Flat-Plate PHP with Gravity-Independent Performance and High Maximum Thermal Load

Abstract

1. Introduction

2. Materials and Methods

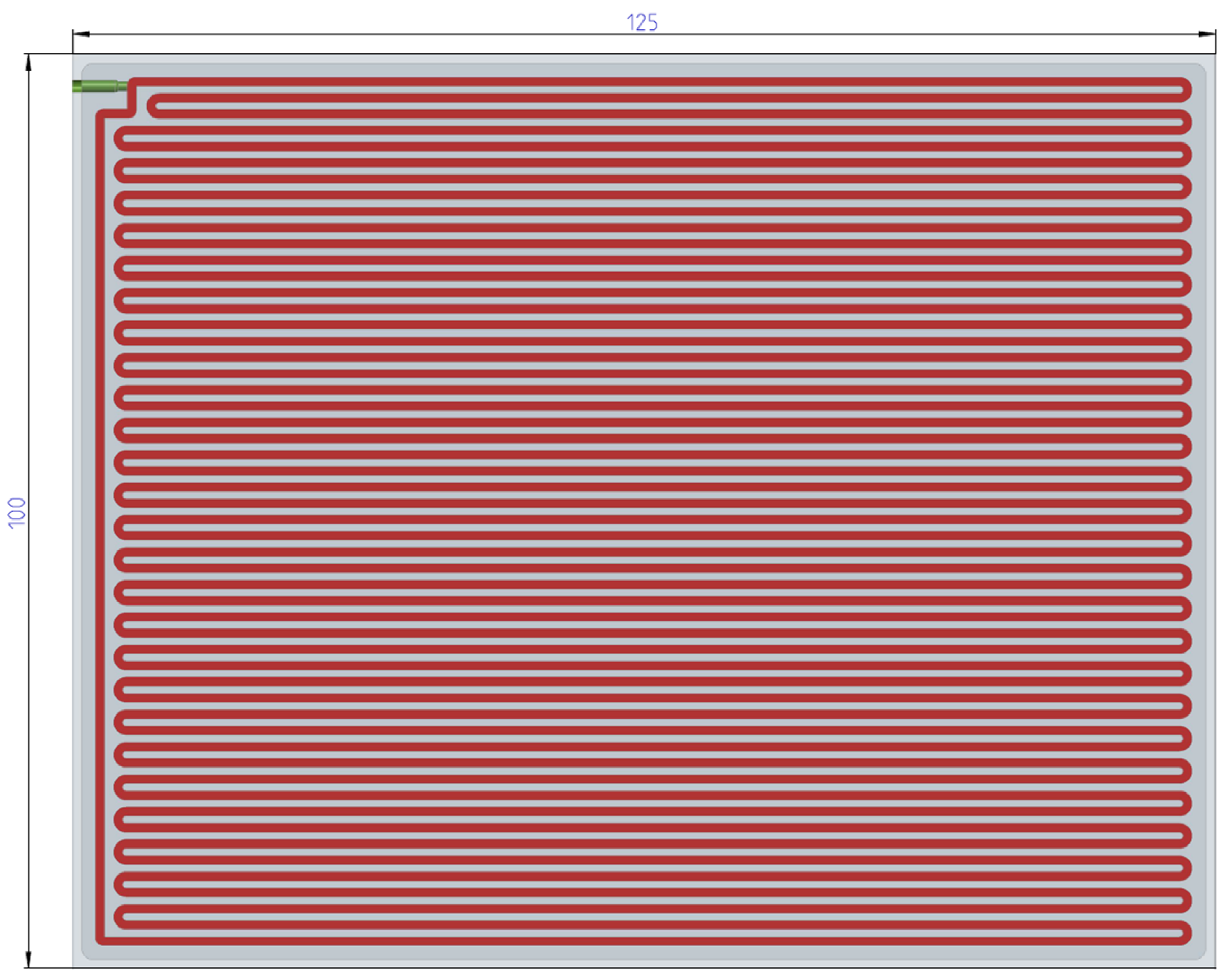

2.1. Design of PHPs

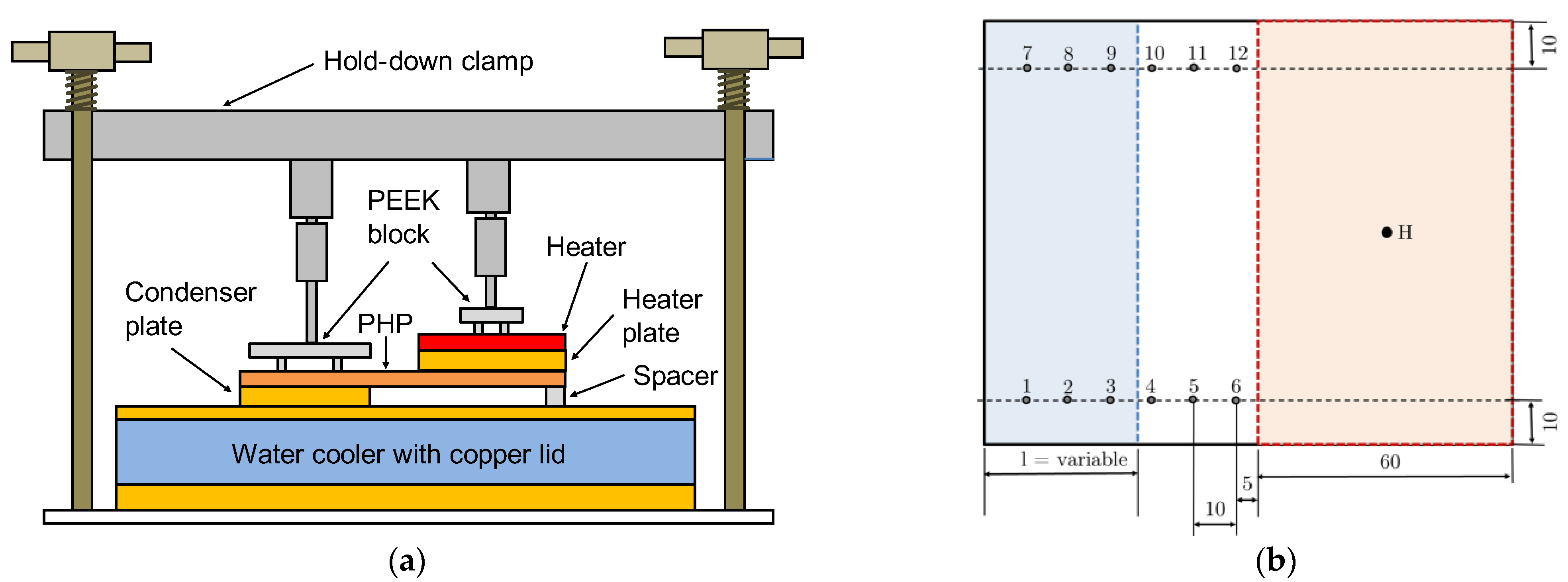

2.2. Setup for Characterization of PHPs

3. Results

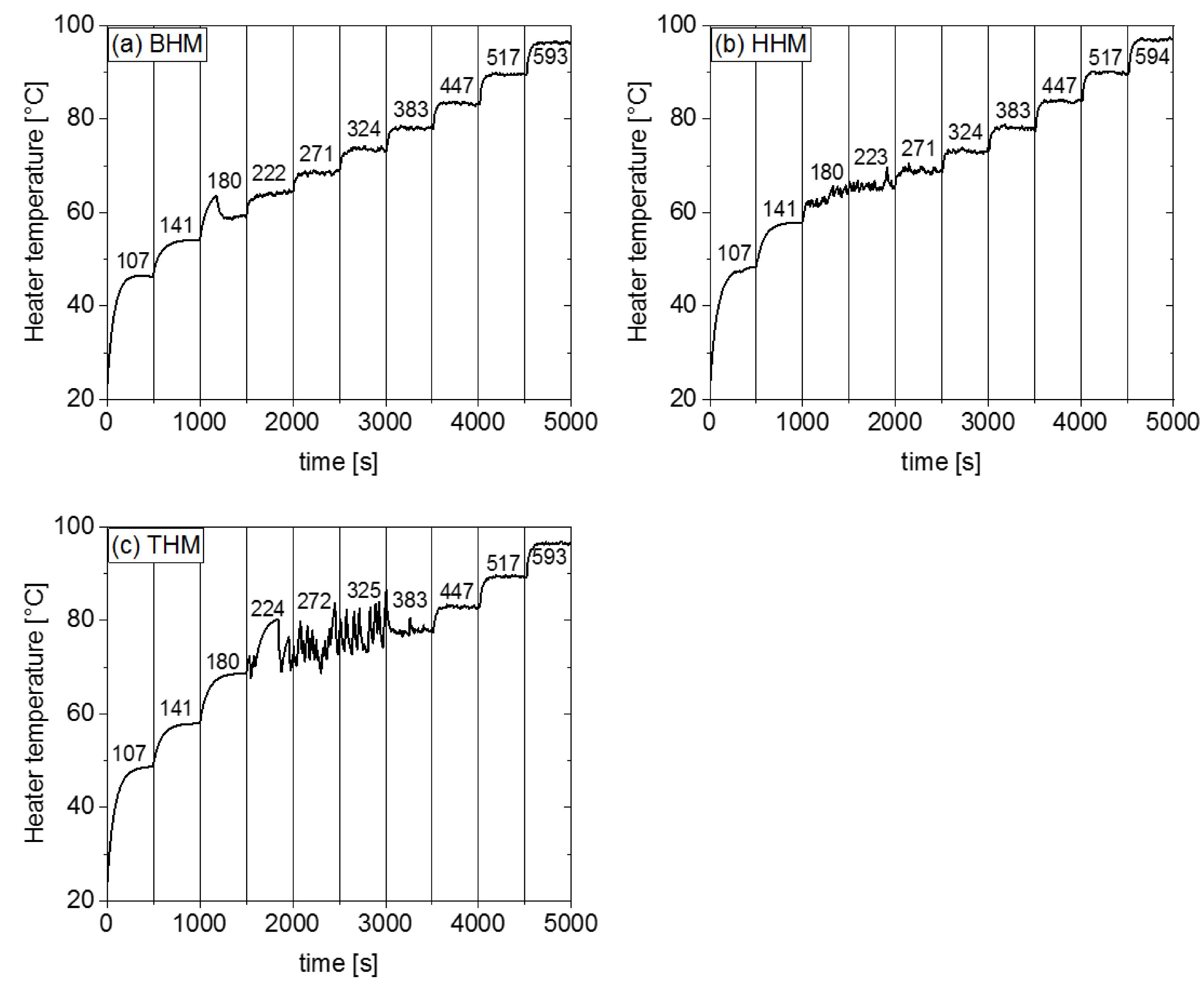

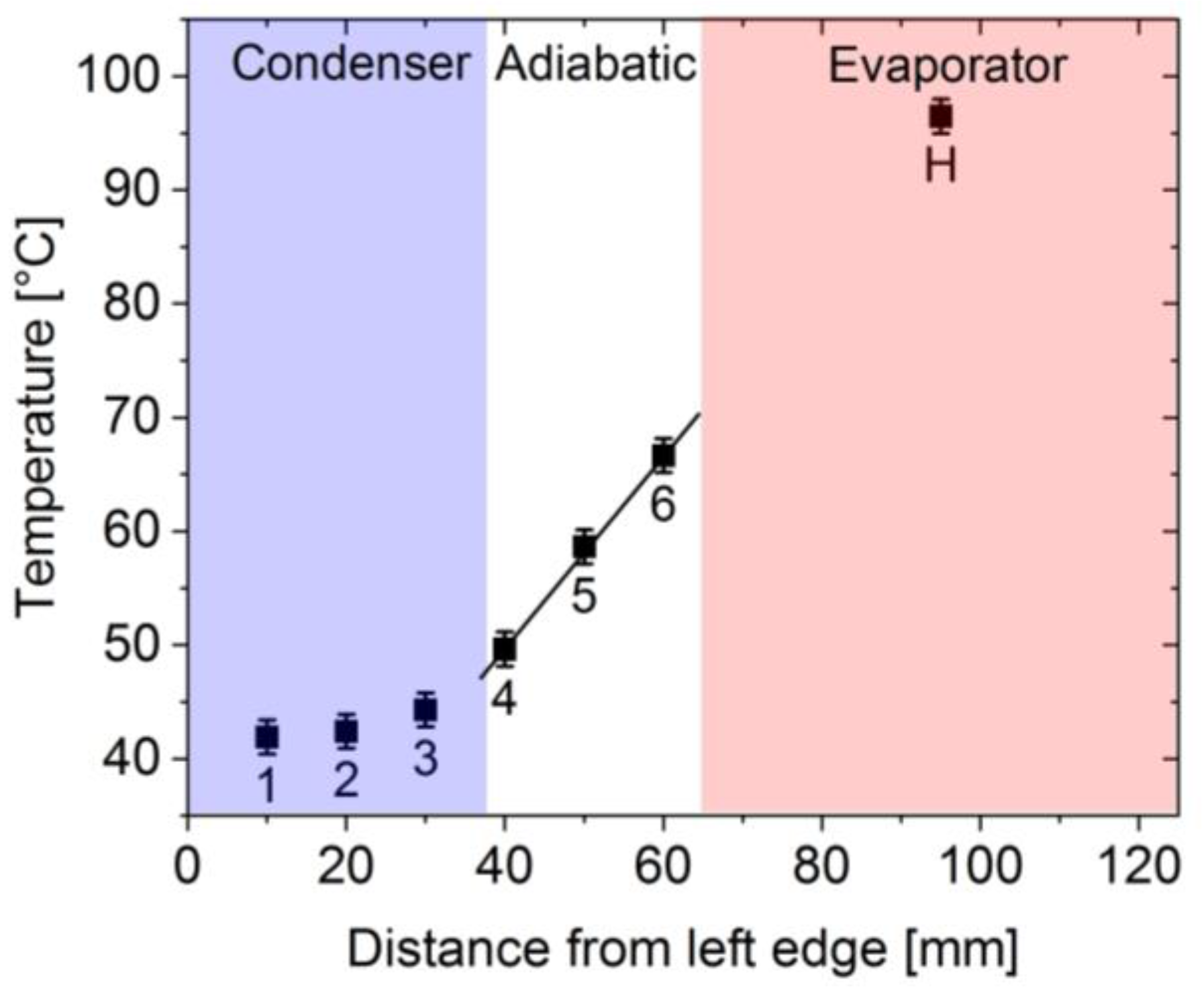

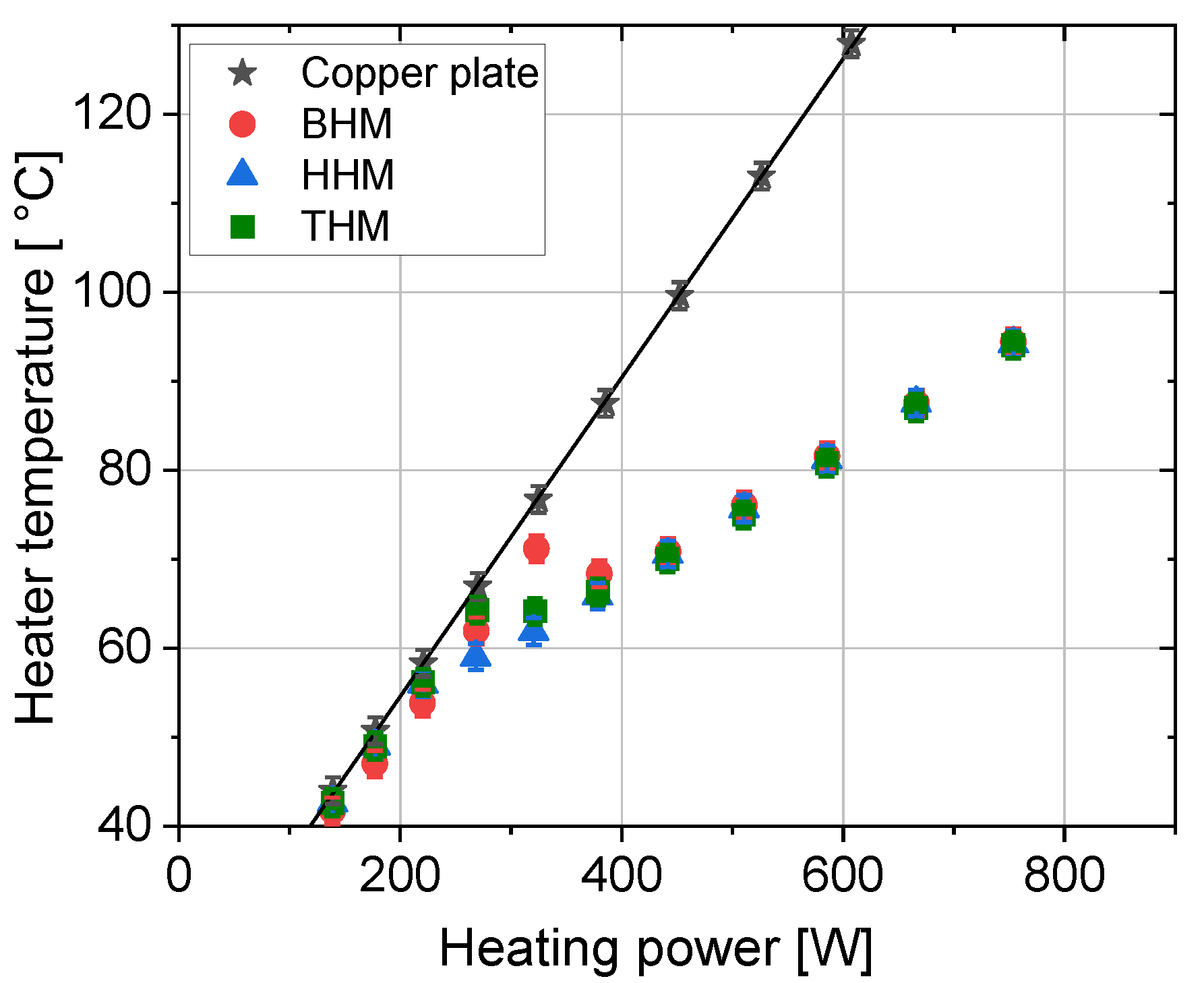

3.1. Condenser Area Length of 38 mm

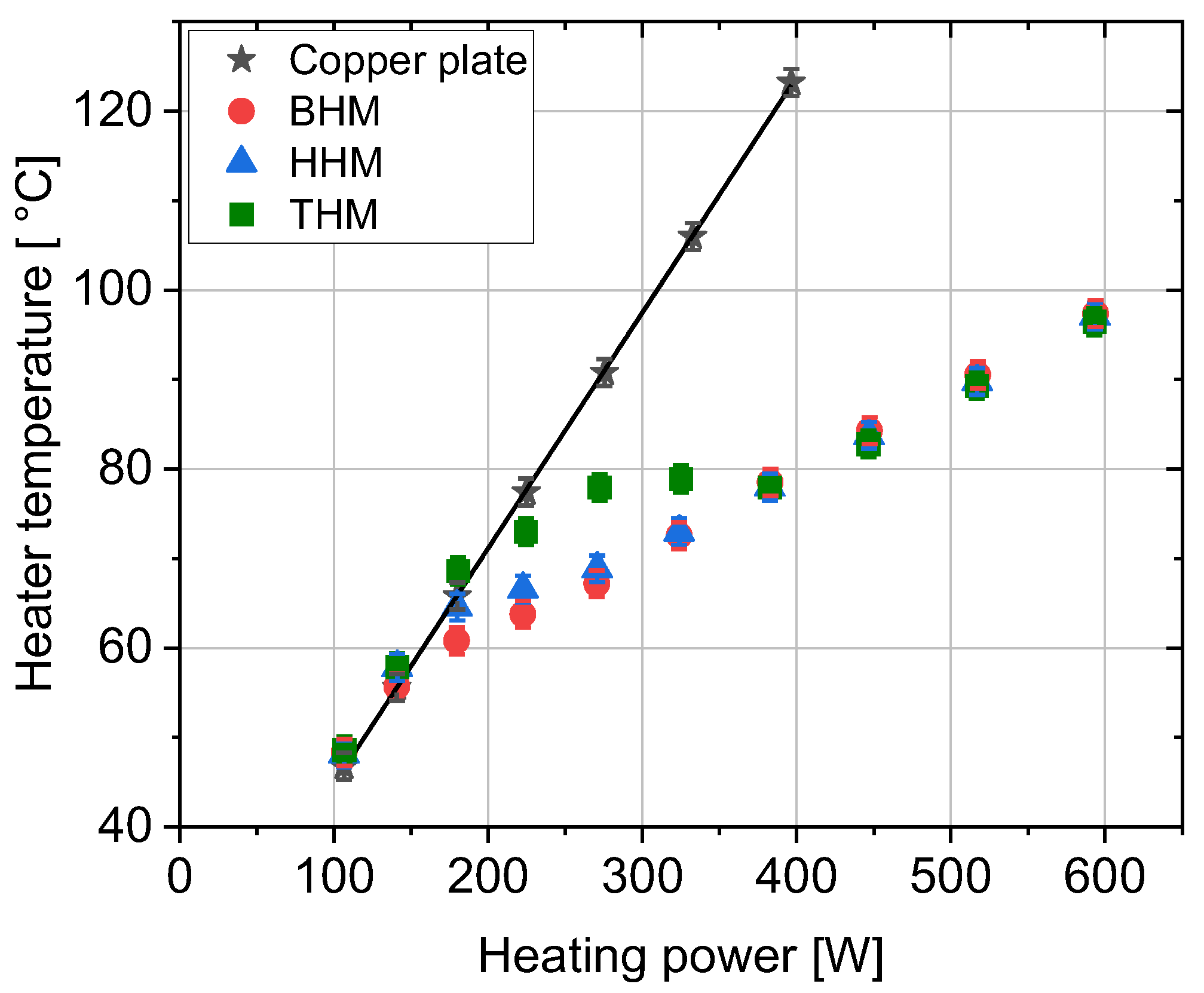

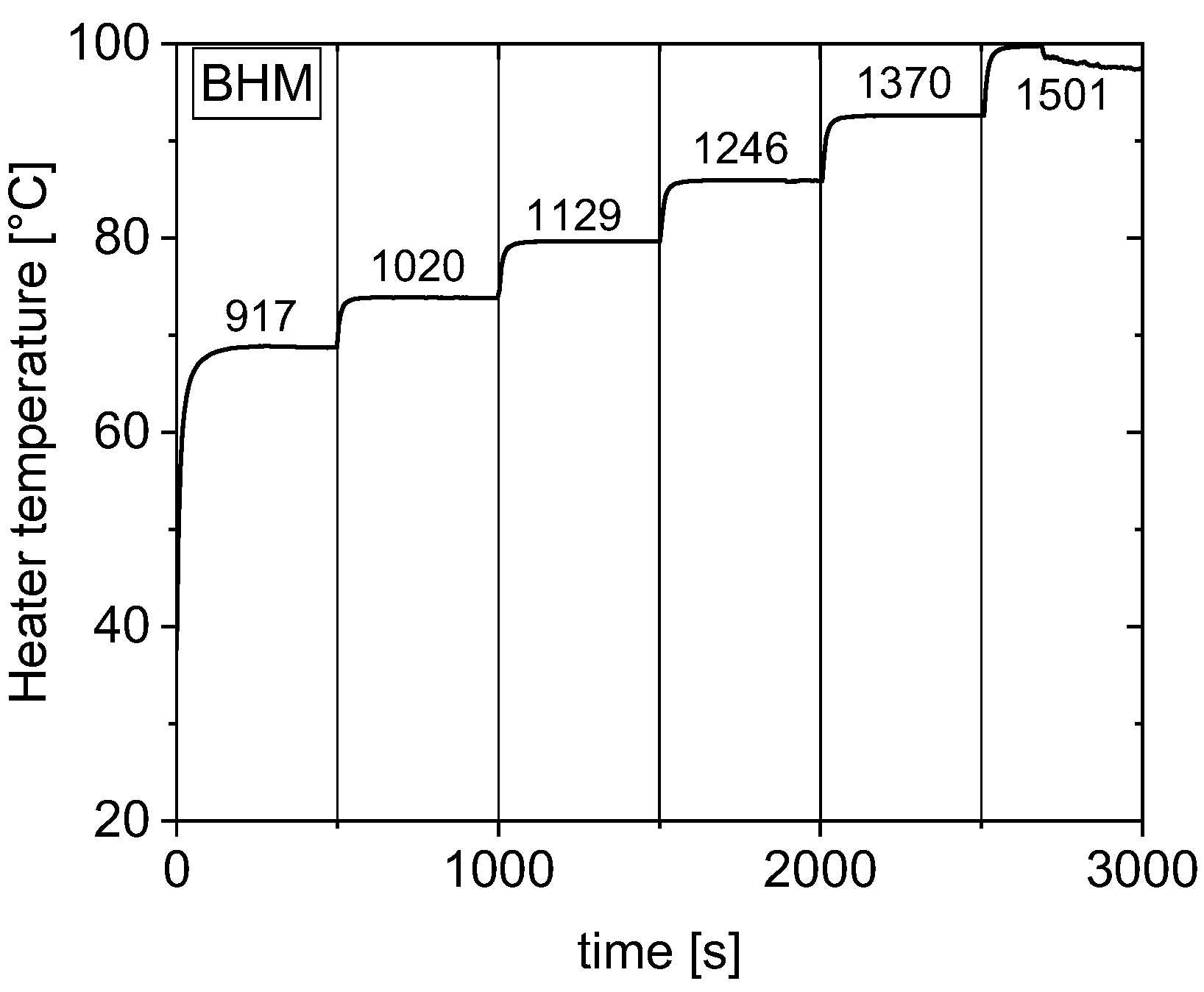

3.2. Condenser Area Length of 60 mm

3.3. Condenser Length Corresponding to Full PHP Length

4. Discussion

4.1. PHP Operation in Different Orientations: BHM, HHM, and THM

4.2. Effect of Condenser Length

5. Conclusions

- In this work, the maximum heater temperature was limited to 100 °C due to safety reasons (avoiding excessive vapor pressure of the working fluid, which might damage the PHP). The next step is to go above this temperature limit and explore the limits of heat that can be dissipated with the presented PHP (indicated by the appearance of dryout phenomena and a stagnation of fluid motion).

- If the PHP fails during these tests, a failure analysis must be carried out, and the stability of the bonding must be improved.

- General tests on the stability of the PHPs against aging and temperature effects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Ma, H. Oscillating Heat Pipes; Springer: New York, NY, USA, 2015; ISBN 978-1-4939-2503-2. [Google Scholar]

- Zhang, Y.; Faghri, A. Advances and Unsolved Issues in Pulsating Heat Pipes. Heat Transfer. Eng. 2008, 29, 20–44. [Google Scholar] [CrossRef]

- Ibrahim, O.T.; Monroe, J.G.; Thompson, S.M.; Shamsaei, N.; Bilheux, H.; Elwany, A.; Bian, L. An investigation of a multi-layered oscillating heat pipe additively manufactured from Ti-6Al-4V powder. Int. J. Heat Mass Transf. 2017, 108, 1036–1047. [Google Scholar] [CrossRef]

- Thompson, S.M.; Cheng, P.; Ma, H.B. An experimental investigation of a three-dimensional flat-plate oscillating heat pipe with staggered microchannels. Int. J. Heat Mass Tran. 2011, 54, 3951–3959. [Google Scholar] [CrossRef]

- Thompson, S.M.; Hathaway, A.A.; Smoot, C.D.; Wilson, C.A.; Ma, H.B. Robust thermal performance of a flat-plate oscillating heat pipe during high-gravity loading. J. Heat Transf. 2011, 133, 104504. [Google Scholar] [CrossRef]

- Thompson, S.M.; Ma, H.B. Effect of Localized Heating on Three-Dimensional Flat-Plate Oscillating Heat Pipe. Adv. Mech. Eng. 2010, 2, 465153. [Google Scholar] [CrossRef]

- Taft, B.S.; Williams, A.D.; Drolen, B.L. Review of pulsating heat pipe working fluid selection. J. Thermophys. Heat Tr. 2012, 26, 651–656. [Google Scholar] [CrossRef]

- Senjaya, R.; Inoue, T. Oscillating heat pipe simulation considering dryout phenomena. Heat Mass Transf. 2014, 50, 1429–1441. [Google Scholar] [CrossRef]

- Marengo, M.; Nikolayev, V.S. Chapter 1: Pulsating Heat Pipes: Experimental Analysis, Design and Application. In Encyclopedia of Two-Phase Heat Transfer and Flow IV: Modeling Methodologies, Boiling of CO2, and Micro-Two-Phase Cooling; Thome, J.R., Ed.; World Scientific: Singapore, 2018; pp. 1–62. [Google Scholar]

- Yang, H.; Khandekar, S.; Groll, M. Performance characteristics of pulsating heat pipes as integral thermal spreaders. Int. J. Therm. Sci. 2009, 48, 815–824. [Google Scholar] [CrossRef]

- Charoensawan, P.; Khandekar, S.; Groll, M.; Terdtoon, P. Closed loop pulsating heat pipes Part A: Parametric experimental investigations. Appl. Therm. Eng. 2003, 23, 2009–2020. [Google Scholar] [CrossRef]

- Borkar, R.S.; Pachghare, P.R. Effect of working fluid, filling ratio and number of turns on pulsating heat pipe thermal performance. Front. Heat Pipes 2015, 6, 1. [Google Scholar] [CrossRef]

- Winkler, M.; Rapp, D.; Mahlke, A.; Zunftmeister, F.; Vergez, M.; Wischerhoff, E.; Clade, J.; Bartholomé, K.; Schäfer-Welsen, O. Small-sized pulsating heat pipes/oscillating heat pipes with low thermal resistance and high heat transport capability. Energies 2020, 13, 1736. [Google Scholar] [CrossRef]

- Patel, V.M.; Gaurav; Mehta, H.B. Influence of working fluids on startup mechanism and thermal performance of a closed loop pulsating heat pipe. Appl. Therm. Eng. 2017, 110, 1568–1577. [Google Scholar] [CrossRef]

- Khandekar, S.; Dollinger, N.; Groll, M. Understanding operational regimes of closed loop pulsating heat pipes: An experimental study. Appl. Therm. Eng. 2003, 23, 707–719. [Google Scholar] [CrossRef]

- Ambrose, D.; Sprake, C.H.S.; Townsend, R. Thermodynamic properties of organic oxygen compounds XXXIII. The vapour pressure of acetone. J. Chem. Thermodyn. 1974, 6, 693–700. [Google Scholar] [CrossRef]

- Betancur, L.; Facin, A.; Gonçalves, P.; Paiva, K.; Mantelli, M.; Nuernberg, G. Study of diffusion bonded flat plate closed loop pulsating heat pipes with alternating porous media. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 19th International Heat Pipe Conference and 13th International Heat Pipe Symposium (IHPC 2018), Pisa, Italy, 10–14 June 2018; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Lin, Z.; Wang, S.; Chen, J.; Huo, J.; Hu, Y.; Zhang, W. Experimental study on effective range of miniature oscillating heat pipes. Appl. Therm. Eng. 2011, 31, 880–886. [Google Scholar] [CrossRef]

- Han, H.; Cui, X.; Zhu, Y.; Sun, S. A comparative study of the behavior of working fluids and their properties on the performance of pulsating heat pipes (PHP). Int. J. Therm. Sci. 2014, 82, 138–147. [Google Scholar] [CrossRef]

- Liebl, S.; Wiedenmann, R.; Ganser, A.; Schmitz, P.; Zaeh, M.F. Laser Welding of Copper Using Multi Mode Fiber Lasers at Near Infrared Wavelength. Phys. Procedia 2014, 56, 591–600. [Google Scholar] [CrossRef]

- Smoot, C.D.; Ma, H.B. Experimental investigation of a three-layer oscillating heat pipe. J. Heat Transf. 2014, 136, 51501. [Google Scholar] [CrossRef]

- Laun, F.F.; Taft, B. Experimental Investigation of in Situ Pressure Measurement of an Oscillating Heat Pipe. Front. Heat Pipes 2014, 5, 8. [Google Scholar] [CrossRef][Green Version]

- Ayel, V.; Araneo, L.; Scalambra, A.; Mameli, M.; Romestant, C.; Piteau, A.; Marengo, M.; Filippeschi, S.; Bertin, Y. Experimental study of a closed loop flat plate pulsating heat pipe under a varying gravity force. Int. J. Therm. Sci. 2015, 96, 23–34. [Google Scholar] [CrossRef]

- Groeneveld, G.; van Gerner, H.-j.; Wits, W.W. An experimental study towards the practical application of closed-loop flat-plate pulsating heat pipes. In Proceedings of the 2017 23rd International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Amsterdam, The Netherlands, 27–29 September 2017; pp. 1–6. [Google Scholar]

- Wits, W.W.; Groeneveld, G.; van Gerner, H.J. Experimental investigation of a flat-plate closed-loop pulsating heat pipe. J. Heat Transf. 2019, 141, 091807. [Google Scholar] [CrossRef]

- Youn, Y.J.; Kim, S.J. Fabrication and evaluation of a silicon-based micro pulsating heat spreader. Sens. Actuators A Phys. 2012, 174, 189–197. [Google Scholar] [CrossRef]

- Ayel, V.; Slobodeniuk, M.; Bertossi, R.; Romestant, C.; Bertin, Y. Flat plate pulsating heat pipes: A review on the thermohydraulic principles, thermal performances and open issues. Appl. Therm. Eng. 2021, 197, 117200. [Google Scholar] [CrossRef]

- Charoensawan, P.; Terdtoon, P. Thermal performance of horizontal closed-loop oscillating heat pipes. Appl. Therm. Eng. 2008, 28, 460–466. [Google Scholar] [CrossRef]

- Lips, S.; Bensalem, A.; Bertin, Y.; Ayel, V.; Romestant, C.; bonjour, j. Experimental evidences of distinct heat transfer regimes in pulsating heat pipes (PHP). Appl. Therm. Eng. 2010, 30, 900–907. [Google Scholar] [CrossRef]

- Smoot, C.D.; Ma, H.B. An experimental investigation of hybrid oscillating heat pipe. Front. Heat Pipes 2011, 2, 023001. [Google Scholar] [CrossRef]

- Wang, J.; Ma, H.; Zhu, Q. Effects of the evaporator and condenser length on the performance of pulsating heat pipes. Appl. Therm. Eng. 2015, 91, 1018–1025. [Google Scholar] [CrossRef]

- Kim, J.; Kim, S.J. Experimental investigation on the effect of the condenser length on the thermal performance of a micro pulsating heat pipe. Appl. Therm. Eng. 2018, 130, 439–448. [Google Scholar] [CrossRef]

- Laun, F.F.; Lu, H.; Ma, H.B. An experimental investigation of an oscillating heat pipe heat spreader. J. Therm. Sci. Eng. Appl. 2015, 7, 021005. [Google Scholar] [CrossRef]

- Noh, H.Y.; Kim, S.J. Thermal characterization and optimization of pulsating heat pipes operating in a circulation mode. Int. J. Heat Mass Transf. 2017, 115, 1234–1246. [Google Scholar] [CrossRef]

- Wilden, H.; Bekhti, N.B.; Hoffmann, R.; Kirchner, C.; Kohlleppel, R.; Reising, C.; Brenner, A.; Eversberg, T. GESTRA—Recent Progress, Mode Design and Signal Processing. In Proceedings of the 2019 IEEE International Symposium on Phased Array System & Technology (PAST), Waltham, MA, USA, 15–18 October 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Reising, C.; Gilles, M.; Hoffmann, R.; Horstmann, S.; Schneider, S. GESTRA—Upgrading to future distributed phased array radar networks for space surveillance. In Proceedings of the 2022 IEEE International Symposium on Phased Array Systems & Technology (PAST), Waltham, MA, USA, 11–14 October 2022; pp. 1–8. [Google Scholar] [CrossRef]

| Author | PHP Size [mm] | Nr. of Turns | [mm] a | [W] | Fluid | Mode | Thermal Resistance [K/W] b | Ref. |

|---|---|---|---|---|---|---|---|---|

| Winkler | 125 × 100 × 6 | 27 | 1 | 754 | Acetone | BHM | 0.074 c | this work |

| HHM | 0.074 c | |||||||

| THM | 0.074 c | |||||||

| Yang d | 180 × 120 × 3 | 33 | 1 | 100 | Ethanol | BHM | 0.63 | [10] |

| HHM | 0.70 | |||||||

| THM | 0.90 | |||||||

| Yang d | 180 × 120 × 3 | 20 | 2 | 400 | Ethanol | BHM | 0.15 | [10] |

| HHM | 0.17 | |||||||

| THM | 0.19 | |||||||

| Laun | 300 × 300 × 6 | 20 | 1.3 | 550 | Acetone | BHM | 0.083 | [22] |

| HHM | 0.091 | |||||||

| THM | 0.101 | |||||||

| Winkler | 100 × 50 × 2.0 | 13 | 1 | 175 | Acetone | BHM | 0.077 e | [13] |

| HHM | 0.081 e | |||||||

| THM | Not tested | |||||||

| Winkler | 100 × 50 × 2.5 | 10 | 1.5 | 115 | Acetone | BHM | 0.057 e | [13] |

| HHM | 0.084 e | |||||||

| THM | Not tested | |||||||

| Ayel | 200 × 120 × 2 | 12 | 1.7 | 150 | FC72 | BHM | 0.126 | [23] |

| HHM | 0.237 | |||||||

| THM | Not tested | |||||||

| Groeneveld | 200 × 50 × 3.5 | 6 | 2 | 100 | Methanol | BHM | 0.48 | [24] |

| HHM | No oper. f | |||||||

| THM | Not tested | |||||||

| Wits g | 200 × 50 × 3.5 | 6 | 2 | 100 | Water | BHM | 0.29 | [25] |

| HHM | No oper. f | |||||||

| THM | Not tested | |||||||

| Wits g | 200 × 50 × 3.5 | 6 | 2 | 100 | Ammonia | BHM | 0.15 | [25] |

| HHM | 0.30 | |||||||

| THM | Not tested | |||||||

| Youn | 50 × 15.5 × 1.5 | 5 | 0.57 | 100 | Ethanol | BHM | 524 b | [26] |

| HHM | 293 b | |||||||

| THM | Not tested |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winkler, M.; Vergez, M.; Mahlke, A.; Gebauer, M.; Müller, P.; Reising, C.; Bartholomé, K.; Schäfer-Welsen, O. Flat-Plate PHP with Gravity-Independent Performance and High Maximum Thermal Load. Energies 2023, 16, 7463. https://doi.org/10.3390/en16227463

Winkler M, Vergez M, Mahlke A, Gebauer M, Müller P, Reising C, Bartholomé K, Schäfer-Welsen O. Flat-Plate PHP with Gravity-Independent Performance and High Maximum Thermal Load. Energies. 2023; 16(22):7463. https://doi.org/10.3390/en16227463

Chicago/Turabian StyleWinkler, Markus, Marc Vergez, Andreas Mahlke, Mathias Gebauer, Phillip Müller, Christoph Reising, Kilian Bartholomé, and Olaf Schäfer-Welsen. 2023. "Flat-Plate PHP with Gravity-Independent Performance and High Maximum Thermal Load" Energies 16, no. 22: 7463. https://doi.org/10.3390/en16227463

APA StyleWinkler, M., Vergez, M., Mahlke, A., Gebauer, M., Müller, P., Reising, C., Bartholomé, K., & Schäfer-Welsen, O. (2023). Flat-Plate PHP with Gravity-Independent Performance and High Maximum Thermal Load. Energies, 16(22), 7463. https://doi.org/10.3390/en16227463