usage in diesel engines, which can influence polluting gas emissions and performance. Therefore, future research may link the application of CNTs in diesel engines and combine the findings with a comprehensive stability study demonstrating the influence of fuel storage in tanks.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A/A0 | Normalized area of the drop |

| CNT | Carbon nanotubes |

| DLS | Dynamic light scattering |

| K | Burning rate constant |

| SDBS | Sodium dodecylbenzene sulfonate |

| TGA | Thermogravimetric analysis |

References

- Heywood, J.B. Internal Combustion Engine Fundamentals, 1st ed; McGraw Hill Education: New York, NY, USA, 1988. [Google Scholar]

- Kegl, T.; Kralj, A.K.; Kegl, B.; Kegl, M. Nanomaterials as fuel additives in diesel engines: A review of current state, opportunities, and challenges. Prog. Energy Combust. Sci. 2021, 83, 100897. [Google Scholar] [CrossRef]

- Shekofteh, M.; Gundoshmian, T.M.; Jahanbakhshi, A.; Heidari-Maleni, A. Performance and emission characteristics of a diesel engine fueled with functionalized multi-wall carbon nanotubes (MWCNTs-OH) and diesel–biodiesel–bioethanol blends. Energy Rep. 2020, 6, 1438–1447. [Google Scholar] [CrossRef]

- Basha, J.S. Impact of Carbon Nanotubes and Di-Ethyl Ether as additives with biodiesel emulsion fuels in a diesel engine—An experimental investigation. J. Energy Inst. 2018, 91, 289–303. [Google Scholar] [CrossRef]

- Müller, V.; Pieta, H.; Schaub, J.; Ehrly, M.; Körfer, T. On-Board Monitoring to meet upcoming EU-7 emission standards – Squaring the circle between effectiveness and robust realization. Transp. Eng. 2022, 10, 100138. [Google Scholar] [CrossRef]

- Guo, X.; Liang, C.; Umar, M.; Mirza, N. The impact of fossil fuel divestments and energy transitions on mutual funds performance. Technol. Forecast. Soc. Chang. 2022, 176, 121429. [Google Scholar] [CrossRef]

- Jena, S.P.; Mahapatra, S.; Acharya, S.K. Optimization of performance and emission characteristics of a diesel engine fueled with Karanja biodiesel using Grey-Taguchi method. Mater Today Proc. 2021, 41, 180–185. [Google Scholar] [CrossRef]

- Saxena, V.; Kumar, N.; Saxena, V.K. Multi-objective optimization of modified nanofluid fuel blends at different TiO2 nanoparticle concentration in diesel engine: Experimental assessment and modeling. Appl. Energy 2019, 248, 330–353. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Birouk, M. Effect of diesel injection timing on the combustion of natural gas/diesel dual-fuel engine at low-high load and low-high speed conditions. Fuel 2019, 235, 838–846. [Google Scholar] [CrossRef]

- Wu, Q.; Xie, X.; Wang, Y.; Roskilly, T. Effect of carbon coated aluminum nanoparticles as additive to biodiesel-diesel blends on performance and emission characteristics of diesel engine. Appl. Energy 2018, 221, 597–604. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Attia, A.M.; El-Batsh, H.M. The effect of Aluminum oxide nanoparticles addition with Jojoba methyl ester-diesel fuel blend on a diesel engine performance, combustion and emission characteristics. Fuel 2018, 224, 147–166. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Khalife, E.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Mohammadi, P.; Shojaei, T.R.; Soltanian, S. Effects of aqueous carbon nanoparticles as a novel nanoadditive in water-emulsified diesel/biodiesel blends on performance and emissions parameters of a diesel engine. Energy Convers. Manag. 2019, 196, 1153–1166. [Google Scholar] [CrossRef]

- Aalam, C.S.; Saravanan, C.; Kannan, M. Experimental investigations on a CRDI system assisted diesel engine fuelled with aluminium oxide nanoparticles blended biodiesel. Alex. Eng. J. 2015, 54, 351–358. [Google Scholar] [CrossRef]

- Ooi, J.B.; Ismail, H.M.; Swamy, V.; Wang, X.; Swain, A.K.; Rajanren, J.R. Graphite oxide nanoparticle as a diesel fuel additive for cleaner emissions and lower fuel consumption. Energy Fuels 2016, 30, 1341–1353. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P.; Rosen, M.A. Effect of injection pressure on the combustion, performance and emission characteristics of a biodiesel engine with cerium oxide nanoparticle additive. Energy 2019, 185, 1163–1173. [Google Scholar] [CrossRef]

- Manigandan, S.; Sarweswaran, R.; Devi, P.B.; Sohret, Y.; Kondratiev, A.; Venkatesh, S.; Vimal, M.R.; Joshua, J.J. Comparative study of nanoadditives TiO2, CNT, Al2O3, CuO and CeO2 on reduction of diesel engine emission operating on hydrogen fuel blends. Fuel 2020, 262, 116336. [Google Scholar] [CrossRef]

- Kegl, T.; Kralj, A.K.; Kegl, M.; Kegl, B. Nanomaterials for Environmental Application; Green Energy and Technology Series; Springer International Publishing: Cham, Switzerland, 2020; ISBN 9780857291356. [Google Scholar]

- Alenezi, R.A.; Norkhizan, A.; Mamat, R.; Erdiwansyah; Najafi, G.; Mazlan, M. Investigating the contribution of carbon nanotubes and diesel-biodiesel blends to emission and combustion characteristics of diesel engine. Fuel 2021, 285, 119046. [Google Scholar] [CrossRef]

- Bello, Y.H.; Ookawara, S.A.; Ahmed, M.A.; El-Khouly, M.A.; Elmehasseb, I.M.; El-Shafai, N.M.; Elwardany, A.E. Investigating the engine performance, emissions and soot characteristics of CI engine fueled with diesel fuel loaded with graphene oxide-titanium dioxide nanocomposites. Fuel 2020, 269, 117436. [Google Scholar] [CrossRef]

- Kolli, V.; Gadepalli, S.; Debbarma, J.; Mandal, P.; Barathula, S. Experimental analysis on performance, combustion & emissions of a diesel engine fueled by Aegle marmelos seed oil biodiesel with additives: Graphene Nanosheets and oxygenated diethyl ether. Energy Sources Recover. Util. Environ. Eff. 2020, 1–20. [Google Scholar] [CrossRef]

- Nagaraja, S.; Rufuss, D.D.W.; Hossain, A. Microscopic characteristics of biodiesel—Graphene oxide nanoparticle blends and their Utilisation in a compression ignition engine. Renew. Energy 2020, 160, 830–841. [Google Scholar] [CrossRef]

- Chacko, N.; Jeyaseelan, T. Comparative evaluation of graphene oxide and graphene nanoplatelets as fuel additives on the combustion and emission characteristics of a diesel engine fuelled with diesel and biodiesel blend. Fuel Process. Technol. 2020, 204, 106406. [Google Scholar] [CrossRef]

- Tanvir, S.; Qiao, L. Droplet burning rate enhancement of ethanol with the addition of graphite nanoparticles: Influence of radiation absorption. Combust. Flame 2016, 166, 34–44. [Google Scholar] [CrossRef]

- Mosadegh, S.; Ghaffarkhah, A.; van der Kuur, C.; Arjmand, M.; Kheirkhah, S. Graphene oxide doped ethanol droplet combustion: Ignition delay and contribution of atomization to burning rate. Combust. Flame 2021, 238, 111748. [Google Scholar] [CrossRef]

- Ooi, J.B.; Rajanren, J.R.; Ismail, H.M.; Swamy, V.; Wang, X. Improving combustion characteristics of diesel and biodiesel droplets by graphite oxide addition for diesel engine applications. Int. J. Energy Res. 2017, 41, 2258–2267. [Google Scholar] [CrossRef]

- Rasid, A.F.A.; Zhang, Y. Comparison of the burning of a single diesel droplet with volume and surface contamination of soot particles. Proc. Combust. Inst. 2021, 38, 3159–3166. [Google Scholar] [CrossRef]

- Singh, G.; Esmaeilpour, M.; Ratner, A. Effect of carbon-based nanoparticles on the ignition, combustion and flame characteristics of crude oil droplets. Energy 2020, 197, 117227. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Ma, Y.; Wang, G.; Han, J.; Dai, M.; Sun, Z. A comprehensive review on the properties of nanofluid fuel and its additive effects to compression ignition engines. Appl. Surf. Sci. 2019, 504, 144581. [Google Scholar] [CrossRef]

- Gundoshmian, T.M.; Heidari-Maleni, A.; Jahanbakhshi, A. Evaluation of performance and emission characteristics of a CI engine using functional multi-walled carbon nanotubes (MWCNTs-COOH) additives in biodiesel-diesel blends. Fuel 2021, 287, 119525. [Google Scholar] [CrossRef]

- Dai, M.; Wang, J.; Wei, N.; Wang, X.; Xu, C. Experimental study on evaporation characteristics of diesel/cerium oxide nanofluid fuel droplets. Fuel 2019, 254, 115633. [Google Scholar] [CrossRef]

- Mehta, R.N.; More, U.; Malek, N.; Chakraborty, M.; Parikh, P.A. Study of stability and thermodynamic properties of water-in-diesel nanoemulsion fuels with nano-Al additive. Appl. Nanosci. 2015, 5, 891–900. [Google Scholar] [CrossRef]

- Wang, X.; Wei, N.; Gao, J.; Yan, J.; Jiang, G. Evaporation Characteristics of Ethanol Diesel Droplets Containing Nanoparticles. J. Shanghai Jiaotong Univ. (Sci.) 2021, 26, 201–209. [Google Scholar] [CrossRef]

- Muthukumar, M.; Senthil Kumar, A.P.; Sasikumar, C.; Yuvaraj, S.; Singh, T.S. Effect of nanoparticles on the droplet combustion of rice bran oil biodiesel. Biomass-Convers. Biorefinery 2021, 11, 1375–1393. [Google Scholar] [CrossRef]

- Wang, X.; Dai, M.; Xie, Y.; Han, J.; Ma, Y.; Chen, C. Experimental investigation of evaporation characteristics of biodiesel-diesel blend droplets with carbon nanotubes and nanoceria as nanoadditives. Appl. Surf. Sci. 2020, 505, 144186. [Google Scholar] [CrossRef]

- Kannaiyan, K.; Sadr, R. The effects of alumina nanoparticles as fuel additives on the spray characteristics of gas-to-liquid jet fuels. Exp. Therm. Fluid Sci. 2017, 87, 93–103. [Google Scholar] [CrossRef]

- Küçükosman, R.; Yontar, A.A.; Ocakoglu, K. Nanoparticle additive fuels: Atomization, combustion and fuel characteristics. J. Anal. Appl. Pyrolysis 2022, 165, 105575. [Google Scholar] [CrossRef]

- Gad, M.; Jayaraj, S. A comparative study on the effect of nano-additives on the performance and emissions of a diesel engine run on Jatropha biodiesel. Fuel 2020, 267, 117168. [Google Scholar] [CrossRef]

- Yusof, S.N.A.; Sidik, N.A.C.; Asako, Y.; Japar, W.M.A.A.; Mohamed, S.B.; Muhammad, N.M. A comprehensive review of the influences of nanoparticles as a fuel additive in an internal combustion engine (ICE). Nanotechnol. Rev. 2020, 9, 1326–1349. [Google Scholar] [CrossRef]

- Liang, D.; Wu, Z.; Jiang, Y.; Ren, K.; Zhou, M.; Chu, S.; Shen, D. Effects of solids’ concentration and oleic acid dispersant on the stability and combustion characteristics of aluminum/bioethanol nanofluid fuel. Powder Technol. 2022, 398, 117108. [Google Scholar] [CrossRef]

- Pandey, K.; Chattopadhyay, K.; Basu, S. Combustion dynamics of low vapour pressure nanofuel droplets. Phys. Fluids 2017, 29, 074102. [Google Scholar] [CrossRef]

- Dong, F.; Koodali, R.T.; Wang, H.; Ho, W.-K. Nanomaterials for Environmental Applications. J. Nanomater. 2014, 2014, 1–4. [Google Scholar] [CrossRef]

- Sayyed, S.; Das, R.K.; Kulkarni, K. Experimental investigation for evaluating the performance and emission characteristics of DICI engine fueled with dual biodiesel-diesel blends of Jatropha, Karanja, Mahua, and Neem. Energy 2022, 238, 121787. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Waly, M.S.; El-Batsh, H.M.; El-Zoheiry, R.M. Enhancement of the waste cooking oil biodiesel usability in the diesel engine by using n-decanol, nitrogen-doped, and amino-functionalized multi-walled carbon nanotube. Energy Convers. Manag. 2023, 277, 116646. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, H.; Zhang, Q.; Qiao, X.; Wang, X.; Ju, D.; Sun, C. Flame spread and combustion characteristics of two adjacent jatropha oil droplets. Fuel 2021, 285, 119077. [Google Scholar] [CrossRef]

- Rentería, J.; Gallego, A.; Gamboa, D.; Cacua, K.; Herrera, B. Effect of amide-functionalized carbon nanotubes as commercial diesel and palm-oil biodiesel additives on the ignition delay: A study on droplet scale. Fuel 2023, 338, 127202. [Google Scholar] [CrossRef]

- Braeuer, A. Chapter 4—Shadowgraph and Schlieren Techniques. In Spectroscopic Techniques at High Pressure; Elsevier: Amsterdam, The Netherlands, 2015; Volume 7, pp. 284–313. [Google Scholar]

- Law, C. Recent advances in droplet vaporization and combustion. Prog. Energy Combust. Sci. 1982, 8, 171–201. [Google Scholar] [CrossRef]

- Balamurugan, S.; Sajith, V. Experimental investigation on the stability and abrasive action of cerium oxide nanoparticles dispersed diesel. Energy 2017, 131, 113–124. [Google Scholar] [CrossRef]

- Dautzenberg, H. Polymeric Stabilization of Colloidal Dispersions. In Acta Polymerica; Academic Press: Cambridge, MA, USA, 1985; Volume 36, p. 457. [Google Scholar] [CrossRef]

- Liu, J.; Li, W.-Y.; Chen, H.-X.; Li, S.-Q.; Yang, L.-H.; Peng, K.-M.; Cai, C.; Huang, X.-F. Applications of functional nanoparticle–stabilized surfactant foam in petroleum-contaminated soil remediation. J. Hazard. Mater. 2023, 443, 130267. [Google Scholar] [CrossRef] [PubMed]

- Ali, N.; Teixeira, J.A.; Addali, A. A Review on Nanofluids: Fabrication, Stability, and Thermophysical Properties. J. Nanomater. 2018, 2018, 1–33. [Google Scholar] [CrossRef]

- Hwang, G.; Gomez-Flores, A.; Bradford, S.A.; Choi, S.; Jo, E.; Kim, S.B.; Tong, M.; Kim, H. Analysis of stability behavior of carbon black nanoparticles in ecotoxicological media: Hydrophobic and steric effects. Colloids Surf. A Physicochem. Eng. Asp. 2018, 554, 306–316. [Google Scholar] [CrossRef]

- Lin, Q.; Xu, M.; Cui, Z.; Pei, X.; Jiang, J.; Song, B. Structure and stabilization mechanism of diesel oil-in-water emulsions stabilized solely by either positively or negatively charged nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2019, 573, 30–39. [Google Scholar] [CrossRef]

- Huber, M.L.; Laesecke, A.; Perkins, R. Transport Properties of n-Dodecane. Energy Fuels 2004, 18, 968–975. [Google Scholar] [CrossRef]

- Gallego, A.; Cacua, K.; Herrera, B.; Cabaleiro, D.; Piñeiro, M.M.; Lugo, L. Experimental evaluation of the effect in the stability and thermophysical properties of water-Al2O3 based nanofluids using SDBS as dispersant agent. Adv. Powder Technol. 2020, 31, 560–570. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Lin, X. Experimental investigations on the thermal performance and phase change hysteresis of low-temperature paraffin/MWCNTs/SDBS nanocomposite via dynamic DSC method. Renew. Energy 2022, 187, 572–585. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, A.; Badruddin, I.; Banapurmath, N.; Akram, N. The effect of nano-additives in diesel-biodiesel fuel blends: A comprehensive review on stability, engine performance and emission characteristics. Energy Convers. Manag. 2018, 178, 146–177. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Gavrilov, A.N.; McCloskey, J.M.; Tolmachev, Y.V.; Sprunt, S.; Lopatina, L.M.; Selinger, J.V. Thermal conductivity and particle agglomeration in alumina nanofluids: Experiment and theory. Phys. Rev. E 2007, 76, 061203. [Google Scholar] [CrossRef] [PubMed]

- Esteban, B.; Riba, J.-R.; Baquero, G.; Puig, R.; Rius, A. Characterization of the surface tension of vegetable oils to be used as fuel in diesel engines. Fuel 2012, 102, 231–238. [Google Scholar] [CrossRef]

- Wang, X.; Dai, M.; Wang, J.; Xie, Y.; Ren, G.; Jiang, G. Effect of ceria concentration on the evaporation characteristics of diesel fuel droplets. Fuel 2019, 236, 1577–1585. [Google Scholar] [CrossRef]

- Bhuiyan, M.; Saidur, R.; Mostafizur, R.; Mahbubul, I.; Amalina, M. Experimental investigation on surface tension of metal oxide–water nanofluids. Int. Commun. Heat Mass Transf. 2015, 65, 82–88. [Google Scholar] [CrossRef]

- Mei, D.; Fang, Y.; Zhang, Z.; Guo, D.; Chen, Z.; Sun, C. Analysis of surface tension for nano-fuels containing disparate types of suspended nanoparticles. Powder Technol. 2021, 388, 526–536. [Google Scholar] [CrossRef]

- Kubo, M.; Ishihara, Y.; Mantani, Y.; Shimada, M. Evaluation of the factors that influence the fabrication of porous thin films by deposition of aerosol nanoparticles. Chem. Eng. J. 2013, 232, 221–227. [Google Scholar] [CrossRef]

- Liu, J.; Swanson, J.J.; Kittelson, D.B.; Pui, D.Y.; Wang, J. Microstructural and loading characteristics of diesel aggregate cakes. Powder Technol. 2013, 241, 244–251. [Google Scholar] [CrossRef]

- Wang, L.; Dong, K.; Wang, C.; Zou, R.; Zhou, Z.; Yu, A. Computer simulation of the packing of nanoparticles. Powder Technol. 2022, 401, 117317. [Google Scholar] [CrossRef]

- Ooi, J.B.; Chow, M.R.; Chee, K.M.; Pun, C.H.; Tran, M.-V.; Leong, J.C.K.; Lim, S. Effects of ethanol on the evaporation and burning characteristics of palm-oil based biodiesel droplet. J. Energy Inst. 2021, 98, 35–43. [Google Scholar] [CrossRef]

- Jiang, G.; Yan, J.; Wang, G.; Dai, M.; Xu, C.; Wang, J. Effect of nanoparticles concentration on the evaporation characteristics of biodiesel. Appl. Surf. Sci. 2019, 492, 150–156. [Google Scholar] [CrossRef]

- Gumus, S.; Ozcan, H.; Ozbey, M.; Topaloglu, B. Aluminum oxide and copper oxide nanodiesel fuel properties and usage in a compression ignition engine. Fuel 2016, 163, 80–87. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Gupta, J.G.; Dhar, A. Potential and challenges for large-scale application of biodiesel in automotive sector. Prog. Energy Combust. Sci. 2017, 61, 113–149. [Google Scholar] [CrossRef]

- Dubey, R.; Dutta, D.; Sarkar, A.; Chattopadhyay, P. Functionalized carbon nanotubes: Synthesis, properties and applications in water purification, drug delivery, and material and biomedical sciences. Nanoscale Adv. 2021, 3, 5722–5744. [Google Scholar] [CrossRef]

- Basha, J.S.; Anand, R.B. The influence of nano additive blended biodiesel fuels on the working characteristics of a diesel engine. J. Braz. Soc. Mech. Sci. Eng. 2013, 35, 257–264. [Google Scholar] [CrossRef]

- Mei, D.; Li, X.; Wu, Q.; Sun, P. Role of Cerium Oxide Nanoparticles as Diesel Additives in Combustion Efficiency Improvements and Emission Reduction. J. Energy Eng. 2016, 142, 04015050. [Google Scholar] [CrossRef]

- Tanvir, S.; Qiao, L. Effect of Addition of Energetic Nanoparticles on Droplet-Burning Rate of Liquid Fuels. J. Propuls. Power 2015, 31, 408–415. [Google Scholar] [CrossRef]

- Gan, Y.; Lim, Y.S.; Qiao, L. Combustion of nanofluid fuels with the addition of boron and iron particles at dilute and dense concentrations. Combust. Flame 2012, 159, 1732–1740. [Google Scholar] [CrossRef]

- Gan, Y.; Qiao, L. Combustion characteristics of fuel droplets with addition of nano and micron-sized aluminum particles. Combust. Flame 2011, 158, 354–368. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.; Nada, S.A. Improvement of CI engine combustion and performance running on ternary blends of higher alcohol (Pentanol and Octanol)/hydrous ethanol/diesel. Fuel 2019, 251, 10–22. [Google Scholar] [CrossRef]

- Li, H.; Pokhrel, S.; Schowalter, M.; Rosenauer, A.; Kiefer, J.; Mädler, L. The gas-phase formation of tin dioxide nanoparticles in single droplet combustion and flame spray pyrolysis. Combust. Flame 2020, 215, 389–400. [Google Scholar] [CrossRef]

| Type | Specification |

|---|---|

| Purity | >95% |

| External diameter | 20–30 nm |

| Internal diameter | 5–10 nm |

| Length | 10–30 µm |

| Surface area | >110 m2/g |

| Density | 2.1 g/cm3 |

| Property | Unit | Diesel | Diesel + SDBS | Diesel + SDBS + CNT 100 ppm | Standard |

|---|---|---|---|---|---|

| Kinematic viscosity at 40 °C | mm2/s | 3.771 | 4.374 | 4.469 | ASTM D445 |

| Cetane index | - | 48.68 | 48.90 | 48.80 | ASTM D976 |

| Heating value | MJ/kg | 45.14 | 44.94 | 44.92 | ASTM D240 |

| API gravity of petroleum products at 15.6 °C | °API | 33.2 | 31.8 | 31.8 | ASTM D287 |

| Gum content in fuel by evaporation jet | mg/100 mL | 49.5 | 35.5 | 15.5 | ASTM D381 |

| Pour point | °C | −15 | −12 | −12 | ASTM D97 |

| Flashpoint | °C | 71 | 72 | 73 | ASTM D93 |

| Cloud point | °C | 2 | −1 | −6 | ASTM D2500 |

| Parameter | Instrument | Uncertainty |

|---|---|---|

| Thermogravimetric analysis | TA Instrument SDTQ 600 | ±1 × 10−7 g and ±1 °C |

| Scanning Electron Microscopy | JEOL JSM-7100F | ±1.2 nm |

| Dynamic Light Scattering (DLS) | Micromeritics Nanoplus HD | ±0.1 nm |

| Carbon nanotubes weight | Precisa EP225-DR | ±1 × 10−6 g |

| Fuel/Nanofuel | Day of the Tests | Coefficient of Variation of A/A0 | ||

|---|---|---|---|---|

| Maximum | Minimum | Mean | ||

| Diesel | - | 19.63% | 0.04% | 2.11% |

| Diesel + SDBS | - | 12.70% | 0.01% | 1.56% |

| Diesel + SDBS + CNT 50 ppm | Preparation day | 20.40% | 0.02% | 2.49% |

| 7 days | 18.64% | 0.01% | 2.21% | |

| 14 days | 18.76% | 0.01% | 1.93% | |

| 21 days | 15.46% | 0.01% | 1.86% | |

| Diesel + SDBS + CNT 100 ppm | Preparation day | 19.52% | 0.02% | 2.86% |

| 7 days | 14.86% | 0.02% | 1.89% | |

| 14 days | 23.24% | 0.02% | 3.50% | |

| 21 days | 12.92% | 0.02% | 1.96% | |

| Fuel/Nanofuel | Day of the Tests | Coefficient of Variation of the Ignition Delay | Coefficient of Variation of the Burning Rate |

|---|---|---|---|

| Diesel | - | 1.76% | 5.98% |

| Diesel + SDBS | - | 2.17% | 3.16% |

| Diesel + SDBS + CNT 50 ppm | Preparation day | 1.87% | 4.03% |

| 7 days | 3.89% | 2.92% | |

| 14 days | 1.12% | 7.00% | |

| 21 days | 2.13% | 8.18% | |

| Diesel + SDBS + CNT 100 ppm | Preparation day | 3.22% | 5.16% |

| 7 days | 2.41% | 2.80% | |

| 14 days | 2.59% | 4.33% | |

| 21 days | 3.30% | 4.92% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallego, A.; Cacua, K.; Gamboa, D.; Rentería, J.; Herrera, B. Ignition Delay and Burning Rate Analysis of Diesel–Carbon Nanotube Blends Stabilized by a Surfactant: A Droplet-Scale Study. Energies 2023, 16, 7740. https://doi.org/10.3390/en16237740

Gallego A, Cacua K, Gamboa D, Rentería J, Herrera B. Ignition Delay and Burning Rate Analysis of Diesel–Carbon Nanotube Blends Stabilized by a Surfactant: A Droplet-Scale Study. Energies. 2023; 16(23):7740. https://doi.org/10.3390/en16237740

Chicago/Turabian StyleGallego, Anderson, Karen Cacua, David Gamboa, Jorge Rentería, and Bernardo Herrera. 2023. "Ignition Delay and Burning Rate Analysis of Diesel–Carbon Nanotube Blends Stabilized by a Surfactant: A Droplet-Scale Study" Energies 16, no. 23: 7740. https://doi.org/10.3390/en16237740

APA StyleGallego, A., Cacua, K., Gamboa, D., Rentería, J., & Herrera, B. (2023). Ignition Delay and Burning Rate Analysis of Diesel–Carbon Nanotube Blends Stabilized by a Surfactant: A Droplet-Scale Study. Energies, 16(23), 7740. https://doi.org/10.3390/en16237740