Exhaust Emissions from Euro 6 Vehicles in WLTC and RDE—Part 1: Methodology and Similarity Conditions Studies

Abstract

:1. Introduction

2. Research Problem

3. Literature Review

4. Research Method

4.1. Test Objects

- A conventional vehicle equipped with a gasoline engine with direct injection and a displacement of 1.6 dm3;

- A conventional vehicle equipped with a diesel engine with common rail direct injection, boosted with a turbocharger, having a displacement of 2.0 dm3;

- A hybrid vehicle equipped with two engines: a gasoline internal combustion engine with direct gasoline injection and a displacement of 1.8 dm3 along with an electric motor.

4.2. Research Equipment Used

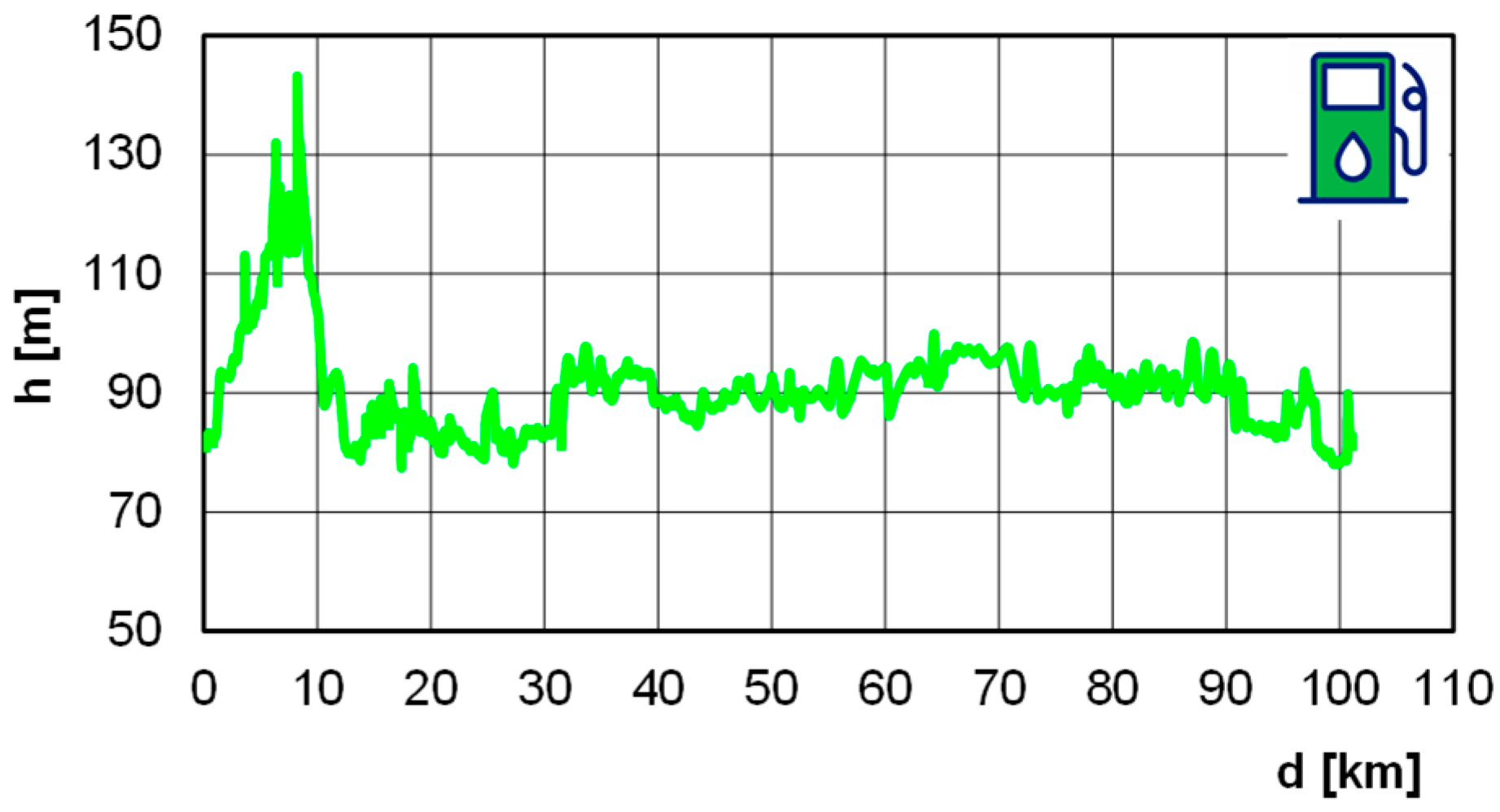

4.3. Test Route—Road Tests

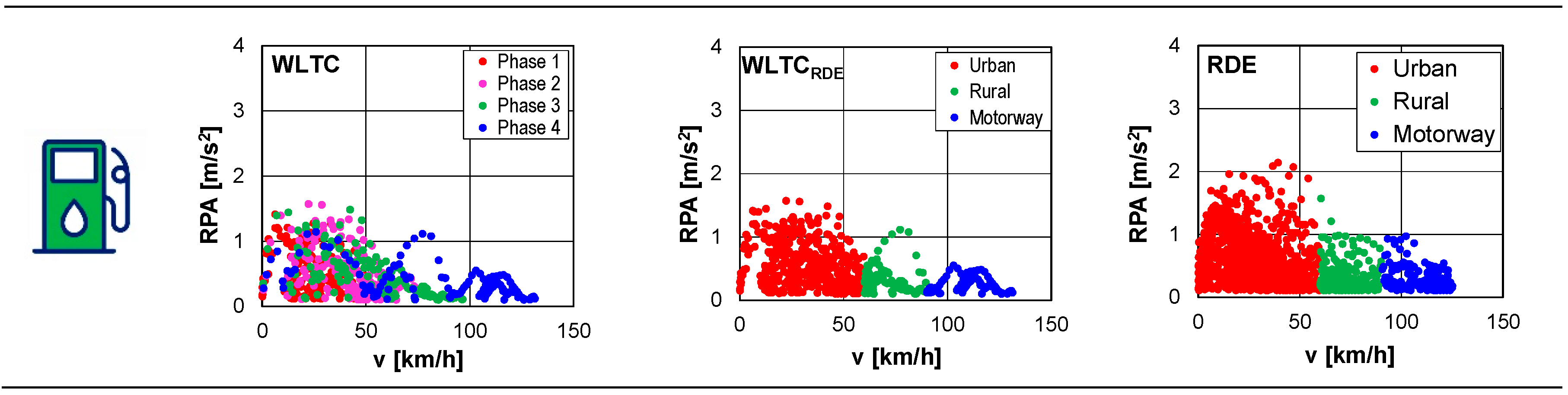

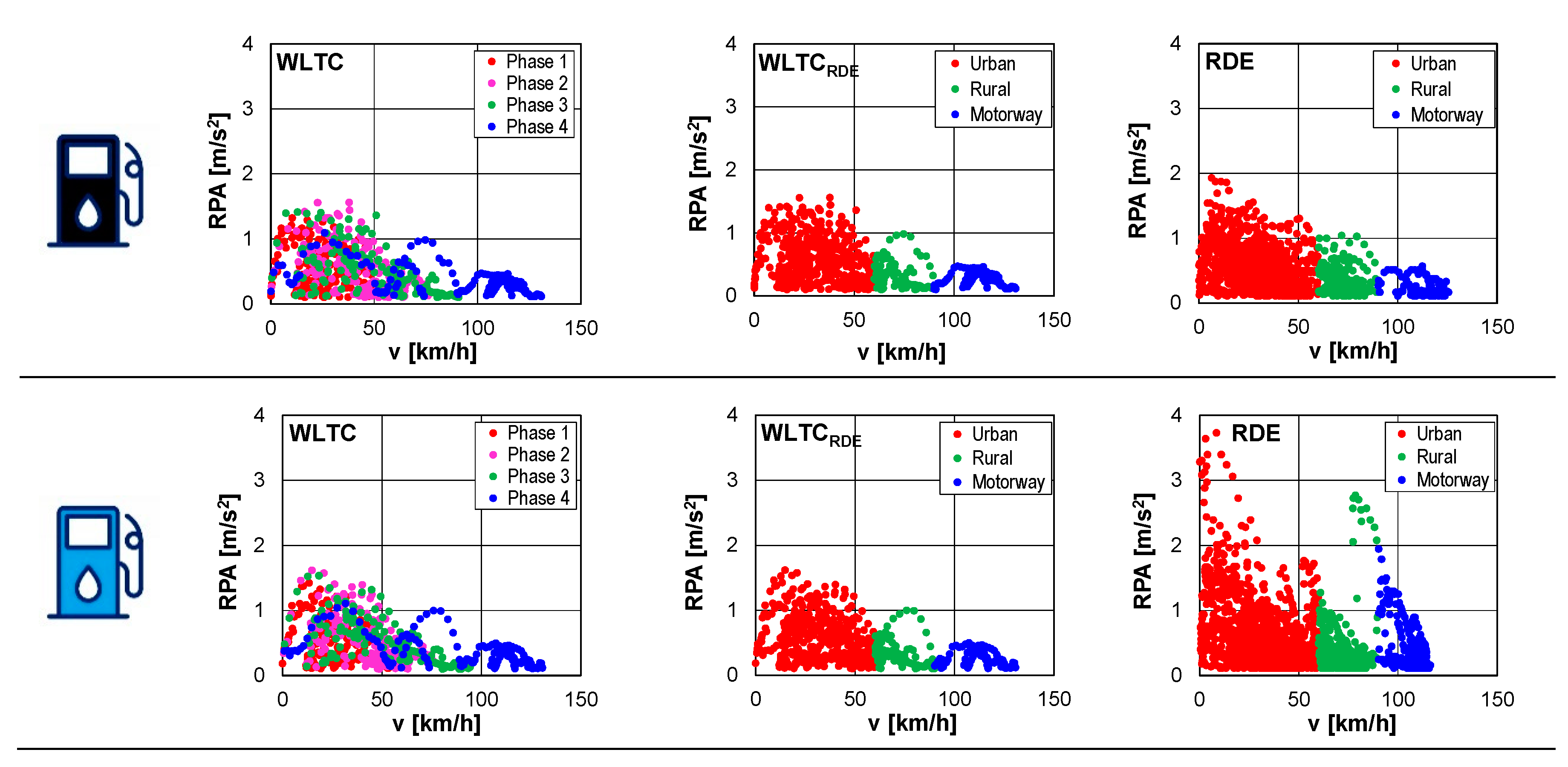

- phase 1, in which the vehicle moved at different speeds in the 0–55 km/h range;

- phase 2, in which the vehicle travelled at a speed in the 0–76 km/h range;

- phase 3, in which the vehicle travelled at a speed in the 0–98 km/h range;

- phase 4, in which the vehicle moved at a momentarily maximum speed of approximately 130 km/h.

- urban section, in which the vehicle travels at different speeds from 0 to 60 km/h;

- rural section, in which the vehicle travels at speeds from 60 km/h to 90 km/h;

- highway section in which the vehicle travels at a speed exceeding 90 km/h,

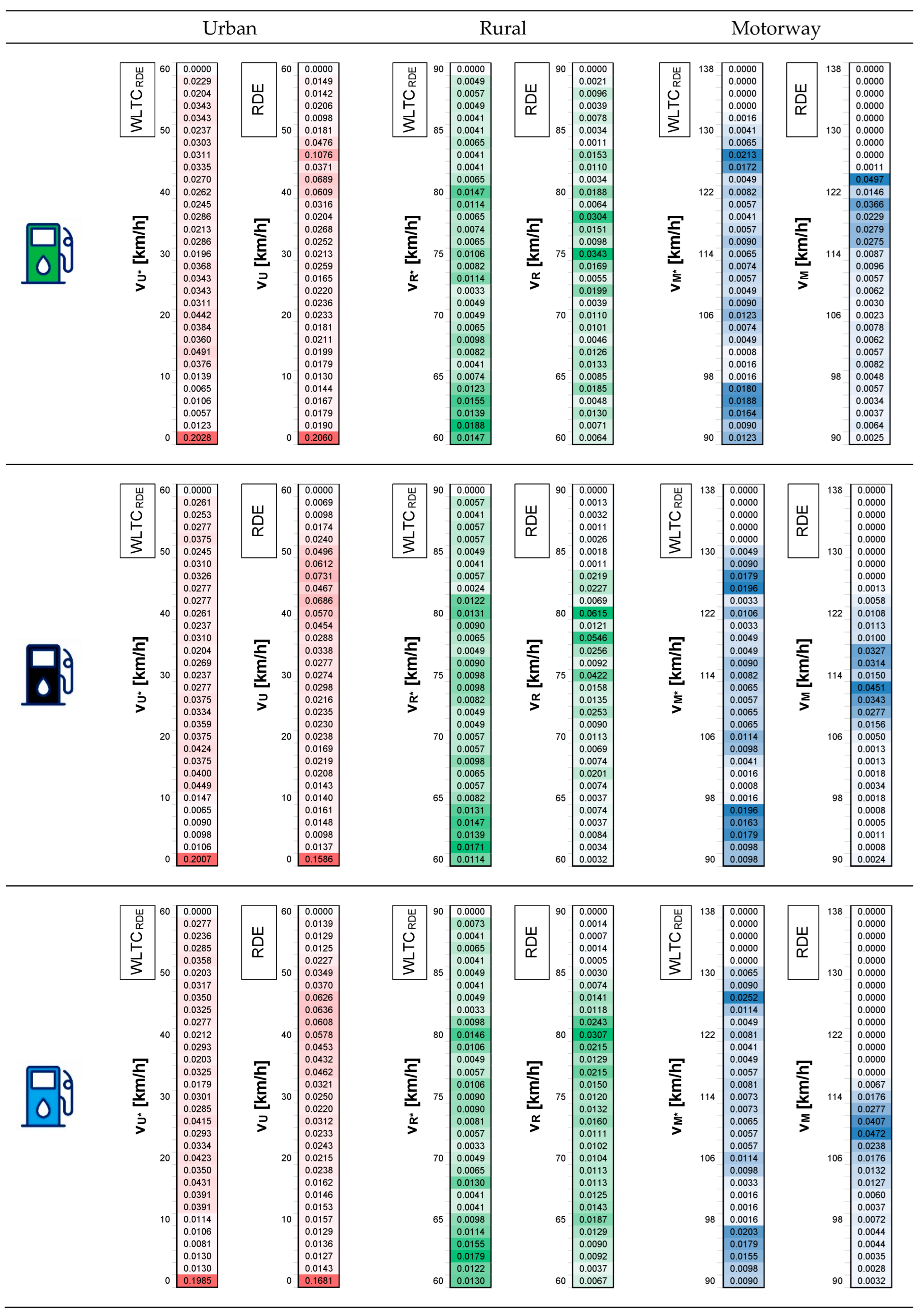

- procedure 1 (labelled WLTC)—division of the driving test in accordance with the WLTP;

- procedure 2 (labelled RDE)—division of the driving test on sections in accordance with the regular RDE test procedure;

- procedure 3 (labelled WLTC1+2)—tests divided into four phases: 1 + 2, 3, and 4; where the combined phases 1 and 2 correspond to the urban driving section of the RDE test;

- procedure 4 (labelled WLTCRDE)—the test phases are divided in accordance with the RDE test procedure, which assumed dividing the phases based on the vehicle travel speed.

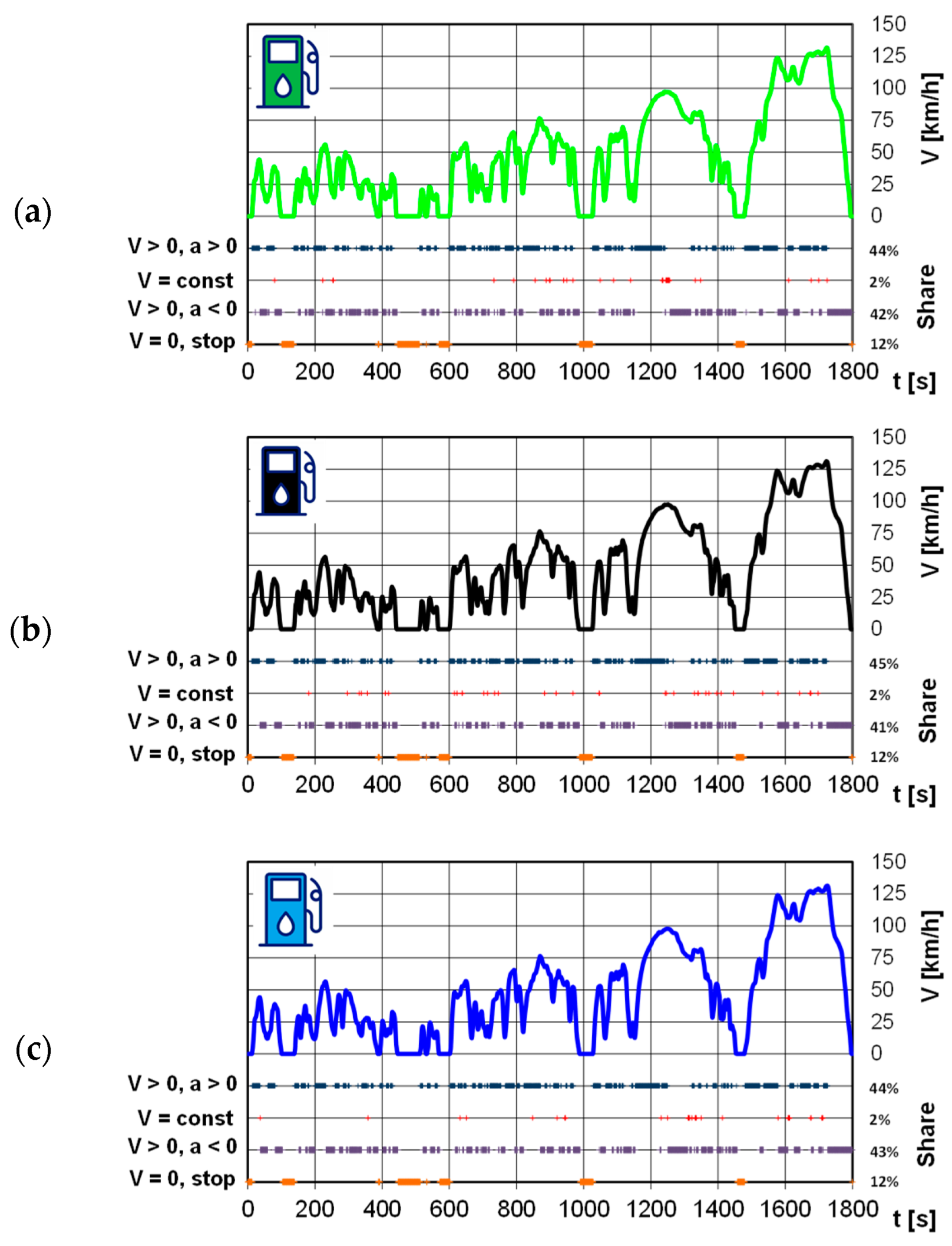

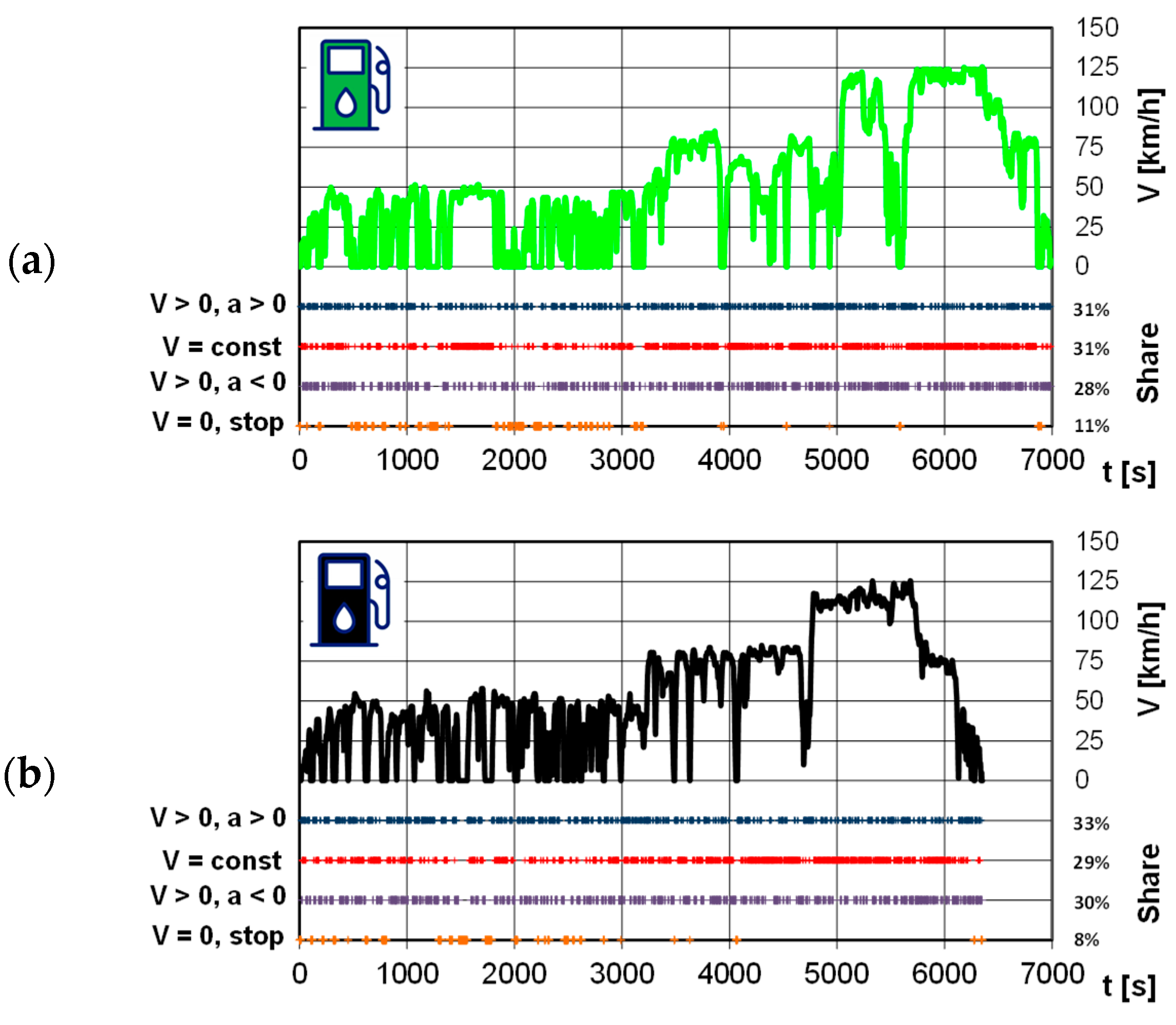

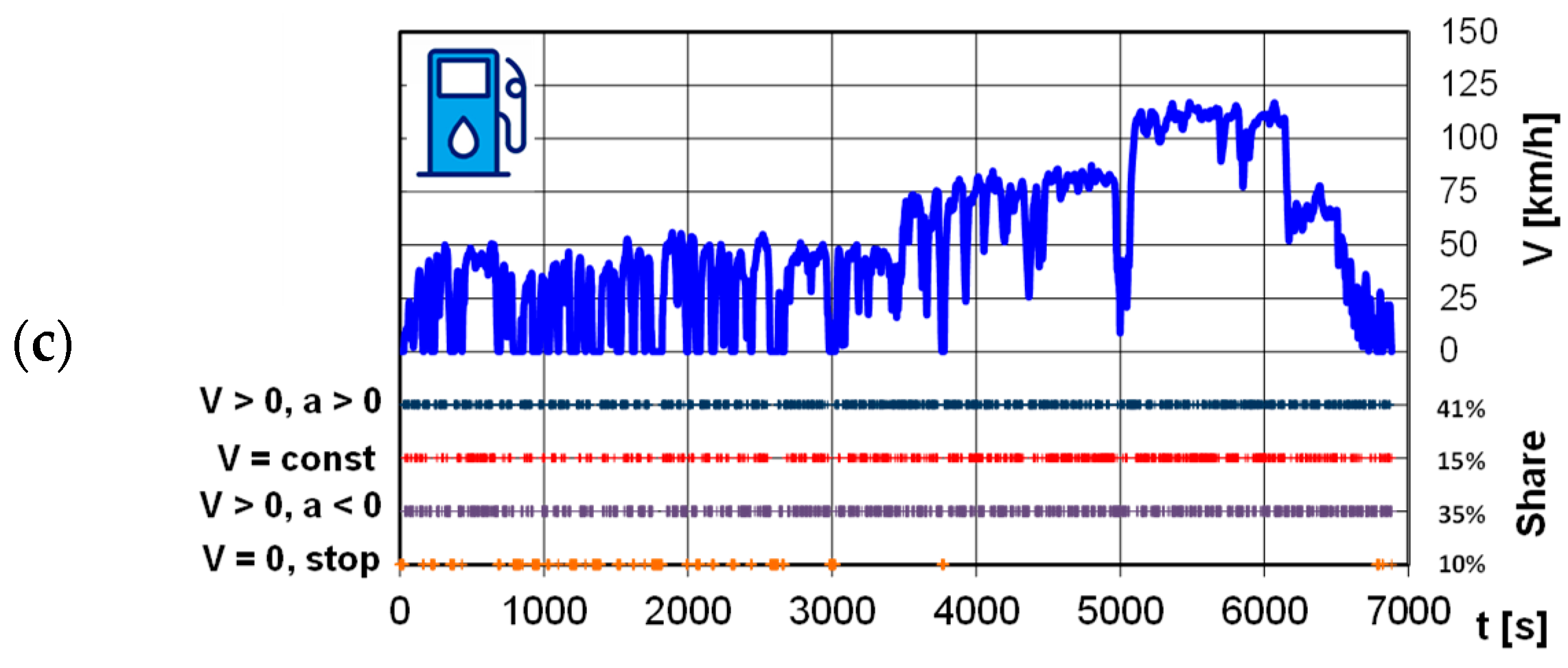

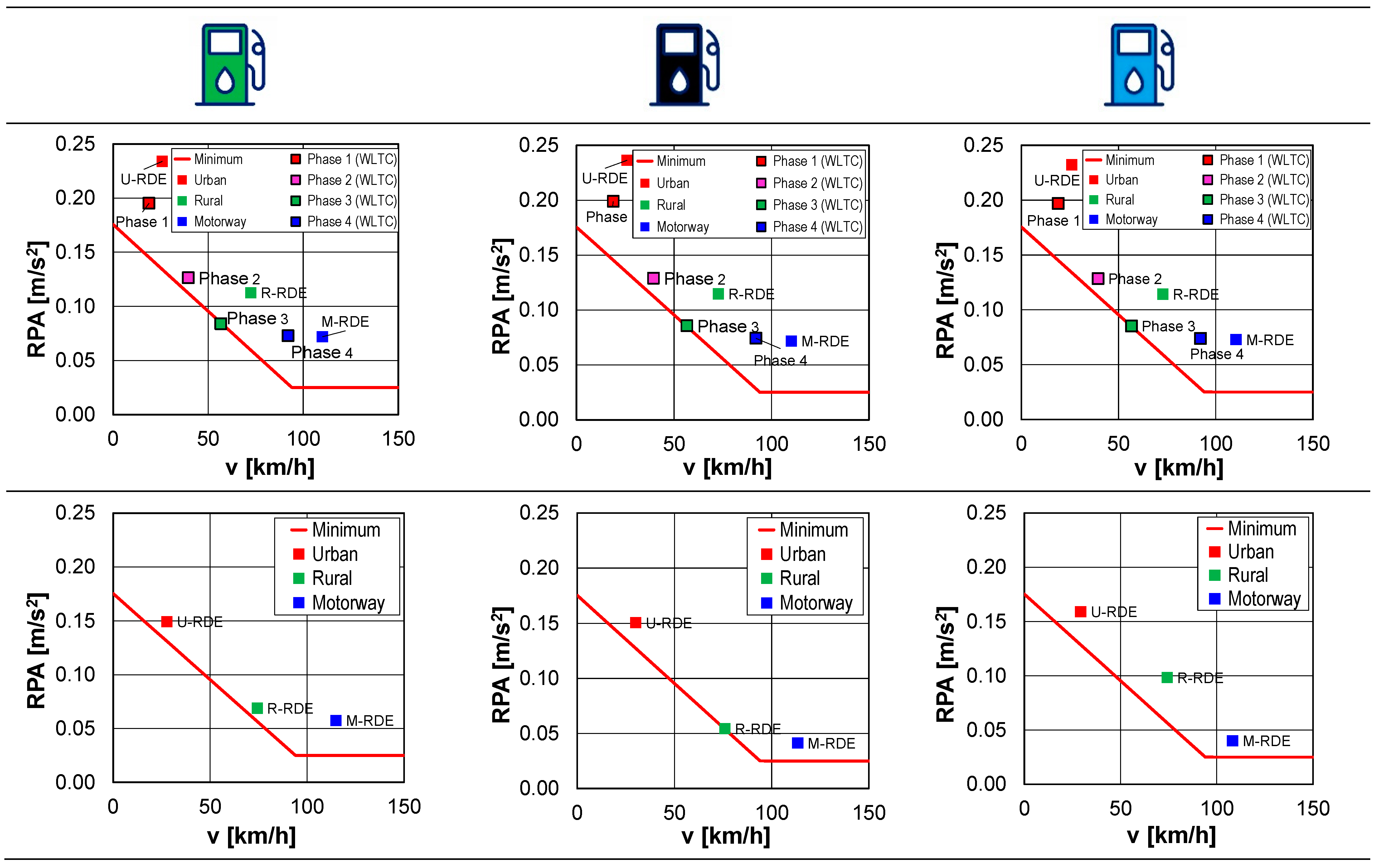

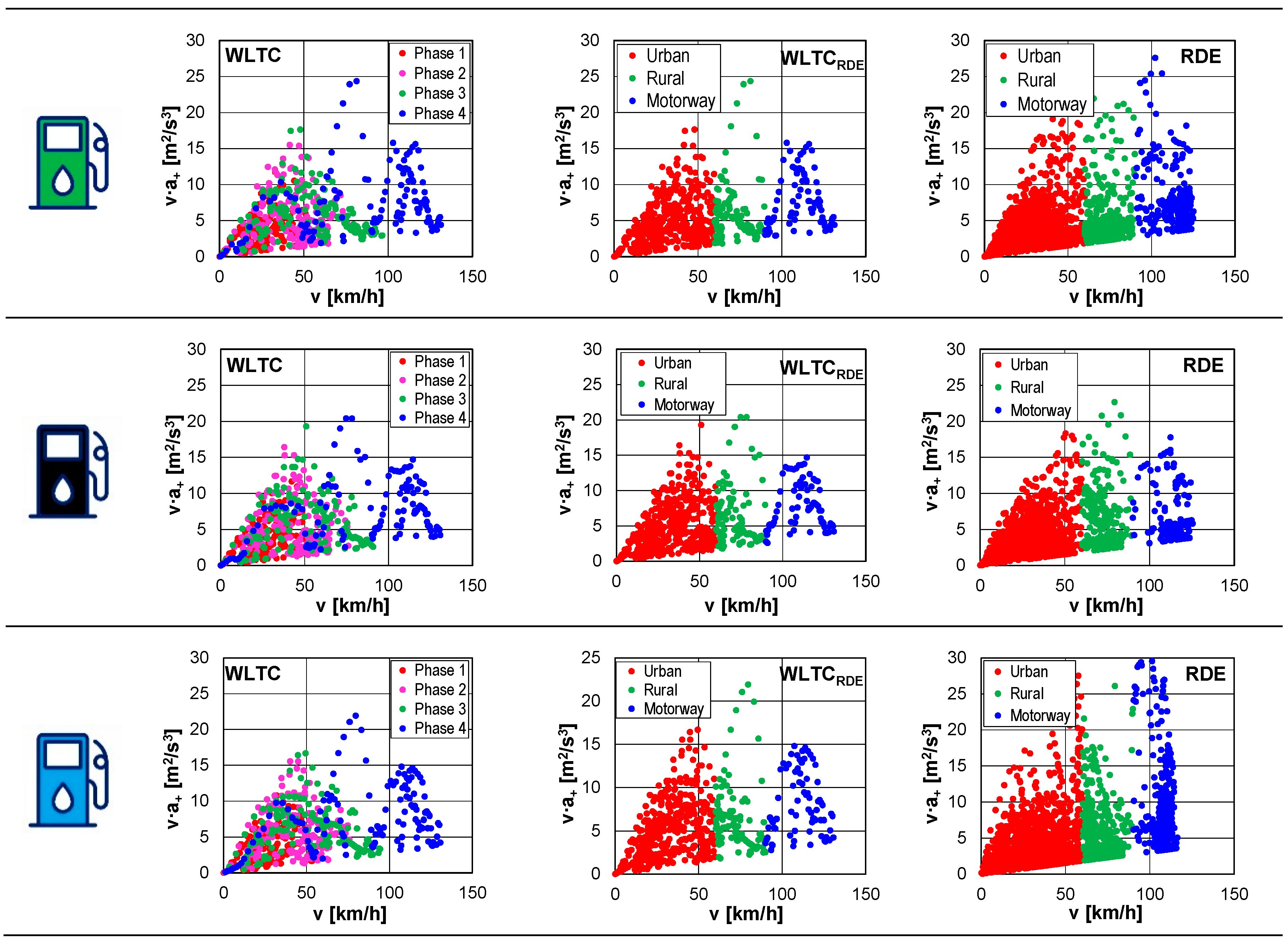

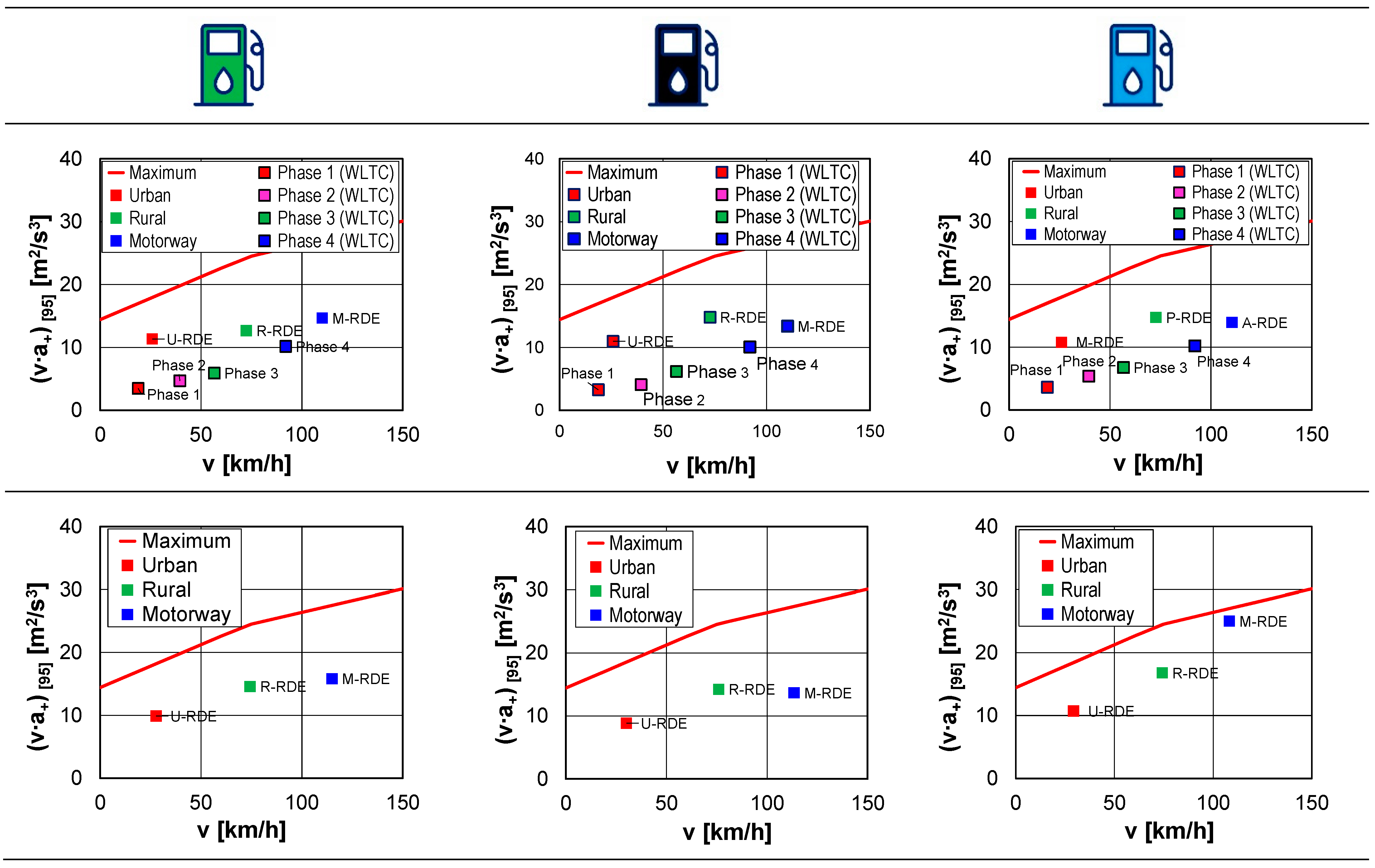

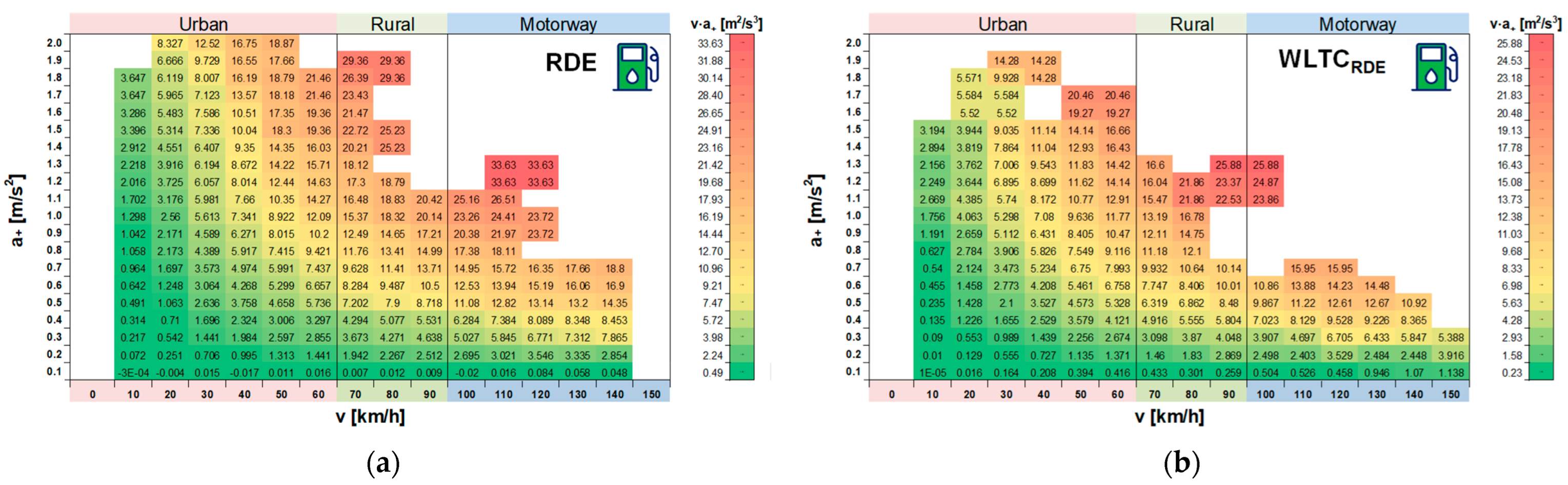

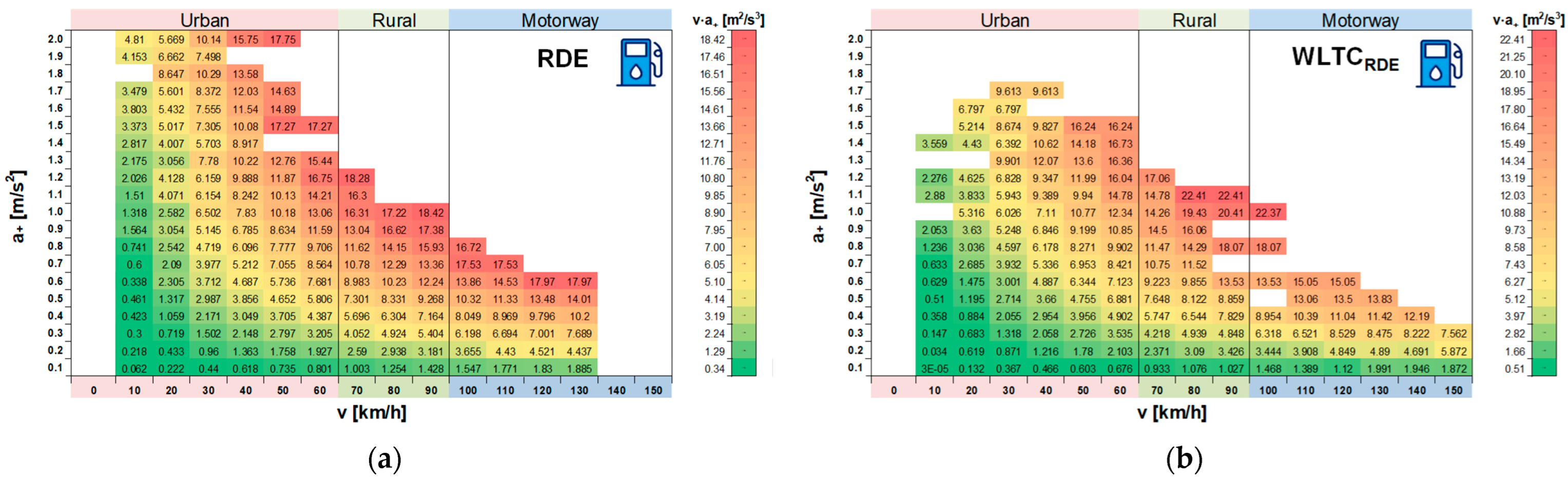

5. Analysis of Driving Parameters in Exhaust Emission Tests

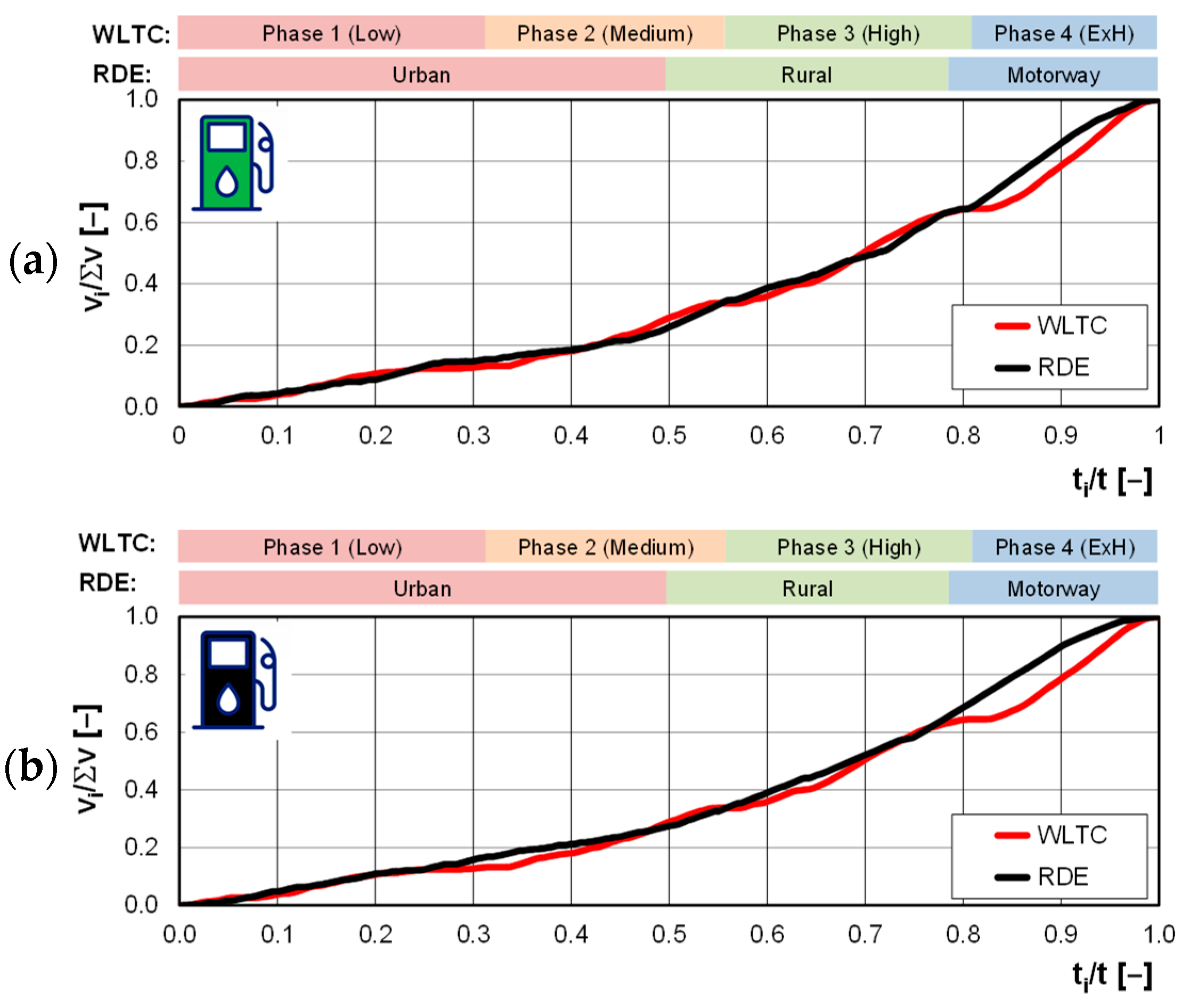

5.1. Comparison of Vehicle Speed Shares in Emission Tests

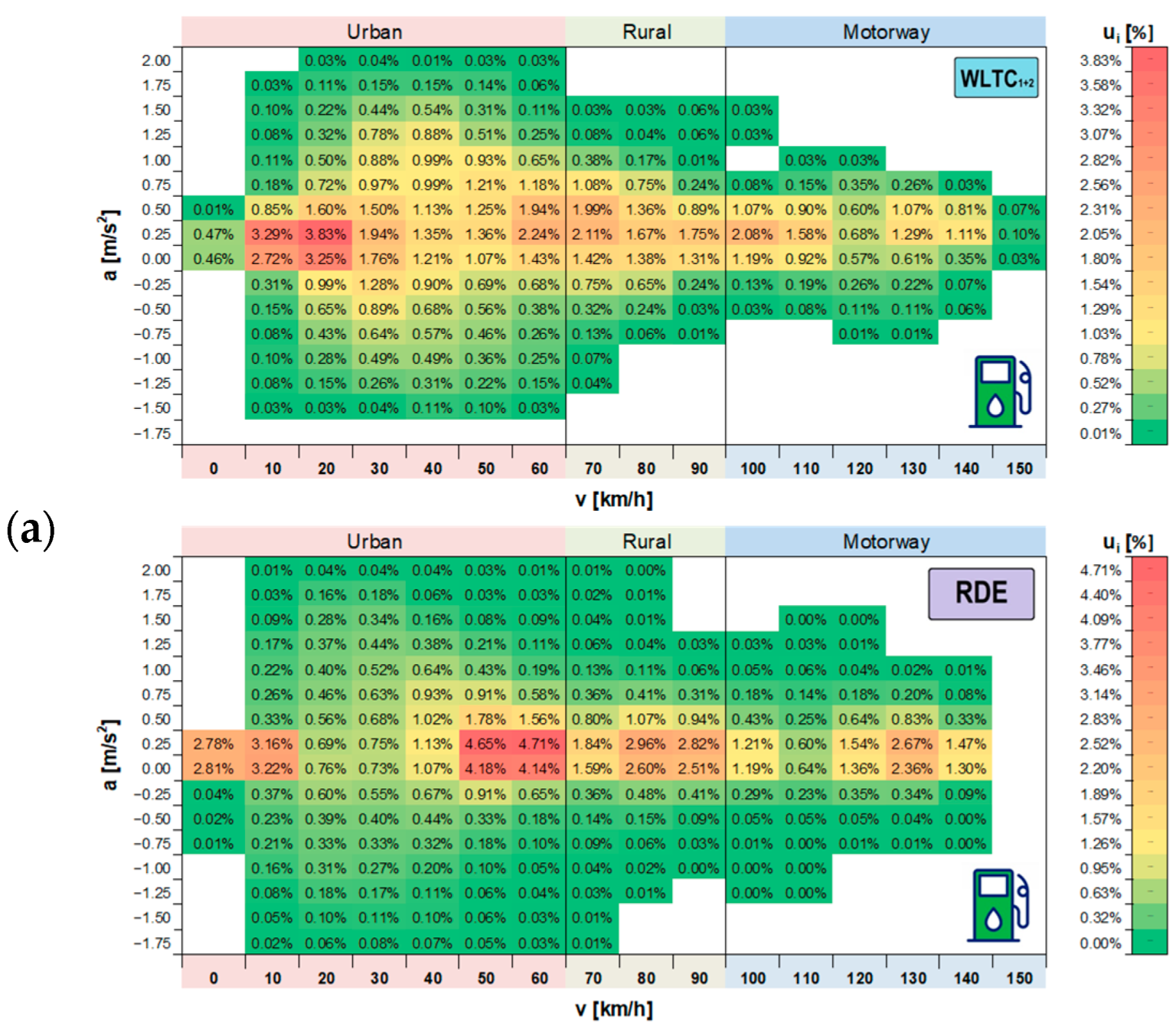

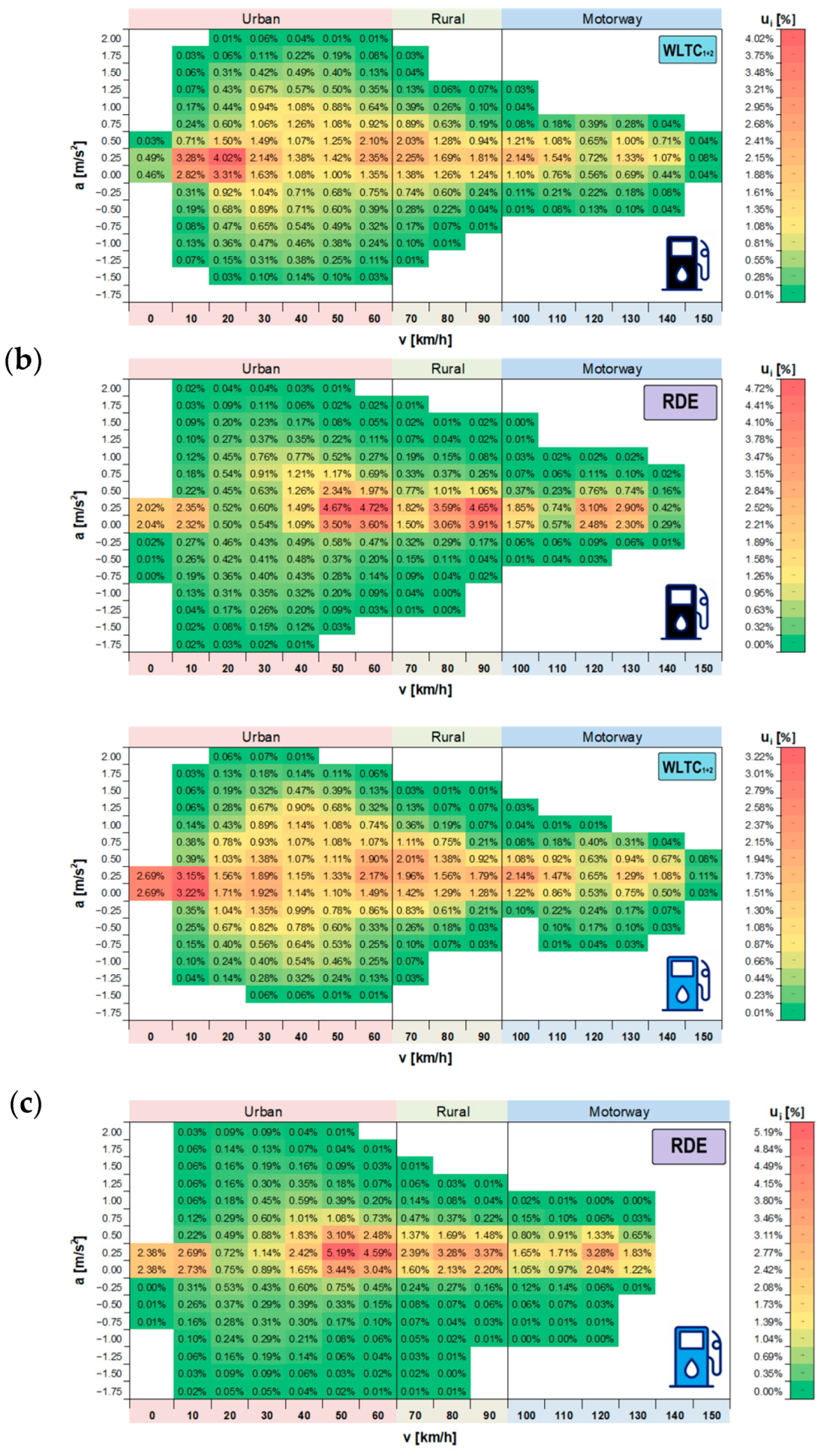

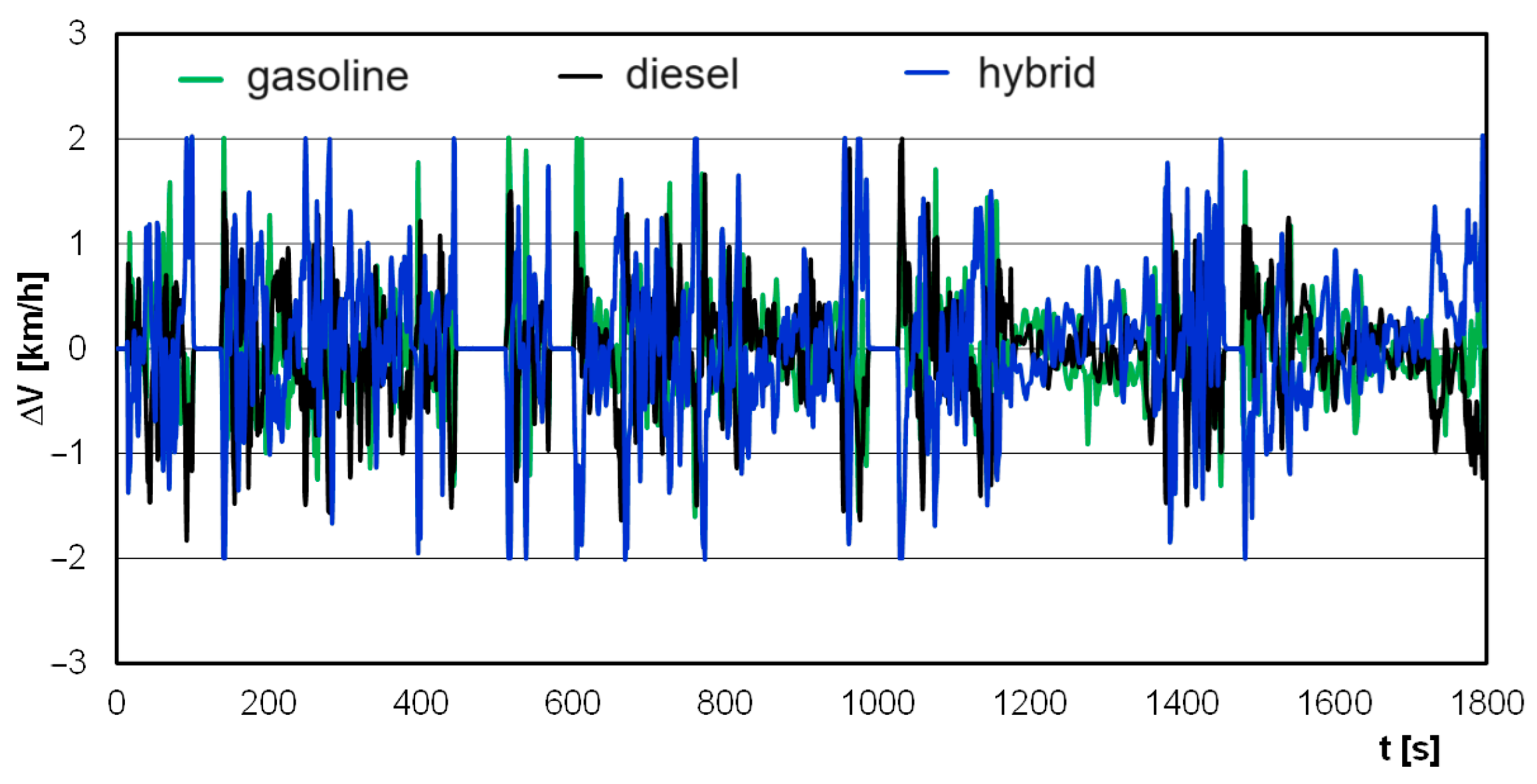

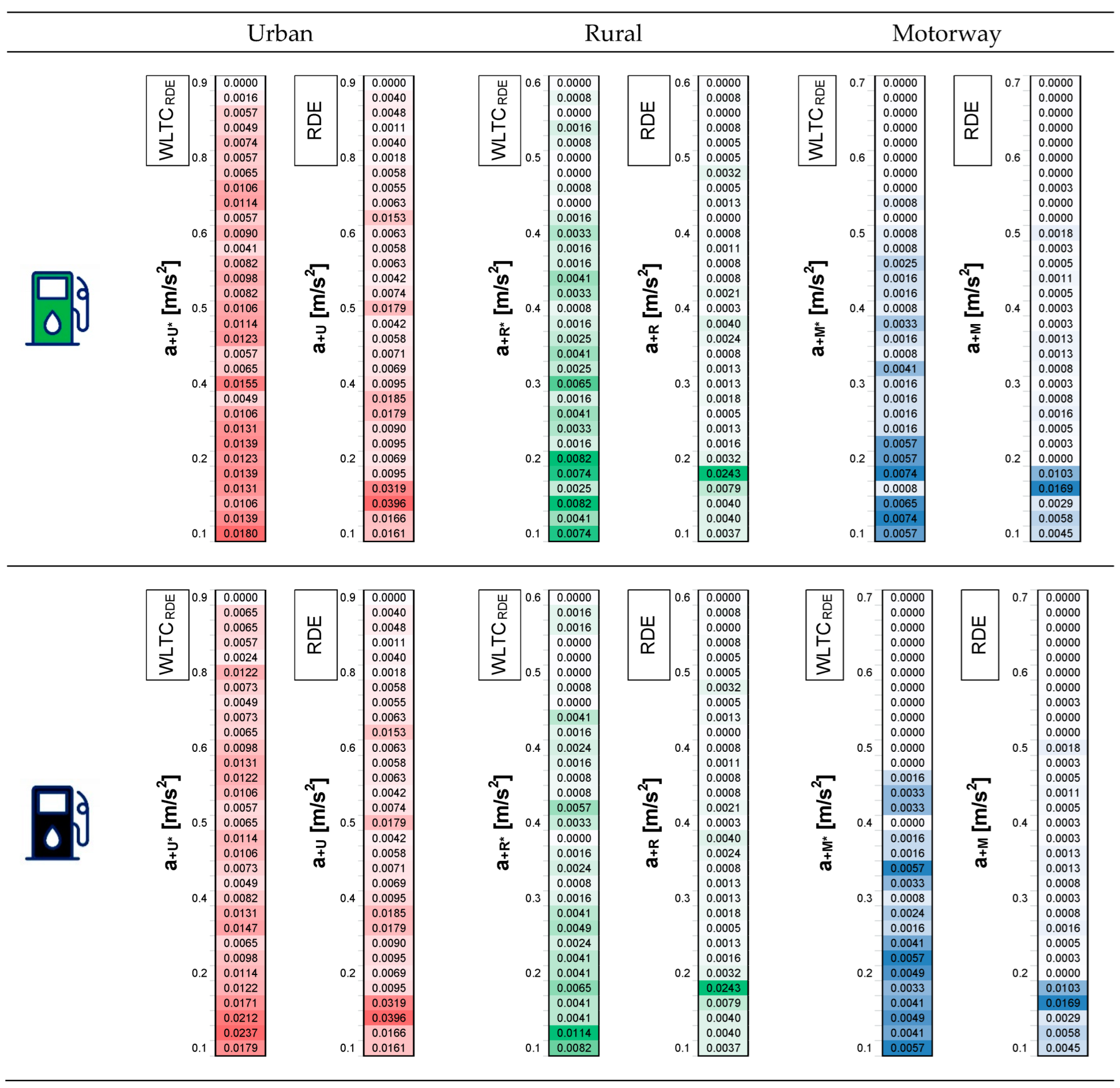

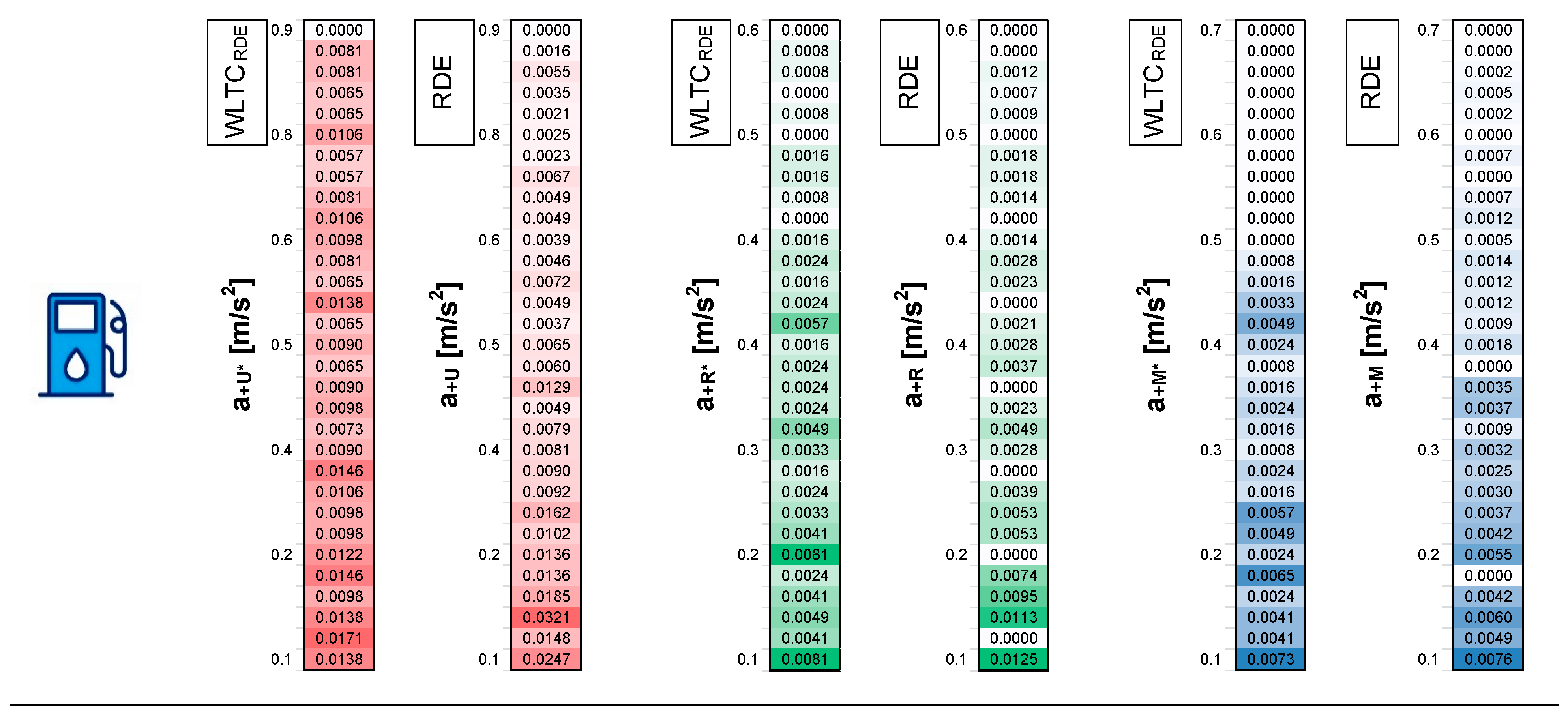

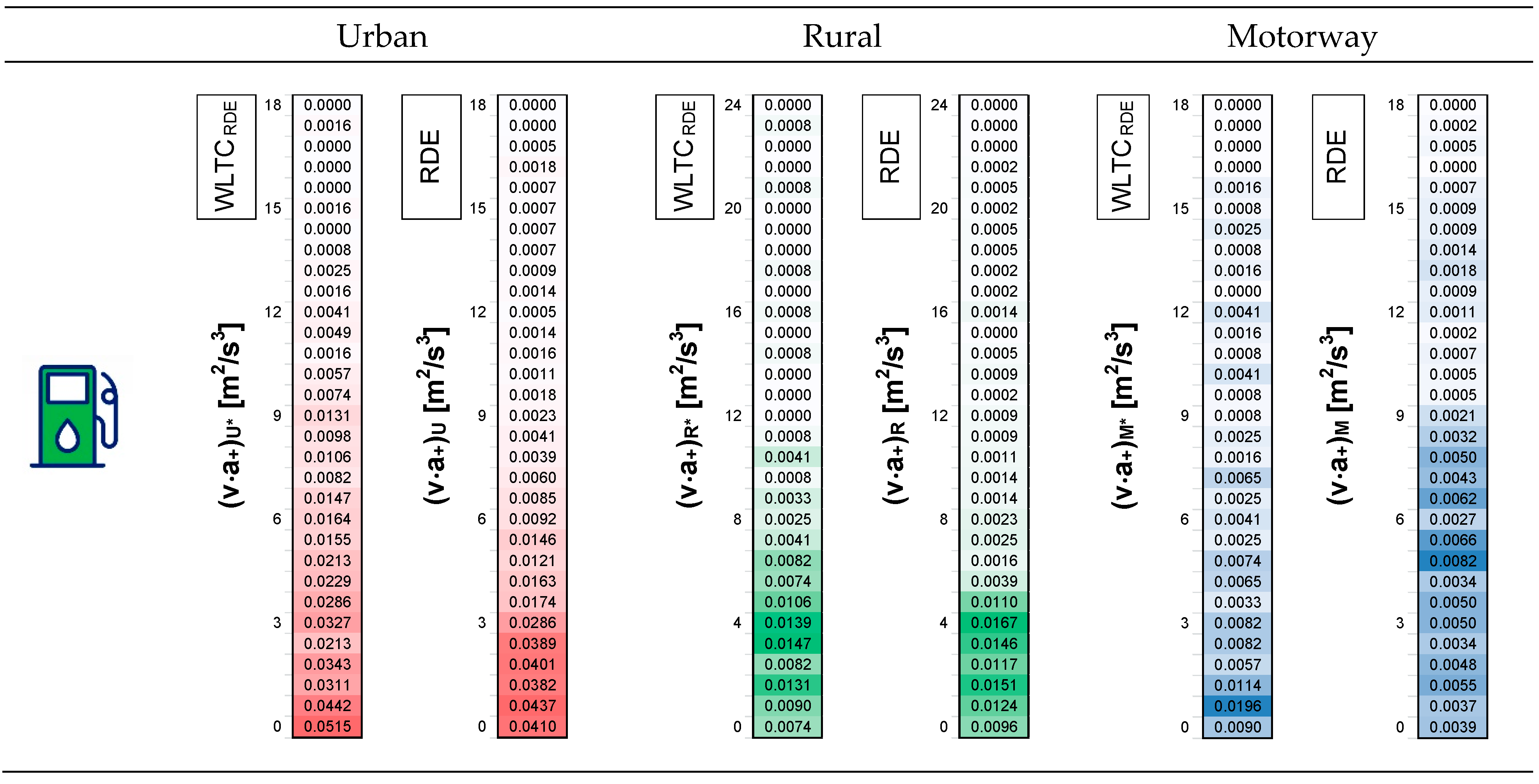

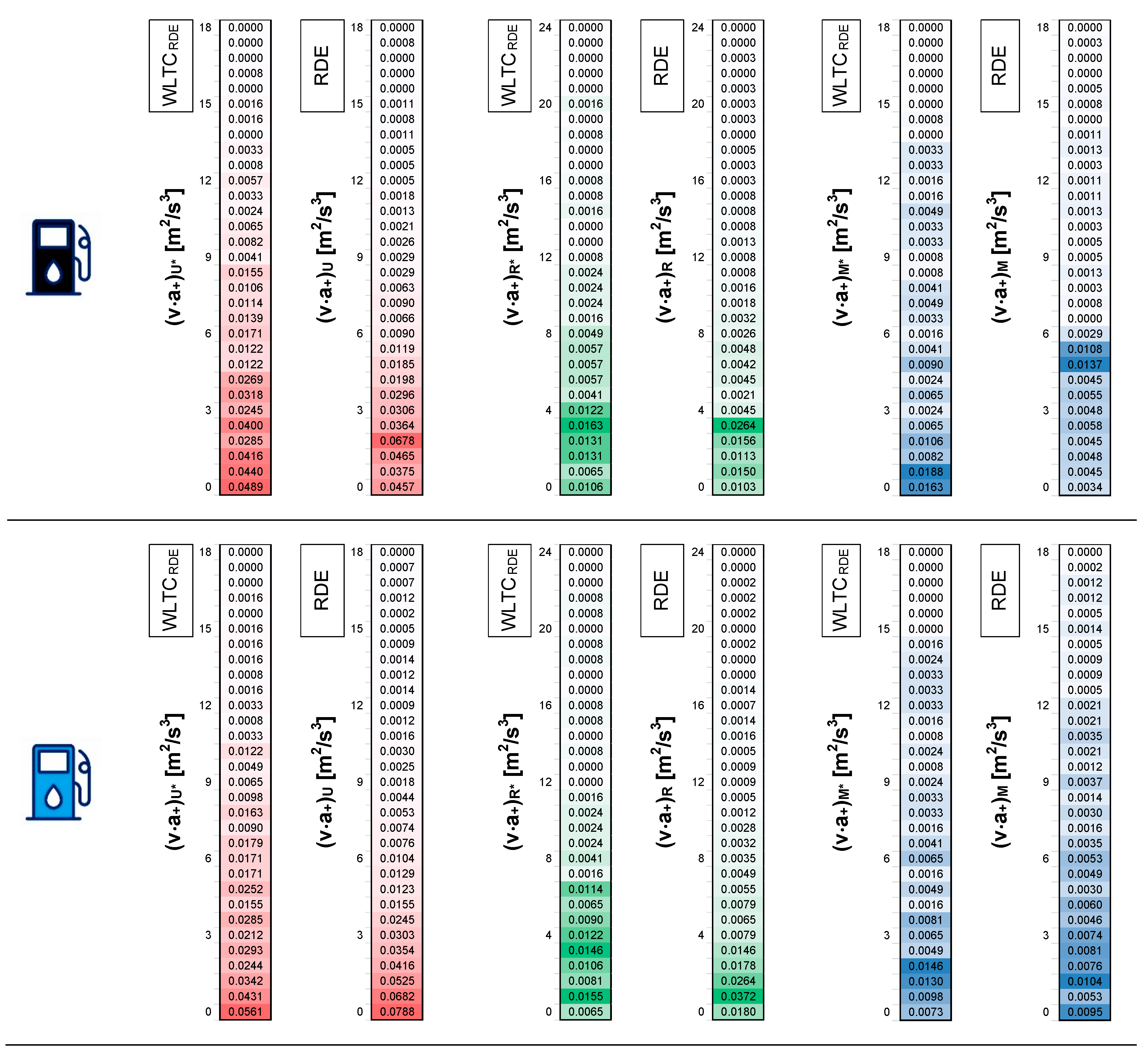

5.2. Comparing the Dynamic Tests Parameters

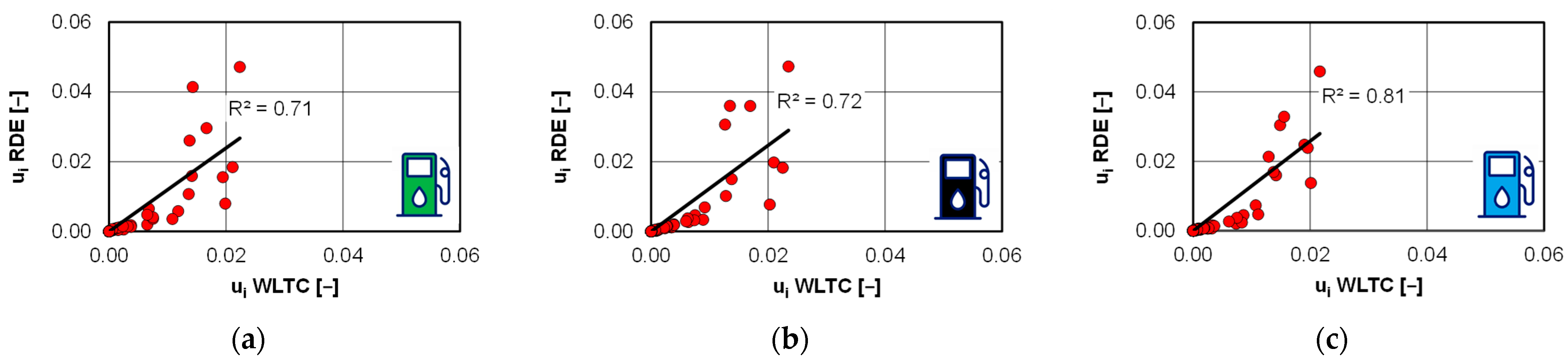

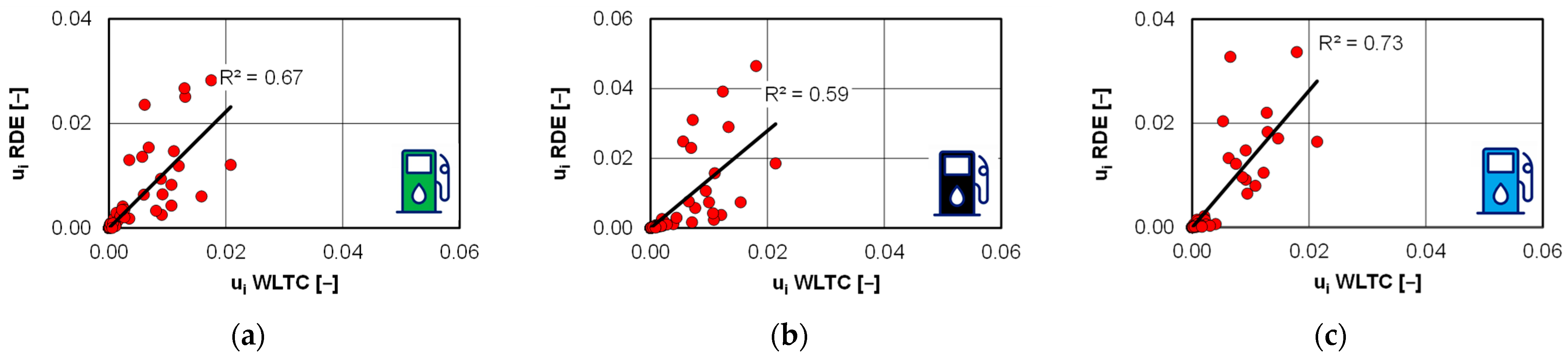

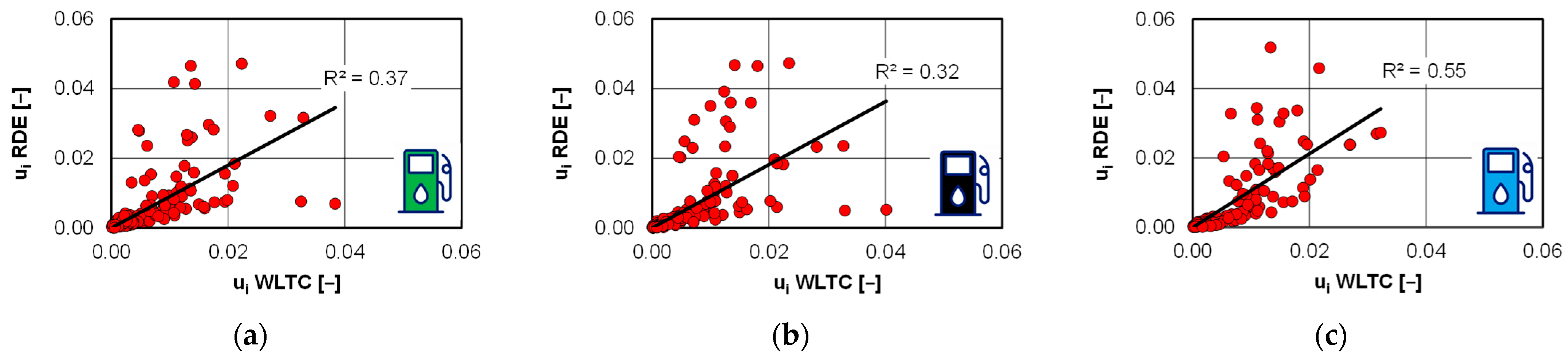

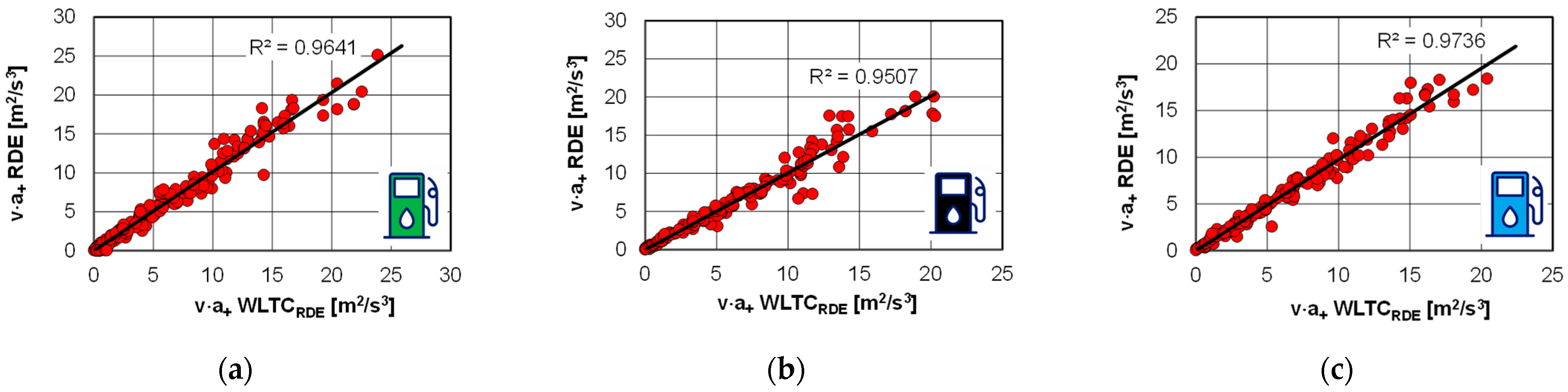

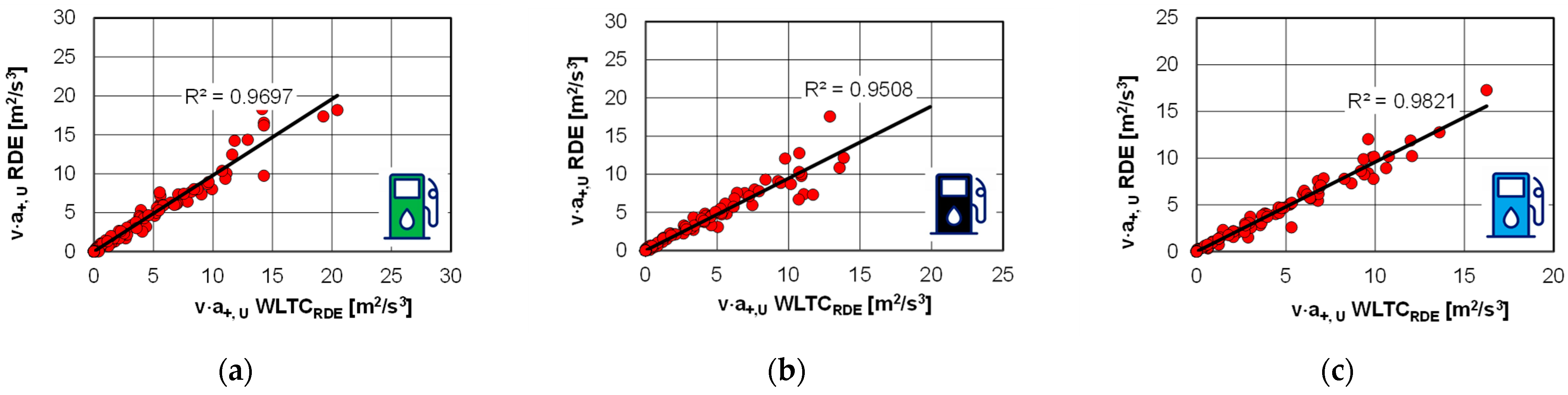

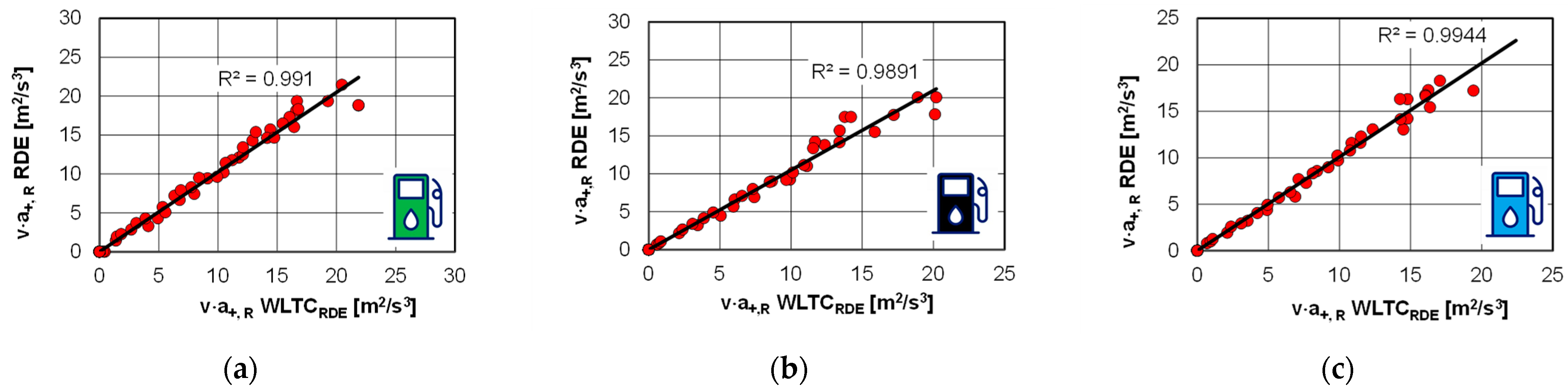

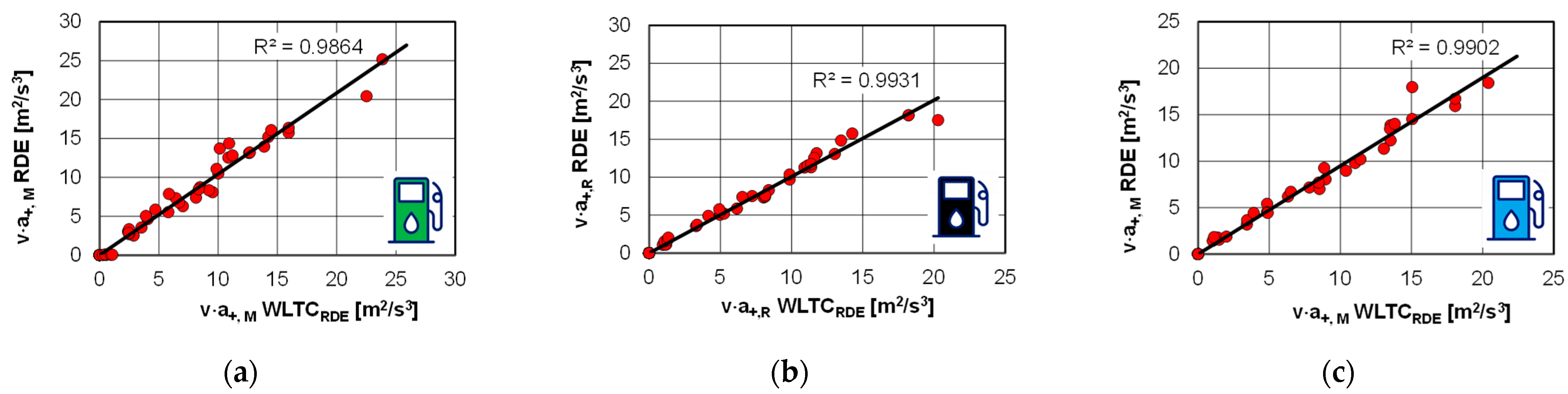

5.3. Correlation of the Dynamic Driving Test Parameters of Tested Vehicles

6. Conclusions

- share of travel speeds in different sections of the tests;

- share of acceleration in entire test cycles as well as their sections;

- share of the product of speed and acceleration in the performed tests and in their sections;

- relative positive acceleration in different test sections as well as its mode (determined for every second of data acquisition);

- the 95th percentile of speed and acceleration in different test sections.

- a new method was proposed for comparing the results determined in the two-dimensional coordinates of vehicle speed–acceleration; the comparison of individual values in the appropriate ranges of the operating parameters creates two independent sets of data that can be correlated;

- comparison of the WLTC and RDE tests allows for a joint comparison of the first and second phases of the WLTC test with the urban section of the RDE test; phase three of the WLTC test corresponds to the rural section of the RDE test, and phase 4 of the WLTC test corresponds to the highway section of the RDE test;

- dividing the WLTC test into phases equivalent to the sections of the RDE procedure (urban, rural and highway) and also calculating the total exhaust emissions in the test according to this procedure resulted in similar values being obtained.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| a | vehicle acceleration |

| DLR | Deutsches Zentrum für Luft- und Raumfahrt (German Transport Institute) |

| EEA | European Environment Agency |

| FCEV | fuel cell electric vehicles |

| HEV | hybrid electric vehicle |

| HiL | Hardware-in-the-Loop |

| ICE | internal combustion engines |

| M | motorway |

| MAW | moving average window |

| NEDC | New European Driving Cycle |

| OBD | on-board diagnostics |

| PEMS | portable emission measurement system |

| PHEV | plug-in hybrid electric vehicle |

| PN | particle number |

| R | rural |

| RDE | real driving emissions |

| RPA | relative positive acceleration |

| S | distance |

| SoC | state of charge |

| SUMO | Simulation of Urban Mobility |

| t | time |

| u | share |

| U | urban |

| UDC | Urban Driving Cycle |

| v | vehicle speed |

| WLTC | Worldwide harmonized Light-duty vehicles Test Cycle |

| WLTP | Worldwide harmonized Light-duty vehicles Test Procedure |

References

- EEA. Monitoring CO2 Emissions from Passenger Cars and Vans in 2018. European Environment Agency, Report 2. 2020. Available online: https://www.eea.europa.eu/publications/co2-emissions-from-cars-and-vans-2018 (accessed on 12 September 2023).

- Transport. 2023. Available online: https://www.eea.europa.eu/pl/themes/transport/intro (accessed on 25 May 2023).

- Paris Agreement. Available online: https://ec.europa.eu/clima/policies/international/negotiations/paris_pl (accessed on 5 September 2023).

- Regulation (EU) 2019/631 of the European Parliament and of the Council of 17 April 2019 Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing Regulations (EC) No 443/2009 and (EU) No 510/2011. Available online: http://data.europa.eu/eli/reg/2019/631/oj (accessed on 9 September 2023).

- Commission Regulation (EU) 2017/1151 of 1 June 2017 Supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on Type-Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information, Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and repealing Commission Regulation (EC) No 692/2008. Available online: http://data.europa.eu/eli/reg/2017/1151/oj (accessed on 9 September 2023).

- Commission Regulation (EU) 2016/427 of 10 March 2016 Amending Regulation (EC) No 692/2008 as Regards Emissions from Light Passenger and Commercial Vehicles (Euro 6). Available online: http://data.europa.eu/eli/reg/2016/427/oj (accessed on 9 September 2023).

- Commission Regulation (EU) 2016/646 of 20 April 2016 Amending Regulation (EC) No 692/2008 as Regards Emissions from Light Passenger and Commercial Vehicles (Euro 6). Available online: http://data.europa.eu/eli/reg/2016/646/oj (accessed on 9 September 2023).

- Commission Regulation (EU) 2017/1154 of 7 June 2017 Amending Regulation (EU) 2017/1151 Supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on Type-Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information, Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and Repealing Regulation (EC) No 692/2008 and Directive 2007/46/EC of the European Parliament and of the Council as Regards Real-Driving Emissions from Light Passenger and Commercial Vehicles (Euro 6). Available online: http://data.europa.eu/eli/reg/2017/1154/oj (accessed on 9 September 2023).

- Commission Regulation (EU) 2018/1832 of 5 November 2018 Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) 2017/1151 for the Purpose of Improving the Emission Type Approval Tests and Procedures for Light Passenger and Commercial Vehicles, including Those for In-Service Conformity and Real-Driving Emissions and Introducing Devices for Monitoring the Consumption of Fuel and Electric Energy. Available online: http://data.europa.eu/eli/reg/2018/1832/oj (accessed on 9 September 2023).

- Donateo, T.; Giovinazzi, M. Some Repeatability and Reproducibility Issues in Real Driving Emission Tests; SAE Technical Paper 2018-01-5020; SAE: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, R.; Yan, Y.; Ou, J.; Liu, Z.; Liu, J. Numerical Study on the Effect of Injector Nozzle Hole Number on Diesel Engine Performance under Plateau Conditions; SAE Technical Paper 2023-24-0033; SAE: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Yan, Y.; Yang, R.; Liu, Z.; Liu, J. Nitrogen Oxides Emission Characteristics of Zero-Carbon Ammonia-Hydrogen Fuels for Internal Combustion Engines; SAE Technical Paper 2023-01-0334; SAE: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Luján, J.M.; Bermudez, V.; Pla, B.; Redondo, F. Engine test bench feasibility for the study and research of real driving cycles: Pollutant emissions uncertainty characterization. Int. J. Engine Res. 2021, 23, 1103–1115. [Google Scholar] [CrossRef]

- Donateo, T.; Giovinazzi, M. Building a cycle for real driving emissions. Energy Procedia 2017, 126, 891–898. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, S.; Kim, H.; Keel, J.; Yoon, T.; Lee, J. Machine learning applied to the NOx prediction of diesel vehicle under real driving cycle. Appl. Sci. 2021, 11, 3758. [Google Scholar] [CrossRef]

- Previti, U.; Brusca, S.; Galvagno, A. Passenger car energy demand assessment: A new approach based on road traffic data. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2020; Volume 197, p. 05006. [Google Scholar] [CrossRef]

- Maddumage, W.U.; Abeyasighe, K.Y.; Perera, M.S.M.; Attalage, R.A.; Kelly, P. Comparing fuel consumption and emission levels of hybrid powertrain configurations and a conventional powertrain in varied drive cycles and degree of hybridization. Sci. Tech. 2020, 19, 20–33. [Google Scholar] [CrossRef]

- Krysmon, S.; Dorscheidt, F.; Claßen, J.; Düzgün, M.; Pischinger, S. Real Driving Emissions—Conception of a data-driven calibration methodology for hybrid powertrains combining statistical analysis and virtual calibration platforms. Energies 2021, 14, 4747. [Google Scholar] [CrossRef]

- Zanelli, A.; Millo, F.; Barbolini, M.; Neri, L. Assessment through Numerical Simulation of the Impact of a 48 V Electric Supercharger on Performance and CO2 Emissions of a Gasoline Passenger Car; SAE Technical Paper 2019-01-1284; SAE: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Hegde, S.; Bonfitto, A.; Galluzzi, R.; Molina, L.M.C.; Amati, N.; Tonoli, A. Equivalent consumption minimization strategy based on belt drive system characteristic maps for P0 hybrid electric vehicles. Energies 2023, 16, 487. [Google Scholar] [CrossRef]

- Molina Campoverde, P.A. Estimation of fuel consumption through PID signals using the real emissions cycle in the city of Quito, Ecuador. Sustainability 2023, 15, 12474. [Google Scholar] [CrossRef]

- Tomanik, E.; Jimenez-Reyes, A.J.; Tomanik, V.; Tormos, B. Machine-learning-based digital twins for transient vehicle cycles and their potential for predicting fuel consumption. Vehicles 2023, 5, 583–604. [Google Scholar] [CrossRef]

- Pulvirenti, L.; Rolando, L.; Millo, F. Energy management system optimization based on an LSTM deep learning model using vehicle speed prediction. Transp. Eng. 2023, 11, 100160. [Google Scholar] [CrossRef]

- Gebisa, A.; Gebresenbet, G.; Gopal, R.; Nallamothu, R.B. Driving cycles for estimating vehicle emission levels and energy consumption. Future Transp. 2021, 1, 615–638. [Google Scholar] [CrossRef]

- Pielecha, I.; Cieslik, W.; Szalek, A. Impact of Combustion Engine Operating Conditions on Energy Flow in Hybrid Drives in RDC Tests; SAE Technical Paper 2020-01-2251; SAE: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Kurtyka, K.; Pielecha, J. The evaluation of exhaust emission in RDE tests including dynamic driving conditions. Transp. Res. Procedia 2019, 40, 338–345. [Google Scholar] [CrossRef]

- Kurtyka, K.; Pielecha, J.; Merkisz, J. The evaluation of NOx emissions in RDE tests including dynamic driving conditions. IOP Conf. Ser. Earth Environ. Sci. 2021, 642, 012017. [Google Scholar] [CrossRef]

- Dollinger, M.; Fischerauer, G. Physics-based prediction for the consumption and emissions of passenger vehicles and light trucks up to 2050. Energies 2023, 16, 3591. [Google Scholar] [CrossRef]

| Parameter | Low | Medium | High | Extra-High |

|---|---|---|---|---|

| Stop duration [%] | 26.5 | 11.1 | 6.8 | 2.2 |

| Average speed [km/h] | 25.7 | 44.5 | 60.8 | 94.0 |

| Maximum speed [km/h] | 56.5 | 76.6 | 97.4 | 131.3 |

| Maximum acceleration [m/s2] | 1.61 | 1.61 | 1.67 | 1.06 |

| Minimum acceleration [m/s2] | −1.50 | −1.50 | −1.50 | −1.44 |

| Parameter | Euro 6d | ||

|---|---|---|---|

| Conformity factor | NOx: 1.43, PN: 1.50 | ||

| Cold start | yes | ||

| Limits for urban and RDE phase | yes | ||

| Altitude | normal | ≤700 m | |

| extended | 700–1300 m | ||

| Ambient temperature | normal | 0 °C to 30 °C | |

| extended | −7 °C to 0 °C and 30 °C to 35 °C | ||

| Trip composition | urban | 34% | ≤60 km/h |

| rural | 33% | 60–90 km/h | |

| motorway | 33% | >90 km/h | |

| Maximum speed | 145 km/h | ||

| Total trip duration | 90–120 min | ||

| Distance (urban, rural, motorway) | >16 km | ||

| Parameter | Unit | Gasoline | Diesel | Hybrid |

|---|---|---|---|---|

| Engine displacement | dm3 | 1.6 | 2.0 | 1.8 |

| Number of cylinders/valves | – | 4/16 | 4/8 | 4/16 |

| Maximum power | kW/rpm | 81/5500 | 75/2750 | 73/5200 100 (electric) |

| Torque | Nm/rpm | 152/4500 | 280/1500 | 142/4000 |

| Volumetric power indicator | kW/dm3 | 50.6 | 37.5 | 55.5 |

| Vehicle curb weight | kg | 1349 | 1584 | 1415 |

| Exhaust emission standard | – | Euro 6d | Euro 6d | Euro 6d |

| Drive type | – | front | front | front |

| Designation used at work | – |  |  |  |

| Parameter | RDE Requirements | Gasoline | Diesel | Hybrid |

|---|---|---|---|---|

| Total trip distance | 101.1 km | 96.1 km | 97.9 km | |

| Urban | min. 16 km | 33.7 km | 31.7 km | 35.3 km |

| Rural | min. 16 km | 29.7 km | 33.2 km | 31.1 km |

| Motorway | min. 16 km | 37.7 km | 31.2 km | 31.5 km |

| Urban share | 29–44% | 33.4% | 33.0% | 36.0% |

| Rural share | 23–43% | 29.4% | 34.5% | 31.8% |

| Motorway share | 23–43% | 37.3% | 32.5% | 32.2% |

| Total trip duration | 90–120 min | 116.5 min | 105.9 min | 114.7 min |

| Urban | 72.8 min | 63.2 min | 72.1 min | |

| Rural | 24.0 min | 26.2 min | 25.2 min | |

| Motorway | 19.7 min | 16.5 min | 17.5 min | |

| Stop duration | 11.3% | 8.19% | 9.5% | |

| Urban | 6–30% | 18.0% | 13.7% | 15.1% |

| Rural | 0.0% | 0.0% | 0.0% | |

| Motorway | 0.0% | 0.0% | 0.0% | |

| Average speed | 52.1 km/h | 54.5 km/h | 51.2 km/h | 52.1 km/h |

| Urban | 27.8 km/h | 30.1 km/h | 29.4 km/h | 27.8 km/h |

| Rural | 74.3 km/h | 76.0 km/h | 74.2 km/h | 74.3 km/h |

| Motorway | 115.0 km/h | 113.4 km/h | 108.3 km/h | 115.0 km/h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pielecha, J.; Kurtyka, K. Exhaust Emissions from Euro 6 Vehicles in WLTC and RDE—Part 1: Methodology and Similarity Conditions Studies. Energies 2023, 16, 7465. https://doi.org/10.3390/en16227465

Pielecha J, Kurtyka K. Exhaust Emissions from Euro 6 Vehicles in WLTC and RDE—Part 1: Methodology and Similarity Conditions Studies. Energies. 2023; 16(22):7465. https://doi.org/10.3390/en16227465

Chicago/Turabian StylePielecha, Jacek, and Karolina Kurtyka. 2023. "Exhaust Emissions from Euro 6 Vehicles in WLTC and RDE—Part 1: Methodology and Similarity Conditions Studies" Energies 16, no. 22: 7465. https://doi.org/10.3390/en16227465

APA StylePielecha, J., & Kurtyka, K. (2023). Exhaust Emissions from Euro 6 Vehicles in WLTC and RDE—Part 1: Methodology and Similarity Conditions Studies. Energies, 16(22), 7465. https://doi.org/10.3390/en16227465