Abstract

The energy and economic performance of a transcritical R744 booster supermarket refrigeration system with and without parallel compression and integrated with an organic Rankine cycle (ORC) was investigated. The results obtained were compared with those of a transcritical R744 booster supermarket refrigeration system with and without parallel compression and those of a conventional R404A direct expansion (DX) system. Nine different locations, namely Copenhagen (Denmark), Paris (France), Athens (Greece), New Delhi (India), Phoenix and Miami (US), Madrid (Spain), Bangkok (Thailand) and Riyadh (Saudi Arabia), were considered. It was discovered that the ORC is effective only at ambient temperatures higher than 27 °C when operating without parallel compression and 28 °C when operating with parallel compression. By using the heat recovered from the gas cooler to fuel the ORC, the latter was found to be capable of covering between 4% and 24% of the electricity demand of the R744 system in warm and hot climates (without parallel compression). The simple payback period of the additional investment associated with the ORC was found to be between 1.4 and 2.5 years in warm climate locations, while the same was found to be less than about 0.5 years in locations experiencing hot climatic conditions.

1. Introduction

According to Gullo et al. [1], carbon dioxide (R744) is widely regarded as a viable and sustainable working fluid for commercial refrigeration applications. Nevertheless, the energy efficiency of a transcritical R744 retail refrigeration system experiences a notable decline when the ambient temperature rises. Various measures have been explored in an effort to address this limitation. Several techniques have been identified as prominent in the field, including the utilization of ejectors (Ringstad et al. [2], Madsen and Kreizi [3]), the implementation of dedicated mechanical subcooling (Dai et al. [4]), the application of parallel compression (Chesi et al. [5]), the utilization of cold thermal energy storages (Polzot et al. [6]), the adoption of overfed evaporators (Minetto et al. [7]), and the implementation of pressure exchangers (Sengupta and Dasgupta [8]). The simultaneous heating–cooling prospects of transcritical R744 systems have also been explored for proper utilization of the waste heat and eliminating the usage of gas boilers and stand-alone electric heaters. A considerable quantity of thermal energy can be recovered from the high-pressure side of an R744 system and employed for various applications, such as space heating, domestic hot water provision and district heating (Sawalha [9]). The considerable capacity for waste heat recuperation in transcritical R744 systems renders them well-suited for integration with an organic Rankine cycle (ORC), as demonstrated by Nemati et al. [10]. Bellos and Tzivanidis [11] and Hu et al. [12] suggested integration of an ORC to partially power a transcritical R744 supermarket refrigeration system. Thus, a part of the heat rejected from the high-pressure side can be utilized as the heat source to the boiler of the ORC system. The high pressure and high temperature fluid at vapour state can expand in the turbine, which in turn is coupled to a generator. The electricity generated by the generator is employed for covering a part of the electricity demand of the refrigeration system.

Bellos and Tzivanidis [11] reported that about 4.60% to 7.03% of electricity demand of the refrigeration system can be met at ambient temperatures between 27 °C and 40 °C. Hu et al. [12] evaluated up to 13% enhancement in the coefficient of performance (COP) at the investigated conditions. The performance of a cascade waste heat recovery system based on a transcritical CO2 cycle for the purpose of waste heat recovery in a waste-to-energy facility was investigated by Ni et al. [13]. The maximum energy efficiency and payback period of the coupled system were reported to be ~72% and 4.33 years, respectively. Tsimpoukis et al. [14] investigated the performance of a transcritical CO2 refrigeration system coupled with a supercritical CO2 Brayton cycle and an ORC. The annual energy savings and payback period of the proposed unit were reported to be ~37% and 7.6 years, respectively. The integration of ORC with an ejector-based R744 supermarket refrigeration system was later reported by Tsimpoukis et al. [15]. The integration of ORC was reported to reduce the energy consumption of the refrigeration system by ~7.54% at 40 °C ambient temperature. The payback period was also reported to be ~4 years. The combined performance of an organic Rankine cycle and absorption refrigeration was evaluated by Souza et al. [16] in terms of energy, exergy, and exergoeconomic outcomes. Their results show that the combined system can meet up to 37.5% of the building’s electrical demands and can maximize energy and energy efficiencies to up to 34.5% and 40%, respectively. A transcritical CO2 ejector-based refrigeration and power system driven by recovered waste heat was studied by Ipakchi et al. [17]. The optimized system was reported to yield energy and exergy efficiencies of 27.42% and 24.21%, respectively, with net power production of 7.55 kW for a cooling capacity of 10 kW. Merino et al. [18] reported the performance of a solar and biomass-operated combined supercritical Brayton and ORC hybrid system. The proposed configuration was reported to have an energy efficiency of 45.79%. Georgousis et al. [19] investigated the performance of a solar-operated CO2 tri-generation plant in order to produce heat to raise the temperature of the heat transfer fluid to temperatures as high as 570 °C. The integration of an ORC is reported to enhance the energy efficiency of the system to 49%. The performance of a dual-evaporator vapour compression system equipped with an ORC was reported by Goyal et al. [20]. The exergy efficiency and payback period of the proposed configuration were reported to be ~11% and 5.8 years, respectively. Several other studies on the integration of ORC with vapour compression systems were also reported by Nasir and Kim [21], Yue et al. [22] and Saleh [23]. These studies reported significant enhancement in energy efficiency with the use of ORC.

Although the reduction in energy consumption of transcritical R744 systems deriving from the use of ORCs have been investigated, to the best of the authors’ knowledge and as revealed by the literature review, the annual energy and economic performance of transcritical R744 supermarket systems with and without parallel compression and equipped with an ORC has not been studied exhaustively. Multi-ejector solutions have also been investigated, but they are too expensive and hence not included in this study. Thus, the objective of this study is to address this existing gap in knowledge by conducting a comprehensive assessment of the potential energy savings offered by a transcritical R744 supermarket system that is partially driven by an organic Rankine cycle (CO2+ORC). Also, the integration of parallel compression with the CO2+ORC system is investigated. Isopentane, being natural, is used as the working fluid for the ORC system. In addition, field measurements from a real supermarket have been used. All the systems considered in the present work have been optimized with respect to the gas-cooler/condenser pressure in order to reduce the power consumption and maximize the COP (coefficient of performance) of the system. Based on sensitivity analysis, the optimum high side pressure was estimated, which resulted in maximum system COP. The mathematical model of the R744 booster refrigeration system is validated with published experimental results. The performance of the proposed system was compared with a conventional R744 booster supermarket refrigeration system (i.e., without ORC), a R744 refrigeration system integrated with parallel compression (CO2+PC), and a R744 system integrated with both parallel compression and ORC (CO2+PC+ORC). Also, the performance of the proposed solutions has been compared to those of widely known baselines in the field. i.e., a conventional R404A direct expansion (DX) system. Furthermore, an evaluation was conducted to determine the payback period associated with the additional investment resulting from the ORC. The energy and economic performance of all the investigated solutions were assessed for nine different locations, i.e., Copenhagen (Denmark), Paris (France), Athens (Greece), New Delhi (India), Phoenix and Miami (US), Madrid (Spain), Bangkok (Thailand) and Riyadh (Saudi Arabia), in order to evaluate the influence of different weather conditions.

2. Methodology

2.1. Investigated Systems

2.1.1. Conventional Transcritical R744 Booster Supermarket Refrigeration System with Flash Vapour By-Pass Valve and Integrated with an ORC (CO2+ORC)

The refrigeration system under consideration is a typical transcritical R744 booster supermarket refrigeration unit equipped with a flash vapour by-pass valve (Figure 1a). It has two evaporation levels, i.e., low temperature (LT) and medium temperature (MT). The pressure of the liquid receiver is maintained to 35 bar by the flash vapour by-pass valve. A portion of the heat rejected by the R744 refrigeration system is utilized for making isopentane vaporize in the boiler (heat recovery HX). Isopentane, being a natural working fluid, is used for the ORC system (Li et al. [24]). The remaining heat is rejected in the air-cooled condenser/gas cooler. The high-pressure, high-temperature isopentane vapour generated in the boiler of the ORC expands in the turbine. The turbine is coupled with a generator. The isopentane vapour is expanded in the turbine down to the condenser pressure. The electricity generated by the generator is utilized to meet part of the electricity demand of the R744 refrigeration system. The isopentane (saturated liquid) at the outlet of the condenser is pumped back to the boiler (heat recovery HX). For the present study, the minimum temperature of the boiler was taken as 90 °C. Thus, the ORC system was assumed to operate only when the temperature of R744 at the compressor outlet was greater than 90 °C. Below a certain ambient temperature, the ORC was turned off since the compressor discharge temperature was not sufficient to maintain the boiler temperature at a minimum of 90 °C, and thus the CO2+ORC system was assumed to work as a typical booster system. The performance of the CO2+ORC system at all the operating ambient temperatures was optimized with respect to the gas cooler pressure in MATLAB, in order to minimize the net power consumption and thereby maximize the COP of the system. The p-h diagram of the configuration is presented in Figure 2a.

Figure 1.

Schematic of the investigated (a) CO2+ORC system and (b) CO2+PC+ORC system.

Figure 2.

p-h diagram of the investigated (a) CO2+ORC system and (b) CO2+PC+ORC system.

2.1.2. Transcritical R744 Booster Supermarket Refrigeration System with Parallel Compression and Integrated with an ORC (CO2+PC+ORC)

Figure 1b shows a transcritical R744 booster supermarket refrigeration system with parallel compression and integrated with ORC. The system is also integrated with an ORC. The parallel compressors operate at ambient temperatures above 13 °C. Above a certain ambient temperature, the ORC was assumed to be turned on. However, below this ambient temperature and up to 13 °C, the ORC was assumed to be turned off and the system was operated with parallel compression. Below 13 °C, the parallel compression was assumed to be turned off due to insufficient flash vapour in the liquid receiver. Thus, below 13 °C ambient temperature, the system worked as a conventional R744 booster refrigeration system with flash vapour by-pass valve. In this mode of operation, the receiver pressure is maintained by the flash vapour by-pass valve. The CO2+PC+ORC system was also optimized (with both ORC and parallel compressors turned on) with respect to the gas cooler pressure to maximize the COP of the system. The p-h diagram of the configuration is presented in Figure 2b.

2.2. Mathematical Modeling and Simulation

The mathematical model of the proposed system was developed from conservation equations and involved Equation (1) to Equation (10). The major assumptions taken for the present analysis were:

- steady-state operations;

- negligible changes in potential and kinetic energy in the components;

- adiabatic compressors;

- negligible pressure drop in the system components and pipe lines;

- saturated vapour enters the turbine.

The bin hour temperature distribution for the selected locations is depicted in Figure 3 [25].

Figure 3.

Bin hour temperature distribution for the selected cities [25].

The global efficiencies of all the compressors are presented in Table 1.

Table 1.

Global efficiency of the compressors (Gullo et al. [26], Purohit et al. [27]).

According to Karampour and Sawalha [28], it is reasonable to consider that the MT refrigeration load of a supermarket exhibits a linear relationship with the ambient temperature. This is due to the presence of air curtains in the MT display cabinets, which causes the load to fluctuate in response to both humidity and ambient temperature inside the supermarket. However, the LT load remains constant (and equal to 35 kW) throughout the year due to the use of glass lids on LT display cabinets [28]. Hence, in this study, the MT refrigeration load was calculated according to Equation (1) [28] within the range of outdoor temperatures spanning from 10 °C to 35 °C. Below 10 °C, the MT load was assumed to be constant at 100 kW due to the fact that at such low temperatures, the humidity was significantly lower. The estimation of the MT load beyond 35 °C was derived using linear extrapolation.

The enthalpy of R744 at state 10 is calculated using Equation (2).

The suction flow rate of the MT compressor is estimated using mass balance in Equation (3).

where is the mass flow rate through the LT evaporator, is the mass flow rate through the MT evaporator and is the mass flow rate of flash gas by-passed using the flash gas by-pass valve. The mass flow rates and are estimated using Equations (4)–(6), respectively.

where is the quality of R744 at the inlet of the liquid receiver.

The enthalpy at state 1 is calculated using Equation (7).

The enthalpy of R744 at the outlets of the LT and MT compressors are estimated using Equations (8) and (9), respectively.

In the boiler of the ORC system, the temperature of R744 at state 23 was calculated using Equation (10) considering a pinch point temperature of 2 K at state c. State c corresponds to saturated liquid state for isopentane i.e., .

The exaggerated view of the Heat recovery HX is presented in Figure 4 for better visualization of the state c and 23. The temperature at state c is same as the temperature at state d [11].

Figure 4.

Exaggerated view of the heat recovery HX.

The temperature of R744 at state 2 is kept 5 K higher than the boiler temperature. The mass flow rate of the isopentane, , was estimated using Equation (11), in which was the specific enthalpy of the isopentane in the heat recovery HX at the state of saturated liquid, while was the specific enthalpy of R744 rejecting heat into the isopentane as it reached the state of saturated liquid.

where enthalpy at state c is the enthalpy of saturated liquid (isopentane).

The specific enthalpy at state 3 (inlet to the condenser/gas cooler) was computed by energy balance in the heat recovery HX (Equation (12)).

where enthalpy at state d is the enthalpy of dry saturated vapour (isopentane).

The total heat rate of heat rejected by the R744 into the boiler of the ORC system was computed using Equation (13).

The condensing temperature of isopentane was considered to be 5 K higher than the ambient temperature [11]. The isentropic efficiency of the pump and turbine were assumed to be 70% and 85%, respectively, as reported by [11] and are defined as in Equation (14) and Equation (15), respectively.

where state a corresponds to the outlet of the condenser. The enthalpy at state a is the enthalpy of saturated liquid (isopentane).

The efficiency of the generator was taken as 95%. The net electricity generated by the ORC system is computed as follows:

where, the power consumed by the pump and mechanical power delivered by the turbine are estimated using Equations (17) and (18), respectively.

The power consumption of the refrigeration system is estimated using Equation (19).

where are estimated using Equations (20) and (21), respectively.

The COP and the annual energy consumption (AEC) of the combined system was computed using Equations (22) and (23), respectively.

In Equation (23), is the frequency of the i-th outdoor temperature. The calculation of the difference in payback period (DPP) for the proposed systems was performed using Equation (24). For payback period computation, the costs of additional investment required to implement the ORC, over and above the R744 system, are computed.

In Equation (24), is the total number of hours when the ORC was active, while is the unit cost of electricity (USDkWh−1). The specific installation cost of the ORC unit was taken as 3159 USD/kWnet electricity [11].

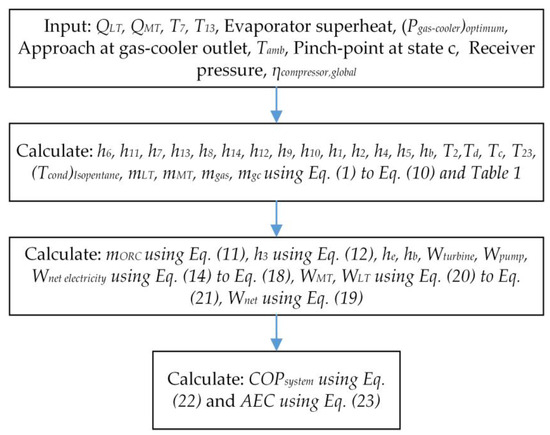

In the simulation, the evaporator temperatures for the LT and MT were selected as −32 °C and −8 °C, respectively [11], while the approach at the outlet of the gas cooler was taken as 3 K [28]. The degree of superheating was considered as 10 K [29]. The pressure of the liquid receiver was considered to be fixed at 35 bar for all the R744 systems considered in the present study. The minimum condensing temperature for the R744 system was taken as 10 °C [28]. For the CO2+PC and CO2+PC+ORC systems, the parallel compressor was turned on at ambient temperatures above 13 °C [28]. Below 13 °C, the receiver pressure was assumed to be controlled by the flash vapour by-pass valve. The flow chart explaining the solution methodology is presented in Figure 5.

Figure 5.

Flow chart of solution methodology.

The costs per kilowatt-hour (kWh) of electricity in several cities considered in the present investigation are as follows: Athens at USD 0.11, New Delhi at USD 0.12, Paris at USD 0.177, Copenhagen at USD 0.346, Madrid at USD 0.175, Bangkok at USD 0.113, Miami at USD 0.14, Phoenix at USD 0.16 and Riyadh at USD 0.068 [30]. The thermo-physical properties of R744 and isopentane were extracted using REFPROP 10.0 [31], while the simulation was carried out using MATLAB (MATLAB, R2022b [32]) and Engineering Equation Solver (EES, V11.257-3D [33]). The performance of all the investigated systems were optimized with respect to the high-side pressure in MATLAB in order to maximize the COP of the system.

3. Results and Discussion

The results and discussions section is organized as follows: the validation of the mathematical model of the R744 booster refrigeration system with experimental results are presented in Section 3.1; the operating ambient temperature limits of the R744 refrigeration system equipped with ORC are presented in Section 3.2; Section 3.3 highlights the energy saving potential of the investigated systems at various locations; the cost aspect of the ORC system is discussed in Section 3.4; and Section 3.5 presents a discussion on the payback period of the additional investment associated with the ORC. Finally, the main conclusions of the present work are summarized in Section 4.

3.1. Model Validation

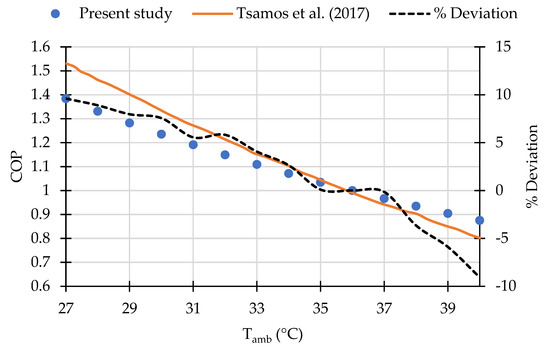

The mathematical model of the R744 booster system is validated against the experimental results reported by [29] for the ambient temperature range of 27 °C to 40 °C. The operating conditions were kept identical to those of [29]. The results of the validation are presented in Figure 6. The mean deviation is found to be ~2.4%, which indicates that the mathematical model is reasonably accurate.

Figure 6.

Validation of the mathematical model of the R744 booster system with experimental results of Tsamos et al. [29].

3.2. Operational Ambient Temperature Limits of ORC

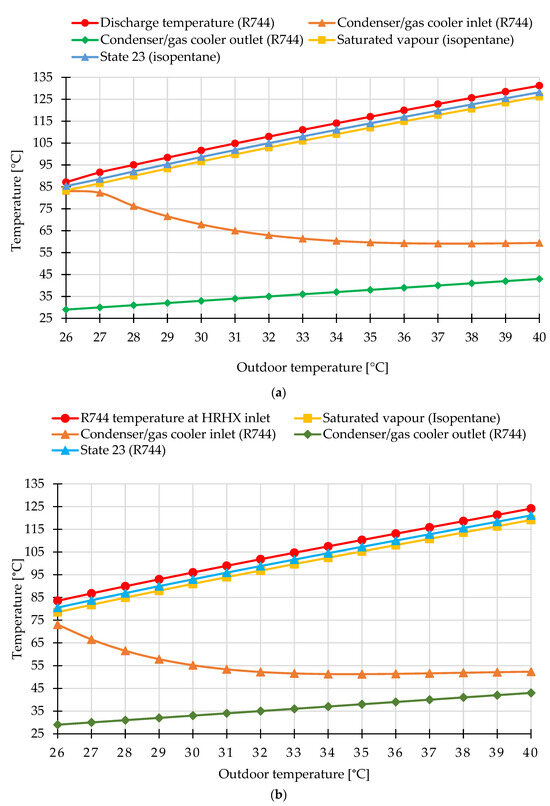

The variation of temperature of R744 and temperature of the organic fluid (isopentane) at various state points with the ambient temperature for the CO2+ORC system and the CO2+PC+ORC system are shown in Figure 7a,b, respectively. It was observed that the temperature of CO2 at the compressor outlet is greater than 90 °C only when the ambient temperature is greater than or equal to 27 °C for the CO2+ORC system, while the same can be operated only above 28 °C for the CO2+PC+ORC system. As previously mentioned, the minimum boiler temperature of the ORC system for the present investigation was taken as 90 °C. In order to maintain the boiler temperature at 90 °C, the temperature of CO2 at the compressor outlet had to be greater than 90 °C. This confined the usage of the ORC to ambient temperatures above 27 °C. Thus, the benefits from the ORC system can only be derived at ambient temperatures above 27 °C. The temperature at the inlet to the condenser/gas cooler is nonlinear due to the shape of the s-shaped isothermal lines in the transcritical region coupled with increasing high-side pressure (at various ambient temperatures) and is computed based on a set of energy equations in the heat recovery heat exchanger. However, the outlet temperature from the gas cooler is given as an input based on the ambient temperature with a fixed approach of 3 K at the gas cooler outlet and is therefore linear.

Figure 7.

(a) Influence of outdoor temperature on R744 temperature and temperature of isopentane with the ambient temperature at various state points of the CO2+ORC system. (b) Influence of outdoor temperature on R744 temperature and temperature of isopentane with the ambient temperature at various state points of the CO2+PC+ORC system.

The temperature and pressure values at various state points of the CO2+ORC and CO2+PC+ORC system corresponding to an ambient temperature of 30 °C are summarized in Table 2 and Table 3 respectively.

Table 2.

Pressure and temperature values at various state points of the CO2+ORC system.

Table 3.

Pressure and temperature values at various state points of the CO2+PC+ORC system.

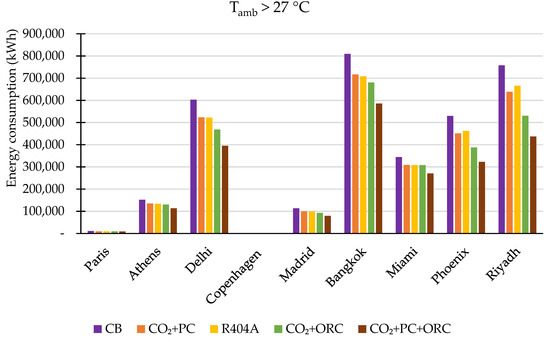

3.3. Energy Analysis of the Investigated Systems

Figure 8 illustrates the proportion of time throughout the year during which the outdoor temperature reached or exceeded 27 °C across the several chosen sites. The annual average temperature ‘avg’ in a given location is also presented in Figure 8. It is the hourly average temperature obtained for a period of 12 months. This is extracted from weather files available in EnergyPlus [25]. It was found that the ORC can be operated for about 40% of the time annually in Miami and Phoenix, more than 50% in New Delhi and Riyadh and ~80% in Bangkok. However, the ORC could be barely used in Paris and Copenhagen due to outdoor air temperature constraints. The energy consumption of all the systems at various locations and at ambient temperatures above 27 °C is shown in Figure 9. It can be observed that the energy consumption of all the configurations operating in Athens and Madrid was significantly less compared with other locations due to predominant sub-critical operation. The highest energy consumption in all the locations is contributed by the conventional booster system (CB), while the lowest contribution was by the CO2+PC+ORC system. It is also interesting to observe that the energy consumption of the CO2+PC system and the R404A system were similar in Athens, Delhi, Madrid and Miami at ambient temperatures above 27 °C. However, the R404A systems operating in Phoenix and Riyadh were found to consume relatively more energy compared with the CO2+PC system. This could be attributed to the fact that the ambient temperatures at Phoenix and Riyadh go as high as about 46 °C and 47 °C, respectively, for a considerable amount of time in a year, which is much higher compared with other locations. At such high temperatures, the amount of flash vapour generated was also high. The excessive amount of flash vapour tended to offset the benefit that can be extracted from the integration of parallel compression.

Figure 8.

Percentage of time over the year when the outdoor temperature is greater than or equal to 27 °C and the annual average temperature at various locations.

Figure 9.

Energy consumption of all the systems at ambient temperatures above 27 °C.

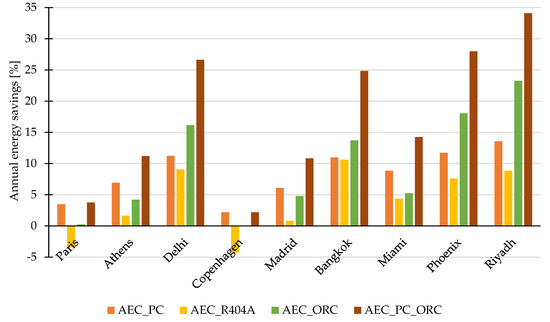

The annual energy saving of all the investigated solutions is listed in Table 4, while the energy savings compared to the transcritical R744 booster supermarket refrigeration system (CB) and R404A system are represented in Figure 10 and Figure 11, respectively.

Table 4.

Annual energy consumption (kWh) of all the systems at various locations.

Figure 10.

Percentage annual energy savings of the investigated systems compared to the conventional booster system (CB) at various locations.

Figure 11.

Percentage annual energy savings of the investigated systems compared to the R404A DX system at various locations.

Figure 10 highlights that the integration of an ORC with an R744 refrigeration system was not energetically beneficial in Paris and Copenhagen. This was due to the fact that the percentage of time that the ORC can be operated in these locations is very limited (Figure 8). As a result, the CO2+ORC system could operate as a standard booster system for the majority of the time annually in these locations. Incorporating parallel compression with the existing CO2+ORC system was capable of improving the energy efficiency by 3.8% and 2.2% in Paris and Copenhagen, respectively. However, the CO2 system integrated with parallel compression (CO2+PC) and without ORC was found to be capable of providing similar energy benefits as compared to the CO2+PC+ORC system. This can be attributed to the fact that parallel compressors could be utilized for a narrow range of ambient temperatures (13 °C to ~29 °C) in Paris and Copenhagen, as the ambient temperature in these locations does not go beyond 29 °C (Figure 2). Below 13 °C, the parallel compressor was assumed to be turned off due to insufficient flash vapour in the liquid receiver. Hence, below 13 °C, both the CO2+PC system and CO2+PC+ORC system were operating as a standard booster system (without ORC). Also, the conventional booster system (CB) was found to outperform the R404A system in Paris as well as in Copenhagen. The CO2+ORC systems operating in Athens, Madrid and Miami were found to be capable of saving relatively more energy compared to the conventional booster system and the R404A system. The system (without parallel compression) has the potential to meet 4.21%, 4.8% and 5.25% of the total electricity demand of the R744 refrigeration system in Athens, Madrid and Miami, respectively. The ambient temperatures in Athens, Madrid and Miami were greater than 13 °C for a relatively longer time. As a result, the integration of parallel compression with the CO2+ORC system was found to be more beneficial in these locations. The combination of parallel compression with the CO2+ORC system was found capable of enhancing the energy saving potential of the CO2+ORC system by 6.9%, 6.1% and 8.9% in Athens, Madrid and Miami, respectively. However, the R404A system was found to outperform the conventional booster system in these locations. The hot climates of New Delhi, Bangkok, Phoenix and Riyadh resulted in relatively higher utilization of the ORC. The integration of ORC with the booster system (without parallel compression) is capable of covering 16.15%, 13.7%, 18% and 23.25% of the electricity demands of the R744 systems in New Delhi, Bangkok, Phoenix and Riyadh, respectively. The use of the parallel compression with the CO2+ORC system was found to enhance the energy savings to 11.2%, 11.0%, 11.7% and 13.6% in these four cities, respectively. However, the R404A system was found to outperform the conventional booster system in all these locations. It is possible to conclude that the CO2+PC+ORC system is the best solution in all the locations except for Paris and Copenhagen. In the cold climates of Paris and Copenhagen, parallel compression seems to be a better option.

The percentage energy savings of the systems compared to the R404A system is presented in Figure 11. The R744 booster refrigeration system (CB) was found not to be a better alternative to the existing R404A systems operating in warm (e.g., Athens and Madrid) or hot climatic conditions (e.g., Delhi, Riyadh, Phoenix, Bangkok and Miami).

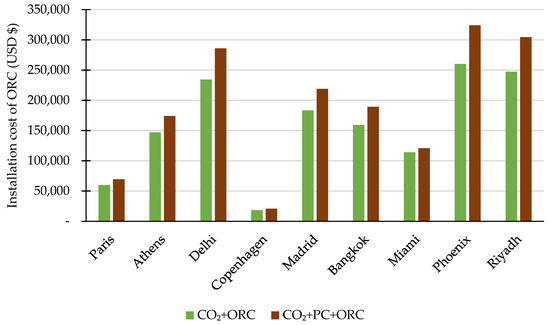

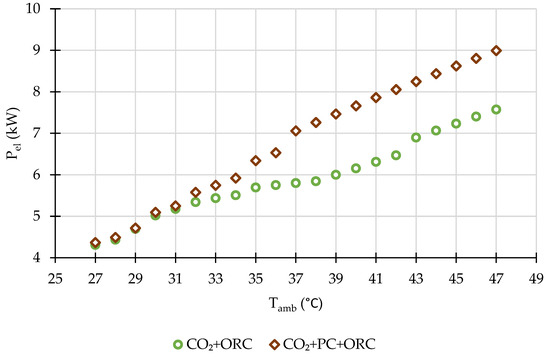

3.4. Cost Analysis of the ORC System

The installation costs of the CO2+ORC system and CO2+PC+ORC system are compared in Figure 12. The cost of ORC was estimated at the design condition which corresponds to the highest operational ambient temperature at which the ORC can operate (30 °C in Paris, 38 °C at Athens, 45 °C in Delhi, 27 °C in Copenhagen, 41 °C in Madrid, 39 °C in Bangkok, 34 °C in Miami, 47 °C in Phoenix and 46 °C in Riyadh). The installation cost was highest in Phoenix, having the highest temperature design condition, followed by Riyadh, Delhi, Madrid, Bangkok, Athens and Miami. With an increase in the ambient temperature, the optimum gas cooler pressure increases. This results in higher heat rejection to the boiler of the ORC system. The higher the heat addition to the boiler, the more electricity is generated by the ORC system. Figure 13 shows the variation in the electricity generated by the CO2+ORC system and the CO2+PC+ORC system (at optimized operating high-side pressure) at various ambient temperatures.

Figure 12.

Installation cost of the CO2+ORC system and CO2+PC+ORC system at various locations.

Figure 13.

Electricity generated by the ORC systems at various ambient temperatures.

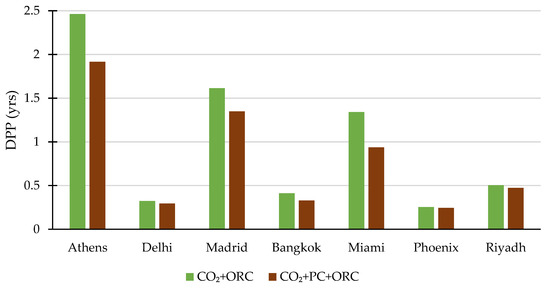

3.5. Difference in Payback Period of the Investigated Systems

The results in terms of difference in payback period are shown in Figure 14. For calculating the payback period, only the additional cost for installation of the ORC system over and above the R744 system was considered as USD 3159/kWel, as per [11]. The cost of the R744 side was not taken into consideration in the present work. The adoption of the ORC over and above a transcritical R744 booster supermarket refrigeration system (CO2+ORC) was found to be 2.5 years in Athens, 0.3 years in New Delhi, 1.6 years in Madrid, 0.4 years in Bangkok, 1.3 years in Miami, 0.3 years in Phoenix and 0.5 years in Riyadh. For the transcritical R744 booster supermarket refrigeration system indicated as CO2+PC+ORC, the combination of the parallel compression and ORC resulted in a further drop in computed simple payback period to 1.9 years in Athens, 0.3 years in New Delhi, 1.4 years in Madrid, 0.3 years in Bangkok, 0.9 years in Miami, 0.2 years in Phoenix and 0.5 years in Riyadh.

Figure 14.

Difference in payback period (years) of the CO2+ORC and CO2+PC+ORC systems at various locations.

4. Conclusions

Transcritical R744 booster supermarket refrigeration systems are widely regarded as viable and sustainable solutions for the future of supermarket applications. However, their energy efficiency needs to be significantly enhanced in warm and hot climates, while preserving their cost-effectiveness. In this work, a comparative study has been presented to evaluate the potential of integration of an ORC into a transcritical R744 booster supermarket refrigeration system for performance enhancement. The combined effect of parallel compression and ORC on the performance of the R744 refrigeration system has also been investigated. Nine different locations, categorized under cold, warm and hot ambient conditions, namely Copenhagen (Denmark), Paris (France), Athens (Greece), New Delhi (India), Phoenix (US), Miami (US), Madrid (Spain), Bangkok (Thailand) and Riyadh (Saudi Arabia), have been explored in order to assess the effect of the climate conditions on their energy and economic performance. The major conclusions drawn are summarized as follows:

- The ORC system can be operated only at ambient temperatures greater than or equal to 27 °C without parallel compression and greater than or equal to 28 °C with parallel compression. This is due to the fact that the boiler temperature of the ORC can be maintained at the desired temperature only when the compressor discharge is hot enough. Only at ambient temperatures above ~27 °C–28 °C is it possible to achieve the required boiler temperature. Thus, below this ambient temperature range, it is not possible to operate the ORC system;

- The integration of an ORC system with the R744 refrigeration system is seen to be beneficial in warm climates (Athens and Madrid) as well as in hot climatic conditions (Delhi, Riyadh, Phoenix and Miami). No energy benefits can be derived from the ORC system in cold climates (Paris and Copenhagen). The operational hours of the ORC in warm and hot climatic locations are significantly higher, which resulted in higher utilization of the ORC, while in cold climatic locations like Paris and Copenhagen, the ambient temperature hardly goes above 27 °C, and thus use of ORC does not seem to a feasible solution;

- The ORC system is capable of supplying ~4.2–5.0% of the electricity demand of the R744 refrigeration system in Athens and Madrid, while it can supply over ~14.0–24.0% of the electricity demand in Delhi, Bangkok, Phoenix and Riyadh;

- The CO2+PC+ORC system is found to be the best solution in all the locations due to relatively lower energy consumption and payback period as compared with the other conventional systems considered in the present work;

- The difference in payback period of the additional investment deriving from the ORC is found to be about 1.9–2.5 years in Athens, 1.4–1.6 years in Madrid, and 0.9–1.3 years in Miami, while the same in Delhi, Bangkok, Phoenix and Riyadh is found to be less than ~0.5 years. Thus, it is possible to conclude that the integration of ORC with the R744 refrigeration system is a better solution in hot climatic locations, followed by warm climatic locations;

- The two locations Paris and Copenhagen were not included in the conclusion, as the operation hours of ORC in these two locations were very small due to ambient temperature constraints. The ambient temperatures in these two locations hardly goes beyond 27 °C–28 °C (Figure 3). As properly explained in the manuscript, the ORC can be operated only at ambient temperatures above 27 °C–28 °C. So, it is hardly possible to use the ORC in these two locations year-round. This means that the use of ORC in cold climatic locations like Paris and Copenhagen is not feasible.

Author Contributions

Conceptualization, P.G. and A.S.; methodology, P.G.; software, A.S.; investigation, A.S.; writing—original draft preparation, P.G. and A.S.; writing—review and editing, P.G., A.S., M.S.D. and V.K.; supervision, P.G., M.S.D. and V.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gullo, P.; Hafner, A.; Banasiak, K. Transcritical R744 refrigeration systems for supermarket applications: Current status and future perspectives. Int. J. Refrig. 2018, 93, 269–310. [Google Scholar] [CrossRef]

- Ringstad, K.E.; Allouche, Y.; Gullo, P.; Ervik, Å.; Banasiak, K.; Hafner, A. A detailed review on CO2 two-phase ejector flow modeling. Therm. Sci. Eng. Prog. 2020, 20, 100647. [Google Scholar] [CrossRef]

- Madsen, K.B.; Kriezi, E.E. Financial aspects of ejector solutions in supermarket and smaller industrial systems. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018; p. 1403. [Google Scholar]

- Dai, B.; Cao, Y.; Liu, S.; Ji, Y.; Sun, Z.; Xu, T.; Zhang, P.; Nian, V. Annual energetic evaluation of multi-stage dedicated mechanical subcooling carbon dioxide supermarket refrigeration system in different climate regions of China using genetic algorithm. J. Clean. Prod. 2021, 333, 130119. [Google Scholar] [CrossRef]

- Chesi, A.; Esposito, F.; Ferrara, G.; Ferrari, L. Experimental analysis of R744 parallel compression cycle. Appl. Energy 2014, 135, 274–285. [Google Scholar] [CrossRef]

- Polzot, A.; D’Agaro, P.; Gullo, P.; Cortella, G. Modelling commercial refrigeration systems coupled with water storage to improve energy efficiency and perform heat recovery. Int. J. Refrig. 2016, 69, 313–323. [Google Scholar] [CrossRef]

- Minetto, S.; Brignoli, R.; Zilio, C.; Marinetti, S. Experimental analysis of a new method for overfeeding multiple evaporators in refrigeration systems. Int. J. Refrig. 2014, 38, 1–9. [Google Scholar] [CrossRef]

- Sengupta, A.; Dasgupta, M.S. CFD supported thermodynamic analysis of a CO2 pressure exchanger based refrigeration system for supermarkets. Int. J. Refrig. 2023, 152, 110–121. [Google Scholar] [CrossRef]

- Sawalha, S. Investigation of heat recovery in CO2 trans-critical solution for supermarket refrigeration. Int. J. Refrig. 2013, 36, 145–156. [Google Scholar] [CrossRef]

- Nemati, A.; Mohseni, R.; Yari, M. A comprehensive comparison between CO2 and Ethane as a refrigerant in a two-stage ejector-expansion transcritical refrigeration cycle integrated with an organic Rankine cycle (ORC). J. Supercrit. Fluids 2018, 133, 494–502. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Incorporation of an organic Rankine cycle in a transcritical booster CO2 refrigeration system. Int. J. Energy Res. 2020, 44, 7974–7988. [Google Scholar] [CrossRef]

- Hu, K.; Zhang, Y.; Yang, W.; Liu, Z.; Sun, H.; Sun, Z. Energy, Exergy, and Economic (3E) Analysis of Transcritical Carbon Dioxide Refrigeration System Based on ORC System. Energies 2023, 16, 1675. [Google Scholar] [CrossRef]

- Ni, T.; Si, J.; Lu, F.; Zhu, Y.; Pan, M. Performance analysis and optimization of cascade waste heat recovery system based on transcritical CO2 cycle for waste heat recovery in waste-to-energy plant. J. Clean. Prod. 2021, 331, 129949. [Google Scholar] [CrossRef]

- Tsimpoukis, D.; Syngounas, E.; Bellos, E.; Koukou, M.; Tzivanidis, C.; Anagnostatos, S.; Vrachopoulos, M.G. Thermodynamic and economic analysis of a supermarket transcritical CO2 refrigeration system coupled with solar-fed supercritical CO2 Brayton and organic Rankine cycles. Energ. Conver. Manag. X 2023, 18, 100351. [Google Scholar] [CrossRef]

- Tsimpoukis, D.; Syngounas, E.; Bellos, E.; Koukou, M.; Tzivanidis, C.; Anagnostatos, S.; Vrachopoulos, M.G. Optimization analysis of Organic Rankine Cycle powered by waste heat of a supermarket transcritical CO2 multi-ejector refrigeration cycle. J. Clean. Prod. 2023, 418, 138106. [Google Scholar] [CrossRef]

- Souza, J.R.; dos Santos, C.A.C.; Ochoa, A.A.V.; Marques, A.S.; Neto, L.M.J.; Michima, P.S.A. Proposal and 3E (energy, exergy, and exergoeconomic) assessment of a cogeneration system using an organic Rankine cycle and an Absorption Refrigeration System in the Northeast Brazil: Thermodynamic investigation of a facility case study. Energy Conver. Manag. 2020, 217, 113002. [Google Scholar] [CrossRef]

- Ipakchi, O.; Mosaffa, A.; Farshi, L.G. Ejector based CO2 transcritical combined cooling and power system utilizing waste heat recovery: A thermoeconomic assessment. Energy Convers. Manag. 2019, 186, 462–472. [Google Scholar] [CrossRef]

- Merino, S.L.; Valencia, O.G.; Duarte, F.J. Energy and exergy assessment of a combined supercritical Brayton cycle-orc hybrid system using solar radiation and coconut shell biomass as energy source. Renew. Energy 2021, 175, 119–142. [Google Scholar] [CrossRef]

- Georgousis, N.; Lykas, P.; Bellos, E.; Tzivanidis, C. Multi-objective optimization of a solar-driven polygeneration system based on CO2 working fluid. Energy Convers. Manag. 2021, 252, 115136. [Google Scholar] [CrossRef]

- Goyal, A.; Rawat, P.; Sherwani, A.F.; Rana, R. Advanced exergy, economic, and environmental evaluation of an Organic Rankine Cycle driven dual evaporators vapour-compression refrigeration system using organic fluids. Int. J. Refrig. 2023, 150, 170–184. [Google Scholar] [CrossRef]

- Nasir, M.T.; Kim, K.C. Working fluids selection and parametric optimization of an Organic Rankine Cycle coupled Vapor Compression Cycle (ORC-VCC) for air conditioning using low grade heat. Energy Build. 2016, 129, 378–395. [Google Scholar] [CrossRef]

- Yue, C.; You, F.; Huang, Y. Thermal and economic analysis of an energy system of an ORC coupled with vehicle air conditioning. Int. J. Refrig. 2016, 64, 152–167. [Google Scholar] [CrossRef]

- Saleh, B. Parametric and working fluid analysis of a combined organic Rankine-vapor compression refrigeration system activated by low-grade thermal energy. J. Adv. Res. 2016, 7, 651–660. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Han, Z.; Jia, X.; Mei, Z.; Han, X.; Wang, Z. Comparative analysis of an organic Rankine cycle with different turbine efficiency models based on multi-objective optimization. Energy Convers. Manag. 2019, 185, 130–142. [Google Scholar] [CrossRef]

- EnergyPlus. EnergyPlus: Weather Data Sources. 2023. Available online: https://energyplus.net/weather (accessed on 29 September 2023).

- Gullo, P.; Elmegaard, B.; Cortella, G. Energy and environmental performance assessment of R744 booster supermarket refrigeration systems operating in warm climates. Int. J. Refrig. 2016, 64, 61–79. [Google Scholar] [CrossRef]

- Purohit, N.; Gullo, P.; Dasgupta, M.S. Comparative Assessment of Low-GWP Based Refrigerating Plants Operating in Hot Climates. Energy Procedia 2017, 109, 138–145. [Google Scholar] [CrossRef]

- Karampour, M.; Sawalha, S. State-of-the-art integrated CO2 refrigeration system for supermarkets: A comparative analysis. Int. J. Refrig. 2018, 86, 239–257. [Google Scholar] [CrossRef]

- Tsamos, K.M.; Ge, Y.T.; Santosa, I.D.; Tassou, S.A.; Bianchi, G.; Mylona, Z. Energy analysis of alternative CO2 refrigeration system configurations for retail food applications in moderate and warm climates. Energy Convers. Manag. 2017, 150, 822–829. [Google Scholar] [CrossRef]

- Electricity Prices Around the World. 2022. Available online: https://www.globalpetrolprices.com/electricity_prices/ (accessed on 25 September 2023).

- Huber, M.L.; Lemmon, E.W.; Bell, I.H.; McLinden, M.O. The NIST REFPROP Database for Highly Accurate Properties of Industrially Important Fluids. Ind. Eng. Chem. Res. 2022, 61, 15449–15472. [Google Scholar] [CrossRef]

- MATLAB, R2022b. Available online: https://in.mathworks.com/products/matlab.html (accessed on 25 September 2023).

- F-Chart Software: Engineering Software. EES: Engineering Equation Solver, V11.257-3D. Available online: https://fchartsoftware.com/ees/ (accessed on 25 September 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).