Sensorless Control Strategy for Interior Permanent Magnet Synchronous Motors in the Full-Speed Section

Abstract

:1. Introduction

2. IPMSM Rotor Position Detection Methods

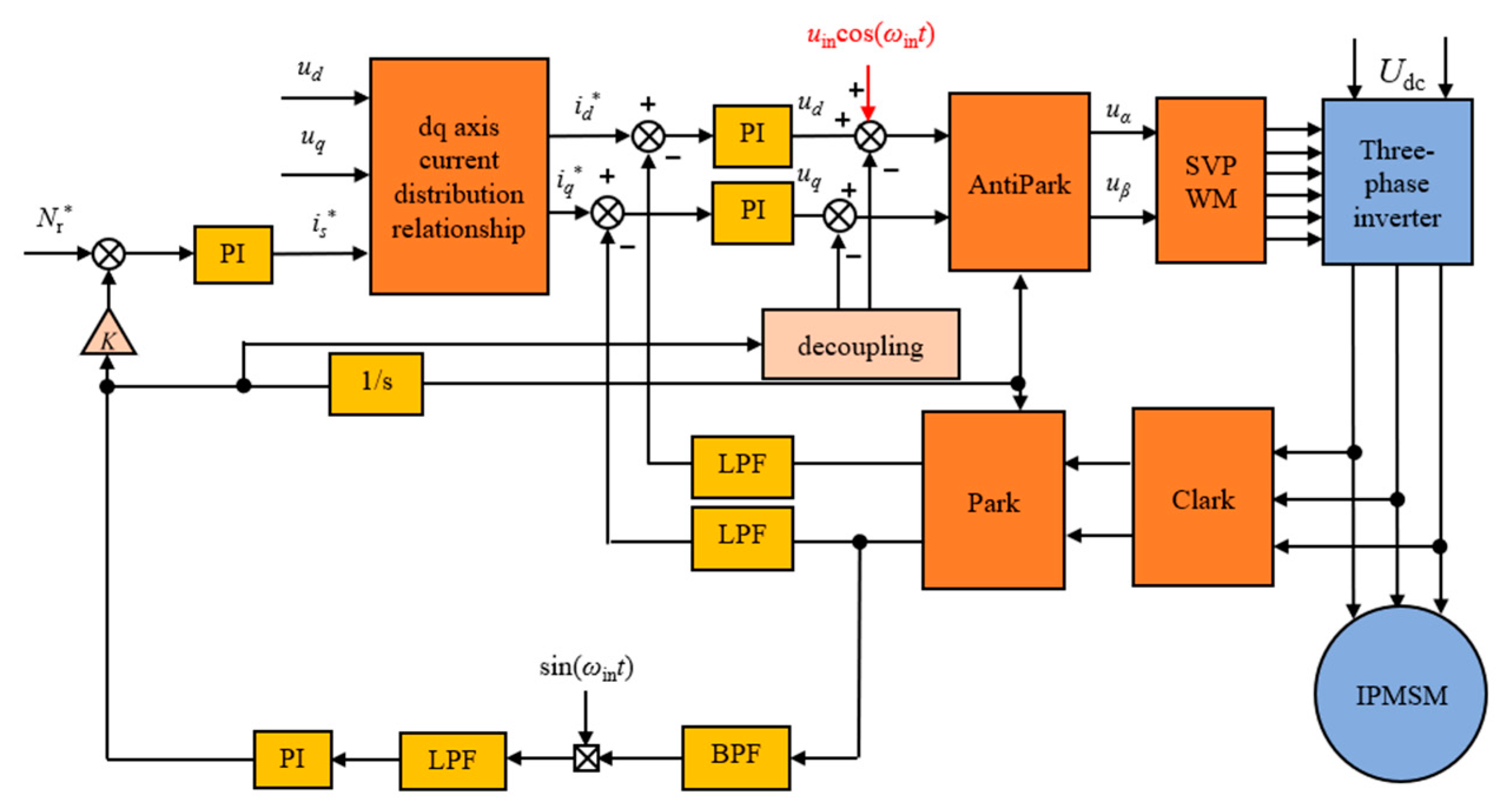

2.1. IPMSM Rotor Position Detection Based on High-Frequency Signal Injection

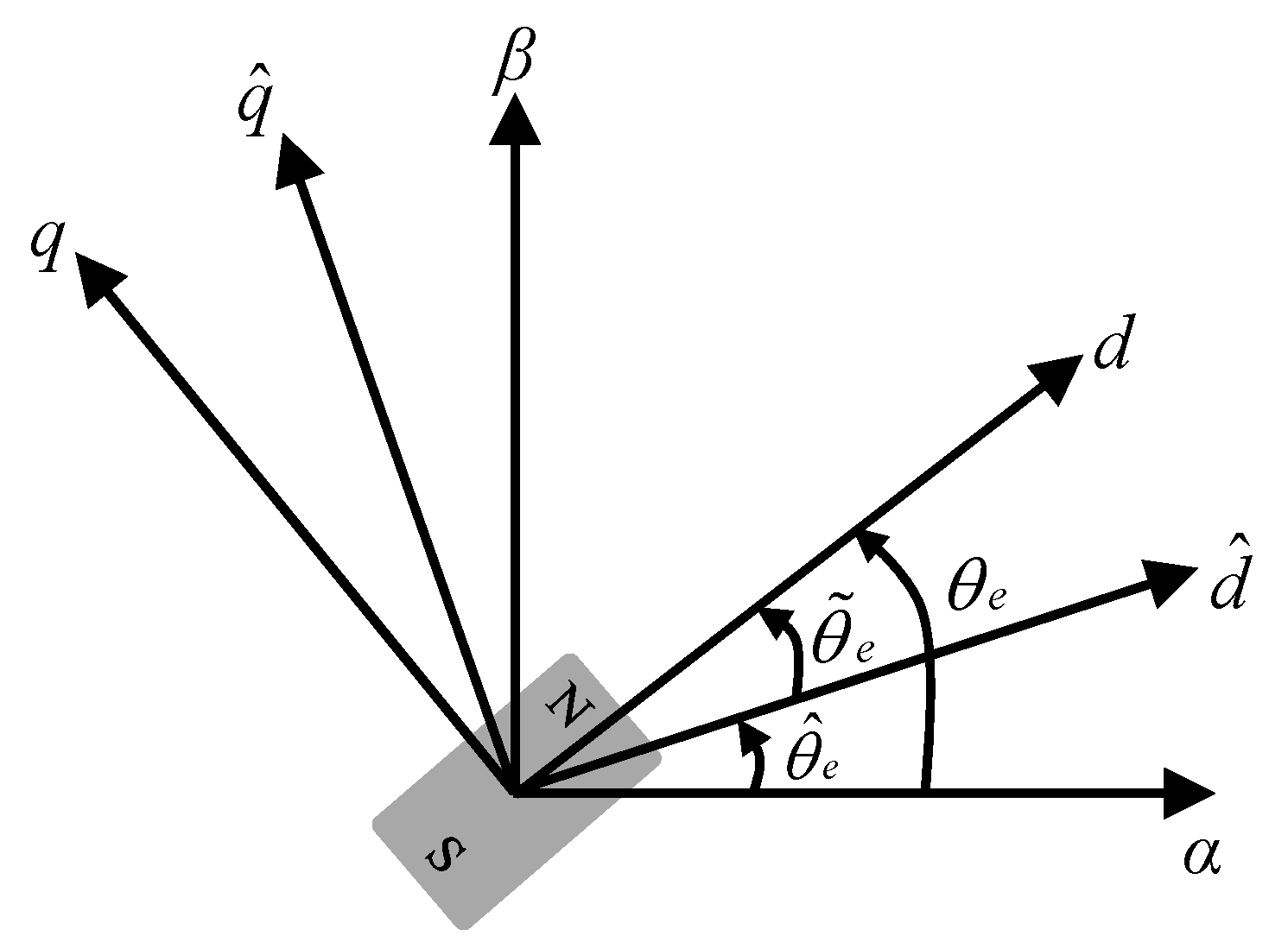

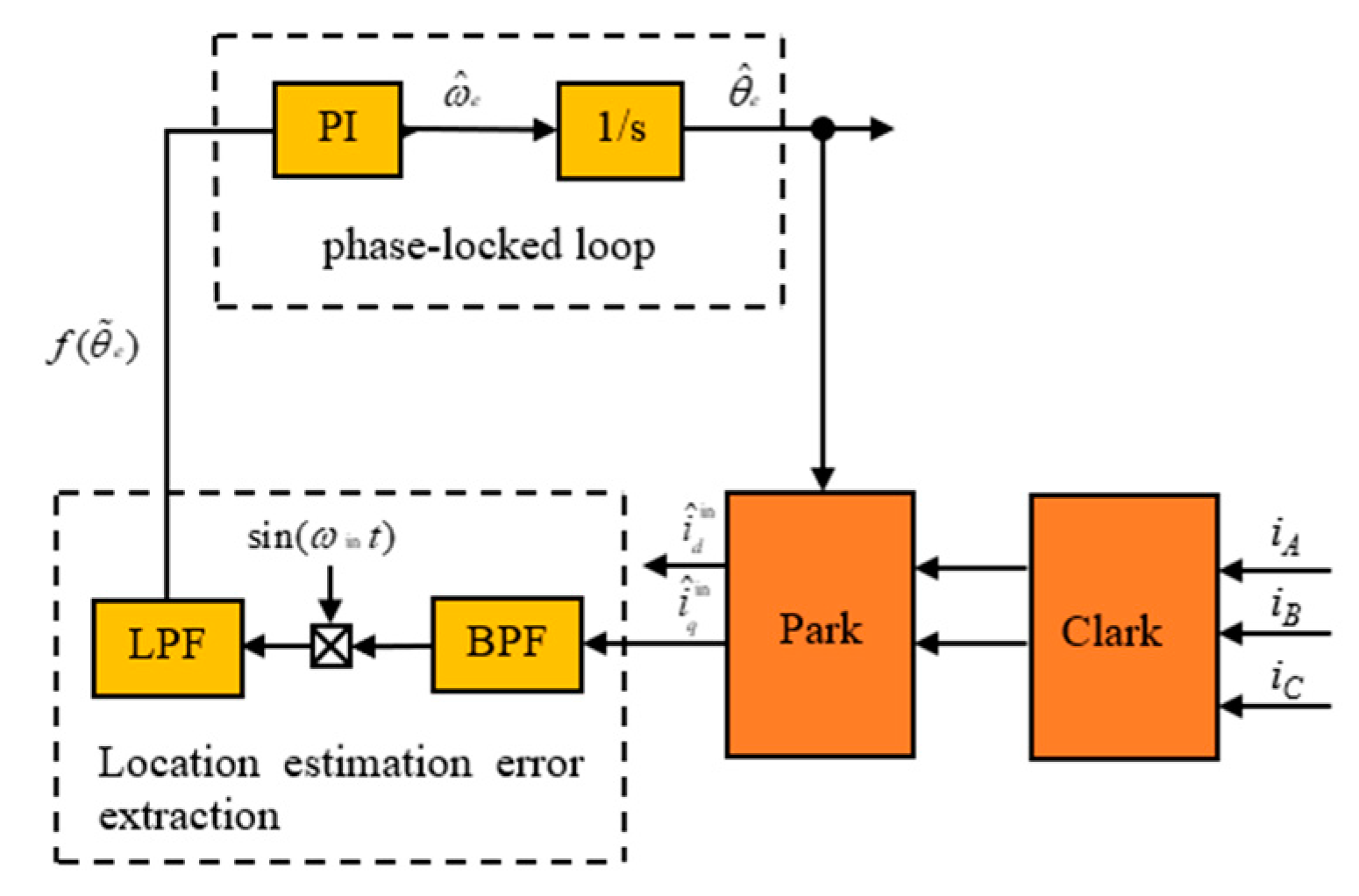

2.1.1. Pulse High-Frequency Voltage Signal Injection Strategy

2.1.2. Rotor Position Estimation Method

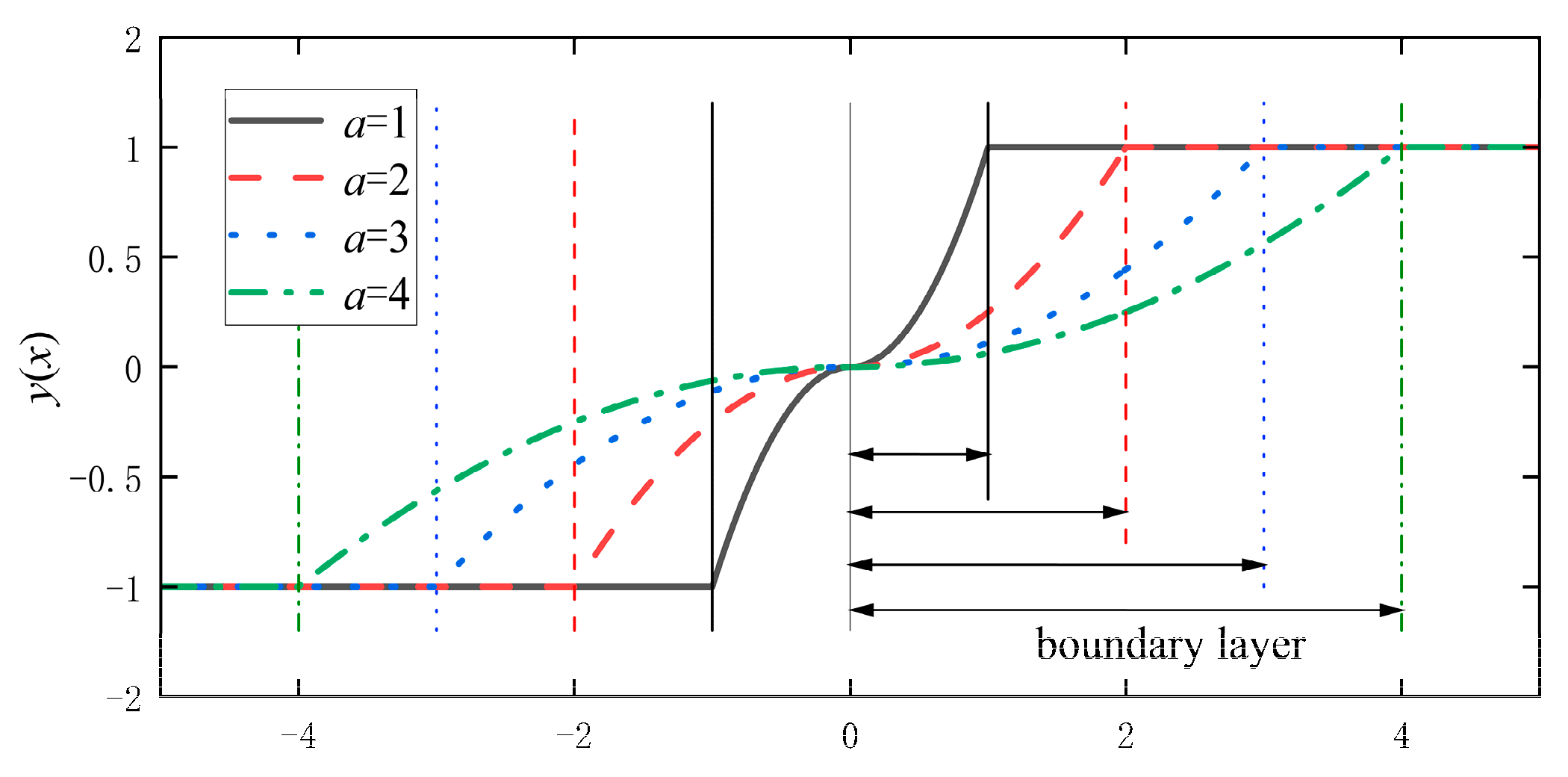

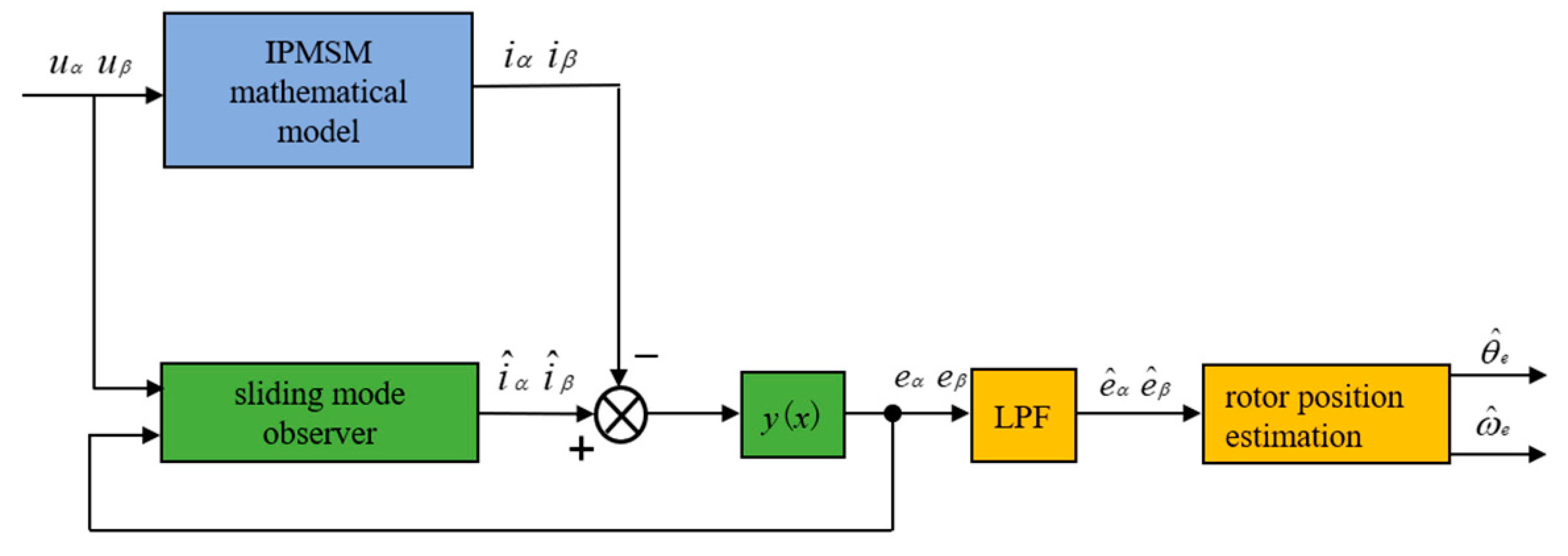

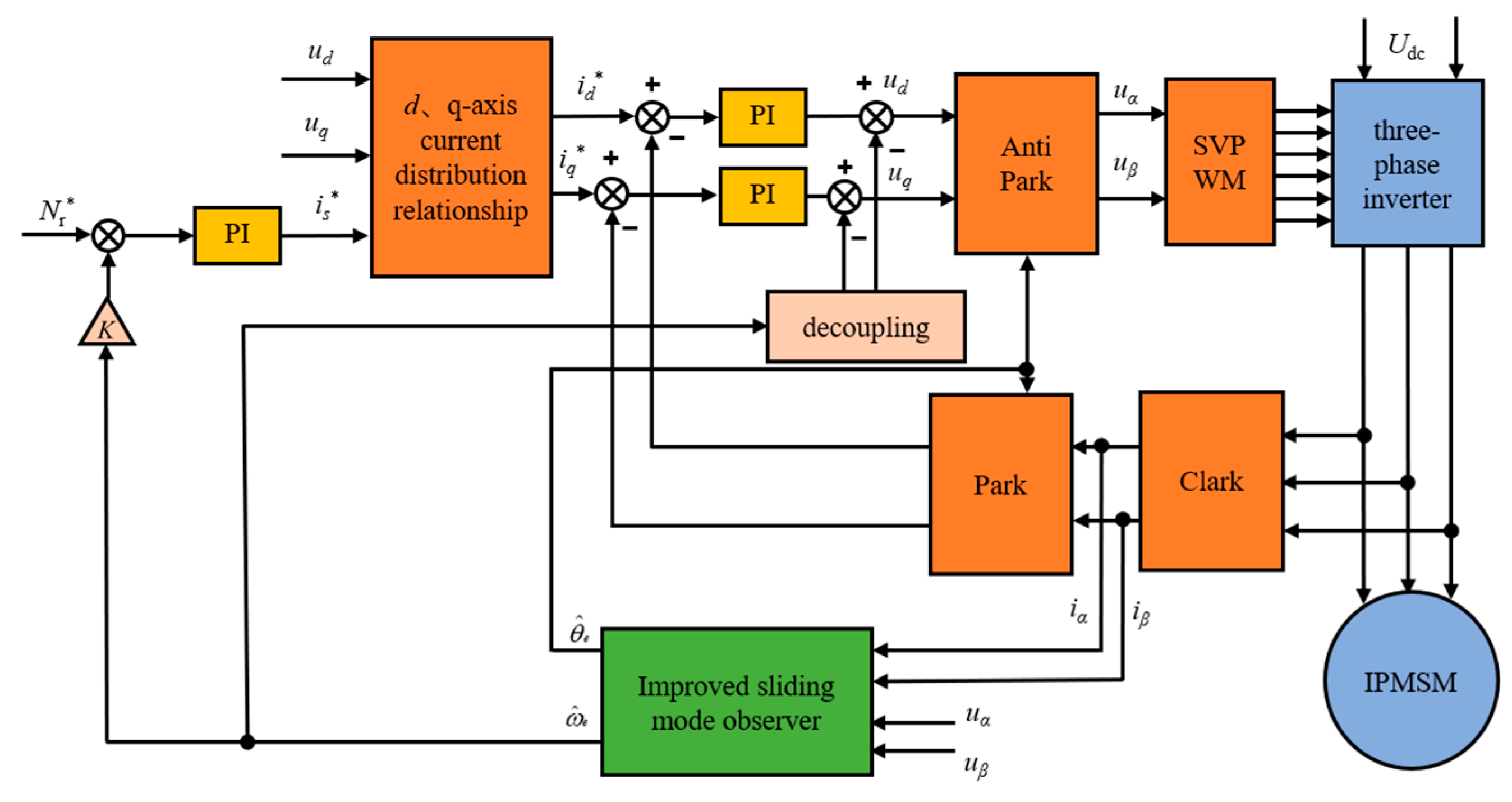

2.2. IPMSM Rotor Position Detection Based on Improved SMO

2.2.1. Design of the Improved SMO

2.2.2. Rotor Position Estimation Method

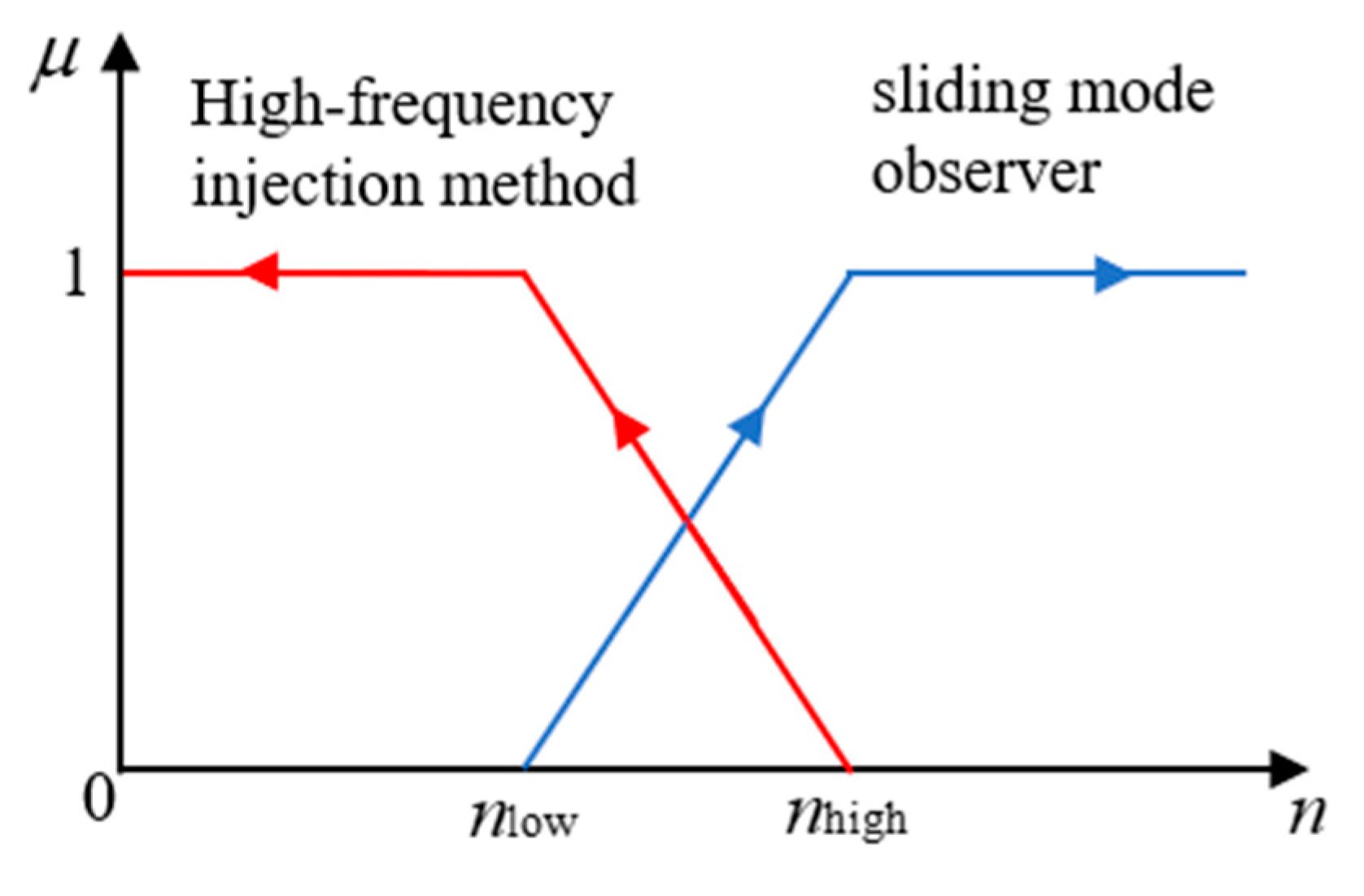

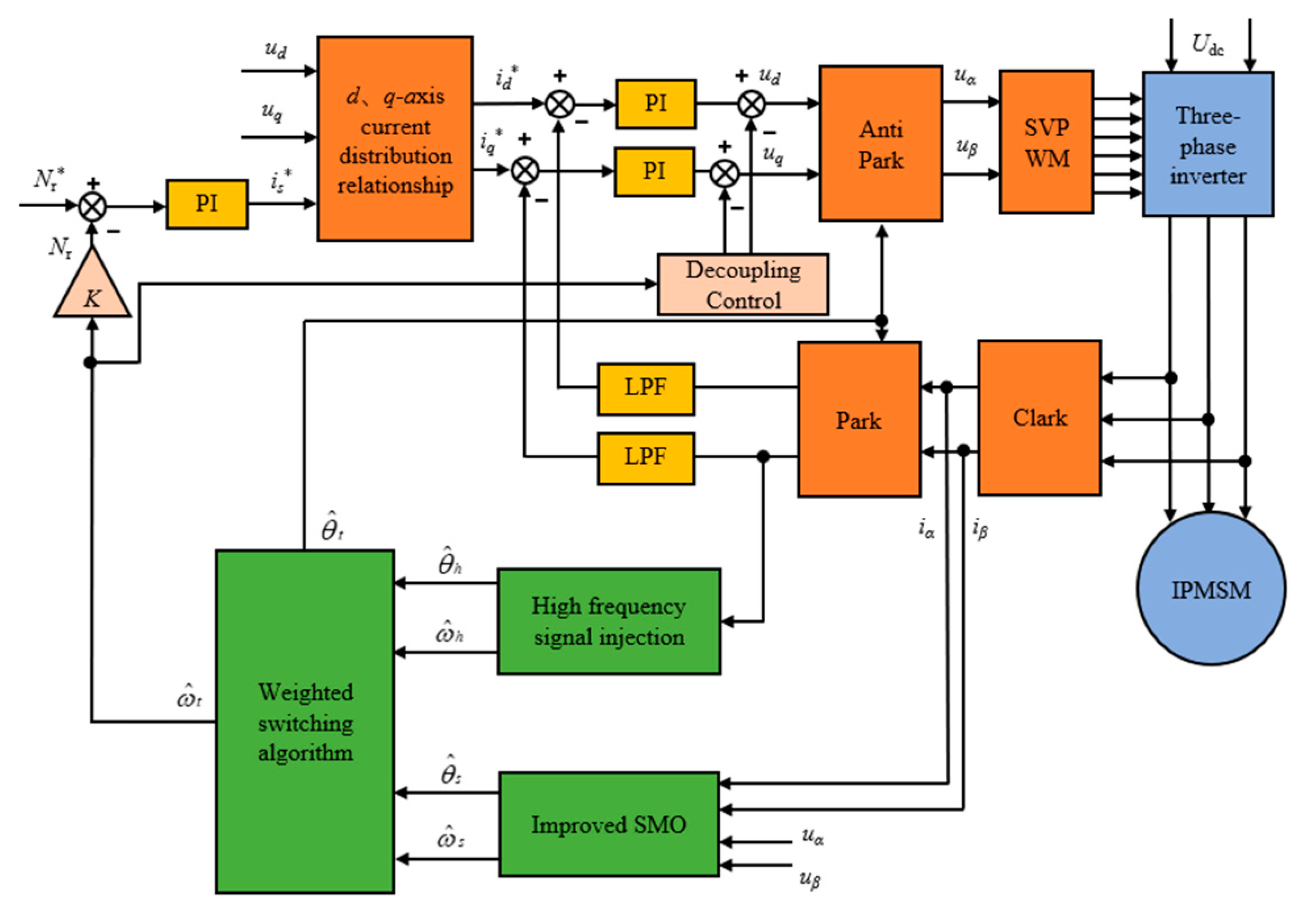

2.3. Composite Control Based on Weighted Switching

3. Sensorless Control Algorithm Simulation

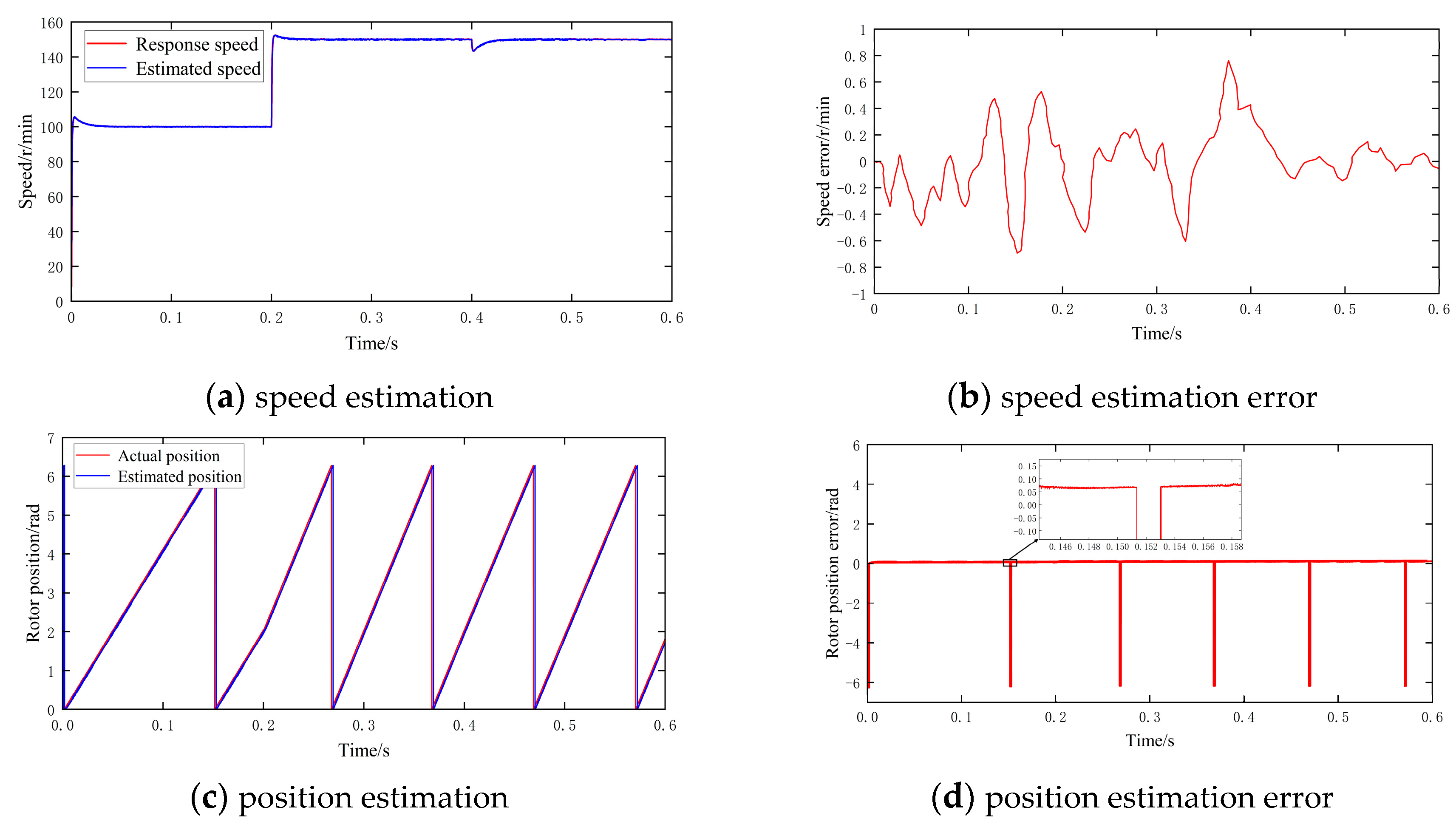

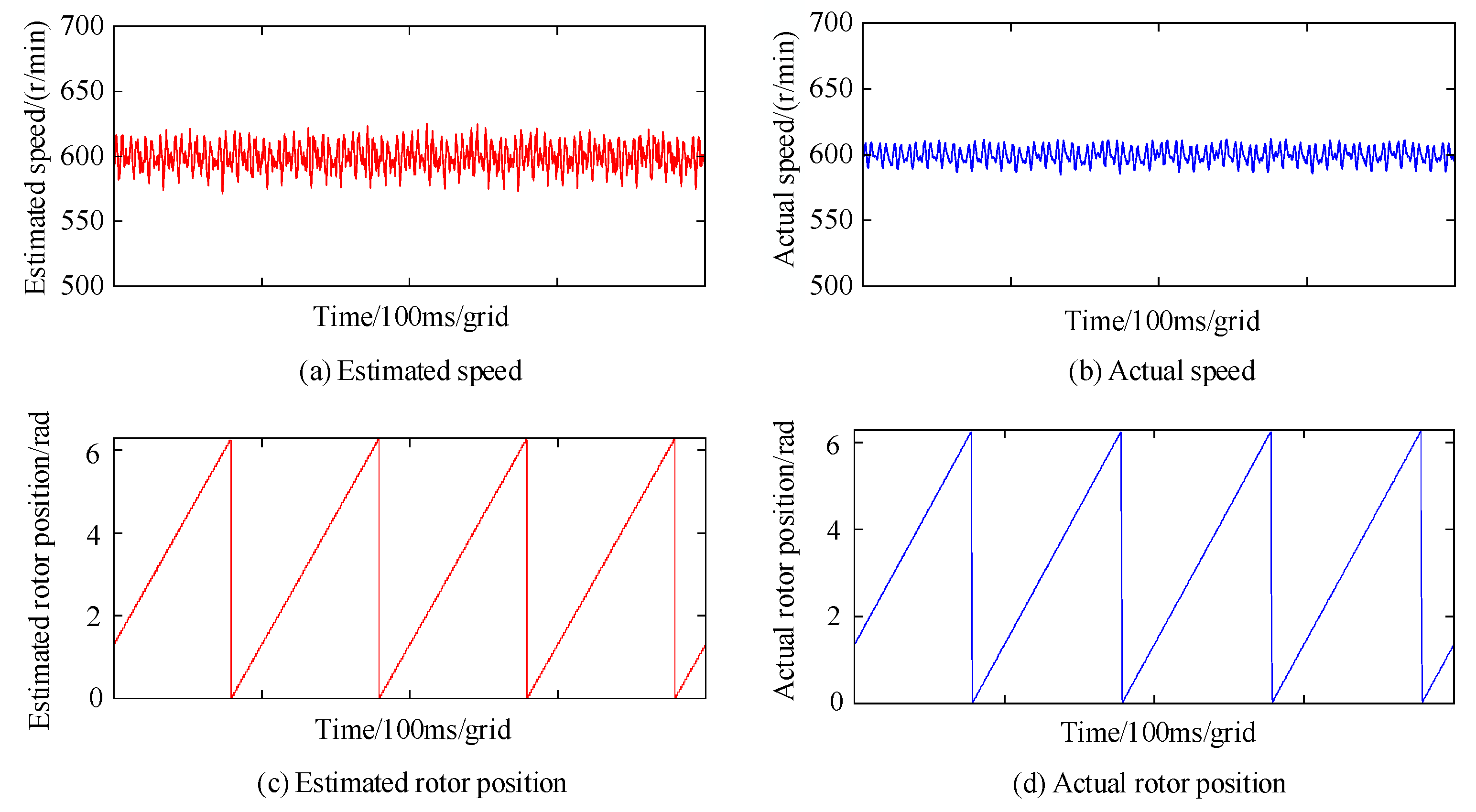

3.1. Sensorless Control Based on High-Frequency Injected Rotor Position Estimation

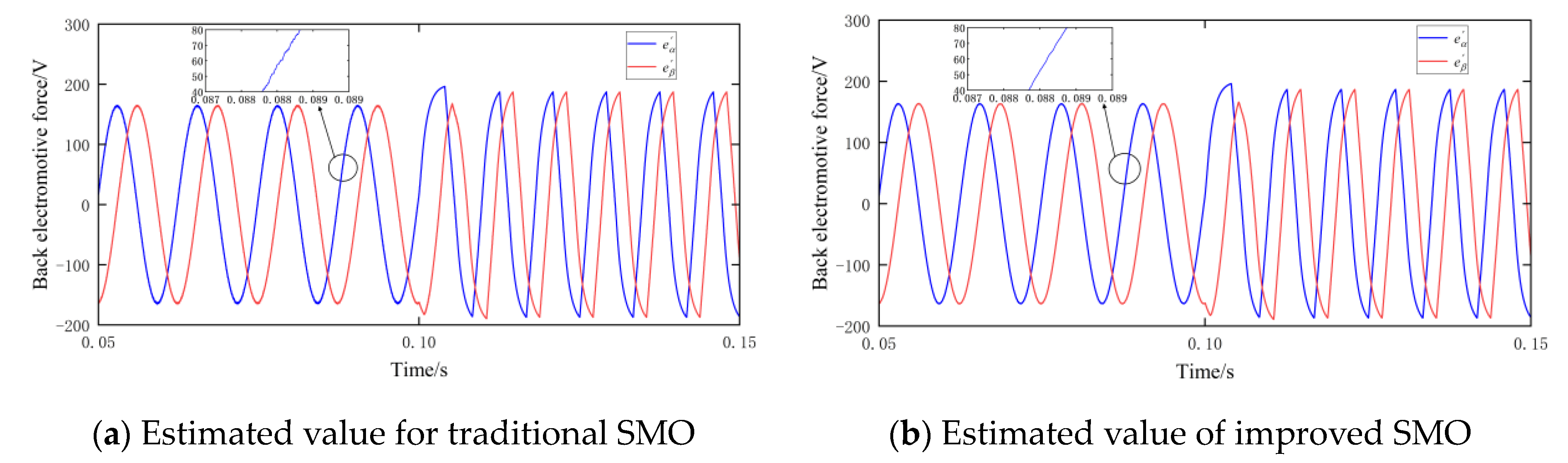

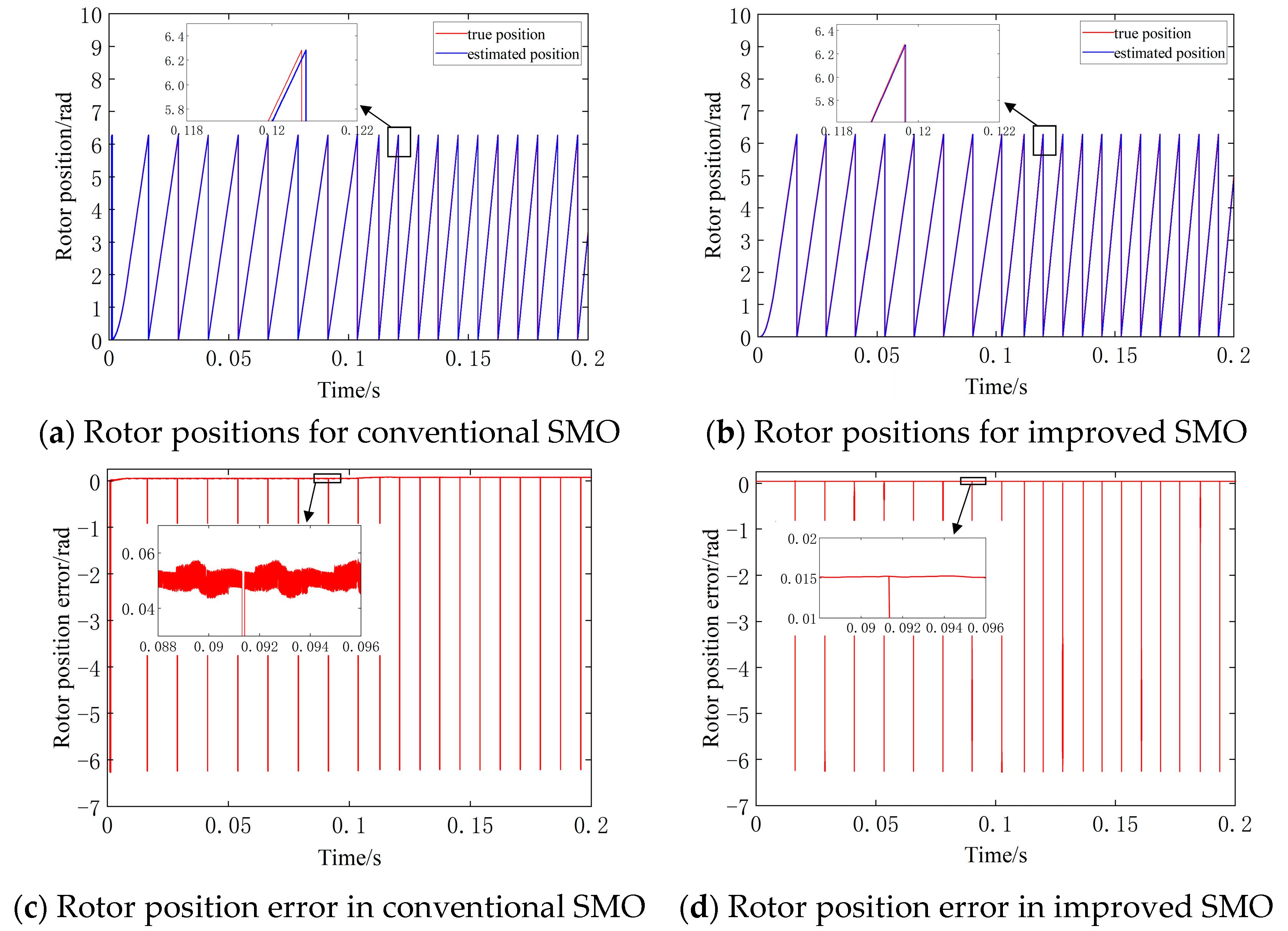

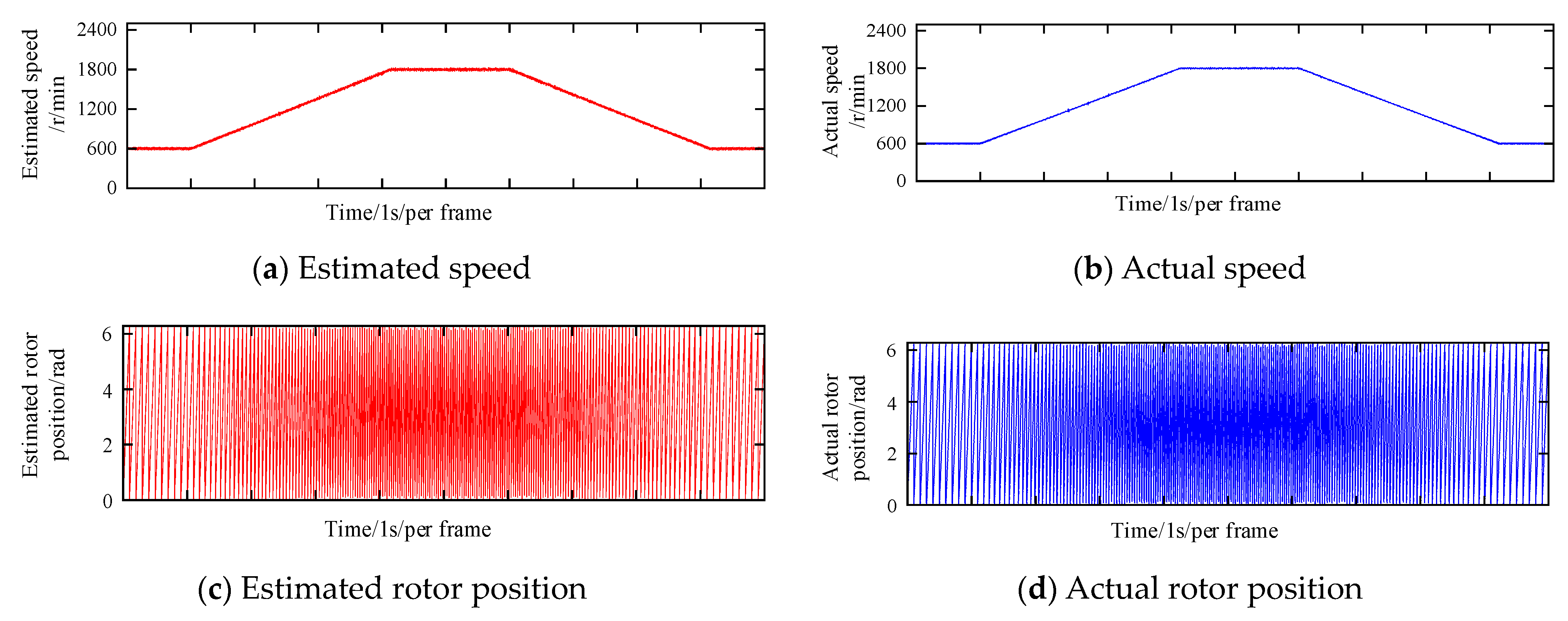

3.2. Sensorless Control Method Based on an Improved SMO

3.3. Weighted Switching Algorithm-Based Sensorless Control in the Full Speed Range

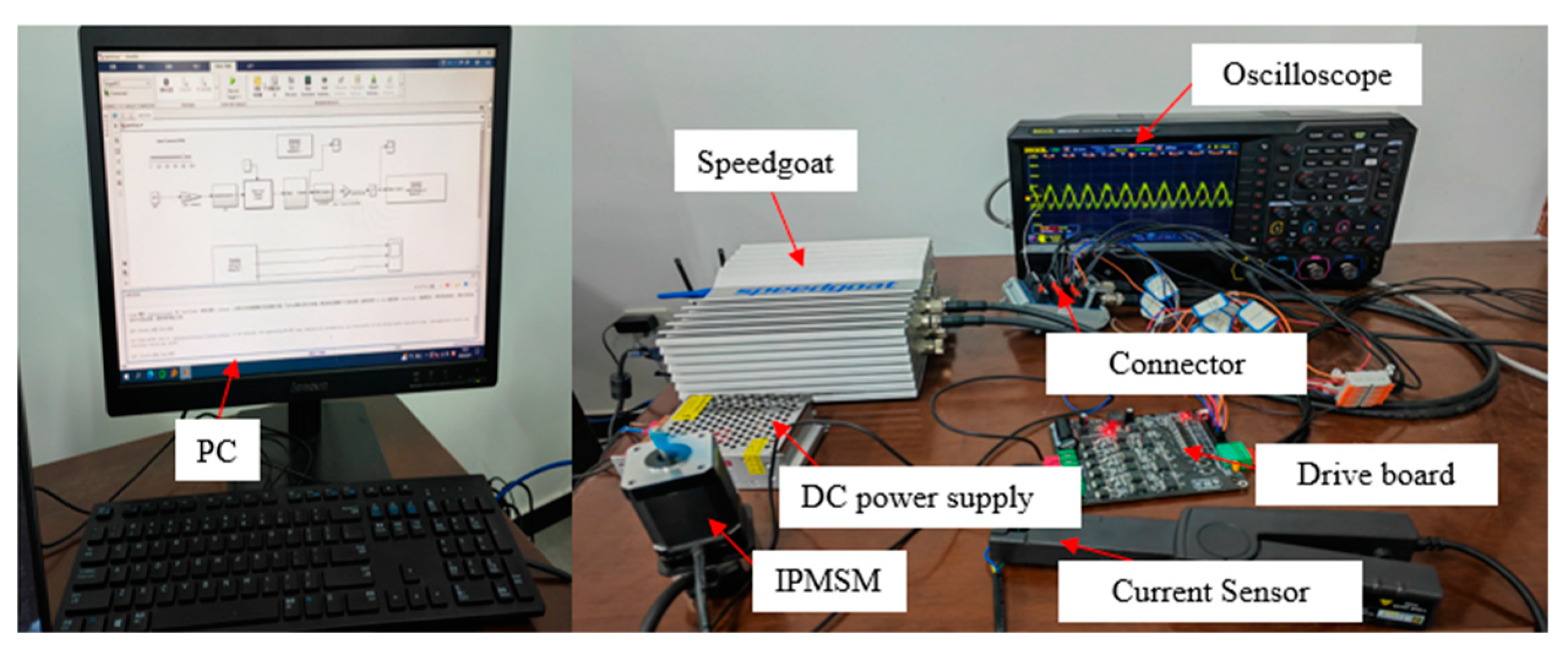

4. Experimental Verification

5. Conclusions

- (1)

- The IPMSM rotor position detection technology based on high-frequency signal injection is analyzed, and its signal injection strategy and position estimation method are studied. The rotor position detection results in the low-speed section are verified through simulation. The results show that the steady state speed error is about 0.2 r/min, and the steady state position error is about 0.07 rad at low speed.

- (2)

- For rotor position detection in the middle and high-speed sections, an SMO method is used. An improved SMO based on a segmented composite function is proposed, and it has smooth signal estimation and a small error compared with the traditional SMO. The steady-state speed error is improved to 0.1 r/min, and the position error is improved from 0.05 rad to 0.015 rad.

- (3)

- For the problem of smooth switching between the rotor position detection algorithms in the low-speed section and the medium-high-speed section, a linear weighting method is used. The interval is determined through simulation to ensure that the errors of the two algorithms are small in the switching interval. Relatively smooth switching between the two algorithms is achieved.

- (4)

- A rapid control prototype hardware platform based on the Speedgoat controller was built. The experimental platform was used to verify the position sensorless control strategy under different speed conditions. The results show that the position sensorless control strategy can track the speed and rotor position well in the full-speed section.

- (5)

- The simulation models and experiments conducted in this study were carried out under the assumption of constant loads. However, it is well recognized that load variations can significantly impact rotor position estimation in IPMSMs. In future research, we plan to analyze the effects of load changes on rotor position estimation. This will involve conducting experiments with varying load gradients to investigate the influence of different loads on the sensorless control strategy. The aim is to enhance the adaptability of this control algorithm to the complex operating conditions of drive motors. Furthermore, we intend to refine the weighted switching strategy to further improve the smoothness of control strategy transitions. These future steps will contribute to a more comprehensive and robust sensorless control approach for IPMSMs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Qi, R. Flux-Weakening Drive for IPMSM Based on Model Predictive Control. Energies 2022, 15, 2543. [Google Scholar] [CrossRef]

- Li, C.; Zhang, W.; Gao, J.; Huang, S. Permanent Magnet Flux Linkage Analysis and Maximum Torque per Ampere (MTPA) Control of High Saturation IPMSM. Energies 2023, 16, 4717. [Google Scholar] [CrossRef]

- Wang, L.; Ma, J.; Zhao, X.; Li, X. Development of a Typical Urban Driving Cycle for Battery Electric Vehicles Based on Kernel Principal Component Analysis and Random Forest. IEEE Access 2021, 9, 15053–15065. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, J.; Zhao, X.; Liu, X.; Zhang, K. A Modified Unscented Kalman Filter Combined with Ant Lion Optimization for Vehicle State Estimation. Math. Probl. Eng. 2021, 2021, 8847075. [Google Scholar] [CrossRef]

- Li, X.; Ma, J.; Zhao, X.; Wang, L. Study on Braking Energy Recovery Control Strategy for Four-Axle Battery Electric Heavy-Duty Trucks. Int. J. Energy Res. 2023, 2023, 1868528. [Google Scholar] [CrossRef]

- Li, X.; Ma, J.; Zhao, X.; Wang, L. Research on characteristic parameter selection and attention-GRU-based model for braking intention identification. Proc. Inst. Mech. Eng. Part D-J. Automob. Eng. 2023. [Google Scholar] [CrossRef]

- Wang, M.-S.; Tsai, T.-M. Sliding Mode and Neural Network Control of Sensorless PMSM Controlled System for Power Consumption and Performance Improvement. Energies 2017, 10, 1780. [Google Scholar] [CrossRef]

- Kyslan, K.; Petro, V.; Bober, P.; Slapak, V.; Durovsky, F.; Dybkowski, M.; Hric, M. A Comparative Study and Optimization of Switching Functions for Sliding-Mode Observer in Sensorless Control of PMSM. Energies 2022, 15, 2689. [Google Scholar] [CrossRef]

- Yoo, J.; Lee, J.; Sul, S.-K. Analysis of Instability in Torque Control of Sensorless PMSM Drives in Flux Weakening Region. IEEE Trans. Power Electron. 2021, 36, 10815–10826. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Q.; Zhang, G.; Wang, G.; Xu, D. Online Temperature Identification Strategy for Position Sensorless PMSM Drives with Position Error Adaptive Compensation. IEEE Trans. Power Electron. 2022, 37, 8502–8512. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, L.; Xiao, X.; Lee, C.H.T.; Que, H. Adjustable-Flux Permanent Magnet Synchronous Motor Sensorless Drive System Based on Parameter-Sensitive Adaptive Online Decoupling Control Strategy. IEEE Trans. Transp. Electrif. 2023, 9, 501–511. [Google Scholar] [CrossRef]

- Shao, Y.; Yu, Y.; Chai, F.; Chen, T. A Two-Degree-of-Freedom Structure-Based Backstepping Observer for DC Error Suppression in Sensorless PMSM Drives. IEEE Trans. Ind. Electron. 2022, 69, 10846–10858. [Google Scholar] [CrossRef]

- Zhu, Q. Complete model-free sliding mode control (CMFSMC). Sci. Rep. 2021, 11, 22565. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, N.; Ozgoli, S.; Ramezani, A. Model-free sliding mode control, theory and application. Proc. Inst. Mech. Eng. Part. I J. Syst. Control. Eng. 2018, 232, 1292–1301. [Google Scholar] [CrossRef]

- Wang, G.; Valla, M.; Solsona, J. Position Sensorless Permanent Magnet Synchronous Machine Drives-A Review. IEEE Trans. Ind. Electron. 2020, 67, 5830–5842. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, S.; Chen, C. Review of sensorless control techniques for PMSM drives. IEEJ Trans. Electr. Electron. Eng. 2019, 14, 1543–1552. [Google Scholar] [CrossRef]

- Varatharajan, A.; Pellegrino, G.; Armando, E.; Hinkkanen, M. Sensorless Synchronous Motor Drives: A Review of Flux Observer-Based Position Estimation Schemes Using the Projection Vector Framework. IEEE Trans. Power Electron. 2021, 36, 8171–8180. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, L.; Yuan, W.; Yin, Z. Disturbance rejection speed sensorless control of PMSMs based on full order adaptive observer. J. Power Electron. 2021, 21, 804–814. [Google Scholar] [CrossRef]

- Liu, J.M.; Zhu, Z.Q. Novel Sensorless Control Strategy with Injection of High-Frequency Pulsating Carrier Signal Into Stationary Reference Frame. IEEE Trans. Ind. Appl. 2014, 50, 2574–2583. [Google Scholar] [CrossRef]

- Fu, X.; Xu, Y.; He, H.; Fu, X. Initial Rotor Position Estimation by Detecting Vibration of Permanent Magnet Synchronous Machine. IEEE Trans. Ind. Electron. 2021, 68, 6595–6606. [Google Scholar] [CrossRef]

- Hirakawa, D.; Yamamoto, K.; Shinohara, A. Estimated Position Error Compensation Method Considering Impact of Speed and Load in Permanent Magnet Synchronous Motor Position Sensorless Control Based on High-Frequency Voltage Injection. IEEJ J. Ind. Appl. 2021, 10, 624–631. [Google Scholar] [CrossRef]

- Luo, X.; Tang, Q.; Shen, A.; Zhang, Q. PMSM Sensorless Control by Injecting HF Pulsating Carrier Signal Into Estimated Fixed-Frequency Rotating Reference Frame. IEEE Trans. Ind. Electron. 2016, 63, 2294–2303. [Google Scholar] [CrossRef]

- Sun, X.; Cai, F.; Yang, Z.; Tian, X. Finite Position Control of Interior Permanent Magnet Synchronous Motors at Low Speed. IEEE Trans. Power Electron. 2022, 37, 7729–7738. [Google Scholar] [CrossRef]

- Repecho, V.; Bin Waqar, J.; Biel, D.; Doria-Cerezo, A. Zero Speed Sensorless Scheme for Permanent Magnet Synchronous Machine Under Decoupled Sliding-Mode Control. IEEE Trans. Ind. Electron. 2022, 69, 1288–1297. [Google Scholar] [CrossRef]

- Malekipour, A.; Corne, A.; Garbuio, L.; Granjon, P.; Gerbaud, L. A Closed-Loop PMSM Sensorless Control Based on the Machine Acoustic Noise. IEEE Trans. Ind. Electron. 2023, 70, 9859–9869. [Google Scholar] [CrossRef]

- Narzary, D.; Asthana, P.; Sarkar, M.K.; Choudhary, P. Sensorless Speed Control of Permanent Magnet Synchronous Machine using Higher Order Sliding Mode Functional Observer. In Proceedings of the 2017 2nd IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT), Bangalore, India, 19–20 May 2017; IEEE: New York, NY, USA, 2017; pp. 1390–1395. [Google Scholar]

- Jung, T.-U.; Jang, J.-H.; Park, C.-S. A Back-EMF Estimation Error Compensation Method for Accurate Rotor Position Estimation of Surface Mounted Permanent Magnet Synchronous Motors. Energies 2017, 10, 1160. [Google Scholar] [CrossRef]

- Gayen, P.K. Magnetizing current based improved rotor position and speed estimation of doubly-fed induction generator using model reference adaptive scheme. Measurement 2021, 173, 108602. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, X.-F. Sensorless Control of Permanent Magnet Synchronous Motors and EKF Parameter Tuning Research. Math. Probl. Eng. 2016, 2016, 3916231. [Google Scholar] [CrossRef]

- Luo, X.; Zhao, J.; Xiong, Y.; Xu, H.; Chen, H.; Zhang, S. Parameter Identification of Five-Phase Squirrel Cage Induction Motor Based on Extended Kalman Filter. Processes 2022, 10, 1440. [Google Scholar] [CrossRef]

- Rigatos, G.G.; Siano, P. Sensorless Control of Electric Motors with Kalman Filters: Applications to Robotic and Industrial Systems. Int. J. Adv. Robot. Syst. 2011, 8, 62–80. [Google Scholar] [CrossRef]

- Gong, C.; Hu, Y.; Gao, J.; Wang, Y.; Yan, L. An Improved Delay-Suppressed Sliding-Mode Observer for Sensorless Vector-Controlled PMSM. IEEE Trans. Ind. Electron. 2020, 67, 5913–5923. [Google Scholar] [CrossRef]

- Saadaoui, O.; Khlaief, A.; Abassi, M.; Tlili, I.; Chaari, A.; Boussak, M. A New Full-Order Sliding Mode Observer Based Rotor Speed and Stator Resistance Estimation for Sensorless Vector Controlled Pmsm Drives. Asian J. Control 2019, 21, 1318–1327. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Guo, Z.; Xie, C.; Liu, J.; Jin, X.; Wang, Z. Fuzzy adaptive super-twisting algorithm based sliding-mode observer for sensorless control of permanent magnet synchronous motor. J. Eng.-JOE 2021, 2021, 788–799. [Google Scholar] [CrossRef]

- Tsujii, Y.; Morimoto, S.; Inoue, Y.; Sanada, M. Effect of Inductance Model on Sensorless Control Performance of SynRM with Magnetic Saturation. IEEJ J. Ind. Appl. 2023, 12, 596–602. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Pair of Poles | 4 |

| Stator resistance/Ω | 0.958 |

| d-axis inductance/mH | 5.25 |

| q-axis inductance/mH | 12 |

| flux linkage/Wb | 0.1827 |

| Damping coefficient/N/(m/s) | 0.008 |

| rotational inertia/kg·m2 | 0.003 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| type | 80AST-M01330LBX | rated torque/N·m | 1.27 |

| rated power/W | 400 | peak torque/N·m | 4.46 |

| rated voltage/V | 220 | d-axis inductance/mH | 9.141 |

| rated speed/rpm | 3000 | q-axis inductance/mH | 13.7425 |

| Pair of Poles | 4 | Stator resistance/Ω | 3.69 |

| Speed Working Condition | Maximum Absolute Error | Average Absolute Error | Standard Deviation | |

|---|---|---|---|---|

| speed error /r/min | 600 | 28.64 | 8.23 | 5.72 |

| 2000 | 23.52 | 7.21 | 5.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Ma, J.; Zhao, X.; Meng, D.; Xu, K.; Guo, D. Sensorless Control Strategy for Interior Permanent Magnet Synchronous Motors in the Full-Speed Section. Energies 2023, 16, 7701. https://doi.org/10.3390/en16237701

Wang J, Ma J, Zhao X, Meng D, Xu K, Guo D. Sensorless Control Strategy for Interior Permanent Magnet Synchronous Motors in the Full-Speed Section. Energies. 2023; 16(23):7701. https://doi.org/10.3390/en16237701

Chicago/Turabian StyleWang, Jianping, Jian Ma, Xuan Zhao, Dean Meng, Kejie Xu, and Dianxiang Guo. 2023. "Sensorless Control Strategy for Interior Permanent Magnet Synchronous Motors in the Full-Speed Section" Energies 16, no. 23: 7701. https://doi.org/10.3390/en16237701

APA StyleWang, J., Ma, J., Zhao, X., Meng, D., Xu, K., & Guo, D. (2023). Sensorless Control Strategy for Interior Permanent Magnet Synchronous Motors in the Full-Speed Section. Energies, 16(23), 7701. https://doi.org/10.3390/en16237701