The Influence of Ink Formulation and Preparation on the Performance of Proton-Exchange Membrane Fuel Cell

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Catalyst Inks

2.3. Preparation of CCMs

2.4. Thickness and Porosity of Coated Samples

2.5. Electrochemical Measurements

2.5.1. Polarization Curves

2.5.2. Cyclic Voltammetry (ECSA Determination)

2.5.3. Electrochemical Impedance Spectroscopy (EIS)

3. Results

3.1. Operating Conditions for a Given Ink Composition

3.2. Optimization of the Composition of Catalyst Inks

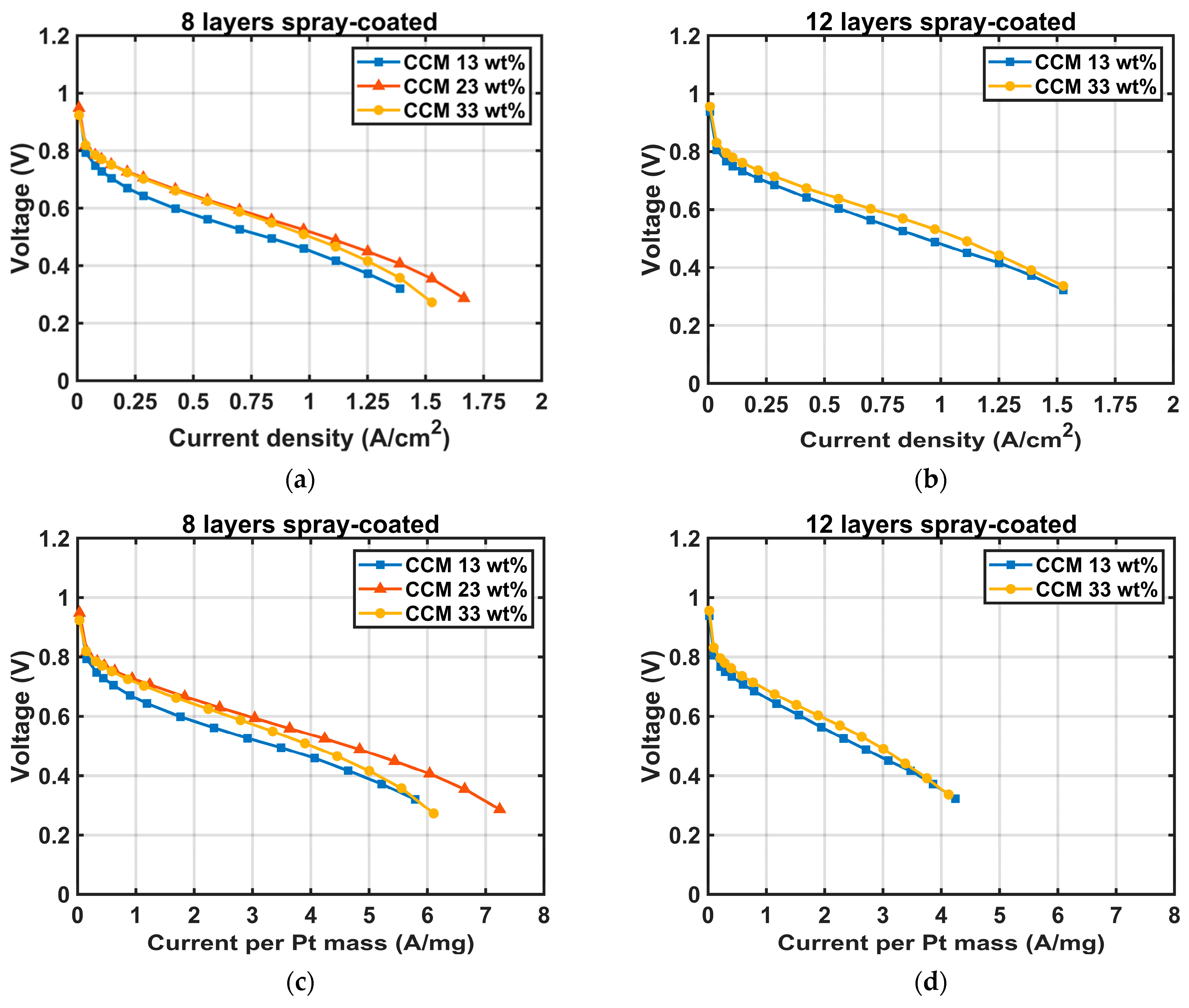

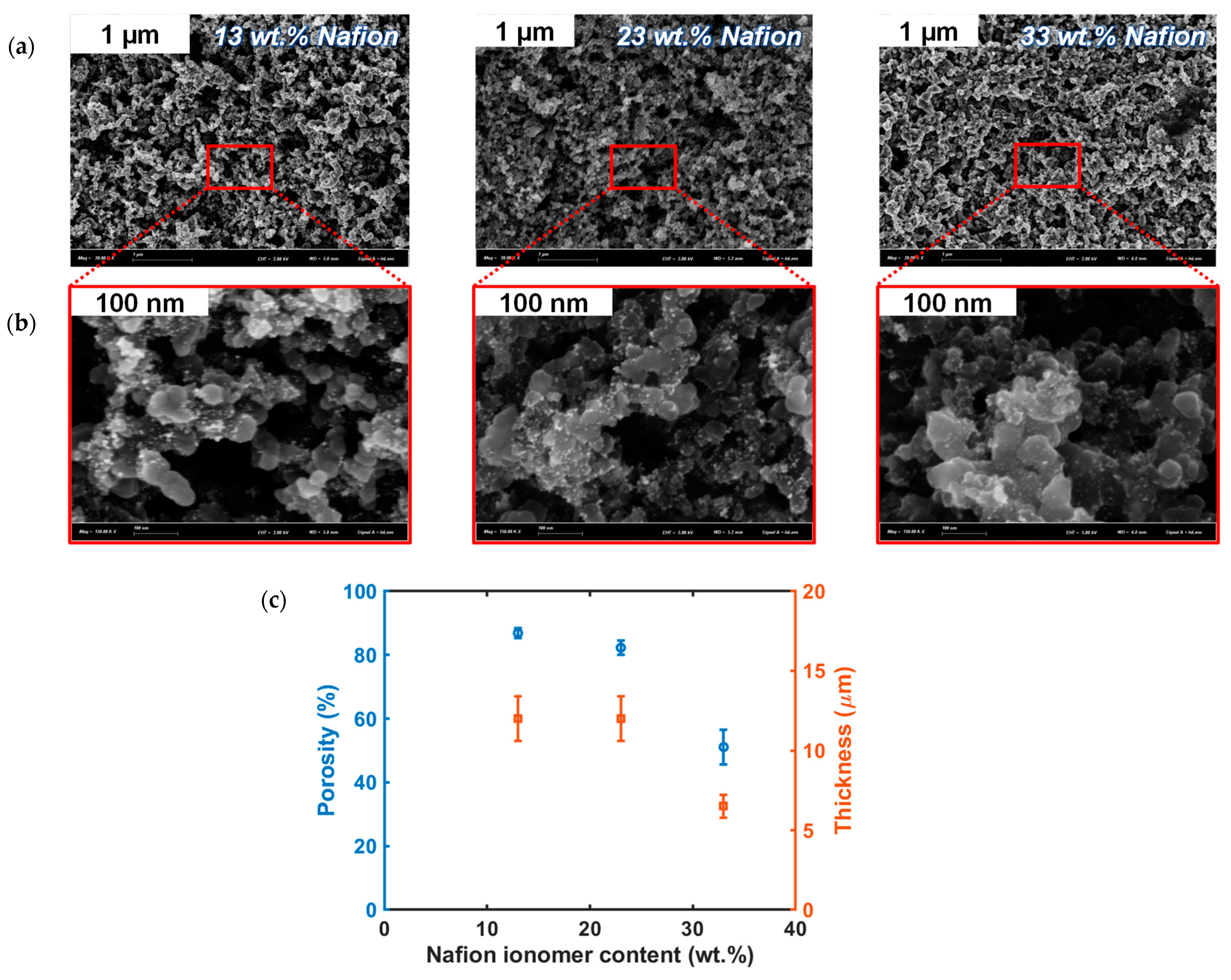

3.2.1. Nafion® Ionomer Content

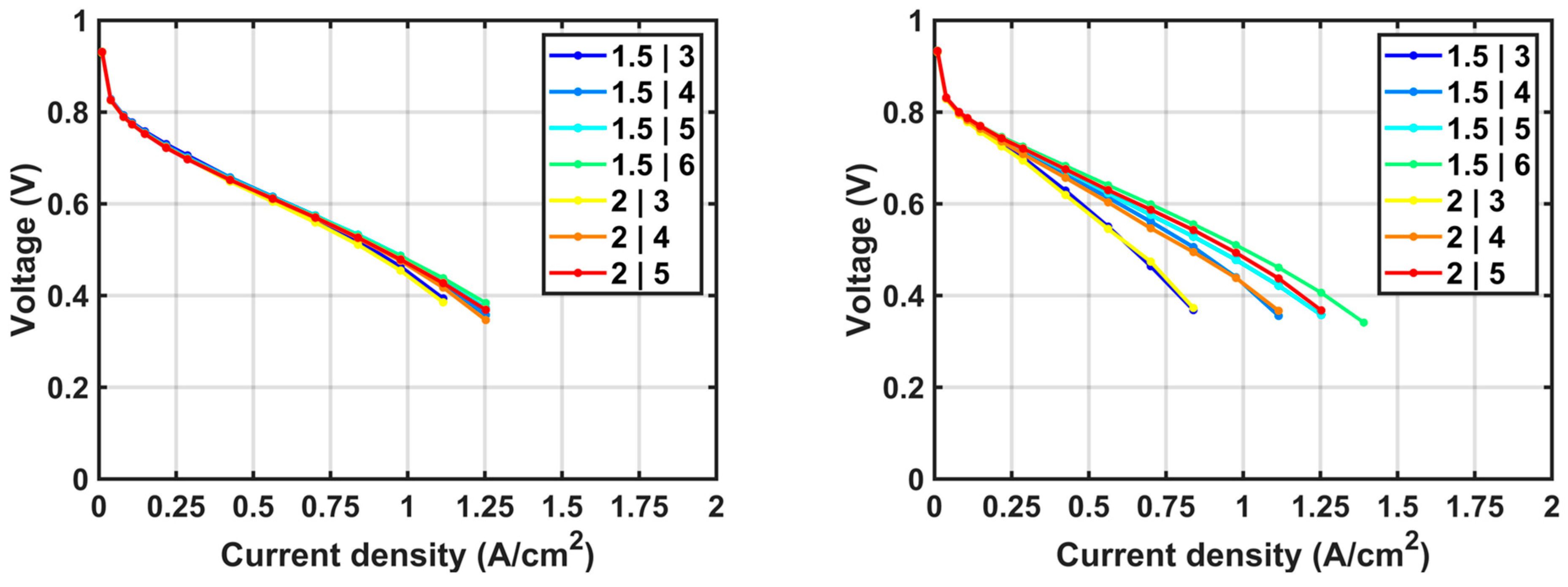

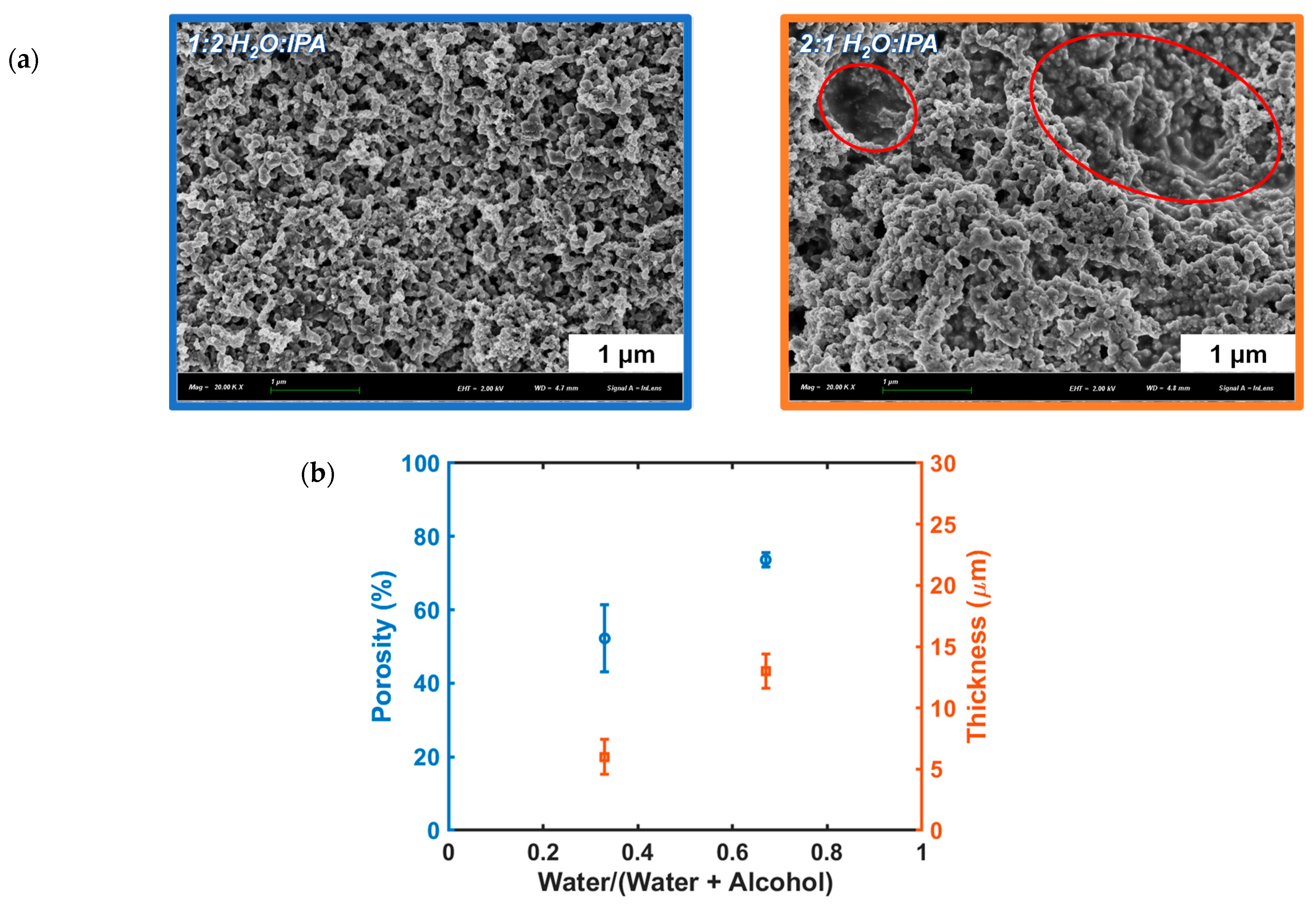

3.2.2. Solvent Ratios (1:2 vs. 2:1 H2O/IPA)

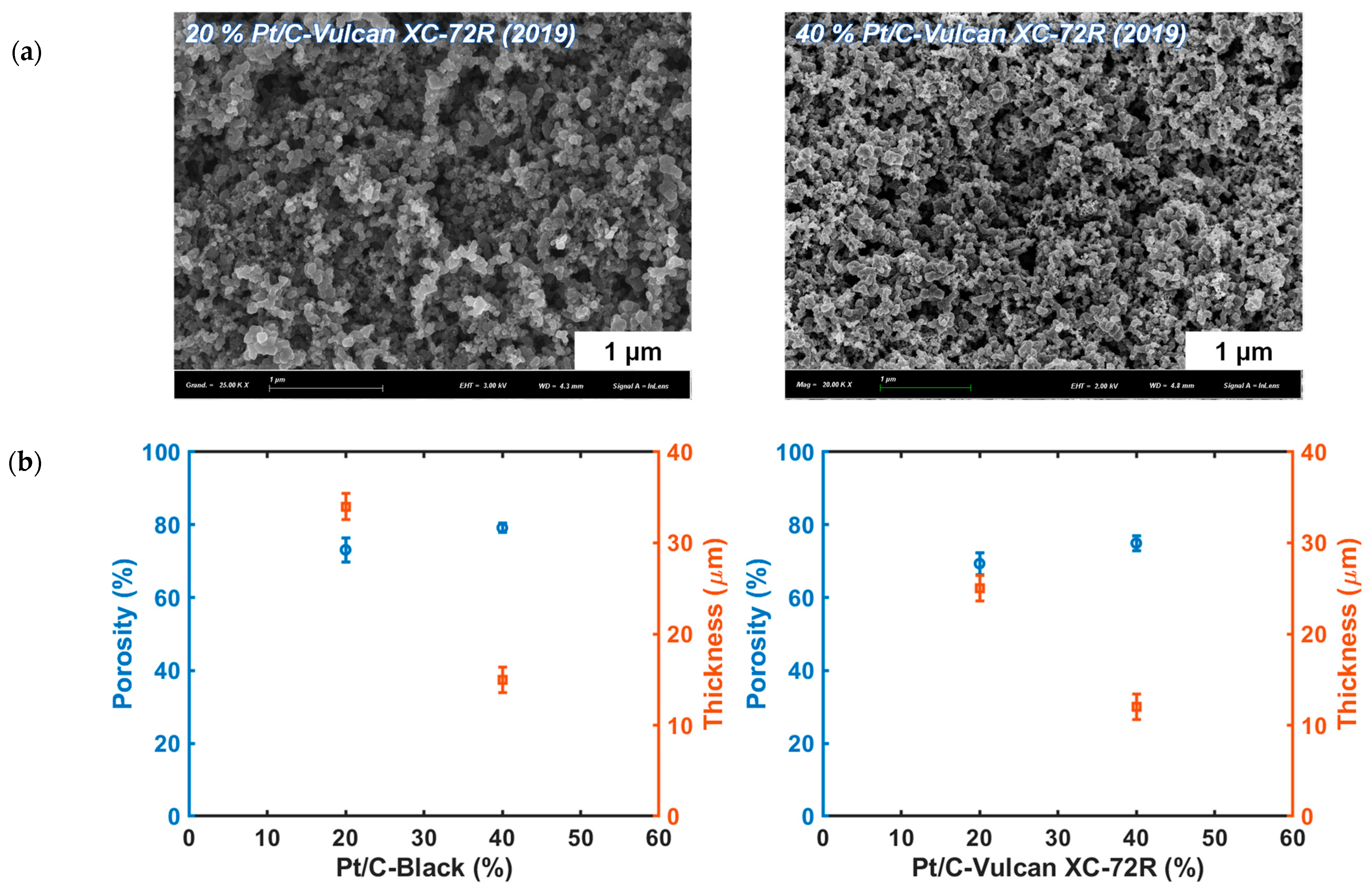

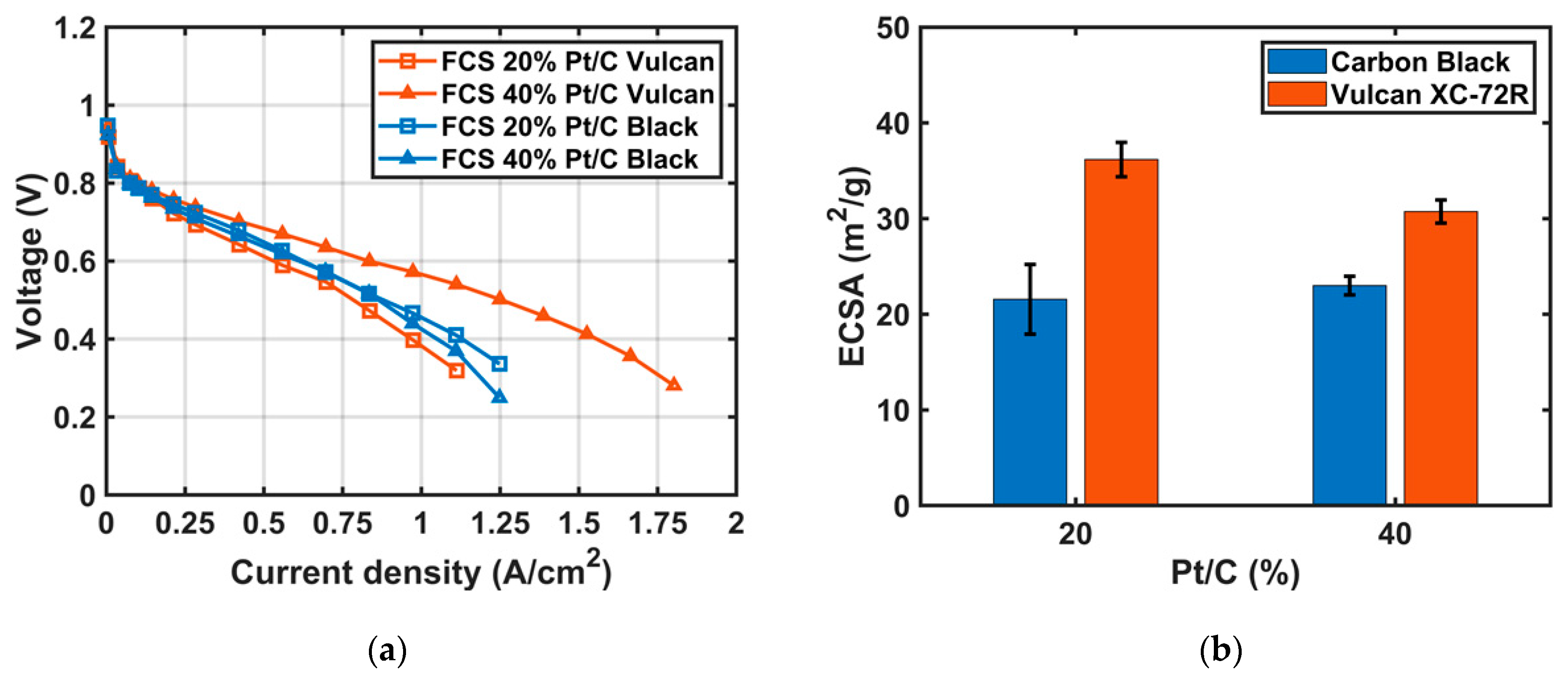

3.2.3. Pt Weights and Carbon Types

- FCS 20% Pt/C-Vulcan XC-72R (2019)

- FCS 40% Pt/C-Vulcan XC-72R (2019)

- FCS 20% Pt/C-Black (2020)

- FCS 40% Pt/C-Black (2020).

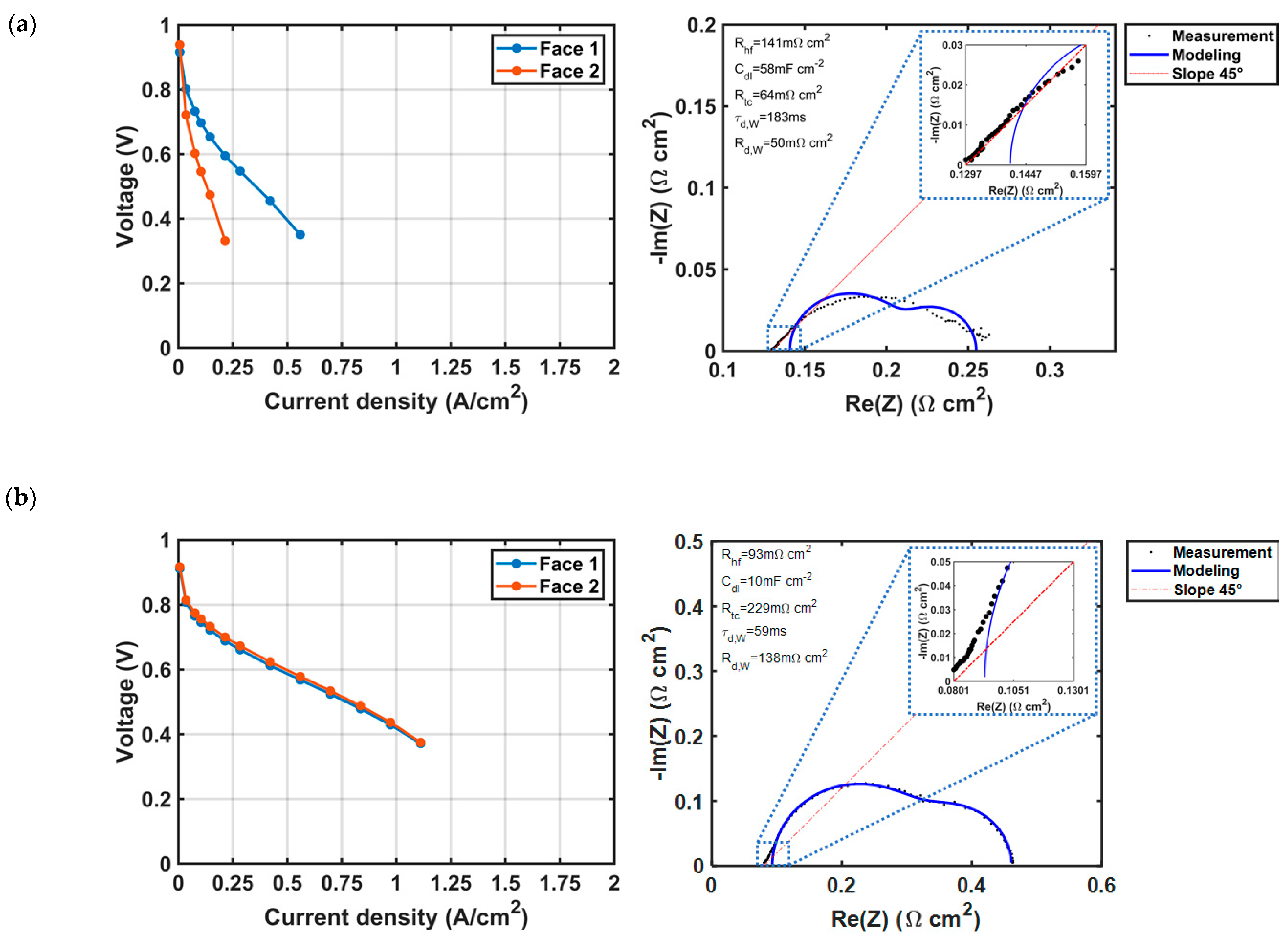

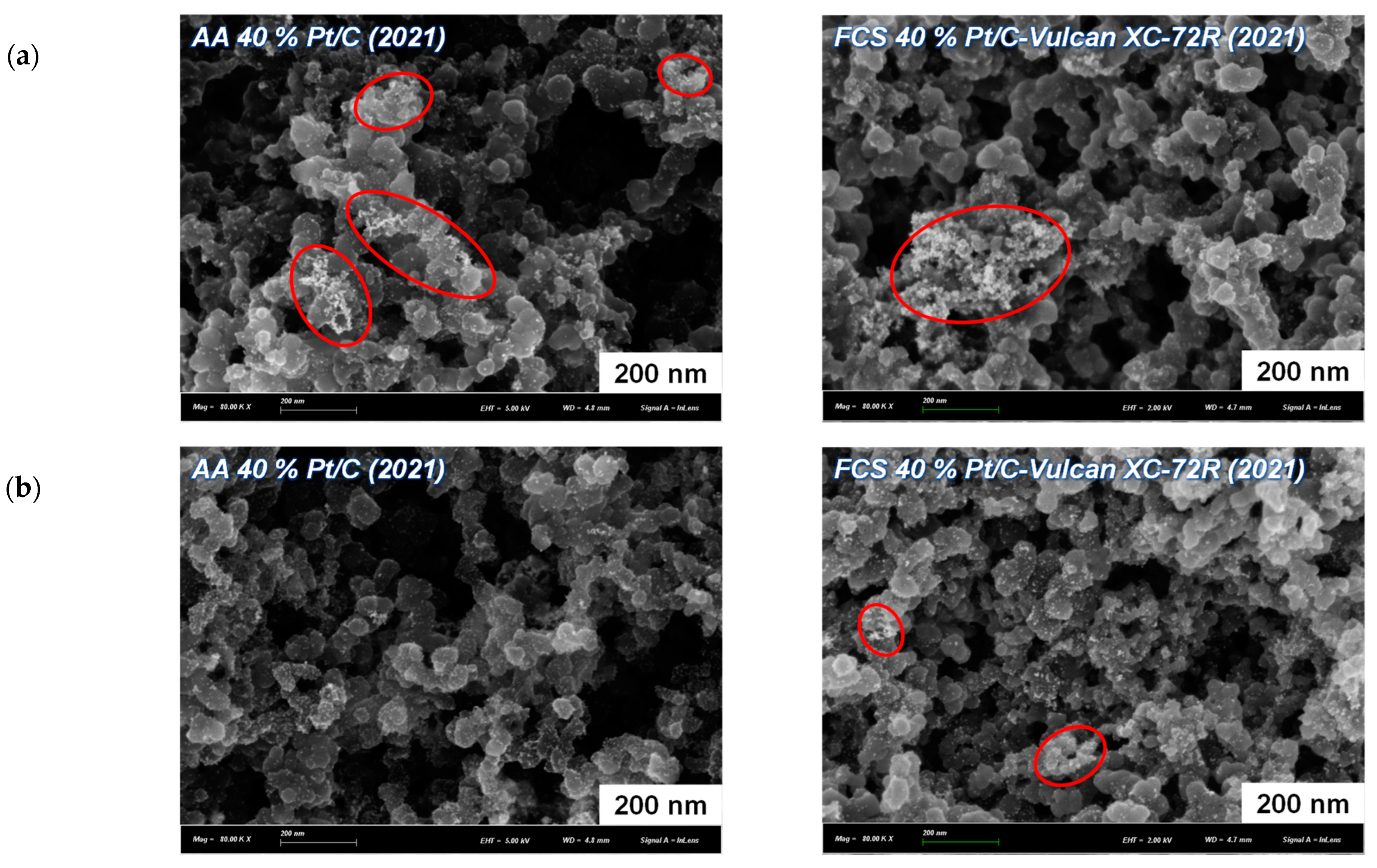

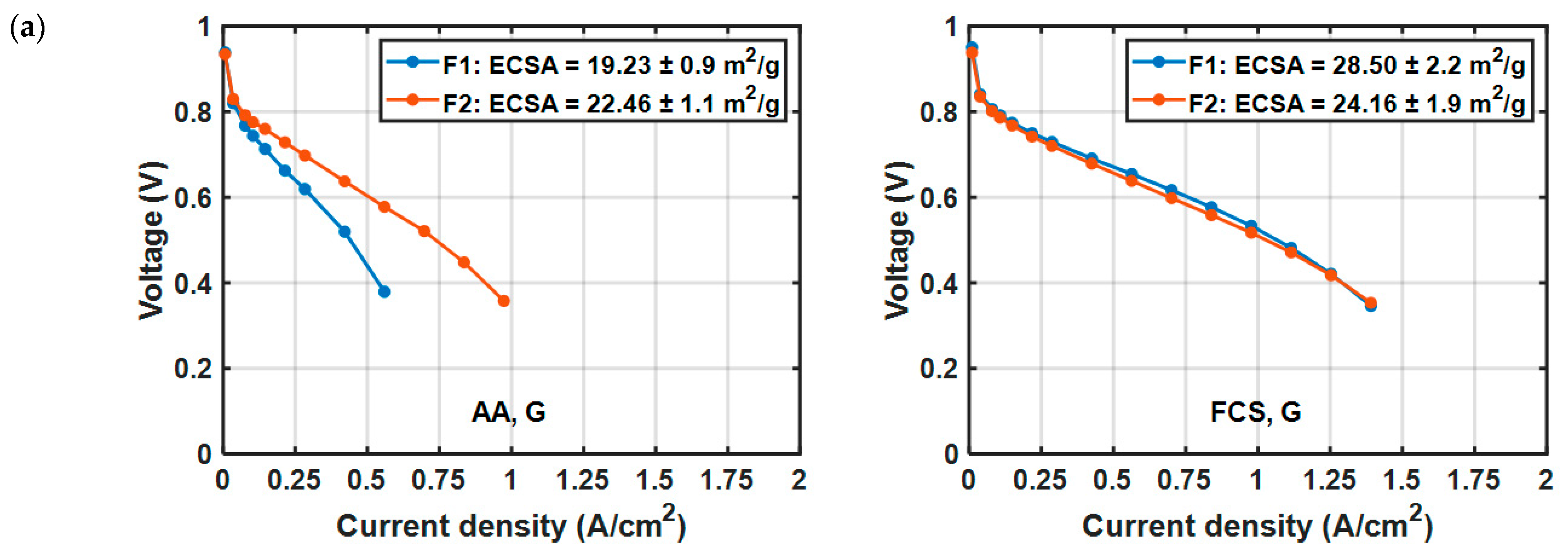

3.3. Ink Preparation Procedure According to Pt/C Origin

3.3.1. Setting Up the Method for Preparing Mixed Catalyst Inks

3.3.2. Comparison of the General and Mixed Methods According to the Pt/C Origin

4. Conclusions

- -

- The increase in the ionomer content in the catalyst ink increases the ionomer concentration on the Pt/C. With eight coating layers, CCM-23% offers the best performance with a high Pt mass activity. However, the CCMs prepared with 12 layers of coating are less sensitive to the ionomer content: CCM-13 and 33% show a similar performance and Pt mass activity.

- -

- The change in the ratio of water to isopropanol in the catalyst ink leads to a change in the porosity of the catalyst layer. Water-rich inks produce large pores in the catalyst layer, reducing the PEMFC performance.

- -

- The increase in Pt in the Pt/C catalyst powder leads to a thinner catalyst layer for a similar Pt loading. However, the performance in the PEMFC depends greatly on the nature of carbon.

- -

- The way in which a given ink is prepared also leads to a change in the structure of the catalyst layer, which can have a considerable impact on performance. For example:

- -

- The use of Ultra-Turrax can damage the ionomer properties, so it is preferable to add the ionomer after the mixing step with Ultra-Turrax.

- -

- Depending on the carbon nature, the use of Ultra-Turrax can improve or reduce the performance.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Staffell, I.; Scamman, D.; Velazquez Abad, A.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef]

- Liu, Q.; Lan, F.; Chen, J.; Zeng, C.; Wang, J. A review of proton exchange membrane fuel cell water management: Membrane electrode assembly. J. Power Sources 2022, 517, 230723. [Google Scholar] [CrossRef]

- Liu, C.-Y.; Sung, C.-C. A review of the performance and analysis of proton exchange membrane fuel cell membrane electrode assemblies. J. Power Sources 2012, 220, 348–353. [Google Scholar] [CrossRef]

- Nondudule, Z.; Chamier, J.; Chowdhury, M. Effect of Stratification of Cathode Catalyst Layers on Durability of Proton Exchange Membrane Fuel Cells. Energies 2021, 14, 2975. [Google Scholar] [CrossRef]

- Tang, H.; Wang, S.; Jiang, S.P.; Pan, M. A comparative study of CCM and hot-pressed MEAs for PEM fuel cells. J. Power Sources 2007, 170, 140–144. [Google Scholar] [CrossRef]

- Umap, V.M.; Ugwekar, R.P. Performance analysis of gas diffusion electrode with varying platinum loading under different oxidant condition. Renew. Energy 2020, 155, 1339–1346. [Google Scholar] [CrossRef]

- Shukla, S.; Domican, K.; Karan, K.; Bhattacharjee, S.; Secanell, M. Analysis of Low Platinum Loading Thin Polymer Electrolyte Fuel Cell Electrodes Prepared by Inkjet Printing. Electrochim. Acta 2015, 156, 289–300. [Google Scholar] [CrossRef]

- Moghaddam, R.B.; Easton, E.B. The interplay between impedance parameters, structure, and performance of fuel cell catalyst layers. Chem. Eng. Sci. 2020, 224, 115792. [Google Scholar] [CrossRef]

- Shahgaldi, S.; Alaefour, I.; Li, X. Impact of manufacturing processes on proton exchange membrane fuel cell performance. Appl. Energy 2018, 225, 1022–1032. [Google Scholar] [CrossRef]

- Lee, M.-R.; Lee, H.-Y.; Yim, S.-D.; Kim, C.-S.; Shul, Y.-G.; Kucernak, A.; Shin, D. Effects of Ionomer Carbon Ratio and Ionomer Dispersity on the Performance and Durability of MEAs. Fuel Cells 2018, 18, 129–136. [Google Scholar] [CrossRef]

- Fouzaï, I.; Gentil, S.; Bassetto, V.C.; Silva, W.O.; Maher, R.; Girault, H.H. Catalytic layer-membrane electrode assembly methods for optimum triple phase boundaries and fuel cell performances. J. Mater. Chem. A 2021, 9, 11096–11123. [Google Scholar] [CrossRef]

- Van Dao, D.; Adilbish, G.; Le, T.D.; Lee, I.-H.; Yu, Y.-T. Triple phase boundary and power density enhancement in PEMFCs of a Pt/C electrode with double catalyst layers. RSC Adv. 2019, 9, 15635–15641. [Google Scholar] [CrossRef]

- Suter, T.A.M.; Smith, K.; Hack, J.; Rasha, L.; Rana, Z.; Angel, G.M.A.; Shearing, P.R.; Miller, T.S.; Brett, D.J.L. Engineering Catalyst Layers for Next-Generation Polymer Electrolyte Fuel Cells: A Review of Design, Materials, and Methods. Adv. Energy Mater. 2021, 11, 2101025. [Google Scholar] [CrossRef]

- Rohendi, D.; Majlan, E.H.; Mohamad, A.B.; Wan Daud, W.R.; Hassan Kadhum, A.A.; Shyuan, L.K. Characterization of electrodes and performance tests on MEAs with varying platinum content and under various operational conditions. Int. J. Hydrogen Energy 2013, 38, 9431–9437. [Google Scholar] [CrossRef]

- Xie, M.; Chu, T.; Wang, T.; Wan, K.; Yang, D.; Li, B.; Ming, P.; Zhang, C. Preparation, Performance and Challenges of Catalyst Layer for Proton Exchange Membrane Fuel Cell. Membranes 2021, 11, 879. [Google Scholar] [CrossRef]

- Liu, H.; Ney, L.; Zamel, N.; Li, X. Effect of Catalyst Ink and Formation Process on the Multiscale Structure of Catalyst Layers in PEM Fuel Cells. Appl. Sci. 2022, 12, 3776. [Google Scholar] [CrossRef]

- Guo, Y.; Pan, F.; Chen, W.; Ding, Z.; Yang, D.; Li, B.; Ming, P.; Zhang, C. The Controllable Design of Catalyst Inks to Enhance PEMFC Performance: A Review. Electrochem. Energy Rev. 2021, 4, 67–100. [Google Scholar] [CrossRef]

- Chen, Y.; Zhong, Q.; Li, G.; Tian, T.; Tan, J.; Pan, M. Electrochemical study of temperature and Nafion effects on interface property for oxygen reduction reaction. Ionics 2018, 24, 3905–3914. [Google Scholar] [CrossRef]

- Wuttikid, K.; Shimpalee, S.; Weidner, J.W.; Punyawudho, K. Evaluation of Nafion with Various Pt–C Concentrations in Membrane Electrode Assemblies for PEMFCs. Fuel Cells 2017, 17, 643–651. [Google Scholar] [CrossRef]

- Huang, B.; He, Y.; Huang, Y.; Zhu, Y.; Zhang, Y.; Wang, Z. Effects of Nafion content in membrane electrode assembly on electrochemical Bunsen reaction in high electrolyte acidity. Int. J. Hydrogen Energy 2019, 44, 11646–11654. [Google Scholar] [CrossRef]

- Chen, G.-Y.; Wang, C.; Lei, Y.-J.; Zhang, J.; Mao, Z.; Mao, Z.-Q.; Guo, J.-W.; Li, J.; Ouyang, M. Gradient design of Pt/C ratio and Nafion content in cathode catalyst layer of PEMFCs. Int. J. Hydrogen Energy 2017, 42, 29960–29965. [Google Scholar] [CrossRef]

- Kim, K.-H.; Lee, K.-Y.; Kim, H.-J.; Cho, E.; Lee, S.-Y.; Lim, T.-H.; Yoon, S.P.; Hwang, I.C.; Jang, J.H. The effects of Nafion® ionomer content in PEMFC MEAs prepared by a catalyst-coated membrane (CCM) spraying method. Int. J. Hydrogen Energy 2010, 35, 2119–2126. [Google Scholar] [CrossRef]

- Sun, L.; Ran, R.; Wang, G.; Shao, Z. Fabrication and performance test of a catalyst-coated membrane from direct spray deposition. Solid State Ionics 2008, 179, 960–965. [Google Scholar] [CrossRef]

- Passos, R.R.; Paganin, V.A.; Ticianelli, E.A. Studies of the performance of PEM fuel cell cathodes with the catalyst layer directly applied on Nafion membranes. Electrochim. Acta 2006, 51, 5239–5245. [Google Scholar] [CrossRef]

- Huang, T.-H.; Shen, H.-L.; Jao, T.-C.; Weng, F.-B.; Su, A. Ultra-low Pt loading for proton exchange membrane fuel cells by catalyst coating technique with ultrasonic spray coating machine. Int. J. Hydrogen Energy 2012, 37, 13872–13879. [Google Scholar] [CrossRef]

- Qi, Z.; Kaufman, A. Low Pt loading high performance cathodes for PEM fuel cells. J. Power Sources 2003, 113, 37–43. [Google Scholar] [CrossRef]

- Cho, Y.-H.; Park, H.-S.; Cho, Y.-H.; Jung, D.-S.; Park, H.-Y.; Sung, Y.-E. Effect of platinum amount in carbon supported platinum catalyst on performance of polymer electrolyte membrane fuel cell. J. Power Sources 2007, 172, 89–93. [Google Scholar] [CrossRef]

- Kim, D.S.; Welch, C.; Hjelm, R.P.; Kim, Y.S.; Guiver, M.D. Polymers in Membrane Electrode Assemblies. Polym. Sci. A Compr. Ref. 2012, 10, 691–720. [Google Scholar] [CrossRef]

- Ngo, T.T.; Yu, T.L.; Lin, H.-L. Influence of the composition of isopropyl alcohol/water mixture solvents in catalyst ink solutions on proton exchange membrane fuel cell performance. J. Power Sources 2013, 225, 293–303. [Google Scholar] [CrossRef]

- Song, C.H.; Park, J.S. Effect of dispersion solvents in catalyst inks on the performance and durability of catalyst layers in proton exchange membrane fuel cells. Energies 2019, 12, 549. [Google Scholar] [CrossRef]

- Lei, C.; Yang, F.; Macauley, N.; Spinetta, M.; Purdy, G.; Jankovic, J.; Cullen, D.A.; More, K.L.; Kim, Y.S.; Xu, H. Impact of Catalyst Ink Dispersing Solvent on PEM Fuel Cell Performance and Durability. J. Electrochem. Soc. 2021, 168, 044517. [Google Scholar] [CrossRef]

- Kim, T.H.; Yi, J.Y.; Jung, C.Y.; Jeong, E.; Yi, S.C. Solvent effect on the Nafion agglomerate morphology in the catalyst layer of the proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2017, 42, 478–485. [Google Scholar] [CrossRef]

- Takahashi, S.; Mashio, T.; Horibe, N.; Akizuki, K.; Ohma, A. Analysis of the Microstructure Formation Process and Its Influence on the Performance of Polymer Electrolyte Fuel-Cell Catalyst Layers. ChemElectroChem 2015, 2, 1560–1567. [Google Scholar] [CrossRef]

- Wang, M.; Park, J.H.; Kabir, S.; Neyerlin, K.C.; Kariuki, N.N.; Lv, H.; Stamenkovic, V.R.; Myers, D.J.; Ulsh, M.; Mauger, S.A. Impact of Catalyst Ink Dispersing Methodology on Fuel Cell Performance Using in-Situ X-ray Scattering. ACS Appl. Energy Mater. 2019, 2, 6417–6427. [Google Scholar] [CrossRef]

- Yang, D.; Guo, Y.; Tang, H.; Wang, Y.; Yang, D.; Ming, P.; Zhang, C.; Li, B.; Zhu, S. Influence of the dispersion state of ionomer on the dispersion of catalyst ink and the construction of catalyst layer. Int. J. Hydrogen Energy 2021, 46, 33300–33313. [Google Scholar] [CrossRef]

- Turtayeva, Z.; Xu, F.; Dillet, J.; Mozet, K.; Peignier, R.; Celzard, A.; Maranzana, G. Manufacturing catalyst-coated membranes by ultrasonic spray deposition for PEMFC: Identification of key parameters and their impact on PEMFC performance. Int. J. Hydrogen Energy 2022, 47, 16165–16178. [Google Scholar] [CrossRef]

- Dillet, J.; Spernjak, D.; Lamibrac, A.; Maranzana, G.; Mukundan, R.; Fairweather, J.; Didierjean, S.; Borup, R.L.; Lottin, O. Impact of flow rates and electrode specifications on degradations during repeated startups and shutdowns in polymer-electrolyte membrane fuel cells. J. Power Sources 2014, 250, 68–79. [Google Scholar] [CrossRef]

- Lamibrac, A. Study of the Degradations Induced by Start-Up/Shut-Down Operations in PEMFC. Ph.D. Thesis, Université de Lorraine, Nancy, France, 2013. [Google Scholar]

- Touhami, S.; Mainka, J.; Dillet, J.; Taleb, S.A.H.; Lottin, O. Transmission Line Impedance Models Considering Oxygen Transport Limitations in Polymer Electrolyte Membrane Fuel Cells. J. Electrochem. Soc. 2019, 166, F1209–F1217. [Google Scholar] [CrossRef]

- Xue, Q.; Yang, D.-J.; Wang, J.; Li, B.; Ming, P.-W.; Zhang, C.-M. Enhanced mass transfer and proton conduction of cathode catalyst layer for proton exchange membrane fuel cell through filling polyhedral oligomeric silsesquioxane. J. Power Sources 2021, 487, 229413. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, R.; Yang, D.; Li, B.; Ming, P.; Zhang, C. Effect of ionomer content on cathode catalyst layer for PEMFC via molecular dynamics simulations and experiments. Int. J. Hydrog. Energy 2022, 47, 23335–23347. [Google Scholar] [CrossRef]

- Sassin, M.B.; Garsany, Y.; Atkinson, R.W.; Hjelm, R.M.E.; Swider-Lyons, K.E. Understanding the interplay between cathode catalyst layer porosity and thickness on transport limitations en route to high-performance PEMFCs. Int. J. Hydrogen Energy 2019, 44, 16944–16955. [Google Scholar] [CrossRef]

- Mauritz, K.A.; Moore, R.B. State of understanding of Nafion. Chem. Rev. 2004, 104, 4535–4585. [Google Scholar] [CrossRef]

- Kusoglu, A.; Weber, A.Z. New Insights into Perfluorinated Sulfonic-Acid Ionomers. Chem. Rev. 2017, 117, 987–1104. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.T.; Yu, T.L.; Lin, H.L. Nafion-based membrane electrode assemblies prepared from catalyst inks containing alcohol/water solvent mixtures. J. Power Sources 2013, 238, 1–10. [Google Scholar] [CrossRef]

| Ionomer (wt.%) | Pt wt. (%) in Pt/C | Solvent (H2O:IPA) | Preparation Mode | |

|---|---|---|---|---|

| 1 | 13 | 40 | 1:2 | General |

| 23 | ||||

| 33 | ||||

| 2 | 33 | 40 | 1:2 | General |

| 2:1 | ||||

| 3 | 33 | 20 | 1:2 | General |

| 40 | ||||

| 4 | 33 | 40 (FCS) | 1:2 | General |

| Mixed | ||||

| 40 (AA) | General | |||

| Mixed |

| Nafion® Ionomer (wt.%) | LPt (mg cm−2) | |

|---|---|---|

| 8 Layers | 12 Layers | |

| 13 wt.% | 0.24 ± 0.01 | 0.36 ± 0.01 |

| 23 wt.% | 0.23 ± 0.01 | - |

| 33 wt.% | 0.25 ± 0.02 | 0.37 ± 0.02 |

| 20% Pt/C | 40% Pt/C | |||

|---|---|---|---|---|

| Number of Coating Layers | 24 | 12 | ||

| Name of catalyst | FCS 20% Pt/C-Vulcan XC-72R (2019) | FCS 20% Pt/C-Black (2020) | FCS 40% Pt/C-Vulcan XC-72R (2019) | FCS 40% Pt/C-Black (2020) |

| mPt (mg cm−2) | 0.33 ± 0.02 | 0.45 ± 0.03 | 0.34 ± 0.01 | 0.37 ± 0.01 |

| mC (mg cm−2) | 1.32 ± 0.02 | 1.8 ± 0.03 | 0.51 ± 0.01 | 0.55 ± 0.01 |

| Ink Preparation Method | Pt Loading (mg cm−2) | |

|---|---|---|

| AA 40% Pt/C (2021) | FCS 40% Pt/C-Vulcan XC-72R (2021) | |

| General | 0.35 ± 0.02 | 0.32 ± 0.03 |

| Mixed | 0.32 ± 0.003 | 0.33 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turtayeva, Z.; Xu, F.; Dillet, J.; Mozet, K.; Peignier, R.; Celzard, A.; Maranzana, G. The Influence of Ink Formulation and Preparation on the Performance of Proton-Exchange Membrane Fuel Cell. Energies 2023, 16, 7519. https://doi.org/10.3390/en16227519

Turtayeva Z, Xu F, Dillet J, Mozet K, Peignier R, Celzard A, Maranzana G. The Influence of Ink Formulation and Preparation on the Performance of Proton-Exchange Membrane Fuel Cell. Energies. 2023; 16(22):7519. https://doi.org/10.3390/en16227519

Chicago/Turabian StyleTurtayeva, Zarina, Feina Xu, Jérôme Dillet, Kévin Mozet, Régis Peignier, Alain Celzard, and Gaël Maranzana. 2023. "The Influence of Ink Formulation and Preparation on the Performance of Proton-Exchange Membrane Fuel Cell" Energies 16, no. 22: 7519. https://doi.org/10.3390/en16227519

APA StyleTurtayeva, Z., Xu, F., Dillet, J., Mozet, K., Peignier, R., Celzard, A., & Maranzana, G. (2023). The Influence of Ink Formulation and Preparation on the Performance of Proton-Exchange Membrane Fuel Cell. Energies, 16(22), 7519. https://doi.org/10.3390/en16227519