Abstract

The role of hydrogen as a clean energy source is a promising but also a contentious issue. The global energy production is currently characterized by an unprecedented shift to renewable energy sources (RES) and their technologies. However, the local and environmental benefits of such RES-based technologies show a wide variety of technological maturity, with a common mismatch to local RES stocks and actual utilization levels of RES exploitation. In this literature review, the collected documents taken from the Scopus database using relevant keywords have been organized in homogeneous clusters, and are accompanied by the registration of the relevant studies in the form of one figure and one table. In the second part of this review, selected representations of typical hydrogen energy system (HES) installations in realistic in-field applications have been developed. Finally, the main concerns, challenges and future prospects of HES against a multi-parametric level of contributing determinants have been critically approached and creatively discussed. In addition, key aspects and considerations of the HES-RES convergence are concluded.

1. Introduction

Globally, the development of economic activities is associated with a great interest in energy-consuming services and the subsequent increase of fuel consumption. However, this fuel demand is commonly followed by high and unregulated carbon dioxide emission, which is the main source generator of the greenhouse gas (GHG) effect. Fossil fuels (mainly in the forms of petroleum, natural gas and coal) are experiencing accelerated consumption and stock depletion, despite meeting today’s global energy demand. Such combustion products are the main contributors to environmental problems and uncontrollable climate changes, thus threatening the global environmental safety and sustainability. Among feasible and realistic solutions to these global problems are those which have been proposed by engineers and scientists who agree to replace the existing fossil-fueled energy systems by the hydrogen energy system (HES). Subsequently, hydrogen can be fed to fuel energy-consuming services in order to improve energy security and simultaneously control the GHG effect [1,2,3]. A plausible hydrogen energy system, which includes its resources, production technologies, storage, fuel-tank, dispensing and utilization, can be primarily analyzed for urban services, but it remains underdeveloped or sparsely studied in alignment with the renewable energy sources (RES). Hydrogen can be characterized as an efficient and clean fuel. Technological advantages are that the hydrogen combustion is neither a GHG producer nor a generator of ozone-layer-depleting chemicals. Moreover, hydrogen combustion does not generate acid rain ingredients or air pollution. It is also noteworthy that hydrogen produced from RES can develop a stable and permanent energy system that is never subject to future changes or modular modifications.

In the following sections of this literature review, a classification of HES-collected studies was developed into five fields (Section 2), followed by a critical overview of the operation characteristics and the technological synergies developed between HES and RES (Section 3). Moreover, the main key aspects, considerations and future prospects of HES and RES convergence are discussed in the Conclusions section (Section 4).

2. Methods and Analysis

Clusters of Hydrogen Energy Systems (HES) and Renewable Energy Sources (RES)

While in the global literature there is a large number of studies focused on HES and RES, the convergence fields of HES and RES have been sparsely investigated or scientifically framed. In response to this research topic, an extensive literature review on both the key phrases HES and RES was undertaken in the first half of the year 2023, in the Scopus database. The historical time of publication dates back to the year 2008 onwards. Then, the collected studies were grouped into the following fields of classification: (a) simulation tests, (b) optimization models and mathematical analyses, (c) experimental pilot industrial and in-field processes including electrolyzer utilities, (d) literature reviews and publication taxonomies of HES, and (e) convergence topics of photovoltaic and hydrogen energy systems. The studies contained in these clusters were grouped and represented in the form of Table 1, following the classifications of (a), (b), (c), (d), and (e). These were collectively represented only in terms of the referencing/citing data collected from a reverse chronological order of publication, without an explanatory text of each one citation listed, due to high conceptual dispersal and heterogeneity of the collected citations. In cases where there arose common fields of classification overlapping among the five determined groups, then the relevant citation was positioned with the classification of the closest conceptual or operation affinity compared to the others. In such a way, all five classifications are presented as follows:

Table 1.

Classifications a, b, c, d, and e: HES and RES overview in the classification/cluster of: (a) “simulation tests”, (b) “optimization models and mathematical analyses”, (c) experimental pilot industrial and in-field processes including the electrolyzer utilities, (d) literature reviews and publication taxonomies of HES, and (e) convergence topics of photovoltaic and hydrogen energy systems.

According to the literature search outcomes, as presented in Table 1 above, the total number of citations collected for all five clusters is 66, which was further allocated per each cluster in absolute and percentage numbers, as it is shown in column 3, above. This percentage numbering revealed the research focus of a cluster topic compared to the other four. Similarly, the absolute number of citations revealed the least- and most-reported clustering topics, showing that cluster e has the lowest number of citations and cluster c has the most literature studied in the field. Therefore, taking “1” as the number of citations (4 citations) for the least-reported cluster 1, then a calculation of “intensity rations” (column 4 of Table 1) enabled the quantification of the relevant research dynamics for each cluster in terms of the citations collected for each cluster. Indeed, based on the aforesaid clustering of the collected citations, it can be concluded that the order of literature interest and research focus was observed as follows (in descending order):

Clusters: c > b > d > a > e, implying that there are also two subtle peaks in research interests, coupled in the following way:

Cluster c, similar to b, followed by cluster d, similar to a. Taking into consideration the above findings, the most popular fields of HES-RES investigation can be denoted as that of experimental–pilot industrial and in-field processes, including the electrolyzer utilities, together with analyses focused on optimization (including mathematical) models. The second most popular group/pair of fields of HES-RES investigation is that of literature reviews and publication taxonomies of HES, together with the cluster of simulation tests. However, there is little literature interest demonstrated for the convergence topics of PVs and HES. However, the aforementioned argument is not bold and affirmative, since research into “channeling and diffusion” has been reported among the five selected clusters, but the critical point here is that all observable and traceable literature production of HES-RES can be categorized with certainty and taxonomized into one of the aforementioned five clusters proposed.

Based on the descriptive statistics of Table 1 and taking as the basis of comparison the lowest number of references (four references in total were reported in class e), five intensity ratios were calculated (in the right-hand column of Table 1) in order to arrive at some remarks and draw important conclusions that are hidden when first confronting these clusters which developed. Indeed, based on the intensity ratios, it can be further inferred that the clusters a (2.75) and d (3.00) refer predominately to approaches of bridging HES and RES, which, between them, have almost equal intensity scores. However, the most attractive cluster c (5.25), which is that of “experimental, pilot, industrial and in-field processes” is of particular interest among researchers, mainly due to its practical utility and problem-solving orientation compared to the other four clusters. This said, it cannot be ignored that insightful remarks and novel knowledge are also disclosed in the more “theoretically oriented” clusters. Therefore, a synergistic and balanced—rather than an antagonistic or detached/mutually autonomous—approach to both the practical and theoretical clusters is realistic, plausible and recommended.

3. Results and Discussion

3.1. Results of the Bibliometric Analysis

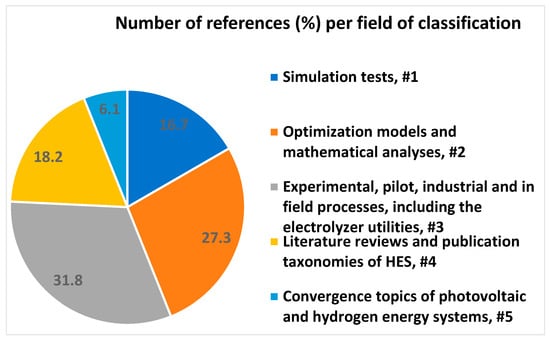

Based on the information collected and classified in this literature review, from Table 1 above, the quantitative information and the relative strength of the five corresponding derived clusters are presented in Figure 1.

Figure 1.

The reference allocation profile for each cluster developed. Source: Authors’ own study.

Based on Figure 1, it can be argued that the clusters b and c, “optimization models and mathematical analyses” and “experimental, pilot, industrial and in-field processes” attract the research interest of almost 60% of the total references linking HES and RES. This result is not surprising since the primary role of HES and RES convergence is to establish practical and problem-solving priorities rather than the rather theoretical attribution of the other three clusters a, d, and e.

The research target and the novelty of this literature review is to reveal the research focus on HES publications regarding the contribution of RES technologies. Such studies of HES-powered technology illustrated the increasing importance of hydrogen in contemporary energy power systems, following the adoption of selected technological procedures and those energy-planning criteria for screening the yearly evolution of publications. Such publications investigated different hydrogen power-system applications within the last three decades, as well as the percentage distribution, as shown in Figure 1.

Based on these research studies, it is noteworthy that research into HES-RES contains energy-storage information in terms of storage materials and tanks, as well as an operational/system overview. The key aspects of energy storage in c pointed to an increasing trend in research effort, due to a high level of interest, owing to the rapid development of material engineering, followed by studies on HES for transportation. Less research activity has been focused on applications of power-to-gas and co- and tri-generation, though these are rapidly emerging fields for advantageous research activities in the coming future [58].

Another critical finding of this literature review is the time evolution of research studies regarding the different and multifaceted HES-RES contexts. In particular, the searched findings included issues of cost, efficiency, durability, feasibility and effectiveness of mature technologies or fast-developing HES with scalability caliber. While research on techno-economic and efficiency interest has attracted the most interest in HES, other fields of investigation are those of durability and lifetime infrastructure. This research emphasis has developed especially in the last two decades of research. A challenging topic for future technological orientation is the durability of powered HES, but it still falls behind in reaching the satisfactory level/full scale of diagnostic, prognostic and fault-tolerant control functioning [58].

3.2. Overview of Selected Hydrogen Applications

3.2.1. HES–RES in Practice

When approaching the technologies involved in hydrogen production from RES, besides the apparent environmental advantages of a highly efficient and clean fuel (no GHG contributor, no chemicals causing ozone depletion), it cannot be ignored that the RES technologies (e.g., solar, wind) are leading to permanent and fixed energy systems that cannot later change to include other RES types which we are interested in [70]. In this context, the results of the review developed above are suitable and significant for a wide spectrum of literature-oriented approaches toward RES utility among various HES. Among these, the electrifying transportation sector, which is a promising approach to alleviating climate change issues arising from increased emissions, is noteworthy [71]. In this study, the examined HES can produce hydrogen, using RES, for the transportation sector (in buses). In this case, the electricity demanded for hydrogen production is harvested from the electrolysis of water, covered by RES. Moreover, fuel cells can use hydrogen to power the bus, while an HES exergy analysis referred to a steady-state model of the processes for which exergy efficiencies were calculated for all subsystems. Therefore, those subsystems showing the highest proportion of irreversibility were identified and compared. An exergetic efficiency of 12.74% for the PV panel, 45% for the wind turbine, 67% for the electrolysis, and 40% for the fuel cells was reported [71].

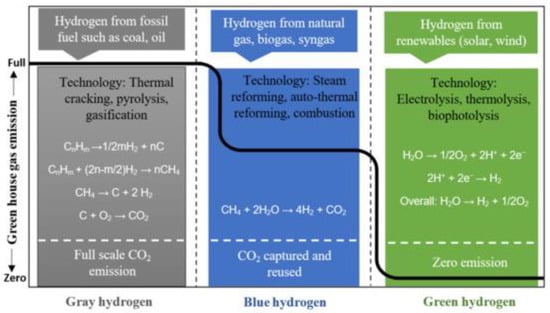

Depending on the production process and the selected (energy planning-based) energy source, the obtained hydrogen can be classified as grey, blue, or green, as shown in Figure 2.

Figure 2.

Outline of hydrogen-based feedstocks and technologies. Source: Sarker et al. [72].

As shown in Figure 2, the grey-hydrogen type is hydrogen produced from steam methane reforming and thermal cracking [72]. As is also shown in Figure 2, the main CO2 production is reported through methane steam reforming, which can be further collected and stored safely in containers in the form of CO2 vapors. Natural gas, biogas, and syngas can also produce hydrogen that is categorized as blue hydrogen, where the CO2 gases formed cannot be stored, and will be released into the atmosphere. Blue hydrogen, which is produced from natural gas, unlike grey hydrogen, is capable of significantly reducing CO2 emissions and simultaneously capturing and reusing carbon. As observed in Figure 2, both grey- and blue-hydrogen production processes generate CO2 as the by-product, but in the case of green-hydrogen production technologies, zero carbon emissions are also apparent. While solar and wind technologies have been utilized to produce green hydrogen, there are other catalytic-reforming technologies of sound capability for producing green hydrogen. Among them, biomass gasification and nuclear thermal/chemical pathways can potentially reduce carbon emissions. Because of this, major challenges such as production technology costs, system durability, reliability, infrastructure, and safety are issues of consideration [72]. It is roughly estimated from the life-cycle assessment that hydrogen production through biomass gasification contributes less GHG emission (405–896.61 g CO2/kg H2) compared to wind-driven electrolysis (600–970 g CO2/kg H2) [72]. However, biomass gasification has not been scaled up so far, and thus it can be expected that its input into global energy production will help to attain its full potential in the near future [72]. Furthermore, higher moisture content, low hydrogen production, and high operating costs are major constraints associated with biomass gasification. On the other hand, the solar- and wind-powered electrolysis techniques were proven to be well-established renewable sources for producing hydrogen through electrolysis [72].

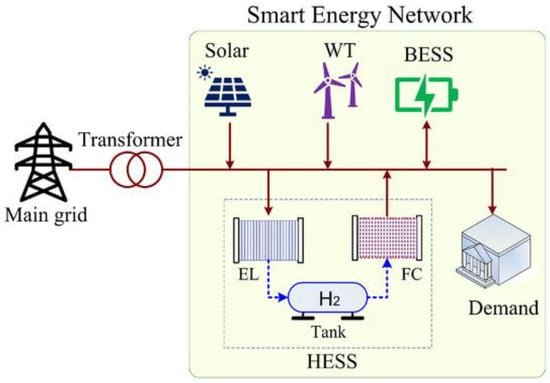

The schematic of the solar–hydrogen hybrid storage system (HESS) for the case study of a house is given in Figure 3. The experimental structure of such an analysis considers a house which is remote from the national power grid with a meteorological solar/wind measurement tower in order to collect data used in the relevant case study. The meteorological measurement system can collect 10 min of data for average solar irradiance, solar duration, wind speed and direction, air temperature and pressure and also relative humidity. The desired characteristics of such an installation are devoted to providing uninterrupted power to houses at any time of the year through the suitable solar-HES.

Figure 3.

A schematic of a typical domestic solar–hydrogen hybrid energy system. Source: Samende et al. [73].

A diagrammatic structure of a wind–hydrogen energy system, with its elements and some of their characteristics and relationships, are all shown in Figure 3. The projected HESS can transform the energy into a storable product, hydrogen [32]. This transformation process uses water electrolysis and the compression of hydrogen for storing. A technical limitation of the hydrogen tank is its finite capacity. Moreover, the latest transformation process is reforming hydrogen into ready-to-be distributed and sold energy. The pricing of energy selling is related to the energy-storage system through which energy can be sold when prices rise due to a demand increase [32]. Apart from the concurring energy losses due to inefficiencies in the processes of transformation and recovery, there is also the limitation of the cost of the hydrogen equipment required. The extreme fluctuations reported for energy prices depend on whether (or not) the amount to be sold has been pre-committed (the day before). In the case of the price of pre-commitment, this is a higher value, but if the agreed amount is ultimately not supplied, then a penalty is paid. When more than the agreed amount is supplied, then the surplus has a lower price [32].

Besides the aforementioned constraint of finite storage of the hydrogen tank, other operational constraints of different system elements are the existence of a maximum capacity for transforming the energy into hydrogen, as well as a finite power limit, that is, a maximum amount of energy that can be dumped into the grid (and then sold) for each time unit. Another limitation is the inefficiency in the processes of transformation and recovery, since for these processes energy output is less than energy input [32]. Because of this, modelling optimization is needed to determine the proper hydrogen storage capacity for the system’s optimization. When selecting from among different tank-size situations, it is noteworthy that storage tank capacity (a) is needed to transform the energy curve into a constant curve through time, and (b) is needed for storage of energy that has been produced above the power limit to dump it into the network again when the production is below the power limit [32].

For an HESS, the simulation design is a key factor, taking into consideration also the constraint of missing data for continuous yearly consumption measurements, whereas measurements are subject to daily and seasonal variations of power consumption in houses. Indeed, energy consumption decreases, since the households are at sleep from sunset and midnight and up until the next morning, where the fuel cell stack is the only available power source in the hybrid system. Regarding seasonal variation, higher energy consumption is reported in winter (the most in-house occupation) than in summer [73]. Regarding the HESS, it is noted that the hydrogen amount in the storage tank decreases from November to February, followed by an increase from March to May, thus shaping repeating hydrogen cycles (second-year cycles) with an arrangement of solar panels and some decades of the cubic meters of storage tanks given. Between June and October there is a full storage tank of hydrogen, showing very little oscillations around the full capacity. Therefore, the decrease and increase in the hydrogen in the storage tank occurs at fewer times of the year, and the hydrogen storage tank stays at almost full capacity for more time of the year. Moreover, changing the volume of the storage tank, therefore, means that the hydrogen cycle in the storage tank changes even though all the other HESS components are kept as they are [73]. The most critical specifications of storage tanks are those of weight, volume, and cost of the cryogenic or high-pressure tanks. Furthermore, the energy efficiency of compressing or liquefying the hydrogen can be also considered. It is also important to signify those pressure tank specifications in future designs which are oriented for concrete/modular applications [70].

From a generalized perspective, the findings of this literature review revealed an imperative need for advances in integrating hydrogen into power systems to be gradually approached in a synergistic way over recent years, ranging from production and storage to re-electrification and safety issues [58]. Therefore, while extensive descriptions of the existing progress can be the research focus of other studies, this literature review reported the need to seek to characterize the current progress in HES-RES integration through novel methods.

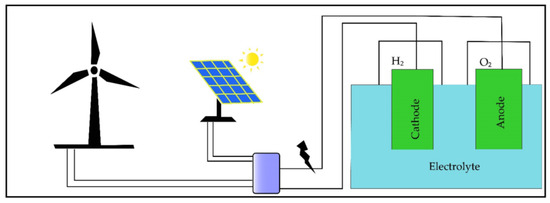

3.2.2. HES and Electrolyzer Efficiency

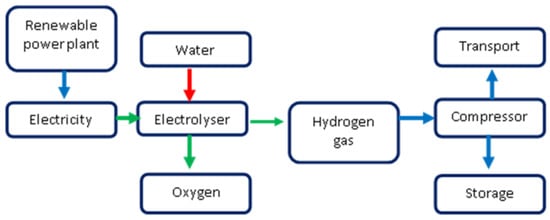

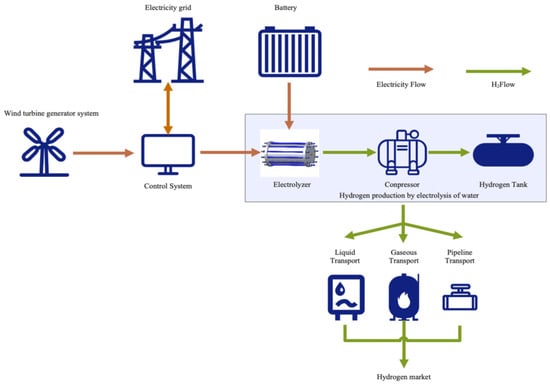

In the relevant literature [49], the general process that researchers follow in order to understand in a comprehensive way the effects of the space between the two electrodes on the rate of hydrogen production, among the different gaps examined, was demonstrated. Loss in mass increase is observed with voltage increase, under the condition of a constant space between the two electrodes. The resulting increase in the percentage mass lost due to the increase in the voltage is attributed to the increase in electrical current. During relevant experimental tests, the pair of electrodes can be exposed to a PV generator with low voltages of 2–5 V. When testing different concentrations of electrolyte solution, then, the percentage water mass lost during a specified time is measurable and the corresponding electrolyzer efficiency is calculated using the mass ratio of the hydrogen in a single molar mass of water [49]. Subsequently, voltage input and the gap between the electrodes play a determining role in the overall performance of the water electrolysis unit. Higher hydrogen production rates are achievable at a closer space between the electrodes, as well as at higher voltage input. Maximum electrolyzer efficiency is realistic for a smaller gap between electrodes, coupled with a specified input voltage value within the designed range [49]. A decrease in space between the pair of electrodes results in lowering the percentage of water mass loss, which increases due to the resulting decrease in electrical resistance between the electrodes, and thus leads to an increase in the electrical current. Hydrogen production rate increase, and thus energy efficiency increase, is due to the decrease in the space between the electrodes (small gaps between the pair of electrodes) being noticeable at higher degrees of input voltage, up to a specified input voltage; then, efficiency decreases by the further increase in the input voltage [49]. Figure 4 illustrates the schematic flow chart for hydrogen production. In the first stage, the electricity is generated from a hybrid renewable source (that is, a combination of wind turbine and solar PV), and then an electrolyzer is used in the second stage. In the electrolyzer, water is split into hydrogen gas as the principal product, while oxygen gas is released and generated as a by-product. Subsequently, hydrogen gas is passed through a compressor for storage purposes. Such compressed hydrogen can be transported in order to be utilized for commercial purposes. In operational terms, an electricity shortfall of hybrid solar and wind electricity is certainly affected by the electrolyzer-produced green hydrogen.

Figure 4.

An overview of RES-based hydrogen hybrid system. Source: Sarker et al. [72].

As depicted in Figure 4, above, the RES-based hydrogen hybrid system, which in the literature is referred to also as a hybrid renewable energy system (HRES), has proven a feasible solution to address the issues related to individual energy sources [72]. Usually, a typical hybrid green-energy system uses various RES, such as wind and solar, as shown in Figure 5.

Figure 5.

Hydrogen production from hybrid energy-based electrolysis. Source: Sarker et al. [72].

The benefits of HRES rely on multiple RES that are able to supply consistent and uninterruptible energy. Therefore, this energy availability will compensate for the unreliability of single renewable-energy sources and reduce GHG emissions [72]. It is also noteworthy that such systems are mainly located very close to the place of demand, thus lowering the possibility of damage to the transmission wire, and supporting also a prompt access to repair and maintenance when needed. Moreover, the fact that GHG emission is the main contributor to global warming is also concerning; thus, low, or zero, emissions achieved from RES technologies is a promising solution, making of utmost importance the priority for the utilization of those reliable renewable-energy generation systems as the best solutions for research projects worldwide [72].

Given specific configurations of electrolyzers and kW power input, the performance of electrolyzers can be subjected to computer tools that support their management by optimizing their efficiency. Since maximum capacity and an efficiency curve can be supported by the electrolyzer, it is observable that at lower than 25% of nominal power, the system cannot be working or in operation [32]. Generalizing, the higher hydrogen–electricity conversion efficiency is feasible while replacing the internal combustion engine with a fuel cell, but also leads to an equally costly system [72].

3.2.3. Hybrid HES-RES Aspects

Hence, hydrogen storage systems should incorporate more compact, more robust and less-costly fuel cell systems, being installed before wind/hydrogen systems. Additionally, multiple-energy-fed hybrid system solutions—such as wind, solar, and bioenergy—should be selected according to the spatial RES characteristics of each location. Moreover, HES and RES projects should be designed in alignment with “green” incentives, green certificates, and CO2 tax-free policies. Other economics incentives are the fluctuation in oil and gas prices, the capital monetization of green energy infrastructure and the energy supply security. These factors justify the construction and motivate the development of a full-scale demonstration system (such as the wind/hydrogen plant at Utsira). In this case, such types of demonstrations can plausibly promote public awareness and acceptance, improving RES cost competitiveness, and regulating the new energy-market barriers and the enablers of new technological solutions (in general) and hydrogen technology (in particular) [72].

A typical integrated modular representation of widely used hydrogen-based hybrid systems is depicted in Figure 6.

Figure 6.

Schematic flow chart of a wind/hydrogen plant. Source: Niu et al. [74].

The system integrates various elements, including renewable energy generation, power storage, hydrogen production, and hydrogen transportation (Figure 5). The electricity generated by a wind turbine can be directly supplied to the power grid or stored in batteries for future use, optimized by the control system. Another fraction of the electricity is utilized in an electrolyzer device, which separates water (H2O) into hydrogen gas (H2) and oxygen gas (O2). The generated hydrogen gas is then compressed and stored in hydrogen tanks for further transportation and utilization [74]. In this process, the electrolyzer, compressor, and hydrogen tanks are essential components for hydrogen production through water electrolysis. Hydrogen gas can be transported to various demand points, being accessible to the hydrogen market through various methods, such as liquid transportation, gas transportation, or pipeline transportation. Liquid transportation is suitable for long-distance transport, while gas and pipeline transportation are commonly used for short-distance distribution. In this context, the term “Electricity Flow” (Figure 6) refers to the movement of electricity from the wind turbine through the control system to the power grid, batteries, and electrolyzer. Similarly, the term “H2 Flow” (Figure 6) represents the process of hydrogen gas being produced by the electrolyzer, compressed, stored, and ultimately transported to the hydrogen market [74].

Based on the configuration of Figure 6, it can be seen that the PV operating voltage and current determine the power output of the PV array and depend on the insolation on the PV module, the ambient temperature, and the manufacture characteristics of the PV module. Such a successful operation system for the wind turbine unit depends on several climatic and technical factors, such as wind speed and the rated cut-out and cut-in speeds (in m/s) for the wind turbine [26]. From a design perspective, the optimal design for off-grid hybrid renewable systems based on solar and wind energy to continuously meet the load necessitates a consideration of the LPSP (loss of power supply probability) and minimizing of the TLCC (total life-cycle cost), subject to constraints. The optimization algorithm is the most determining factor that can be efficiently used for this type of designed hybrid energy system. In particular, at low LPSP values (0–5%), the combination of a hydrogen and photovoltaic (PV) scheme with weather forecasting data leads to the most cost-effective system, and at LPSP = 10% the combination of wind, PV and a hydrogen scheme is proven to be the most cost-effective hybrid system [26].

In a similar optimization study of a stand-alone renewable H2-based microgrid, its optimal sizing requires a reliable load demand to satisfy, by means of local renewable energy supported by a hybrid battery/hydrogen storage unit, the minimization of the system costs. A crucial factor is the price reduction, due to the installation and operation of a high number of components. In similar studies, the development and application of a mixed-integer linear programming technique (MILP) optimization framework to an off-grid village in Italy was reported, which is a typical insular case study of the Mediterranean area [21]. To model the seasonal storage, a year-long time horizon was considered necessary for off-grid areas in order to achieve energy independence by relying on local RES. The degradation costs of batteries and H2-based devices were included in the objective function of the optimization problem, such as the annual cost of the system. Efficiency and investment-cost curves were considered for the electrolyzer and fuel cell components, while the design optimization was also performed while employing a general demand response program (DRP) to assess the sizing effects on the whole performance. It is also noteworthy that there is a reduction in the electricity generation cost, depending on the load amounts that are allowed to participate in the DRP scheme. In this context, a decreased capacity of the battery storage system is associated with the cost reduction in the system [21]. The MILP optimization framework allowed the identification of a cheap system configuration but, due to the larger number of decision variables, intensive computational resources are required for the resolution of the MILP problem. In electricity tariffs, the reliance on local renewables, coupled with batteries and hydrogen, was found to be economically more competitive than the current diesel-based power system. Thus, a levelized cost of energy of around 0.455 EUR/kWh can be computed using the MILP methodology for the renewable hydrogen-battery system. Such a hydrogen storage system is necessary in the optimal hybrid renewable energy system (HRES) configuration, due to its cost-effective long-term capability that can reduce the required battery capacity and lead to a better exploitation of the local RES [21].

3.2.4. HES-RES and Safety Aspects

In HES, hydrogen is an intermediary or secondary form of energy or an energy carrier. Hydrogen complements the primary energy sources, putting them into a convenient form accessible to the desired locations and at times convenient for consumers. Hydrogen can be stored underground in ex-mines, caverns and/or aquifers, which is of utmost importance for large-scale storage cases. The main safety aspects of the HES operation refer to hydrogen re-electrification. Indeed, hydrogen re-electrification refers to electricity generation from hydrogen. Through combustion, hydrogen can be re-electrified. Some combustion engines or turbines can run directly on hydrogen, similarly to internal combustion engines running on gasoline. Nevertheless, comparing the efficiencies of hydrogen and gasoline combustion engines, the former performed less efficiently than the latter, having a thermodynamic efficiency of around 20–25%, since hydrogen has a relatively low volumetric energy density. Moreover, while no CO2 is released, through hydrogen combustion NOx are emitted. The fuel cell-fed engines can be proven advantageous for hydrogen, as fuel cells convert the hydrogen chemical energy directly into electrical energy, achieving almost 60–80% efficiency, having as a byproduct only water [58]. The wide commercial applicability of fuel cells in various stationary and transportation applications can be stressed [58].

The exact procedure is the following: hydrogen transportation is occurs through pipelines or super tankers, making it directly disposable to energy consumption centers. Subsequently, specific applications regarding the electricity and transportation, and industrial, residential and commercial uses such as a fuel and/or an energy carrier, take place. Regarding the water production, recycling of water and water vapor follows when these effluents are disposed through rain, rivers, lakes and oceans, making up for the water used in the first place to manufacture hydrogen [70]. Similarly, the industrial plant produces oxygen that can be either released into the atmosphere, or shipped or piped to industrial and city centers for use in fuel cells (instead of air) for electricity generation. Rejuvenating the polluted rivers and lakes, or speeding up sewage treatment are similar beneficial non-energy uses of the produced oxygen [70].

Regarding the safety aspects of hydrogen, these involve its toxicity on one hand and its fire hazard properties on the other. In relation to this, regarding the toxicity of hydrogen combustion products, the toxicity increases as the carbon-to-hydrogen ratio increases. For instance, hydrogen and its main combustion product, water or water vapor, are not toxic, but NOx, which can be produced through the flame combustion of hydrogen (also reported in fossil fuel combustion) displays toxic effects [70]. In general, higher specific heat causes a gaseous fuel to be safer, since it slows down the temperature increases for a given heat input. Wider ignition limits, lower ignition energies, and lower ignition temperatures make gaseous fuels less safe, as they increase the limits at which a fire could commence. Higher flame temperature, higher explosion energy, and higher flame emissivity all make gaseous fuels less safe as well, due to the damaging fire consequences [70]. Extra safety concerns and provisions have to be prioritized in the design of in-site plants such as the Utsira plant [75]. However, it is also noteworthy that a serious accident could occur in such a high-profile demonstration project, which would be particularly detrimental to the development of hydrogen as an energy carrier. Another critical issue, similar to the Utsira plant, is that it is possible to contain explosive zones and advanced equipment which regularly receive many unskilled visitors. Because of this, safety measures have to be prioritized, in alignment with the proper training of operators and other personnel and the provision of good working instructions for all parts of the system, together with clear distribution and instructions of responsibility all over the site [75].

3.2.5. HES-RES and Techno-Economic Aspects

As hydrogen can be further used in internal combustion engines that are designed similarly to traditional combustion engines, it can be pointed out that both the mature industry and the vast availability of production infrastructure regarding internal combustion engines are making hydrogen internal combustion engines economically attractive. Moreover, unlike fuel cell vehicles, these types of vehicles do not rely on materials that may limit their large-scale production [63]. These engines support different characteristics, such as traditional gasoline engines that utilize electronic control units for the proper pressure management in the injection and in the hydrogen combustor. In addition, these engines mainly emit nitrogen mixtures, and thus they are not emission free [63].

In economic terms, the increase in pressure in the hydrogen storage from 200 bar to 450 bar, or even 700 bar, would increase the overall energy density of the hydrogen storage, thus making it possible to store more wind energy on the same footprint. However, high-pressure hydrogen storage systems are likely to be more costly than low-pressure systems, both from an investment and an operational point of view. It is noteworthy that investment cost increase is mainly linked to the installment of stronger storage tanks (thicker steel walls and/or use of composite materials), while operational cost increase is mainly linked to the increase in energy consumption for hydrogen compression [75]. It is also likely that extra costs associated with the required safety system concur, being dependent on the type of system installed. because of this, two basic techniques for high-pressure hydrogen gas production are: (a) low-pressure electrolysis, with a long compression stage, or (b) high-pressure electrolysis without compression [75].

While the majority of research studies have been focused on the HES-RES coordination, it is noteworthy that there are also reported RES studies, other than those of solar- and wind-energy infrastructure for hydrogen production. Among these studies, wastewater was characterized as an issue of general concern for environmental sustainability, making the development of a circular low-waste economy a necessity. In this context, lignocellulosic biomass processing (mainly hydrolysis, pyrolysis, and hydrothermal liquefaction) can result in secondary aqueous streams in which there are low quantities of carbon and biomass, making the conventional valorization treatment complicated. In this respect, biodiesel production leads to a glycerol excess on the market, which needs to be valorized [76]. In the relevant literature research, complex feedstock valorizations are considered with respect to real waste streams or synthetic mixtures, demonstrating the outcomes derived from laboratory-scale experiments. Subsequently, aqueous-phase reforming (APR) was a mild-condition process able to convert oxygenated molecules into hydrogen. The catalytic process of APR involves the conversion of water-dissolved oxygenates into a hydrogen-rich gas for biocrude upgrading purposes. The full development and the scalability to industrial level are the main challenges of this type of APR process [76].

In a similar study, hydrothermal liquefaction was proposed as a promising technology for renewable advanced biofuel production [77]. The main constraints in its large-scale applications are the significant carbon loss in the aqueous phase (AP) and the necessity of biocrude upgrading. Therefore, a techno-economic feasibility analysis was followed, in which different lignocellulosic feedstocks, corn stover (CS) and lignin-rich stream (LRS) from cellulosic ethanol production were tested for the evaluation of hydrothermal liquefaction (HTL) coupling with aqueous-phase reforming (APR). Following the carrying out of the mass and energy balances, the equipment design and the capital and operating costs calculation, it was shown that the biofuel minimum selling price (in the case of 0% internal rate of return) was fixed at 1.23 (in the case of LRS) and 1.27 EUR/kg (in the case of CS), respectively [77]. Moreover, the fixed capital investment was devoted to heat exchangers, while electricity and feedstock sustained the highest share of the operating costs. It can be also be pointed out that, in the case of CS, a production of 107% of the required hydrogen was reported for biocrude upgrading, making the APR process particularly profitable. In this context, APR reduced the hydrogen production cost significantly (1.5 EUR/kg), making it a cost-effective and competitive technology compared with conventional electrolysis [77].

3.2.6. HES-RES and Environmental Aspects

As already mentioned above, hydrogen utilization involves oxidation, and the only direct major product from the hydrogen oxidation is water. Small quantities of nitrogen oxides are released when hydrogen is combusted in air, but these effluents can be controlled with careful engine design [63]. The environmental impacts from other phases in the life cycle of a hydrogen system are similar to those for other energy technologies, and may be small or large, depending on the source of the hydrogen [63]. Regarding the environmental concerns and considerations, an HES is prone to cause direct and indirect environmental (especially atmospheric) impacts, at three steps: production, transportation-storage and utilization. At the production step: the leaking of hydrogen and carbon dioxide release in the case of production from fossil fuels; at the transport–storage steps: the leaking of hydrogen; and at the utilization step: the release of water and the leaking of hydrogen. On the basis of experience with technologies associated with the transportation of natural gas and other volatiles, it seems likely that systems of hydrogen production, storage, and transport will involve losses to the atmosphere. Although the average leak rate to be expected in a full-scale hydrogen-driven economy is very uncertain, regarding the relevant literature estimates, around 10% of all hydrogen manufactured is ready to leak into the atmosphere during these steps [64]. Losses during the current commercial transport of hydrogen are substantially greater than this, suggesting a range of 10–20% losses should be expected. If so, and if all current technologies based on oil or gasoline combustion could be replaced by hydrogen fuel cells, then anthropocentric emissions of hydrogen would be in the order of 60–120 Tg/year, or roughly four to eight times the estimates of current anthropocentric hydrogen emissions (15 ± 10 Tg/year) [64].

At this point, it can be seen that human activity can result in approximate duplication or triplication of the scheduled annual production of hydrogen from all sources combined. In the case of replacing all fossil-fuel energy generation with hydrogen fuel cells, then an amount of approximately 60 million tons annually of human-made hydrogen would leak into the atmosphere: this is roughly four times the current amount. Subsequently, such hydrogen leaks might increase water vapor and cool the stratosphere, through retarding the ozone-layer recovery. This excessive release of hydrogen into the atmosphere is also worsening, due to natural sources of hydrogen [64]. Furthermore, hydrogen participates in stratospheric chemical cycles of water and various GHGs, where this substantial increase in its concentration can cause irreversible changes in the stratosphere regarding the imbalance of equilibrium in the concentration of its constituent components. High amounts of hydrogen emissions are also unavoidable from a global fleet of fuel cell vehicles, further impacting on local or regional distribution of water vapor. Water vapor increase can also affect local, regional, and global climatic conditions, mainly due to an increase in relative humidity among areas of widely applied fuel cell technologies, compared to the operation of internal combustion engines. Such an increase in relative humidity can cause shifts in temperature patterns, causing an imbalance in the living conditions of people and ecosystems. On the other hand, hydrogen fuel cells are characterized as a “clean” technology of only water vapor exhaust, GHGs and ozone precursors associated with hydrogen production [64].

3.2.7. Miscellaneous Aspects

Other critical design aspects of hydrogen utility in combined sources of energy generation are the following [33]:

- –

- The selection of the number of fuel cell stacks should consider the price increase of additional fuel cells with the decrease in the price of the smaller storage tank.

- –

- An analysis of the solar–hydrogen hybrid system should consider the effect of the solar irradiance and the ambient air temperature, which are key determinants for calculating the power from the solar panel array. Those reliable and uninterrupted systems of energy are depended on the number of solar panels used in the system. The number of solar panels used in the system affects the electrolyzer size as well as the storage tank volume.

- –

- The efficiency of the hybrid system is dependent on the nominal electrolyzer power. Proper sizing of the electrolyzer can reduce the non-utilizable energy and therefore increase efficiency. The nominal power of the electrolyzer also determines the number of solar panels and the storage tank volume.

- –

- Modular designers cannot ignore the fact that simulations have to consider short time intervals for constructing the properly sized components in the system; otherwise, there will be inevitable interruptions in the power from time to time with undersized hybrid system components.

Other researchers proposed the following design, aspects of hydrogen utility in combined sources of energy generation [70]:

- –

- Liquid and gaseous hydrogen are valued as the best transportation fuels when compared to liquid fuels such as gasoline, jet fuel and alcohols.

- –

- Hydrogen is a versatile fuel that can be converted to useful thermal-, mechanical- and electrical-energy forms for end-users through a variety of processes, whereas fossil fuels can only be converted through one process, i.e., flame combustion.

- –

- In quantitative terms, hydrogen is 39% more efficient than fossil fuels. Moreover, hydrogen is an energy-conserving fuel that can save primary energy resources.

- –

- In safety terms, hydrogen is safe for use, avoiding fire hazard and toxicity cases.

Moreover, the design aspects cannot ignore the selection of the site for the HES installation. Indeed, an appropriate location has to support the following features: good-to-excellent wind conditions, small but representative load, back-up systems in place, not too remote, a supporting community, and access to service personnel. In general, all equipment should be kept as simple and robust as possible, and redundancy should be considered. Due to the uncertainty in precisely forecasting wind power production and customer power demand, a slightly oversized installation should also be considered. However, there is a tradeoff to be made between plant availability and overall system cost [75].

In general, in urban contexts, HES problems are mainly environmentally-centered. Indeed, in this context the main problems are those of high air-pollution levels in many urban cities and sustainability of the transportation fuels; thus, the need to address control measures using HES has been proposed [78]. The majority of the global transportation vehicle fleets consume the fuels derived from fossil resources. The development of economic activities indicated the increase in transportation services resulting in increased fuel consumption and high emissions, especially the unregulated emission of GHG-induced carbon dioxide. Therefore, the utilization of hydrogen as fuel in vehicle fleets can improve energy security and reduce GHG emission. The feasibility of a hydrogen energy system, which includes its resources, production technologies, storage, fuel transportation, dispensing and utilization, was analyzed for the road transportation sector [78]. Moreover, the methodology of this study focused on the use of hydrogen as a clean and green fuel for road transportation systems, also meeting the criteria of high energy efficiency and zero-carbon-based emissions (CO, CO2, HC, PM). Subsequently, many countries employed ambitious policies for the development of HES and, with the aid of research organizations, universities and companies, a wider commercialization of hydrogen-fueled vehicles such as internal combustion engines, or fuel cell-based, or hybrid technology should be a reality [78].

Another noteworthy approach of RES and HES is the “Hydrogen Office building (HO)” which presented a wind-hydrogen energy system, located in Fife, in Scotland, prepared to demonstrate the role of hydrogen in reducing the impact of wind intermittency in a grid-tied microgrid. The main components of this system were a wind turbine, alkaline electrolyzer, hydrogen storage and a PEM fuel cell. The building demand was met by the wind turbine, while the fuel cell provided back-up power to the ground floor when wind power was unable to meet the demand. Accurate modelling of wind–hydrogen systems allowed for an effective implementation and operation. However, past research lacks global methodologies for a whole-system scope simulation. Moreover, experimental validation is imperfect, since in most of these models no guidelines are given for parameter estimation, which is essential for repeatability and reproduction [79]. For achieving this, a comprehensive modelling, simulation and performance methodology was employed on wind–hydrogen systems, containing experimental validation and guidelines for parameter estimation. The conducted quantitative analysis also showed how this methodology can contribute to improve the design and performance of such a system in an accurate, reliable, and easily adaptable manner. At its modelling scale, a precise prediction of the HO dynamic behavior was shown, with an error of less than 2% on average. Other modelling parameters for evaluating the HO system were those of average energy production, stand-alone operation and round-trip efficiency [79].

In a similar study, researchers employed a set of updated HES modeling tools (HYDROGEMS) for the operation evaluation of the Utsira plant: an autonomous wind/hydrogen energy demonstration system that was located at the island of Utsira in Norway and installed in July 2004. After successive designing and testing optimizations for increasing the wind/hydrogen energy system efficiency, it was observed that specific recommendations and improvements for a full (100%) autonomy can be achieved, following the simulated operation for a specific year, as well as the evaluation performance of several alternative system designs [75].

3.3. Limitations, Challenges and Future Research Prospects of HES-RES Synergies

The shift to a carbon-neutral society requires a substantial transformation of the present global electricity generation and consumption, together with the adoption of other technologies than those of fossil-based technologies for electric power. In response to this need, hydrogen should play a determining role in the scaling-up of a clean, plausible and environmentally friendly RES. The main critique is that its integration into existing power systems remains sparsely studied, while the majority of the existing literature production overlooks potential hydrogen technologies and their application in power systems for hydrogen production, re-electrification and storage [58]. Therefore, in an era where most of the world’s energy sources become non-fossil based, hydrogen and electricity can be proven to be two dominant energy carriers for the provision of end-use services. In this context, hydrogen can play a globally decisive role as a future energy carrier regarding energy systems, especially since existing fossil-fuel supplies are becoming scarcer and environmental concerns are increasing. It is also realistic for hydrogen to become an increasingly important chemical-energy carrier and eventually a principal chemical-energy carrier through upgrading the infrastructure needed to support the development of a hydrogen economy [63].

In this type of economy, termed a “hydrogen economy”, the two complementary energy carriers, hydrogen and electricity, are coordinated to satisfy most of the requirements of energy consumers. With this prospect, a transition era will bridge the gap between the current fossil-fuel economy and a hydrogen economy, where non-fossil-derived hydrogen can be exploited to extend the lifetime of the global deposits of fossil fuels [63]. In this respect, besides the technological issues of hydrogen as an energy carrier and hydrogen energy systems, the economic–financial dimension has also to be considered in the light of the potential social and political implications of hydrogen energy to be confronted, especially regarding when and where hydrogen is likely to become important player of energy management strategies [63].

Subsequently, hydrogen technologies must be developed to the stage where they can be proven to be economically and commercially viable. This technological and managerial target includes overcoming all existing safety problems regarding the HES infrastructure, probably in a gradual manner. As mentioned before, numerous social and political implications of shifting to a hydrogen era have to be confronted by governments, universities and private industries, and some of them are the following: healthy levels of employment, a reasonably successful rate of economic growth, reasonable stability in prices, a viable balance of payments and an equitable distribution of rising incomes [63].

Financial gains, environmental concerns, safety and knowledge about the new technology seem to be all hot-spot issues in the HES-RES synergies prospected. Moreover, public perceptions of these HES-RES synergies are attributed to the willingness to pay (WtP) in order to participate in projects that foster the use of fuel cell vehicles, despite their current limitations (i.e., reduced range and limited refueling possibilities). Such a WtP reflects the users’ expectation of personal financial gains (i.e., reduced running costs), and thus, a financially attractive package is always an essential to be offered to energy end-users and consumers for a feasible and realistic hydrogen promotion among local societies [63]. For other significant stakeholders and those interested in HES, which are the manufacturing industries, it seems that regulations have to be issued for rigorous tests in order to ensure safety and environmental consciousness, to attract public awareness of such technologies, and for the control of air pollution through promoting the wider use of these technologies in the future [63]. Indeed, it has been reported that environmental considerations are found to affect users’ WtP for hydrogen technologies, while there are other users—being acquainted with a better knowledge of the technology—who emphasize more the difficulties of a hydrogen future [63].

Regarding the challenges and the prospects of HES-RES synergies, a challenge of utmost importance is the use of wastewater. Indeed, while there are several approaches to wastewater treatment for improving the water-energy nexus with the hydrogen fuel production option, these approaches are limited and confined to the small, pilot, experimental-modeling simulation scale, while there are no fully developed studies on large-scale and in-field applications. Among such small-scale studies, it was argued that the use of fresh water for green-hydrogen fuel production through water electrolysis can exacerbate the challenges of water scarcity [80]. In this context, the utility of non-potable water can effectively design the whole process in a highly secure, reliable and sustainable manner. Therefore, an integration of a solid oxide electrolyzer (SOE) with a water-treatment and recovery process can represent the conceptualization and the techno-economic evaluation of an innovative process of hydrogen energy production. Accordingly, purified wastewater and the waste heat of flue gases from the power plants have been utilized as feedstocks for the electrolysis process. The required thermal energy of the electrolyzer can be supplied under the following two scenarios: first, by the utilization of a preheater based on fossil energies, and second, where the required thermal energy is supplied through a parabolic trough collector (PTC)-based solar farm [80]. The results showed that the integration of fossil fuel-driven power plants with evolving green technologies is plausible for managing the GHG emission crisis and for further reducing the limitations of fossil energies. In parallel, the overall conversion efficiency for the proposed hydrogen production process was calculated as 53.26%. Overall, the proposed system is a competitive and reliable way to support substantial water consumption savings, while further net potential energy savings and carbon emission abatement were also realistic [80].

Regarding the aforementioned term of the “integration” endeavors of energy and environmental impact, it cannot be ignored that energy policy makers and strategic designers also envisage and consider a wider spectrum of optimization features, such as household appliances in the building sector [81,82,83], the agricultural sector [84], and the business or entrepreneurship sectors [85].

4. Conclusions

During the last three decades of analysis, fossil fuels (mainly petroleum, natural gas and coal) have satisfied the world’s energy demand against an unprecedented accelerating pace of stock depletion. Moreover, their combustion products are criticized for global environmental problems such as the GHG effect, ozone layer depletion, acid rain and pollution, threatening the natural environment and causing an imbalance in the natural climate cycles of our planet [86,87]. There is an ongoing debate among engineers, scientists, and governors globally, who agree that the solution to these global problems would be the replacement of, or at least a supplementary role for, HES in the existing fossil fuel systems, since hydrogen is produced from renewable energy (e.g., solar) sources, ensuring a stable and permanent operation [70]. Besides the environmental benefits of HES, the two most prevalent RES for the post-fossil fuel era are those of the solar-HES and the synthetic fossil fuel system. Considering the production costs, the environmental damage and the utilization efficiencies, the solar-HES is the best energy system for ascertaining a sustainable future, being able to replace the fossil fuel system before the end of the 21st century. In this post-petroleum era, the synthetic fossil fuel system is also a promising technology, in which synthetic gasoline and synthetic natural gas can be produced using abundant deposits of coal to ensure the continuation of the existing fossil fuel system [70]. An integrated perception of HES design can consider environmentally friendly modulation like the installment of a solar–hydrogen system for vapor generation. Other design specifications should take into consideration the production, storage, transportation, distribution, utilization, environmental impact and economies-of-scale prospects [70]. Regarding the external costs, which are more common and intensive for fossil fuel utilities, they include the costs of the physical damage done to humans, fauna, flora and the environment due to harmful emissions, oil spills and leaks, and coal strip mining, as well as governmental expenditures for pollution abatement and expenditures for military protection of oil supplies [70].

The research focus of this review was the collection and the classification of the existing studies that jointly address the fields of Hydrogen Energy Systems (HES) and Renewable Energy Sources (RES). The bibliometric analysis of this literature production considered five fields of classification-clusters, revealing firstly the most-reported and the least-reported research areas of interest, secondly the evolution of problem solving approaches, which are primarily experimental, small-scale modelling and simulation studies, followed by problem-solving and large-scale in-field case studies. These large-scale endeavors have been directed toward handling problems of high air-pollution levels in many urban cities, and the sustainability of the transportation fuels could be optimally addressed. The technological dimension of HES and RES convergence and synergies entails the promotion of hybrid systems that ensure stability, storage capacities, operational safety and energy efficiency increase. On the social and the political side, theoretical approaches or legislative measures or policies can be proven to be more flexible and reliable if HES and RES bridge theoretical office designs with practical real world/in-field situations of applicability. On the RES side of utility in HES, the most densely reported studies have been concentrated on the successful collaboration of wind energy (turbines), solar energy (photovoltaics, PVs) and HES. However, the locality characteristics are also the primary precondition of such HES-RES synergy; therefore, among other RES control measures, using HES involves the utility of biomass sources, even at pilot scales of applicability.

In conclusion, we can stress the important economic and environmental consequences that follow the transition of a sustainable hydrogen economy, as a part of a wider energy-solving strategic problem. For this to be achieved, it is important to follow a logical sequence of actions: (a) the design of an optimal hydrogen supply system, (b) the evaluation of its environmental impacts, and (c) an understanding of the effects of various factors that aid the selection and the installation of an optimal hydrogen supply system through a scenario plan and sensitivity analysis. A research limitation of this approach is the inability to directly foresee the actual magnitude of hydrogen emissions associated with a hydrogen fuel cell economy, particularly since today budgets for hydrogen are not fully or well known, while there are also technical constraints, and the future fuel cell industry can be only forecasted. In this case, the evolution and the shift from a fossil-fuel combustion energy planning to the prevalence of hydrogen fuel cells can actually result in unpleasant anthropocentric hydrogen emissions, because fossil fuel combustion is a source of hydrogen itself. On the other hand, researchers are deemed to take into account the climatic effects of HES in the near-future energy plans, especially those based on electrolysis from water, where the simultaneous reduction of fossil-fuel emissions must be also considered [64].

Author Contributions

The authors have contributed equally to this study. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ntona, E.; Arabatzis, G.; Kyriakopoulos, G.L. Energy saving: Views and attitudes of students in secondary education. Renew. Sustain. Energy Rev. 2015, 46, 1–15. [Google Scholar] [CrossRef]

- Kyriakopoulos, G.L.; Arabatzis, G. Electrical energy storage systems in electricity generation: Energy policies, innovative technologies, and regulatory regimes. Renew. Sustain. Energy Rev. 2016, 56, 1044–1067. [Google Scholar] [CrossRef]

- Kyriakopoulos, G.L. Energy Communities Overview: Managerial Policies, Economic Aspects, Technologies, and Models. J. Risk Financ. Manag. 2022, 15, 521. [Google Scholar] [CrossRef]

- Lu, Z.; Zhu, Q.; Zhang, W.; Lin, H. Economic operation strategy of integrated hydrogen energy system considering the uncertainty of PV power output. Energy Rep. 2023, 9, 463–471. [Google Scholar] [CrossRef]

- Çiçek, A. Multi-Objective Operation Strategy for a Community with RESs, Fuel Cell EVs and Hydrogen Energy System Considering Demand Response. Sustain. Energy Technol. Assess. 2023, 55, 102957. [Google Scholar] [CrossRef]

- Ren, J.; Xu, D.; Cao, H.; Wei, S.; Dong, L.; Goodsite, M.E. Sustainability decision support framework for the prioritization of hydrogen energy systems. In Hydrogen Economy: Processes, Supply Chain, Life Cycle Analysis and Energy Transition for Sustainability, 2nd ed.; Academic Press: Cambridge, MA, USA, 2023; pp. 273–313. [Google Scholar] [CrossRef]

- Virji, M.; Randolf, G.; Ewan, M.; Rocheleau, R. Analyses of hydrogen energy system as a grid management tool for the Hawaiian Isles. Int. J. Hydrogen Energy 2020, 45, 8052–8066. [Google Scholar] [CrossRef]

- Maghami, M.R.; Hassani, R.; Gomes, C.; Hizam, H.; Othman, M.L.; Behmanesh, M. Hybrid energy management with respect to a hydrogen energy system and demand response. Int. J. Hydrogen Energy 2020, 45, 1499–1509. [Google Scholar] [CrossRef]

- Parra, D.; Valverde, L.; Pino, F.J.; Patel, M.K. A review on the role, cost and value of hydrogen energy systems for deep decarbonisation. Renew. Sustain. Energy Rev. 2019, 101, 279–294. [Google Scholar] [CrossRef]

- Cho, S.; Won, W.; Han, S.; Kim, S.; Youa, C.; Kim, J. An optimization-based design and analysis of a biomass derived hydrogen energy system. Comput. Aided Chem. Eng. 2018, 44, 1573–1578. [Google Scholar] [CrossRef]

- Rosen, M.A. The prospects for hydrogen as an energy carrier: An overview of hydrogen energy and hydrogen energy systems. In Hydrogen Production: Prospects and Processes; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2012; pp. 1–28. [Google Scholar]

- Özden, E.; Tari, I. Numerical investigation of a stand-alone solar hydrogen energy system: Effects of pefc degradation. In Proceedings of the Thermal and Fluids Engineering Summer Conference, New York, NY, USA, 9–12 August 2015; pp. 673–684. [Google Scholar] [CrossRef]

- Lanjewar, P.B.; Rao, R.V.; Kale, A.V. A combined graph theory and analytic hierarchy process approach for multicriteria evaluation of hydrogen energy systems. Int. J. Energy Technol. Policy 2014, 10, 80–96. [Google Scholar] [CrossRef]

- Contreras, A.; Posso, F. Technical and financial study of the development in Venezuela of the hydrogen energy system. Renew. Energy 2011, 36, 3114–3123. [Google Scholar] [CrossRef]

- Wang, B.; Sun, L.; Diao, N.; Zhang, L.; Guo, X.; Guerrero, J.M. GaN-based step-down power converter and control strategy for hydrogen energy systems. Energy Rep. 2023, 9, 252–259. [Google Scholar] [CrossRef]

- Zhao, X.; Yao, Y.; Liu, W.; Jain, R.; Zhao, C. A Hydrogen Load Modeling Method for Integrated Hydrogen Energy System Planning. In Proceedings of the 2023 IEEE Power and Energy Society Innovative Smart Grid Technologies Conference, ISGT, Washington, DC, USA, 16–19 January 2023. [Google Scholar] [CrossRef]

- Sun, Q.; Wu, Z.; Gu, W.; Liu, P.; Wang, J.; Lu, Y.; Zheng, S.; Zhao, J. Multi-stage Co-planning Model for Power Distribution System and Hydrogen Energy System Under Uncertainties. J. Mod. Power Syst. Clean Energy 2023, 11, 80–93. [Google Scholar] [CrossRef]

- Alanazi, A.; Alanazi, M.; Arabi Nowdeh, S.; Abdelaziz, A.Y.; El-Shahat, A. An optimal sizing framework for autonomous photovoltaic/hydrokinetic/hydrogen energy system considering cost, reliability and forced outage rate using horse herd optimization. Energy Rep. 2022, 8, 7154–7175. [Google Scholar] [CrossRef]

- Dong, W.; Shao, C.; Feng, C.; Zhou, Q.; Bie, Z.; Wang, X. Cooperative Operation of Power and Hydrogen Energy Systems with HFCV Demand Response. IEEE Trans. Ind. Appl. 2022, 58, 2630–2639. [Google Scholar] [CrossRef]

- Schrotenboer, A.H.; Veenstra, A.A.T.; uit het Broek, M.A.J.; Ursavas, E. A Green Hydrogen Energy System: Optimal control strategies for integrated hydrogen storage and power generation with wind energy. Renew. Sustain. Energy Rev. 2022, 168, 112744. [Google Scholar] [CrossRef]

- Marocco, P.; Ferrero, D.; Martelli, E.; Santarelli, M.; Lanzini, A. An MILP approach for the optimal design of renewable battery-hydrogen energy systems for off-grid insular communities. Energy Convers. Manag. 2021, 245, 114564. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, Y.; Yang, Y.; Cai, C.; Chen, Y. Optimal configuration of an off-grid hybrid wind-hydrogen energy system: Comparison of two systems. Energy Eng. J. Assoc. Energy Eng. 2021, 118, 1641–1658. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, T.; Tan, J. Business model and planning approach for hydrogen energy systems at three application scenarios. J. Renew. Sustain. Energy 2021, 13, 044101. [Google Scholar] [CrossRef]

- Onwe, C.A.; Rodley, D.; Reynolds, S. Modelling and simulation tool for off-grid PV-hydrogen energy system. Int. J. Sustain. Energy 2020, 39, 1–20. [Google Scholar] [CrossRef]

- Manilov, A.I. Hydrogen Energy System Based on Silicon Nanopowders: Prospects and Problems. In Proceedings of the 2019 IEEE 39th International Conference on Electronics and Nanotechnology (ELNANO), Kyiv, Ukraine, 16–18 April 2019; pp. 60–63. [Google Scholar] [CrossRef]

- Zhang, W.; Maleki, A.; Rosen, M.A.; Liu, J. Sizing a stand-alone solar-wind-hydrogen energy system using weather forecasting and a hybrid search optimization algorithm. Energy Convers. Manag. 2019, 180, 609–621. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, J.; Zong, Z.; Chen, Q.; Zhang, P.; Wu, K. Development and modelling of a novel electricity-hydrogen energy system based on reversible solid oxide cells and power to gas technology. Int. J. Hydrogen Energy 2019, 44, 28305–28315. [Google Scholar] [CrossRef]

- Alavi, O.; Mostafaeipour, A.; Sedaghat, A.; Qolipour, M. Feasibility of a Wind-Hydrogen Energy System Based on Wind Characteristics for Chabahar, Iran. Energy Harvest. Syst. 2017, 4, 143–163. [Google Scholar] [CrossRef]

- Ren, J.; Xu, D.; Cao, H.; Wei, S.; Dong, L.; Goodsite, M.E. Sustainability Decision Support Framework for the Prioritization of Hydrogen Energy Systems. In Hydrogen Economy: Processes, Supply Chain, Life Cycle Analysis and Energy Transition for Sustainability; Academic Press: Cambridge, MA, USA, 2017; pp. 225–276. [Google Scholar] [CrossRef]

- Lacko, R.; Drobnič, B.; Sekavčnik, M.; Mori, M. Hydrogen energy system with renewables for isolated households: The optimal system design, numerical analysis and experimental evaluation. Energy Build. 2014, 80, 106–113. [Google Scholar] [CrossRef]

- Patrício, R.A.; Sales, A.D.; Sacramento, E.M.; De Lima, L.C.; Veziroglu, T.N. Wind hydrogen energy system and the gradual replacement of natural gas in the State of Ceará-Brazil. Int. J. Hydrogen Energy 2012, 37, 7355–7364. [Google Scholar] [CrossRef]

- Aguado, M.; Ayerbe, E.; Azcárate, C.; Blanco, R.; Garde, R.; Mallor, F.; Rivas, D.M. Economical assessment of a wind-hydrogen energy system using WindHyGen® software. Int. J. Hydrogen Energy 2009, 34, 2845–2854. [Google Scholar] [CrossRef]

- Acar, C.; Erturk, E.; Firtina-Ertis, I. Performance analysis of a stand-alone integrated solar hydrogen energy system for zero energy buildings. Int. J. Hydrogen Energy 2023, 48, 1664–1684. [Google Scholar] [CrossRef]

- Karaca, A.E.; Dincer, I. Development and evaluation of a solar based integrated hydrogen energy system for mobile applications. Energy Convers. Manag. 2023, 280, 116808. [Google Scholar] [CrossRef]

- Lin, X.-M.; Li, J.-F. Applications of In Situ Raman Spectroscopy on Rechargeable Batteries and Hydrogen Energy Systems. ChemElectroChem 2023, 10, 202201003. [Google Scholar] [CrossRef]

- Alex, A.; Petrone, R.; Tala-Ighil, B.; Bozalakov, D.; Vandevelde, L.; Gualous, H. Optimal techno-enviro-economic analysis of a hybrid grid connected tidal-wind-hydrogen energy system. Int. J. Hydrogen Energy 2022, 47, 36448–36464. [Google Scholar] [CrossRef]

- Ibrahim, M.D.; Binofai, F.A.S.; Mohamad, M.O.A. Transition to Low-Carbon Hydrogen Energy System in the UAE: Sector Efficiency and Hydrogen Energy Production Efficiency Analysis. Energies 2022, 15, 6663. [Google Scholar] [CrossRef]

- Balasubramanian, V.; Haque, N.; Bhargava, S.; Madapusi, S.; Parthasarathy, R. Techno-economic evaluation methodology for hydrogen energy systems. In Bioenergy Resources and Technologies; Elsevier: Amsterdam, The Netherlands, 2021; pp. 237–260. [Google Scholar] [CrossRef]

- Endo, N.; Goshome, K.; Tetsuhiko, M.; Segawa, Y.; Shimoda, E.; Nozu, T. Thermal management and power saving operations for improved energy efficiency within a renewable hydrogen energy system utilizing metal hydride hydrogen storage. Int. J. Hydrogen Energy 2021, 46, 262–271. [Google Scholar] [CrossRef]

- Endo, N.; Segawa, Y.; Goshome, K.; Shimoda, E.; Nozu, T.; Maeda, T. Use of cold start-up operations in the absence of external heat sources for fast fuel cell power and heat generation in a hydrogen energy system utilizing metal hydride tanks. Int. J. Hydrogen Energy 2020, 45, 32196–32205. [Google Scholar] [CrossRef]

- Endo, N.; Shimoda, E.; Goshome, K.; Yamane, T.; Nozu, T.; Maeda, T. Operation of a stationary hydrogen energy system using TiFe-based alloy tanks under various weather conditions. Int. J. Hydrogen Energy 2020, 45, 207–215. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; Zhang, R.; Sun, H. Development of renewable energy multi-energy complementary hydrogen energy system (A Case Study in China): A review. Energy Explor. Exploit. 2020, 38, 2099–2127. [Google Scholar] [CrossRef]

- Yilmaz, C. Life cycle cost assessment of a geothermal power assisted hydrogen energy system. Geothermics 2020, 83, 101737. [Google Scholar] [CrossRef]

- Sorgulu, F.; Dincer, I. A renewable source based hydrogen energy system for residential applications. Int. J. Hydrogen Energy 2018, 43, 5842–5851. [Google Scholar] [CrossRef]

- Kalinci, Y.; Dincer, I.; Hepbasli, A. Energy and exergy analyses of a hybrid hydrogen energy system: A case study for Bozcaada. Int. J. Hydrogen Energy 2017, 42, 2492–2503. [Google Scholar] [CrossRef]

- Ewan, M.; Rocheleau, R.; Swider-Lyons, K.E.; Devlin, P.; Virji, M.; Randolf, G. Development of a hydrogen energy system as a grid frequency management tool. ECS Trans. 2016, 75, 403–419. [Google Scholar] [CrossRef]

- Khalid, F.; Dincer, I.; Rosen, M.A. Analysis and assessment of an integrated hydrogen energy system. Int. J. Hydrogen Energy 2016, 41, 7960–7967. [Google Scholar] [CrossRef]

- Maleki, A.; Pourfayaz, F.; Ahmadi, M.H. Design of a cost-effective wind/photovoltaic/hydrogen energy system for supplying a desalination unit by a heuristic approach. Sol. Energy 2016, 139, 666–675. [Google Scholar] [CrossRef]

- Balabel, A.; Zaky, M.S. Experimental investigation of solar-hydrogen energy system performance. Int. J. Hydrogen Energy 2011, 36, 4653–4663. [Google Scholar] [CrossRef]

- Bendaikha, W.; Larbi, S.; Mahmah, B. Hydrogen energy system analysis for residential applications in the southern region of Algeria. Int. J. Hydrogen Energy 2011, 36, 8159–8166. [Google Scholar] [CrossRef]

- Chao, C.-H.; Shieh, J.-J. Control and management for hydrogen energy systems. Recent Researches in Energy, Environment, Entrepreneurship, Innovation. In Proceedings of the International Conference on Energy, Environment, Entrepreneurship, Innovation, ICEEEI, Canary Islands, Spain, 27–29 May 2011; pp. 27–31. [Google Scholar]

- Kikkinides, E.S. Hydrogen-Based Energy Systems: The Storage Challenge. In Process Systems Engineering: Volume 5: Energy Systems Engineering; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; Chapter 3; pp. 85–123. [Google Scholar] [CrossRef]

- Gabriel García Clúa, J.; Julián Mantz, R.; De Battista, H. Hybrid control of a photovoltaic-hydrogen energy system. Int. J. Hydrogen Energy 2008, 33, 3455–3459. [Google Scholar] [CrossRef]

- Cheng, L.; Guo, Z.; Xia, G. A Review on Research and Technology Development of Green Hydrogen Energy Systems with Thermal Management and Heat Recovery. Heat Transf. Eng. 2023. [Google Scholar] [CrossRef]

- Blanco, H.; Leaver, J.; Dodds, P.E.; Dickinson, R.; García-Gusano, D.; Iribarren, D.; Lind, A.; Wang, C.; Danebergs, J.; Baumann, M. A taxonomy of models for investigating hydrogen energy systems. Renew. Sustain. Energy Rev. 2022, 167, 112698. [Google Scholar] [CrossRef]

- Sezgin, B.; Devrim, Y.; Ozturk, T.; Eroglu, I. Hydrogen energy systems for underwater applications. Int. J. Hydrogen Energy 2022, 47, 19780–19796. [Google Scholar] [CrossRef]

- Temiz, M.; Dincer, I. Development and assessment of an onshore wind and concentrated solar based power, heat, cooling and hydrogen energy system for remote communities. J. Clean. Prod. 2022, 374, 134067. [Google Scholar] [CrossRef]

- Yue, M.; Lambert, H.; Pahon, E.; Roche, R.; Jemei, S.; Hissel, D. Hydrogen energy systems: A critical review of technologies, applications, trends and challenges. Renew. Sustain. Energy Rev. 2021, 146, 111180. [Google Scholar] [CrossRef]

- Martin, A.; Agnoletti, M.-F.; Brangier, E. Users in the design of Hydrogen Energy Systems: A systematic review. Int. J. Hydrogen Energy 2020, 45, 11889–11900. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Cumulative energy demand of hydrogen energy systems. In Environmental Footprints and Eco-Design of Products and Processes; Springer: Berlin/Heidelberg, Germany, 2019; pp. 47–75. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Life cycle assessment of hydrogen energy systems: A review of methodological choices. Int. J. Life Cycle Assess. 2017, 22, 346–363. [Google Scholar] [CrossRef]

- Zini, G.; Tartarini, P. Solar Hydrogen Energy Systems: Science and Technology for the Hydrogen Economy; Springer: Berlin/Heidelberg, Germany, 2012; 184p, ISBN 9788847019980. [Google Scholar] [CrossRef]

- Rosen, M.A.; Koohi-Fayegh, S. The prospects for hydrogen as an energy carrier: An overview of hydrogen energy and hydrogen energy systems. Energy Ecol. Environ. 2016, 1, 10–29. [Google Scholar] [CrossRef]

- Noyan, Ö.F. Some approach to possible atmospheric impacts of a hydrogen energy system in the light of the geological past and present-day. Int. J. Hydrogen Energy 2011, 36, 11216–11228. [Google Scholar] [CrossRef]

- Li, Z.; Chang, L.; Gao, D.; Liu, P.; Pistikopoulos, E.N. Hydrogen Energy Systems. In Process Systems Engineering: Volume 5: Energy Systems Engineering; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; Chapter 4; pp. 125–157. [Google Scholar] [CrossRef]